2022 Vol. 39, No. 9

column

2022, 39(9): 4179-4186.

doi: 10.13801/j.cnki.fhclxb.20220525.001

Abstract:

"One generation of new materials, one generation of new equipment" illustrates the importance of material technology in the development of equipment. The development history of aviation equipment shows that the research and development of a new equipment is always supported by a new generation of materials, and the development of a new generation of equipment leads the application of a new generation of materials. That is to say the different aviation equipment uses different structural materials. The fourth-generation aircraft had a very marked difference with the third-generation aircraft on the usage of structural materials. The advanced composites are widely used for structural materials in the fourth-generation aircraft. In this article, the development process and current situation of domestic aviation composite technology is reviewed. The opportunities and challenges of the advanced composite technology are introduced. The significant future trends of domestic advanced composite technology are also proposed.

"One generation of new materials, one generation of new equipment" illustrates the importance of material technology in the development of equipment. The development history of aviation equipment shows that the research and development of a new equipment is always supported by a new generation of materials, and the development of a new generation of equipment leads the application of a new generation of materials. That is to say the different aviation equipment uses different structural materials. The fourth-generation aircraft had a very marked difference with the third-generation aircraft on the usage of structural materials. The advanced composites are widely used for structural materials in the fourth-generation aircraft. In this article, the development process and current situation of domestic aviation composite technology is reviewed. The opportunities and challenges of the advanced composite technology are introduced. The significant future trends of domestic advanced composite technology are also proposed.

2022, 39(9): 4187-4195.

doi: 10.13801/j.cnki.fhclxb.20220926.003

Abstract:

Advanced composite materials are critical for thermal protection system and structure of various aerospace vehicles. The performance and reliability of the aerospace vehicle are depended on the application and properties of the advanced composite materials. The paper presents the recent progress of the ceramic matrix composite for thermal structure, polymer based light weight ablative materials, high performance wave transparent materials, high temperature thermal insulation and structural composite materials. The future directions of advanced composite materials for aerospace application are discussed.

Advanced composite materials are critical for thermal protection system and structure of various aerospace vehicles. The performance and reliability of the aerospace vehicle are depended on the application and properties of the advanced composite materials. The paper presents the recent progress of the ceramic matrix composite for thermal structure, polymer based light weight ablative materials, high performance wave transparent materials, high temperature thermal insulation and structural composite materials. The future directions of advanced composite materials for aerospace application are discussed.

2022, 39(9): 4196-4212.

doi: 10.13801/j.cnki.fhclxb.20220530.003

Abstract:

3D printing is an innovative additive manufacturing technology, enabling the integrated moulding of composite structure with a complex contour. 3D printing eliminates the need for the expensive moulds, which can greatly reduce the manufacturing costs and time. This paper reviewed the recent research progress of processing techniques and mechanical performance of 3D printed fiber reinforced composite. Processing techniques, printing equipment, printing materials and mechanical properties of the printed composites were analyzed and discussed in details. More focuses were paid on the recent advances in the continuous fiber reinforced composite prepared by a fused filament fabrication method. Mechanical performance of the composites manufactured by 3D printing and traditional manufacturing techniques were compared. Finally, the existing issues in the research of 3D printed fiber reinforced composites were summarized with the outline of a roadmap for the future research trend in this field.

3D printing is an innovative additive manufacturing technology, enabling the integrated moulding of composite structure with a complex contour. 3D printing eliminates the need for the expensive moulds, which can greatly reduce the manufacturing costs and time. This paper reviewed the recent research progress of processing techniques and mechanical performance of 3D printed fiber reinforced composite. Processing techniques, printing equipment, printing materials and mechanical properties of the printed composites were analyzed and discussed in details. More focuses were paid on the recent advances in the continuous fiber reinforced composite prepared by a fused filament fabrication method. Mechanical performance of the composites manufactured by 3D printing and traditional manufacturing techniques were compared. Finally, the existing issues in the research of 3D printed fiber reinforced composites were summarized with the outline of a roadmap for the future research trend in this field.

2022, 39(9): 4213-4226.

doi: 10.13801/j.cnki.fhclxb.20220526.003

Abstract:

Thermoelectric materials can realize the direct conversion of heat and electricity by using the internal carrier transport characteristics of solid. This process is noiseless and pollution-free, which has a wide and impor-tant potential in application. Thermoelectric conversion efficiency depends on the material itself. Continuously improving the performance of existing thermoelectric materials and developing new high-performance thermoelectric material systems are important research hotpots in the thermoelectric field. The type, content and microstructure control of the second phase are the keys to design high-performance thermoelectric composite materials. Compositing the second phase is an effective strategy to optimize the thermoelectric performance, which can not only reduce the lattice thermal conductivity by introducing phonon scattering centers, but also improve the Seebeck coefficient through the energy filtering effect. Meanwhile, this strategy enhances the conductivity by the percolation effect, owning to form a conductive network in the matrix. This paper first introduces the common physical effects in composites, and then reviews the recent progress of the research on several typical thermoelectric mater-ials. The effects of the second phase on the electrical and thermal transports will be also discussed.

Thermoelectric materials can realize the direct conversion of heat and electricity by using the internal carrier transport characteristics of solid. This process is noiseless and pollution-free, which has a wide and impor-tant potential in application. Thermoelectric conversion efficiency depends on the material itself. Continuously improving the performance of existing thermoelectric materials and developing new high-performance thermoelectric material systems are important research hotpots in the thermoelectric field. The type, content and microstructure control of the second phase are the keys to design high-performance thermoelectric composite materials. Compositing the second phase is an effective strategy to optimize the thermoelectric performance, which can not only reduce the lattice thermal conductivity by introducing phonon scattering centers, but also improve the Seebeck coefficient through the energy filtering effect. Meanwhile, this strategy enhances the conductivity by the percolation effect, owning to form a conductive network in the matrix. This paper first introduces the common physical effects in composites, and then reviews the recent progress of the research on several typical thermoelectric mater-ials. The effects of the second phase on the electrical and thermal transports will be also discussed.

2022, 39(9): 4227-4243.

doi: 10.13801/j.cnki.fhclxb.20220725.003

Abstract:

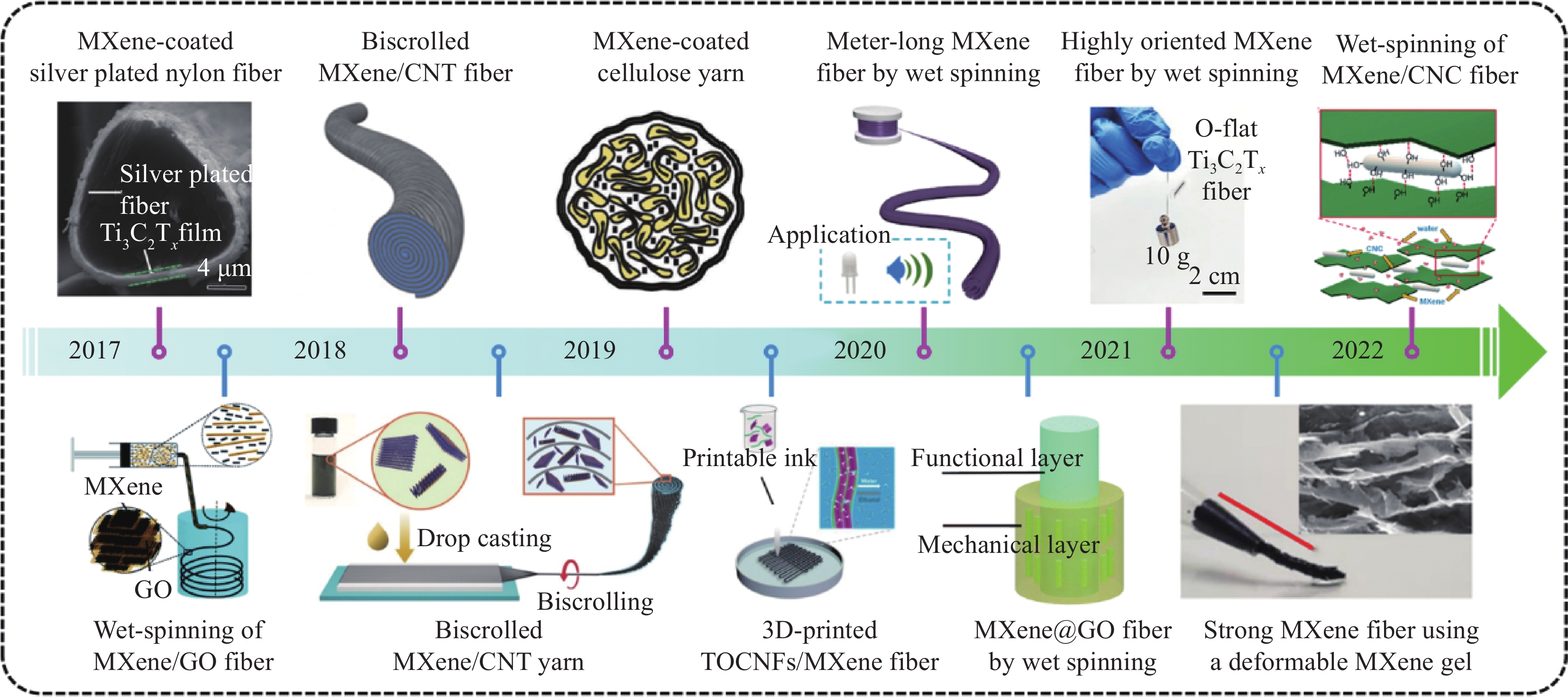

2D transition metal carbides and nitrides (MXenes) are a novel two-dimensional nanomaterial, which attracted extensive attention in the field of functional materials due to outstanding electrical, mechanical properties and abundant surface terminations. Therefore, it often has been used as building block for constructing macroscopic composites, such as MXene fibers, which are expected to be another structure-function integrated fiber after graphene fiber, and have widespread applications prospect in numerous fields, including smart textiles, sensing, energy, electromagnetic shielding, etc. However, the mechanical and electrical properties of MXene composite fibers are far lower than the intrinsic properties of MXene flakes. The main problems are that the existence of defects and voids in the MXene fiber caused by the wrinkling, disorder and weak interface interactions of MXene flakes during assembly, as well as the irregular shape of the fibers. In view of the existing problems as well as the future development direction, this review first introduces the fabrication approaches of MXene fiber. Then, we statement the mechanical and electrical properties of MXene composite fibers in detail, and discuss the strategies for improving the mechanical and electrical properties. Meanwhile, we outline the applications of MXene composite fibers by some instances. Finally, the existing scientific problems and challenges of MXene fiber are summarized, and the upcoming trends in MXene fiber are prospected, and some helpful viewpoint is provided for the research and application of MXene fiber in the future.

2D transition metal carbides and nitrides (MXenes) are a novel two-dimensional nanomaterial, which attracted extensive attention in the field of functional materials due to outstanding electrical, mechanical properties and abundant surface terminations. Therefore, it often has been used as building block for constructing macroscopic composites, such as MXene fibers, which are expected to be another structure-function integrated fiber after graphene fiber, and have widespread applications prospect in numerous fields, including smart textiles, sensing, energy, electromagnetic shielding, etc. However, the mechanical and electrical properties of MXene composite fibers are far lower than the intrinsic properties of MXene flakes. The main problems are that the existence of defects and voids in the MXene fiber caused by the wrinkling, disorder and weak interface interactions of MXene flakes during assembly, as well as the irregular shape of the fibers. In view of the existing problems as well as the future development direction, this review first introduces the fabrication approaches of MXene fiber. Then, we statement the mechanical and electrical properties of MXene composite fibers in detail, and discuss the strategies for improving the mechanical and electrical properties. Meanwhile, we outline the applications of MXene composite fibers by some instances. Finally, the existing scientific problems and challenges of MXene fiber are summarized, and the upcoming trends in MXene fiber are prospected, and some helpful viewpoint is provided for the research and application of MXene fiber in the future.

2022, 39(9): 4244-4258.

doi: 10.13801/j.cnki.fhclxb.20220629.001

Abstract:

Polymer gradient materials are functional heterogeneous polymer-based materials, where their compositions or structures change continuously or quasi continuously in one or multi-dimensional direction. The gradient structure endows the material with unique advantages, such as adjustable spatial distribution of components, avoidance of interfacial stress and compatibility with a variety of properties. Polymer gradient materials have a wide range of applications in aerospace, biomedicines, electronic information, mechanical engineering and other fields. In this paper, they are divided into one-dimensional, two-dimensional and three-dimensional polymer gradient materials according to the variation dimension of gradient. The preparation methods, performance advantages and application fields of the three materials are introduced respectively. The gradient refractive index of one-dimensional polymer gradient fiber improves the speed and distance of optical fiber transmission and contributes to the development of optical communication field. Two-dimensional polymer gradient materials can be divided into the coating and thin film materials. Gradient structures can be prepared by surface modification and field gradient methods. The resulting gradient surface can provide a high-throughput platform to study and optimize the interaction between materials and organisms. Three-dimensional polymer gradient materials include gradient crosslinking network polymer materials, gradient filled polymer composites and gradient crystallization polymer materials. The gradient structure can improve their mechanical properties and stress concentration, and expand the applications of polymers in mechanical engineering and biomedical fields. Finally, the challenges in the preparation, characterization and application of polymer gradient materials are prospected.

Polymer gradient materials are functional heterogeneous polymer-based materials, where their compositions or structures change continuously or quasi continuously in one or multi-dimensional direction. The gradient structure endows the material with unique advantages, such as adjustable spatial distribution of components, avoidance of interfacial stress and compatibility with a variety of properties. Polymer gradient materials have a wide range of applications in aerospace, biomedicines, electronic information, mechanical engineering and other fields. In this paper, they are divided into one-dimensional, two-dimensional and three-dimensional polymer gradient materials according to the variation dimension of gradient. The preparation methods, performance advantages and application fields of the three materials are introduced respectively. The gradient refractive index of one-dimensional polymer gradient fiber improves the speed and distance of optical fiber transmission and contributes to the development of optical communication field. Two-dimensional polymer gradient materials can be divided into the coating and thin film materials. Gradient structures can be prepared by surface modification and field gradient methods. The resulting gradient surface can provide a high-throughput platform to study and optimize the interaction between materials and organisms. Three-dimensional polymer gradient materials include gradient crosslinking network polymer materials, gradient filled polymer composites and gradient crystallization polymer materials. The gradient structure can improve their mechanical properties and stress concentration, and expand the applications of polymers in mechanical engineering and biomedical fields. Finally, the challenges in the preparation, characterization and application of polymer gradient materials are prospected.

2022, 39(9): 4259-4273.

doi: 10.13801/j.cnki.fhclxb.20220712.001

Abstract:

Metamaterials are artificially constructed composite structural materials. By designing the structural parameters of units, we can realize a great wealth of wave functions and even break the wave response limit of traditional materials. Metamaterials have great potential application in civil and defense industries such as aerospace engineering, transportation, among others. First, we briefly introduce the basic concept, properties and development history of metamaterials. Then, we introduce the basic functions of metamaterials in detail from three aspects: Band gap induced vibration reduction and its intelligent design, low-frequency broadband noise reduction and energy harvesting. Furthermore, based on the multi requirements of practical applications, we introduce the design principles and properties of different types of multi-functions integrated metamaterials such as lightweight-load bearing-vibration/noise reduction integration and energy harvesting-vibration/noise reduction integration. Finally, we summarize the above research progress and give a perspective on the cross research of metamaterials with composite materials, artificial intelligence and non-Hermitian time-varying systems, which can further improve the performance and application ability of metamaterials in future.

Metamaterials are artificially constructed composite structural materials. By designing the structural parameters of units, we can realize a great wealth of wave functions and even break the wave response limit of traditional materials. Metamaterials have great potential application in civil and defense industries such as aerospace engineering, transportation, among others. First, we briefly introduce the basic concept, properties and development history of metamaterials. Then, we introduce the basic functions of metamaterials in detail from three aspects: Band gap induced vibration reduction and its intelligent design, low-frequency broadband noise reduction and energy harvesting. Furthermore, based on the multi requirements of practical applications, we introduce the design principles and properties of different types of multi-functions integrated metamaterials such as lightweight-load bearing-vibration/noise reduction integration and energy harvesting-vibration/noise reduction integration. Finally, we summarize the above research progress and give a perspective on the cross research of metamaterials with composite materials, artificial intelligence and non-Hermitian time-varying systems, which can further improve the performance and application ability of metamaterials in future.

2022, 39(9): 4274-4285.

doi: 10.13801/j.cnki.fhclxb.20220809.008

Abstract:

With excellent mechanical properties, low hygroscopicity, good chemical resistance, short molding cycle and convenience to be reformed, continuous carbon fiber reinforced high-performance thermoplastic composites are widely used in aerospace and other high-tech fields. The interfacial problems, prepreg preparation and compo-site molding in the research of continuous carbon fiber reinforced high-performance thermoplastic composites were introduced. The reference for the domestic application research of this kind of composites is expected to be provided.

With excellent mechanical properties, low hygroscopicity, good chemical resistance, short molding cycle and convenience to be reformed, continuous carbon fiber reinforced high-performance thermoplastic composites are widely used in aerospace and other high-tech fields. The interfacial problems, prepreg preparation and compo-site molding in the research of continuous carbon fiber reinforced high-performance thermoplastic composites were introduced. The reference for the domestic application research of this kind of composites is expected to be provided.

2022, 39(9): 4286-4309.

doi: 10.13801/j.cnki.fhclxb.20220803.002

Abstract:

Ultra high molecular weight polyethylene (UHMWPE) fiber, together with carbon fiber and aramid fiber, is one of the three high-performance fibers. It has the characteristics of low density, high impact resistance, high breaking strength and modulus, and excellent chemical stability. This paper reviews the current research status and recent progress of UHMWPE fiber and its composites, including the performance comparison between UHMWPE fiber and other high-performance fibers, the typical production process of UHMWPE fiber and its influence on fiber performance, the types of resin matrix matched with UHMWPE fiber, the modification methods to improve fiber surface adhesion, thermal stability and creep resistance, weaving and composite processes, and the application of UHMWPE fibers and their composite applications. Finally, the main problems existing in UHMWPE fiber and its composite materials are analyzed, and the possible development direction in the future is discussed.

Ultra high molecular weight polyethylene (UHMWPE) fiber, together with carbon fiber and aramid fiber, is one of the three high-performance fibers. It has the characteristics of low density, high impact resistance, high breaking strength and modulus, and excellent chemical stability. This paper reviews the current research status and recent progress of UHMWPE fiber and its composites, including the performance comparison between UHMWPE fiber and other high-performance fibers, the typical production process of UHMWPE fiber and its influence on fiber performance, the types of resin matrix matched with UHMWPE fiber, the modification methods to improve fiber surface adhesion, thermal stability and creep resistance, weaving and composite processes, and the application of UHMWPE fibers and their composite applications. Finally, the main problems existing in UHMWPE fiber and its composite materials are analyzed, and the possible development direction in the future is discussed.

2022, 39(9): 4310-4318.

doi: 10.13801/j.cnki.fhclxb.20220812.002

Abstract:

In order to meet the requirements of safety, economy, comfortability, and environmental protection, high specific strength advanced material, represented by carbon fiber reinforced plastics (CFRP), has been widely used in the airframe of the new generation commercial aircraft. CFRP composite fuselage panels have different assembly characteristics in comparison with traditional metal fuselage panels, which put forward new requirements for aircraft assembly. This paper firstly summaries the manufacturing process of composite fuselage panel, and analyzes the current status and problems of composite fuselage panel assembly. Then, the methods in composite fuselage panel assembly is discussed, and a fully-active-drive flexible assembly method for force/shape control of composite fuselage panel assembly is proposed. Finally, the feasibility and effectiveness of the proposed method are verified by simulation and physical experiments, with optimized control of force/shape control reached.

In order to meet the requirements of safety, economy, comfortability, and environmental protection, high specific strength advanced material, represented by carbon fiber reinforced plastics (CFRP), has been widely used in the airframe of the new generation commercial aircraft. CFRP composite fuselage panels have different assembly characteristics in comparison with traditional metal fuselage panels, which put forward new requirements for aircraft assembly. This paper firstly summaries the manufacturing process of composite fuselage panel, and analyzes the current status and problems of composite fuselage panel assembly. Then, the methods in composite fuselage panel assembly is discussed, and a fully-active-drive flexible assembly method for force/shape control of composite fuselage panel assembly is proposed. Finally, the feasibility and effectiveness of the proposed method are verified by simulation and physical experiments, with optimized control of force/shape control reached.

2022, 39(9): 4319-4326.

doi: 10.13801/j.cnki.fhclxb.20220922.006

Abstract:

Ultra-high temperature ceramic matrix (UHTC) composites play a key role for the application of thermal structures of high-speed launch vehicle due to their lightweight, high melting point, high specific strength/stiffness and excellent anti-oxidation/ablation resistance. It is known that UHTC composites consist of carbon fiber reinforcement and ultra-high temperature ceramic matrix, where reinforcement and ceramic matrix possess different physical and chemical properties. To make better performance of UHTC composites, it is quite necessary to think about how to incorporate carbon fiber with ceramic matrix effectively, where the advantages for both fiber and matrix should be taken into accounts. In order to provide a guidance for the fundamental research and engineering application of UHTC composites, in this paper, the synthesis of precursors and the performance of C/ZrC-SiC and C/HfTaC-ZrC-SiC composites are reviewed. And then the technical route for the fabrication of UHTC composites via organic-inorganic transformation is proposed. It is expected to overcome the main issues which encountered in the development of composite design and fabrication.

Ultra-high temperature ceramic matrix (UHTC) composites play a key role for the application of thermal structures of high-speed launch vehicle due to their lightweight, high melting point, high specific strength/stiffness and excellent anti-oxidation/ablation resistance. It is known that UHTC composites consist of carbon fiber reinforcement and ultra-high temperature ceramic matrix, where reinforcement and ceramic matrix possess different physical and chemical properties. To make better performance of UHTC composites, it is quite necessary to think about how to incorporate carbon fiber with ceramic matrix effectively, where the advantages for both fiber and matrix should be taken into accounts. In order to provide a guidance for the fundamental research and engineering application of UHTC composites, in this paper, the synthesis of precursors and the performance of C/ZrC-SiC and C/HfTaC-ZrC-SiC composites are reviewed. And then the technical route for the fabrication of UHTC composites via organic-inorganic transformation is proposed. It is expected to overcome the main issues which encountered in the development of composite design and fabrication.

2022, 39(9): 4327-4336.

doi: 10.13801/j.cnki.fhclxb.20220530.005

Abstract:

In order to further improve the interfacial adhesive properties of aramid fiber/rubber composites, based on the traditional "two-step" method was used to dip resorcinol-formaldehyde-latex (RFL), and aramid nanofibers (ANF) was added to the predipping solution and RFL dipping solution, respectively. The effects of addition process and content of ANF on the interfacial adhesion properties of aramid fiber/rubber composites were studied. The results show that when only 0.05wt% ANF is added to the predipping solution, the H pull-out force is 209.0 N, the peel force of single fiber is 19.8 N, and the dynamic fatigue life is 9829 times, which are 18.1%, 14.4% and 41.0% higher than those of the unreinforced system. Added 0.15wt% ANF to the RFL dipping solution, the H pull-out force is 206.5 N, the peel force of single fiber is 19.8 N, and the dynamic fatigue life is 8095 times, which are 15.9%, 16.1% and 16.1% higher than those of the unreinforced system. Adding ANF to the pretreatment system can effectively improve the dynamic adhesion properties, because the ANF has a good chemical effect with aramid fiber and isocyanate in the predipping solution, which is beneficial to the modulus transition at the interface and improves the stress transfer efficiency.

In order to further improve the interfacial adhesive properties of aramid fiber/rubber composites, based on the traditional "two-step" method was used to dip resorcinol-formaldehyde-latex (RFL), and aramid nanofibers (ANF) was added to the predipping solution and RFL dipping solution, respectively. The effects of addition process and content of ANF on the interfacial adhesion properties of aramid fiber/rubber composites were studied. The results show that when only 0.05wt% ANF is added to the predipping solution, the H pull-out force is 209.0 N, the peel force of single fiber is 19.8 N, and the dynamic fatigue life is 9829 times, which are 18.1%, 14.4% and 41.0% higher than those of the unreinforced system. Added 0.15wt% ANF to the RFL dipping solution, the H pull-out force is 206.5 N, the peel force of single fiber is 19.8 N, and the dynamic fatigue life is 8095 times, which are 15.9%, 16.1% and 16.1% higher than those of the unreinforced system. Adding ANF to the pretreatment system can effectively improve the dynamic adhesion properties, because the ANF has a good chemical effect with aramid fiber and isocyanate in the predipping solution, which is beneficial to the modulus transition at the interface and improves the stress transfer efficiency.

2022, 39(9): 4337-4343.

doi: 10.13801/j.cnki.fhclxb.20220825.002

Abstract:

Carbon/carbon (C/C) composites have been widely used as ablative materials with excellent performance, it has great potential to be used as laser ablation resistant material. In this paper, C/C composites with different densities were prepared. CO2 laser was used as the heat source to explore the interaction mechanism between high-energy laser and C/C composite material under oxygen-free atmosphere, and systematically analyze the influence of C/C properties and laser parameters on ablation performance. The ablation depth was characterized by 3D profilometer. The results show that the variation of C/C ablation behavior is nonlinear with the change of ablation time or laser power. Intrinsic properties of C/C composites determine the thermal load, which determines the ablative performance of C/C composites. When the laser heat flux is greater than the thermal load of the material, the linear ablation rate will rise drastically.

Carbon/carbon (C/C) composites have been widely used as ablative materials with excellent performance, it has great potential to be used as laser ablation resistant material. In this paper, C/C composites with different densities were prepared. CO2 laser was used as the heat source to explore the interaction mechanism between high-energy laser and C/C composite material under oxygen-free atmosphere, and systematically analyze the influence of C/C properties and laser parameters on ablation performance. The ablation depth was characterized by 3D profilometer. The results show that the variation of C/C ablation behavior is nonlinear with the change of ablation time or laser power. Intrinsic properties of C/C composites determine the thermal load, which determines the ablative performance of C/C composites. When the laser heat flux is greater than the thermal load of the material, the linear ablation rate will rise drastically.

2022, 39(9): 4344-4353.

doi: 10.13801/j.cnki.fhclxb.20220621.002

Abstract:

Composite divergent section is the key component of solid rocket motor nozzle, with the composite structure of ultra-thick and variable curvature to resist the comprehensive effects of high temperature, ablation, high-speed gas and mechanical load. Due to the low thermal conductivity of the divergent section, the characteristics of ultra-thick and the unreasonable curing cycle, severe overheating peaks are easy to appear during the molding process. In order to reduce the curing deformation and improve the forming quality of the divergent section, it is necessary to restrain the curing overheating and improve the curing uniformity. Firstly, the kinetics of high silica glass fiber/phenolic and carbon fiber/phenolic prepreg at 2 MPa were characterized by high pressure differential scanning calorimetry in this study. Then, considering the characteristics of multi field coupling in the molding process and the influence of molding die and curing process, the coupling model of curing process was constructed to analyze the phenomenon of overheating and non-uniform curing of the divergent section. Finally, the method of inserting a cooling process before vigorous curing was proposed to optimize the curing cycle and restrain the curing overheating. The results show that the optimized cycle can effectively suppress the overheating of the divergent section. After optimization, the maximum overheating peak decreases from 54.2℃ to 23.5℃, and the maximum curing degree difference decreases from 0.6 to 0.34, with the decrease ranges of 56.64% and 43.33% respectively.

Composite divergent section is the key component of solid rocket motor nozzle, with the composite structure of ultra-thick and variable curvature to resist the comprehensive effects of high temperature, ablation, high-speed gas and mechanical load. Due to the low thermal conductivity of the divergent section, the characteristics of ultra-thick and the unreasonable curing cycle, severe overheating peaks are easy to appear during the molding process. In order to reduce the curing deformation and improve the forming quality of the divergent section, it is necessary to restrain the curing overheating and improve the curing uniformity. Firstly, the kinetics of high silica glass fiber/phenolic and carbon fiber/phenolic prepreg at 2 MPa were characterized by high pressure differential scanning calorimetry in this study. Then, considering the characteristics of multi field coupling in the molding process and the influence of molding die and curing process, the coupling model of curing process was constructed to analyze the phenomenon of overheating and non-uniform curing of the divergent section. Finally, the method of inserting a cooling process before vigorous curing was proposed to optimize the curing cycle and restrain the curing overheating. The results show that the optimized cycle can effectively suppress the overheating of the divergent section. After optimization, the maximum overheating peak decreases from 54.2℃ to 23.5℃, and the maximum curing degree difference decreases from 0.6 to 0.34, with the decrease ranges of 56.64% and 43.33% respectively.

2022, 39(9): 4354-4365.

doi: 10.13801/j.cnki.fhclxb.20220803.003

Abstract:

Developing structural composites with integration of lightning strike resistance is one of the trend of developing new composites. In this paper, a composite co-modified with graphene and carbon nanotubes was prepared. Its microstructure, mechanical properties, electrical conductivity and lightning-strike properties were studied. Morphology study shows that the conductive fillers are mainly distributed in the interlayer and the adjacent intralaminar regions, while much less in the deep intralaminar regions. The composite has 0° flexural strength of (1538±86) MPa and 0° interlaminar shear strength of (107.0±1.0) MPa. Three laminates of 2 mm, 3 mm and 4 mm thickness were prepared for studying the electrical conductivity and lightning-strike properties. The in-plane conductivity of the composites is around 100 S/cm. The conductivity through thickness direction are 0.128 S/cm, 0.094 S/cm and 0.088 S/cm, respectively. The lightning-strike test shows that the total damage area of the three thickness samples is similar. The deep damage area decreases, while the damage depth increases with the decrease in conductivity through thickness direction. The damage mode is mainly the ablation damage of fiber and resin. No obvious delamination is found. The minimum flexural strength and the corresponding retention rates of the flexural strength and modulus of the damaged 2 mm thick laminate at the damage center are 782 MPa, 75% and 59.2%, respectively. The average flexural strength retention rates of the damage centers of the 2 mm and 3 mm thick laminates reached 87.4% and 87.2%, respectively. Their damage depths are only around 0.3 mm and 0.4 mm respectively.

Developing structural composites with integration of lightning strike resistance is one of the trend of developing new composites. In this paper, a composite co-modified with graphene and carbon nanotubes was prepared. Its microstructure, mechanical properties, electrical conductivity and lightning-strike properties were studied. Morphology study shows that the conductive fillers are mainly distributed in the interlayer and the adjacent intralaminar regions, while much less in the deep intralaminar regions. The composite has 0° flexural strength of (1538±86) MPa and 0° interlaminar shear strength of (107.0±1.0) MPa. Three laminates of 2 mm, 3 mm and 4 mm thickness were prepared for studying the electrical conductivity and lightning-strike properties. The in-plane conductivity of the composites is around 100 S/cm. The conductivity through thickness direction are 0.128 S/cm, 0.094 S/cm and 0.088 S/cm, respectively. The lightning-strike test shows that the total damage area of the three thickness samples is similar. The deep damage area decreases, while the damage depth increases with the decrease in conductivity through thickness direction. The damage mode is mainly the ablation damage of fiber and resin. No obvious delamination is found. The minimum flexural strength and the corresponding retention rates of the flexural strength and modulus of the damaged 2 mm thick laminate at the damage center are 782 MPa, 75% and 59.2%, respectively. The average flexural strength retention rates of the damage centers of the 2 mm and 3 mm thick laminates reached 87.4% and 87.2%, respectively. Their damage depths are only around 0.3 mm and 0.4 mm respectively.

2022, 39(9): 4366-4374.

doi: 10.13801/j.cnki.fhclxb.20220804.003

Abstract:

The brittleness and insufficient thermal-shock resistance are the critical problems for the extensive applications of SiC ceramics. Low-density SiC ceramics decorated with in-situ SiC nanowires were fabricated via the pyrolysis of polycarbosilane assisted by ferrocene. They were further densified by the technique of precursor infiltration and pyrolysis to prepare in-situ SiC nanowire-toughened SiC ceramics. The experimental results showed that, compared with the SiC ceramics without nanowires, the thermal shock resistance of the in-situ SiC nanowire-toughened SiC ceramics was improved significantly, whose oxidation mass gain was only 2.53% and decreased by 59% after 30 thermal cycles between room temperature and 1500 ℃. The corresponding microstructural analysis indicated that the synthesized SiC nanowires were β-SiC and contained some stacking faults. The β-SiC nanowires grew along the preferential orientation of <111> and its growth was governed by a vapor-liquid-solid mechanism. The in-situ SiC nanowires could effectively alleviate the stress concentration due to the ceramic preparation and the thermal cycles between high and low temperatures. The improved fracture toughness and thermal-shock resistance could be attributed to the toughening mechanism including nanowire bridging and pull-out, as well as the decrease of crack number and size in SiC ceramics. After the introduction of SiC nanowires, the average crack length of SiC ceramics decreased from 27.7 μm to 18.2 μm, and the fracture toughness increased from 3.76 MPa·m1/2 to 7.83 MPa·m1/2.

The brittleness and insufficient thermal-shock resistance are the critical problems for the extensive applications of SiC ceramics. Low-density SiC ceramics decorated with in-situ SiC nanowires were fabricated via the pyrolysis of polycarbosilane assisted by ferrocene. They were further densified by the technique of precursor infiltration and pyrolysis to prepare in-situ SiC nanowire-toughened SiC ceramics. The experimental results showed that, compared with the SiC ceramics without nanowires, the thermal shock resistance of the in-situ SiC nanowire-toughened SiC ceramics was improved significantly, whose oxidation mass gain was only 2.53% and decreased by 59% after 30 thermal cycles between room temperature and 1500 ℃. The corresponding microstructural analysis indicated that the synthesized SiC nanowires were β-SiC and contained some stacking faults. The β-SiC nanowires grew along the preferential orientation of <111> and its growth was governed by a vapor-liquid-solid mechanism. The in-situ SiC nanowires could effectively alleviate the stress concentration due to the ceramic preparation and the thermal cycles between high and low temperatures. The improved fracture toughness and thermal-shock resistance could be attributed to the toughening mechanism including nanowire bridging and pull-out, as well as the decrease of crack number and size in SiC ceramics. After the introduction of SiC nanowires, the average crack length of SiC ceramics decreased from 27.7 μm to 18.2 μm, and the fracture toughness increased from 3.76 MPa·m1/2 to 7.83 MPa·m1/2.

2022, 39(9): 4375-4383.

doi: 10.13801/j.cnki.fhclxb.20220630.005

Abstract:

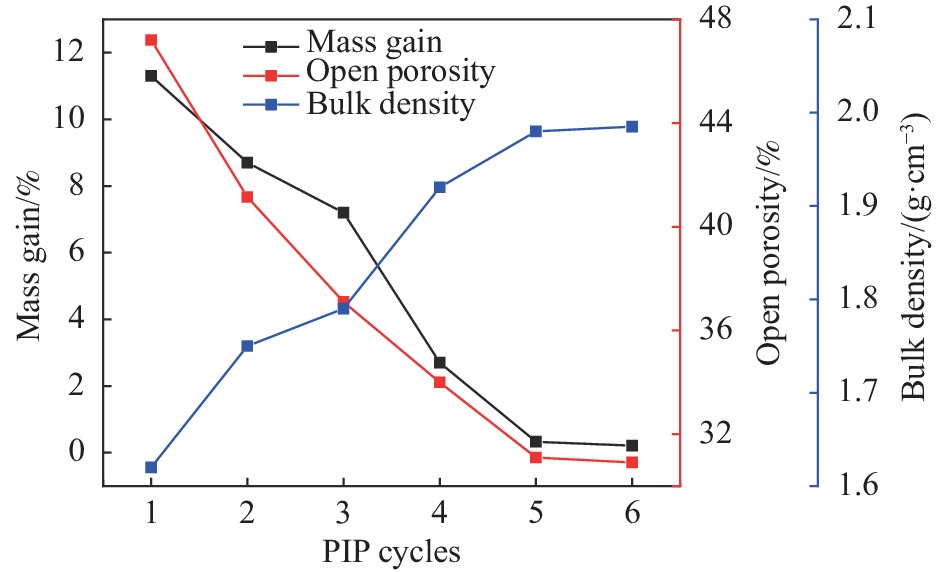

To prepare a high-temperature wave-transparent material with excellent dielectric and mechanical properties, the BNmf-Si3N4w/Si3N4 composite material was prepared by gel-casting (GC) and precursor infiltration and pyrolysis (PIP) process. The effects of the cycles of PIP and the BNmf content on the mechanical properties and dielectric properties of composite materials were studied. The results show that: (1) As the number of PIP cycles increases, the density of the composite material increases, the porosity decreases, and the mechanical properties improve. The silicon nitride matrix gradually forms a three-dimensional network structure wrapped around the multiphase micro-reinforcement; (2) When the content of BNmf increases from 4vol% to 12vol%, the bending strength decreases from 175.5 MPa to 139.3 MPa, and the fracture toughness increases from 2.36 MPa·m1/2 to 2.73 MPa·m1/2, the dielectric constant decreases from 3.62 to 3.25, and the dielectric loss tangent decreases from 0.012 to 0.007; (3) The strengthening and toughening mechanisms of BNmf-Si3N4w/Si3N4 composites are mainly crack bifurcation, crack deflection, and pull-out of BNmf and Si3N4w. Three mechanisms effectively reduce the damage of the main crack to the composite.

To prepare a high-temperature wave-transparent material with excellent dielectric and mechanical properties, the BNmf-Si3N4w/Si3N4 composite material was prepared by gel-casting (GC) and precursor infiltration and pyrolysis (PIP) process. The effects of the cycles of PIP and the BNmf content on the mechanical properties and dielectric properties of composite materials were studied. The results show that: (1) As the number of PIP cycles increases, the density of the composite material increases, the porosity decreases, and the mechanical properties improve. The silicon nitride matrix gradually forms a three-dimensional network structure wrapped around the multiphase micro-reinforcement; (2) When the content of BNmf increases from 4vol% to 12vol%, the bending strength decreases from 175.5 MPa to 139.3 MPa, and the fracture toughness increases from 2.36 MPa·m1/2 to 2.73 MPa·m1/2, the dielectric constant decreases from 3.62 to 3.25, and the dielectric loss tangent decreases from 0.012 to 0.007; (3) The strengthening and toughening mechanisms of BNmf-Si3N4w/Si3N4 composites are mainly crack bifurcation, crack deflection, and pull-out of BNmf and Si3N4w. Three mechanisms effectively reduce the damage of the main crack to the composite.

Array ultrasonic total-focus imaging for advanced resin matrix composite fiber wrinkle defect arrays

2022, 39(9): 4384-4392.

doi: 10.13801/j.cnki.fhclxb.20220707.001

Abstract:

Advanced resin matrix composites were widely used in aerospace applications because of light weight and high strength. Fiber wrinkle defects were one of the defects in advanced resin matrix composites, which were inefficiently detected by conventional ultrasonic inspection, while the array ultrasound total-focus imaging detection technique relies on accurate acoustic propagation delay. To address the problem of difficult acoustic delay calculation due to anisotropy and multilayer refractive interfaces in advanced resin matrix composites, ray tracing method based on the Viterbi search algorithm was proposed for calculating the time delay of array ultrasonic total focus imaging inspection. The results of the array ultrasonic full-focus imaging inspection experiments on 5.92 mm thick multidirectional carbon fiber composite laminates show that the use of the ray tracing method to calculate the delay time allows the collected full-matrix signals to be accurately and coherently superimposed, effectively detecting the fiber winkle defects in multidirectional carbon fiber composite laminates.

Advanced resin matrix composites were widely used in aerospace applications because of light weight and high strength. Fiber wrinkle defects were one of the defects in advanced resin matrix composites, which were inefficiently detected by conventional ultrasonic inspection, while the array ultrasound total-focus imaging detection technique relies on accurate acoustic propagation delay. To address the problem of difficult acoustic delay calculation due to anisotropy and multilayer refractive interfaces in advanced resin matrix composites, ray tracing method based on the Viterbi search algorithm was proposed for calculating the time delay of array ultrasonic total focus imaging inspection. The results of the array ultrasonic full-focus imaging inspection experiments on 5.92 mm thick multidirectional carbon fiber composite laminates show that the use of the ray tracing method to calculate the delay time allows the collected full-matrix signals to be accurately and coherently superimposed, effectively detecting the fiber winkle defects in multidirectional carbon fiber composite laminates.

2022, 39(9): 4393-4405.

doi: 10.13801/j.cnki.fhclxb.20220104.001

Abstract:

Carbon fiber has a series of excellent properties such as low density, high specific strength, high specific modulus, corrosion resistance, high temperature resistance, and good fatigue resistance. In recent years, it has been widely used in important fields such as aviation and aerospace. Compared with the high-strength medium-mold carbon fiber abroad, although there is T800 grade carbon fiber in China, the research work on high-performance carbon fiber in China has started late, and the research is not enough, and the products are not comparable to those in foreign countries. Sizing agent , as an important part of carbon fiber surface, has an important effect on the surface properties of carbon fiber and the interfacial properties of composites. The effect of sizing agent on domestic T800 carbon fiber was studied and analyzed by means of SEM, TGA and XPS. In this work, the surface characteristics of carbon fiber and the microscopic interface of the composite material has been studied, which provide a reference for the development of domestic high-performance carbon fiber products.

Carbon fiber has a series of excellent properties such as low density, high specific strength, high specific modulus, corrosion resistance, high temperature resistance, and good fatigue resistance. In recent years, it has been widely used in important fields such as aviation and aerospace. Compared with the high-strength medium-mold carbon fiber abroad, although there is T800 grade carbon fiber in China, the research work on high-performance carbon fiber in China has started late, and the research is not enough, and the products are not comparable to those in foreign countries. Sizing agent , as an important part of carbon fiber surface, has an important effect on the surface properties of carbon fiber and the interfacial properties of composites. The effect of sizing agent on domestic T800 carbon fiber was studied and analyzed by means of SEM, TGA and XPS. In this work, the surface characteristics of carbon fiber and the microscopic interface of the composite material has been studied, which provide a reference for the development of domestic high-performance carbon fiber products.

2022, 39(9): 4406-4419.

doi: 10.13801/j.cnki.fhclxb.20220916.002

Abstract:

Unidirectional carbon fiber reinforced epoxy resin composites (CFRP), glass fiber reinforced epoxy resin composites (GFRP) and flax fiber reinforced epoxy resin composites (FFRP) were manufactured with fiber volume fraction of 60vol% to compare the hygrothermal durability of composites. Water absorption tests were conducted at 23℃, 37.8℃ and 60℃. The swelling rate in the thickness direction, tensile properties and interlaminar shear properties were also monitored, and the time-temperature superposition principle was used to predict the water absorption and mechanical properties. The results show that the water absorption behaviors of three kinds of compo-sites conformed to Fickian's law in the early stage and gradually deviated in the later stage. In terms of water absorption performance, FFRP has the highest diffusion coefficient, saturation water absorption rate and swelling rate. In terms of mechanical properties, the tensile properties of CFRP are almost unchanged with the increase of aging time, while the interlaminar shear strength decreases slightly, and the tensile properties and interlaminar shear properties after drying are the same as those without aging, which indicate that no irreversible changes occurred in CFRP. The tensile strength and interlaminar shear strength of GFRP decrease a lot after aging, while the tensile modulus decrease less. The tensile properties are partially restored after drying, while the interlaminar shear strength is barely restored, which indicate that irreversible changes such as hydrolysis of glass fibers and interfacial debonding occurred during the aging process. Due to the plasticization of flax fibers after aging, the tensile strength of FFRP increase slightly while the tensile modulus and interlaminar shear strength decrease sharply and then remaine stable. After drying, the tensile strength decrease significantly, while the tensile modulus and interlaminar shear strength increase significantly, which are related to the changes of plasticization, expansion and degradation of fiber and matrix. From the long-term performance of the three kinds of composites, it can be seen that the long-term mechanical properties retention rates of CFRP are good, while that of GFRP are poor, and FFRP has an advantage in tensile strength retention rate. The results can provide a theoretical basis for the selection and design of engineering materials under hygrothermal environment.

Unidirectional carbon fiber reinforced epoxy resin composites (CFRP), glass fiber reinforced epoxy resin composites (GFRP) and flax fiber reinforced epoxy resin composites (FFRP) were manufactured with fiber volume fraction of 60vol% to compare the hygrothermal durability of composites. Water absorption tests were conducted at 23℃, 37.8℃ and 60℃. The swelling rate in the thickness direction, tensile properties and interlaminar shear properties were also monitored, and the time-temperature superposition principle was used to predict the water absorption and mechanical properties. The results show that the water absorption behaviors of three kinds of compo-sites conformed to Fickian's law in the early stage and gradually deviated in the later stage. In terms of water absorption performance, FFRP has the highest diffusion coefficient, saturation water absorption rate and swelling rate. In terms of mechanical properties, the tensile properties of CFRP are almost unchanged with the increase of aging time, while the interlaminar shear strength decreases slightly, and the tensile properties and interlaminar shear properties after drying are the same as those without aging, which indicate that no irreversible changes occurred in CFRP. The tensile strength and interlaminar shear strength of GFRP decrease a lot after aging, while the tensile modulus decrease less. The tensile properties are partially restored after drying, while the interlaminar shear strength is barely restored, which indicate that irreversible changes such as hydrolysis of glass fibers and interfacial debonding occurred during the aging process. Due to the plasticization of flax fibers after aging, the tensile strength of FFRP increase slightly while the tensile modulus and interlaminar shear strength decrease sharply and then remaine stable. After drying, the tensile strength decrease significantly, while the tensile modulus and interlaminar shear strength increase significantly, which are related to the changes of plasticization, expansion and degradation of fiber and matrix. From the long-term performance of the three kinds of composites, it can be seen that the long-term mechanical properties retention rates of CFRP are good, while that of GFRP are poor, and FFRP has an advantage in tensile strength retention rate. The results can provide a theoretical basis for the selection and design of engineering materials under hygrothermal environment.

2022, 39(9): 4420-4430.

doi: 10.13801/j.cnki.fhclxb.20220908.001

Abstract:

In recent years, with the rapid development and application of automated fiber placement (AFP), the demand for prepreg tow has increased considerably. However, no consensus has been achieved on the evaluation system including the analysis method of the quality of prepreg tows in domestic. In this paper, the quality of prepreg slitting tows had been comprehensively analyzed by systematic methods. It was found that the slitting qualities of the domestic prepreg tows, including the width uniformity, the paralleling degree of fibers at the joint and the fiber fracture at the edge were all well controlled by using image and weight analysis. Effect of preparation methods, namely discontinuous hot-press process and continuous rolling process, on the quality of tow joint was investi-gated through the tensile-shear strength and peeling force testing. The results show that the process temperature and the time of duration are the key factors. In contrast, the joints made by continuous rolling process have more stable mechanical properties than those prepared by hot-press process. Meanwhile, the joint performance is impacted by the environmental conditions, wherein the humidity has more significant influence than the test temperature. With the prolongation of storage at room temperature, the mechanical properties of the joints first increased and then decreased. The DSC and IR characterization indicates that the property changes relate closely to chemical reactions and increasing curing degree of the resin matrix at the interface. The fatigue performance of the joint was tested by repeated roller passing and subsequent damage analysis. It reveals that the tensile-shear strengths of the fatigued joints decrease with increasing roller temperature, higher tension and more turns.

In recent years, with the rapid development and application of automated fiber placement (AFP), the demand for prepreg tow has increased considerably. However, no consensus has been achieved on the evaluation system including the analysis method of the quality of prepreg tows in domestic. In this paper, the quality of prepreg slitting tows had been comprehensively analyzed by systematic methods. It was found that the slitting qualities of the domestic prepreg tows, including the width uniformity, the paralleling degree of fibers at the joint and the fiber fracture at the edge were all well controlled by using image and weight analysis. Effect of preparation methods, namely discontinuous hot-press process and continuous rolling process, on the quality of tow joint was investi-gated through the tensile-shear strength and peeling force testing. The results show that the process temperature and the time of duration are the key factors. In contrast, the joints made by continuous rolling process have more stable mechanical properties than those prepared by hot-press process. Meanwhile, the joint performance is impacted by the environmental conditions, wherein the humidity has more significant influence than the test temperature. With the prolongation of storage at room temperature, the mechanical properties of the joints first increased and then decreased. The DSC and IR characterization indicates that the property changes relate closely to chemical reactions and increasing curing degree of the resin matrix at the interface. The fatigue performance of the joint was tested by repeated roller passing and subsequent damage analysis. It reveals that the tensile-shear strengths of the fatigued joints decrease with increasing roller temperature, higher tension and more turns.

2022, 39(9): 4431-4440.

doi: 10.13801/j.cnki.fhclxb.20220530.001

Abstract:

In order to improve the comprehensive electrochemical performance of the CoFe2O4 electrode material for lithium-ion batteries (LIBs), the CoFe2O4 is integrated with highly conductive carbon materials. Flexible carbon nanofibers uniformly embedded with CoFe2O4 nanoparticles (CoFe2O4@CNFs) composite films were synthesized by an electrospinning and subsequent low-temperature carbonization process, and were characterized by XRD, TG, Raman, SEM, TEM, CV, GCD and EIS. The influence of CoFe2O4 content on the lithium storage performances of CoFe2O4@CNFs composites was investigated in detail. It is found that the as-prepared composite films directly used as self-standing anodes in lithium ion batteries exhibit good electrochemical properties. The incorporation of CoFe2O4 nanoparticles into CNFs can significantly improve their electrochemical performances, and the specific capacities first increase and then decrease with increasing CoFe2O4 content in CoFe2O4@CNFs, in which the CoFe2O4@CNFs-3 electrode with about 33.3% (w/w) CoFe2O4 presents an optimal specific capacity as well as better cycle stability and rate capability. The CoFe2O4@CNFs-3 electrode delivers a high reversible specific capacity of 611.4 mA·h·g−1 after 100 charge/discharge cycles at the current density of 0.1 A·g−1, corresponding to a capacity retention of 94% relative to the capacity of the second cycle. Moreover, even at a high current density of 2 A·g−1, the specific capacity still remains at 353.6 mA·h·g−1. The superior performance for CoFe2O4@CNFs-3 is mainly attributed to the proper combination and highly synergistic effect of electrochemically active CoFe2O4 and high conductive CNFs matrix.

In order to improve the comprehensive electrochemical performance of the CoFe2O4 electrode material for lithium-ion batteries (LIBs), the CoFe2O4 is integrated with highly conductive carbon materials. Flexible carbon nanofibers uniformly embedded with CoFe2O4 nanoparticles (CoFe2O4@CNFs) composite films were synthesized by an electrospinning and subsequent low-temperature carbonization process, and were characterized by XRD, TG, Raman, SEM, TEM, CV, GCD and EIS. The influence of CoFe2O4 content on the lithium storage performances of CoFe2O4@CNFs composites was investigated in detail. It is found that the as-prepared composite films directly used as self-standing anodes in lithium ion batteries exhibit good electrochemical properties. The incorporation of CoFe2O4 nanoparticles into CNFs can significantly improve their electrochemical performances, and the specific capacities first increase and then decrease with increasing CoFe2O4 content in CoFe2O4@CNFs, in which the CoFe2O4@CNFs-3 electrode with about 33.3% (w/w) CoFe2O4 presents an optimal specific capacity as well as better cycle stability and rate capability. The CoFe2O4@CNFs-3 electrode delivers a high reversible specific capacity of 611.4 mA·h·g−1 after 100 charge/discharge cycles at the current density of 0.1 A·g−1, corresponding to a capacity retention of 94% relative to the capacity of the second cycle. Moreover, even at a high current density of 2 A·g−1, the specific capacity still remains at 353.6 mA·h·g−1. The superior performance for CoFe2O4@CNFs-3 is mainly attributed to the proper combination and highly synergistic effect of electrochemically active CoFe2O4 and high conductive CNFs matrix.

2022, 39(9): 4441-4458.

doi: 10.13801/j.cnki.fhclxb.20220824.003

Abstract:

In order to guarantee the good adhesion between layers of dry fiber preform, the interlayer bonding properties of two kinds of automatic fiber placement dry fiber tows were investigated, one has been maturely used in aerospace primary force-taking structure and the other one is under development. Dry fiber laminate samples were prepared by hot pressing to simulate the automatic fiber placement. The interlayer bonding property, surface properties and binder extension of dry fibers were measured by the T-type peeling test and various characterization methods. The interlayer bonding strength of the two kinds of dry fibers was compared and the interlayer bonding mechanism was studied. The results show that the interlayer bonding strength of mature dry fibers is much greater than that of developing dry fibers in a certain temperature range. Both of them are significantly affected by lamination temperature, lamination time and the synergistic effect, but the most significant factors of the two materials are different. The interlayer bonding mechanism of dry fibers is related to surface properties of dry fibers, properties of binder and the binder extension at elevated temperature. It is speculated that the interlayer bonding force of mature dry fibers is related to the crosslinking of the binder. In addition, through the verification of the automatic laying process, the hot pressing process has good reliability in the evaluation of interlayer bonding between the dry fiber layers within a certain lamination time comparing to the automatic fiber placement. Finally, when the dry fiber surface is coated with the thermoplastic toughening material, the adhesion between layers decreases significantly. Through the study of materials and technology, this paper provides data and theoretical support for the optimization of automatic fiber placement process.

In order to guarantee the good adhesion between layers of dry fiber preform, the interlayer bonding properties of two kinds of automatic fiber placement dry fiber tows were investigated, one has been maturely used in aerospace primary force-taking structure and the other one is under development. Dry fiber laminate samples were prepared by hot pressing to simulate the automatic fiber placement. The interlayer bonding property, surface properties and binder extension of dry fibers were measured by the T-type peeling test and various characterization methods. The interlayer bonding strength of the two kinds of dry fibers was compared and the interlayer bonding mechanism was studied. The results show that the interlayer bonding strength of mature dry fibers is much greater than that of developing dry fibers in a certain temperature range. Both of them are significantly affected by lamination temperature, lamination time and the synergistic effect, but the most significant factors of the two materials are different. The interlayer bonding mechanism of dry fibers is related to surface properties of dry fibers, properties of binder and the binder extension at elevated temperature. It is speculated that the interlayer bonding force of mature dry fibers is related to the crosslinking of the binder. In addition, through the verification of the automatic laying process, the hot pressing process has good reliability in the evaluation of interlayer bonding between the dry fiber layers within a certain lamination time comparing to the automatic fiber placement. Finally, when the dry fiber surface is coated with the thermoplastic toughening material, the adhesion between layers decreases significantly. Through the study of materials and technology, this paper provides data and theoretical support for the optimization of automatic fiber placement process.

2022, 39(9): 4459-4470.

doi: 10.13801/j.cnki.fhclxb.20220725.002

Abstract:

The mechanical properties of needling carbon/phenolic composites were simulated and described along with a general finite element modeling (FEM) approach for 3D needling composites. First, the numerical simulation of the needling process of laminated materials was accomplished using virtual fiber technology with the commercial FEM program ABAQUS, and the deformation of the fiber near the needling area in the formation process was simulated. Based on this, a correlation between fiber orientation, damage rate, and needling parameters was found in the needling process-affected area. This relationship was then introduced into the representative volume element (RVE) of needling composites, which can accurately reflect the structural characteristics of real materials. This model was used to predict the stiffness and strength of materials, and the results are in good agreement with the experimental values, which verifies the validity of the model. Based on this, the effects of needling parameters, such as needling density and needing depth, on mechanical properties of composites were discussed. The results of this study are expected to contribute to the mechanical analysis and optimal design of needling composites.

The mechanical properties of needling carbon/phenolic composites were simulated and described along with a general finite element modeling (FEM) approach for 3D needling composites. First, the numerical simulation of the needling process of laminated materials was accomplished using virtual fiber technology with the commercial FEM program ABAQUS, and the deformation of the fiber near the needling area in the formation process was simulated. Based on this, a correlation between fiber orientation, damage rate, and needling parameters was found in the needling process-affected area. This relationship was then introduced into the representative volume element (RVE) of needling composites, which can accurately reflect the structural characteristics of real materials. This model was used to predict the stiffness and strength of materials, and the results are in good agreement with the experimental values, which verifies the validity of the model. Based on this, the effects of needling parameters, such as needling density and needing depth, on mechanical properties of composites were discussed. The results of this study are expected to contribute to the mechanical analysis and optimal design of needling composites.

2022, 39(9): 4471-4482.

doi: 10.13801/j.cnki.fhclxb.20220719.002

Abstract:

Fiber network material is a kind of multifunctional lightweight material which exists widely and has important application prospect. At present, researches mainly focus on networks consisting of one type of fibers. However, in practice, most fiber networks are hybrid fiber networks composed of fibers with different properties, which have larger performance and function design space but more complex failure mechanism. In order to further improve the mechanical properties of fiber networks, it is very important to study the failure process and failure mechanism of hybrid fiber networks. Therefore, the hybrid fiber network model was established in this paper to take account of both the mechanical properties of fibers and the inter-fiber connections. Based on the model, the failure process of hybrid fiber networks was systematically studied, and the effects of the fiber mixture ratio, the strength of inter-fiber connections and the total fiber volume fraction were analyzed. The results show that for typical hybrid fiber networks, there are three failure modes: inter-fiber connection dominated failure, inter-fiber connection and fiber co-dominated failure, and fiber dominated failure, with the variation of fiber mixture ratio. When the failure is co-dominated by the connection and fiber damages, the damages disperse throughout the network, and the network presents better toughness and strength. Therefore, the design space of mechanical properties of hybrid fiber network is much larger than that of networks consisting of only one type of fibers, and the hybrid network exhibits a wider application prospect.

Fiber network material is a kind of multifunctional lightweight material which exists widely and has important application prospect. At present, researches mainly focus on networks consisting of one type of fibers. However, in practice, most fiber networks are hybrid fiber networks composed of fibers with different properties, which have larger performance and function design space but more complex failure mechanism. In order to further improve the mechanical properties of fiber networks, it is very important to study the failure process and failure mechanism of hybrid fiber networks. Therefore, the hybrid fiber network model was established in this paper to take account of both the mechanical properties of fibers and the inter-fiber connections. Based on the model, the failure process of hybrid fiber networks was systematically studied, and the effects of the fiber mixture ratio, the strength of inter-fiber connections and the total fiber volume fraction were analyzed. The results show that for typical hybrid fiber networks, there are three failure modes: inter-fiber connection dominated failure, inter-fiber connection and fiber co-dominated failure, and fiber dominated failure, with the variation of fiber mixture ratio. When the failure is co-dominated by the connection and fiber damages, the damages disperse throughout the network, and the network presents better toughness and strength. Therefore, the design space of mechanical properties of hybrid fiber network is much larger than that of networks consisting of only one type of fibers, and the hybrid network exhibits a wider application prospect.

2022, 39(9): 4483-4497.

doi: 10.13801/j.cnki.fhclxb.20220928.001

Abstract:

This paper studied the damage failure mechanism of fiber-reinforced ceramic composites under unidirectional loading. According to the conventional shear-lag model, Coulomb’s law was introduced to describe the interfacial shear stress. According to the energy balance method and the debonding criterion of fracture mechanics, the steady-state cracking stress of the matrix and the debonding length of the interface were calculated. The difference and applicable range of the steady-state cracking stress of the matrix under different shear lag models were analyzed, and the effects of the interfacial shear stress, the interfacial friction coefficient, the interfacial debonding energy, and the fiber volume fraction on the steady-state cracking stress of the matrix were discussed. The shear lag model was used to describe the microstructure stress field of the fiber-reinforced ceramic composites after damage, the distance between the matrix cracks was determined according to the random evolution method of matrix cracks, and the debonding behavior of the interface was described according to the fracture mechanics debonding criterion. Combined with the damage model, the stress-strain curve of unidirectional fiber-reinforced ceramic composites under unidirectional load was predicted, and the influence of various factors on the stress-strain curve was discussed.

This paper studied the damage failure mechanism of fiber-reinforced ceramic composites under unidirectional loading. According to the conventional shear-lag model, Coulomb’s law was introduced to describe the interfacial shear stress. According to the energy balance method and the debonding criterion of fracture mechanics, the steady-state cracking stress of the matrix and the debonding length of the interface were calculated. The difference and applicable range of the steady-state cracking stress of the matrix under different shear lag models were analyzed, and the effects of the interfacial shear stress, the interfacial friction coefficient, the interfacial debonding energy, and the fiber volume fraction on the steady-state cracking stress of the matrix were discussed. The shear lag model was used to describe the microstructure stress field of the fiber-reinforced ceramic composites after damage, the distance between the matrix cracks was determined according to the random evolution method of matrix cracks, and the debonding behavior of the interface was described according to the fracture mechanics debonding criterion. Combined with the damage model, the stress-strain curve of unidirectional fiber-reinforced ceramic composites under unidirectional load was predicted, and the influence of various factors on the stress-strain curve was discussed.

2022, 39(9): 4498-4508.

doi: 10.13801/j.cnki.fhclxb.20220329.001

Abstract:

Carbon fiber reinforced polymer (CFRP) is gradually used in aircraft main load-bearing structure due to its good mechanical properties. Delamination is one of the most common damage forms of composite laminates, and it is also the focus of damage tolerance design and analysis of aircraft composite structures. For mode II delamination, the existing research mainly focuses on unidirectional laminates, while multidirectional laminates are widely used in engineering practice, and there is a lack of in-depth understanding of the influence of ply angle on mode II delamination. Therefore, experimental and numerical investigations were conducted in this paper. Firstly, three different interfaces (0°/5°, 45°/−45° and 90°/90°) were designed for composite laminates made of T700/QY9511 carbon fiber/bismaleimide prepregs, in order to reduce the coupling effect and ensure the mode II dominant delamination propagation. The mode II delamination test was carried out using end-notched flexure device and the fracture toughness was measured. The results show that the ply angle has a significant effect on the fracture toughness and delamination failure behavior. The control variable method is used for establishing the key parameter model of cohesive zone model. On this basis, the simulation of mode II delamination propagation behavior of multidirectional laminates is realized. The predicted load-displacement curve response is in good agreement with the experimental results, which shows the effectiveness of the finite element model. The finite element results show that the energy dissipated by the matrix damage increases with the increase of interfacial angle. In order to reveal the relationship between the energy dissipated by matrix damage and the size of damage area around the crack tip, the damage area around the crack tip of specimens with different interfaces was simulated by using user-defined subroutine.

Carbon fiber reinforced polymer (CFRP) is gradually used in aircraft main load-bearing structure due to its good mechanical properties. Delamination is one of the most common damage forms of composite laminates, and it is also the focus of damage tolerance design and analysis of aircraft composite structures. For mode II delamination, the existing research mainly focuses on unidirectional laminates, while multidirectional laminates are widely used in engineering practice, and there is a lack of in-depth understanding of the influence of ply angle on mode II delamination. Therefore, experimental and numerical investigations were conducted in this paper. Firstly, three different interfaces (0°/5°, 45°/−45° and 90°/90°) were designed for composite laminates made of T700/QY9511 carbon fiber/bismaleimide prepregs, in order to reduce the coupling effect and ensure the mode II dominant delamination propagation. The mode II delamination test was carried out using end-notched flexure device and the fracture toughness was measured. The results show that the ply angle has a significant effect on the fracture toughness and delamination failure behavior. The control variable method is used for establishing the key parameter model of cohesive zone model. On this basis, the simulation of mode II delamination propagation behavior of multidirectional laminates is realized. The predicted load-displacement curve response is in good agreement with the experimental results, which shows the effectiveness of the finite element model. The finite element results show that the energy dissipated by the matrix damage increases with the increase of interfacial angle. In order to reveal the relationship between the energy dissipated by matrix damage and the size of damage area around the crack tip, the damage area around the crack tip of specimens with different interfaces was simulated by using user-defined subroutine.