Isocyanate modified fumed silica and its effects on the mechanical properties of casting polyurethane elastomer

-

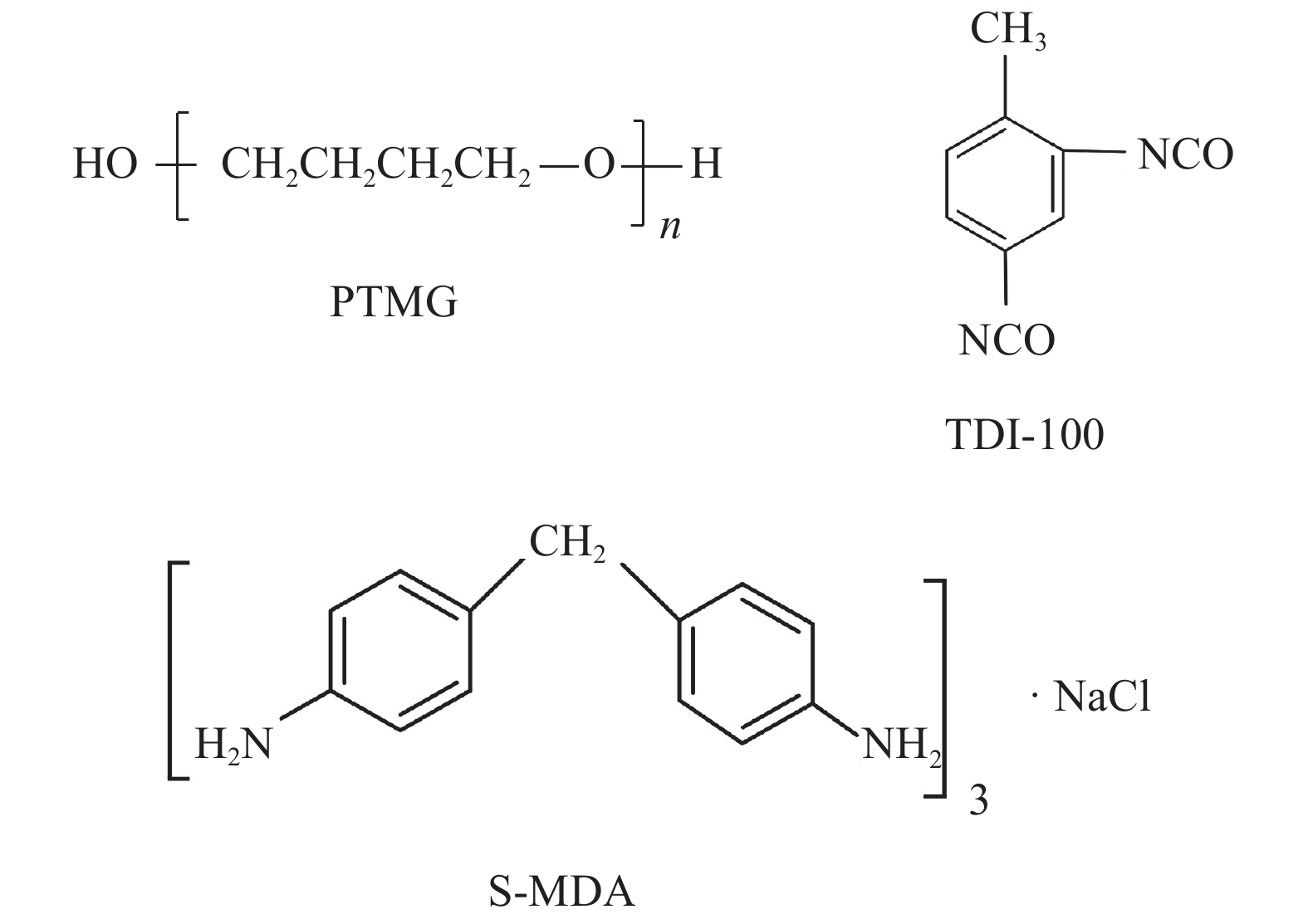

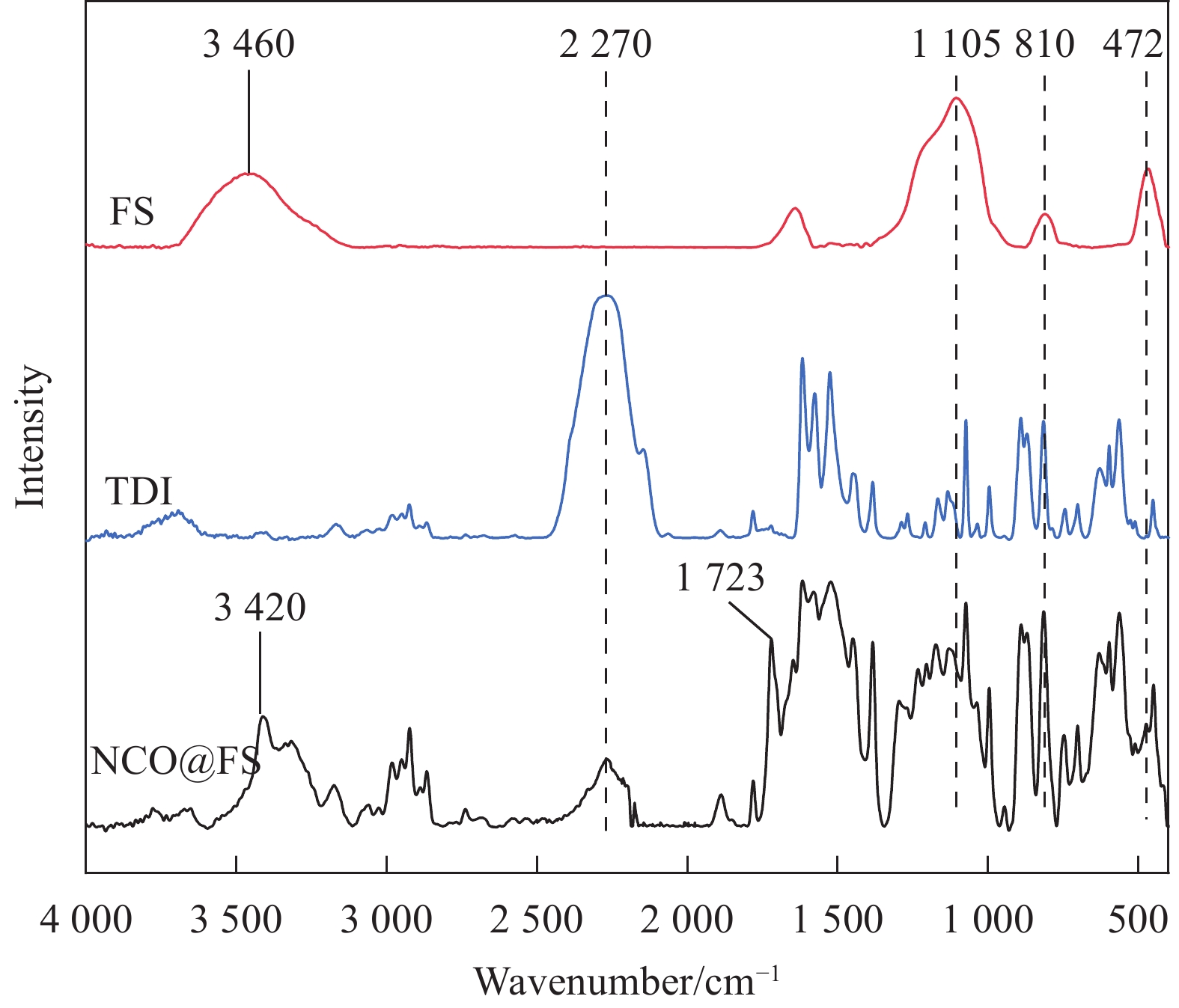

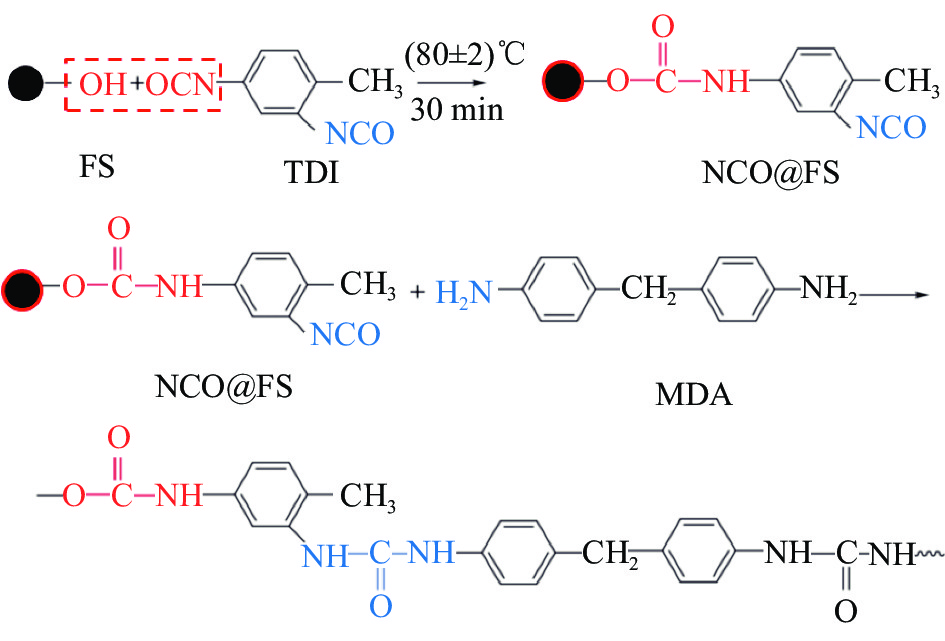

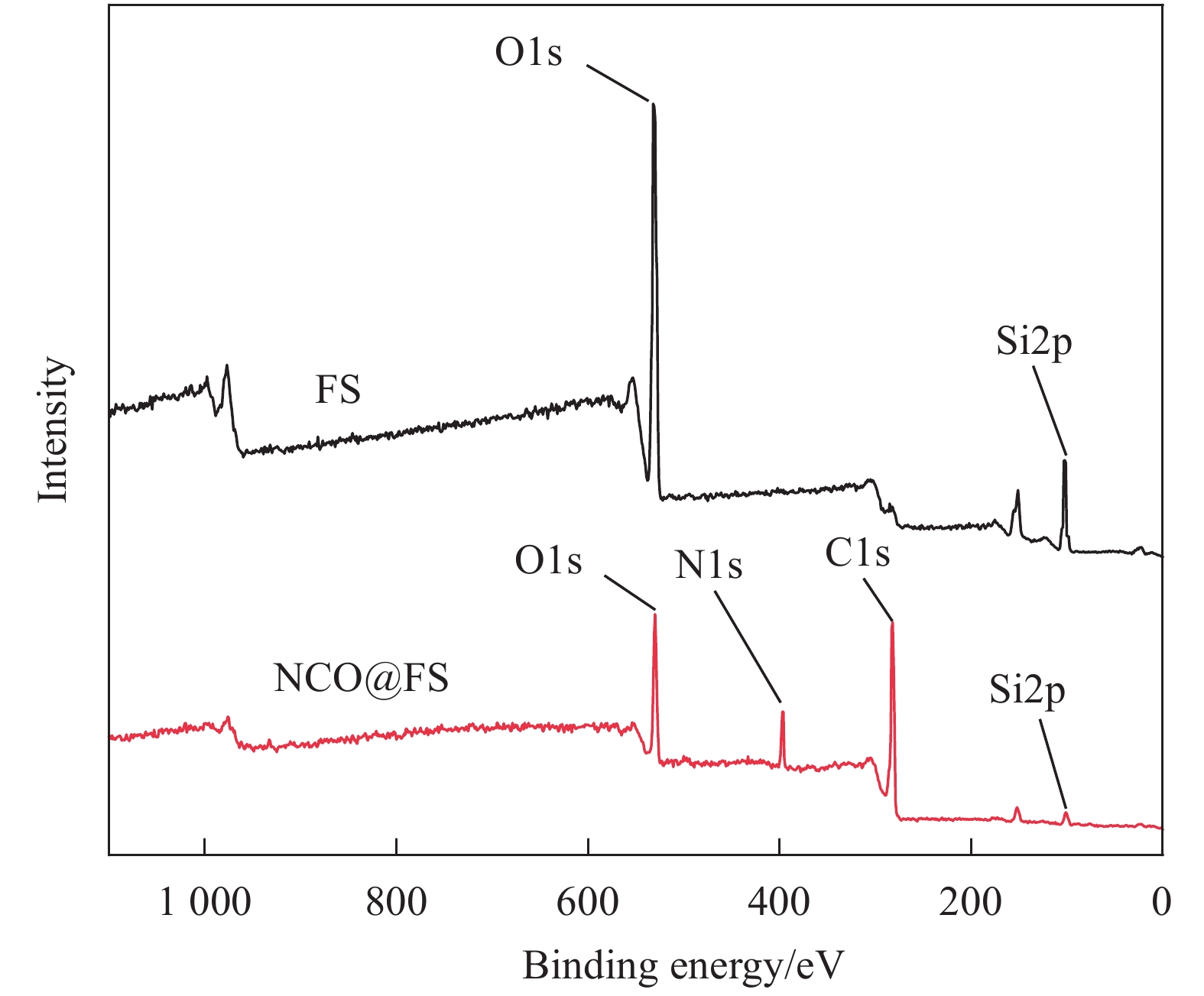

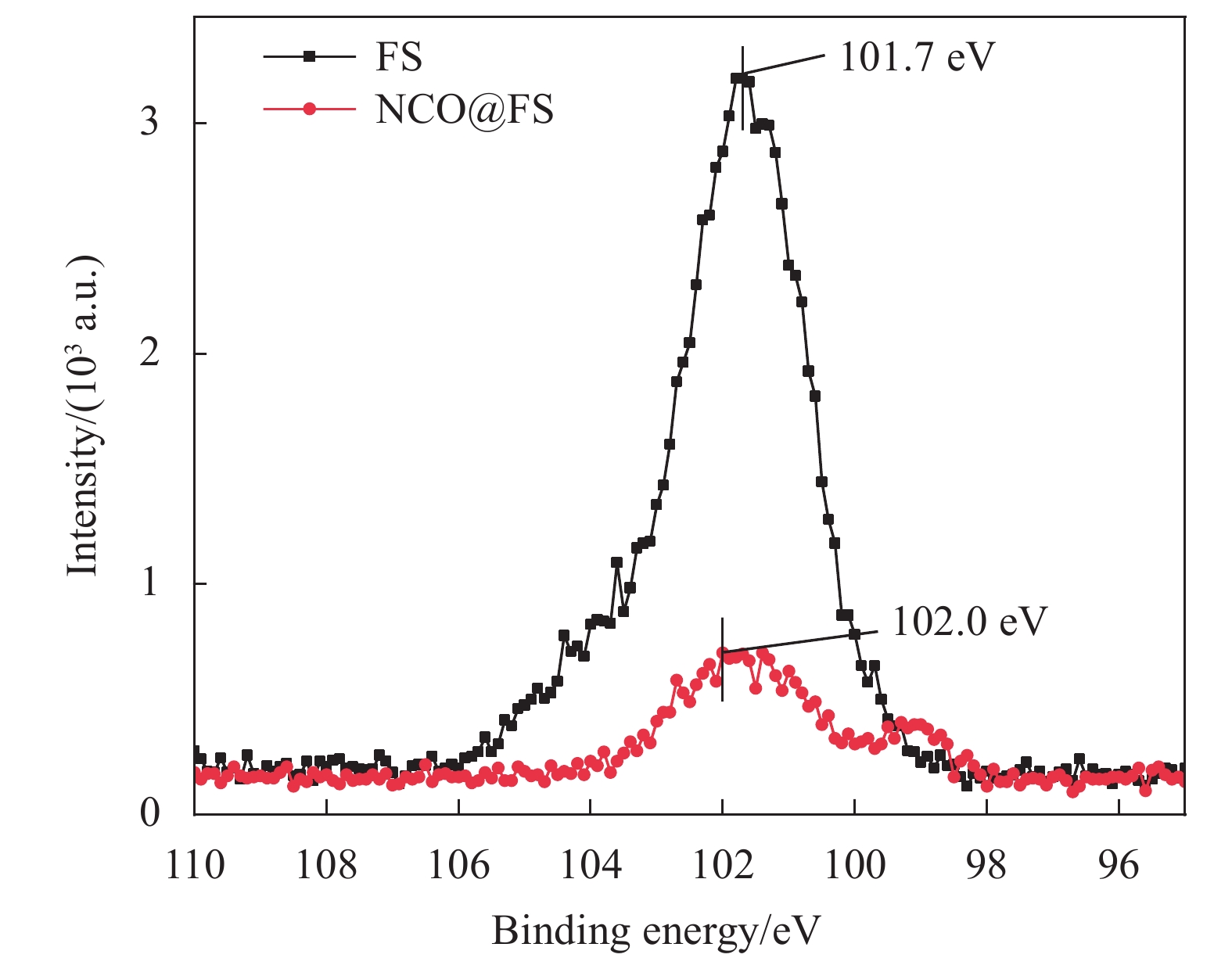

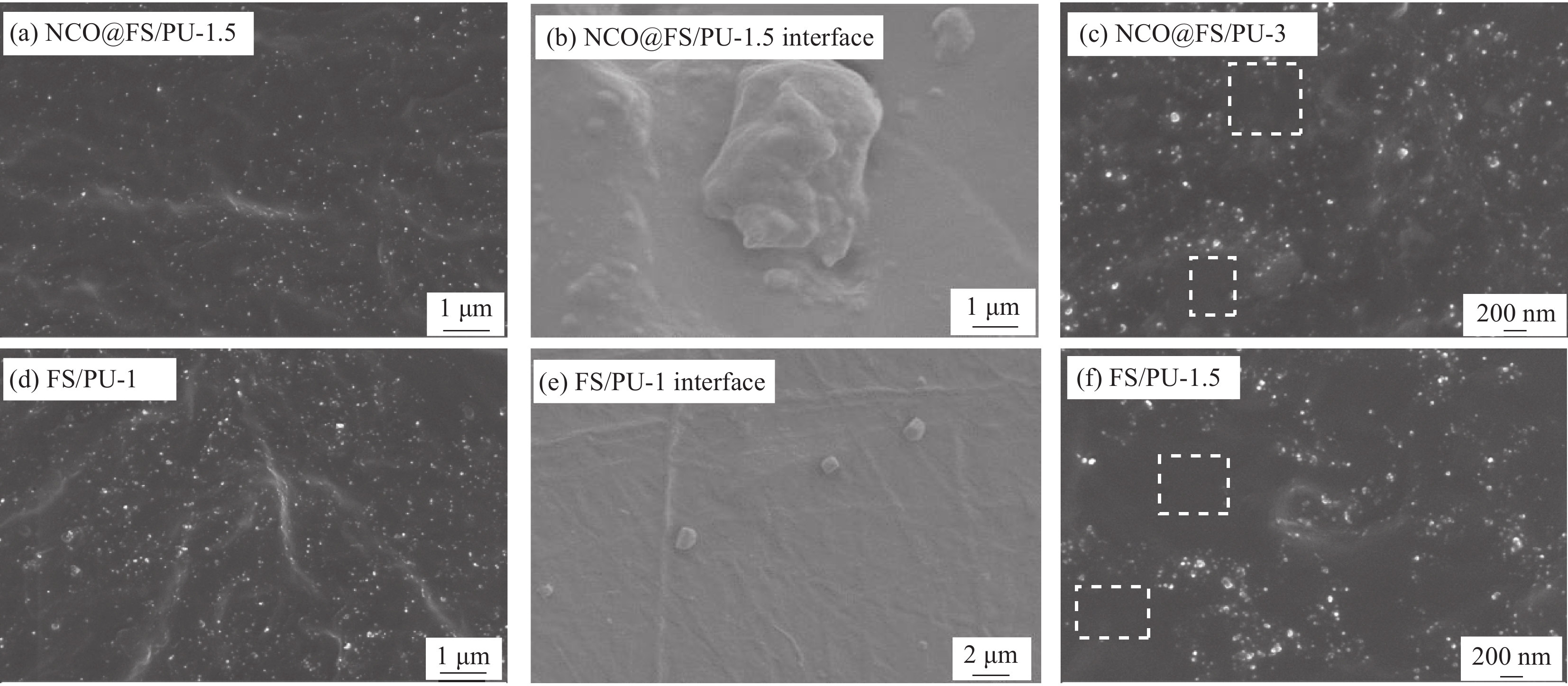

摘要: 为了改善气相二氧化硅(FS)/浇注型聚氨酯(PU)体系成型流动性,在制备预聚体的过程中,采用2, 4-甲苯二异氰酸酯(TDI)进行改性获得异氰酸酯改性的二氧化硅(NCO@FS),通过原位聚合法制备了NCO@FS/PU弹性体复合材料。采用FTIR、XPS及动态接触角对NCO@FS及FS进行了表征。结果表明:FS的表面羟基与TDI的—NCO基团发生反应生成了氨酯基(—NHCOO),改善了FS与PU间的界面相容性及界面结合。复合材料中NCO@FS质量分数为1.5wt%时,NCO@FS/PU复合材料的拉伸和撕裂强度分别为57 MPa和110.5 kN/m,比纯浇注型PU分别提高了31.6%和23.6%;玻璃化转变温度由3.4℃下降到−11.2℃,损耗因子tanδ由0.59下降到0.46。异氰酸酯改性FS适合制备FS增强浇注型聚氨酯复合材料。Abstract: In order to improve the molding fluidity of fumed silica (FS)/cast polyurethane (PU) system, in the process of preparing prepolymer, the fumed silica (FS) was modified by 2, 4-toluene diisocyanate (TDI) to obtain TDI modified silica (NCO@FS), and TDI modified silica/reinforced pouring polyurethane (NCO@FS/PU) elastomer composite material was prepared by in-situ polymerization. NCO@FS and FS were characterized by fourier transform infrared spectroscopy (FTIR), X-ray photoelectron spectroscopy (XPS) and contact angle testing. The results show that the active hydroxyl groups on the surface of FS react with the —NCO groups of TDI to form urethane groups aminoester group (—NHCOO), which improves the interfacial compatibility and interfacial bonding between silica and casting polyurethane. When the mass fraction of NCO@FS in the composite material is 1.5wt%, the tensile and tearing strengths of the NCO@FS/PU composite material are 57 MPa and 110.5 kN/m, respectively, which are 31.6% and 23.6% higher than that of pure casting PU. The glass transition temperature dropped from 3.4°C to –11.2°C, and the loss factor tanδ dropped from 0.59 to 0.46. TDI modified fumed silica is suitable for preparing silica-reinforced cast polyurethane composites.

-

Keywords:

- isocyanate modification /

- fumed silica /

- polyurethane /

- composites /

- mechanical properties

-

蜂窝夹层结构具有比模量大、隔音、隔热、吸能强、成本低等优点,在航空航天、交通运输、土木建筑、海洋船舶等许多领域都有广泛的应用[1]。碳纤维增强树脂复合材料(CFRP)蒙皮-铝蜂窝夹层板主要通过蜂窝芯和蒙皮的变形、损伤及内能形式将冲击能量加以耗散,从而达到吸能的目的[2-3]。CFRP板和铝蜂窝在生产和使用过程中都容易受到低速冲击的影响,而且蜂窝夹层板在低速冲击下的损伤一般是目视不可见的,但这种损伤却能够明显降低零部件的寿命和强度[4-5]。因此,研究结构参数对CFRP蒙皮-铝蜂窝夹层结构低速冲击性能的影响很有必要。

国内外有大量关于蜂窝夹层板在不同载荷下力学性能的研究[6-11]。Zhang等[12]通过摆锤冲击试验和数值模拟方法研究了铝蜂窝夹层结构在低速冲击下的动力学特性,并得出结论:蜂窝芯是主要的吸能构件。Chen等[13]通过落锤式低速冲击试验与数值模拟方法验证了试验与仿真结果的一致性,并探究了CFRP面板-Nomex蜂窝夹层结构的损伤机制。A. Riccio等[14]结合落锤冲击试验和仿真模型探究了亚麻天然纤维蜂窝的吸能效果,试验与仿真结果吻合较好。Sun等[15]通过解析法研究了金属蒙皮蜂窝夹层板在低速冲击下的动态响应,通过与已有的试验结果对比,证明了其解析法的可靠性。Vincenzo Crupi等[16]结合试验方法和数值模型,研究了玻璃纤维增强树脂复合材料(GFRP)面板对低速冲击下铝蜂窝结构动力学性能的影响,发现GFRP面板是增强蜂窝夹层板能量吸收和承载能力的重要构件。Inés Ivañez等[17]基于材料用户子程序建立了CFRP面板-铝蜂窝夹层梁低速冲击有限元模型,通过多次试验对比验证了仿真模型的有效性,并得出结论:蜂窝夹层结构受低速冲击时,冲击能量较大时,蒙皮吸能较多,冲击能量较小时,蜂窝芯吸能较多。

目前对不同材料蜂窝夹层板在低速冲击下动态响应的研究有很多[18-22],但CFRP蒙皮-铝蜂窝夹层板在低速冲击下的损伤模式相对较复杂,关于建立该类型夹层板在低速冲击下的精细化仿真模型,以探究其结构参数对抗低速冲击性能的影响以及各组件损伤对吸能占比的研究比较少,研究结构参数对该类型蜂窝夹层板低速冲击性能的影响,对其在实际工程中的应用及结构参数优化有重要的指导意义。本文使用半球头式落锤冲击试验平台和高速摄像分析平台,进行了蜂窝芯单元边长对CFRP蒙皮-铝蜂窝夹层板抗低速冲击性能影响的试验探究,根据试验结果验证了所建仿真模型的准确性。利用该数值模型进一步探究了蜂窝芯高度、蒙皮厚度和蜂窝芯壁厚等结构参数对蜂窝夹层板低速冲击性能的影响。

1. 试 验

1.1 试验材料及设备

基于D7766/D7766M—11标准[23],搭建了如图1所示的CFRP蒙皮-铝蜂窝夹层板落锤冲击试验平台,平台主要构成设备包括:XBL-300型落锤式低速冲击试验机及数据采集装置,厂家为长春科新试验仪器有限公司。其中,控制平台、落锤、夹具和防二次冲击装置是试验机的主要构件。使用的i-speed 2系列高速摄像机及配备的ProAnalyst数码分析软件由Xcitex公司提供,如图2所示。

试件蒙皮均采用由威海光威复合材料有限公司提供的CFRP层合板,CFRP蒙皮是型号为T300/7901的碳纤维增强环氧树脂复合材料,铺层顺序为(45/-45/0)2s,单层厚度为0.1 mm,单块蒙皮长L=100 mm,宽W=100 mm,厚Tf =1.2 mm;铝蜂窝采用Al 3003-H19铝箔粘接而成,蜂窝芯壁厚Tc=0.06 mm,铝芯高Hc=20 mm,正六边形蜂窝芯单元边长Lc=2 mm、4 mm、6 mm;蜂窝芯与蒙皮之间采用LJM-170胶膜进行粘接;夹层板总体尺寸为100 mm×100 mm×22.4 mm。图3为蜂窝夹层板的几何构型示意图及试件,表1为T300/7901层合板的材料参数[24],表2为Al 3003-H19铝箔的材料参数。

表 1 CFRP蒙皮的材料参数Table 1. Mechanical properties of CFRP laminatesT300/7901 Value Adhesive Value E1/MPa 125 000 GCn/(N⋅mm−1) 0.52 E2,E3/MPa 11 300 GCs,GCt/(N⋅mm−1) 0.92 G12,G13/MPa 5 430 σn,max 50 {G_{23}}{\rm{/MPa}} 3 979 {\sigma _{{\rm{s}},\max }}{\rm{/MPa}} 94 ν12, ν23 0.3 {\sigma _{{\rm{t}},\max }}{\rm{/MPa}} 94 ν23 0.42 {K_{\rm{n}}}{\rm{/(N}} \cdot {\rm{m}}{{\rm{m}}^{ - {\rm{3}}}}{\rm{)}} 100 000 {X_{\rm{T}}}{\rm{/MPa}} 2 000 {K_{\rm{s} } },{K_{\rm{t} } }{\rm{/(N} } \cdot {\rm{m} }{ {\rm{m} }^{ - {\rm{3} } } }{\rm{)} } 100 000 {X_{\rm{C}}}{\rm{/MPa}} 1 100 {Y_{\rm{T}}},{Z_{\rm{T}}}{\rm{/MPa}} 80 {Y_{\rm{C}}},{Z_{\rm{T}}}{\rm{/MPa}} 280 S{\rm{/MPa}} 120 Notes: Ei(i=1,2,3) is Young’s modulus in i direction; Gij(i,j=1,2,3) is shear modulus in i-j plane; νij(i,j=1,2,3) is Poisson’s ratio in i-j plane; Xt/Xc and Yt/Yc are the tensile/compressive strengths in 1 and 2 directions, respectively; S is shear strength; G_{\rm{n}}^{\rm{C}} is toughness in tension; G_{\rm{s}}^{\rm{C}}and G_{\rm{t}}^{\rm{C}} are toughness components in shear; σn,max is maximum nominal stress of normal-only mode; σs,max and σt,max are maximum nominal stress in 1 and 2 directions, respectively; Kn is stiffness in tension; Ks and Kt are stiffness components in shear. 表 2 Al 3003-H19铝箔材料参数Table 2. Material properties of Al3003-H19 aluminum alloy foilProperty Value Density/(kg·m−3) 2 730 Young’s modulus/GPa 70 Poisson’s ratio 0.3 Yield strength/MPa 183 1.2 试验过程

在进行落锤冲击试验时,用夹具将试件固定,设置好落锤下降高度后进行冲击试验。落锤完成冲击时,防二次冲击装置会立刻夹紧落锤。冲击时压力传感器采集的冲击力数据由数据采集装置记录并保存;同时通过高速摄像机记录冲击过程,以便使用ProAnalyst数码分析软件获得落锤在冲击过程中的运动数据。冲击过程中的冲击试验参数:落锤质量m=2.5 kg,半球形冲头直径为25 mm,落锤下降高度h=0.48 m,理论冲击能量为E=11.76 J。由于落锤在下降过程中存在摩擦,通过高速摄像平台测得落锤接触夹层板时初始冲击速度为3.0 m/s,即实际冲击能量为11.25 J。

2. 数值计算模型

2.1 CFRP层合板本构模型

2.1.1 CFRP层合板层内渐进损伤模型

本文引用文献[24-25]中基于渐进损伤力学(CDM)方法对受损的CFRP蒙皮进行刚度退化,此方法定义了损伤因子Df,其值随着材料损伤的扩展而逐渐增大。层合板损伤后利用基于应力描述的三维Hashin准则进行损伤判定:

纤维拉伸失效

\left( {{\sigma _{11}} \geqslant 0} \right) :{\left( {\frac{{{\sigma _{11}}}}{{{X_{\rm{T}}}}}} \right)^2} + \frac{1}{{{S^2}}}\left( {\sigma _{12}^2 + \sigma _{13}^2} \right) \geqslant 1 (1) 纤维压缩失效

\left( {{\sigma _{11}} < 0} \right) :{\left( {\frac{{{\sigma _{11}}}}{{{X_{\rm{C}}}}}} \right)^2} \geqslant 1 (2) 基体开裂失效

\left( {{\sigma _{22}} + {\sigma _{33}} \geqslant 0} \right) :\frac{1}{{Y_{\rm{T}}^2}}{\left( {{\sigma _{22}} + {\sigma _{33}}} \right)^2} + \frac{1}{{{S^2}}}\left( {\sigma _{23}^2 - {\sigma _{22}}{\sigma _{23}}} \right) + \frac{1}{{{S^2}}}\left( {\sigma _{12}^2 + \sigma _{13}^2} \right) \geqslant 1 (3) 基体压溃失效

\left( {{\sigma _{22}} + {\sigma _{33}} < 0} \right) :\begin{split} \frac{1}{{{Y_{\rm{C}}}}}\left[ {{{\left( {\frac{{{Y_{\rm{C}}}}}{{2S}}} \right)}^2} - 1} \right]\left( {{\sigma _{22}} + {\sigma _{33}}} \right) + \frac{1}{{4{S^2}}}{\left( {{\sigma _{22}} + {\sigma _{33}}} \right)^2} + \\ \frac{1}{{{S^2}}}\left( {\sigma _{23}^2 - {\sigma _{22}}{\sigma _{23}}} \right) + \frac{1}{{{S^2}}}\left( {\sigma _{12}^2 + \sigma _{13}^2} \right) \geqslant 1 \end{split} (4) 其中,σij(i,j=1,2,3)为CFRP面板单元的各个方向应力张量。

2.1.2 CFRP层合板层间胶层损伤模型

基于内聚力(Cohesive)单元的双线性本构模型,建立了CFRP层合板胶层模型以模拟CFRP层合板的分层损伤。内聚力单元的双线性本构模型如图4所示[26-28],σ轴表示单元的应力,δ横轴表示单元的相对分离位移。当δ<δ0时,内聚力单元未破坏,其应力和相对位移呈线性关系,刚度为K,即O→A段;当δ0≤δ<δmax时,内聚力单元发生部分破坏,卸载时单元进入线性软化阶段,如图4中虚线部分,此时刚度为(1-Df)K,Df为损伤因子,即O→A→B→O段,如重加载,初始阶段内聚力单元的σ与δ的关系即对应O→B段;当δ≥δmax时,内聚力单元完全失效。

A点表示材料开始出现损伤,其对应的损伤准则为

{\left( {\frac{{{{\left( {{t_{\rm{n}}}} \right)}^2}}}{{t_{\rm{n}}^0}}} \right)^2} + {\left( {\frac{{{{\left( {{t_{\rm{s}}}} \right)}^2}}}{{t_{\rm{s}}^0}}} \right)^2} + {\left( {\frac{{{{\left( {{t_{\rm{t}}}} \right)}^2}}}{{t_{\rm{t}}^0}}} \right)^2} \geqslant 1 (5) 其中,

t_{\rm{n}}^0 、t_{\rm{s}}^0 、t_{\rm{t}}^0 分别表示内聚力单元的法向和两个切向强度。AB段表示内聚力单元的损伤扩展,本文选择与试验吻合度较高的基于能量释放率的B-K准则[24]:G_{\rm{n}}^{\rm{C}} + \left( {G_{\rm{s}}^{\rm{C}} - G_{\rm{n}}^{\rm{C}}} \right){\left( {\frac{{{G_{\rm{S}}}}}{{{G_{\rm{T}}}}}} \right)^\eta } = {G^{\rm{C}}} (6) 其中:GS=Gs+Gt,GT=Gn+GS,

G_{\rm{s}}^{\rm{C}} = G_{\rm{t}}^{\rm{C}} ;Gi(i=n,s,t)为Cohesive单元的应变能释放率;G_i^{\rm{C}} 为单元的临界应变能释放率;GC对应图4中△OAC的面积,即单元开裂对应的总临界能释放率;η为单元材料修正系数。2.2 CFRP蒙皮-铝蜂窝夹层板低速冲击有限元模型

基于CFRP层合板本构模型和用户材料子程序VUMAT,在ABAQUS有限元分析软件上建立蜂窝夹层板在低速冲击下的精细化仿真模型,如图5所示,蜂窝夹层板结构参数如表3所示。其中,层合板采用C3D8R单元,层间胶层采用COH3D8单元,铝蜂窝芯采用S4R壳单元;夹具和落锤均设置为刚体,夹具限制所有自由度,落锤仅保留冲击方向的自由度;假设蒙皮与蜂窝芯始终保持粘接,其接触类型设置为“Tie”,冲头与蒙皮采用“面-面接触”;为了节约计算成本,仅对临近冲击区域蒙皮进行网格细化,细化区域网格大小为1.5 mm×1.5 mm,其余区域网格大小为3 mm×3 mm,蜂窝芯网格大小为1 mm×2 mm。

表 3 CFRP蒙皮-铝蜂窝夹层板的结构参数Table 3. Structural parameters of aluminum honeycomb sandwich plate with CFRP face sheetsLabel Cell side length {L_{\rm{c}}}/mm Core height {H_{\rm{c}}}/mm Facesheet thickness {T_{\rm{f}}}/mm Cell wall thickness {T_{\rm{c}}}/mm A1 2 20 1.2 0.06 A2 4 20 1.2 0.06 A3 6 20 1.2 0.06 B1 4 10 1.2 0.06 B2 4 20 1.2 0.06 B3 4 30 1.2 0.06 C1 4 20 1.2 0.06 C2 4 20 1.8 0.06 C3 4 20 2.4 0.06 D1 4 20 1.2 0.06 D2 4 20 1.2 0.10 D3 4 20 1.2 0.14 3. 模型验证

为了证明数值模拟方法所建有限元模型的准确性,以本文的试验参数为参照,将数值模拟计算结果与试验结果进行对比。在保证其他参数相同的条件下,蜂窝芯单元边长Lc=2 mm、4 mm、6 mm的CFRP蒙皮-铝蜂窝夹层板在质量m=2.5 kg、下降高度h=0.46 m的半球头落锤的冲击下(仿真中设置落锤初始速度为3 m/s),仿真与试验的接触力历程对比如图6所示,通过高速摄像平台采集分析了落锤的速度历程,仿真与试验速度历程对比如图7所示。

通过对比图6和图7的仿真和试验数据可知:在相同能量的冲击作用下,三种蜂窝芯单元边长夹层板在仿真中的接触力峰值分别为4 037 N、3 666 N和2 854 N,试 验d接触力峰值分别为3 799 N、3 476 N和2 811 N,仿真和试验接触力峰值的偏差分别为6.24%、5.47%和1.53%;仿真和试验的接触时长的差值分别为0.72 ms、0.40 ms和0.11 ms。试验与仿真在接触力历程和速度历程的总体趋势方面具有良好的一致性。

将A组所有受冲击后的蜂窝夹层板由冲击区域的中心纵向切开,会发现受冲击位置的上蒙皮与芯层之间的胶层脱粘,蜂窝芯存在折叠和屈曲,上蒙皮的下表面均有部分基体开裂的现象。试验与仿真的蜂窝芯损伤深度对比如表4所示,不同蜂窝芯单元边长的夹层板在相同的冲击能量下得到了三种不同的变形深度,A组试验中受低速冲击区域蜂窝芯变形深度分别为2.15 mm、2.77 mm和4.32 mm,仿真中的蜂窝芯变形深度δ分别为2.20 mm、3.03 mm和4.10 mm。仿真与试验得到夹层板的蜂窝芯变形量之间的偏差分别为2.33%、9.39%和5.09%。由于本文设置的低速冲击能量较小,下蒙皮未发生任何形式的损伤,故不再在文中赘述其受载情况。

表 4 试验与仿真中蜂窝芯损伤深度δ的对比Table 4. Comparison of experimental and numerical deformations δ of honeycomb coresLabel Top face sheet Cross-section Experiment Simulation-Honeycomb core A1

A2

A3

综上所述,所搭建的低速冲击有限元仿真模型可以较为准确地预测低速冲击下CFRP蒙皮-铝蜂窝夹层板的动力学响应。

图8为三种不同蜂窝芯边长的CFRP蒙皮-铝蜂窝夹层板在质量m=2.5 kg、初始冲击速度为3 m/s的半球头落锤的冲击下,有限元模型预测的A组落锤动能历程,图9为预测的接触力-位移关系。可知,相同冲击能量下的蜂窝芯边长Lc分别为2 mm、4 mm、6 mm的CFRP蒙皮-铝蜂窝夹层板的最大变形深度依次增大,分别为5.26 mm、6.25 mm、7.40 mm。

通过分析可知:随着蜂窝芯单元边长的增大,夹层板受冲击时,落锤动能减小速率逐渐降低,接触时长逐渐增加,接触力峰值随之减小,夹层板受冲击位置的变形深度随之增大。可见,增大蜂窝芯单元的边长会降低蜂窝夹层板的刚度,但其吸能效果会随之增强。

4. 结构参数对CFRP蒙皮-铝蜂窝夹层板吸能的影响

4.1 蜂窝芯高度对CFRP蒙皮-铝蜂窝夹层板吸能的影响

为了确定在低速冲击载荷下,蜂窝芯高度Hc对CFRP蒙皮-铝蜂窝夹层板吸能特性的影响,在仿真中使用了Hc=10 mm、20 mm、30 mm三种不同高度的蜂窝芯,蜂窝芯单元边长Lc=4 mm,蒙皮厚度Tf=1.2 mm,蜂窝芯壁厚Tc=0.06 mm,其余条件保持不变。图10为该工况下落锤的接触力历程对比,图11为落锤的动能历程对比,图12为落锤的接触力-位移关系对比。

由图10~12可知:在蜂窝芯高度Hc=10 mm、20 mm、30 mm的该组仿真中,三种蜂窝夹层板在低速冲击载荷下,落锤的接触力峰值分别为3852N、3666N、3674N,接触时长分别为5.81 ms、5.85 ms、5.82 ms,最大变形深度分别为6.25 mm、6.26 mm、6.38 mm,且落锤的接触力历程、动能历程和接触力-位移的图形几乎保持一致。B组仿真中预测的蜂窝夹层板冲击损伤如表5所示。可知,蜂窝芯受冲击区域的最终变形量δ分别为2.97 mm、3.03 mm和3.08 mm,其变形量相差较小。由该组仿真结果可见,蜂窝芯高度的变化对于CFRP蒙皮-铝蜂窝夹层板的刚度和抗低速冲击性能影响不大。

表 5 仿真预测的B组CFRP蒙皮-铝蜂窝夹层板冲击损伤Table 5. Simulation predicted impact damage of group B aluminum honeycomb sandwich plate with CFRP face sheetsLabel Cross-section Honeycomb sandwich plate Honeycomb core B1

B2

B3

4.2 蒙皮厚度对CFRP蒙皮-铝蜂窝夹层板吸能的影响

为了确定蒙皮厚度Tf对低速冲击载荷下CFRP蒙皮-铝蜂窝夹层板吸能特性的影响,在仿真中使用了Tf=1.2 mm、1.8 mm、2.4 mm三种不同厚度的CFRP蒙皮,蜂窝芯单元边长为4 mm,蜂窝芯高度Hc=20 mm,蜂窝芯壁厚Tc=0.06 mm,其余条件保持不变。图13为该工况下落锤的接触力历程对比,图14为落锤的动能历程对比,图15为落锤的接触力-位移关系对比。

由图13~15可知:在蒙皮厚度Tf=1.2 mm、1.8 mm、2.4 mm的该组仿真中,三种蜂窝夹层板在相同冲击能量的低速冲击载荷下,落锤的接触力峰值分别为3666N、3923N、4314N,接触时长分别为5.85 ms、5.13 ms、4.28 ms,最大变形深度分别为6.26 mm、5.14 mm、4.39 mm。C组仿真中预测的蜂窝夹层板冲击损伤如表6所示。可知,蜂窝芯受冲击区域的最终变形量δ分别为3.03 mm、2.41 mm和2.13 mm。随着蜂窝夹层板蒙皮厚度的增大,冲击时,落锤动能的减小速率随之增大,接触时间随之减少,接触力的峰值随之增大,夹层板受冲击区域的变形量随之减小。可见,蒙皮厚度的增加会使蜂窝夹层板的刚度增大,吸能效果随之降低。

表 6 仿真预测的C组CFRP蒙皮-铝蜂窝夹层板冲击损伤Table 6. Simulation predicted impact damage of group C aluminum honeycomb sandwich plate with CFRP face sheetsLabel Cross-section Honeycomb sandwich plate Honeycomb core C1

C2

C3

4.3 蜂窝芯壁厚对CFRP蒙皮-铝蜂窝夹层板吸能的影响

为了探究低速冲击载荷下,蜂窝芯壁厚Tc对CFRP蒙皮-铝蜂窝夹层板吸能特性的影响,在仿真中使用了Tc=0.06 mm、0.10 mm、0.14 mm三种不同壁厚的蜂窝芯,蜂窝芯单元边长为4 mm,蜂窝芯高度Hc=20 mm,蒙皮厚度Tf=1.2 mm,其余条件保持不变。图16为该工况下落锤的接触力历程对比,图17为落锤的动能历程对比,图18为落锤的接触力-位移关系对比。

根据图16~18可知:在蜂窝芯壁厚Tc=0.06 mm、0.10 mm、0.14 mm的该组仿真中,三种蜂窝夹层板在相同冲击能量的低速冲击载荷下,落锤的接触力峰值分别为3666N、4153N、4454N,接触时长分别为5.85 ms、5.31 ms、4.99 ms,最大变形深度分别为6.26 mm、5.50 mm、5.28 mm。仿真预测的D组蜂窝夹层板冲击损伤如表7所示。可知,蜂窝芯受冲击区域的最终变形量δ分别为3.03 mm、2.83 mm和2.77 mm。随着蜂窝夹层板蜂窝芯壁厚的增大,在低速冲击下,落锤动能的减小速率随之增大,接触时间随之减少,落锤与夹层板之间的接触力峰值随之增大,夹层板受冲击区域的变形量随之减小。可见,增加蜂窝芯的壁厚会使蜂窝夹层板的刚度增大,抗低速冲击的性能增强。

表 7 仿真预测的D组CFRP蒙皮-铝蜂窝夹层板冲击损伤Table 7. Simulation predicted impact damage of group D aluminum honeycomb sandwich plate with CFRP face sheetsLabel Cross-section Honeycomb sandwich plate Honeycomb core D1

D2

D3

4.4 各组件吸能占比

表8为不同结构参数的CFRP蒙皮-铝蜂窝夹层板在相同能量的低速冲击下,各组件的吸能占比情况。可知:在本文设置的较低能量级冲击载荷下,CFRP蒙皮-铝蜂窝夹层板的吸能占比均大于60%,足以证明蜂窝夹层结构具有较好的冲击吸能特性;在该规格的冲击条件下,CFRP蒙皮-铝蜂窝夹层板最主要的吸能组件是铝蜂窝芯,上蒙皮吸能次之,下蒙皮吸能最少。由A组夹层板吸能占比分析可知,随着蜂窝芯单元边长的增大,蜂窝芯吸能占比逐渐增大,上蒙皮吸能占比逐渐减小,夹层板总吸能逐渐增大;由B组数据分析可知,随着蜂窝芯高度的增大,蜂窝芯吸能占比逐渐增大,上蒙皮吸能逐渐减少,夹层板总吸能逐渐增大;由C组数据分析可知,随着蒙皮厚度的增大,蜂窝芯层吸能占比逐渐减小,上蒙皮吸能占比逐渐增大,夹层板总吸能逐渐增大;由D组数据分析可知,随着蜂窝芯壁厚的增大,蜂窝芯吸能占比逐渐减小,上蒙皮吸能占比逐渐增大,夹层板总吸能逐渐增大。综上所述,在本文所设置的载荷条件下,增大蜂窝芯单元边长、蜂窝芯高度、蒙皮厚度和蜂窝芯壁厚,均能增加蜂窝夹层板的吸能量。然而吸能效果需结合碰撞时的接触时长、接触力峰值、变形损伤深度和吸能量综合考虑,故需结合图表才能得到合理的结论。

表 8 不同结构参数的CFRP蒙皮-铝蜂窝夹层板组件吸能占比Table 8. Absorbed energy rates by components of aluminum honeycomb sandwich plate with CFRP face sheets with different structural parameters% Parameters Cell side length {L_{\rm{c}}} Core height {H_{\rm{c}}} Facesheet thickness {T_{\rm{f}}} Cell wall thickness {T_{\rm{c}}} A1 A2 A3 B1 B2 B3 C1 C2 C3 D1 D2 D3 Upper plate 20.43 17.29 16.49 19.53 17.29 16.04 17.29 26.97 31.72 17.29 20.88 30.02 Honeycomb 45.16 50.01 58.60 38.45 50.01 57.35 50.01 43.20 39.78 50.01 45.61 41.75 Lower plate 1.88 1.70 2.51 2.15 1.70 1.70 1.70 1.08 0.72 1.70 2.69 3.32 Impactor 32.53 31.00 22.40 39.87 31.00 24.91 31.00 28.05 27.78 31.00 30.82 24.91 Sandwich plate 67.37 69.00 77.60 60.13 69.00 75.09 69.00 71.95 72.22 69.00 69.18 75.09 5. 结 论

建立了碳纤维增强树脂复合材料(CFRP)蒙皮-铝蜂窝夹层板精细化低速冲击仿真模型,通过对比不同蜂窝芯边长的夹层板在相同冲击能量下的仿真与试验结果,证明了试验与仿真结果具有较好的一致性。进而利用该数值模型探究了蜂窝芯高度、蒙皮厚度和蜂窝芯壁厚等结构参数对于蜂窝夹层板低速冲击性能的影响。

(1)随着蜂窝芯单元边长的增大,夹层板受冲击时,落锤动能减小速率逐渐降低,接触时长逐渐增加,接触力峰值随之减小,夹层板受冲击位置的变形深度随之增大。可见,蜂窝芯单元边长尺寸的增大会降低蜂窝夹层板的刚度,但其吸能效果会随之增强。

(2)蜂窝夹层板的芯层高度对夹层板的刚度及抗低速冲击性能影响较小。

(3)增大蜂窝夹层板的蒙皮厚度,可以提高夹层板的刚度,但会降低夹层板的吸能效果。

(4)增大蜂窝芯壁厚,会提高蜂窝夹层板的刚度和抗低速冲击性能。

(5)在本文的低速冲击条件下,CFRP蒙皮-铝蜂窝夹层板的蜂窝芯是主要的吸能组件,上蒙皮吸能占比次之,下蒙皮吸能最少。

-

表 1 不同2, 4-甲苯二异氰酸酯改性的二氧化硅(NCO@FS)和气相二氧化硅(FS)含量的聚氨酯 (PU)试样

Table 1 Polyurethane (PU) samples with different content of 2, 4-toluene diisocyanate modified silica (NCO@FS) and fumed silica (FS)

Sample NCO@FS/wt% FS/wt% NCO@FS/PU-0.5 0.5 – NCO@FS/PU-1.0 1.0 – NCO@FS/PU-1.5 1.5 – NCO@FS/PU-3.0 3.0 – FS/PU-1.0 – 1.0 FS/PU-1.5 – 1.5 FS/PU-3.0 – 3.0 表 2 FS和NCO@FS的XPS图谱中元素含量比较

Table 2 XPS atomic content for elements in FS and NCO@FS

System C/at% O/at% Si/at% N/at% C/Si O/Si FS 45.74 38.03 16.23 0.00 2.82 2.34 NCO@FS 71.96 14.06 4.89 9.09 14.72 2.88 表 3 FS/PU和NCO@FS/PU复合材料力学性能随FS质量分数的变化

Table 3 Variations in mechanical properties of FS/PU and NCO@FS/PU with the mass fraction of FS

Sample Tensile strength

/MPaTear strength

/(kN·m−1)Elongation at break/% Hardness

(Shore D)PU 43.3(0.9) 89.4(1.6) 447(10) 40(1) NCO@FS/PU-0.5 45.4(1.3) 88.7(1.9) 424(18) 41(1) NCO@FS/PU-1 51.6(1.0) 95.1(2.3) 576(14) 43(1) NCO@FS/PU-1.5 57.0(0.8) 110.5(1.3) 516(10) 43(1) NCO@FS/PU-3 17.7(1.5) 87.2(2.9) 303(23) 43(1) FS/PU-1 47.7(0.8) 82.8(2.0) 459(15) 40(1) FS/PU-1.5 28.0(0.6) 51.9(1.3) 478(20) 41(1) FS/PU-3 7.9(1.2) 36.3(2.6) 243(21) 42(2) -

[1] GHOLAMIPOUR N, SADEGHI M, SHAFIEI M. Effect of silica nanoparticles on the performance of polysulfone membranes for olefin-paraffin separation[J]. Chemical Engineering & Technology,2019,42(11):2292-2301.

[2] GORKY F, GUTHRIE S R, SMOLJAN C S, et al. Plasma ammonia synthesis over mesoporous silica SBA-15[J]. Journal of Physics D: Applied Physics,2021,54(26):1-10.

[3] JALIL R R, HUSSEIN H. Influence of nano fluid on interfacial tension oil/water and wettability alteration of limestone[J]. IOP Conference Series: Materials Science and Engineering,2019,518(6):1-7.

[4] SALAHUDDIN N, ABO-EI-ENEIN S A, SELIM A, et al. Synthesis and characterization of polyurethane-urea clay nanocomposites using montmorillonite modified by oxyethylene-oxypropylene copolymer[J]. Polymers for Advanced Technologies,2010,21(8):533-542. DOI: 10.1002/pat.1449

[5] AKRAM D, AHMAD S, SHARMIN E, et al. Silica reinforced organic-inorganic hybrid polyurethane nanocomposites from sustainable resource[J]. Macromolecular Chemistry & Physics,2010,211(4):412-419.

[6] KURIYAGAWA M, KAWAMURA T, HAYASHI S, et al. Reinforcement of polyurethane-based shape memory polymer by hindered phenol compounds and silica particles[J]. Journal of Applied Polymer Science,2010,117(3):1695-1702.

[7] ZHANG J, JIANG G, HUANG T, et al. Preparation and characterization of polyurethane-silica hybrid films[J]. Pigment and Resin Technology,2019,48(5):357-362. DOI: 10.1108/PRT-03-2019-0029

[8] NAVIDFAR A, SANCAK A, YILDIRIM K B, et al. A study on polyurethane hybrid nanocomposite foams reinforced with multiwalled carbon nanotubes and silica nanoparticles[J]. Journal of Macromolecular Science: Part D-Reviews in Polymer Processing,2018,57(14):1463-1473.

[9] CHUNG Y C, CHUNG K H, CHOI J W, et al. Preparation of hybrid polyurethane-silica composites by a lateral sol-gel process using tetraethyl orthosilicate[J]. Journal of Composite Materials,2017,52(2):159-168.

[10] 李灵琦, 叶伟华, 童真, 等. 聚氨酯预聚物对沉淀法SiO2表面改性的研究[J]. 聚氨酯工业, 2012, 27(3):21-23. DOI: 10.3969/j.issn.1005-1902.2012.03.006 LI Lingqi, YE Weihua, TONG Zhen, et al. Study on surface modification of precipitation method SiO2 with polyurethane prepolymer[J]. Polyurethane Industry,2012,27(3):21-23(in Chinese). DOI: 10.3969/j.issn.1005-1902.2012.03.006

[11] NGUYEN T V, NGUYEN T A, NGUYEN T H. The synergistic effects of SiO2 nanoparticles and organic photo stabilizers for enhanced weathering resistance of acrylic polyurethane coating[J]. Journal of Composites Science,2020,4(23):1-11.

[12] 穆晓东, 崔雨果, 方庆红, 等. 白炭黑的功能化改性及其改性橡胶基复合材料的制备与表征[J]. 复合材料学报, 2017, 34(1):67-74. MU Xiaodong, CUI Yuguo, FANG Qinghong, et al. Preparation and characterization of functionalization of silica and its rubber matrix composites[J]. Acta Materiae Compositae Sinica,2017,34(1):67-74(in Chinese).

[13] XIA T, CHEN X, XU J H, et al. Key role of network formation in rutting, fatigue and brittle performance of bitumen/PEG/MDI/SiO2 composites[J]. Construction and Building Materials,2021,296:1-8.

[14] HU F, QI F, XIANG Z H, et al. Synergistic enhancement effect of nano-SiO2 and ionic liquids on mechanical properties and impact resistance of polyurethane elastomer[J]. Composites Communications,2021,27:1-7.

[15] 李嘉晋, 范仁祥, 李雅迪, 等. 三种形貌纳米SiO2的调控合成及其原位增强亲水性聚氨酯注浆复合材料[J]. 复合材料学报, 2017, 34(5):957-962. LI Jiajin, FAN Renxiang, LI Yadi, et al. Synthesis and characterization of three kinds of nano SiO2 particles with different morphologies and their application in reinforced polyurethane grouting composities[J]. Acta Materiae Compositae Sinica,2017,34(5):957-962(in Chinese).

[16] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定: GB/T 528—2009[S]. 北京: 中国标准出版社, 2009. Standardization Administration of the People’s Republic of China. Rubber, vulcanized or thermoplastic—Determination of tensile stress-strain properties: GB/T 528—2009[S]. Beijing: China Standards Press, 2009(in Chinese).

[17] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶撕裂强度的测定(裤形、直角形和新月形试样): GB/T 529—2008[S]. 北京: 中国标准出版社, 2008. Standardization Administration of the People’s Republic of China. Rubber, vulcanized or thermoplastic—Determination of tear strength (Trouser, angle and crescent test pieces): GB/T 529—2008[S]. Beijing: China Standards Press, 2008(in Chinese).

[18] 中国国家标准化管理委员会. 橡胶袖珍硬度计压入硬度试验方法: GB/T 531—1999[S]. 北京: 中国标准出版社, 1999. Standardization Administration of the People’s Republic of China. Rubber—Determination of indentation hardness by means of pocket hardness meters: GB/T 531—1999[S]. Beijing: China Standards Press, 1999(in Chinese).

[19] 陈和生, 孙振亚, 邵景昌. 八种不同来源二氧化硅的红外光谱特征研究[J]. 硅酸盐通报, 2011, 30(4):934-937. CHEN Hesheng, SUN Zhenya, SHAO Jingchang. Investigation on FTIR spectroscopy for eight different sources of SiO2[J]. Bulletin of the Chinese Ceramic Society,2011,30(4):934-937(in Chinese).

[20] 李延洁, 周竹发, 王春蓉, 等. 纳米白碳黑的复合改性及性能表征[J]. 化工学报, 2010, 61(3):789-794. LI Yanjie, ZHOU Zhufa, WANG Chunrong, et al. Compo-site modification and characterization of nano silica[J]. Journal of Chemical Engineering,2010,61(3):789-794(in Chinese).

[21] CHEN L J, WANG X P, JIA Z X, et al. Use of precipitated silica with silanol groups as an inorganic chain extender in polyurethane[J]. Materials & Design,2015,87:324-330.

[22] 艾青松, 陈虹, 赵磊, 等. 反应温度对PTMG-MDI型聚氨酯弹性体结构及性能的影响[J]. 塑料科技, 2017, 45(1):46-50. AI Qingsong, CHEN Hong, ZHAO Lei, et al. Influence of reaction temperature on structure and properties of PTMG-MDI type polyurethane elastomer[J]. Plastics Science and Technology,2017,45(1):46-50(in Chinese).

[23] 谭井华. 聚氨酯/白炭黑有机-无机杂化材料及其对橡胶的互穿网络改性研究[D]. 广州: 华南理工大学, 2012. TAN Jinghua. PU/silica organic-inorganic hybrid materials and their interpenetrating networks with rubber[D]. Guangzhou: South China University of Technology, 2012(in Chinese).

-

期刊类型引用(0)

其他类型引用(4)

-

下载:

下载: