Integration manufacturing and testing verification for composite cross stiffened cabin via hybrid prepreg-resin transfer moulding process

-

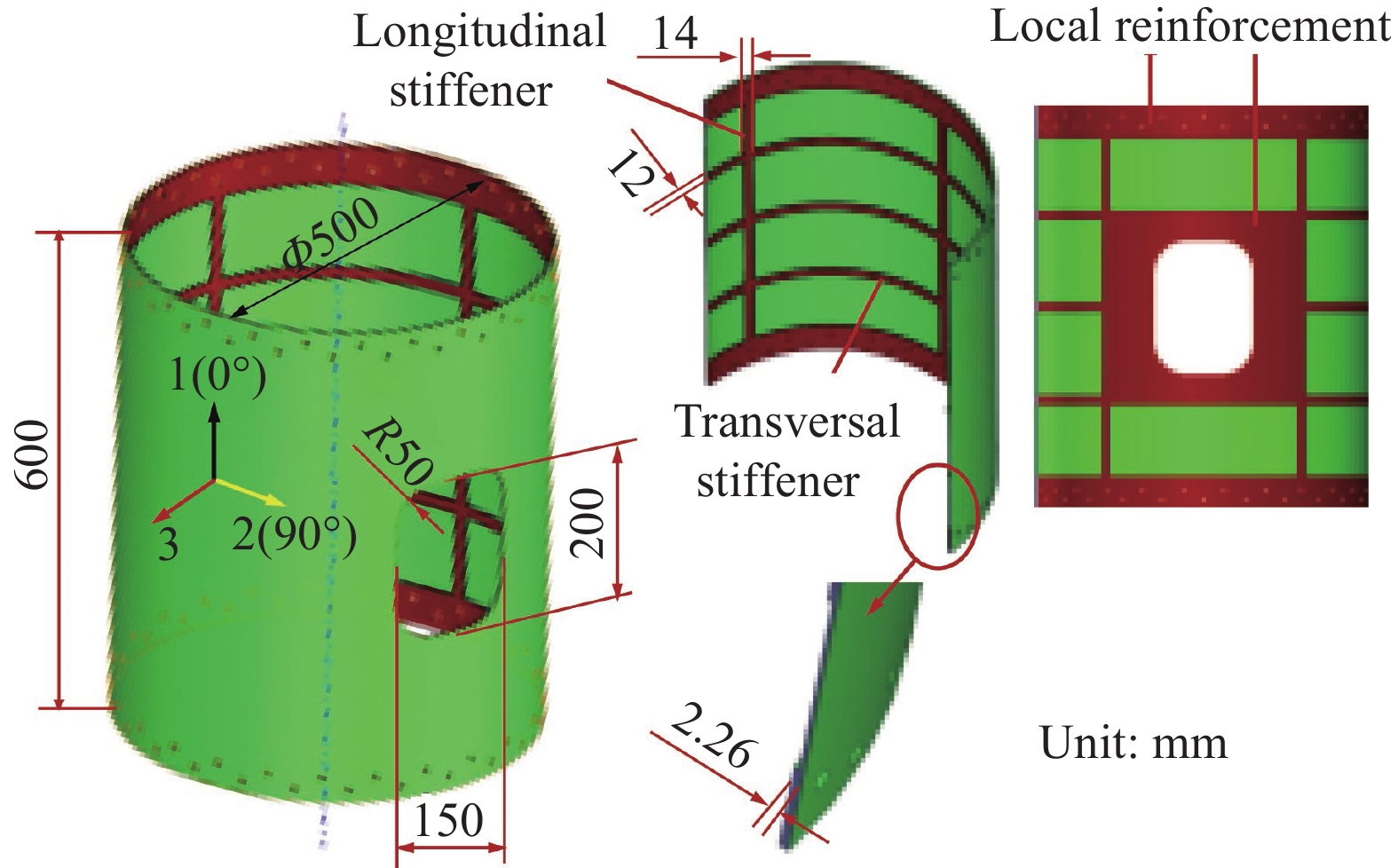

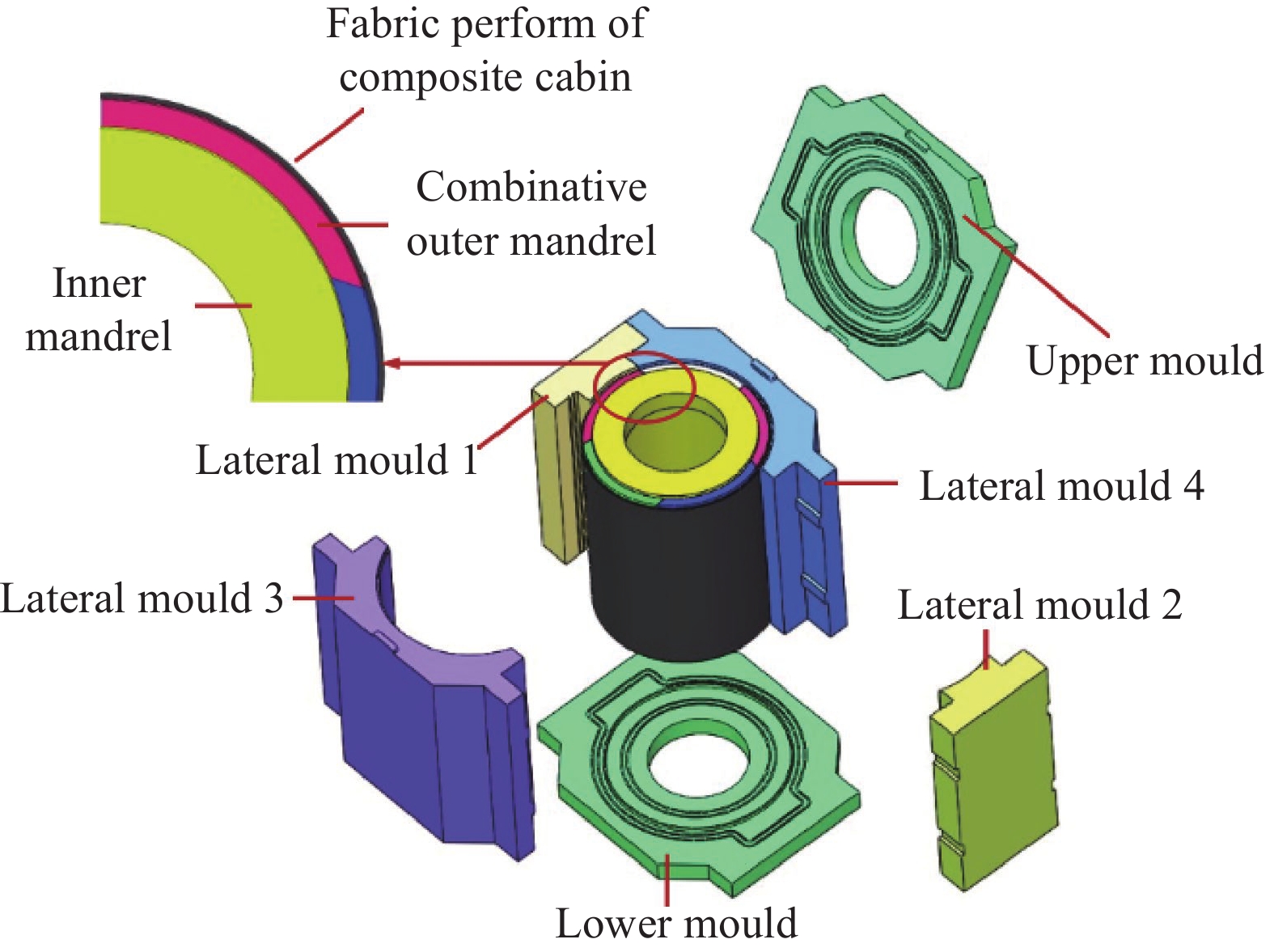

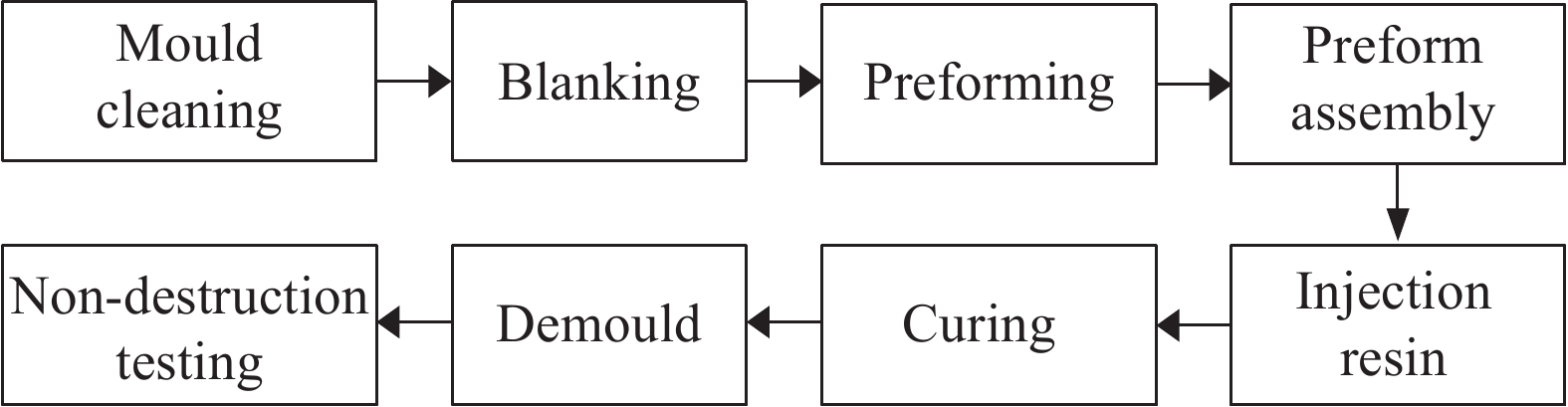

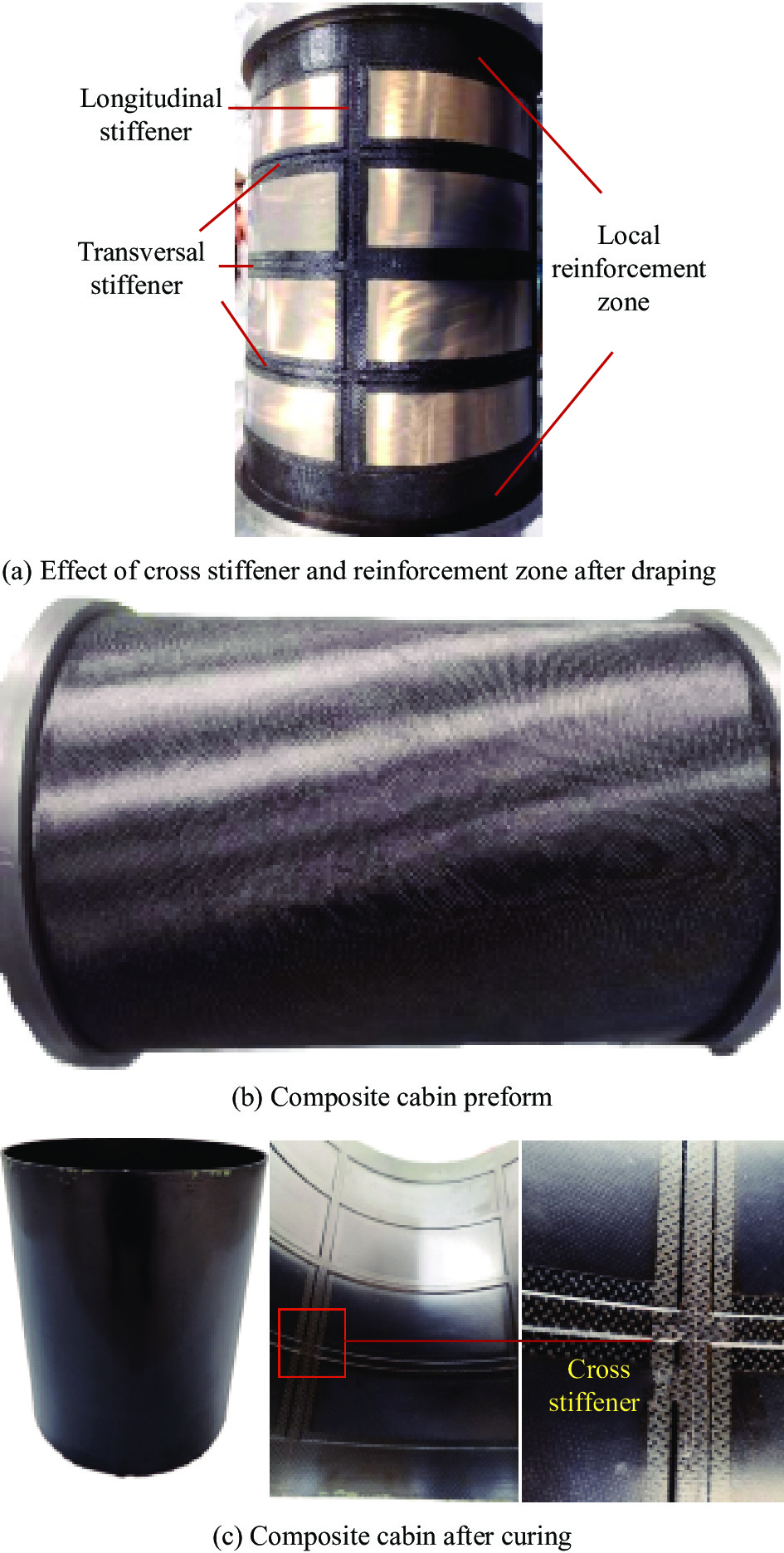

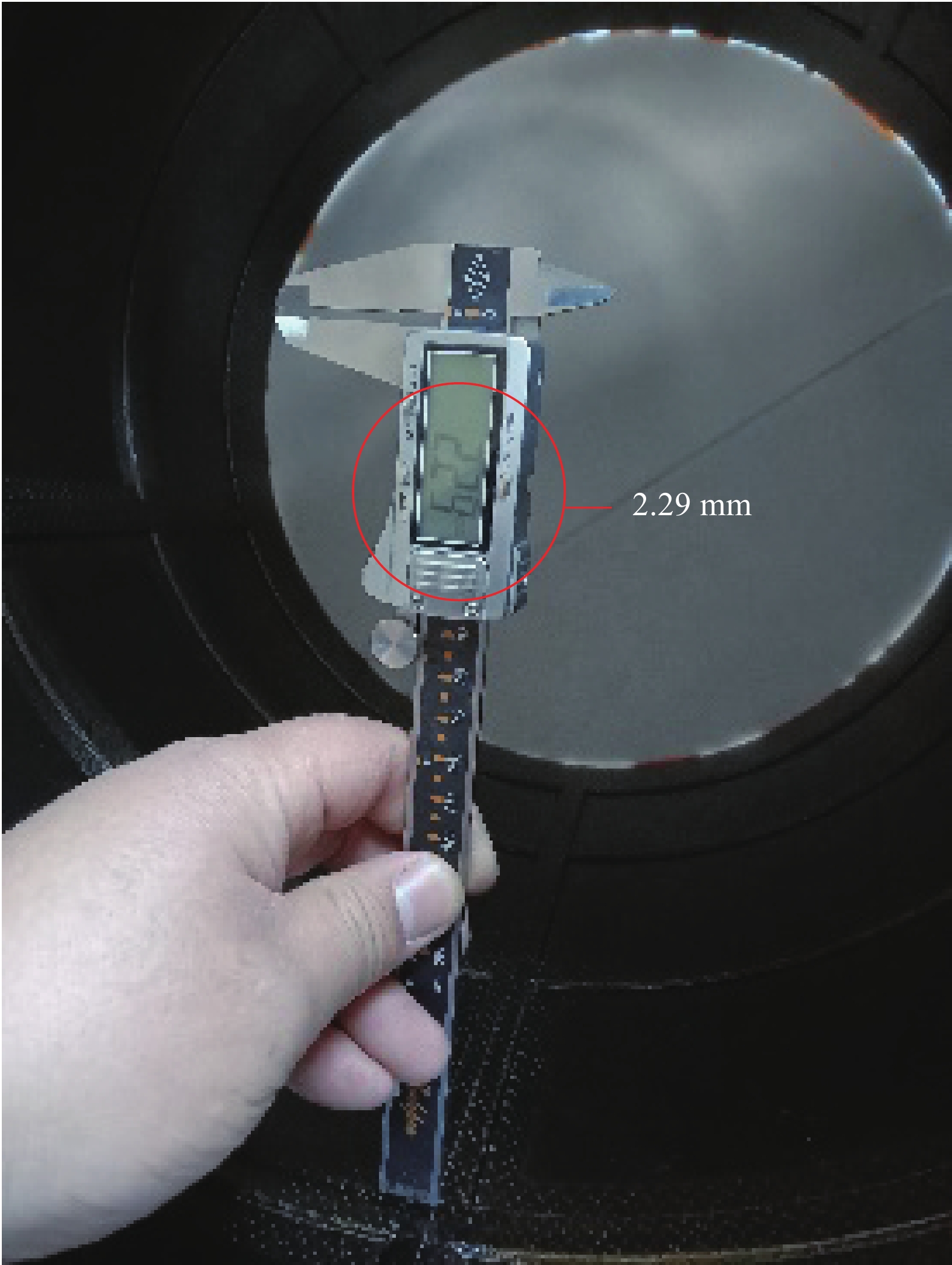

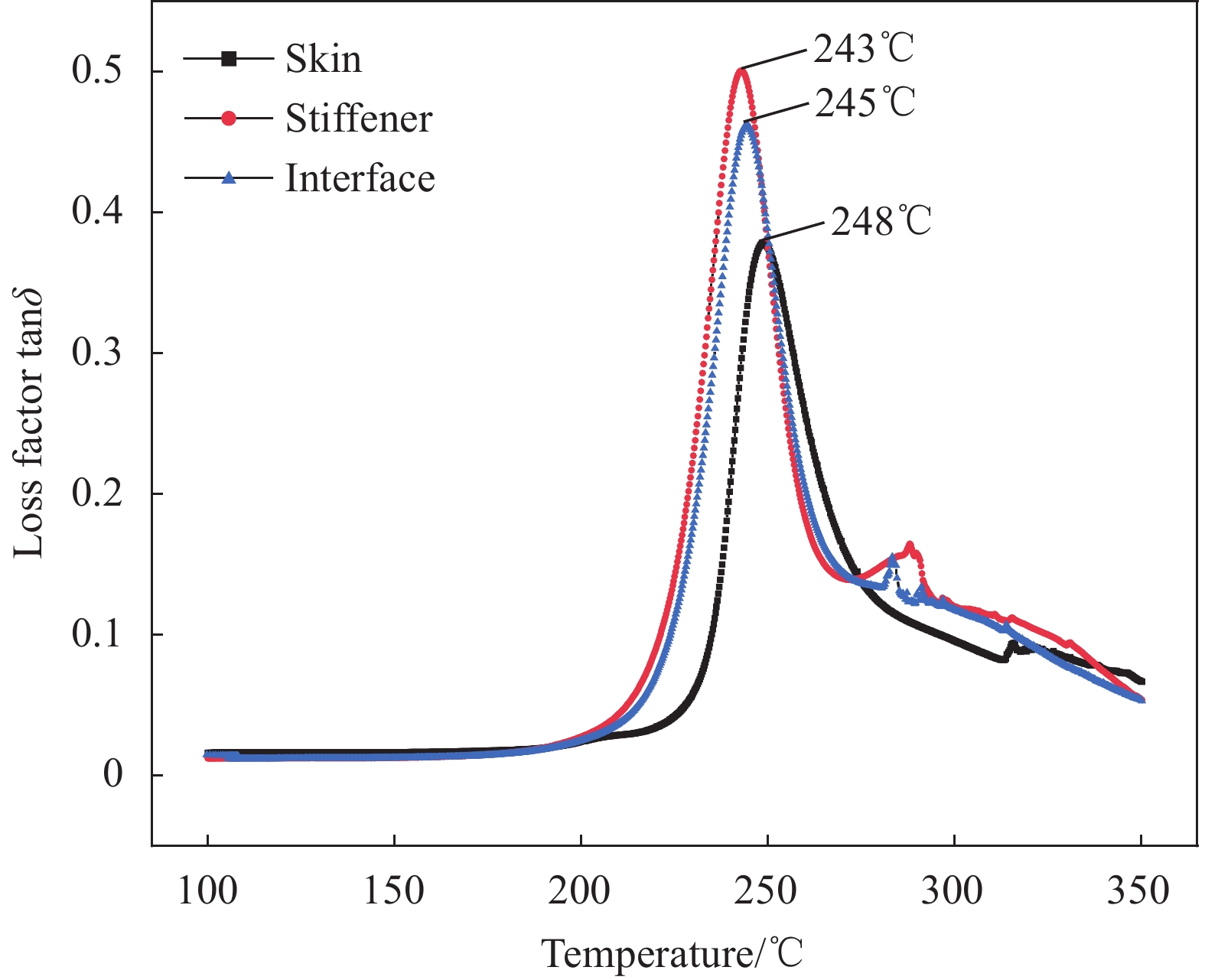

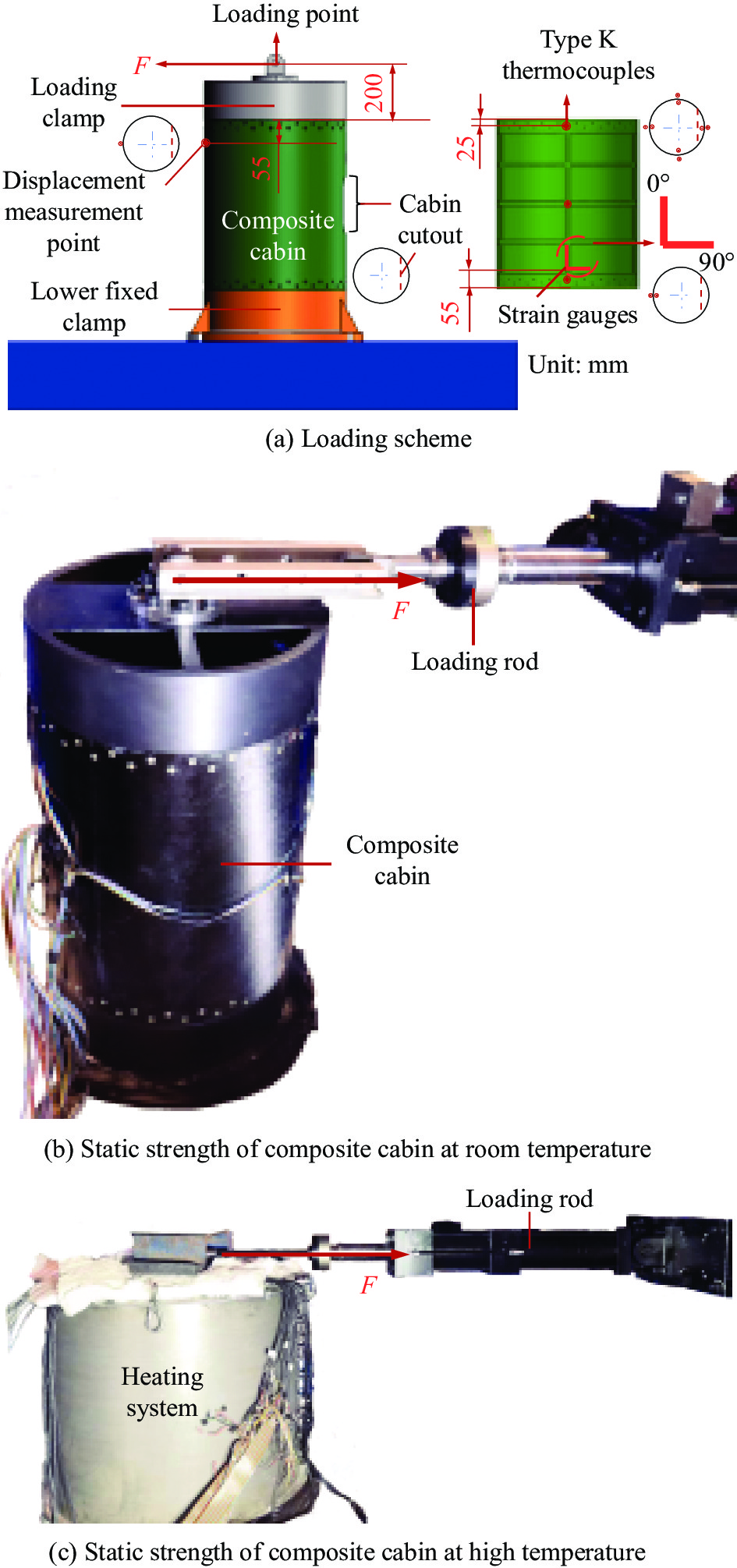

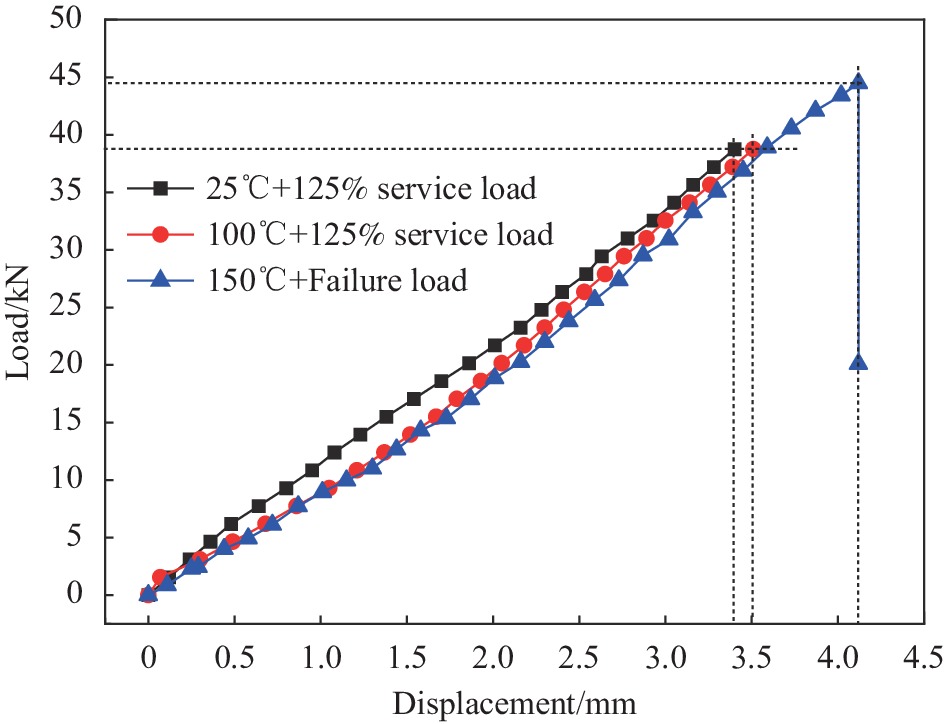

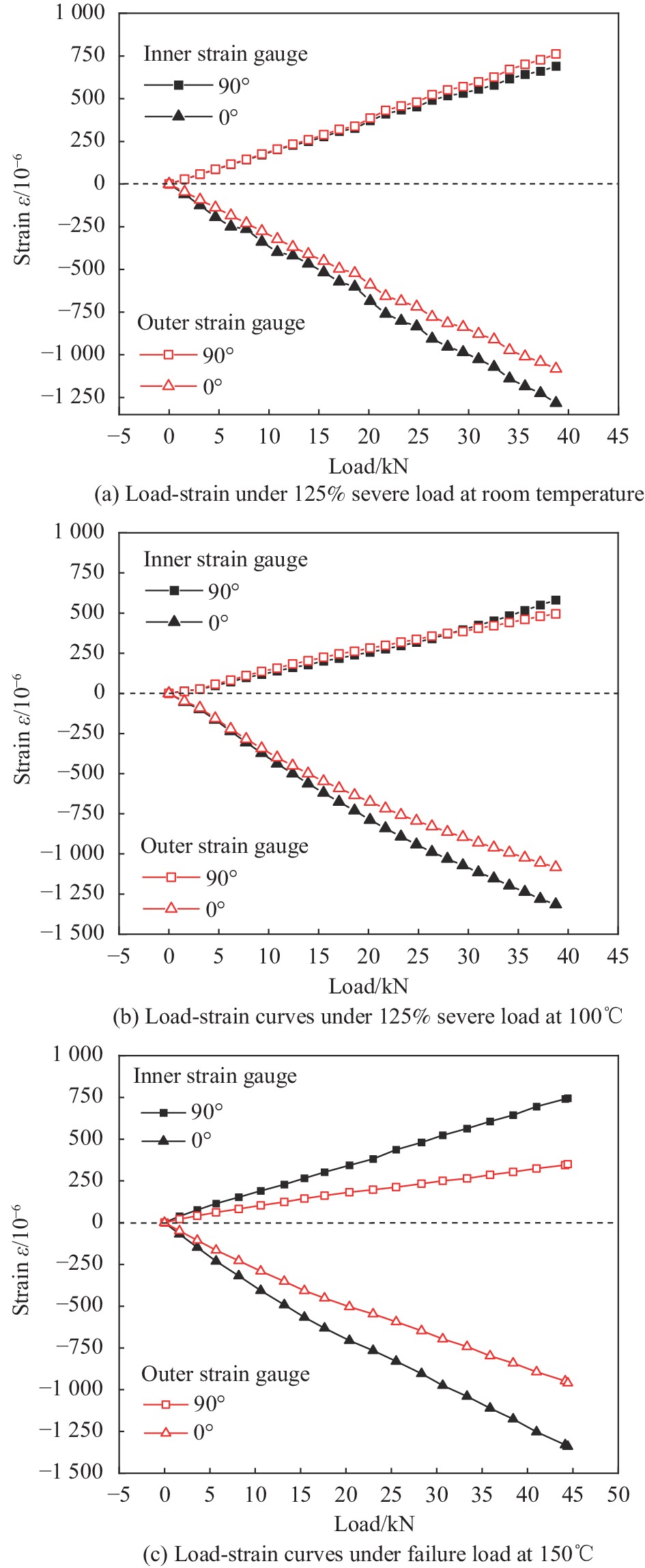

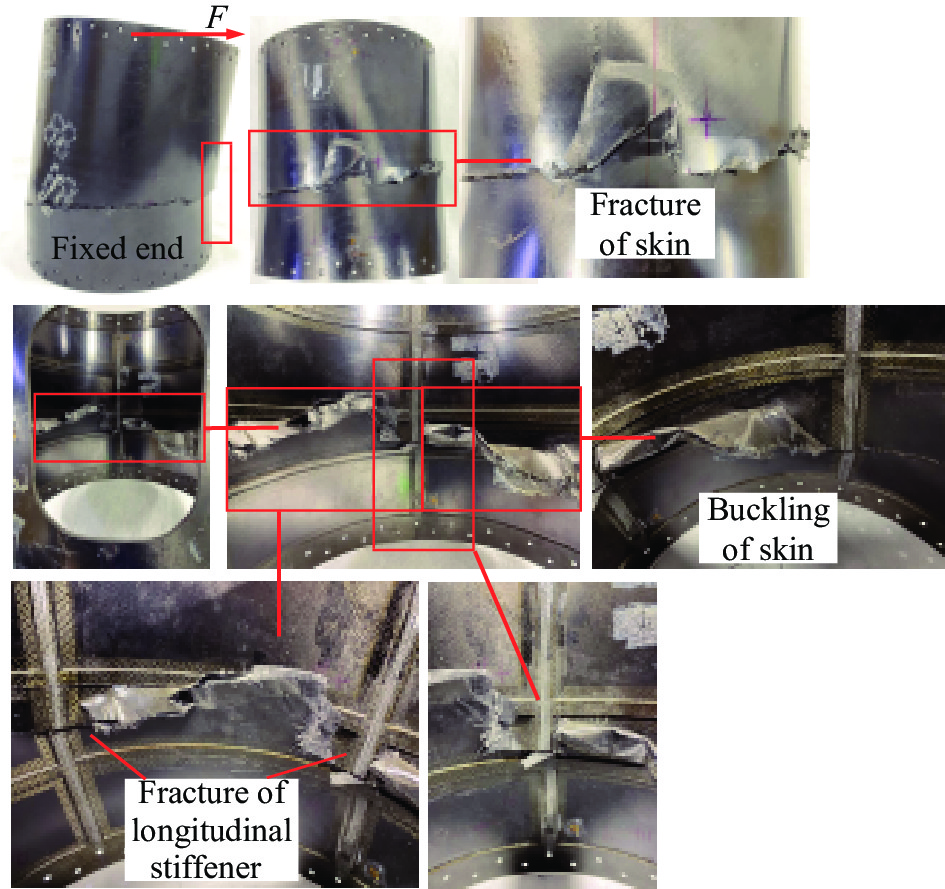

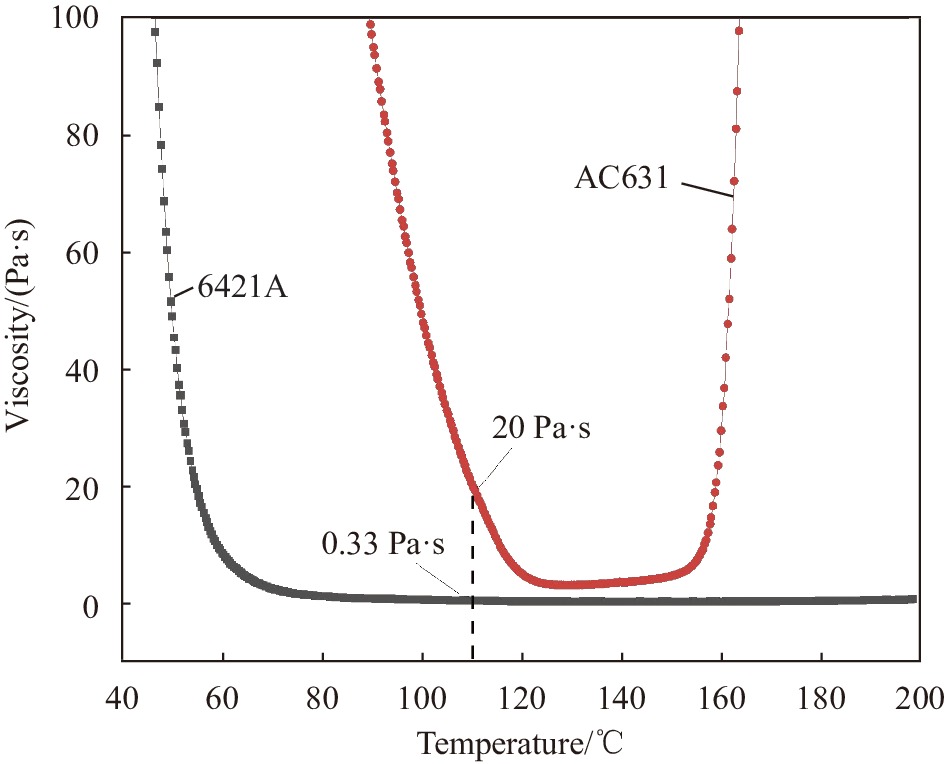

摘要: 针对舱段的结构特点设计了一种预浸料-树脂传递模塑(RTM)成型工艺。研究了预浸料树脂(AC631)与RTM树脂(6421A)的流变特性,结果表明两种树脂体系具有良好的共成型工艺基础。结合舱段结构设计、铺层设计、模具设计,开展了基于预浸料-RTM共成型技术的复合材料纵横加筋舱段一体化制备工艺验证,结果表明舱段结构具有良好的表观质量、尺寸精度及内部质量。常温、高温两种条件静强度试验验证了其使用强度,高温破坏试验研究了其失效机制与破坏模式。常温力学试验结果表明:在125%严酷机械载荷下,复合材料舱段能够保持良好的结构完整性,其最大应变仅为−1283×10−6 ,满足常温静强度设计要求。100℃下静强度试验结果显示,舱段在125%严酷机械载荷下未出现失稳、破坏等异常状态,最大应变仅为−1315 ×10−6,满足热力耦合工况条件下的强度设计要求。150℃高温破坏试验结果显示,舱段在143.2%严酷机械载荷下,加载侧纵向加强筋发生断裂破坏,裂纹向两侧延伸,舱段丧失承载能力,破坏模式为轴向筋条断裂导致蒙皮局部屈曲失稳破坏。

-

关键词:

- 复合材料 /

- 纵横加筋舱段 /

- 预浸料-树脂传递模塑共成型工艺 /

- 力学响应 /

- 破坏机制

Abstract: A hybrid prepreg-resin transfer moulding (Prepreg-RTM) process was proposed to realize the integration manufacturing of composite cross stiffened composite cabin. The rheological properties of prepreg resin (AC631) and RTM resin (6421A) were studied. The results show that the two resin systems have good co-forming processes basis. Combined with cabin structure design, layup design and mould design, the integrated preparation process of composite cross stiffened cabin based on hybrid Prepreg-RTM technology was verified. The results show that the cabin structure has good surface quality, dimensional accuracy and internal quality. The service strength of cabin was verified by static strength tests at room temperature and high temperature, and its failure mechanism and failure mode were studied by high temperature failure test. The results of static strength test at room temperature show that the cabin maintains good structural integrity under 125% service load, and the maximum strain of the cabin is −1283×10−6 which meets the static strength design requirements. The static strength test results at 100℃ reveal that the maximum strain of the cabin is −1315 ×10−6. There is no abnormal state such as instability and failure occurred in the cabin, which meets the requirements of thermal-mechanical coupling condition design. The high temperature failure experiment results demonstrated that the cross stiffened composite cabin failed under 143.2% service load at high temperature of 150℃, caused by the fracture of the longitudinal stiffener in loading side, where the crack propagated to both sides. The failure model of the cabin is local buckling of skin due to the fracture of the longitudinal stiffener. -

-

表 1 预浸料及定型织物物理性能

Table 1 Physical property parameter of prepreg and tackified fabric

Project Area density of fiber/(g·m−2) Resin con-

tent/wt%Ply thickness/

mmAC631/CCF800H 133±5 33±2 0.125±0.010 AC631/CF8611 196±7 40±3 0.260±0.010 ET-280/U-8190 190±7 6±1 0.200±0.010 -

[1] 罗楚养, 张朋, 李伟东, 等. 高温复合材料在空空导弹上的应用研究[J]. 航空科学技术, 2017, 28(1):19-24. LUO Chuyang, ZHANG Peng, LI Weidong, et al. Application research of high temperature composite on airborne missile[J]. Aeronautical Science and Technology,2017,28(1):19-24(in Chinese).

[2] 庄羊澎, 文子豪, 江晟达, 等. 耐高温复合材料舵面根部结构设计与验证[J]. 复合材料科学与工程, 2022(2):45-51. DOI: 10.19936/j.cnki.2096-8000.20220228.007 ZHUANG Yangpeng, WEN Zihao, JIANG Shengda, et al. Design and testing of root junctional structure of high temperature composite rudders[J]. Composites Science and Engineering,2022(2):45-51(in Chinese). DOI: 10.19936/j.cnki.2096-8000.20220228.007

[3] SUDHIN A U, REMANANB M, AJEESH G C, et al. Comparison of properties of carbon fiber reinforced thermoplastic and thermosetting composites for aerospace applications[J]. Materials Today,2020,24:453-462.

[4] 罗楚养, 孙毓凯, 王文博, 等. 空空导弹结构技术的研究进展[J]. 航空兵器, 2019, 26(5):1-10. LUO Chuyang, SUN Shukai, WANG Wenbo, et al. Research and development on structure technology of air-to-air missile[J]. Aero Weaponry,2019,26(5):1-10(in Chinese).

[5] 张国庆, 罗楚养, 胡凯征. 耐高温复合材料舱体口盖设计方法研究[J]. 机械设计与制造, 2021(2):23-26. ZHANG Guoqing, LUO Chuyang, HU Kaizheng. Study on design method of high temperature composite material hatch cover[J]. Machinery Design and Manufacture,2021(2):23-26(in Chinese).

[6] SEIF M A, KHASHABA U A, ROJAS-OVIEDO R. Residual stress measurements in CFRE and GFRE composite missile shells[J]. Composite Structures,2007,79(2):261-269. DOI: 10.1016/j.compstruct.2006.01.002

[7] 罗楚养, 吴催生, 魏仲委, 等. 高温复合材料舵面研制与试验验证[J]. 复合材料学报, 2014, 31(5):1312-1320. LUO Chuyang, WU Cuisheng, WEI Zhongwei, et al. Manufacturing and testing for high temperature composite rudder[J]. Acta Materiae Compositae Sinica,2014,31(5):1312-1320(in Chinese).

[8] 房雷. 复合材料壳体在空空导弹固体火箭发动机中的应用研究[J]. 航空兵器, 2013(2):42-45. DOI: 10.3969/j.issn.1673-5048.2013.02.011 FANG Lei. Study on application of composite case in solid rocket motor in airborne missile[J]. Aero Weaponry,2013(2):42-45(in Chinese). DOI: 10.3969/j.issn.1673-5048.2013.02.011

[9] HARDWICK J G. CFRP rocket motor tubes wound with continuous pre-impregnated fibres[J]. Composites,1981,12(1):41-47. DOI: 10.1016/0010-4361(81)90399-2

[10] 王强. 面向复合材料J字型加强筋的自动化成型工艺设计[D]. 大连: 大连理工大学, 2021. WANG Qiang. Automated molding process design for J-shaped reinforcing ribs of composite materials[D]. Dalian: Dalian University of Technology, 2021(in Chinese).

[11] CZAPSKI P, JAKUBCZAK P, BIENIAŚ J, et al. Influence of autoclaving process on the stability of thin-walled, composite columns with a square cross-section—Experimental and numerical studies[J]. Composite Structures,2020,250:112594. DOI: 10.1016/j.compstruct.2020.112594

[12] DONG C C, ZHOU J X, YIN Y J, et al. Study of the curing process of carbon fiber reinforced resin matrix composites in autoclave processing[J]. Procedia Manufacturing,2019,37:450-458. DOI: 10.1016/j.promfg.2019.12.073

[13] 岳波, 许英杰, 徐宁鑫, 等. 热压罐成型框架式模具结构拓扑优化设计[J]. 航空学报, 2022, 43(3):541-553. YUE Bo, XU Yingjie, XU Ningxin, et al. Technology optimization of frame mold for autoclave process[J]. Atca Aeronautica et Astronautica Sinica,2022,43(3):541-553(in Chinese).

[14] 徐竹. 栅格天线反射面的热压罐成型工艺研究[J]. 工业加热, 2021, 50(11):21-23. DOI: 10.3969/j.issn.1002-1639.2021.11.005 XU Zhu. Research on autoclave forming process of reflecting surface of grid antenna[J]. Industrial Heating,2021,50(11):21-23(in Chinese). DOI: 10.3969/j.issn.1002-1639.2021.11.005

[15] 李树健, 湛利华, 彭文飞, 等. 先进复合材料构件热压罐成型工艺研究进展[J]. 稀有金属材料与工程, 2015, 44(11):2927-2931. LI Shujian, ZHAN Lihua, PENG Wenfei, et al. Research progress of autoclave molding for advanced composite components[J]. Rare Metal Materials and Engineering,2015,44(11):2927-2931(in Chinese).

[16] 李奇辉, 郭俊刚. 圆柱形复合材料螺旋单元的成型技术研究[J]. 复合材料科学与工程, 2020(4):125-128. DOI: 10.3969/j.issn.1003-0999.2020.04.021 LI Qihui, GUO Jungang. The research on molding technology of cylindrical spiral element in composite material[J]. Composite Science and Engineering,2020(4):125-128(in Chinese). DOI: 10.3969/j.issn.1003-0999.2020.04.021

[17] 陈磊. 复合材料热压罐成型固化回弹变形预测及其优化[D]. 长沙: 湖南大学, 2017. CHEN Lei. The prediction and optimization of the spring back of composite structure for autoclave molding[D]. Changsha: Hunan University, 2017(in Chinese).

[18] STARK W, JAUNICH M, MCHUGH J. Carbon-fibre epoxy prepreg (CFC) curing in an autoclave analogue process controlled by dynamic mechanical analysis (DMA)[J]. Polymer Testing,2013,32(8):1487-1494. DOI: 10.1016/j.polymertesting.2013.09.014

[19] 凌辉, 周宇, 尚呈元, 等. 非热压罐预浸料成型技术研究进展[J]. 宇航材料工艺, 2019, 49(5):6-11. DOI: 10.12044/j.issn.1007-2330.2019.05.002 LING Hui, ZHOU Yu, SHANG Chengyuan, et al. Research progress of out-of-autoclave prepreg processing technology[J]. Aerospace Materials and Technology,2019,49(5):6-11(in Chinese). DOI: 10.12044/j.issn.1007-2330.2019.05.002

[20] 曾竟成, 尹昌平, 刘钧. 软模辅助RTM成型舱段构件及其性能研究[J]. 材料工程, 2006(6):28-32. DOI: 10.3969/j.issn.1001-4381.2006.06.008 ZENG Jingcheng, YIN Changping, LIU Jun. Fabrication of the cabin component by flexible-mould assisted RTM process and its performance[J]. Journal of Materials Engineering,2006(6):28-32(in Chinese). DOI: 10.3969/j.issn.1001-4381.2006.06.008

[21] POODTS E, MINAK G, MAZZOCCHETTI L, et al. Fabrication, process simulation and testing of a thick CFRP component using the RTM process[J]. Composites Part B: Engineering,2014,56:673-680. DOI: 10.1016/j.compositesb.2013.08.088

[22] VITA A, CASTORANI V, GERMANI M, et al. Comparative life cycle assessment of low-pressure RTM, compression RTM and high-pressure RTM manufacturing processes to produce CFRP car hoods[J]. Procedia CIRP,2019,80:352-357. DOI: 10.1016/j.procir.2019.01.109

[23] 李琼, 王强, 朱成香, 等. RTM整体成型机尾罩结构设计技术研究[J]. 教练机, 2016(3):57-61. LI Qiong, WANG Qiang, ZHU Chengxiang, et al. Study on structural design techniques of tail fairing integrally formed using RTM[J]. Trainer,2016(3):57-61(in Chinese).

[24] AOKI Y, ISHIKAWA T, TAKEDA S I, et al. Fatigue test of lightweight composite wing structure[J]. International Journal of Fatigue,2006,28(10):1109-1115. DOI: 10.1016/j.ijfatigue.2006.02.017

[25] 江晟达, 罗楚养, 张朋, 等. 基于RTM技术的碳纤维/聚酰亚胺复合材料舵面一体化制备与验证[J]. 复合材料学报, 2020, 37(9):2152-2162. JIANG Shengda, LUO Chuyang, ZHANG Peng, et al. Integration manufacturing and testing verification for RTM able carbon fiber/polyimide composite rudder[J]. Acta Materiae Compositae Sinica,2020,37(9):2152-2162(in Chinese).

[26] LIU G, LUO C Y, ZHANG D J, et al. Mechanical performance and failure mechanism of thick-walled composite connecting roads fabricated by resin transfer moulding technique[J]. Applied Composite Material,2015,22(4):423-436. DOI: 10.1007/s10443-014-9415-2

[27] 罗楚养, 江晟达, 陈梦熊, 等. 基于高温RTM工艺的碳纤维/聚酰亚胺复合材料连接环制备与验证[J]. 航空学报, 2021, 42(7):69-81. DOI: 10.7527/S1000-6893.2021.25438 LUO Chuyang, JIANG Shengda, CHEN Mengxiong, et al. Preparation and evaluation for carbon fiber/polyimide composite attaching collars based on resin transfer mould process[J]. Acta Aeronautica et Astronautica Sinica,2021,42(7):69-81(in Chinese). DOI: 10.7527/S1000-6893.2021.25438

[28] 罗维, 郭强, 赵文琛, 等. 复合材料纵横加筋隔框RTM成型工艺[J]. 宇航材料工艺, 2021, 51(6):44-48. DOI: 10.12044/j.issn.1007-2330.2021.06.007 LUO Wei, GUO Qiang, ZHAO Wenchen, et al. Composite frame with stringer-stiffened feature by resin transfer moulding[J]. Aerospace Materials and Technology,2021,51(6):44-48(in Chinese). DOI: 10.12044/j.issn.1007-2330.2021.06.007

[29] 陈吉平, 苏佳智, 韩小勇, 等. 复合材料工型肋的RTM工艺模拟与优化[J]. 玻璃钢/复合材料, 2017(7):82-87. CHEN Jiping, SU Jiazhi, HAN Xiaoyong, et al. Simulation and optimization of RTM technology for composite “I” section rib parts[J]. Composites Science and Engineering,2017(7):82-87(in Chinese).

[30] 张明龙, 肖加余. 气囊辅助RTM工艺成型导弹舱段构件[J]. 复合材料学报, 2008(1):23-27. DOI: 10.3321/j.issn:1000-3851.2008.01.004 ZHANG Minglong, XIAO Jiayu. Missile cabin fabrication by bladder-assisted RTM[J]. Acta Materiae Compositae Sinica,2008(1):23-27(in Chinese). DOI: 10.3321/j.issn:1000-3851.2008.01.004

[31] 蒋诗才, 包建文, 张连旺, 等. 液体成型树脂基复合材料及其工艺研究进展[J]. 航空制造技术, 2021, 64(5):70-81, 102. JIANG Shicai, BAO Jianwen, ZHANG Lianwang, et al. Research progress of liquid molding resin matrix composites and its technology[J]. Aeronautical Manufacturing Technology,2021,64(5):70-81, 102(in Chinese).

[32] 赵秀芬, 刘刚, 李伟东. 液态成型复合材料在直升机上的应用[J]. 航空制造技术, 2017, 536(17):60-64. DOI: 10.16080/j.issn1671-833x.2017.17.060 ZHAO Xiufen, LIU Gang, LI Weidong. Application of liquid molding composites in helicopter[J]. Aeronautical Manufacturing Technology,2017,536(17):60-64(in Chinese). DOI: 10.16080/j.issn1671-833x.2017.17.060

[33] 李伟东, 刘刚, 包建文, 等. 贫胶预浸料-RTM成型工艺及其复合材料力学性能研究[J]. 航空材料学报, 2014, 34(3):57-62. DOI: 10.11868/j.issn.1005-5053.2014.3.009 LI Weidong, LIU Gang, BAO Jianwen, et al. Research of processing characteristics and mechanical properties of semi-prepreg RTM composites[J]. Journal of Aeronautical Materials,2014,34(3):57-62(in Chinese). DOI: 10.11868/j.issn.1005-5053.2014.3.009

[34] 郑亚萍, 陈伟, 李江红, 等. RTM和预浸料共固化树脂体系界面层特性[J]. 复合材料学报, 2013, 30(3):35-38. ZHENG Yaping, CHEN Wei, LI Jianghong, et al. Interface properties of RTM and prepreg process co-curing system[J]. Acta Materiae Compositae Sinica,2013,30(3):35-38(in Chinese).

[35] 何先成, 刘刚, 包建文. 预浸料在RTM工艺中的应用研究[J]. 玻璃钢/复合材料, 2015(4):71-75, 34. HE Xiancheng, LIU Gang, BAO Jianwen. Application of prepreg in RTM process[J]. Composites Science and Engineering,2015(4):71-75, 34(in Chinese).

[36] 许亚洪. 巡航导弹树脂基结构复合材料的应用与发展[J]. 热固性树脂, 2008, 23(S1):36-38, 46. DOI: 10.3969/j.issn.1002-7432.2008.z1.009 XU Yahong. Application and development of resin matrix structural composite for cruise missile[J]. Thermosetting Resin,2008,23(S1):36-38, 46(in Chinese). DOI: 10.3969/j.issn.1002-7432.2008.z1.009

[37] 国防科学技术工业委员会. 纤维增强复合材料无损检验方法 第1部分 超声波检验: GJB 1038.1 A—2004[S]. 北京: 国防科工委军标出版社, 2004. Commission of Science, Technology and Industry for National Defense. Non-destructive inspecting methods of fiber reinforced composite Part 1: Ultrasonic testing: GJB 1038.1 A—2004[S]. Beijing: Military Commission for Science, Technology and Industry for National Defense Press, 2004(in Chinese).

[38] 中国航空工业总公司. 复合材料构件通用技术条件: HB 7224—1995[S]. 北京: 中国航空工业总公司第301研究所出版社, 1995. China National Aviation Corporation. General specification for composite components: HB 7224—1995[S]. Beijing: China Aviation Industry Corporation 301st Research Institute Press, 1995(in Chinese).

[39] 郭志峰, 郭丽敏, 肖文刚, 等. 受内压复合材料压力容器应力状态数值模拟[C]//第十五届玻璃钢/复合材料学术年会论文集. 北京: 2003, 7-12. GUO Zhifeng, GUO Limin, XIAO Wengang, et al. Finite element analysis on the stress of composite pressure vessel under internal pressure loading[C]//Proceedings of the Fifteen Annual FRP/Composites Conference. Beijing: 2003, 7-12(in Chinese).

[40] 马少华, 费昺强, 许良, 等. 热氧老化对碳纤维双马树脂基复合材料性能的影响[J]. 材料工程, 2017, 45(12):50-57. DOI: 10.11868/j.issn.1001-4381.2016.000981 MA Shaohua, FEI Bingqiang, XU Liang, et al. Influence of thermal-oxidative aging on property of carbon fiber bismaleimide resin composites[J]. Material Engineering,2017,45(12):50-57(in Chinese). DOI: 10.11868/j.issn.1001-4381.2016.000981

[41] 邹田春, 安涛, 杨旭东, 等. 干燥温度对CFRP力学性能的影响及作用机理[J]. 塑料, 2019, 48(3):12-15, 18. ZOU Tianchun, AN Tao, YANG Xudong, et al. Effect of dried temperatures on mechanical properties and mecha-nism of CERP[J]. Plastic,2019,48(3):12-15, 18(in Chinese).

[42] EFTEKHARI M, FATEMI A. Tensile behavior of thermoplastic composites including temperature, moisture, and hygrothermal effects[J]. Polymer Testing,2016,51:151-164. DOI: 10.1016/j.polymertesting.2016.03.011

[43] 张荣荣. 开孔变刚度复合材料壁板结构的压缩屈曲性能及失效分析[D]. 南京: 南京航空航天大学, 2017. ZHANG Rongrong. Research on variable-stiffness compo-site thin plates with holes of buckling and failure under compression[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2017(in Chinese).

[44] 邹华民. 含初始分层缺陷复合材料加筋壁板承载性能分析[D]. 大连: 大连理工大学, 2017. ZOU Huamin. Bearing capacity analysis of composite stiffened panels with initial delamination defects[D]. Dalian: Dalian University of Technology, 2017(in Chinese).

-

下载:

下载: