2022 Vol. 39, No. 10

2022, 39(10): 4509-4517.

doi: 10.13801/j.cnki.fhclxb.20211109.001

Abstract:

Due to the fast curing speed, high precision and smooth surface, UV-curing 3D printing has become one of the preferred technologies to rapidly manufacture sophisticated devices. However, the photosensitive resins for UV-curing 3D printing are still challenged by poor mechanical strength and toughness. Carbon fiber has been widely utilized in diverse structural or functional composites because of its excellent characteristics like electrical conductivity, heat conductivity, high specific strength and high specific modulus. Therefore, modified short carbon fiber (MCF) was prepared by chemical oxidation and modification with silane coupling agent (KH580). Then, the modified carbon fiber/photosensitive resin (MCF/PR) composite was prepared by compositing MCF with 3D printing photosensitive resin (PR). The UV-curing kinetics of MCF/PR composite and mechanical performances of 3D printed samples were also studied. The results indicate that when the grafted amount of KH580 is 0.5wt% and the content of MCF is 0.15wt%, the viscosity of MCF/PR composite is increased to some extent, but the curing depth and critical exposure are insignificantly influenced by MCF, which still meets the requirements of UV-curing 3D printing. A variety of devices are successfully fabricated by stereolithography (SLA) 3D printing. The tensile strength and impact strength of 3D printed samples are 70 MPa and 1.91 kJ/m2, respectively, which are increased by about 100% and 60% compared with pure PR. Moreover, the 3D printed MCF/PR composite has good thermostability below 350℃.

Due to the fast curing speed, high precision and smooth surface, UV-curing 3D printing has become one of the preferred technologies to rapidly manufacture sophisticated devices. However, the photosensitive resins for UV-curing 3D printing are still challenged by poor mechanical strength and toughness. Carbon fiber has been widely utilized in diverse structural or functional composites because of its excellent characteristics like electrical conductivity, heat conductivity, high specific strength and high specific modulus. Therefore, modified short carbon fiber (MCF) was prepared by chemical oxidation and modification with silane coupling agent (KH580). Then, the modified carbon fiber/photosensitive resin (MCF/PR) composite was prepared by compositing MCF with 3D printing photosensitive resin (PR). The UV-curing kinetics of MCF/PR composite and mechanical performances of 3D printed samples were also studied. The results indicate that when the grafted amount of KH580 is 0.5wt% and the content of MCF is 0.15wt%, the viscosity of MCF/PR composite is increased to some extent, but the curing depth and critical exposure are insignificantly influenced by MCF, which still meets the requirements of UV-curing 3D printing. A variety of devices are successfully fabricated by stereolithography (SLA) 3D printing. The tensile strength and impact strength of 3D printed samples are 70 MPa and 1.91 kJ/m2, respectively, which are increased by about 100% and 60% compared with pure PR. Moreover, the 3D printed MCF/PR composite has good thermostability below 350℃.

2022, 39(10): 4518-4530.

doi: 10.13801/j.cnki.fhclxb.20211228.001

Abstract:

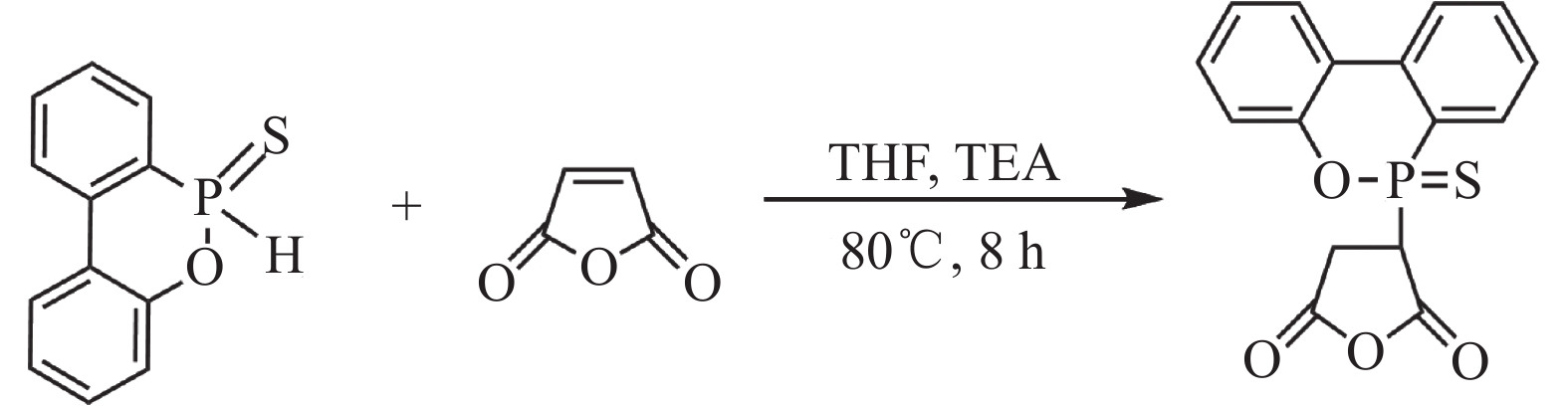

In order to obtain the flame retardant epoxy resin (EP) composites with good comprehensive properties, the 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-sulfide (DOPS) derivative was applied to EP. First, maleic anhydride-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-sulfide (MAH-DOPS) was synthesized by the reaction of DOPS and maleic anhydride (MAH). The structure was determined by FTIR, 1H NMR and 31P NMR. Secondly, DOPS and MAH-DOPS were added to EP respectively, to prepare composites DOPS/EP and MAH-DOPS/EP by blending. Thirdly, the thermal stability, flame retardancy and mechanical properties of DOPS/EP and MAH-DOPS/EP were compared. Finally, the effects of MAH-DOPS on the combustion performance and thermal degradation behavior of EP were discussed, and its flame retardant mechanism was analyzed in depth. The results show that the initial decomposition temperature of flame retardant DOPS (205.4℃) is lower than that of MAH-DOPS (235.2℃), and the thermal stability of DOPS/EP is lower than that of MAH-DOPS/EP when the same mass fraction of flame retardants is added, which is consistent with the thermal stability of flame retardants. Both flame retardants DOPS and MAH-DOPS can improve the flame retardancy of EP, and MAH-DOPS/EP has better flame retardant effect. When the amount of flame retardant is 15wt%, limit oxygen index (LOI) values of MAH-DOPS/EP and DOPS/EP are 28.6% and 29.1%, reaching UL-94 V-0 and V-1 rating, respectively. The mechanical test results show that compared with EP, the bending strength of MAH-DOPS/EP increases by 45.8%, while DOPS/EP decreases by 62.5%. The mechanical properties of DOPS/EP system decrease obviously, and almost lose the use value. Cone calorimeter tests show that the average heat release rate (av-HRR) and total heat release (THR) of the composite MAH-DOPS/EP decrease significantly. The results of TG-IR show that the H•, O• or HO• free radicals are captured by the phosphorus-containing free radicals generated by the pyrolysis of MAH-DOPS/EP, and the free radicals are quenched. SEM-EDS results show that MAH-DOPS/EP can form a more complete and compact char layer, and the content of P in the char layer is higher. The study shows that MAH-DOPS plays a flame retardant role in gas phase and condensed phase through flame suppression and char formation respectively, and the gas phase flame retardant mechanism is the main one.

In order to obtain the flame retardant epoxy resin (EP) composites with good comprehensive properties, the 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-sulfide (DOPS) derivative was applied to EP. First, maleic anhydride-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-sulfide (MAH-DOPS) was synthesized by the reaction of DOPS and maleic anhydride (MAH). The structure was determined by FTIR, 1H NMR and 31P NMR. Secondly, DOPS and MAH-DOPS were added to EP respectively, to prepare composites DOPS/EP and MAH-DOPS/EP by blending. Thirdly, the thermal stability, flame retardancy and mechanical properties of DOPS/EP and MAH-DOPS/EP were compared. Finally, the effects of MAH-DOPS on the combustion performance and thermal degradation behavior of EP were discussed, and its flame retardant mechanism was analyzed in depth. The results show that the initial decomposition temperature of flame retardant DOPS (205.4℃) is lower than that of MAH-DOPS (235.2℃), and the thermal stability of DOPS/EP is lower than that of MAH-DOPS/EP when the same mass fraction of flame retardants is added, which is consistent with the thermal stability of flame retardants. Both flame retardants DOPS and MAH-DOPS can improve the flame retardancy of EP, and MAH-DOPS/EP has better flame retardant effect. When the amount of flame retardant is 15wt%, limit oxygen index (LOI) values of MAH-DOPS/EP and DOPS/EP are 28.6% and 29.1%, reaching UL-94 V-0 and V-1 rating, respectively. The mechanical test results show that compared with EP, the bending strength of MAH-DOPS/EP increases by 45.8%, while DOPS/EP decreases by 62.5%. The mechanical properties of DOPS/EP system decrease obviously, and almost lose the use value. Cone calorimeter tests show that the average heat release rate (av-HRR) and total heat release (THR) of the composite MAH-DOPS/EP decrease significantly. The results of TG-IR show that the H•, O• or HO• free radicals are captured by the phosphorus-containing free radicals generated by the pyrolysis of MAH-DOPS/EP, and the free radicals are quenched. SEM-EDS results show that MAH-DOPS/EP can form a more complete and compact char layer, and the content of P in the char layer is higher. The study shows that MAH-DOPS plays a flame retardant role in gas phase and condensed phase through flame suppression and char formation respectively, and the gas phase flame retardant mechanism is the main one.

2022, 39(10): 4531-4539.

doi: 10.13801/j.cnki.fhclxb.20211028.007

Abstract:

The development of polymer-based thermally conductive composites with low filling and high thermally conductivity remains a bottleneck problem that needs to be solved. Based on the layer-by-layer hydrogen-bond assembly, the low filling and high thermally conductive BNNS@PDA/PU composites are prepared by the dip coating-hot pressing method, using the porous polyurethane (PU) foams as template, and polydopamine functionalized nitride boron nanosheets (BNNS@PDA) as thermally conductive fillers. The microstructures, thermal conductive properties and thermal stability of BNNS@PDA and BNNS@PDA/PU composites were investigated in detail. The results show that the surface functionalization of BNNS by PDA can make it coat well on the three-dimensional skeleton of porous PU foams. After hot pressing, the highly effective double heat-conduction networks with the PU skeleton as the main heat-conduction network and BNNS@PDA on the surface of PU skeleton as the secondary heat-conduction network are constructed, leading to the decreased interfacial thermal resistance of the thermally conductive composites. When the filling amount of BNNS@PDA is 16.3wt%, the thermal conductivity of BNNS@PDA/PU composites with double heat-conduction networks reaches 0.783 W/(m·K), which is 102.3% higher than that of PU with single heat-conduction network (0.387 W/(m·K)).

The development of polymer-based thermally conductive composites with low filling and high thermally conductivity remains a bottleneck problem that needs to be solved. Based on the layer-by-layer hydrogen-bond assembly, the low filling and high thermally conductive BNNS@PDA/PU composites are prepared by the dip coating-hot pressing method, using the porous polyurethane (PU) foams as template, and polydopamine functionalized nitride boron nanosheets (BNNS@PDA) as thermally conductive fillers. The microstructures, thermal conductive properties and thermal stability of BNNS@PDA and BNNS@PDA/PU composites were investigated in detail. The results show that the surface functionalization of BNNS by PDA can make it coat well on the three-dimensional skeleton of porous PU foams. After hot pressing, the highly effective double heat-conduction networks with the PU skeleton as the main heat-conduction network and BNNS@PDA on the surface of PU skeleton as the secondary heat-conduction network are constructed, leading to the decreased interfacial thermal resistance of the thermally conductive composites. When the filling amount of BNNS@PDA is 16.3wt%, the thermal conductivity of BNNS@PDA/PU composites with double heat-conduction networks reaches 0.783 W/(m·K), which is 102.3% higher than that of PU with single heat-conduction network (0.387 W/(m·K)).

2022, 39(10): 4540-4550.

doi: 10.13801/j.cnki.fhclxb.20211119.002

Abstract:

In order to reduce the melting point of polyacrylonitrile (PAN) and improve the properties of melt-spun PAN fibers, the effects of isotropic naphthalene pitch (INP) and coal tar pitch (ICP) as plasticizers on 85∶14∶1 mole percent poly(acrylonitrile-methyl acrylate-4-acryloxy dibenzophenone) terpolymer (P(AN-MA-ABP)) were investigated in detail. The 1wt%INP/P(AN-MA-ABP) terpolymer fibers were prepared by mixing 1wt%INP with P(AN-MA-ABP), and then melting spinning and drawing. The effects of UV irradiation time on 1wt%INP/P(AN-MA-ABP) terpolymer fibers were studied. The results show that the long-chain sulfur heterocyclic INP has a better plasticizing effect than the ICP with a thick ring structure. The diameter of the 1wt%INP/P(AN-MA-ABP) terpolymer fibers is about 52 μm, and the tensile strength is about 250 MPa, which has a smooth surface and a dense structure. Delaying the UV irradiation from 0 min to 60 min, the oxygen content on the surface of 1wt%INP/P(AN-MA-ABP) terpolymer fibers increases from 17.3% to 26.0%. Under nitrogen conditions, the initial cyclization temperature decreases from 303.8℃ to 292.4℃, and the cyclization peak temperature decreases from 318.0℃ to 308.8℃. Under air conditions, the initial cyclization temperature decrease from 299.9℃ to 295.0℃, and the cyclization peak temperature decreases from 316.4℃ to 312.6℃. After UV irradiation for 20 min, the carbon yield of 1wt%INP/P(AN-MA-ABP) terpolymer fibers carbonized at 800℃ under nitrogen increases from 41.0% to 43.4%. UV irradiation decreases the initial cyclization temperature, peak temperature, and enthalpy value of 1wt%INP/P(AN-MA-ABP) terpolymer fibers and increases the carbon yield, which are beneficial to the subsequent heat-treatment process.

In order to reduce the melting point of polyacrylonitrile (PAN) and improve the properties of melt-spun PAN fibers, the effects of isotropic naphthalene pitch (INP) and coal tar pitch (ICP) as plasticizers on 85∶14∶1 mole percent poly(acrylonitrile-methyl acrylate-4-acryloxy dibenzophenone) terpolymer (P(AN-MA-ABP)) were investigated in detail. The 1wt%INP/P(AN-MA-ABP) terpolymer fibers were prepared by mixing 1wt%INP with P(AN-MA-ABP), and then melting spinning and drawing. The effects of UV irradiation time on 1wt%INP/P(AN-MA-ABP) terpolymer fibers were studied. The results show that the long-chain sulfur heterocyclic INP has a better plasticizing effect than the ICP with a thick ring structure. The diameter of the 1wt%INP/P(AN-MA-ABP) terpolymer fibers is about 52 μm, and the tensile strength is about 250 MPa, which has a smooth surface and a dense structure. Delaying the UV irradiation from 0 min to 60 min, the oxygen content on the surface of 1wt%INP/P(AN-MA-ABP) terpolymer fibers increases from 17.3% to 26.0%. Under nitrogen conditions, the initial cyclization temperature decreases from 303.8℃ to 292.4℃, and the cyclization peak temperature decreases from 318.0℃ to 308.8℃. Under air conditions, the initial cyclization temperature decrease from 299.9℃ to 295.0℃, and the cyclization peak temperature decreases from 316.4℃ to 312.6℃. After UV irradiation for 20 min, the carbon yield of 1wt%INP/P(AN-MA-ABP) terpolymer fibers carbonized at 800℃ under nitrogen increases from 41.0% to 43.4%. UV irradiation decreases the initial cyclization temperature, peak temperature, and enthalpy value of 1wt%INP/P(AN-MA-ABP) terpolymer fibers and increases the carbon yield, which are beneficial to the subsequent heat-treatment process.

2022, 39(10): 4551-4560.

doi: 10.13801/j.cnki.fhclxb.20211101.001

Abstract:

Water-assisted co-injection molding (WACIM) technology is an novel injection molding process that combines co-injection molding technology and water-assisted injection molding technology. Its special process makes the glass fiber reinforced composite used in the process have special characteristics of fiber orientation and enhancement. WACIM pipes with polypropylene (PP) as inner material and short glass fiber reinforced polypropylene (GF/PP) as outer material were prepared to investigate the effects of glass fiber mass fraction on the thicknesses of pipe inner and outer layers, glass fiber orientation and tensile strength. It is found that when the mass fraction of glass fiber is less than 30wt%, the variations of pipe inner and outer layer thicknesses are not obvious. When the mass fraction of glass fiber increases to 40wt%, both the inner and outer layer thicknesses of pipe increase. According to the distribution characteristics of glass fiber orientation, the outer layer of WACIM pipes can be divided into three layers: Near interface layer, intermediate layer and near mold wall layer. The orientation degree of glass fiber along the flow direction decreases from inside to outside. The tensile properties of pipes increased first and then decreased with the increase of glass fiber mass fraction. The highest tensile strength of pipes can be obtained when the glass fiber mass fraction is 30wt%. It is found by comparison that the influences of glass fiber mass fraction on thickness, glass fiber orientation and tensile strength of WACIM and water-assisted injection molding (WAIM) pipes are different, and the influence mechanism are different.

Water-assisted co-injection molding (WACIM) technology is an novel injection molding process that combines co-injection molding technology and water-assisted injection molding technology. Its special process makes the glass fiber reinforced composite used in the process have special characteristics of fiber orientation and enhancement. WACIM pipes with polypropylene (PP) as inner material and short glass fiber reinforced polypropylene (GF/PP) as outer material were prepared to investigate the effects of glass fiber mass fraction on the thicknesses of pipe inner and outer layers, glass fiber orientation and tensile strength. It is found that when the mass fraction of glass fiber is less than 30wt%, the variations of pipe inner and outer layer thicknesses are not obvious. When the mass fraction of glass fiber increases to 40wt%, both the inner and outer layer thicknesses of pipe increase. According to the distribution characteristics of glass fiber orientation, the outer layer of WACIM pipes can be divided into three layers: Near interface layer, intermediate layer and near mold wall layer. The orientation degree of glass fiber along the flow direction decreases from inside to outside. The tensile properties of pipes increased first and then decreased with the increase of glass fiber mass fraction. The highest tensile strength of pipes can be obtained when the glass fiber mass fraction is 30wt%. It is found by comparison that the influences of glass fiber mass fraction on thickness, glass fiber orientation and tensile strength of WACIM and water-assisted injection molding (WAIM) pipes are different, and the influence mechanism are different.

2022, 39(10): 4561-4571.

doi: 10.13801/j.cnki.fhclxb.20211012.001

Abstract:

Thermoplastic polyurethane elastomer (TPU) was equipped with excellent properties, which was widely used in various fields of industry and living. However, the application scope of TPU was limited because the material was a kind of organic polymer material with high inflammability. Moreover, a large amount of CO, CO2, NOx and other toxic asphyxiating gases from TPU material were released during combustion. The design of MXene-based hybrid flame retardant based on layered titanium carbide (Ti3C2Tx) and manganese dioxide (MnO2) was proposed for preparation of MXene-based hybrid/TPU nanocomposites. The mechanisms of flame retardancy, smoke suppression and toxicity reduction of the TPU nanocomposites were studied by means of TGA, XRD, SEM and other techniques. In the case of Ti3C2Tx-MnO2/TPU systems, the total heat release (THR), the total smoke release (TSR), the total CO yield (CO TY) and the total CO2 yield (CO2 TY) of the TPU nanocomposite were maximally decreased by 28.62%, 33.41%, 34.12% and 29.77% respectively compared to those of TPU, besides 91.89% increase in residual char at 700℃. According to the analysis, Ti3C2Tx in MXene-based hybrid flame retardant was oxidized to TiO2 and co-catalyzed with MnO2 to form carbon, which not only improved the continuity and compactness of carbon layer after combustion of nanocomposite materials, but also blocked the entry of heat and oxygen and inhibit the release of flue gas.

Thermoplastic polyurethane elastomer (TPU) was equipped with excellent properties, which was widely used in various fields of industry and living. However, the application scope of TPU was limited because the material was a kind of organic polymer material with high inflammability. Moreover, a large amount of CO, CO2, NOx and other toxic asphyxiating gases from TPU material were released during combustion. The design of MXene-based hybrid flame retardant based on layered titanium carbide (Ti3C2Tx) and manganese dioxide (MnO2) was proposed for preparation of MXene-based hybrid/TPU nanocomposites. The mechanisms of flame retardancy, smoke suppression and toxicity reduction of the TPU nanocomposites were studied by means of TGA, XRD, SEM and other techniques. In the case of Ti3C2Tx-MnO2/TPU systems, the total heat release (THR), the total smoke release (TSR), the total CO yield (CO TY) and the total CO2 yield (CO2 TY) of the TPU nanocomposite were maximally decreased by 28.62%, 33.41%, 34.12% and 29.77% respectively compared to those of TPU, besides 91.89% increase in residual char at 700℃. According to the analysis, Ti3C2Tx in MXene-based hybrid flame retardant was oxidized to TiO2 and co-catalyzed with MnO2 to form carbon, which not only improved the continuity and compactness of carbon layer after combustion of nanocomposite materials, but also blocked the entry of heat and oxygen and inhibit the release of flue gas.

2022, 39(10): 4572-4579.

doi: 10.13801/j.cnki.fhclxb.20211027.002

Abstract:

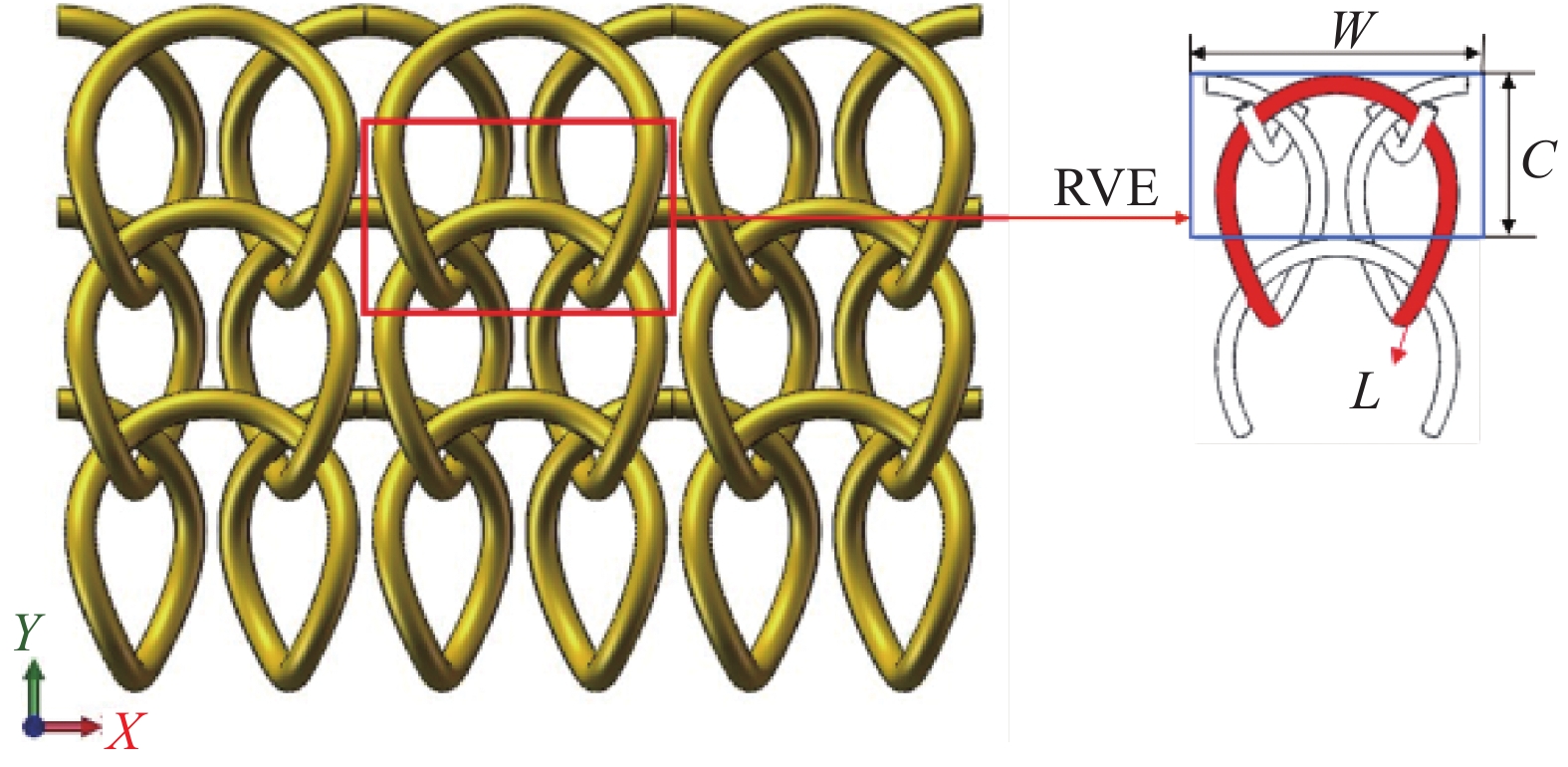

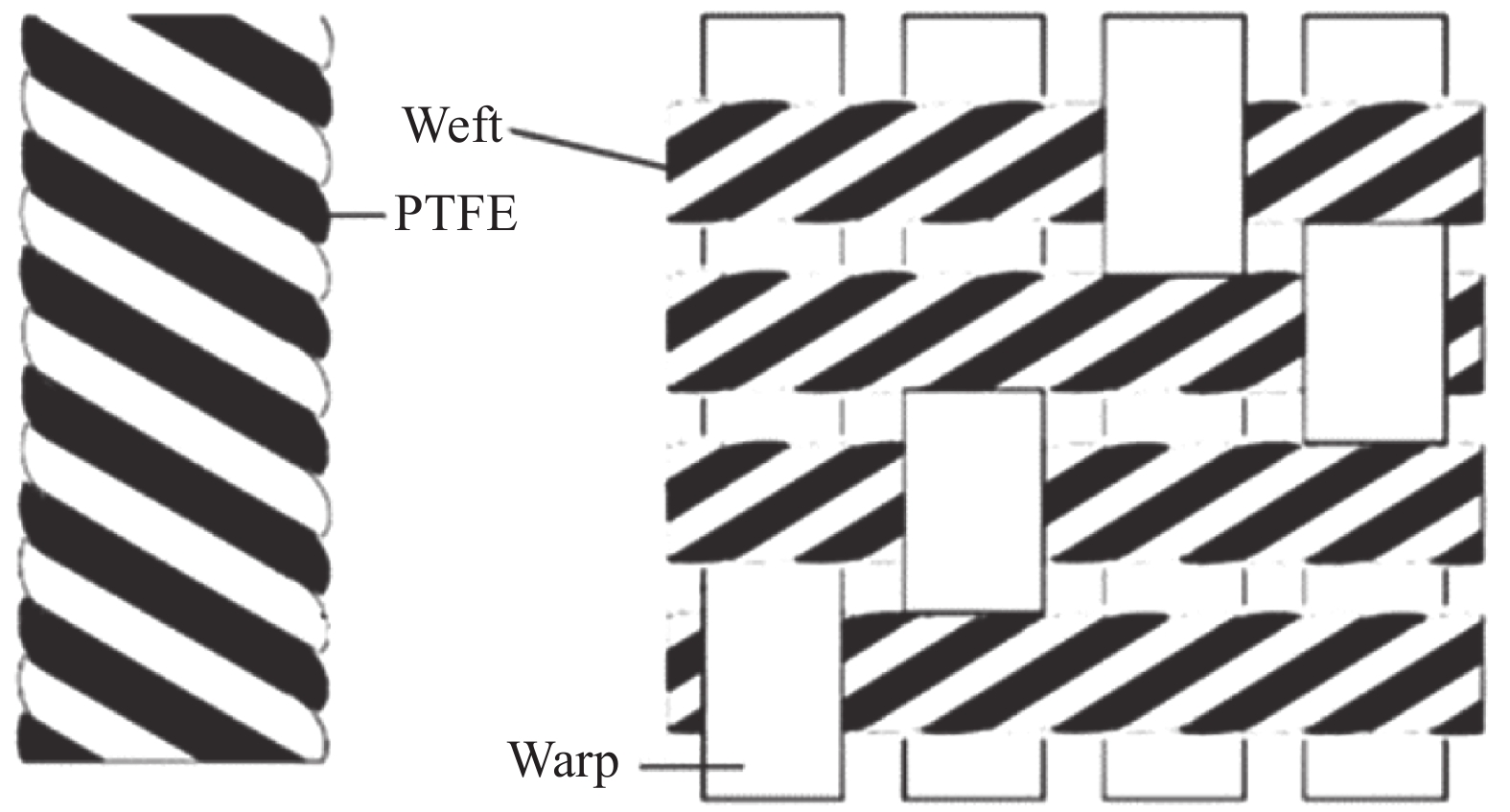

According to the failure problem of the solid rocket engine insulation material caused by deformation incompatibility between the reinforced fabric and rubber matrix under impact loading, the polyimide fiber weft knitted fabric reinforced nitrile rubber (NBR) composites were designed and prepared. Based on the rib structure, two kinds of fiber fineness, three kinds of loop length and two lay-up structures were selected. The effects of reinforced structure on the low velocity impact properties of composites were investigated. Results show that the composites with large tow fiber, long loop length and orthogonal lay-up have higher peak load and absorbed energy. Profilometer and microscope observation were adapted to observe the damage modes of impacted composites. The specimens are not penetrated under 20.1 J impact loading. It is found that matrix cracking along the fiber direction and plastic deformation along the thickness direction are the main damage mode of composites.

According to the failure problem of the solid rocket engine insulation material caused by deformation incompatibility between the reinforced fabric and rubber matrix under impact loading, the polyimide fiber weft knitted fabric reinforced nitrile rubber (NBR) composites were designed and prepared. Based on the rib structure, two kinds of fiber fineness, three kinds of loop length and two lay-up structures were selected. The effects of reinforced structure on the low velocity impact properties of composites were investigated. Results show that the composites with large tow fiber, long loop length and orthogonal lay-up have higher peak load and absorbed energy. Profilometer and microscope observation were adapted to observe the damage modes of impacted composites. The specimens are not penetrated under 20.1 J impact loading. It is found that matrix cracking along the fiber direction and plastic deformation along the thickness direction are the main damage mode of composites.

2022, 39(10): 4580-4589.

doi: 10.13801/j.cnki.fhclxb.20211028.001

Abstract:

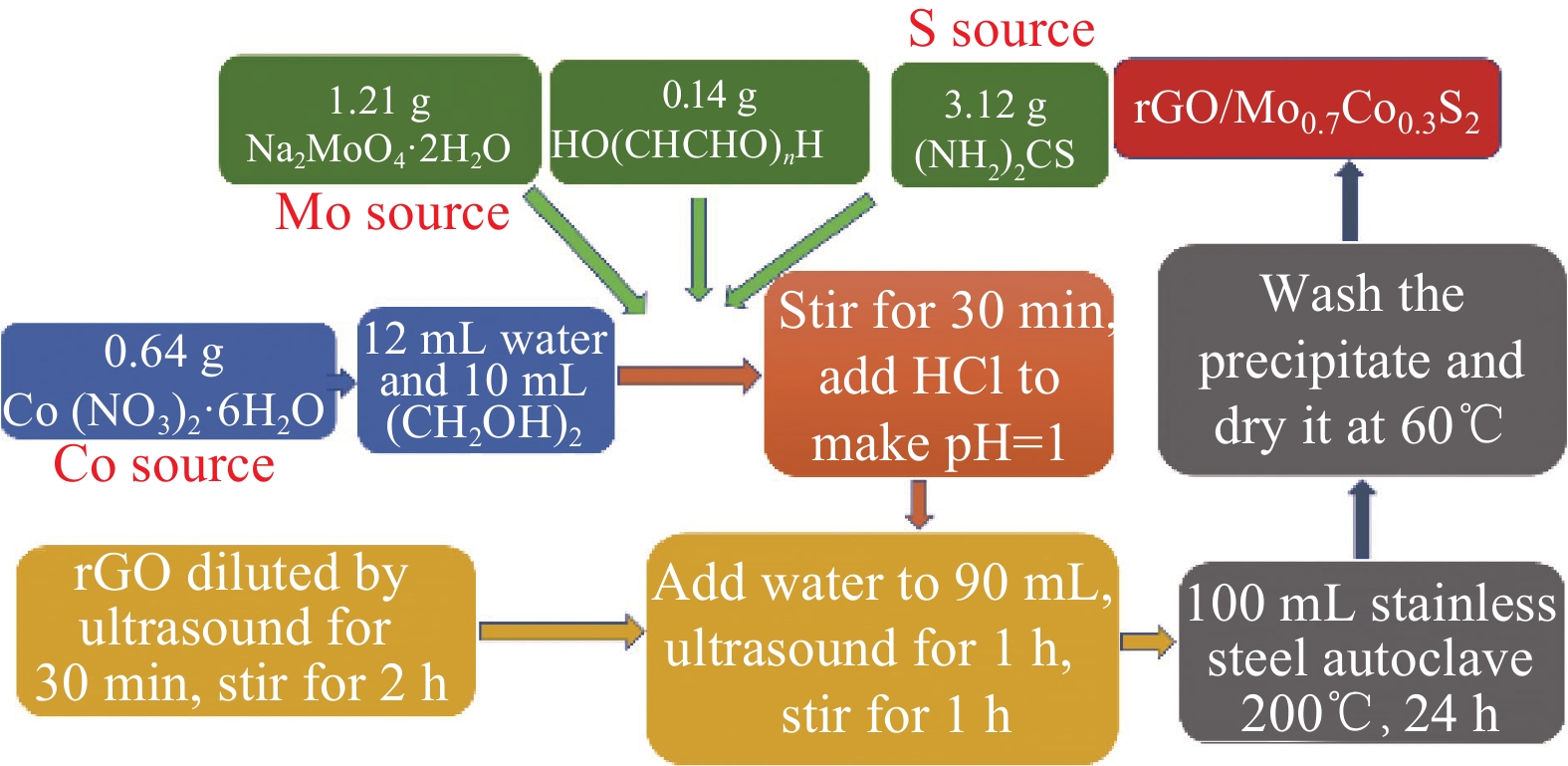

Graphene oxide (rGO) has become a leader in supercapacitors with a wide specific surface area (SSA) (2630 m2/g), high electrical conductivity and chemical stability, and excellent mechanical, thermal and optical properties. However, rGO itself has poor electrical conductivity, so in this paper, rGO is combined with Mo0.7Co0.3S2 to improve its performance. This paper was successfully synthesized different mass ratios of rGO and Mo0.7Co0.3S2 by a simple hydrothermal method. The microstructure was characterized by XRD, SEM, HRTEM, EDS. The electrode is made by using foamed nickel as the substrate, polyvinylidene chlorofluoride as the binder, and N-methyl pyrrolidone as the auxiliary agent. The electrochemical performance was tested on a three-electrode electrochemical workstation with KOH as the electrolyte. The experimental results show that all samples exhibit hexagonal system structure with good crystallization, the morphologies are flower-like microsphere shape with a certain degree of agglomeration. The surface of Mo0.7Co0.3S2 nanoparticles is wrapped by a layer of rGO like yarn. rGO/Mo0.7Co0.3S2 nanocomposite exhibits pseudo-capacitance behavior and excellent electrochemical performance, especially the Mo0.7Co0.3S2 electrode (30wt% rGO content) exhibits the largest specific capacitance and smallest impedance, and the Mo0.7Co0.3S2 electrode (30wt% rGO content) electrode reduced from 1377.00 F·g−1 to 1307.87 F·g−1 after 3000 cycles at a current density of 5 A·g−1, the coulombic efficiency is 95%, which may be due to the Coupling effect between Mo0.7Co0.3S2 and rGO.

Graphene oxide (rGO) has become a leader in supercapacitors with a wide specific surface area (SSA) (2630 m2/g), high electrical conductivity and chemical stability, and excellent mechanical, thermal and optical properties. However, rGO itself has poor electrical conductivity, so in this paper, rGO is combined with Mo0.7Co0.3S2 to improve its performance. This paper was successfully synthesized different mass ratios of rGO and Mo0.7Co0.3S2 by a simple hydrothermal method. The microstructure was characterized by XRD, SEM, HRTEM, EDS. The electrode is made by using foamed nickel as the substrate, polyvinylidene chlorofluoride as the binder, and N-methyl pyrrolidone as the auxiliary agent. The electrochemical performance was tested on a three-electrode electrochemical workstation with KOH as the electrolyte. The experimental results show that all samples exhibit hexagonal system structure with good crystallization, the morphologies are flower-like microsphere shape with a certain degree of agglomeration. The surface of Mo0.7Co0.3S2 nanoparticles is wrapped by a layer of rGO like yarn. rGO/Mo0.7Co0.3S2 nanocomposite exhibits pseudo-capacitance behavior and excellent electrochemical performance, especially the Mo0.7Co0.3S2 electrode (30wt% rGO content) exhibits the largest specific capacitance and smallest impedance, and the Mo0.7Co0.3S2 electrode (30wt% rGO content) electrode reduced from 1377.00 F·g−1 to 1307.87 F·g−1 after 3000 cycles at a current density of 5 A·g−1, the coulombic efficiency is 95%, which may be due to the Coupling effect between Mo0.7Co0.3S2 and rGO.

2022, 39(10): 4590-4601.

doi: 10.13801/j.cnki.fhclxb.20211105.001

Abstract:

In order to improve the shortages of big density and narrow absorption bandwidth of Fe3O4 absorbing material, in this study, wood-based porous charcoal (WPC)/Fe3O4 composites were prepared from fast-growing masson pine wood by delignification and high temperature in-situ growth methods. The microwave absorption properties of the composites were regulated by tailoring the carbonization temperature. The results of micromorphology, structure and electromagnetic parameters show that, the WPC/Fe3O4 composites retain the natural three-dimensional porous structure of wood with Fe3O4 particles evenly loaded in the carbon walls and channels of WPC. The increment of carbonization temperature (630-690℃) can enhance the electric conductivity and microwave attenuation capacity of the composites, but too high temperature causes the impedance mismatching. The composite prepared at 670℃ exhibits excellent microwave absorption performance with a minimum reflection loss of −49.5 dB and an effective absorption bandwidth of 6.24 GHz (9.04-15.28 GHz), due to its strong attenuation capability and good impedance matching characteristics. The main dissipation mechanism includes conductive loss, polarization relaxation, and synergistic effect of dielectric and magnetic loss. The strong reflection loss and wide effective absorption bandwidth of WPC/Fe3O4 composite suggest a good prospect in electromagnetic absorption field, which can promote the value-added and functional application of fast-growing wood.

In order to improve the shortages of big density and narrow absorption bandwidth of Fe3O4 absorbing material, in this study, wood-based porous charcoal (WPC)/Fe3O4 composites were prepared from fast-growing masson pine wood by delignification and high temperature in-situ growth methods. The microwave absorption properties of the composites were regulated by tailoring the carbonization temperature. The results of micromorphology, structure and electromagnetic parameters show that, the WPC/Fe3O4 composites retain the natural three-dimensional porous structure of wood with Fe3O4 particles evenly loaded in the carbon walls and channels of WPC. The increment of carbonization temperature (630-690℃) can enhance the electric conductivity and microwave attenuation capacity of the composites, but too high temperature causes the impedance mismatching. The composite prepared at 670℃ exhibits excellent microwave absorption performance with a minimum reflection loss of −49.5 dB and an effective absorption bandwidth of 6.24 GHz (9.04-15.28 GHz), due to its strong attenuation capability and good impedance matching characteristics. The main dissipation mechanism includes conductive loss, polarization relaxation, and synergistic effect of dielectric and magnetic loss. The strong reflection loss and wide effective absorption bandwidth of WPC/Fe3O4 composite suggest a good prospect in electromagnetic absorption field, which can promote the value-added and functional application of fast-growing wood.

2022, 39(10): 4602-4609.

doi: 10.13801/j.cnki.fhclxb.20211115.001

Abstract:

In view of the harmness and resource utilization of chlorosilane residues, the by-products are prepared into dimethyldichlorosilane with higher economic benefit through disproportionation reaction. The ZSM-5@γ-Al2O3 core-shell carrier was constructed by modifying the surface of ZSM-5 molecular sieve with Tianjing gum as the binder and γ-Al2O3 as the shell. NaAlCl4 was loaded on the surface of ZSM-5@γ-Al2O3 core-shell carrier by high-temperature impregnation loading method. The effect of ZSM-5 molecular sieve with different Si/Al molar ratios on the disproportionation preparation of dimethyldichlorosilane, the effect of different NaAlCl4 loading ratios and the impregnation time of AlCl3 solution on the reaction of disproportionation preparation of dimethyldichlorosilane were investigated comprehensively, and the samples were characterized by XRD, SEM, SEM-EDS, BET and FTIR. The results show that the catalyst activity reach the optimum with 71.81% yield when the temperature is 200°C, the silica-alumina molar ratio is 50, the compound salt NaAlCl4 ratio is 8wt%, and the AlCl3 impregnation time is 3 h. The NaAlCl4 compound salt loading on the surface of the ZSM-5@γ-Al2O3 core-shell catalyst shows the improved catalytic efficiency and enhanced performance instability compared with single catalytic component. Further redistribution chlorosilane by-products methyl trichlorosilane (M1) and trimethylchlorosilane (M3) synthesis can obtain high commercial value dimethyl dichlorosilane (M2), so as to realize the transformation of waste into treasure.

In view of the harmness and resource utilization of chlorosilane residues, the by-products are prepared into dimethyldichlorosilane with higher economic benefit through disproportionation reaction. The ZSM-5@γ-Al2O3 core-shell carrier was constructed by modifying the surface of ZSM-5 molecular sieve with Tianjing gum as the binder and γ-Al2O3 as the shell. NaAlCl4 was loaded on the surface of ZSM-5@γ-Al2O3 core-shell carrier by high-temperature impregnation loading method. The effect of ZSM-5 molecular sieve with different Si/Al molar ratios on the disproportionation preparation of dimethyldichlorosilane, the effect of different NaAlCl4 loading ratios and the impregnation time of AlCl3 solution on the reaction of disproportionation preparation of dimethyldichlorosilane were investigated comprehensively, and the samples were characterized by XRD, SEM, SEM-EDS, BET and FTIR. The results show that the catalyst activity reach the optimum with 71.81% yield when the temperature is 200°C, the silica-alumina molar ratio is 50, the compound salt NaAlCl4 ratio is 8wt%, and the AlCl3 impregnation time is 3 h. The NaAlCl4 compound salt loading on the surface of the ZSM-5@γ-Al2O3 core-shell catalyst shows the improved catalytic efficiency and enhanced performance instability compared with single catalytic component. Further redistribution chlorosilane by-products methyl trichlorosilane (M1) and trimethylchlorosilane (M3) synthesis can obtain high commercial value dimethyl dichlorosilane (M2), so as to realize the transformation of waste into treasure.

2022, 39(10): 4610-4619.

doi: 10.13801/j.cnki.fhclxb.20211108.002

Abstract:

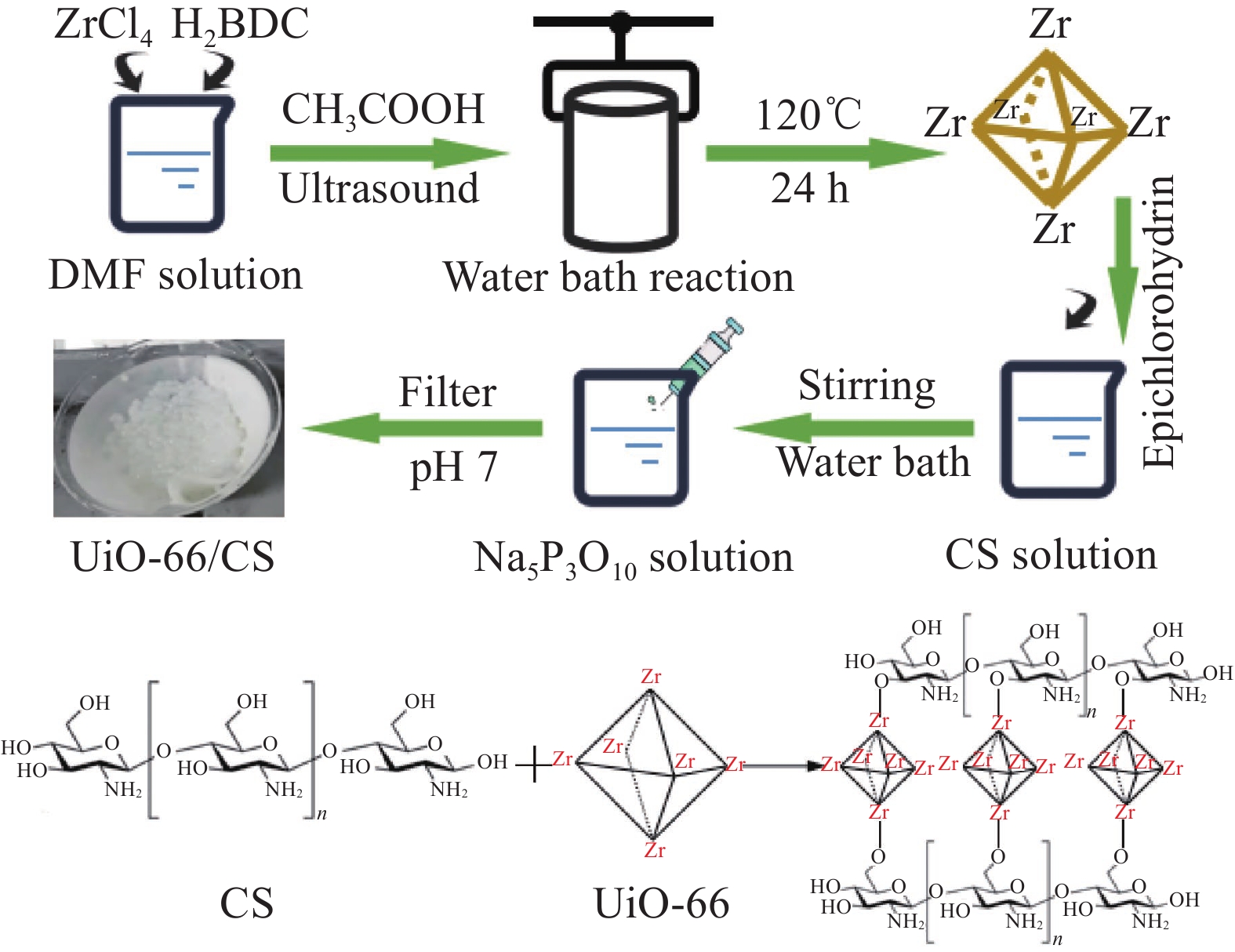

LiNi0.5Mn1.5O4 cathode material is considered as a promising cathode material due to its advantages of high voltage, cobalt-free and high energy density. But its further application is limited by its poor cyclic stability as the decomposition of electrolyte under high voltage. In this study, LiNi0.5Mn1.5O4 was prepared by low temperature self-propagating combustion method, and then different sugars were used as carbon sources to study the coating modification. The results show that the properties of LiNi0.5Mn1.5O4 composite prepared with chitosan at 400℃/Air is improved significantly. The specific discharge capacity of LiNi0.5Mn1.5O4 composite is 113.3 mA·h/g after 400 cycles at 148 mA·h/g, and the capacity retention rate is 91.07%. This is mainly attributed to the carbon layer on the surface of the material, which improves the electrical conductivity of the material, alleviates the erosion of electrolyte, reduces the electrode reaction polarization, and improves the transport rate of lithium ions. In this study, cheap sugars are used as carbon source, and the synthesis process is simple, which provides a new idea for the application of LiNi0.5Mn1.5O4.

LiNi0.5Mn1.5O4 cathode material is considered as a promising cathode material due to its advantages of high voltage, cobalt-free and high energy density. But its further application is limited by its poor cyclic stability as the decomposition of electrolyte under high voltage. In this study, LiNi0.5Mn1.5O4 was prepared by low temperature self-propagating combustion method, and then different sugars were used as carbon sources to study the coating modification. The results show that the properties of LiNi0.5Mn1.5O4 composite prepared with chitosan at 400℃/Air is improved significantly. The specific discharge capacity of LiNi0.5Mn1.5O4 composite is 113.3 mA·h/g after 400 cycles at 148 mA·h/g, and the capacity retention rate is 91.07%. This is mainly attributed to the carbon layer on the surface of the material, which improves the electrical conductivity of the material, alleviates the erosion of electrolyte, reduces the electrode reaction polarization, and improves the transport rate of lithium ions. In this study, cheap sugars are used as carbon source, and the synthesis process is simple, which provides a new idea for the application of LiNi0.5Mn1.5O4.

2022, 39(10): 4620-4630.

doi: 10.13801/j.cnki.fhclxb.20211025.001

Abstract:

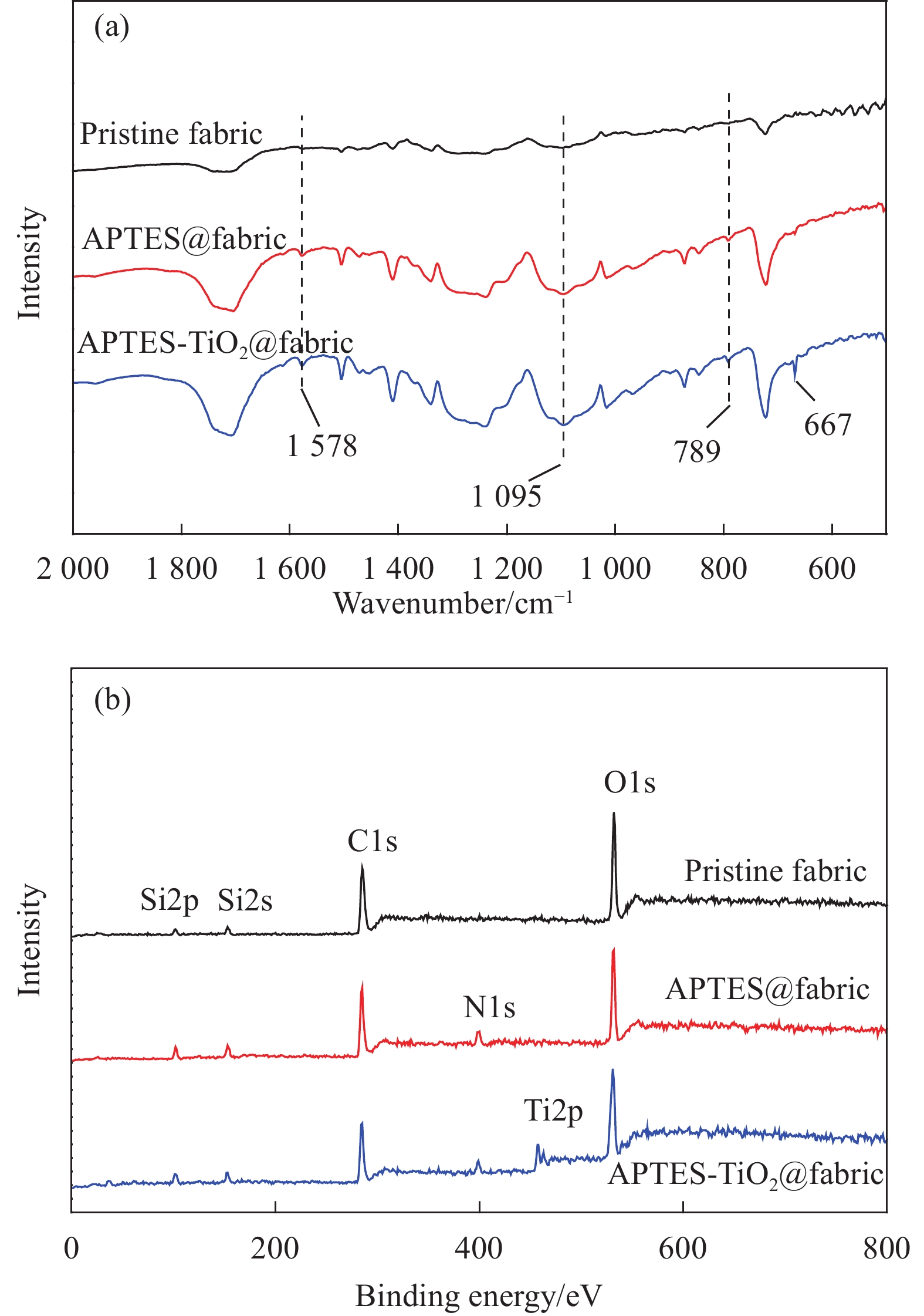

Anisotropic wettable materials have become a hot spot in oil-water separation research because of their apparently opposite absorption characteristics for oil and water. In this paper, γ-aminopropyltriethoxysilane (APTES) and hydrophilic nano TiO2 were mixed and applied to the fabric. APTES-TiO2 coated superhydrophilic underwater superoleophobic fabric (APTES-TiO2@fabric) was obtained after hydrolyzing and crosslinking. The modified fabric was characterized by contact angle measuring instrument, FTIR, XPS, FESEM, XRD and EDS. The results show that APTES-TiO2 is successfully coated on the surface of the fabric, which has a water contact angle of 0° in air and an oil contact angle of greater than 152° for the selected oil in water. In the oil-water separation test, the separation efficiency of APTES-TiO2@fabric for the several light oils is above 99%, and it still has a good separation efficiency after 5 separation cycles and soaked in acid-base salt solution. In addition, the fabric also has excellent photocatalytic performance. Under 12 h of ultraviolet irradiation, it can degrade the methylene blue in water and adsorb to itself, achieving the effect of water purification and self-cleaning. The results show that APTES-TiO2@fabric has good oil-water separation and photocatalytic performance, which can be used as a reference for water purification in practical applications.

Anisotropic wettable materials have become a hot spot in oil-water separation research because of their apparently opposite absorption characteristics for oil and water. In this paper, γ-aminopropyltriethoxysilane (APTES) and hydrophilic nano TiO2 were mixed and applied to the fabric. APTES-TiO2 coated superhydrophilic underwater superoleophobic fabric (APTES-TiO2@fabric) was obtained after hydrolyzing and crosslinking. The modified fabric was characterized by contact angle measuring instrument, FTIR, XPS, FESEM, XRD and EDS. The results show that APTES-TiO2 is successfully coated on the surface of the fabric, which has a water contact angle of 0° in air and an oil contact angle of greater than 152° for the selected oil in water. In the oil-water separation test, the separation efficiency of APTES-TiO2@fabric for the several light oils is above 99%, and it still has a good separation efficiency after 5 separation cycles and soaked in acid-base salt solution. In addition, the fabric also has excellent photocatalytic performance. Under 12 h of ultraviolet irradiation, it can degrade the methylene blue in water and adsorb to itself, achieving the effect of water purification and self-cleaning. The results show that APTES-TiO2@fabric has good oil-water separation and photocatalytic performance, which can be used as a reference for water purification in practical applications.

2022, 39(10): 4631-4641.

doi: 10.13801/j.cnki.fhclxb.20211123.002

Abstract:

Due to the low cost, high safety and easy assembly, rechargeable aqueous zinc-manganese oxide (Zn-MnOx) batteries are the best devices for energy storage. However, poor conductivity of MnOx results in the bad cycle performance. Herein, highly conductive and layered Ti3C2Tx MXene with rich terminations (Tx, for example, =O, —F, —OH) were used as carriers for MnOx particles. Due to the electronegativity of the terminations, Mn2+ was intercalated into the layers and adsorbed on the surface of Ti3C2Tx MXene, making the generated Mn3O4 particles can firmly anchored, forming the Ti3C2@Mn3O4 composites. As for the cathode of zinc-ion batteries, Ti3C2@Mn3O4 was fully converted to Ti3C2@ε-MnO2 during the 1st charge process. Thanks to the excellent conductivity and layered structure of Ti3C2Tx MXene, Ti3C2@ε-MnO2 cathode presents excellent kinetic properties and electrochemical performance with a high specific capacity of 440 mA·h·g−1 and high energy density (607 W·h·kg−1) at 0.2 C (1 C=308 mA·h·g−1), and the capacities increase from 270 mA·h·g−1 to 480 mA·h·g−1 after 150 cycles at 1 C. Excellent electrochemical performance, simple material preparation methods, combined with the low cost, high safety and easy assembly characteristics, enable the possible application of rechargeable aqueous Zn-MnOx batteries in large-scale energy storage.

Due to the low cost, high safety and easy assembly, rechargeable aqueous zinc-manganese oxide (Zn-MnOx) batteries are the best devices for energy storage. However, poor conductivity of MnOx results in the bad cycle performance. Herein, highly conductive and layered Ti3C2Tx MXene with rich terminations (Tx, for example, =O, —F, —OH) were used as carriers for MnOx particles. Due to the electronegativity of the terminations, Mn2+ was intercalated into the layers and adsorbed on the surface of Ti3C2Tx MXene, making the generated Mn3O4 particles can firmly anchored, forming the Ti3C2@Mn3O4 composites. As for the cathode of zinc-ion batteries, Ti3C2@Mn3O4 was fully converted to Ti3C2@ε-MnO2 during the 1st charge process. Thanks to the excellent conductivity and layered structure of Ti3C2Tx MXene, Ti3C2@ε-MnO2 cathode presents excellent kinetic properties and electrochemical performance with a high specific capacity of 440 mA·h·g−1 and high energy density (607 W·h·kg−1) at 0.2 C (1 C=308 mA·h·g−1), and the capacities increase from 270 mA·h·g−1 to 480 mA·h·g−1 after 150 cycles at 1 C. Excellent electrochemical performance, simple material preparation methods, combined with the low cost, high safety and easy assembly characteristics, enable the possible application of rechargeable aqueous Zn-MnOx batteries in large-scale energy storage.

2022, 39(10): 4642-4651.

doi: 10.13801/j.cnki.fhclxb.20210927.003

Abstract:

Z-scheme BiVO4−x/g-C3N4−x heterostructure mediated by double defects were prepared by solid phase sintering and hydrothermal methods to acquire an efficient photocatalytic system for full water splitting. The microstructure and optoelectronic properties of the heterostructure were characterized, and the photocatalytic properties of BiVO4−x/g-C3N4−x heterostructure for hydrogen and oxygen production by overall photocatalytic water splitting were tested. The results show that the introduction of abundant oxygen vacancy and nitrogen vacancy, the tightly connected interface and the construction of direct Z-scheme heterojunction improve the visible light absorption and accelerate the separation and transfer of photogenerated charge. As a result, the material has highly efficient photocatalytic activity. The Z-scheme BiVO4−x/g-C3N4−x heterojunction mediated by double defects show excellent photocatalytic activity and stability. Under visible light irradiation, the hydrogen and oxygen evolution rate reach 654 μmol·h−1·g−1, which is 6.5 times as high as that of g-C3N4−x precursor, and the oxygen evolution rate reach 302 μmol·h−1·g−1. After 20 h of visible light irradiation, the photocatalytic activity of the sample doesn’t decrease.

Z-scheme BiVO4−x/g-C3N4−x heterostructure mediated by double defects were prepared by solid phase sintering and hydrothermal methods to acquire an efficient photocatalytic system for full water splitting. The microstructure and optoelectronic properties of the heterostructure were characterized, and the photocatalytic properties of BiVO4−x/g-C3N4−x heterostructure for hydrogen and oxygen production by overall photocatalytic water splitting were tested. The results show that the introduction of abundant oxygen vacancy and nitrogen vacancy, the tightly connected interface and the construction of direct Z-scheme heterojunction improve the visible light absorption and accelerate the separation and transfer of photogenerated charge. As a result, the material has highly efficient photocatalytic activity. The Z-scheme BiVO4−x/g-C3N4−x heterojunction mediated by double defects show excellent photocatalytic activity and stability. Under visible light irradiation, the hydrogen and oxygen evolution rate reach 654 μmol·h−1·g−1, which is 6.5 times as high as that of g-C3N4−x precursor, and the oxygen evolution rate reach 302 μmol·h−1·g−1. After 20 h of visible light irradiation, the photocatalytic activity of the sample doesn’t decrease.

2022, 39(10): 4652-4663.

doi: 10.13801/j.cnki.fhclxb.20220506.001

Abstract:

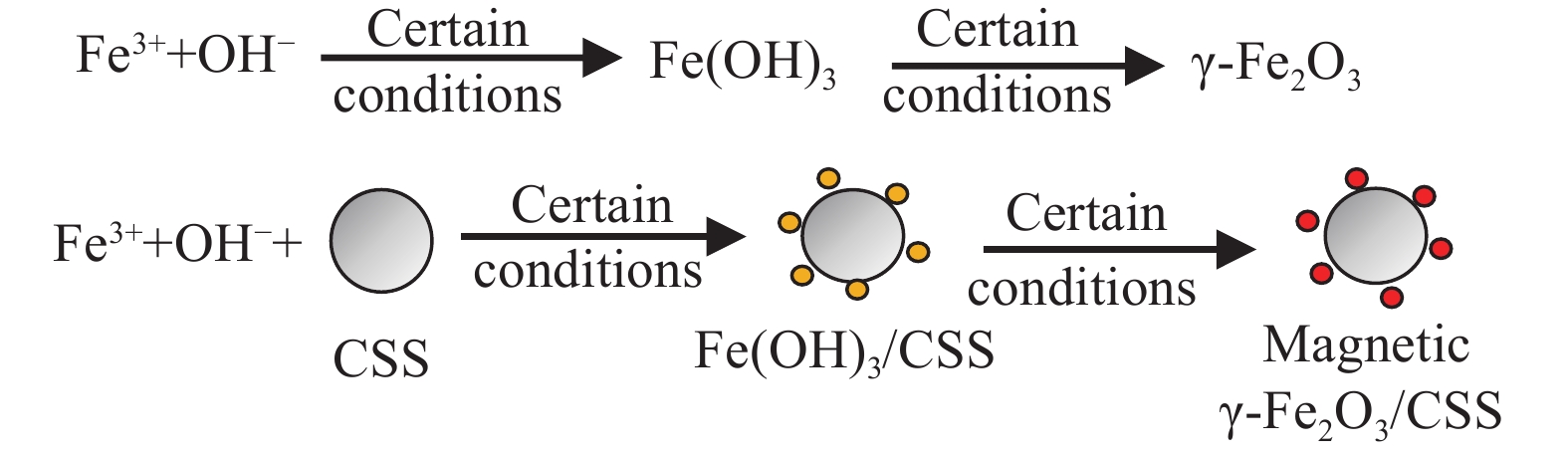

In order to develop a multi-functional oil-water separation sponge that is rich in raw materials, environmentally friendly, easy to operate in complex environment, and of good reusability, superhydrophobic collagen-based composite sponge (Fe3O4/PDMS-COL) was prepared by impregnating collagen sponge with polydimethylsiloxane (PDMS)/ferroferric oxide nanoparticles (Fe3O4). The changes of chemical structure and microstructure after modification were characterized, and the oil-water separation performance was studied. According to the measurement of contact angle, when the concentration of collagen (COL) is 10 mg/mL and the concentration of PDMS is 15vol%, the water contact angle of the composite sponge reaches 150.3°. The results from FTIR, XPS, XRD and TG show that Fe3O4/PDMS compounds with collagen sponge successfully. FE-SEM observation shows that the addition of Fe3O4 nanoparticles construct rough surface structures effectively. Fe3O4/PDMS-COL can adsorb a variety of oil phases, including benzene, n-hexane, ethyl acetate, vacuum pump oil, peanut oil, among which the adsorption capacity (47 g/g) toward ethyl acetate is the highest, meanwhile the separation efficiency towards various oil phases reaches no less than 99%. After recycling for 20 times for absorbing benzene, both of the contact angle and magnetism of the sponge do not reduce significantly. Moreover, Fe3O4/PDMS-COL has a desirable emulsion separation ability and can effectively separate oil-in-water emulsion. Oil-water separation experiments were carried out in various scenarios under the action of external magnetic field, demonstrating the favourable magnetic responsiveness and manipulation. In addition, Fe3O4/PDMS-COL exhibits a good flame retardant performance. Furthermore, Fe3O4/PDMS-COL possesses an excellent separation capacity toward solid oil/water system in a complex environment, due to its near infrared photothermal effect.

In order to develop a multi-functional oil-water separation sponge that is rich in raw materials, environmentally friendly, easy to operate in complex environment, and of good reusability, superhydrophobic collagen-based composite sponge (Fe3O4/PDMS-COL) was prepared by impregnating collagen sponge with polydimethylsiloxane (PDMS)/ferroferric oxide nanoparticles (Fe3O4). The changes of chemical structure and microstructure after modification were characterized, and the oil-water separation performance was studied. According to the measurement of contact angle, when the concentration of collagen (COL) is 10 mg/mL and the concentration of PDMS is 15vol%, the water contact angle of the composite sponge reaches 150.3°. The results from FTIR, XPS, XRD and TG show that Fe3O4/PDMS compounds with collagen sponge successfully. FE-SEM observation shows that the addition of Fe3O4 nanoparticles construct rough surface structures effectively. Fe3O4/PDMS-COL can adsorb a variety of oil phases, including benzene, n-hexane, ethyl acetate, vacuum pump oil, peanut oil, among which the adsorption capacity (47 g/g) toward ethyl acetate is the highest, meanwhile the separation efficiency towards various oil phases reaches no less than 99%. After recycling for 20 times for absorbing benzene, both of the contact angle and magnetism of the sponge do not reduce significantly. Moreover, Fe3O4/PDMS-COL has a desirable emulsion separation ability and can effectively separate oil-in-water emulsion. Oil-water separation experiments were carried out in various scenarios under the action of external magnetic field, demonstrating the favourable magnetic responsiveness and manipulation. In addition, Fe3O4/PDMS-COL exhibits a good flame retardant performance. Furthermore, Fe3O4/PDMS-COL possesses an excellent separation capacity toward solid oil/water system in a complex environment, due to its near infrared photothermal effect.

2022, 39(10): 4664-4673.

doi: 10.13801/j.cnki.fhclxb.20211129.003

Abstract:

Biomass porous carbon materials are widely used in lithium ion batteries due to their wide sources and high cost performance, while activators used in the preparation process have a great influence on the lithium storage performance of materials. Therefore, using soybean shell as carbon source, porous carbon materials were prepared under different technological conditions, and the effect of activator on lithium storage performance of porous carbon materials was investigated through structural characterization and electrochemical performance tests. It may be shown as follows: (1) When the current density is 185 mA·g−1, the initial discharge and charge specific capacity of CaCl2-activated porous carbon (DK-CaCl2) is 639.0/269.5 mA·h·g−1, while that of KOH activated porous carbon (DK-KOH) is 986.7/307.5 mA·h·g−1; (2) When the mass ratios of soybean shell to KOH are 1∶2, 1∶4 and 1∶8, the first specific capacities of the obtained porous carbon are 544.9/136.8, 986.7/307.5 and 375.1/93.4 mA·h·g−1, after 200 cycles, their discharges retain 88.8, 318.9 and 94.7 mA·h·g−1, respectively. This indicates that the lithium storage performance of porous carbon materials prepared with different activators and activation ratios are different, which is due to the different specific surface area of materials, resulting in different electrochemical performance.

Biomass porous carbon materials are widely used in lithium ion batteries due to their wide sources and high cost performance, while activators used in the preparation process have a great influence on the lithium storage performance of materials. Therefore, using soybean shell as carbon source, porous carbon materials were prepared under different technological conditions, and the effect of activator on lithium storage performance of porous carbon materials was investigated through structural characterization and electrochemical performance tests. It may be shown as follows: (1) When the current density is 185 mA·g−1, the initial discharge and charge specific capacity of CaCl2-activated porous carbon (DK-CaCl2) is 639.0/269.5 mA·h·g−1, while that of KOH activated porous carbon (DK-KOH) is 986.7/307.5 mA·h·g−1; (2) When the mass ratios of soybean shell to KOH are 1∶2, 1∶4 and 1∶8, the first specific capacities of the obtained porous carbon are 544.9/136.8, 986.7/307.5 and 375.1/93.4 mA·h·g−1, after 200 cycles, their discharges retain 88.8, 318.9 and 94.7 mA·h·g−1, respectively. This indicates that the lithium storage performance of porous carbon materials prepared with different activators and activation ratios are different, which is due to the different specific surface area of materials, resulting in different electrochemical performance.

2022, 39(10): 4674-4684.

doi: 10.13801/j.cnki.fhclxb.20211018.004

Abstract:

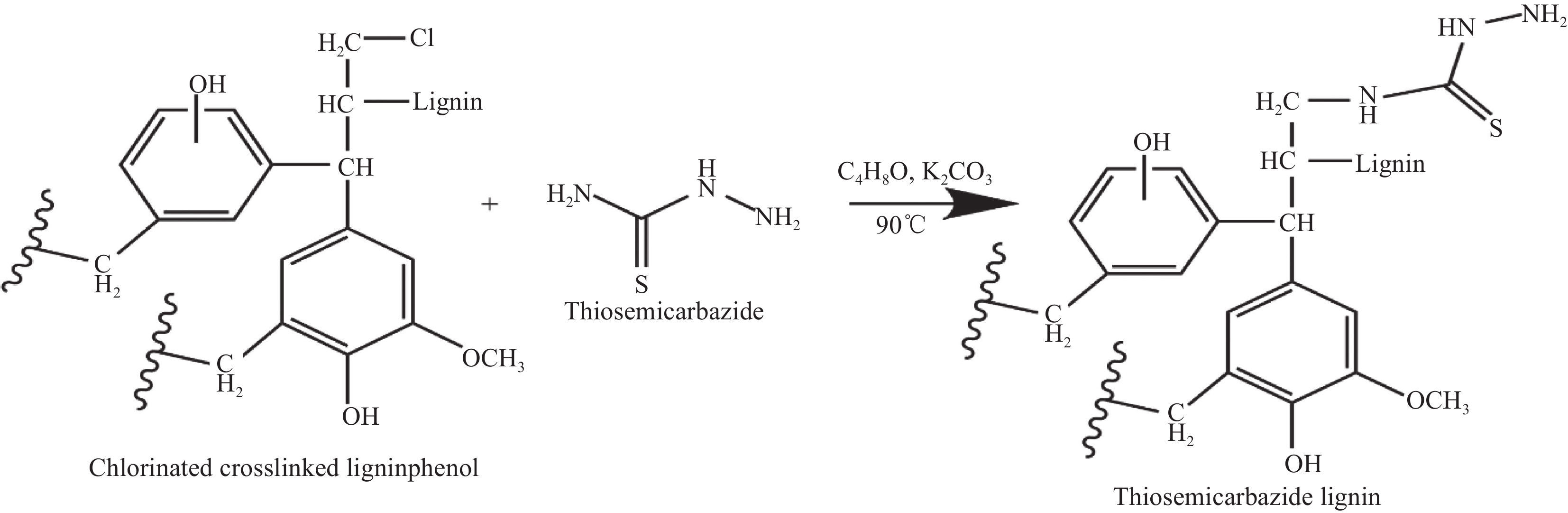

Lignin and its derivatives have broad application prospects in the fields of extraction of valuable metals and removal of toxic metal ions because of the characteristics of economical, efficient and friendly. Platinum was adsorbed by thiosemicarbazide/quaternary ammonium lignin in this study. The mechanism of adsorption was revealed by FTIR and the influence factors such as initial concentration of Pt(IV), hydrochloric acid concentration, adsorption time and adsorbent dosage on adsorption were optimized. The results show that the modified lignin contains a large number of phenolic hydroxyl, amino and quaternary ammonium functional groups. PtCl62− is reduced to PtCl42− by phenolic hydroxyl and then reacts with amino group by coordination reaction and chloride by ion exchange reaction. Using the optimum conditions, which include hydrochloric acid of 0.5 mol·L−1, Pt(IV) of 1 170 mg·L−1, adsorption time of 120 min and thiosemicarbazide/quaternary ammonium lignin addition of 1 g·L−1, the maximum adsorption capacity is 267.80 mg·g−1. Under the same conditions besides 7 g·L−1 thiosemicarbazide/quaternary ammonium lignin, the maximum adsorption ratio is 88.50%. The adsorption process can be simulated by Freundlich model and quasi-second-order kinetic model, which indicates that adsorption is chemisorptions of monolayer heterogeneous.

Lignin and its derivatives have broad application prospects in the fields of extraction of valuable metals and removal of toxic metal ions because of the characteristics of economical, efficient and friendly. Platinum was adsorbed by thiosemicarbazide/quaternary ammonium lignin in this study. The mechanism of adsorption was revealed by FTIR and the influence factors such as initial concentration of Pt(IV), hydrochloric acid concentration, adsorption time and adsorbent dosage on adsorption were optimized. The results show that the modified lignin contains a large number of phenolic hydroxyl, amino and quaternary ammonium functional groups. PtCl62− is reduced to PtCl42− by phenolic hydroxyl and then reacts with amino group by coordination reaction and chloride by ion exchange reaction. Using the optimum conditions, which include hydrochloric acid of 0.5 mol·L−1, Pt(IV) of 1 170 mg·L−1, adsorption time of 120 min and thiosemicarbazide/quaternary ammonium lignin addition of 1 g·L−1, the maximum adsorption capacity is 267.80 mg·g−1. Under the same conditions besides 7 g·L−1 thiosemicarbazide/quaternary ammonium lignin, the maximum adsorption ratio is 88.50%. The adsorption process can be simulated by Freundlich model and quasi-second-order kinetic model, which indicates that adsorption is chemisorptions of monolayer heterogeneous.

2022, 39(10): 4685-4693.

doi: 10.13801/j.cnki.fhclxb.20211101.003

Abstract:

In order to improve the photocatalytic performance of BiOI under visible light, the O-terminated Ti3C2 was prepared by etching Ti3AlC2 with NH4HF2, Ti3C2/BiOI composite materials were prepared by precipitation under ultrasonic radiation, using bismuth nitrate pentahydrate as bismuth source, potassium iodide as iodine source. The composition, morphology, structure, light absorption, transient photocurrent response and spectral response of Ti3C2/BiOI composite materials were characterized and measured by XRD, SEM, UV-vis, FTIR, EIS, I-t and PL. The photocatalytic degradation property of Ti3C2/BiOI composite material was carried out using methyl orange (MO) as targeted pollutant under simulated visible light. The results show that BiOI is successfully loaded on Ti3C2, the Ti3C2/BiOI composite material exhibits an appreciable photocatalytic activity under simulated visible light. The 6wt%Ti3C2/BiOI composite material shows the highest efficiency of 91.6% within 0.5 h, which is nearly 4.5 times higher than that of the BiOI. The O-terminated Ti3C2 as a cocatalyst to transfer photogenerated electrons in time, the charge separation is maintained in the charge depletion layer, which is helpful to improve the photocatalytic activity.

In order to improve the photocatalytic performance of BiOI under visible light, the O-terminated Ti3C2 was prepared by etching Ti3AlC2 with NH4HF2, Ti3C2/BiOI composite materials were prepared by precipitation under ultrasonic radiation, using bismuth nitrate pentahydrate as bismuth source, potassium iodide as iodine source. The composition, morphology, structure, light absorption, transient photocurrent response and spectral response of Ti3C2/BiOI composite materials were characterized and measured by XRD, SEM, UV-vis, FTIR, EIS, I-t and PL. The photocatalytic degradation property of Ti3C2/BiOI composite material was carried out using methyl orange (MO) as targeted pollutant under simulated visible light. The results show that BiOI is successfully loaded on Ti3C2, the Ti3C2/BiOI composite material exhibits an appreciable photocatalytic activity under simulated visible light. The 6wt%Ti3C2/BiOI composite material shows the highest efficiency of 91.6% within 0.5 h, which is nearly 4.5 times higher than that of the BiOI. The O-terminated Ti3C2 as a cocatalyst to transfer photogenerated electrons in time, the charge separation is maintained in the charge depletion layer, which is helpful to improve the photocatalytic activity.

2022, 39(10): 4694-4700.

doi: 10.13801/j.cnki.fhclxb.20211028.002

Abstract:

The anisotropic conductive polymer composites (ACPCs) have been applied in many fields owing to their unique anisotropic conductive property. In this article, a three-layer composite membrane with conductive middle layer and insulative inner and outer layers was prepared by three-layer film blowing technique, using high-density polyethylene (HDPE), polypropylene (PP) and multi-walled carbon nanotubes (MWCNTs) as raw materials. PP-MWCNTs/HDPE composite with anisotropic conductivity and alternating microlayers were then fabricated by hot-compression molding technique. A combination of DSC, POM, SEM, TEM, tensile and conductivity test was performed to provide a comprehensive analysis of structure and properties. The results show that the alternating arrangement of insulative PP layers and conductive MWCNTs/HDPE layers is successfully fabricated, and there is no structural defect (layer breakup or interlayer connection) in the microlayers, which indicates good adhesion in such multilayered structure. The PP-MWCNTs/HDPE composites exhibit excellent electrical conductivity in X and Y direction with electrical resistivity as low as 1.6 Ω·m, that almost 6-9 orders of magnitude lower than that in Z direction. The composites also demonstrate enhanced mechanical property, broadening the application field of conductive composite materials.

The anisotropic conductive polymer composites (ACPCs) have been applied in many fields owing to their unique anisotropic conductive property. In this article, a three-layer composite membrane with conductive middle layer and insulative inner and outer layers was prepared by three-layer film blowing technique, using high-density polyethylene (HDPE), polypropylene (PP) and multi-walled carbon nanotubes (MWCNTs) as raw materials. PP-MWCNTs/HDPE composite with anisotropic conductivity and alternating microlayers were then fabricated by hot-compression molding technique. A combination of DSC, POM, SEM, TEM, tensile and conductivity test was performed to provide a comprehensive analysis of structure and properties. The results show that the alternating arrangement of insulative PP layers and conductive MWCNTs/HDPE layers is successfully fabricated, and there is no structural defect (layer breakup or interlayer connection) in the microlayers, which indicates good adhesion in such multilayered structure. The PP-MWCNTs/HDPE composites exhibit excellent electrical conductivity in X and Y direction with electrical resistivity as low as 1.6 Ω·m, that almost 6-9 orders of magnitude lower than that in Z direction. The composites also demonstrate enhanced mechanical property, broadening the application field of conductive composite materials.

2022, 39(10): 4701-4708.

doi: 10.13801/j.cnki.fhclxb.20211108.003

Abstract:

Epoxide is an important organic synthesis intermediate and chemical raw material that is mainly prepared from the olefin epoxidation. It is a very interesting work to prepare efficient catalysts with stability and recyclability for aerobic olefins epoxidation. Composite PCuMo11/PC was prepared by using the nitrogen rich covalent organic framework material (PC) as support and the polyoxometalate PCuMo11 as active substance. The materials were characterized by FT-IR, N2 adsorption and desorption, XPS, TEM and EDS. The application of PCuMo11/PC for heterogeneous catalytic epoxidation of olefins (styrene, 1-octene, cyclooctene, cyclododecene) with molecular oxygen oxidant has obtained high catalytic activity and selectivity. There is no significant decrease in catalytic activity after recycling over five times. The experimental results show that large surface area and rich nitrogen content in the skeleton of the two-dimensional layered nitrogen rich covalent organic framework material are benefit to disperse the catalytic active substance polyoxometalate uniformly and establish a relatively stable chemical link, so as to improve the catalytic activity and stability of the composite.

Epoxide is an important organic synthesis intermediate and chemical raw material that is mainly prepared from the olefin epoxidation. It is a very interesting work to prepare efficient catalysts with stability and recyclability for aerobic olefins epoxidation. Composite PCuMo11/PC was prepared by using the nitrogen rich covalent organic framework material (PC) as support and the polyoxometalate PCuMo11 as active substance. The materials were characterized by FT-IR, N2 adsorption and desorption, XPS, TEM and EDS. The application of PCuMo11/PC for heterogeneous catalytic epoxidation of olefins (styrene, 1-octene, cyclooctene, cyclododecene) with molecular oxygen oxidant has obtained high catalytic activity and selectivity. There is no significant decrease in catalytic activity after recycling over five times. The experimental results show that large surface area and rich nitrogen content in the skeleton of the two-dimensional layered nitrogen rich covalent organic framework material are benefit to disperse the catalytic active substance polyoxometalate uniformly and establish a relatively stable chemical link, so as to improve the catalytic activity and stability of the composite.

2022, 39(10): 4709-4717.

doi: 10.13801/j.cnki.fhclxb.20211103.001

Abstract:

Because of the unique structure and function of zeolitic imidazolate frameworks (ZIFs), the utilization of ZIFs to enhance the properties of polymer and prepare new functional composites have attracted growing attention. To clarify the reinforcing effects of ZIFs on poly(vinyl alcohol) (PVA), zeolitic imidazolate framework ZIF-L was used as reinforcer and series of PVA composite films with different concentrations of ZIF-L were prepared by solution casting process. The structure, optical properties, mechanical properties, color, barrier performance and thermostability of the composite films were analyzed. The results indicate that the composite films show an enhanced anti-ultraviolet property with the addition of ZIF-L. The tensile strength initially increases and then decreases with increasing content of ZIF-L while the water vapor permeability and thermal degradation temperature show an opposite tendency. In addition, the incorporation of ZIF-L increases the oxygen permeability of the films gradually. When the ZIF-L content is 1wt%, the tensile strength of the composite film is increased by about 15%, while the water vapor permeability is reduced by 1.8%, ZIF-L significantly enhances the properties of PVA and the composite film show good comprehensive performance. When the ZIF-L content is larger than 5wt%, the maximum decomposition temperature begins to increase and reaches up to 297.84℃. The ZIF-L reinforced PVA composites in the present work will advance the development of new functional packaging composite films.

Because of the unique structure and function of zeolitic imidazolate frameworks (ZIFs), the utilization of ZIFs to enhance the properties of polymer and prepare new functional composites have attracted growing attention. To clarify the reinforcing effects of ZIFs on poly(vinyl alcohol) (PVA), zeolitic imidazolate framework ZIF-L was used as reinforcer and series of PVA composite films with different concentrations of ZIF-L were prepared by solution casting process. The structure, optical properties, mechanical properties, color, barrier performance and thermostability of the composite films were analyzed. The results indicate that the composite films show an enhanced anti-ultraviolet property with the addition of ZIF-L. The tensile strength initially increases and then decreases with increasing content of ZIF-L while the water vapor permeability and thermal degradation temperature show an opposite tendency. In addition, the incorporation of ZIF-L increases the oxygen permeability of the films gradually. When the ZIF-L content is 1wt%, the tensile strength of the composite film is increased by about 15%, while the water vapor permeability is reduced by 1.8%, ZIF-L significantly enhances the properties of PVA and the composite film show good comprehensive performance. When the ZIF-L content is larger than 5wt%, the maximum decomposition temperature begins to increase and reaches up to 297.84℃. The ZIF-L reinforced PVA composites in the present work will advance the development of new functional packaging composite films.

2022, 39(10): 4718-4731.

doi: 10.13801/j.cnki.fhclxb.20211011.002

Abstract:

In order to study the hydration development law of cement with different molding temperatures under continuous −5°C and 20°C curing environment, the hydration heat tests of cement paste with different molding temperatures of 5°C, 10°C, 15°C and 20°C were carried out under two curing systems. The hydration heat mechanism of cement paste with different curing systems and molding temperatures was analyzed. The effect of free water phase transformation on the performance of cement under negative temperature was explored. The hydration heat prediction model considering molding temperature ( 5~20°C ) under two curing systems was established. The results show that when the curing system is fixed, the hydration heat and hydration degree of cement paste increase gradually with the increase of curing age and mold temperature. The peak value of hydration heat difference and the equivalent age of hydration rate of 20°C curing and continuous −5°C curing are advanced by the molding temperature. Both negative temperature and low molding temperature will cause the age ' lag ' phenomenon in the hydration process. By analyzing the development law of hydration heat and its microscopic mechanism of action on cement paste, it is suggested that the molding temperature can be appropriately increased within a reasonable range to optimize the macro-micro performance of concrete under the negative temperature environment.

In order to study the hydration development law of cement with different molding temperatures under continuous −5°C and 20°C curing environment, the hydration heat tests of cement paste with different molding temperatures of 5°C, 10°C, 15°C and 20°C were carried out under two curing systems. The hydration heat mechanism of cement paste with different curing systems and molding temperatures was analyzed. The effect of free water phase transformation on the performance of cement under negative temperature was explored. The hydration heat prediction model considering molding temperature ( 5~20°C ) under two curing systems was established. The results show that when the curing system is fixed, the hydration heat and hydration degree of cement paste increase gradually with the increase of curing age and mold temperature. The peak value of hydration heat difference and the equivalent age of hydration rate of 20°C curing and continuous −5°C curing are advanced by the molding temperature. Both negative temperature and low molding temperature will cause the age ' lag ' phenomenon in the hydration process. By analyzing the development law of hydration heat and its microscopic mechanism of action on cement paste, it is suggested that the molding temperature can be appropriately increased within a reasonable range to optimize the macro-micro performance of concrete under the negative temperature environment.

2022, 39(10): 4732-4745.

doi: 10.13801/j.cnki.fhclxb.20211019.002

Abstract:

Large-rupture-strain fiber reinforced polymers (LRS FRPs) have the large tensile rupture strain value of more than 5%. This characteristic might enhance the load-bearing capacity and ductility and provide a new choice for seismic strengthening of reinforced concrete (RC) columns. The FRPs provide lateral support for the longitudinal bars through the cover concrete, which might prevent or delay the buckling of longitudinal steel bars. However, the buckling of the longitudinal reinforcement might still be observed when the stirrup spacing is relatively large. Especially, for the FRP-confined rectangular columns, the ununiform confinement provided by the external FRP for the specimen might result in the buckling of longitudinal bars and reduce the load-bearing capacity of the specimen. In order to study the buckling behavior of longitudinal bars in rectangular RC columns confined by FRP, a total of 28 polyethylene terephthalate (PET) FRP-confined rectangular columns, comprising 16 RC columns and 12 plain concrete (PC) columns, were prepared and tested under monotonic axial compression. The effects of the thickness of external FRP jackets, stirrup spacing and section aspect ratio on the load-bearing capacity of FRP-confined RC columns were studied. To carry out a quantitative study on the buckling behavior of longitudinal steel bars in FRP-confined RC columns, the average axial stress-strain curve of a single longitudinal bar was obtained from the test results. The experimental results show that the application of PET FRP jackets can effectively improve the load-bearing capacity and ductility of RC columns. A large confinement stiffness and a low section aspect ratio close to 1 lead to a high confinement level for RC columns. And the lateral support of FRP can delay the buckling of the steel bars to a higher deformation level.

Large-rupture-strain fiber reinforced polymers (LRS FRPs) have the large tensile rupture strain value of more than 5%. This characteristic might enhance the load-bearing capacity and ductility and provide a new choice for seismic strengthening of reinforced concrete (RC) columns. The FRPs provide lateral support for the longitudinal bars through the cover concrete, which might prevent or delay the buckling of longitudinal steel bars. However, the buckling of the longitudinal reinforcement might still be observed when the stirrup spacing is relatively large. Especially, for the FRP-confined rectangular columns, the ununiform confinement provided by the external FRP for the specimen might result in the buckling of longitudinal bars and reduce the load-bearing capacity of the specimen. In order to study the buckling behavior of longitudinal bars in rectangular RC columns confined by FRP, a total of 28 polyethylene terephthalate (PET) FRP-confined rectangular columns, comprising 16 RC columns and 12 plain concrete (PC) columns, were prepared and tested under monotonic axial compression. The effects of the thickness of external FRP jackets, stirrup spacing and section aspect ratio on the load-bearing capacity of FRP-confined RC columns were studied. To carry out a quantitative study on the buckling behavior of longitudinal steel bars in FRP-confined RC columns, the average axial stress-strain curve of a single longitudinal bar was obtained from the test results. The experimental results show that the application of PET FRP jackets can effectively improve the load-bearing capacity and ductility of RC columns. A large confinement stiffness and a low section aspect ratio close to 1 lead to a high confinement level for RC columns. And the lateral support of FRP can delay the buckling of the steel bars to a higher deformation level.

2022, 39(10): 4746-4756.

doi: 10.13801/j.cnki.fhclxb.20211214.002

Abstract:

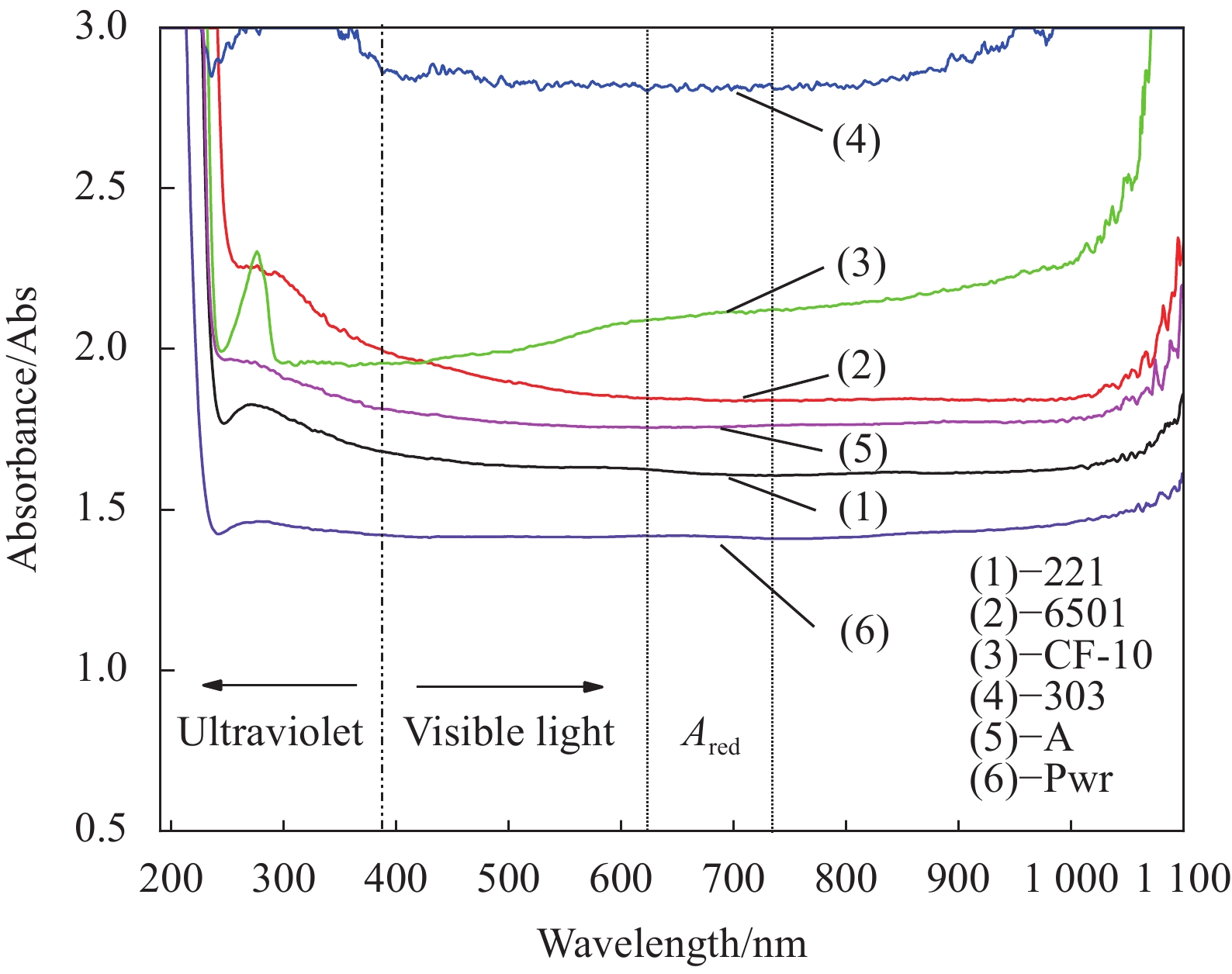

In order to evaluate the dispersion method and dispersion degree of graphene in pure cement mud, different anionic surfactants were used as dispersion graphene materials, and graphene dispersion was prepared by high-speed physical mixing and ultrasonic dispersion methods.Their dispersion uniformity was analyzed by UV-visible spectrophotometry, static settlement, resistivity, SEM and energy spectroscopy test to observe the distribution of graphene in alkaline solutions, pure cement mud, and its pure cement mud hydrochemical hardening products.The results show that in the pure cement mud alkaline environment, the introduction of bubble microbeads helps to improve the dispersion uniformity of graphene and the stability for time and weaken the floating effect of graphene in pure cement mud. At the same time, the cross-section graphene dispersion uniformity can be improved by 30%. The dispersion effect of graphene in alkaline solution was evaluated by visible spectrophotometry, static settlement and resistivity, which is simple and effective.

In order to evaluate the dispersion method and dispersion degree of graphene in pure cement mud, different anionic surfactants were used as dispersion graphene materials, and graphene dispersion was prepared by high-speed physical mixing and ultrasonic dispersion methods.Their dispersion uniformity was analyzed by UV-visible spectrophotometry, static settlement, resistivity, SEM and energy spectroscopy test to observe the distribution of graphene in alkaline solutions, pure cement mud, and its pure cement mud hydrochemical hardening products.The results show that in the pure cement mud alkaline environment, the introduction of bubble microbeads helps to improve the dispersion uniformity of graphene and the stability for time and weaken the floating effect of graphene in pure cement mud. At the same time, the cross-section graphene dispersion uniformity can be improved by 30%. The dispersion effect of graphene in alkaline solution was evaluated by visible spectrophotometry, static settlement and resistivity, which is simple and effective.

Flexural properties of ultra high performance concrete reinforced with steel wire mesh or fiber mesh

2022, 39(10): 4757-4768.

doi: 10.13801/j.cnki.fhclxb.20211022.002

Abstract:

To study the influence of steel wire mesh on the bending properties of ultra-high performance concrete (UHPC) slabs, a bending test of simply supported two-way slabs with four sides was carried out. The chopped fibers in UHPC ware: Steel fiber and steel fiber were mixed with polyvinyl alcohol fiber, glass fiber and basalt fiber, respectively. The research parameters were: Number of layers of wire mesh and glass fiber mesh, pore size and proportion of blended fibers. The results show that when UHPC is single-doped with 1.5vol% steel fiber, the ultimate bearing capacity and energy absorption at 25 mm deflection of UHPC slabs with 3 layers and 4 layers are increased by 14.9%, 32.3% and 14.1%, 25.2%, respectively compared with UHPC slabs with 2 layers of steel wire mesh. When the total volume fraction of hybrid fibers is 1.5vol% and the steel wire mesh is 2 layers, the blending of 1.0vol% steel fiber and 0.5vol% polyvinyl alcohol fiber has better reinforcing and toughening effect on UHPC slabs, and the UHPC slab mixed with 0.5vol% steel fiber and 1.0vol% glass fiber or basalt fiber has a stronger ability to maintain load after peak load than 1.0vol% polyvinyl alcohol fiber, namely the mixing of steel fiber with higher modulus of elasticity non-metallic fiber is advantageous to increase the post-cracking bearing capacity. Compared with glass fiber mesh, UHPC slabs with steel mesh have better ductility after peak load. A method for evaluating the flexibility of UHPC slabs with peak load deflection as initial cracking parameter was proposed, which can characterize the contribution of mesh and fibers to the post-crack toughness of UHPC slabs. Based on the concept of effective utilization of mesh, the theoretical value is in good agreement with the experimental value by calculating the bending capacity.

To study the influence of steel wire mesh on the bending properties of ultra-high performance concrete (UHPC) slabs, a bending test of simply supported two-way slabs with four sides was carried out. The chopped fibers in UHPC ware: Steel fiber and steel fiber were mixed with polyvinyl alcohol fiber, glass fiber and basalt fiber, respectively. The research parameters were: Number of layers of wire mesh and glass fiber mesh, pore size and proportion of blended fibers. The results show that when UHPC is single-doped with 1.5vol% steel fiber, the ultimate bearing capacity and energy absorption at 25 mm deflection of UHPC slabs with 3 layers and 4 layers are increased by 14.9%, 32.3% and 14.1%, 25.2%, respectively compared with UHPC slabs with 2 layers of steel wire mesh. When the total volume fraction of hybrid fibers is 1.5vol% and the steel wire mesh is 2 layers, the blending of 1.0vol% steel fiber and 0.5vol% polyvinyl alcohol fiber has better reinforcing and toughening effect on UHPC slabs, and the UHPC slab mixed with 0.5vol% steel fiber and 1.0vol% glass fiber or basalt fiber has a stronger ability to maintain load after peak load than 1.0vol% polyvinyl alcohol fiber, namely the mixing of steel fiber with higher modulus of elasticity non-metallic fiber is advantageous to increase the post-cracking bearing capacity. Compared with glass fiber mesh, UHPC slabs with steel mesh have better ductility after peak load. A method for evaluating the flexibility of UHPC slabs with peak load deflection as initial cracking parameter was proposed, which can characterize the contribution of mesh and fibers to the post-crack toughness of UHPC slabs. Based on the concept of effective utilization of mesh, the theoretical value is in good agreement with the experimental value by calculating the bending capacity.

2022, 39(10): 4769-4777.

doi: 10.13801/j.cnki.fhclxb.20211014.001

Abstract:

The rapid chloride migration coefficient (RCM) method and the natural immersion method were used to study the chloride ion penetration resistance of multi-walled carbon nanotubes (MWCNTs) reinforced concrete. The chloride ion diffusion depth on the longitudinal section of the concrete specimen was measured, and the chloride ion diffusion coefficient was calculated based on this. The test results show that when the content of MWCNTs is 0.15wt%, the chloride ion diffusion depth and chloride ion diffusion coefficient of concrete at 28 days are reduced by 25.7% and 19.1%, respectively. Under four different erosion ages of natural soaking, mixing in the concrete of MWCNTs, the internal chloride ion concentration is always lower than that of the control group. Combining the analysis of the two methods, it is concluded that the free chloride ion concentration at each depth of the concrete decreases with the increase of the MWCNTs content, so that the chloride diffusion coefficient decreases with the increase of the MWCNTs content, and the incorporation of MWCNTs improves the resistance of concrete to chloride ion penetration. In addition, through SEM and mercury intrusion (MIP) tests, the microscopic enhancement mechanism of MWCNTs on the anti-chloride ion permeability of concrete was further explored. The analysis results show that MWCNTs have a certain bridging and filling effect, which may cause concrete crack propagation to be affected, inhibit and refine the pores, thereby improving the microstructure of concrete and improving the resistance of concrete to chloride ion penetration.