Preparation and wear resistance of ZrO2 toughened Al2O3 ceramic particles reinforced high chromium cast iron matrix composites by powder sintering and casting

-

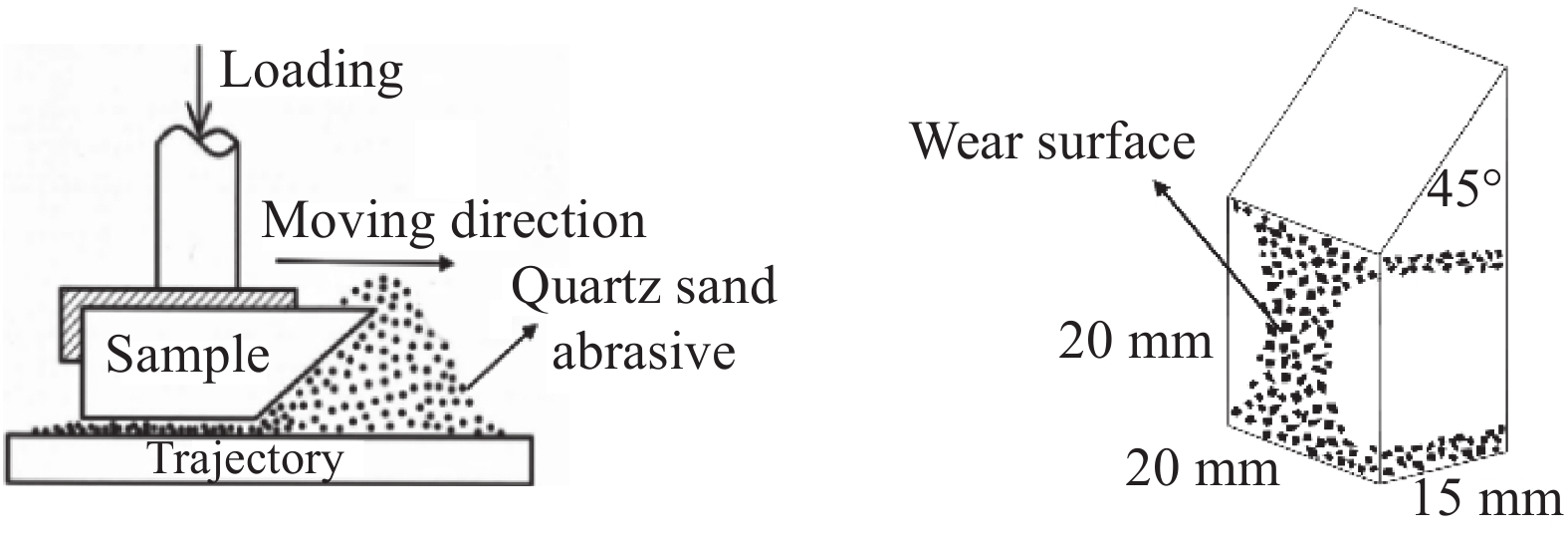

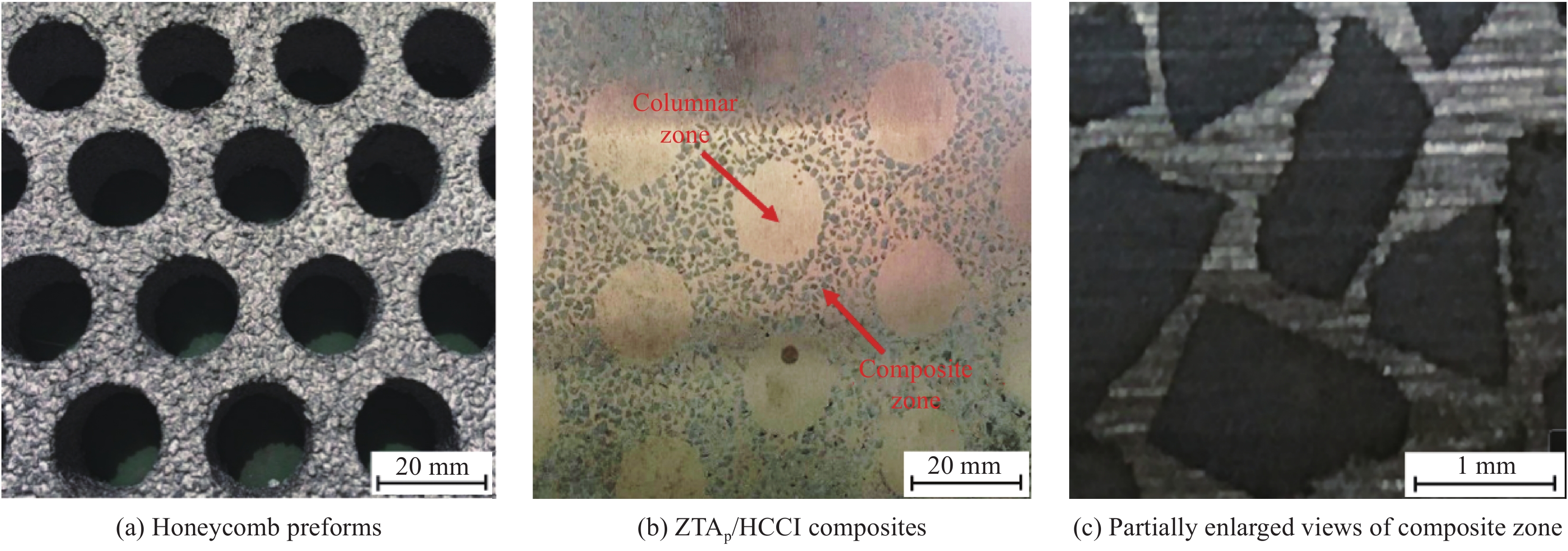

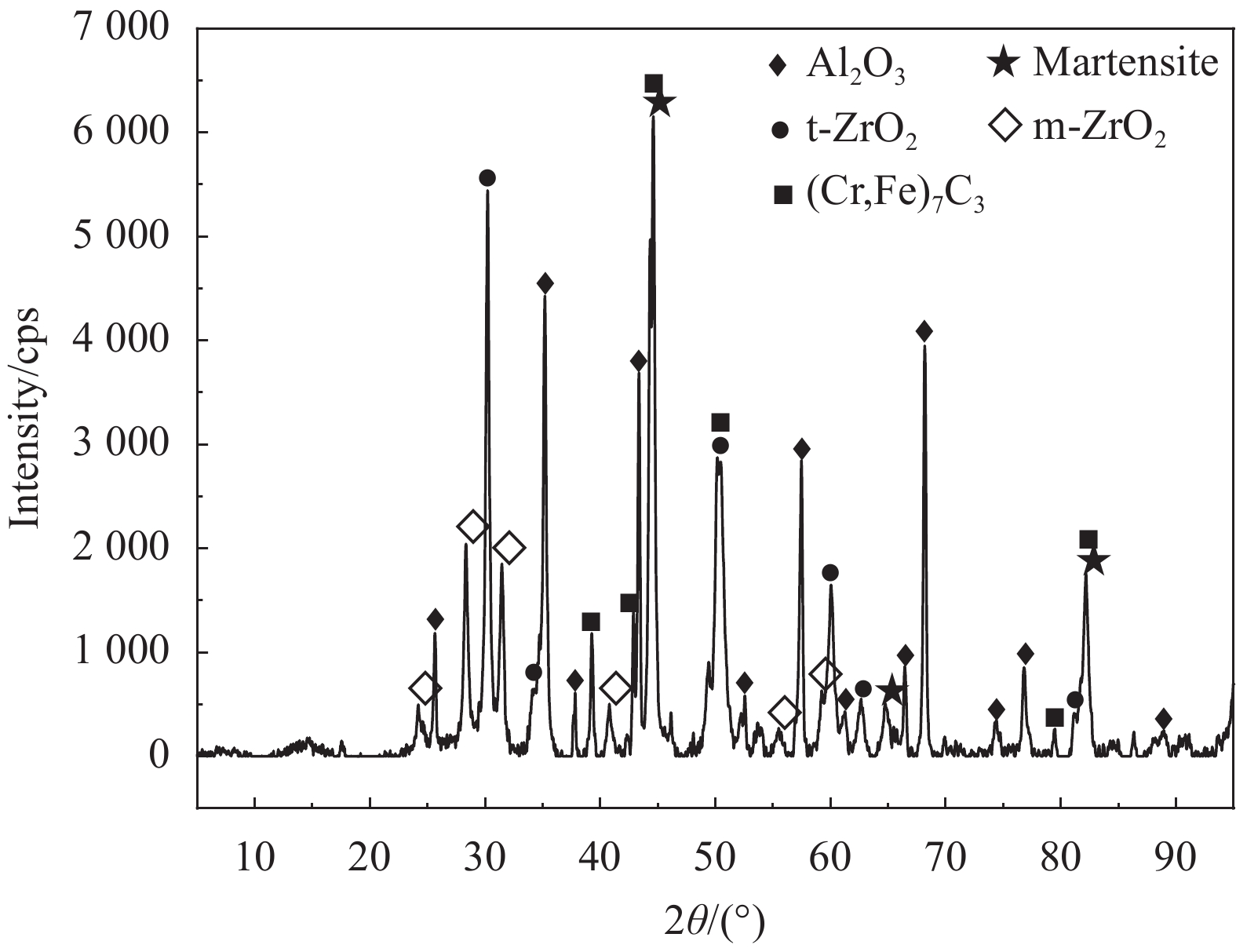

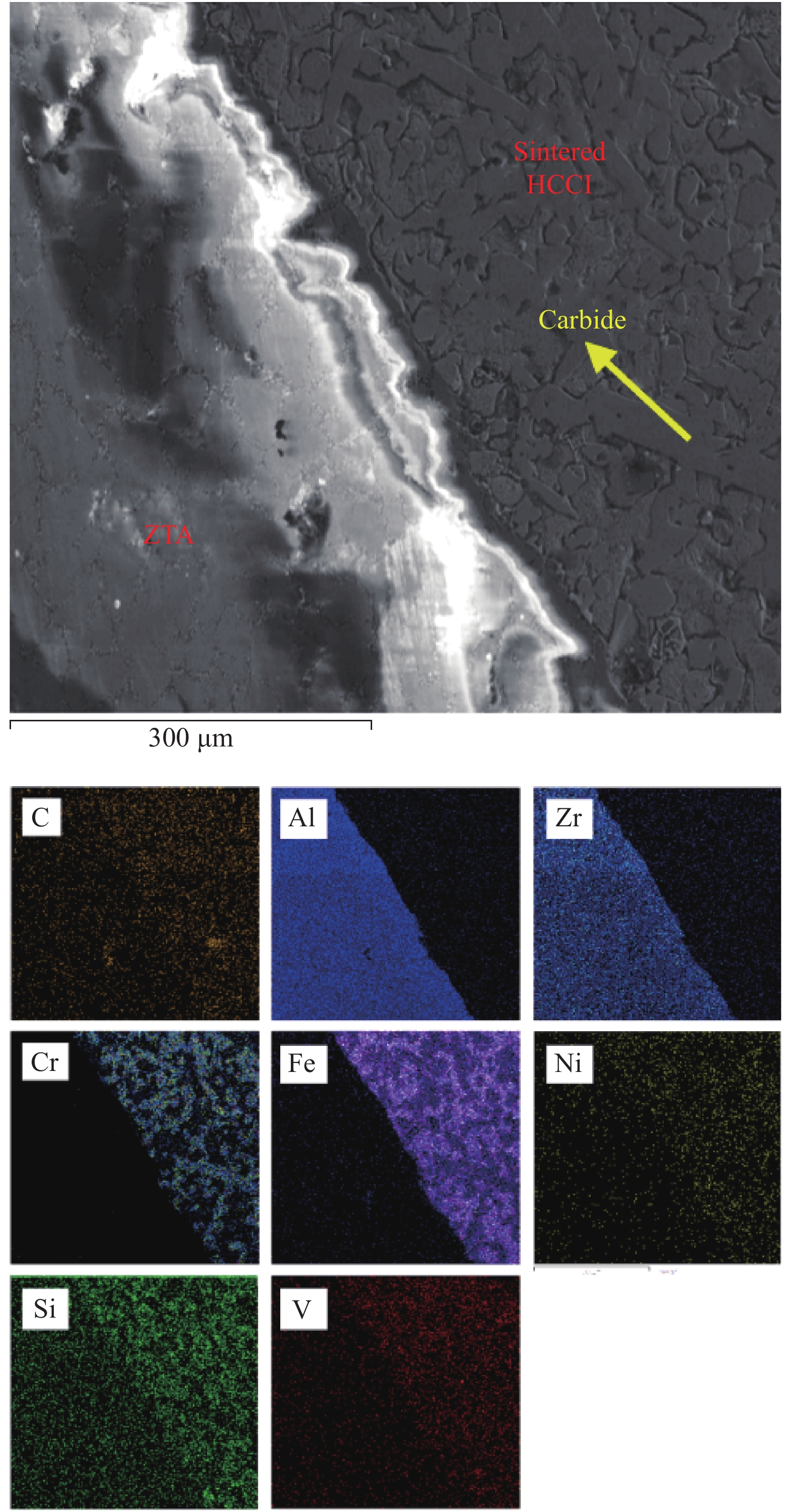

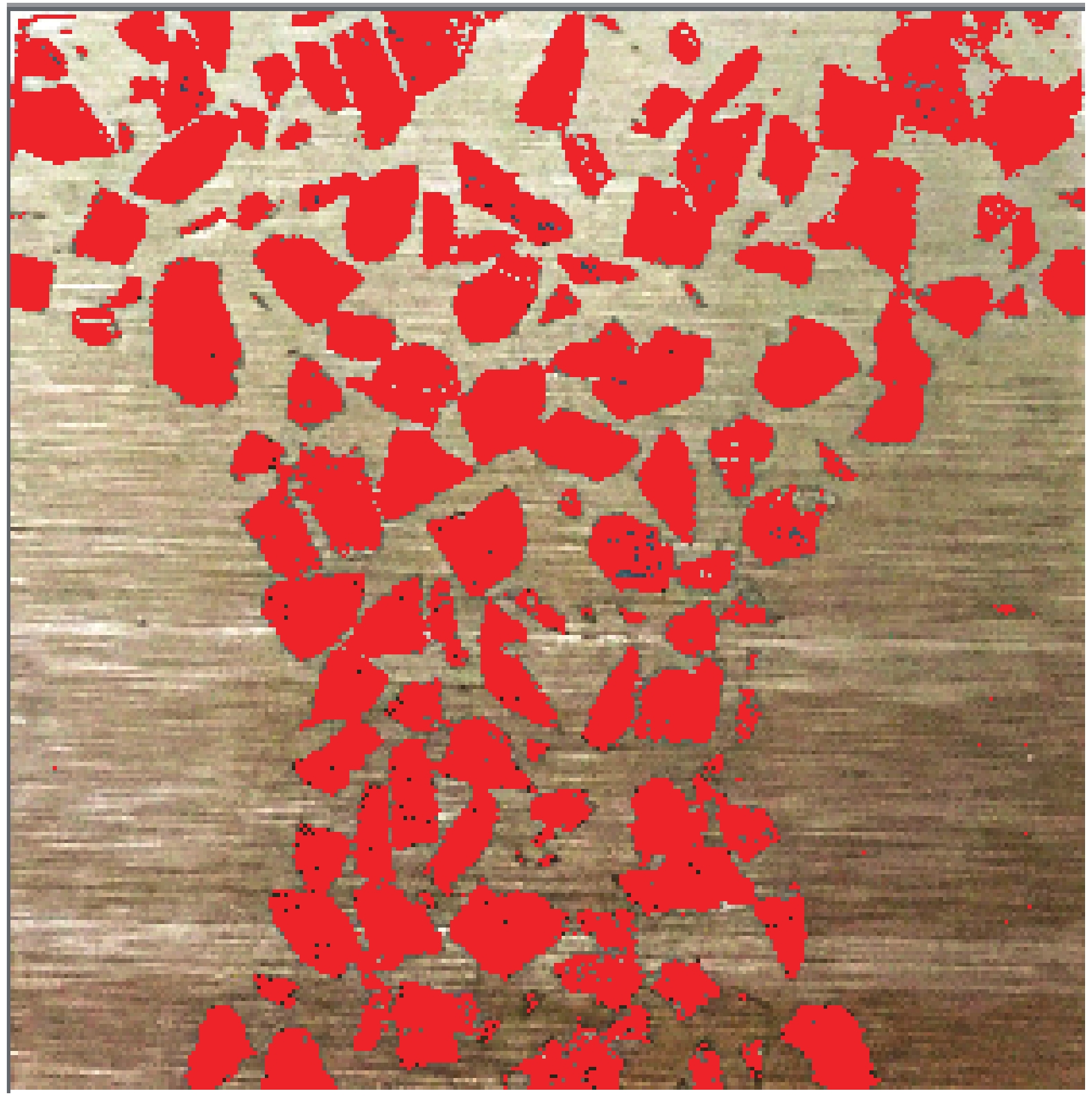

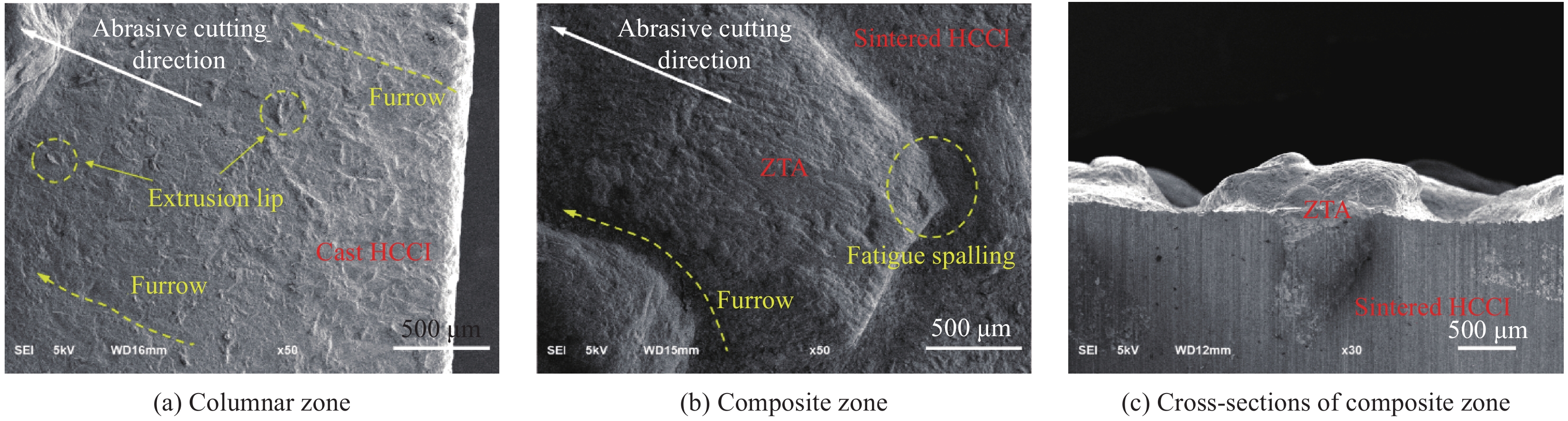

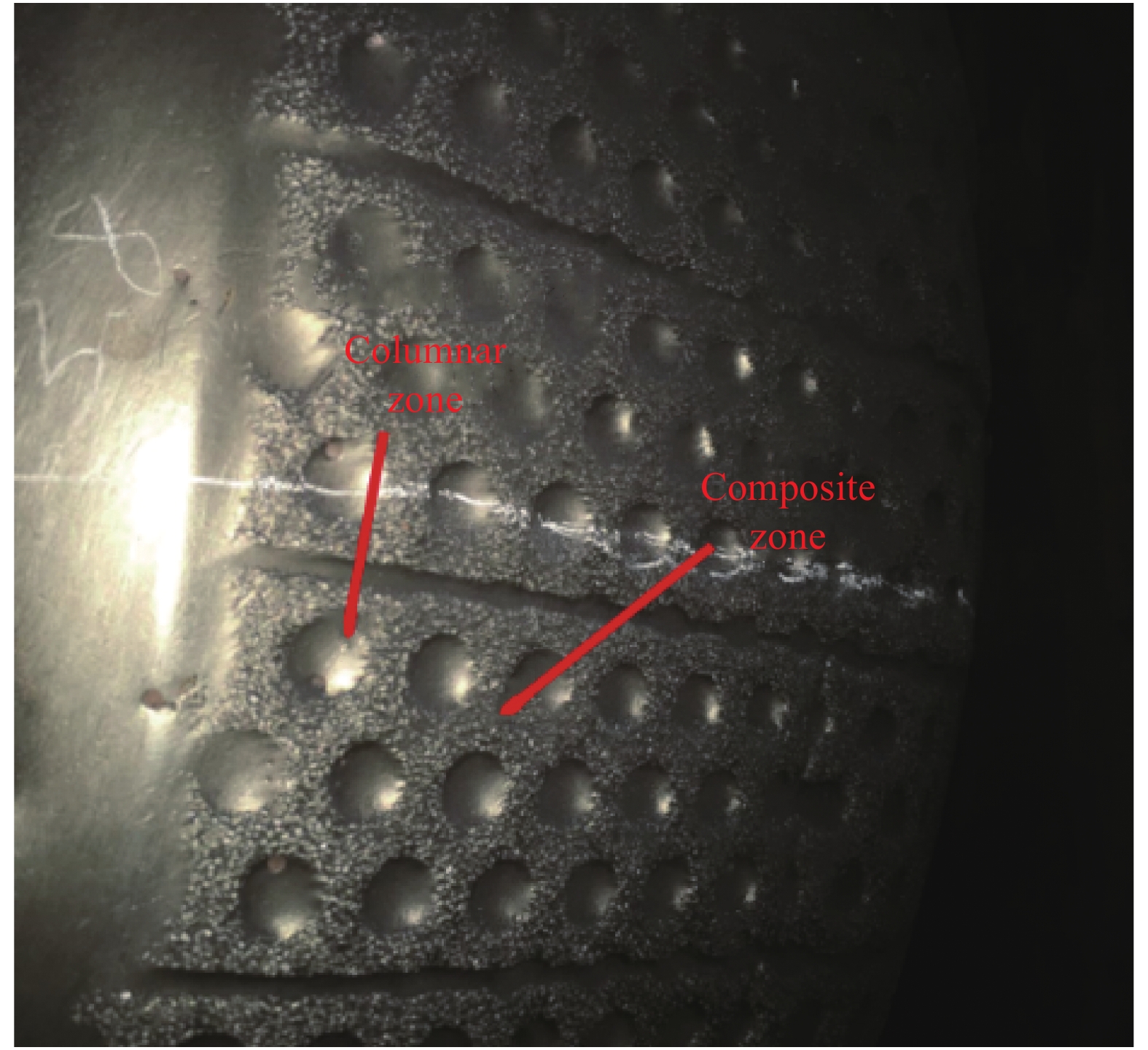

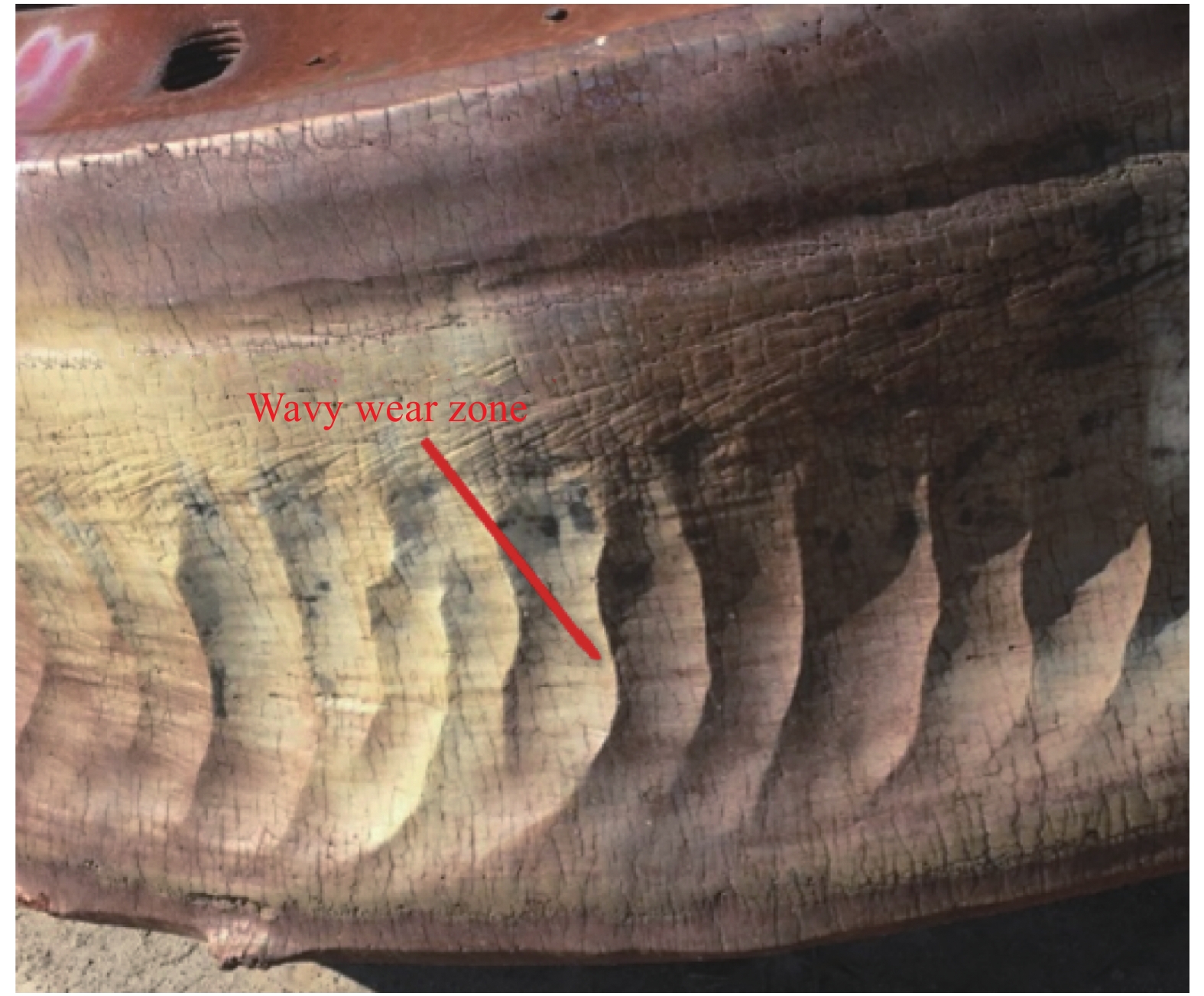

摘要: 将粒径为1~2 mm的ZrO2增韧Al2O3陶瓷颗粒(ZTAp)、高铬合金粉末和黏结剂混合真空烧结制备蜂窝状预制体,再浇注高铬铸铁液制备出ZTAp增强高铬铸铁基复合材料。采用SEM、EDS、XRD分析复合材料的界面微观结构和物相组成,通过三体磨损试验评价复合材料的耐磨性能。结果表明,烧结高铬铸铁基体在铸造过程中发生重熔,与铸造高铬铸铁基体呈冶金结合,ZTAp与金属基体界面结合致密,无裂纹、气孔等缺陷。复合材料三体耐磨性能达到高铬铸铁的3倍以上。将该复合材料应用于制备磨辊件,经过5 000 h服役,柱状区和复合区在磨辊半径方向上的磨损量分别为8.2 mm、5.9 mm,预计寿命可达到高铬铸铁磨辊的2倍以上。Abstract: The honeycomb preforms were prepared by vacuum sintering the mixture of ZrO2 toughened Al2O3 ceramic particles (ZTAp) of 1-2 mm, high chromium alloy powder and binder. ZTAp reinforced high chromium cast iron composites were then prepared by pouring high chromium cast iron. The interface microstructure and phase composition of the composites were analyzed by SEM, EDS and XRD. The wear resistance of the composite was evaluated by three-body abrasive wear test. The results show that the matrix of sintered high chromium cast iron is remelted in the process of casting and is metallurgical bonded with cast high chromium cast iron matrix. The interface between ZTAp and metal matrix is compact, and there are no defects such as cracks and pores. The three-body abrasive wear resistance of the composites is more than 3 times of that of high chromium cast iron. The composites are applied to the preparation of grinding roller parts. After 5 000 h of service, the wear loss of the columnar zone and composite zone in the direction of grinding roller radius are 8.2 mm and 5.9 mm, respectively, and the expected service life can be more than twice that of the high chromium cast iron grinding roller.

-

Keywords:

- ZrO2 toughened Al2O3 /

- high chromium cast iron /

- composites /

- powder sintering /

- casting /

- three-body abrasive wear

-

目前我国土木工程领域已经进入新建和加固并重的新时期。碳纤维增强树脂复合材料(Carbon fiber reinforced polymer,CFRP)具有耐腐蚀、轻质高强及耐久性好等优点,且外贴CFRP片材加固有可操作性高、经济效益高等优点。因此外贴CFRP片材来加固既有混凝土结构引起了广泛关注。但采用CFRP片材加固后的混凝土结构易遭受二次腐蚀,混凝土表面裂缝的出现导致应力集中,易发生CFRP片材与混凝土界面的过早剥离破坏,会大大降低CFRP片材的利用率和结构的安全性能[1]。外贴CFRP片材和既有混凝土结构之间能否保证有效粘结从而有效传递应力是决定加固效果的关键[2-3]。

工程水泥基复合材料(Engineered cementitious composites,ECC)因其多裂缝开裂、耐久性好等特性在加固既有混凝土结构领域引起了学者广泛关注。结构用ECC加固后耐久性能提升明显,但其极限承载力提高有限[4-5]。在CFRP片材和混凝土之间设置ECC层,ECC良好的耐久性可减少外界环境对混凝土结构的侵蚀,细密裂缝的特性则可以延缓CFRP片材的剥离,有效地传递界面剪应力,从而更好地发挥CFRP片材高抗拉强度的优点。葛文杰等[6]和Wu等[7]的研究表明:混凝土结构用CFRP布和ECC复合加固后其综合性能得到明显改善,大大提高了加固效益。

学者们用纤维增强树脂复合材料(FRP)对受弯梁进行抗弯加固进行了大量研究[8-12],结果表明:若用FRP材料对混凝土结构进行加固,其综合性能会得到明显改善。而对于ECC作为过渡层来研究FRP加固的界面粘结性能方面的研究较少,试验数据有限导致影响变量尚不明确。因此ECC与CFRP片材的结合使用时两者界面粘结性能需进一步研究。Sui等[13]研究了常规环境下FRP-ECC-混凝土单面剪切试件的性能,结果表明随着ECC的加入,极限滑移、耗能能力及FRP的有效利用率均显著提高。

本文通过单面剪切试验对CFRP片材-ECC-混凝土复合界面抗剪性能进行研究,设计变量为混凝土/ECC强度、和ECC厚度,研究其对复合界面承载力、应变分布规律、粘结滑移曲线规律等的影响。

1. 试验概况

1.1 材料性能

试验所用CFRP片材厚度为1.2 mm,其拉伸强度、弹性模量分别为2451 MPa和167 GPa,极限延伸率可达到1.41%。CFRP-A/B胶作为CFRP片材-ECC复合界面的结构胶结剂,按2∶1的质量进行配比使用。粘结胶的抗拉强度为38.2 MPa,弹性模量为2530 MPa,极限延伸率为1.72%,胶层刚度Ka

为5 MPa左右。 采用C30和C50两种强度的ECC,其配合比见表1。水泥为P42.5普通硅酸盐水泥,粉煤灰采用I级粉煤灰,石英砂采用74~106 μm石英砂,所用减水剂的减水率在25%以上。聚乙烯醇(PVA)纤维材料性能指标见表2。

表 1 工程水泥基复合材料(ECC)配合比Table 1. Proportion of engineered cementitious composites (ECC)ECC Cement Fly ash Silica fume Quartz sand Water PVA Water reducer Thickener C30 1 3.0 0.3 0.4 1.37 2.00% 0.2% 0.08% C50 1 2.0 0.3 0.4 0.92 2.00% 0.2% 0.05% Notes: Fly ash, silica fume, quartz sand, water—Relative mass ratios to cement; PVA, water reducer, thickener—Relative volume ratios to ECC; PVA—Polyvinyl alcohol. 表 2 聚乙烯醇(PVA)纤维的材料性能Table 2. Material properties of polyvinyl alcohol (PVA) fibersDiameter/μm Length/mm Tensile strength/MPa Young’s modulus/GPa Density/(g·cm−3) 40 12 1560 41 1.3 ECC基本拉伸力学性通过狗骨状试件拉伸试验进行,加载装置如图1(a)所示,加载速率设定为0.5 mm/min。ECC拉伸应力-应变曲线见图1(b),其主要分为3个阶段:(1) 弹性阶段:应力应变线性增长且没有裂缝产生;(2) 屈服阶段:试件出现多条细密裂纹,曲线斜率下降,没有出现应力集中的现象,为ECC的应变硬化阶段;(3) 下降阶段:试件上某条裂缝宽度增大,出现应力集中,直至最终破坏。C30和C50强度ECC极限抗拉强度分别为5.5 MPa和6.3 MPa。

采用C30和C50两种强度的混凝土且配合比见表3。水泥为P42.5普通硅酸盐水泥,细骨料为细度模数为2.3~3.0的Ⅱ区河砂,粗骨料为粒径为5~20 mm的碎石。C30和C50强度混凝土28天平均立方体抗压强度分别为38.3 MPa和59.1 MPa。

表 3 混凝土配合比Table 3. Proportion of concretekg/m3 Concrete Water Cement Fly ash Sand Gravel C30 165 281 70 678 1206 C50 165 376 95 565 1199 1.2 试件设计

试件尺寸为300 mm×150 mm×150 mm。ECC尺寸为260 mm×120 mm,设置10 mm、20 mm、30 mm三种厚度。CFRP片材厚度为1.2 mm,宽度为50 mm,在ECC上的粘贴长度为200 mm。在加载端有30 mm的非粘结区以避免加载过程中出现应力集中现象。试件示意图如图2(a)所示。将混凝土/ECC强度(混凝土和ECC强度一致)、ECC厚度作为试验变量,单面剪切试件共7组21个试件。其中1组为不设置ECC层的对照组,其混凝土强度为C30。每组包含3个试件以提高结果可靠性。具体试件设计见表4。C30和C50为混凝土/ECC强度等级,E10/E20/E30为ECC层厚度,试件序号为最后一个数字。为防止混凝土和ECC界面发生剥离破坏,提高CFRP片材利用率,使用高压水射法对混凝土表面进行处理从而提高其粗糙度,处理后的界面如图3所示。

表 4 CFRP片材-ECC-混凝土试件设计Table 4. Design of CFRP plate-ECC-concrete specimensSpecimen Concrete/ECC strength/MPa ECC thickness/mm C30-E10 30 10 C30-E20 30 20 C30-E30 30 30 C50-E10 50 10 C50-E20 50 20 C50-E30 50 30 C30 30 – 1.3 加载装置

试件尺寸及加载示意图如图2所示。该试验用1对量程为10 T的液压千斤顶手动施加荷载。加载时调整加载端垫板的高度使千斤顶、力传感器及CFRP片材三者的中心在同一水平面上。然后用螺栓把加载端CFRP片材固定防止在加载过程中脱落。在CFRP片材表面每隔30 mm粘贴1个120-5AA应变片以测量加载过程中CFRP片材的应变变化和分布。

2. CFRP片材-ECC-混凝土试验破坏现象

设置ECC层的试件破坏模式均为CFRP片材-ECC复合界面的剥离破坏,如图4所示,这是希望出现的破坏模式,表明高压水枪喷射法处理混凝土表面可保证混凝土和ECC界面的有效粘结。初加荷载时,界面粘结应力主要集中在加载端,CFRP片材通过胶层与ECC粘结在一起,试件处于线弹性阶段,各部分变形协调。随着荷载的增加,参与受力的CFRP片材的长度增加,试件开始发出断断续续“噔”的声音,此时CFRP片材-ECC复合界面粘结应力开始从加载端逐渐向自由端传递。荷载达加到极限承载力的80%左右时,加载端ECC达到其抗拉强度,CFRP片材-ECC复合界面在加载端开始出现明显剥离,胶层与ECC的接触面开始出现裂缝,试件持续发出“噔”的声音。当参与受力的CFRP片材长度达到有效锚固长度后,荷载基本不再增加,但CFRP片材应变持续增大,最大剪应力处向自由端发展。复合界面剥离达到极限状态时,伴着较大的一声“砰”的声响,CFRP片材从ECC表面剥离,试件最终破坏。

不设置ECC层的试件破坏模式均为CFRP片材与混凝土界面的剥离。加载初期,混凝土和CFRP片材界面间无明显滑移。随着荷载的增加,可以听见轻微剥离声。荷载达到极限承载力的80%左右时,相对滑移明显增加,试件持续发出剥离的声音。伴随一声“砰”的声响,CFRP片材完全剥离,试件发生脆性破坏。

试件破坏后,有不同厚度的ECC被CFRP片材粘下,如图5所示。当ECC厚度为10 mm时,剥离表面可以清晰的看到PVA纤维,被粘下的ECC较薄。ECC厚度增加到20 mm时,约3~4 mm的ECC附着在CFRP片材上。当ECC厚度为30 mm时,约5 mm厚ECC被剥离,且ECC表面被拔出纤维更加明显。

3. 试验结果分析

3.1 CFRP片材-ECC-混凝土极限承载力

单面剪切试件极限承载力分布汇总见图6和表5,复合界面极限承载力随着ECC厚度及混凝土/ECC强度的增加而增加,但厚度越大增长的速率反而呈下降的趋势。设置3种不同ECC层厚度的单面剪切试件相比于无ECC层试件C30的极限承载力增加了27.3%~59.6%。对于混凝土/ECC强度为C30的试件,随着ECC厚度的增加最大承载力与未设置ECC层试件相比分别提高27.3%、49.5%和59.6%。当混凝土/ECC强度为C50,ECC厚度为20 mm、30 mm时,相比于ECC厚度为10 mm的试件极限承载力分别增加25%、27.4%。厚度为30 mm时相比20 mm厚度的ECC强度增加有限,表明单面剪切试件受力时,CFRP片材-ECC复合界面粘结应力无法传递到20 mm厚度以上的ECC或传递的力较小,因此不能仅靠提高ECC厚度来在增强极限承载力,否则无法发挥材料的最佳性能。对于ECC层厚度为10 mm、20 mm和30 mm的单面剪切试件,混凝土/ECC强度为C50时试件其极限承载力比强度为C30的试件分别提高了30.2%、38.5%和32.3%。由此可知:ECC厚度为30 mm时,随着混凝土强度提高极限承载力提高率不增反降,表明在ECC厚度较大时提高混凝土强度不是提高极限承载力有效方法。

表 5 CFRP片材-ECC-混凝土试验结果汇总Table 5. Summary of test results of CFRP plate-ECC-concrete specimensSpecimen Ultimate load/kN Average/kN Theoretical/kN E/T YANG yongxin et al[14] Neubauer et al[15] LU xinzheng et al[16] C30-1 9.2 C30-2 9.6 9.9 – – 12.5 20.8 15.4 C30-3 10.8 C30-E10-1 12.3 0.88 C30-E10-2 12.4 12.6 13.9 0.89 27.9 42.3 28.2 C30-E10-3 13.0 0.94 C30-E20-1 14.8 0.89 C30-E20-2 14.6 14.8 16.6 0.88 27.9 42.3 28.2 C30-E20-3 14.9 0.90 C30-E30-1 15.3 0.86 C30-E30-2 15.8 15.8 18.3 0.84 27.9 42.3 28.2 C30-E30-3 16.2 0.89 C50-E10-1 15.9 1.14 C50-E10-2 16.8 16.4 13.9 1.20 30.3 45.2 29.2 C50-E10-3 16.4 1.17 C50-E20-1 20.4 1.22 C50-E20-2 21.5 20.5 16.6 1.19 30.3 45.2 29.2 C50-E20-3 19.6 1.18 C50-E30-1 22.3 1.21 C50-E30-2 20.5 20.9 18.3 1.12 30.3 45.2 29.2 C50-E30-3 20.0 1.09 Notes: E—Experimental value; T—Theoretical value. 3.2 CFRP片材应变分布

典型试件的CFRP片材沿长度方向应变分布见图7。在加载初期,CFRP片材应变近似呈线性分布,且此时应变均较小。应变随着荷载的增加而增加,且近似呈二次分布,相邻区域应变差值逐渐增大,CFRP片材-ECC复合界面剪应力也逐渐增大,且粘结应力从加载端逐渐向自由端传递。随着荷载的增加,加载端ECC逐渐达到其极限抗拉强度,CFRP片材-ECC界面在加载端开始出现明显剥离,胶层与ECC的接触面开始出现裂缝,此时在加载端处ECC传递至CFRP片材上的应力有限,相对应的CFRP片材的应变也相对较小。传递应力最大处转移至未开裂的远离加载端的CFRP-ECC界面,因此应变峰值点也转移至未出现剥离的远离加载端的部位。CFRP片材应变表现为先增大后减小的趋势。这与试件破坏规律相对应,此时CFRP片材应变为典型的“S”形应变分布直到失效。对于具有ECC层的试件,试件破坏时距加载端160 mm以上时也存在应变,覆盖整个粘合区域,对于无ECC层试件则始终为零,这证实了ECC的裂缝控制能力可以有效地传递界面剪切应力,延缓CFRP板的剥离。试件C50-E30-3极限承载力达到20.0 kN,CFRP片材极限微应变可达到17.23×10−4,表明混凝土/ECC强度以及ECC厚度的增加有利于发挥CFRP片材性能。而对比组试件C30-3材料未充分利用,试件极限承载力和CFRP片材极限微应变均最小分别为10.8 kN和10.24×10−4。

4. CFRP片材-ECC-混凝土复合界面承载力计算模型

试件极限承载力与ECC厚度关系拟合曲线如图8所示,混凝土/ECC强度对极限承载力影响较大,因此区分不同的强度分别进行拟合。当混凝土/ECC强度为C30和C50时,曲线拟合相关系数R2分别达到0.925和0.763,表明ECC厚度与试件极限承载力间有良好的线性相关性。

国内外学者经过大量试验及理论分析,提出多个极限承载力计算模型。可以得出:模型考虑因素越多,计算结果越为精准。经典承载力模型如下:

杨勇新等[14]的模型,考虑了混凝土强度、有效锚固长度及FRP片材刚度的影响:

τu=0.5ft (1a) Le=100mm (1b) Pu=(0.5+0.08√Eftf100ft)bfLeτu (1c) Neubauer等[15]的模型,考虑了混凝土强度、有效锚固长度、FRP片材刚度及宽度比的影响:

βw=√1.1252−bf/bc1+bf/400 (2a) Le=√Eftf2ft (2b) {Pu=0.64βwbf√EftfftL⩾ (2c) Lu等[16]综合诸多模型后对承载力计算模型提出简化:

{P_{\rm{u}}} = {\beta _{\rm{l}}}{b_{\rm{f}}}\sqrt {2{E_{\rm{f}}}{t_{\rm{f}}}{G_{\rm{f}}}} (3a) {G_{\rm{f}}} = 0.308\sqrt {{f_{\rm{t}}}} \beta _{_{\rm{w}}}^2 (3b) {\beta _{\rm{w}}} = \sqrt {\frac{{2.25 - {b_{\rm{f}}}/{b_{\rm{c}}}}}{{1.25 + {b_{\rm{f}}}/{b_{\rm{c}}}}}} (3c) {\beta _{\rm{l}}} = \left\{ {\begin{array}{*{20}{l}} {\dfrac{L}{{{L_{\rm{e}}}}}(2 - \dfrac{L}{{{L_{\rm{e}}}}})\;L < {L_{\rm{e}}}{\rm{ }}}\\ {1\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;L \geqslant {L_{\rm{e}}}{\rm{ }}} \end{array}} \right.{L_{\rm{e}}} = 1.33\dfrac{{\sqrt {{E_{\rm{f}}}{t_{\rm{f}}}} }}{{{f_{\rm{t}}}}} (3d) 式中:τu为平均粘结应力;Pu为剥离承载力;Gf为界面破坏能;ft为混凝土抗拉强度;βw和βl分别为尺寸影响系数;Ef、tf和bf分别为CFRP片材的弹性模量、厚度和宽度;L和Le分别为粘结长度和有效粘结长度;bc为混凝土块体的宽度;Gf为破坏能。

以上3种模型计算所得结果见表5。模型计算值均与试验值有所偏差,主要原因可能是以往研究的是FRP与混凝土界面的剥离承载力,而混凝土的厚度远高于比本文所用ECC厚度且没有考虑在计算模型中[17]。而本文所用ECC厚度较小,复合界面剪应力可能传递到普通混凝土,因此在对本文单面剪切试件进行复合界面承载力计算时,不可忽略ECC厚度的影响。本文在Lu等[16]的模型基础上考虑ECC厚度对界面承载力的影响,对公式进一步改进:

{P_{\rm{u}}} = \frac{{{\beta _{\rm{l}}}{b_{\rm{f}}}\sqrt {2{E_{\rm{f}}}{t_{\rm{f}}}{G_{\rm{f}}}\sqrt {{t_{\rm{E}}}} } }}{{3.6}} (4) 式中,tE为ECC厚度。按照此极限承载力计算模型计算结果见表5。计算结果表明:本文考虑ECC厚度影响的承载力计算模型理论值与试验值吻合较好,优于Lu等[16]提出的模型。

5. CFRP片材-ECC-混凝土粘结-滑移模型

粘结-滑移关系反映了界面局部剪应力和相对滑移的发展规律,对采用理论和数值方法分析CFRP片材加固混凝土结构的性能非常重要。粘结-滑移关系决定了界面的受力过程、CFRP片材应变分布等指标。因此,为了更好地研究CFRP片材-混凝土界面性能,需更深入分析复合界面的粘结-滑移关系,其应力和变形分布如图9所示。

![]() 图 9 CFRP片材-ECC-混凝土复合界面应力分布示意图Figure 9. Schematic diagram of interface stress distribution between CFRP plate-ECC-concrete compositeP—External force applied; εf—Strain of CFRP plate; σf(x), σc(x)—Stresses of CFRP plate and ECC, respectively; xi—Bonding position for strain gauges of CFRP plate; τ(x)—Interfacial shear stress

图 9 CFRP片材-ECC-混凝土复合界面应力分布示意图Figure 9. Schematic diagram of interface stress distribution between CFRP plate-ECC-concrete compositeP—External force applied; εf—Strain of CFRP plate; σf(x), σc(x)—Stresses of CFRP plate and ECC, respectively; xi—Bonding position for strain gauges of CFRP plate; τ(x)—Interfacial shear stress由图9中受力平衡可得:

\tau (x){\rm{d}}x = {t_{\rm{f}}}{\rm{d}}{\sigma _{\rm{f}}}(x) (5) 进一步可得相邻两应变测点间界面剪应力:

{\tau _{i + 1/2}} = {E_{\rm{f}}}{t_{\rm{f}}}\frac{{{\rm{d}}{\varepsilon _{\rm{f}}}}}{{{\rm{d}}x}} = {E_{\rm{f}}}{t_{\rm{f}}}\frac{{{\varepsilon _i} - {\varepsilon _{i + 1}}}}{{\Delta l}} (6) 局部滑移可按照下式计算:

{s_i} = {s_{i + 1}} + \frac{{{\varepsilon _{{\rm{f}},i}} - {\varepsilon _{{\rm{f}},i + 1}}}}{2}\Delta l + {\varepsilon _{{\rm{f}},i + 1}}\Delta l{\kern 1pt} (7) 式中:

{\tau _{i + 1/2}} 和\Delta l 分别为i和i+1点间的剪应力和中心间距;{\varepsilon _i} 为第i个应变测点的值,i=1、2、…、6。选取典型试件的粘结-滑移曲线如图10所示。由式(6)和式(7)计算得到的是相邻应变测点间的平均剪应力和相对滑移值。剪应力基本符合随滑移值的增大先增大后减小的规律。从施加荷载直到剪应力峰值前,曲线近似为直线,试件处于线弹性阶段;随着荷载的增加,参与受力的CFRP片材的长度增加,此时CFRP片材-ECC复合界面进一步出现损伤,表现为达到峰值剪应力后曲线开始下降。以试件C50-E30-1为例,剪应力下降到1 MPa左右时,滑移量迅速增加。此时CFRP片材-ECC复合界面正在发生较大的剥离。滑移值达到0.1 mm左右时,大部分剪应力值已为0,但由于ECC特殊的应变硬化作用,小部分CFRP片材-ECC复合界面在滑移较大时仍能传递一定的剪应力。当剪应力降低直至于0时,CFRP片材从ECC表面剥离。

![]() 图 11 CFRP片材-ECC-混凝土试件粘结-滑移数据拟合曲线Figure 11. Bond-slip data fitting curves of CFRP plate-ECC-concrete specimensτ—Corresponding shear stress when the slip is S(Sp); τmax, \bar \tau—Peak shear stress; S_0 , \bar S —Slip corresponding to τmax; Sp—Slip; Su, Sf—Maximum slip; fc, ft—Compressive strength, tensile strength of concrete; βw, Gf—Size influence coefficient and fracture energy; Ef, tf—Elastic modulus and thickness of CFRP plate; bf, bc—Width of CFRP plate and concrete; Ga, ta—Shear modulus and thickness of the adhesive; n—Coefficient

图 11 CFRP片材-ECC-混凝土试件粘结-滑移数据拟合曲线Figure 11. Bond-slip data fitting curves of CFRP plate-ECC-concrete specimensτ—Corresponding shear stress when the slip is S(Sp); τmax, \bar \tau—Peak shear stress; S_0 , \bar S —Slip corresponding to τmax; Sp—Slip; Su, Sf—Maximum slip; fc, ft—Compressive strength, tensile strength of concrete; βw, Gf—Size influence coefficient and fracture energy; Ef, tf—Elastic modulus and thickness of CFRP plate; bf, bc—Width of CFRP plate and concrete; Ga, ta—Shear modulus and thickness of the adhesive; n—Coefficient采用几种典型的FRP-混凝土界面粘结-滑移本构关系,对试件C50-E30-1的粘结-滑移数据进行拟合分析以得到一般性规律,如图11所示。图中:

\tau 为滑移为s 时对应的粘结剪应力;{\tau _{\max }} 、\overline \tau 为峰值剪应力;n为系数;{S_0} 、\overline S 为{\tau _{\max }} 对应的滑移;{S_{\rm{u}}} 、{S_{\rm{f}}} 为最大滑移;fc为混凝土抗压强度;Ga/ta=Ka,Ga和ta分别为胶层剪切模量和厚度。Ferracuti等[18]的模型相比于其他3种模型,在下降段显示了更柔软的响应,考虑的影响因素较全面(混凝土强度、FRP片材刚度、有效锚固长度及宽度比等均考虑),模型的计算结果与试验数据拟合较好。Dai等[19]的模型是基于较小的胶层刚度(Ka<1 MPa)的试验结果,对于有普通胶层刚度(本文Ka为5 MPa左右)的粘结-滑移数据拟合结果滑移量明显偏大。Lu等[20]模型对Gf和τmax的预测值均偏小,低估了界面的抗剪承载力,与试验数据也有一定的偏差。陆新征[21]的模型在粘结-滑移曲线上升段拟合较好,但在下降段没有考虑材料应变硬化特性和界面软化的影响,下降段拟合结果不理想。用Ferracuti等[18]模型拟合典型试件的曲线见图12。设置ECC层的单面剪切试件在达到最大剪切应力时的滑移量均比无ECC层的对照试件大,且最大剪切应力均有增加。由于ECC多缝开裂及应变硬化特性,有ECC层的试件的初始刚度均比无ECC层的对比试件小。大部分试件拟合值与试验结果吻合较好,相关系数可达到0.8以上。

6. 结 论

(1) 采用碳纤维增强树脂复合材料(CFRP)片材-工程水泥基复合材料(ECC)复合界面可有效延缓CFRP片材的剥离,可以更有效地传递界面剪应力。研究表明,复合界面的抗剪性能明显优于纤维增强树脂复合材料(FRP)-混凝土界面的抗剪性能。

(2) 设置ECC层的单面剪切试件破坏模式均为CFRP片材-ECC复合界面的剥离破坏。ECC厚度增加为20 mm以上时,试件破坏后CFRP片材上附着的ECC厚度为3~5 mm,表明ECC厚度的增加有利于提高复合界面抗剪承载力。

(3) 设置ECC层的试件相比于无ECC层试件的极限承载力增加了27.3%~59.6%。ECC厚度由20 mm增加到30 mm时,强度提高率有限,表明不能仅靠提高ECC厚度来在增强极限承载力。

(4) 本文提出的考虑ECC厚度的极限承载力计算模型计算值与试验结果吻合较好。不同的粘结滑移本构关系中,考虑下降段曲线软化的模型与本文试验结果相吻合。

-

表 1 ZrO2增韧Al2O3陶瓷颗粒(ZTAp)物理/力学性能

Table 1 Physical and mechanical properties of ZrO2 toughened Al2O3 ceramic particles (ZTAp)

Material Density/

(g·cm−3)Vickers

hardnessCoefficient of thermal

expansion/10−6℃−1Fracture toughness/

(MPa·m1/2)Flexural strength/

MPaZTAp 4.6 1 800-2 100 7.5-9.0 6.5-9.0 350-550 表 2 高铬合金粉末化学成分

Table 2 Chemical compositions of high chromium cast iron alloy powder

wt% Element C Cr Si Mn Ni V Mo Fe Content 3.2-3.5 26-28 0.7-1.0 1.1-1.4 2.3-2.5 0.2-0.3 0.4-0.6 Bal. 表 3 铸造渗高铬铸铁(HCCI)化学成分

Table 3 Chemical compositions of cast high chromium cast iron (HCCI)

wt% Element C Cr Si Mn Ni Mo Cu Fe Content 3.0-3.3 24-26 0.5-0.8 0.6-1.0 0.3-0.5 0.4-0.6 0.2-0.3 Bal. -

[1] 魏世忠, 徐流杰. 钢铁耐磨材料研究进展[J]. 金属学报, 2020, 56(4):523-538. DOI: 10.11900/0412.1961.2019.00370 WEI S Z, XIU L J. Review on research progress of steel and iron wear-resistant materials[J]. Acta Metallurgica Sinica,2020,56(4):523-538(in Chinese). DOI: 10.11900/0412.1961.2019.00370

[2] 钱兵, 孙书刚, 朱昱, 等. 中速磨煤机金属陶瓷复合磨辊及磨盘的研究[J]. 中国电力, 2014, 47(10):122-125. QIAN B, SUN S G, ZHU Y, et al. Development of ceramal compound grinding roller and refiner plate of medium speed mill[J]. Electric Power,2014,47(10):122-125(in Chinese).

[3] OJALA N , VALTONEN K , ANTIKAINEN A, et al. Wear performance of quenched wear resistant steels in abrasive slurry erosion[J]. Wear,2016,354–355:21-31.

[4] HU Y B, CONG W L. A review on laser deposition-additive manufacturing of ceramics and ceramic reinforced metal matrix composites[J]. Ceramics International,2018,44(17):20599-20612. DOI: 10.1016/j.ceramint.2018.08.083

[5] SAHOO B P, DAS D. Tribological behaviour of ceramic and carbon nano-tube reinforced metal matrix composites-A review[J]. Materials Today: Proceedings,2018,5(9):20549-20559. DOI: 10.1016/j.matpr.2018.06.433

[6] MONILA J M, NARCISO J, WEBER L, et al. Thermal con-ductivity of Al-SiC composites with monomodal and bimodal particle size distribution[J]. Materials Science and Engineering A,2008,480(1-2):483-488.

[7] 周谟金, 蒋业华, 温放放. 热处理对高铬铸铁基蜂窝陶瓷复合材料耐磨性的影响[J]. 材料导报, 2017, 31(14):117-121. DOI: 10.11896/j.issn.1005-023X.2017.014.025 ZHOU M J, JIANG Y H, WEN F F. Effect of heat treatment on wear resistance of honeycomb ceramic preform reinforced chromium cast iron matrx composite[J]. Materials Reports,2017,31(14):117-121(in Chinese). DOI: 10.11896/j.issn.1005-023X.2017.014.025

[8] 王文龙, 刘海云, 王晓杰, 等. 浸渗法制备ZTA陶瓷/铁基复合材料研究进展[J]. 特种铸造及有色合金, 2020, 40(1):37-41. WANG W L, LIU H Y, WANG X J, et al. Research progress in ZTA ceramic/iron matrix composites prepared by infiltration method[J]. Special Casting & Nonferrous Alloys,2020,40(1):37-41(in Chinese).

[9] 范瑞瑞, 张瑞, 李炎, 等. 粉末冶金法制备Al2O3颗粒增强Fe基复合材料[J]. 热加工工艺, 2011, 40(24):120-123. DOI: 10.3969/j.issn.1001-3814.2011.24.038 FAN R R, ZHANG R, LI Y, et al. Fabrication of Fe matrix composite reinforced with Al2O3 particles by powder metallurgical method[J]. Hot Working Technology,2011,40(24):120-123(in Chinese). DOI: 10.3969/j.issn.1001-3814.2011.24.038

[10] KONOPKA K, OLSZÓWKA-MYALSKA A, SZAFRAN M. Ceramic-metal composites with an interpenetrating network[J]. Materials Chemistry & Physics, 2003, 81(2-3): 329-332.

[11] 郑开宏, 高义民, 陈亮, 等. 颗粒增强铁基复合材料的三体磨料磨损性能[J]. 摩擦学学报, 2012, 32(2):176-182. ZHENG K H, GAO Y M, CHEN L, et al. Three-body abrasive wear behavior of iron matrix composites reinforced with tungsten carbide particles[J]. Tribology,2012,32(2):176-182(in Chinese).

[12] KIHARA M, OGATA T, NAKAMURA K, et al. Effect of Al2O3additions on mechanical properties and microstructure of Y-TZP[J]. Journal of the Ceramic Society of Japan,1988,96:635-642.

[13] QIU B, XING S, DONG Q. Fabrication and wear behavior of ZTA particles reinforced iron matrix composite produced by flow mixing and pressure compositing[J]. Wear,2019,428-429:167-177. DOI: 10.1016/j.wear.2019.03.013

[14] Magotteaux International SA (BE). Cast parts with enhanced wear resistance: US, 7513295[P]. 2006-01-20.

[15] 陈建, 潘复生. 合金元素影响铝/陶瓷界面润湿性的研究现状[J]. 兵器材料科学与工程, 1999(4):3-5. DOI: 10.3969/j.issn.1004-244X.1999.04.001 CHEN J, PAN F S. Research status of influence of alloying elements on wettability of Al/ceramic interface[J]. Ordnance Material Science and Engineering,1999(4):3-5(in Chinese). DOI: 10.3969/j.issn.1004-244X.1999.04.001

[16] WITTIG D, GLAUCHE A. ANEZIRIS C G, et al. Activated pressureless melt infiltration of zirconia-based metal matrix composites[J]. Materials Science and Engineering,2008,A488(1-2):580-585.

[17] 孙书刚, 钱兵, 李小武, 等. ZTA颗粒增强高铬铸铁基复合材料制备及磨损性能研究[J]. 铸造技术, 2018, 39(8):1663-1666. SUN S G, QIAN B, LI X W, et al. Preparation and wear properties of ZTA particle reinforced high chromium cast iron matrix composites[J]. Foundry Technology,2018,39(8):1663-1666(in Chinese).

[18] SOBOLEV A, MIRZOEV A. Structure and stability of (Cr, Fe)7C3 ternary carbides in solid and liquid state[J]. Journal of Alloys and Compounds,2019,804:566-572. DOI: 10.1016/j.jallcom.2019.06.282

[19] 肖平安, 肖璐琼, 顾景洪, 等. 15Cr系亚共晶高铬铸铁的烧结制备与性能研究[J]. 湖南大学学报(自然科学版), 2019, 46(12):58-64. XIAO P A, XIAO L Q, GU J H, et al. Study on sintering preparation and properties of 15Cr hypoeutectic high-chromium cast iron[J]. Journal of Hu'nan University (Natural Sciences),2019,46(12):58-64(in Chinese).

[20] BAJWA R S, KHAN Z, BAKOLAS V, et al. Water-lubricated Ni-based composite(Ni-Al2O3, Ni-SiC and Ni-ZrO2) thin film coatings for industrial applications[J]. Acta Metallurgica Sinica,2016,29(1):1-9.

[21] 贾建民, 齐纪渝, 谢敬学. MPS 中速磨煤机磨辊磨损机理研究[J]. 华北电力大学学报, 1998, 25(4):88-91. JIA J M, QI J Y, XIE J X. Research on wear mechanism of MPS type mill roll[J]. Journal of North China Electric Power University,1998,25(4):88-91(in Chinese).

-

期刊类型引用(7)

1. 房恩惠,杨树桐,庞瑞阳,孙忠科,兰天. 树脂预浸技术提升CFRP-混凝土界面力学性能研究. 复合材料科学与工程. 2025(02): 117-128 .  百度学术

百度学术

2. 丛龙宇,张方,钱永久. 外部粘贴CFRP-ECC粘结性能的影响因素试验. 复合材料学报. 2025(03): 1538-1554 .  本站查看

本站查看

3. 温小栋,王俊豪,殷光吉,邵璟璟,冯蕾. 海水与腐蚀电流耦合作用下铝合金与混凝土界面黏结性能. 建筑结构学报. 2024(04): 237-246 .  百度学术

百度学术

4. 朱红兵,付正昊,王烨,陈经毅. 界面剂对全轻陶粒混凝土与普通混凝土粘结界面力学性能的影响. 复合材料学报. 2024(06): 3154-3167 .  本站查看

本站查看

5. 叶华勇. 界面处理方式对CFRP-ECC复合加固混凝土梁受弯性能影响研究. 福建建筑. 2024(11): 49-54 .  百度学术

百度学术

6. 姜天华,万聪聪,颜斌. BFRP筋与钢-PVA混杂ECC粘结性能. 复合材料学报. 2023(06): 3499-3512 .  本站查看

本站查看

7. 昝鹏,陈燕萍. 水利工程混凝土复合材料的制备与力学性能分析. 塑料助剂. 2023(03): 30-33 .  百度学术

百度学术

其他类型引用(9)

-

下载:

下载: