Synergistic flame retardant mechanism of nano SiO2 and resorcinol bis(diphenylphosphate) on polycarbonate-ABS blends

-

摘要: 选用以凝聚相阻燃机制为主的间苯二酚-双(二苯基磷酸酯)(RDP)作为阻燃剂,纳米SiO2为协效剂,以熔融共混法制备了聚碳酸酯(PC)-丙烯腈-丁二烯-苯乙烯共聚物(ABS)阻燃合金。通过垂直燃烧(UL94)和锥形量热测试(Cone)探究了纳米SiO2与RDP复配对PC-ABS合金阻燃性能和燃烧行为的影响。采用SEM观察燃烧残炭的微观形貌,用EDS分析炭层表面元素含量的变化,进一步探究了纳米SiO2与RDP在PC-ABS凝聚相中的协效阻燃机制。通过拉伸性能和冲击性能测试研究纳米SiO2与RDP复配对PC-ABS合金力学性能的影响及甲基丙烯酸甲酯-丁二烯-苯乙烯(MBS)对PC-ABS合金的增韧增容作用。结果表明,纳米SiO2与RDP可以在凝聚相中形成Si—O—P化合物,对PC-ABS合金的燃烧炭层起到增强作用,从而改善PC-ABS合金的阻燃性能;适量MBS的加入可以提高PC-ABS合金的冲击强度和断裂伸长率,但会降低其阻燃性能。Abstract: The flame retardant polycarbonate (PC)-acrylonitrile-butadiene-styrene (ABS) blends was prepared by melt blending with resorcinol bis(diphenylphosphate) (RDP) (mainly based on condensed phase flame retardant mechanism) and nano SiO2 as the synergist. The effects of nano SiO2 and RDP on the flame retardancy and combustion behavior of PC-ABS blends were investigated by vertical combustion (UL94) and cone calorimetry (Cone). SEM was used to observe the micro morphology of burning carbon residue, and EDS was used to analyze the change of element content on the surface of carbon layer, so as to further explore the synergistic flame retardant mechanism of nano SiO2 and RDP in the condensed phase of PC-ABS. The effects of nano SiO2 and RDP on the mechanical properties of PC-ABS blends and the toughening and compatibilizing effects of methyl methacrylate-butadiene-styrene (MBS) on the blends were studied by tensile and impact tests. The results show that nano SiO2 and RDP can form Si—O—P compound in the condensed phase, which can enhance the combustion carbon layer, thus improving the flame retardancy of PC-ABS blends; The impact strength and elongation at break of the PC-ABS blends can be increased with the addition of MBS, but the flame retardancy can be decreased.

-

由于对水优异的排斥性能,超疏水表面在自清洁[1]、防覆冰[2]、油水分离[3]、防腐[4]等领域具有广阔的应用前景。制备超疏水表面需要两大要素:(1) 表面具有微纳米粗糙结构;(2) 二是具有低的表面能[5]。而在实际应用过程中,超疏水表面不可避免地会受到外界机械损伤或污染,从而破坏表面的微纳米结构或表面受污染而使表面能升高,最终导致超疏水特性下降或丧失。因此如何提高超疏水表面的力学和化学稳定性[6-7],成为超疏水技术实现大规模应用的关键[8]。

目前关于强化超疏水表面机械和化学稳定性的研究主要集中在三个方面:(1) 将树脂作为疏水性纳米颗粒与基底之间的粘结剂,Lu等[9]首次提出“超疏水表面+粘结剂+基底”的概念,先用商业化粘结剂作为底漆,再将全氟硅烷低表面能改性后的纳米TiO2喷涂在粘结剂上,提高超疏水颗粒的耐磨性。超疏水表面在100 g负载条件下,240#砂纸循环40周磨损后,表面接触角仍能稳定在160°以上。Wu等[10]采用类似思路,将全氟硅烷改性的环氧树脂作为底漆进行预固化处理,再将氟化环氧树脂/纳米Al2O3喷涂到底漆表面,获得具有良好机械稳定性的超疏水表面。磨损实验表明,在预固化20 min时,纳米Al2O3既能保证与基底有效结合又能构筑微纳米粗糙表面,在磨损120周次后仍能保持超疏水特性;(2) 利用硬质材料对脆弱的纳米结构进行保护。Wang等[11]提出铠装超疏水表面的概念,将脆弱的纳米结构填充到相互连接的耐磨微米级结构之间,结果表明铠装超疏水涂层具有优异的机械稳定性,在商业应用方面具有巨大的潜力。Li等[12]在脆弱的微纳米结构表面浸渍涂敷一层磷酸二氢铝(ADP),并进行热处理。ADP可以作为保护铜纳米结构的铠甲,即使在长时间高温和沙子冲击试验后,其超疏水特性基本维持稳定;(3) 对受损的微纳米结构和低表面能物质进行自修复。Qian等[13]从微纳米结构的自修复入手,用平整的荷叶做模板,以双酚A-二缩水甘油醚作为基体,Jeffamine D230和n-癸胺为固化剂,得到形状记忆聚合物(SMP)。结果表明,在磨损或划伤条件下,SMP在60℃下加热20 min即可恢复原有的微纳米形貌,恢复超疏水性能。Wang等[14]则是聚焦低表面能物质的自修复,用聚二甲基硅氧烷(PDMS)在荷叶表面制备倒模,将PDMS/石蜡共混浇铸后获得超疏水表面。由于石蜡的低沸点和PDMS的三维网络,石蜡可在室温下快速迁移至表面,恢复表面的低表面能状态和超疏水特性。Jiang等[15]采用微弧氧化与氟化硅油实现合金表面的超疏水涂层的高耐蚀性和损伤快速修复。

除了上述三种策略外,近年来提出了一种三维超疏水涂层概念,这种涂层不仅表面呈现超疏水,当表面微纳米结构或低表面能物质被破坏后,暴露出的新表面仍能自动形成超疏水性,即材料本体能对受损微纳米结构和低表面能物质进行自我修复,大大延长了超疏水涂层的服役寿命[16-18]。Liu等[19]用PDMS和环氧丙烯酸酯作为基底,用硅烷偶联剂连接基体树脂和纳米SiO2,在紫外光照下共聚得到三维超疏水涂层,在经过较长时间磨损后其表面形貌及低表面能物质成分基本不变,仍能维持超疏水性。

制备超疏水表面往往需要氟硅烷进行低表面能改性,而氟硅烷成本高,环境不友好,因此发展无氟低表面能涂层甚至无需低表面能涂层的超疏水表面引起了学者的广泛关注[20]。聚苯并噁嗪(PBA)是一种含氮杂环酚醛的热固型树脂,具有吸水率低、抗磨损、耐高温、阻燃等诸多特性。PBA单体开环聚合后产生的活泼酚羟基可与其分子内的氮原子形成分子内氢键,从而大大降低膜层表面能,最低可达15.1 mJ/m2[21]。因此将本征低表面能的PBA树脂作为基体,即使其表面不涂低表面能物质,仅靠添加微纳米颗粒来构筑粗糙表面就可以得到三维超疏水结构。尽管有这些优势,有关PBA涂层的研究还是相对较少[22],对其摩擦磨损机制研究也不够深入。

本文以PBA树脂为基底,添加微米级ZrO2和纳米级Al2O3作为填料构筑粗糙结构,无需涂覆低表面能氟化物,制备了一种三维超疏水涂层。通过对填料质量比及ZrO2-Al2O3的配比进行优化,获得了最佳的填料添加量及微纳米颗粒配比。在此基础上,根据三维超疏水涂层的质量损失与摩擦负荷之间的关系构建了一个简单数学模型,用于预测涂层在模拟工况条件下的使用寿命。此外还分别研究了三维超疏水涂层在高温、酸碱、UV光照条件下的化学稳定性和耐蚀性,并考察了超疏水涂层的抗蚀能力,以期为三维超疏水涂层的工程应用提供理论依据。

1. 实验材料及方法

1.1 原材料

双酚A苯并噁嗪单体(Bisphenol A benzoxazine,BA),平均粒径为180 μm,购自成都科宜高分子公司;微米级ZrO2,纯度为99.9%,平均粒径1 μm,购自上海肴戈合金材料公司;纳米Al2O3,纯度为99.9%,γ相,平均粒径20 nm,购自阿拉丁试剂公司;无水乙醇,丙酮,分析纯,均购自国药集团化学试剂公司;去离子水,实验室自制。

1.2 三维超疏水涂层制备

先将1 g BA加入到20 mL丙酮溶剂中,常温搅拌0.5 h,然后依次加入适量ZrO2和Al2O3,先超声搅拌0.5 h,再在40℃下磁力搅拌6 h,最后超声搅拌0.5 h,得到乳白色混合悬浮液。用180#SiC砂纸打磨碳钢金属片,除去金属片表面氧化层和油污,接着用乙醇超声5 min后吹干,放入60℃鼓风干燥箱中进行30 min预热。将得到的混合悬浮液刷涂到预热后的碳钢表面,并在鼓风干燥箱中60℃干燥1 h,再放入马弗炉内进行100℃、140℃、160℃、180℃、200℃和220℃各1 h的梯度升温固化,固化完成后将试样炉冷至室温取出,用涂层测厚仪(Elcometer415)测量其涂层厚度。表1为不同填料质量比及配比的涂层试样及其简称。

表 1 不同填料添加量及配比的Al2O3- ZrO2/聚苯并噁嗪(PBA)复合涂层配方及简称Table 1. Al2O3- ZrO2/poly-benzoxazine (PBA) composite coatings with different filler contents and filler mass ratios and corresponding abbreviations of coatingsAbbreviation BA/g Al2O3/g ZrO2/g Filler content/% Coating thickness/μm PBA 1 0 0 0 280±10 1Al2O3-1ZrO2/15PBA 1 0.09 0.09 15 280±10 1Al2O3-1ZrO2/30PBA 1 0.3 0.3 30 280±10 1Al2O3-1ZrO2/50PBA 1 0.5 0.5 50 280±10 1Al2O3-1ZrO2/55PBA 1 0.6 0.6 55 280±10 1Al2O3-2ZrO2/50PBA 1 0.33 0.67 50 280±10 2Al2O3-1ZrO2/50PBA 1 0.67 0.33 50 280±10 Note: BA—Bisphenol A benzoxazine. 1.3 性能测试与表征

接触角测试:采用光学接触角测试仪(JC2000DM,上海中晨数字技术公司)记录不同涂层表面的浸润性,将约3 μL去离子水滴到涂层表面,待液滴稳定1 min后开始拍照记录,测量液滴在涂层表面的接触角,随机取5个点重复测量,最终结果取平均值。

形貌表征:采用SEM (Nova Nano SEM 450,美国赛默飞) 在5000倍下观察不同涂层形貌,并用EDS面扫描表征涂层中的元素分布;采用超景深体式显微镜(VHX-5000,日本基恩士)在放大1000倍下观察磨损前后表面三维变化,记录涂层表面的粗糙度。

摩擦实验:向直径15 mm的圆形涂层试样分别施加2.83 kPa、5.66 kPa、11.32 kPa载荷,分别对应砝码质量为50 g、100 g、200 g,在320#砂纸表面每直线摩擦10 cm后开始涂层表面接触角测量。涂层试样摩擦后用吹风机吹去表面浮屑,再用电子分析天平(精度0.1 mg)称量涂层质量,并用涂层测厚仪测量摩擦后的涂层厚度,并根据摩擦前后涂层试样质量差计算涂层质量损失。实验采用磨擦磨损试验仪(MS-ECT3000,兰州华汇仪器公司)在100 g载荷和转速50 r/min条件下,分别测试干燥环境和去离子水中涂层的摩擦系数,测试时间为600 s,摩擦副为SiC。

化学稳定性测试:用HCl溶液和NaOH溶液与去离子水分别配制不同pH值的溶液,测试这些溶液在涂层表面的接触角。将涂层试样放入马弗炉中,以40℃为区间,从100℃升温到300℃均保温1 h后测试涂层的接触角。用紫外汞灯(250 W、365 nm)照射样品,测试涂层的抗紫外性能,涂层表面与UV灯距离为5 cm,每10 min测一次接触角,共6次。

耐蚀性测试:用电化学工作站(CS350H,武汉科思特)来评价1Al2O3-1ZrO2/50PBA涂层的防腐性能。对碳钢基体和涂层在相对于开路电位±0.5 V范围内进行动电位扫描,扫描速度为0.5 mV/s。对不同时间中性盐雾(5wt% NaCl、35℃)测试后的涂层试样进行电化学阻抗谱(EIS)测量, 扫频范围为105~10−2 Hz,振幅为10 mV。以工作面积为1 cm2的涂层试样做工作电极,饱和甘汞电极(SCE)用作参比电极,Pt片电极作为辅助电极,在3.5wt%NaCl溶液中测试。用PosiTestAT附着力测试仪(DeFelsko,美国)测量盐雾前后涂层的附着力。

2. 结果与讨论

2.1 填料添加量及配比对Al2O3-ZrO2/PBA涂层超疏水性的影响

超疏水涂层中微纳米填料添加量直接影响超疏水效果[23],图1为在填料质量比Al2O3∶ZrO2=1∶1条件下,不同填料添加量下复合涂层的表面接触角。可知,接触角随填料添加量的增加先增后减。PBA的接触角为91°,在添加15%的Al2O3-ZrO2复合填料后,接触角变化不大;当填料添加量为30%时,接触角快速升到128°;当添加量为50%时,涂层接触角为154°,达到超疏水效果;当继续增加填料量到55%,涂层接触角降低到136°。这可能是当微纳米填料添加量<50%时,涂层表面的填料不足以构筑微纳米分级结构,难以产生足够的气穴而获得超疏水效果;而当填料质量比>50%时,涂层表面的填料过多,容易产生填料团聚,导致气穴减少,且有限的PBA树脂基料无法为过多的微纳米填料提供低表面能,导致涂层疏水性降低。

在填料添加量为50%时,进一步考察了填料中Al2O3-ZrO2质量比对涂层接触角的影响。图2为不同Al2O3/ZrO2质量比的涂层表面微观形貌及接触角,并给出了涂层表面的元素组成及分布。可知,纯PBA表面光滑平整,局部出现凹坑但未形成孔洞缺陷;当Al2O3∶ZrO2质量比为1∶2时,用高倍SEM观察表面时,由于涂层导电性差,出现局部放电现象,但仍可以清晰看出表面有微米级块状颗粒堆积;当Al2O3∶ZrO2质量比为2∶1时,表面以纳米级颗粒为主,少量微米级块状颗粒;当Al2O3∶ZrO2质量比降为1∶1时,表面以微米级和纳米级颗粒弥散分布为主。将图2(d)放大20000倍观察,见图2(e),可见微米颗粒间出现大量纳米颗粒,组成了典型的微纳米分级结构。通过对该区域进行元素面扫描,如图2(e)~2(i)所示,可见主要存在Zr、Al、O、N等,且Al元素分布最弥散,这与Al2O3颗粒的纳米尺寸有关,N元素则来自于PBA,说明Al2O3-ZrO2微纳米填料与PBA已形成有效掺杂。根据表面微纳米结构与宏观的疏水性之间的构-效关系可知,当Al2O3∶ZrO2质量比为1∶2时,微米级的块状颗粒形成的气穴较少,接触角在三者中最小;而当Al2O3∶ZrO2质量比为2∶1时,接触角达到147°,接近超疏水状态,但过多的纳米颗粒导致形成的气穴不稳定而限制了其疏水性;而当Al2O3∶ZrO2质量比为1∶1时,表面形成微纳米分级结构,进而形成较多稳定的气穴[24],使接触角达到154°,宏观上表现出超疏水性。

2.2 三维超疏水Al2O3-ZrO2/PBA涂层的摩擦磨损性能

摩擦系数是摩擦学研究中重要的物理量,与接触表面的粗糙度有关,而与接触面积无关。图3为不同填料添加量复合涂层的摩擦系数随时间的变化曲线,进一步对比了1Al2O3-1ZrO2/50PBA涂层在干燥和去离子水中的摩擦系数,并对原始曲线进行同参数Savitzky-Golay平滑去噪(见粗实线)。可知,各涂层摩擦系数均存在上升和稳定两个阶段,且填料质量分数越高,涂层摩擦系数越大。对于PBA涂层,摩擦系数在摩擦105 s后稳定在0.43;而1Al2O3-1ZrO2/15PBA涂层在摩擦60 s后开始稳定,最终稳定在0.58;对于1Al2O3-1ZrO2/30PBA涂层,摩擦系数快速上升,在30 s后稳定在0.65;1Al2O3-1ZrO2/50PBA涂层摩擦系数的变化较为特殊,先在30 s快速上升至峰值0.82,后缓慢下降,最终摩擦系数稳定在0.72,而在去离子水中进行测试时,1Al2O3-1ZrO2/50PBA涂层摩擦系数的变化趋势与1Al2O3-1ZrO2/30PBA涂层类似,且噪声振幅更低,最终摩擦系数稳定在0.64。为了定性表征涂层表面的粗糙度,用体式显微镜测量涂层表面的高度差,高度差越大则表面越粗糙,结果如表2所示,可见随着填料质量比增加,表面高度差也随之增大。PBA的表面高度差为1.08 μm,与图2(a)结果吻合;当填料添加量为50%时,1Al2O3-1ZrO2/50PBA涂层的高度差值达到69.61 μm。据此可知PBA表面光滑平整,摩擦阻力较小,因而摩擦系数最小。随着Al2O3/ZrO2微纳米硬质填料含量增加,表面粗糙度随之增加,剥离的硬质颗粒能够粘附到摩擦副表面,抑制了摩擦转移膜的滑动,从而增大了摩擦系数。对于1Al2O3-1ZrO2/50PBA涂层,表面裸露出大量的微纳米硬质颗粒,初期摩擦阻力最大,短时间内达到峰值,而后硬质颗粒被逐渐磨平,粗糙度逐渐降低,摩擦系数也随之缓慢下降并最终稳定[25];而当在水中进行摩擦测试时,涂层表面与摩擦副之间形成水膜,减少了两者之间的实际接触面积且可以起到润滑作用[26],因此与干燥摩擦条件相比,1Al2O3-1ZrO2/50PBA涂层在水中的摩擦系数降低。

表 2 Al2O3∶ZrO2质量比为1∶1时不同填料添加量Al2O3-ZrO2/PBA复合涂层表面的高度差Table 2. Height differences of Al2O3-ZrO2/PBA composite coatings with different filler contents at mass ratio Al2O3∶ZrO2=1∶1PBA 1Al2O3-

1ZrO2/

15PBA1Al2O3-

1ZrO2/

30PBA1Al2O3-

1ZrO2/

50PBAHeight difference

of coating

surface/μm1.08±0.3 3.71±1.1 31.68±1.2 69.61±0.8 Note: Height difference—Value between the highest and the lowest points of coating surface. 由2.1节结果可知,1Al2O3-1ZrO2/50PBA涂层表现出超疏水特性。因此后续主要针对1Al2O3-1ZrO2/50PBA涂层进行砂纸摩擦测试,图4(a)为经过不同摩擦距离后涂层表面接触角的变化,可见在整个摩擦过程中接触角先下降后水平波动,但涂层表面接触角均超过150°,滚动角小于7°,呈现出良好的超疏水状态。摩擦180 cm后的试样宏观形貌可看出明显划痕,相较于原始涂层更平整。为了定性描述水滴在涂层表面的黏附力大小,用接触角测量仪记录了水滴在经过180 cm摩擦后的涂层表面先接触后分离的动态过程,可以看到测试针头将水滴下压到涂层表面后再上升针头,水滴随针头一起上升并发生轻微拉伸变形,直到完全脱离涂层表面,说明在经过180 cm的摩擦后,涂层表面对液滴的黏附力依旧很小,表现出良好的Cassie状态[27],与滚动角结果相吻合。表3为经不同摩擦距离后的涂层剩余厚度值,可见在摩擦过程中涂层厚度从初始值280 μm逐步减薄至32 μm。结合图4(a)可知,涂层不仅表面表现出超疏水特性,表面磨损后暴露出的本体依旧维持超疏水性,表明1Al2O3-1ZrO2/50PBA涂层整体上表现出三维连续的超疏水特性。这是由于涂层表面的Al2O3/ZrO2微纳米结构和低表面能的PBA的协同作用,可以有效捕捉和储存空气,抑制水滴与涂层表面的直接接触和水分渗入。

表 3 1Al2O3-1ZrO2/50PBA涂层厚度在不同摩擦走长后的涂层剩余厚度Table 3. Thickness of 1Al2O3-1ZrO2/50PBA coating after suffering different friction distanceFriction distance/cm 0 60 120 180 Coating thickness/μm 280±10 202±10 126±10 32±10 为了进一步探究不同载荷下1Al2O3-1ZrO2/50PBA涂层的质量损失,分别向涂层试样施加2.83 kPa、5.66 kPa、11.32 kPa载荷后进行摩擦测试,图5为不同载荷下涂层的质量损失M与载荷和摩擦距离之间的关系。可见在固定载荷下,随着摩擦距离的增加,质量损失呈线性增加;而在相同摩擦距离下,载荷越大,涂层质量损失量加速增大。为此可采用指数方程描述了涂层质量损失与载荷和摩擦距离的关系,如下式:

![]() 图 5 1Al2O3-1ZrO2/50PBA涂层质量损失在不同载荷下随摩擦距离的变化及线性拟合结果Figure 5. Mass loss rate change of 1Al2O3-1ZrO2/50PBA coating versus friction distance and linear fitting resultsF2.83 kPa, F5.66 kPa, F11.32 kPa—Mass loss of 1Al2O3-1ZrO2/50PBA after friction under 2.83 kPa, 5.66 kPa, 11.32 kPa pressure, respectively

图 5 1Al2O3-1ZrO2/50PBA涂层质量损失在不同载荷下随摩擦距离的变化及线性拟合结果Figure 5. Mass loss rate change of 1Al2O3-1ZrO2/50PBA coating versus friction distance and linear fitting resultsF2.83 kPa, F5.66 kPa, F11.32 kPa—Mass loss of 1Al2O3-1ZrO2/50PBA after friction under 2.83 kPa, 5.66 kPa, 11.32 kPa pressure, respectivelyM=(Ae−PL/T+R)×D (1) 其中:M为涂层质量损失(mg);A为指前因子;PL为载荷(kPa);D为摩擦距离(cm);T、R为系数。

图5显示不同载荷Pi下涂层质量损失M与摩擦距离D之间具有较好的线性相关性。由指数拟合结果可知式(1)中的A=0.126,T=−5.80,R=0.18,即在相同摩擦距离下,随着载荷增加,磨损量呈缓慢的指数增加。根据涂层质量损失与载荷和摩擦距离的关系式,可以对三维超疏水涂层在不同载荷下的磨损寿命进行简单预测,作为耐磨涂层施工的工程参考。

图6为1Al2O3-1ZrO2/50PBA涂层表面的原始和在不同载荷下摩擦180 cm后的三维形貌。可见摩擦前涂层表面的高度差达到70.76 μm,粗糙度较大,摩擦后涂层表面的高度差明显降低。对于载荷为2.83 kPa和5.66 kPa的摩擦表面,两者的高度差接近,均在32 μm左右,而载荷为11.32 kPa摩擦后的表面,高度差下降到22.84 μm,说明载荷越大磨损后涂层磨损越平整,这与式(1)的描述基本一致。

2.3 三维超疏水Al2O3-ZrO2/PBA涂层的环境稳定性

由2.2节可知1Al2O3-1ZrO2/50PBA涂层具备可自修复的超疏水特性,但超疏水涂层的环境稳定性是保证其长效服役的关键。为此,首先观察了1Al2O3-1ZrO2/50PBA涂层在不同温度下保温1 h后的表面接触角,结果如图7所示。在100~300℃整个温度区间内,涂层接触角均在150°以上,说明1Al2O3-1ZrO2/50PBA涂层具有良好的耐热性。这是由于PBA的热稳定性高(分解温度>300℃)[28],而Al2O3-ZrO2填料是陶瓷材料,熔点均在2 000℃以上。

图8为PBA超疏水涂层的酸碱耐受性,随着液滴pH值从1~13的变化,液滴在涂层表面的接触角呈先增大后减小的趋势。在强酸条件下(pH=1),液滴接触角为144°;在中性条件下(pH=7),液滴接触角为154°;在强碱性条件下(pH=13),液滴接触角为141°。原因是Al2O3是一种典型的两性氧化物,在强酸和强碱性条件下,Al2O3纳米填料发生轻微溶解,尤其是纳米Al2O3颗粒,其比表面积大,更易被强酸溶液腐蚀,使涂层表面微气垫受损,宏观上表现出涂层疏水性降低。

1Al2O3-1ZrO2/50PBA涂层的耐紫外辐射性能测试结果见图9,随着UV光照时间的延长,涂层表面的接触角不断降低,从初始的153°,到UV光照30 min后的142°,辐照1 h后接触角仍在140°以上,说明涂层具有一定的耐紫外能力。在60 min UV辐照结束后,将涂层放在320#砂纸上,于5.66 kPa载荷下摩擦移动10 cm,可以看到接触角又重新上升到151°表明该三维涂层具有较好的自修复能力。由于PBA在UV照射下会发生分子内氢键的断裂,生成分子间的苯醌结构,使表面能上升,导致涂层的表面接触角减小[29]。但UV光对涂层表面的微纳米结构破坏较小,在较短时间内依旧可以保持良好的疏水性能。涂层打磨后,表面损伤层被去除,裸露出新鲜涂层依旧可以保持超疏水性,从而实现了超疏水性的快速修复,这无疑会延长三维超疏水涂层的使用寿命。

2.4 三维超疏水Al2O3-ZrO2/PBA涂层的耐蚀性能

作为防腐蚀涂层,1Al2O3-1ZrO2/50PBA的抗蚀性十分重要。图10为表面有超疏水涂层的碳钢电极在3.5% NaCl溶液中的极化曲线和电化学阻抗谱(EIS),其中图10(a)中的极化曲线采用Tafel拟合。计算表明:裸碳钢电极的自腐蚀电位Ecorr为−0.624 V,腐蚀电流Icorr为80.54 µA·cm−2;表面喷涂层后其Ecorr升至−0.385 V,Icorr降至0.398 µA·cm−2。可见涂层电极的自腐蚀电位显著正移,且腐蚀电流密度下降200倍左右,说明涂层能为碳钢基体提供良好保护。图10(b)为不同盐雾时间后涂层的EIS,其中EIS中的低频阻抗|Z|0.01 Hz可用于评价涂层的屏蔽能力[30]。盐雾试验前,裸钢基体在盐溶液中的|Z|0.01 Hz为134 Ω·cm2,而涂层的|Z|0.01 Hz为1.18×106 Ω·cm2,表明涂层将碳钢的耐蚀性提升了4个数量级。

![]() 图 10 裸钢和1Al2O3-1ZrO2/50PBA涂层电极在3.5wt% NaCl 溶液中的极化曲线和电化学阻抗(不同盐雾时间)Figure 10. Polarization curves of bare and 1Al2O3-1ZrO2/50PBA coated steel electrodes and EIS of coated electrode (enduring salt praying test) in 3.5wt% NaCl solution after salt spray testsEcorr—Corrosion potential; Icorr—Corrosion current

图 10 裸钢和1Al2O3-1ZrO2/50PBA涂层电极在3.5wt% NaCl 溶液中的极化曲线和电化学阻抗(不同盐雾时间)Figure 10. Polarization curves of bare and 1Al2O3-1ZrO2/50PBA coated steel electrodes and EIS of coated electrode (enduring salt praying test) in 3.5wt% NaCl solution after salt spray testsEcorr—Corrosion potential; Icorr—Corrosion current经过72 h盐雾试验后,涂层的|Z|0.01 Hz降至6.47×104 Ω·cm2。盐雾试验前,三维超疏水涂层表面完整,微结构中储存的空气垫可有效抑制H2O、Cl−、O2等腐蚀介质渗入,因而表现出良好耐蚀性[31]。盐雾72 h后,盐水逐步取代微纳结构中的空气层,降低了涂层耐蚀性。此外,1Al2O3-1ZrO2/50PBA涂层中的填料质量比达到50%,填料难以被树脂完全包裹[32],易形成孔洞缺陷,如图10(b)中涂层试样宏观形貌所示。正是通过这些缺陷,腐蚀介质可突破空气垫和超疏水涂层本体到达碳钢基体,而基体的腐蚀进一步弱化了涂层与基体的结合力。如图11所示,72 h盐雾试验使涂层附着力从3.93 MPa下降到3.28 MPa,这就限制了超疏水涂层的耐蚀性提升。可见三维超疏水涂层尽管具有很好的超疏水自修复能力和一定的防腐蚀效果,但由于在强腐蚀性介质中空气垫不稳定,抗蚀能力不够,后续还需进一步优化涂层的填料组成,或通过梯度层设计,采用高耐蚀性底漆+超疏水自修复面漆协同来提高其耐蚀性和超疏水性。

3. 结论

(1) 通过优化Al2O3-ZrO2微纳米填料在聚苯并噁嗪(PBA)树脂中的质量比及两者的配比,尤其当Al2O3∶ZrO2∶PBA质量比为1∶1∶2时,制得了一种三维超疏水耐磨涂层1Al2O3-1ZrO2/50PBA,其水接触角达到154°,并具有良好的超疏水自修复能力。1Al2O3-1ZrO2/50BA涂层在100~300℃温度区间内均表现出超疏水性,在pH值=1~13范围内,涂层表面接触角均在140°以上,表现出良好的化学稳定性;在UV光照60 min后,尽管接触角初期有所下降,但一直维持为142°,表明该涂层具有良好的环境稳定性。

(2) 1Al2O3-1ZrO2/50PBA三维超疏水涂层具有较好的抗磨性,即使由于环境降解导致疏水性下降,但通过服役过程中的主动或被动磨损,该涂层可以快速修复表面的微纳米结构,恢复超疏水性。与裸碳钢电极相比,1Al2O3-1ZrO2/50PBA涂层保护的碳钢电极自腐蚀电流下降两个数量级,屏蔽性能提高4个数量级,表明该涂层对碳钢有一定的防腐效果。但由于在强腐蚀性介质中空气垫不稳定,其耐蚀性还需进一步通过优化涂层填料组成来改善,或采用高耐蚀性底漆+超疏水自修复面漆协同来提高其耐蚀性和超疏水性。

-

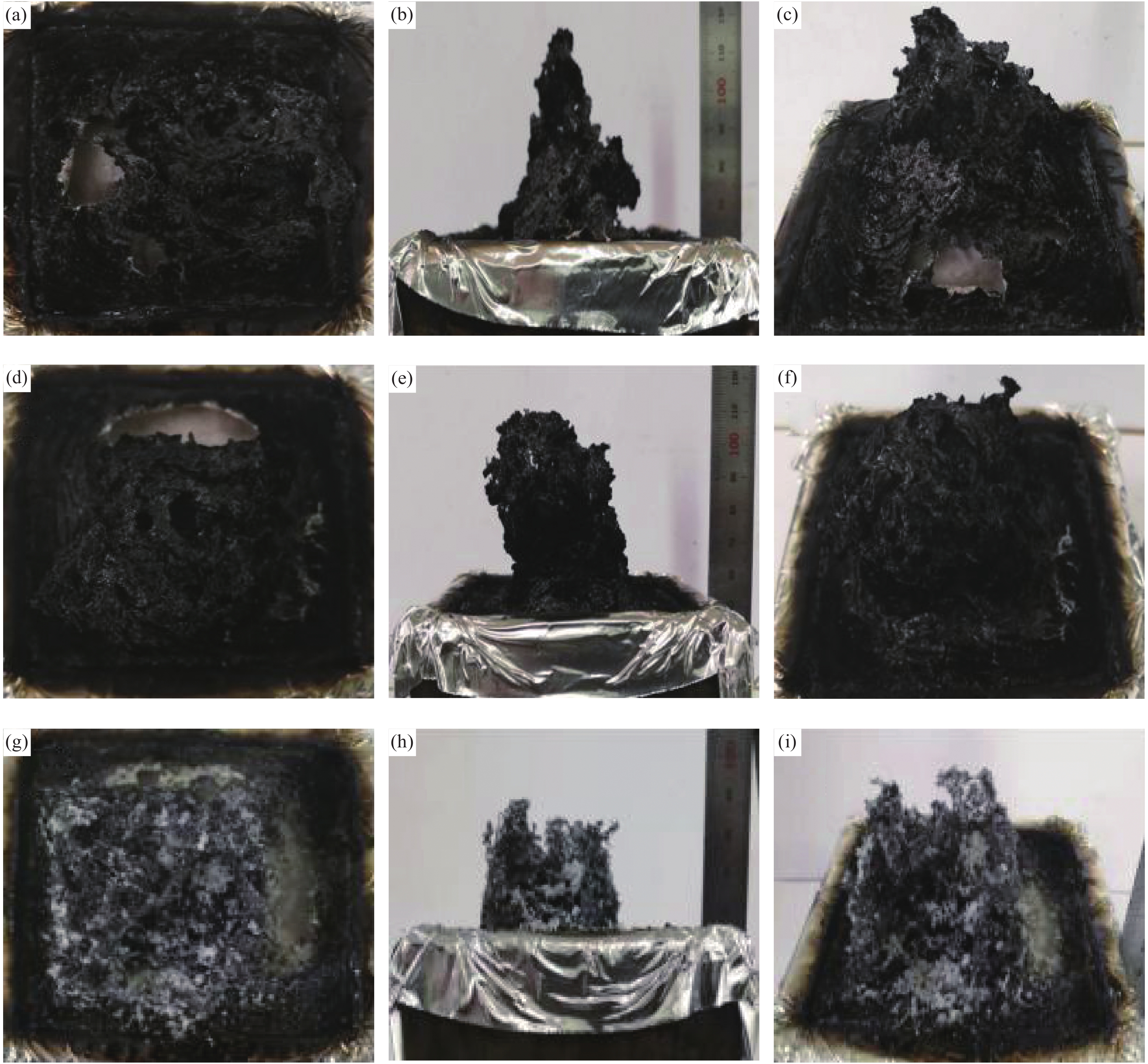

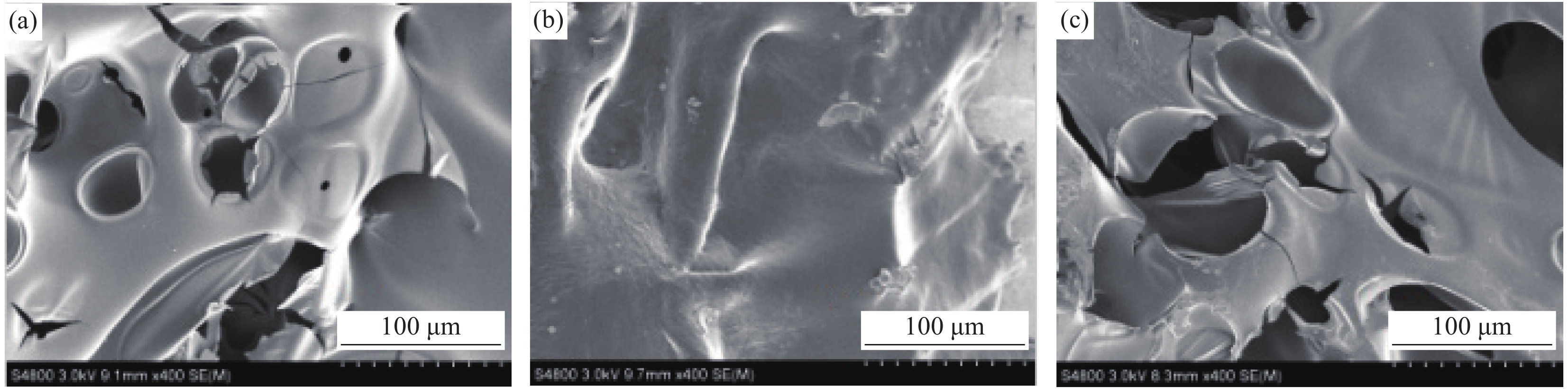

图 6 PC-ABS ((a)、(b))、10RDP/(PC-ABS) ((c)、(d))、1SiO2-10RDP/(PC-ABS) ((e)、(f))和1SiO2-10RDP-20MBS/(PC-ABS)((g)、(h))阻燃合金缺口冲击断面的SEM图像

Figure 6. SEM images of notched impact cross section of PC-ABS ((a),(b)), 10RDP/(PC-ABS) ((c),(d)), 1SiO2-10RDP/(PC-ABS) ((e),(f)) and 1SiO2-10RDP-20MBS/(PC-ABS) ((g),(h)) flame retardant blends

表 1 SiO2-间苯二酚-双(二苯基磷酸酯)-甲基丙烯酸甲酯-丁二烯-苯乙烯/(聚碳酸酯-丙烯腈-丁二烯-苯乙烯共聚物)(SiO2-RDP-MBS/(PC-ABS))阻燃合金配比

Table 1 Formulations of SiO2-resorcinol bis(diphenylphosphate)-methyl methacrylate-butadiene-styrene/(polycarbonate-acrylonitrile-butadiene-styrene)(SiO2-RDP-MBS/(PC-ABS)) flame retardant blends

wt% Sample PC ABS RDP SiO2 PTFE MBS 10RDP/(PC-ABS) 62.7 26.9 10 — 0.4 — 0.5SiO2-10RDP/(PC-ABS) 62.4 26.7 10 0.5 0.4 — 1SiO2-10RDP/(PC-ABS) 62.0 26.6 10 1 0.4 — 2SiO2-10RDP/(PC-ABS) 61.3 26.3 10 2 0.4 — 3SiO2-10RDP/(PC-ABS) 60.6 26.0 10 3 0.4 — 4SiO2-10RDP/(PC-ABS) 59.9 25.7 10 4 0.4 — 5SiO2-10RDP/(PC-ABS) 58.9 25.2 10 5 0.4 — 6SiO2-10RDP/(PC-ABS) 58.5 25.1 10 6 0.4 — 7SiO2-10RDP/(PC-ABS) 57.8 24.8 10 7 0.4 — 1SiO2/(PC-ABS) 69.0 29.6 — 1 0.4 — 1SiO2-10RDP-5MBS/(PC-ABS) 58.5 25.1 10 1 0.4 5 1SiO2-10RDP-10MBS/(PC-ABS) 55.0 23.6 10 1 0.4 10 1SiO2-10RDP-15MBS/(PC-ABS) 51.5 22.1 10 1 0.4 15 1SiO2-10RDP-20MBS/(PC-ABS) 48.0 20.6 10 1 0.4 20 1SiO2-10RDP-25MBS/(PC-ABS) 44.5 19.1 10 1 0.4 25 Note: PTFE—Polytetrafluoroethylene. 表 2 SiO2-RDP-MBS/(PC-ABS)阻燃合金的垂直燃烧 (UL94) 测试结果

Table 2 Vertical combustion (UL94) results of SiO2-RDP-MBS/(PC-ABS) flame retardant blends

Sample t1/s t2/s t1+t2/s Dripping UL94 10RDP/(PC-ABS) 12.1 20.3 32.4 N V-1 0.5SiO2-10RDP/(PC-ABS) 21.4 24.5 45.9 N V-1 1SiO2-10RDP/(PC-ABS) 3.1 8.9 12.0 N V-0 2SiO2-10RDP/(PC-ABS) 11.3 31.4 42.7 N V-1 3SiO2-10RDP/(PC-ABS) 16.8 26.1 42.9 N V-1 4SiO2-10RDP/(PC-ABS) 25.7 38.7 64.4 N V-1 5SiO2-10RDP/(PC-ABS) >30.0 >60.0 >60.0 Y No-rating 6SiO2-10RDP/(PC-ABS) >30.0 >60.0 >60.0 Y No-rating 7SiO2-10RDP/(PC-ABS) >30.0 >60.0 >60.0 Y No-rating 1SiO2/(PC-ABS) >30.0 >60.0 >60.0 N No-rating 1SiO2-10RDP-5MBS/(PC-ABS) 16.2 24.5 40.7 N V-1 1SiO2-10RDP-10MBS/(PC-ABS) 31.3 50.4 81.7 N V-2 1SiO2-10RDP-15MBS/(PC-ABS) >30.0 >60.0 >60.0 Y No-rating 1SiO2-10RDP-20MBS/(PC-ABS) >30.0 >60.0 >60.0 Y No-rating 1SiO2-10RDP-25MBS/(PC-ABS) >30.0 >60.0 >60.0 Y No-rating Notes: t1—Self-extinguishing time after the first ignition; t2—Self-extinguishing time after the second ignition;Y—Yes; N—No. 表 3 SiO2-RDP/(PC-ABS)阻燃合金的锥形量热测试结果

Table 3 Cone data for SiO2-RDP/(PC-ABS) flame retardant blends

Sample 10RDP/(PC-ABS) 1SiO2-10RDP/(PC-ABS) 1SiO2/(PC-ABS) tign/s 41.5±0.5 42.0±1.0 38.5±0.5 tPHRR/s 155.0±5.0 167.5±2.5 70±0.1 PHRR/(kW·m−2) 444.8±22.3 379.1±5.4 566.1±16.8 THR/(MJ·m−2) 68.2±0.4 70.4±1.5 92.0±1.3 AHRR/(kW·m−2) 135.9±2.1 142.7±0.6 224.3±2.3 AMLR/(g·s−1) 0.060±0.001 0.062±0.002 0.082±0.002 AEHC/(MJ·kg−1) 19.9±0.1 20.4±0.6 24.5±0.4 ASEA/(m2·kg−1) 1 048.1±35.8 1 068.0±15.1 838.2±45.4 ACOY/(kg·kg−1) 0.146±0.001 0.156±0.002 0.083±0.001 ACO2Y/(kg·kg−1) 1.383±0.001 1.382±0.014 1.738±0.041 TSR/(m2·m−2) 3 592.1±102.9 3 682.1±85.3 3 156.6±182.8 CHR/% 6.86±0.03 6.94±0.53 5.76±0.98 FGI/(kW·m−2·s−1) 2.87 2.26 8.09 FPI/(m2·s·kW−1) 0.093 0.110 0.068 Notes: PHRR—Peak heat release rate; THR—Total heat release at 600 s; AHRR—Average heat release rate; AMLR—Average mass loss rate; AEHC—Average effective heat of combustion; ASEA—Average specific extinction area; ACOY—Average yield of CO; ACO2Y—Average yield of CO2; TSR—Total smoke release; CHR—Char residue; FGI—Fire spread index; FPI—Fire performance index; tign—Time to ignition; tPHRR—Time to PHRR. 表 4 10RDP/(PC-ABS)、1SiO2-10RDP/(PC-ABS)和1SiO2/(PC-ABS)阻燃合金锥形量热测试后残炭的EDS分析

Table 4 EDS analysis of char residues of 10RDP/(PC-ABS), 1SiO2-10RDP/(PC-ABS) and 1SiO2/(PC-ABS) flame retardant blends after Cone tests

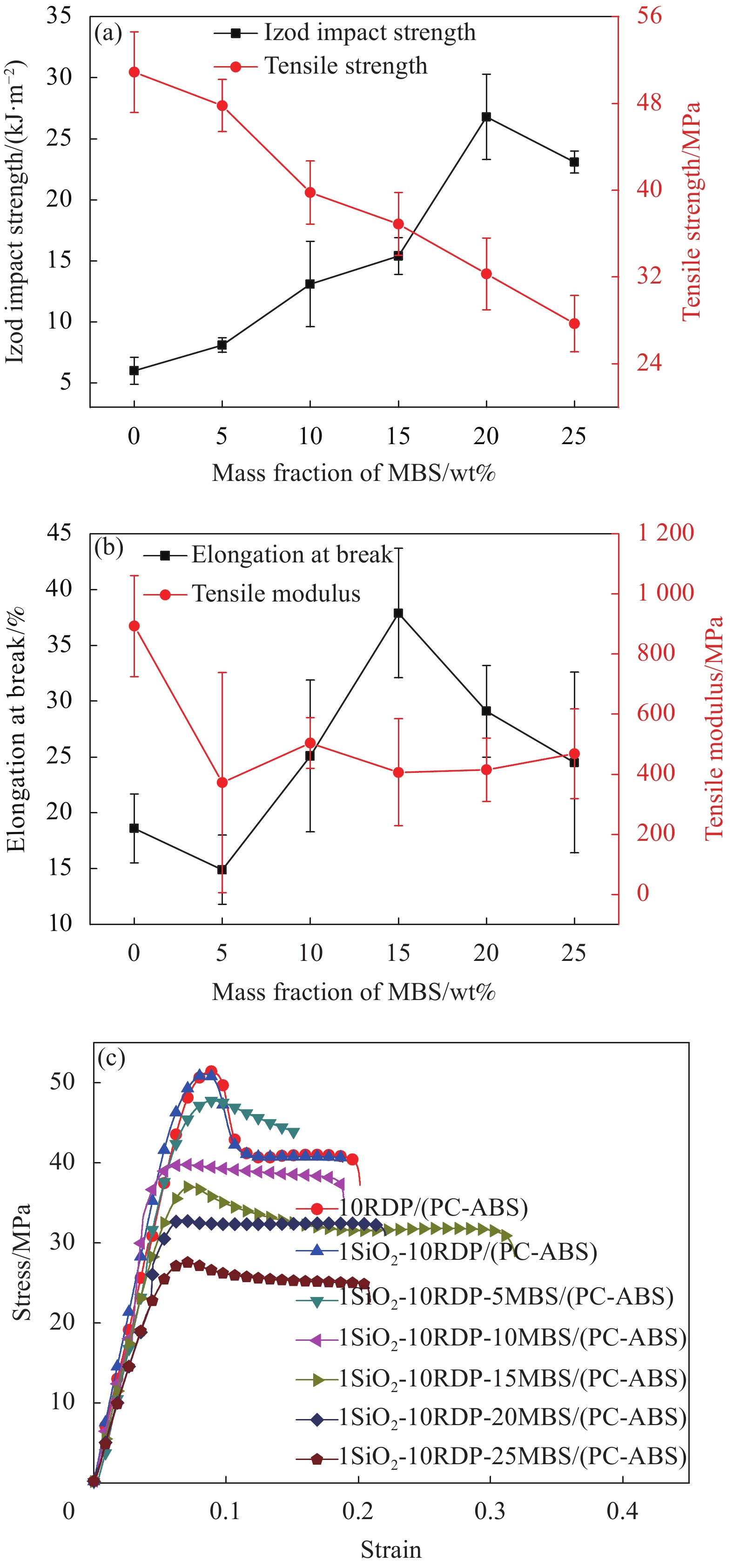

Sample Element/at% C O P Si 1SiO2/(PC-ABS) 83.89 16.09 — 0.03 10RDP/(PC-ABS) 79.44 18.02 2.54 — 1SiO2-10RDP/(PC-ABS) 54.17 36.71 7.24 1.88 表 5 SiO2-RDP-MBS/(PC-ABS)阻燃合金的缺口冲击强度、拉伸强度、断裂伸长率和弹性模量

Table 5 Izod impact strength、tensil strength、elongation at break and tensile modulus of SiO2-RDP-MBS/(PC-ABS) flame retardant blends

Sample Izod impact strength/(kJ·m−2) Tensile strength/MPa Elongation at break/% Tensile modulus/MPa 10RDP/(PC-ABS) 8.6±2.4 51.4±2.8 19.2±5.1 838.7±146.2 1SiO2-10RDP/(PC-ABS) 6.0±1.1 50.9±3.7 18.6±3.1 893.2±168.4 1SiO2-10RDP-5MBS/(PC-ABS) 8.1±0.6 47.8±2.4 14.9±3.1 372.2±366.1 1SiO2-10RDP-10MBS/(PC-ABS) 13.1±3.5 39.8±2.9 25.1±6.8 504.1±84.6 1SiO2-10RDP-15MBS/(PC-ABS) 15.4±1.5 36.9±2.9 37.9±5.8 406.2±178.5 1SiO2-10RDP-20MBS/(PC-ABS) 26.8±3.5 32.3±3.3 29.1±4.1 414.9±105.9 1SiO2-10RDP-25MBS/(PC-ABS) 23.1±0.9 27.7±2.6 24.5±8.1 468.1±149.1 -

[1] LEE E J, PARK H J, KIM S M, et al. Effects of molecular weight of PC on mechanical properties of PC/ABS blends using high-shear rate processing[J]. Korean Chemical Engineering Research,2018,56(3):343-348.

[2] PAWLOWSKI K H, SCHARTEL B. Flame retardancy mechanisms of aryl phosphates in combination with boehmite in bisphenol a polycarbonate/acrylonitrile-butadiene-styrene blends[J]. Polymer Degradation and Stability,2008,93(3):657-667. DOI: 10.1016/j.polymdegradstab.2008.01.002

[3] 朱世东, 徐自强, 白真权 , 等. 纳米材料国内外研究进展Ⅱ: 纳米材料的应用与制备方法法[J]. 热处理技术与装备, 2010, 31(4):1-8. DOI: 10.3969/j.issn.1673-4971.2010.04.001 ZHU Shidong, XU Ziqiang, BAI Zhenquan, et al. Research of the nano-materials at home and abroad Ⅱ: The applications and preparation of the nano-material[J]. Heat Treatment Technology and Equipment,2010,31(4):1-8(in Chinese). DOI: 10.3969/j.issn.1673-4971.2010.04.001

[4] BEE S T, LIM K S, SIN L T, et al. Interactive effect of ammonium polyphosphate and montmorillonite on enhancing flame retardancy of PC/ABS composites[J]. Iranian Polymer Journal,2018,27(11):899-911. DOI: 10.1007/s13726-018-0664-z

[5] ZHANG W, LI Y G, MA H J, et al. Novel phosphorus-nitrogen-silicon copolymers with double-decker silsesquioxane in the main chain and their flame retardancy application in PC/ABS[J]. Fire and Materials,2018,42(8):946-957. DOI: 10.1002/fam.2649

[6] WEI P, TIAN G H, YU H Z, et al. Synthesis of a novel organic-inorganic hybrid mesoporous silica and its flame retardancy application in PC/ABS[J]. Polymer Degradation and Stability,2013,98(5):1022-1029. DOI: 10.1016/j.polymdegradstab.2013.02.006

[7] ZHENG K, CHEN L, LI Y, et al. Praparation and thermal properties of silica-graft acrylonitrile-butadiene-styrene nanocomposites[J]. Polymer Engineering and Science,2004,44(6):1077-1082. DOI: 10.1002/pen.20100

[8] 徐晓楠, 卢林刚, 殷全明, 等. 四苯基双酚A二磷酸酯及复配纳米SiO2体系阻燃PC/ABS合金的热动力学分析[J]. 火灾科学, 2009, 18(2):95-100. DOI: 10.3969/j.issn.1004-5309.2009.02.008 XU Xiaonan, LU Lingang, YIN Quanming, et al. Kinetic study on pyrolysis of rolysis of bisphenol A diphosphate flame-retarded PC/ABS[J]. Fire Science,2009,18(2):95-100(in Chinese). DOI: 10.3969/j.issn.1004-5309.2009.02.008

[9] 钟柳, 刘治国, 欧育湘. BDP阻燃PC/ABS及其复合材料的阻燃性和热降解动力学[J]. 中国塑料, 2008, 22(5):25-29. ZHONG Liu, LIU Zhiguo, OU Yuxiang. Flame retardancy and kinetics of thermal degradation of flame retardant PC/ABS and its nanocomposites[J]. China Plastics,2008,22(5):25-29(in Chinese).

[10] ASTM International. Standard test method for measuring the minimum oxygen concentration to support candle-like combustion of plastics (oxygen index): ASTM D2863—19[S]. West Conshohocken: ASTM International, 2019.

[11] 中国国家标准化管理委员会. 塑料 悬臂梁冲击强度的测定: GB/T 1843—2008[S]. 北京: 中国标准出版社, 2009. Standardization Administration of the People’s Republic of China. Plastics: Determination of izod impact strength: GB/T 1843—2008[S]. Beijing: China Standards Press, 2009(in Chinese).

[12] 中国国家标准化管理委员会. 塑料 拉伸性能的测定 第2部分: 模塑和挤塑塑料的试验条件: GB/T 1040.2—2006[S]. 北京: 中国标准出版社, 2007. Standardization Administration of the People’s Republic of China. Plastics: Determination of tensile properties Part 2: Test conditions for moulding and extrusion plastics: GB/T 1040.2—2006[S]. Beijing: China Standards Press, 2007(in Chinese).

[13] International Organization for Standardization. Reaction-to-fire tests: Heat release, smoke production and mass loss rate Part 1: Heat release rate (cone calorimeter method) and smoke production rate (dynamic measurement): ISO 5660—1∶2015[S]. Geneva: International Organization for Standardization, 2015.

[14] JANG B N, WILKIE C A. The thermal degradation of bisphenol A polycarbonate in air[J]. Thermochimica Acta,2005,426(1-2):73-84.

[15] REALINHO V, HAURIE L, FORMOSA J, et al. Flame retardancy effect of combined ammonium polyphosphate and aluminium diethyl phosphinate in acrylonitrile-butadiene-styrene[J]. Polymer Degradation and Stability,2018,155:208-219. DOI: 10.1016/j.polymdegradstab.2018.07.022

[16] FENG J, CARPANESE C, FINA A. Thermal decomposition investigation of ABS containing Lewis-acid type metal salts[J]. Polymer Degradation and Stability,2016,129:319-327. DOI: 10.1016/j.polymdegradstab.2016.05.013

[17] PAPASPYRIDES C D, KILIARIS P. Polymer green flame retardants[M]. Elsevier, 2014.

[18] QI Z, ZHANG W, HE X, et al. High-efficiency flame retardency of epoxy resin composites with perfect T8 caged phosphorus containing polyhedral oligomeric silsesquioxanes (P-POSSs)[J]. Composites Science and Technology,2016,127:8-19.

[19] MONTERO B, RAMIREZ C, RICO M, et al. Effect of an epoxy octasilsesquioxane on the thermodegradation of an epoxy/amine system[J]. Polymer International,2010,59(1):112-118. DOI: 10.1002/pi.2698

[20] LIU Y L, CHOU C I. The effect of silicon sources on the mechanism of phosphoruse-silicon synergism of flame retardation of epoxy resins[J]. Polymer Degradation and Stability,2005,90(3):515-522. DOI: 10.1016/j.polymdegradstab.2005.04.004

[21] 王德义. 含磷共聚酯/无机纳米复合材料的制备、性能与阻燃机理研究[D]. 成都: 四川大学, 2007. WANG Deyi. Preparation, properties and flame retardant mechanism of phosphorus containing copolyester/inorganic nanocomposites[D]. Chengdu: Sichuan University, 2007(in Chinese).

[22] YANG F, NELSON G L. PMMA/silica nanocomposite studies: Synthesis and properties[J]. Journal of Applied Polymer Science,2004,91(6):3844-3850. DOI: 10.1002/app.13573

[23] 李斌, 王建祺. 聚合物材料燃烧性和阻燃性的评价: 锥形量热仪(CONE)法[J]. 高分子材料科学与工程, 1998, 14(5):15-19. DOI: 10.16865/j.cnki.1000-7555.1998.05.004 LI Bin, WANG Jianqi. Utilization of CONE calorimeter for the appraisal of the flammability and flame retardancy of polymeric materials[J]. Polymer Materials Science and Engineering,1998,14(5):15-19(in Chinese). DOI: 10.16865/j.cnki.1000-7555.1998.05.004

[24] KASHIWAGI T, GILMAN J W, BUTLER K M, et al. Flame retardant mechanism of silica gel/silica[J]. Fire and Materials,2000,24(6):277-289. DOI: 10.1002/1099-1018(200011/12)24:6<277::AID-FAM746>3.0.CO;2-A

[25] CHIANG C L, MA C C M. Synthesis, characterization, thermal properties and flame retardance of novel phenolic resin/silica nanocomposites[J]. Polymer Degradation and Stability,2004,83(2):207-214. DOI: 10.1016/S0141-3910(03)00262-3

[26] SONG R J, ZHANG B Y, HUANG B T, et al. Synergistic effect of supported nickel catalyst with intumescent flame-retardants on flame retardancy and thermal stability of polypropylene[J]. Journal of Applied Polymer Science,2006,102(6):5988-5993. DOI: 10.1002/app.25178

[27] SPONTÓN M, MERCADO L A, RONGDA J C, et al. Preparation, thermal properties and flame retardancy of phosphorus and silicon containing epoxy resins[J]. Polymer Degradation and Stability,2008,93(11):2025-2031. DOI: 10.1016/j.polymdegradstab.2008.02.014

[28] LI J, WEI P, LI L K, et al. Synergistic effect of mesoporous silica SBA-15 on intumescent flame-retardant polypropylene[J]. Fire and Materials,2011,35(2):83-91. DOI: 10.1002/fam.1040

[29] 徐晓楠, 张健. 二氧化硅对膨胀型阻燃聚乙烯的性能影响研究[J]. 火灾科学, 2004, 13(3):168-172. XU Xiaonan, ZHANG Jian. Experimental study of the effect of SiO2 on performance of intumencent fire retardant PE[J]. Fire Safety Science,2004,13(3):168-172(in Chinese).

[30] DEMIR H, ARKIŞ E, BALKÖSE D, et al. Synergistic effect of natural zeolites on flame retardant additives[J]. Polymer Degradation and Stability,2005,89(3):478-483. DOI: 10.1016/j.polymdegradstab.2005.01.028

[31] PICOUET P A, FERNANDEZ A, REALINI C E, et al. Influence of PA6 nanocomposite films on the stability of vacuum-aged beef loins during storage inmodified atmospheres[J]. Meat Science,2014,96(1):574-580. DOI: 10.1016/j.meatsci.2013.07.020

-

期刊类型引用(6)

1. 刘应书,张璇,卞文博,姜理俊,刘文海,侯环宇,孙方舟,杨雄,李子宜. 涂覆型蜂窝体催化剂的制备与烟气一氧化碳催化净化性能. 复合材料学报. 2023(08): 4539-4548 .  本站查看

本站查看

2. 李婷婷,王薇,范迎迎,薛东涵,戴明珏,张琦,刘博,韩博林,关桦楠. 接枝功能化磁性纳米粒子去除饮用水中Cu~(2+)研究. 哈尔滨商业大学学报(自然科学版). 2020(01): 25-29 .  百度学术

百度学术

3. 龙星宇,陈柯锦,谭兴力,李秋华. Fe_3O_4@MnO_2复合纳米材料的制备及其对染料刚果红的吸附研究. 化工新型材料. 2020(05): 255-260+265 .  百度学术

百度学术

4. 张磊. Fe_3O_4-MnO_2复合材料催化降解水中有机污染物的研究进展. 化工环保. 2020(05): 474-479 .  百度学术

百度学术

5. 杨思楠,赵萍,陈永春,安士凯,郑刘根. 改性蛭石-蒙脱土对煤矸石充填复垦区镉污染土壤的修复. 环境化学. 2020(10): 2777-2783 .  百度学术

百度学术

6. 于常武,刘春怡,周立岱,陈国伟,郭星. 磁载TiO_2光催化剂处理喷漆废水的影响因素及动力学特性. 环境污染与防治. 2019(10): 1137-1141 .  百度学术

百度学术

其他类型引用(9)

-

下载:

下载: