Compressive deformation behavior and energy absorption of Al foam-filled carbon fiber reinforced plastic thin-walled tube

-

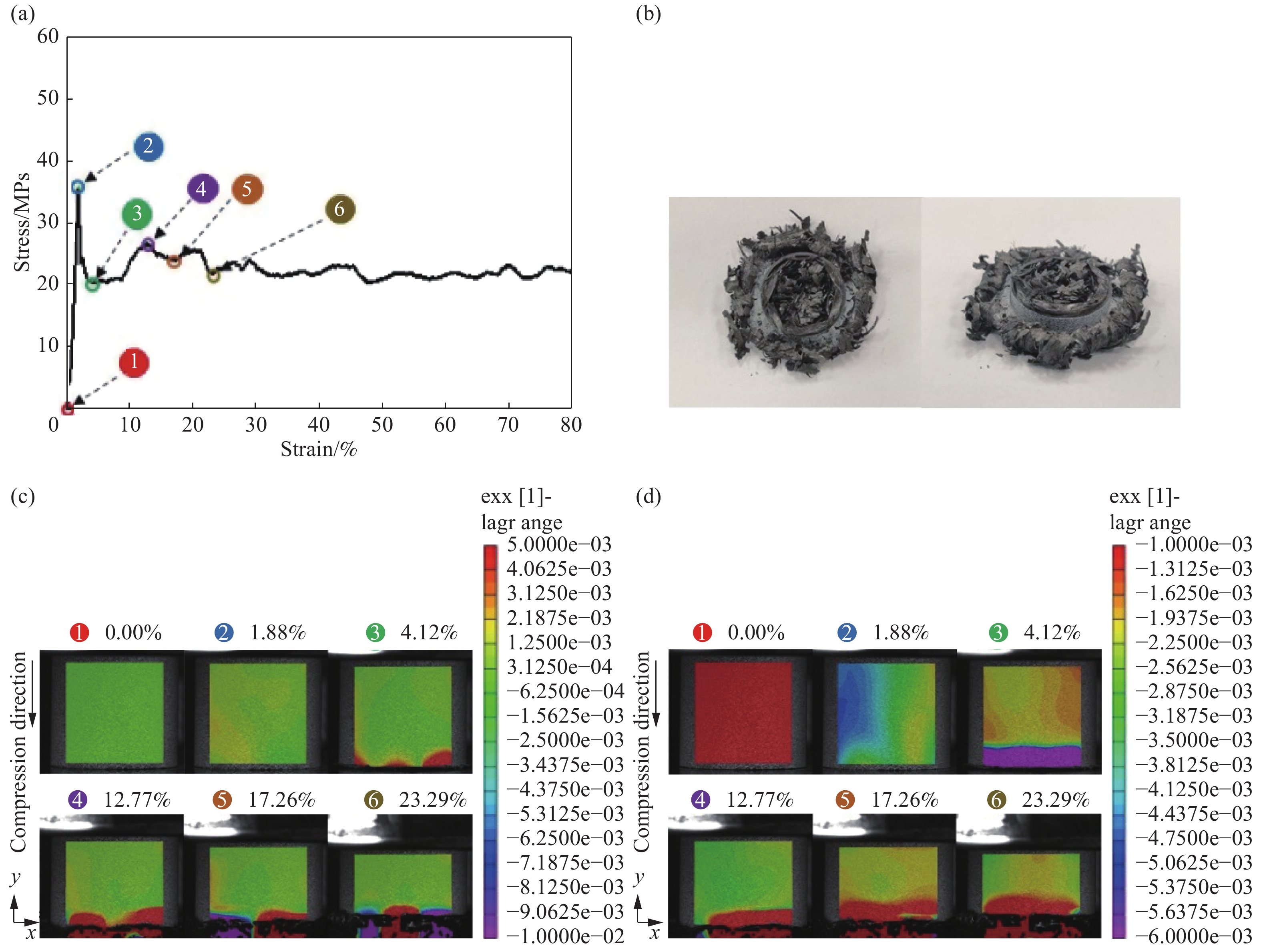

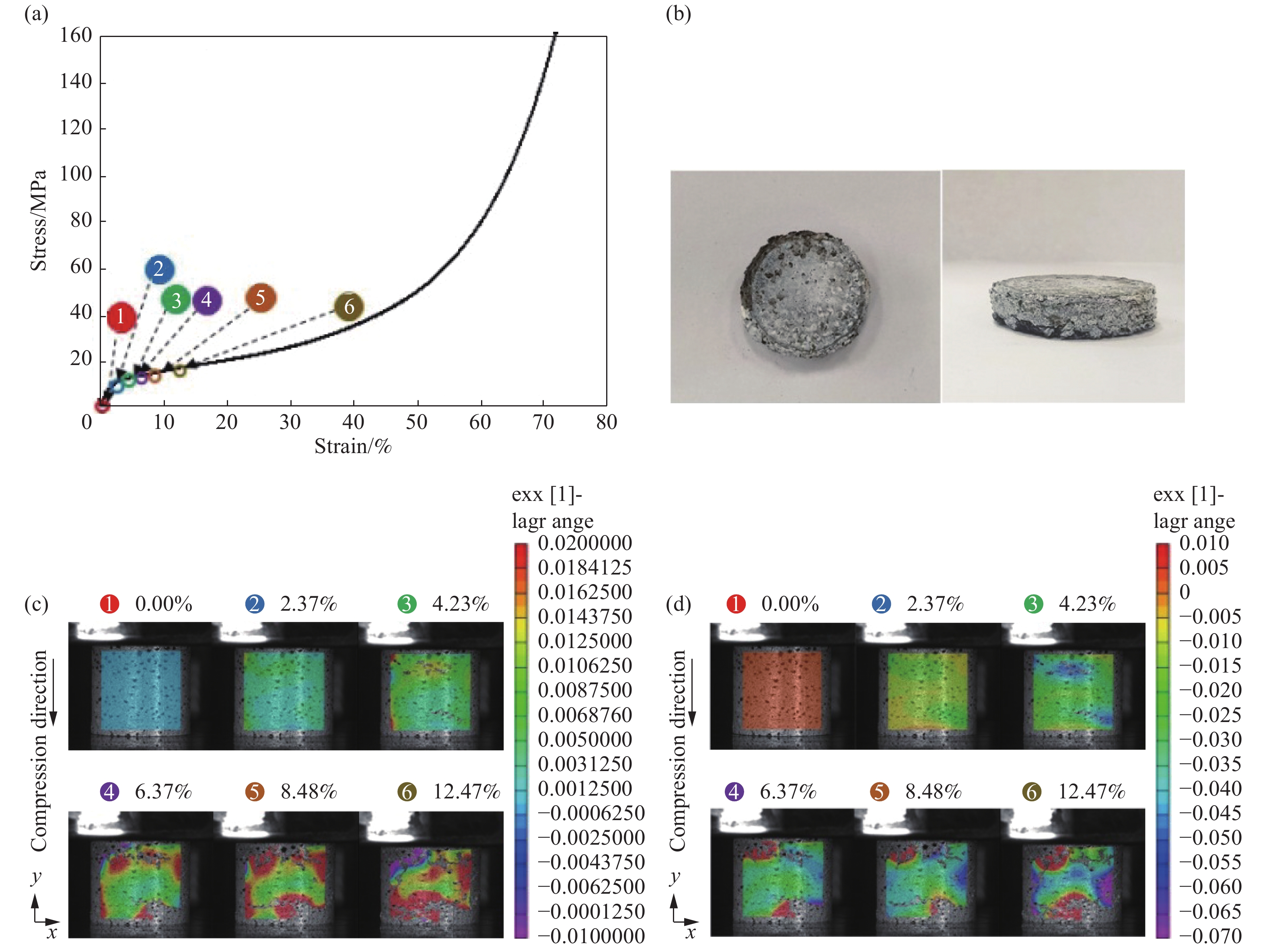

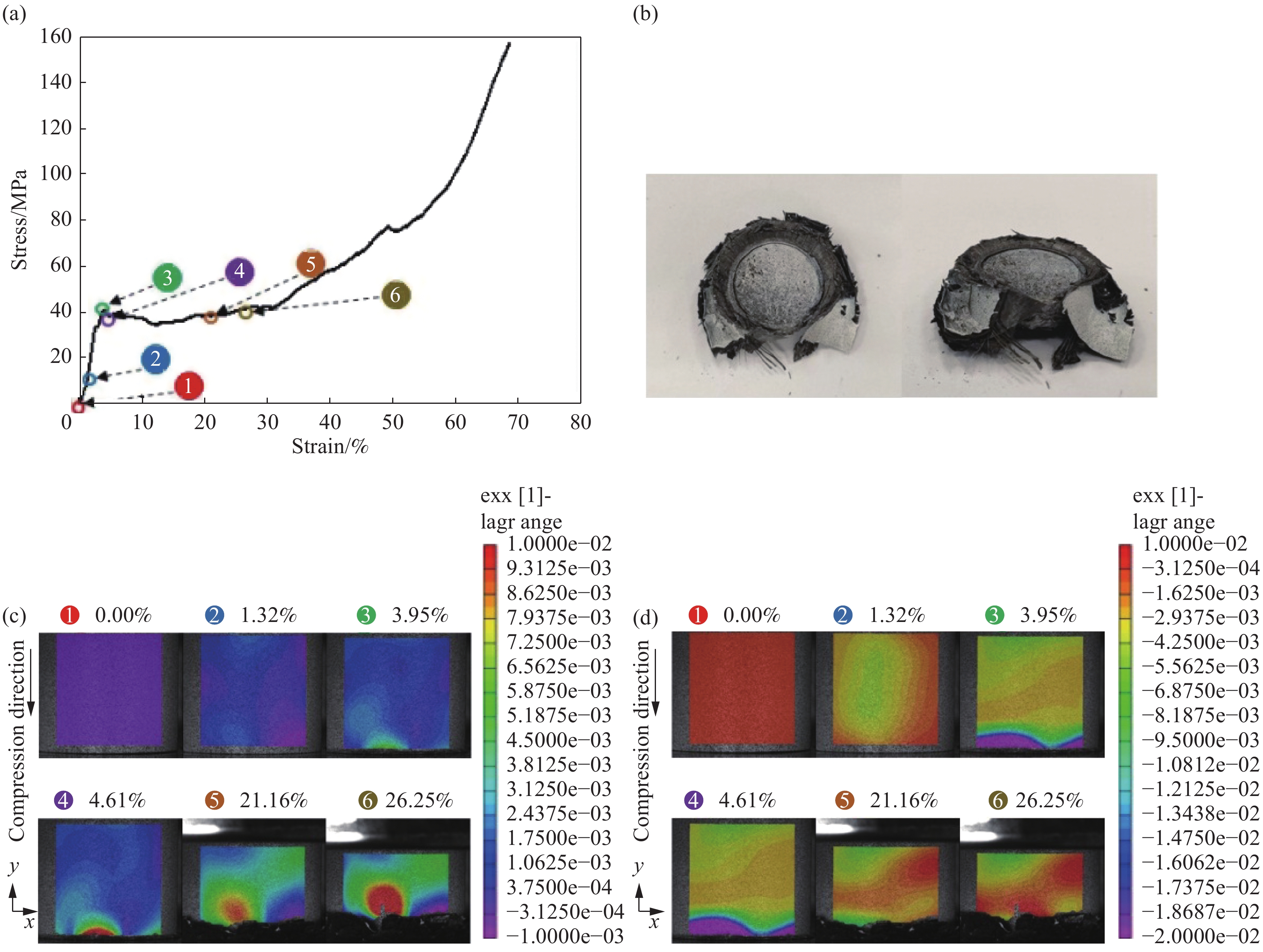

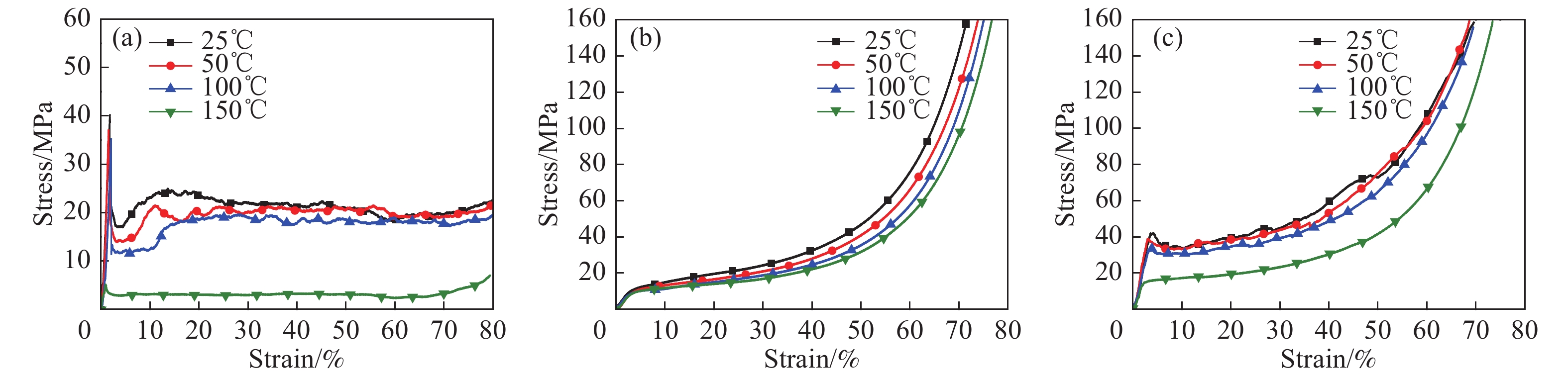

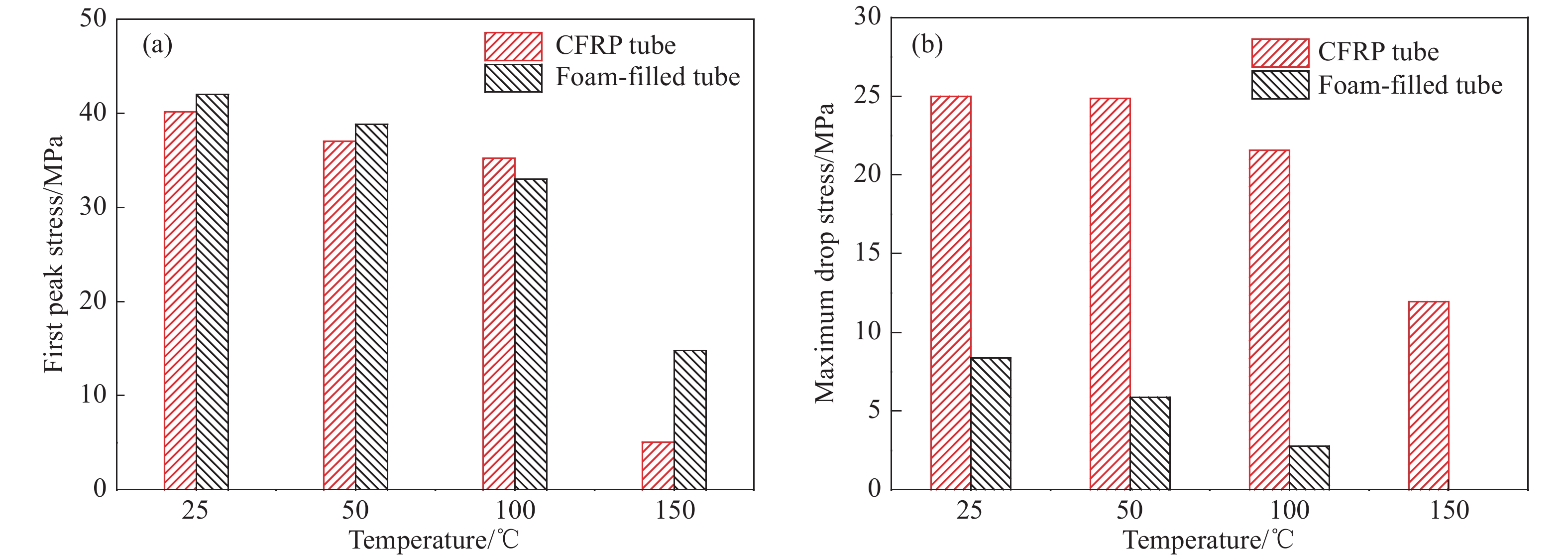

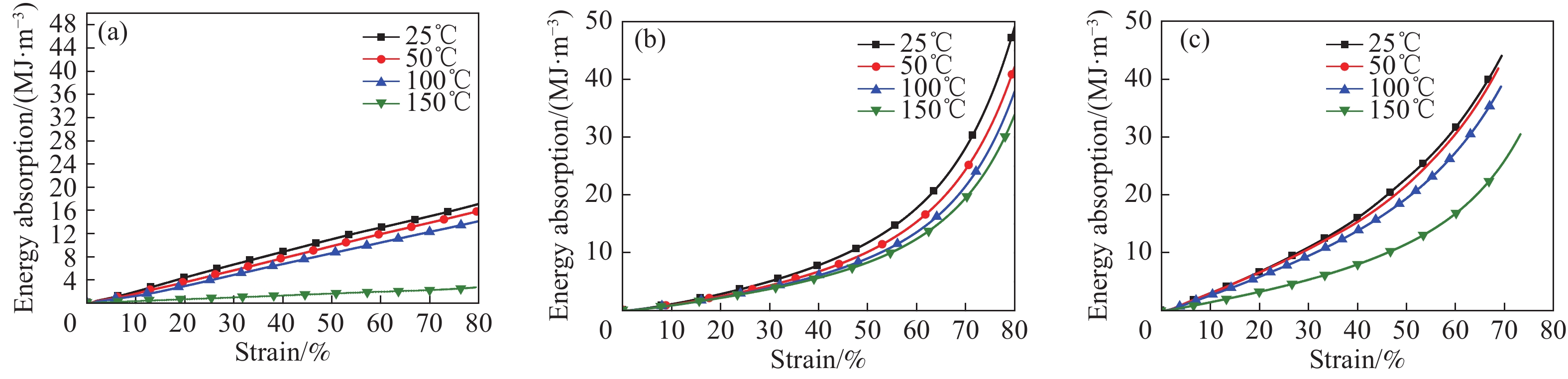

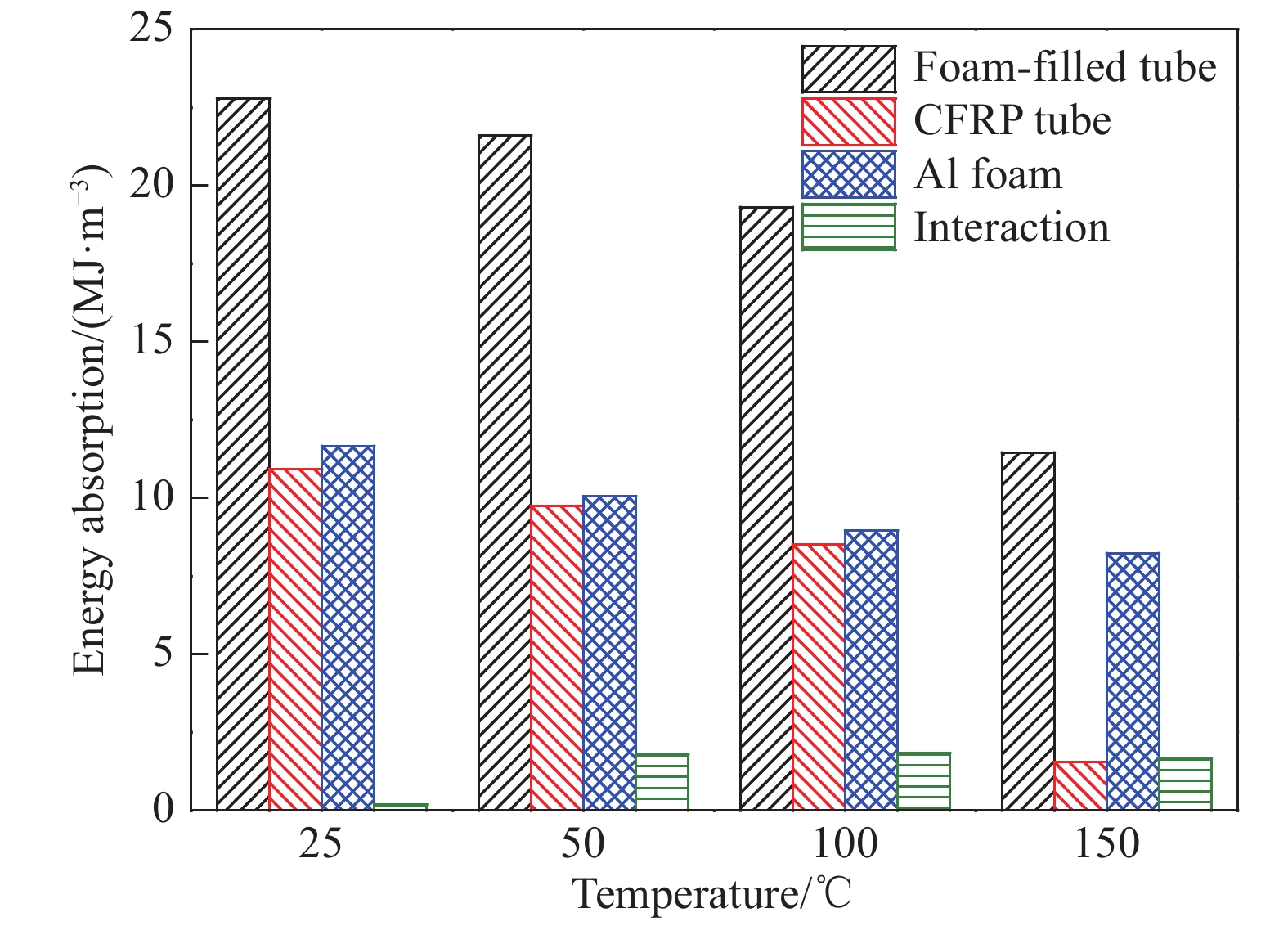

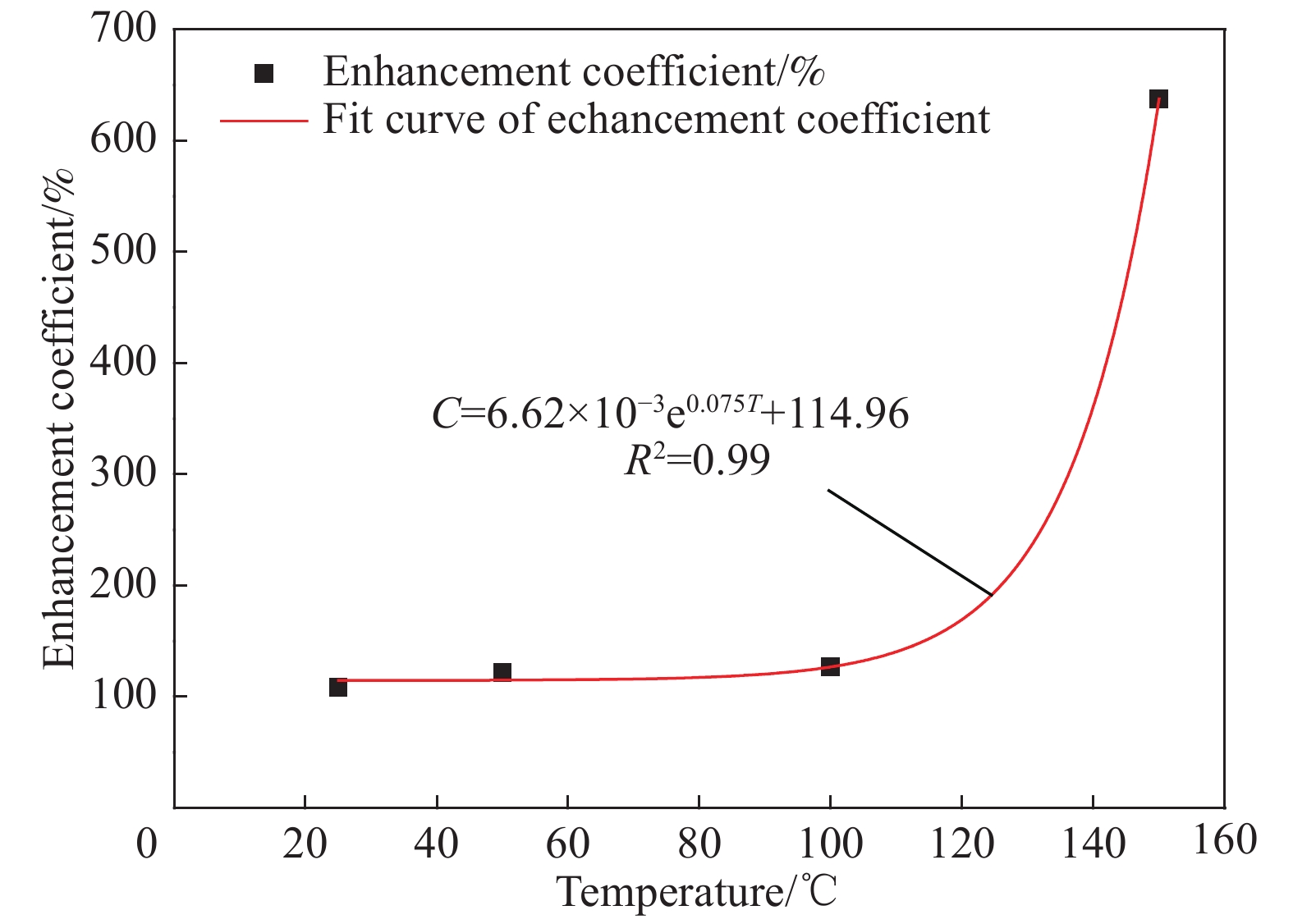

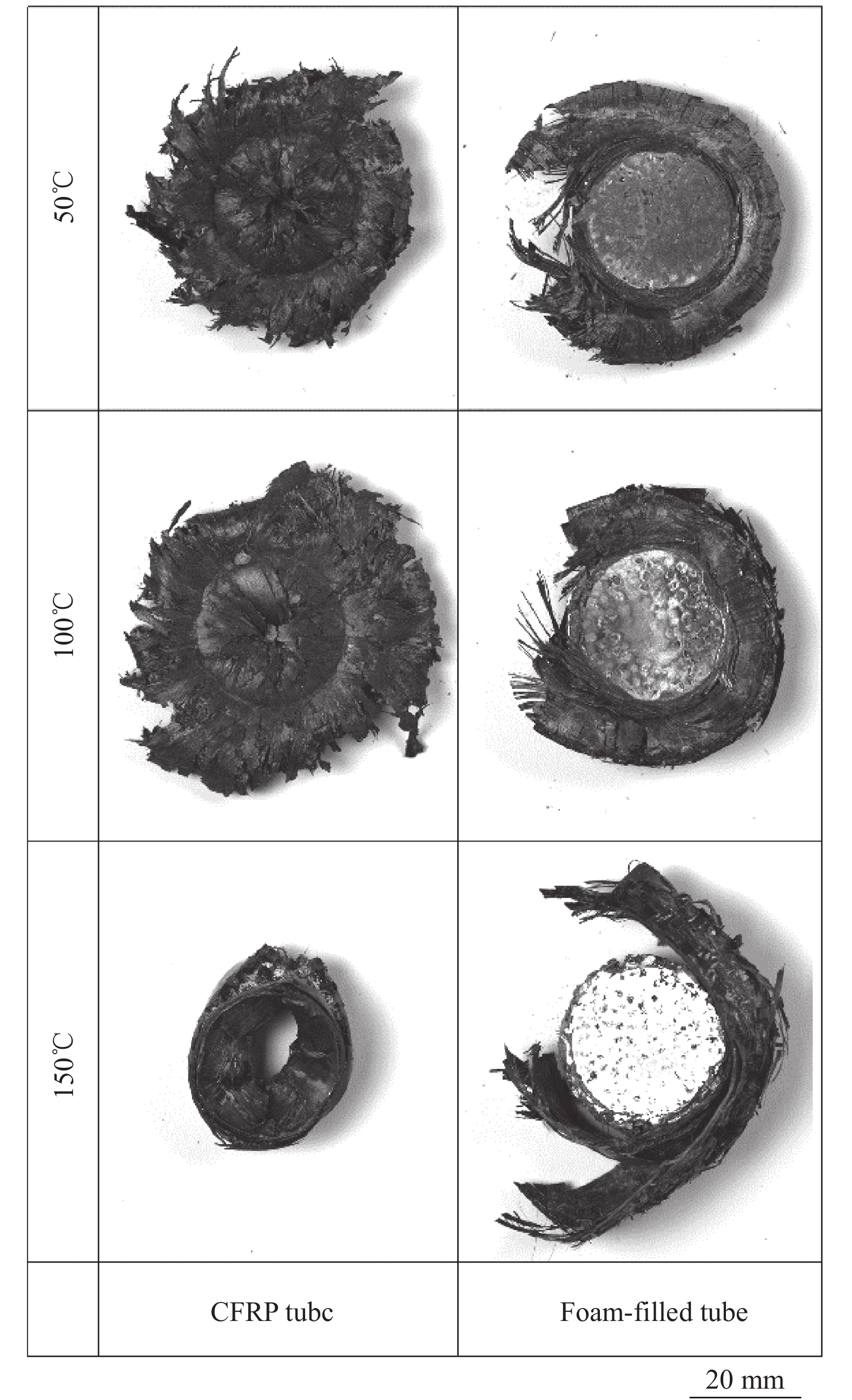

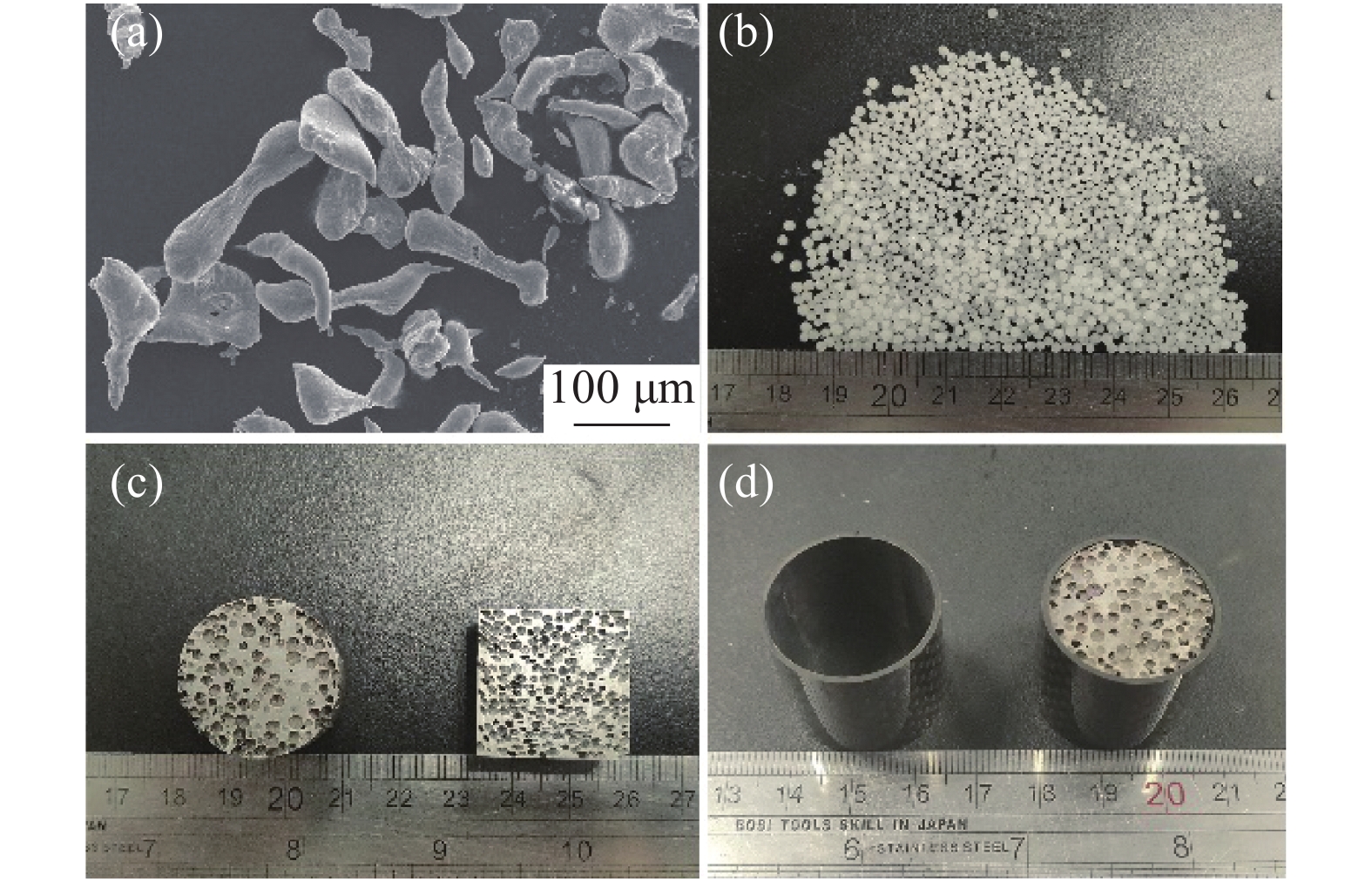

摘要: 将填加造孔剂法制备的泡沫铝物理嵌入碳纤维增强树脂(Carbon fiber reinforced plastic,CFRP)复合材料薄壁管中,从而获得泡沫铝填充CFRP复合材料薄壁管的复合结构。针对CFRP薄壁管、泡沫铝和泡沫铝填充CFRP复合材料薄壁管分别开展准静态压缩试验测试其压缩和吸能性能,并在压缩过程中采用数字图像相关技术(Digital image correlation,DIC)同步分析其变形模式;进一步研究在不同环境温度下(25~150℃)泡沫铝填充CFRP复合材料薄壁管的压缩与吸能性能及失效模式。结果表明:泡沫铝作为填充芯材改变了CFRP复合材料薄壁管的压缩变形行为,由单一CFRP复合材料薄壁管的散射开花失效转变为泡沫铝填充CFRP复合材料薄壁管的纤维层断裂失效。同CFRP复合材料薄壁管相比,泡沫铝填充CFRP复合材料薄壁管的应力波动显著减小。随环境温度的升高,CFRP复合材料薄壁管、泡沫铝和泡沫铝填充CFRP复合材料薄壁管的压缩与吸能性能均不断降低,但泡沫铝与CFRP复合材料薄壁管之间的交互作用增强,泡沫铝对CFRP复合材料薄壁管的增强作用在高温下表现更为显著。

-

关键词:

- 泡沫铝填充CFRP复合材料薄壁管 /

- DIC /

- 温度压缩 /

- 吸能 /

- 变形模式

Abstract: The Al foams made by space-holder method were physically inserted into carbon fiber reinforced plastic (CFRP) composite thin-wall tubes to obtain the composite structure of Al foam-filled CFRP composite thin-wall tubes. Quasi-static compression tests of CFRP composite tubes, Al foams and Al foam-filled CFRP composite thin-wall tubes were carried out to study their compression properties. Meanwhile, digital image correlation (DIC) was applied to analyze their deformation modes. Furthermore, the compressive properties, energy absorption properties and failure modes of Al foam-filled CFRP composite thin-wall tubes at different temperatures (25-150℃) were studied. The results show that Al foams as fillers change the compression deformation behavior of CFRP composite thin-walled tubes from the scattering flowering failure of a single CFRP composite tube to the fiber layer fracture failure of a foam-filled tube. Comparing to CFRP composite thin-walled tubes, the stress fluctuations of Al foam-filled CFRP composite thin-wall tubes decrease obviously. With environmental temperature increasing, both the compressive properties and energy absorption properties of CFRP composite thin-walled tubes, Al foams and Al foam-filled CFRP composite thin-wall tubes decrease. But the interaction between Al foams and CFRP composite thin-walled tubes is enhanced, the enhancement effect of Al foams on CFRP composite thin-walled tubes is more obvious at high temperature. -

-

-

[1] BISAGNI C. Crashworthiness of helicopter subfloor structures[J]. Aircraft Engineering and Aerospace Technology,2002,27(10):1067-1082.

[2] OLABI A G, MORRIS E, HASHMI S. Metallic tube type energy absorbers: A synopsis[J]. Steel Construction,2008,45(7):706-726.

[3] ALGHAMDI A A A. Collapsible impact energy absorbers: An overview[J]. Thin-Walled Structures,2001,39(2):189-213. DOI: 10.1016/S0263-8231(00)00048-3

[4] GUO L W, YU J L, LI Z B. Experimental studies on the quasi-static bending behavior of double square tubes filled with aluminum foam[J]. Acta Mechanica,2010,213(3-4):349-358. DOI: 10.1007/s00707-010-0281-1

[5] GUILLOW S R, LU G, GRZEBIETE R H. Quasi-static axial compression of thin-walled circular aluminium tubes[J]. International Journal of Mechanical Sciences,2001,43(9):2103-2123. DOI: 10.1016/S0020-7403(01)00031-5

[6] NIKNEJAD A, MOEINIFARD M. Theoretical and experimental studies of the external inversion process in the circular metal tubes[J]. Materials <italic>&</italic> Design,2012,40:324-330.

[7] QIU X M, YU X H, LI Y L, et al. The deformation mechanism analysis of a circular tube under free inversion[J]. Thin-Walled Structures,2016,107:49-56. DOI: 10.1016/j.tws.2016.05.019

[8] YU X H, QIU X M, YU T X. Analysis of the free external inversion of circular tubes based on deformation theory[J]. International Journal of Mechanical Sciences,2015,100:262-268. DOI: 10.1016/j.ijmecsci.2015.06.017

[9] SUMANA B G, SAGAR H N V, KRISHNA M, et al. Investigation of burst pressure on carbon/glass fiber reinforced polymer metal tube for high pressure applications[J]. Procedia Materials Science,2014,5:535-539. DOI: 10.1016/j.mspro.2014.07.297

[10] 沈勇, 柯俊, 吴震宇. 不同编织角CFRP 增强铝方管的吸能特性[J]. 复合材料学报, 2020, 37(3):591-600. SHEN Yong, KE Jun, WU Zhenyu. Energy-absorbing characteristics of CFRP/Al square tubes with different braiding angles[J]. Acta Materiae Compositae Sinica,2020,37(3):591-600(in Chinese).

[11] REID S R. Plastic deformation mechanisms in axially compressed metal tubes used as impact energy absorbers[J]. International Journal of Mechanical Sciences,1993,35(12):1035-1052. DOI: 10.1016/0020-7403(93)90054-X

[12] 杨旭东, 许佳丽, 邹田春, 等. 泡沫铝填充金属薄壁管复合结构的研究进展[J]. 材料导报, 2019, 33(21):3637-3643. DOI: 10.11896/cldb.18080101 YANG Xudong, XU Jiali, ZOU Tianchun, et al. Advances in the composite structure of aluminum foam filled metal thin-walled tube[J]. Materials and Report,2019,33(21):3637-3643(in Chinese). DOI: 10.11896/cldb.18080101

[13] 刘伟明, 程和法, 黄笑梅, 等. 开孔泡沫铝填充圆管的准静态压缩行为[J]. 爆炸与冲击, 2009, 29(6):97-101. LIU Weiming, CHENG Hefa, HUANG Xiaomei, et al. Quasi-static compression behaviors of cylindrical tubes filled with open-cell aluminum foam[J]. Explosion and Shock Waves,2009,29(6):97-101(in Chinese).

[14] 卢子兴, 赵亚斌, 陈伟, 等. 金属泡沫填充薄壁圆管的轴压载荷-位移关系[J]. 力学学报, 2010, 42(6):1211-1218. LU Zixing, ZHAO Yabin, CHEN Wei, et al. Relation of load and displacement for the metal foam-filled tube during the axial compression[J]. Chinese Journal of Theoretical and Applied Mechanics,2010,42(6):1211-1218(in Chinese).

[15] 卢子兴, 陈伟. 泡沫变形模式对泡沫填充圆管压溃行为的影响[J]. 复合材料学报, 2011, 28(5):168-173. LU Zixing, CHEN Wei. Effect of the foam deformation modes on the crushing behavior of foam-filled circular tube[J]. Acta Materiae Compositae Sinica,2011,28(5):168-173(in Chinese).

[16] DUARTE I, KRSTULOVIC-OPARA L, VESENJAK M. Characterisation of aluminium alloy tubes filled with aluminium alloy integral-skin foam under axial compressive loads[J]. Composite Structures,2015,12:154-162.

[17] DUARTE I, VESENJAK M, KRSTULOVIC-OPARA L, et al. Static and dynamic axial crush performance of in-situ foam-filled tubes[J]. Composite Structures,2015,124:128-139. DOI: 10.1016/j.compstruct.2015.01.014

[18] DUARTE I, KRSTULOVIC-OPARA L L, VESENJAK M. Axial crush behaviour of the aluminium alloy in-situ foam filled tubes with very low wall thickness[J]. Composite Structures,2018,192:184-192. DOI: 10.1016/j.compstruct.2018.02.094

[19] HANGAI Y, NAKANO Y, UTSUNOMIYA T, et al. Drop weight Impact behavior of Al-Si-Cu alloy foam-filled thin-walled steel pipe fabricated by friction stir back xxtrusion[J]. Journal of Materials Engineering <italic>&</italic> Performance,2017,26(2):894-900.

[20] HUSSEIN R D, RUAN D, LU G, et al. Axial crushing behaviour of honeycomb-filled square carbon fibre reinforced plastic (CFRP) tubes[J]. Composite Structures,2016,140:166-179.

[21] GAN N, FENG Y, YIN H, et al. Quasi-static axial crushing experiment study of foam-filled CFRP and aluminum alloy thin-walled structures[J]. Composite Structures,2016,157:303-319. DOI: 10.1016/j.compstruct.2016.08.043

[22] SUN G, LI S, LIU Q, et al. Experimental study on crashworthiness of empty/aluminum foam/honeycomb-filled CFRP tubes[J]. Composite Structures,2016,152:969-993. DOI: 10.1016/j.compstruct.2016.06.019

[23] SUN G, WANG Z, YU H, et al. Experimental and numerical investigation into the crashworthiness of metal-foam-composite hybrid structures[J]. Composite Structures,2019,209:535-547. DOI: 10.1016/j.compstruct.2018.10.051

[24] MAHBOD M, ASGARI M. Energy absorption analysis of a novel foam-filled corrugated composite tube under axial and oblique loadings[J]. Thin-Walled Structures,2018,129:58-73. DOI: 10.1016/j.tws.2018.03.023

[25] WANG J, YANG X, ZHANG M, et al. A novel approach to obtain in-situ growth carbon nanotube reinforced aluminum foams with enhanced properties[J]. Materials Letters,2015,161:763-766. DOI: 10.1016/j.matlet.2015.09.093

[26] 杨旭东, 李宗岷, 杨昆明, 等. 碳纳米管增强铝基复合泡沫的阻尼性能[J]. 复合材料学报, 2019, 36(2):418-424. YANG Xudong, LI Zongmin, YANG Kunming, et al. Damping properties of Al matrix composite foams reinforced by carbon nanotubes[J]. Acta Materiae Compositae Sinica,2019,36(2):418-424(in Chinese).

[27] YANG X D, HU Q, DU J, et al. Compression fatigue properties of open-cell aluminum foams fabricated by space-holder method[J]. International Journal of Fatigue,2019,121:272-280. DOI: 10.1016/j.ijfatigue.2018.11.008

[28] ISO. Mechanical testing of metals-Ductility testing-Compression test of porous and cellular metals: ISO–13314: 2011[S]. Geneva: ISO International Standard, 2011.

[29] SAHU S, GOEL M D, MONDAL D P, et al. High temperature compressive deformation behavior of ZA27–SiC foam[J]. Materials Science and Engineering: A,2014,607:162-172. DOI: 10.1016/j.msea.2014.04.004

[30] GUDEN M, YUKSEL S, TASDEMIRCI A, et al. Effect of aluminum closed-cell foam filling on the quasi-static axial crush performance of glass fiber reinforced polyester composite and aluminum/composite hybrid tubes[J]. Composite Structures,2007,81(4):480-490. DOI: 10.1016/j.compstruct.2006.09.005

[31] 冯青, 李敏, 顾轶卓, 等. 不同湿热条件下碳纤维/环氧复合材料湿热性能实验研究[J]. 复合材料学报, 2010, 27(6):16-20. FENG Qing, LI Min, GU Yizhuo, et al. Experimental research on hygrothermal properties of carbon fiber/epoxy resin composite under different hygrothermal conditions[J]. Acta Materiae Compositae Sinica,2010,27(6):16-20(in Chinese).

[32] HANSSEN A G, LANGSETH M, HOPPERSTAD O S. Static and dynamic crushing of circular aluminium extrusions with aluminium foam filler[J]. International Journal of Impact Engineering,2000,24(5):475-507. DOI: 10.1016/S0734-743X(99)00170-0

[33] HALL I W, GUDEN M, CLAAR T D. Transverse and longitudinal crushing of aluminum-foam filled tubes[J]. Scripta Materialia,2002,46(7):513-518. DOI: 10.1016/S1359-6462(02)00024-6

[34] 马少华, 费昺强, 许良, 等. 热氧老化对碳纤维双马树脂基复合材料性能的影响[J]. 材料工程, 2017, 45(12):50-57. DOI: 10.11868/j.issn.1001-4381.2016.000981 MA Shaohua, FEI Bingqiang, XU Liang, et al. Effect of thermal oxygen aging on properties of carbon fiber double horse resin matrix composites[J]. Journal of Materials Engineering,2017,45(12):50-57(in Chinese). DOI: 10.11868/j.issn.1001-4381.2016.000981

-

期刊类型引用(1)

1. 李佥,王添誉,孙西同,陈晓艺,李苗,韩雨擎,曾祥冰,孙芳鸿,李宪臻. 贻贝仿生修饰多孔磁性材料的制备及其在固定化脂肪酶中的应用. 复合材料学报. 2024(11): 6156-6169 .  本站查看

本站查看

其他类型引用(0)

-

下载:

下载: