2022 Vol. 39, No. 4

2022, 39(4): 1363-1377.

doi: 10.13801/j.cnki.fhclxb.20210909.010

Abstract:

With the large-scale application of meter-wave and decimeter-wave low-frequency radars in the military field, aircraft, especially long-range strategic bombers, are facing increasing air threats. In order to improve their survive capabilities, low-frequency radars are used to absorb microwave except the external design. To overcome this difficult point, long-wave microwave absorption materials are one of the key measures for its stealth effectiveness. This article discusses the low-frequency absorbing mechanism, summarizes the applications of traditional absorbing materials at low frequencies, including ferrites, composites, magnetic metal powders, then analyzes various factors that affect low-frequency absorbing performance. Finally, the current development of absorbing materials is explored, and the future development direction of low-frequency absorbent is prospected.

With the large-scale application of meter-wave and decimeter-wave low-frequency radars in the military field, aircraft, especially long-range strategic bombers, are facing increasing air threats. In order to improve their survive capabilities, low-frequency radars are used to absorb microwave except the external design. To overcome this difficult point, long-wave microwave absorption materials are one of the key measures for its stealth effectiveness. This article discusses the low-frequency absorbing mechanism, summarizes the applications of traditional absorbing materials at low frequencies, including ferrites, composites, magnetic metal powders, then analyzes various factors that affect low-frequency absorbing performance. Finally, the current development of absorbing materials is explored, and the future development direction of low-frequency absorbent is prospected.

2022, 39(4): 1378-1394.

doi: 10.13801/j.cnki.fhclxb.20211008.001

Abstract:

Electrospun nanofiber membrane has a unique network structure and connected micropores. With the advantages of large specific surface area, high porosity, easy modification, easy recycling and good chemical stability, it has been widely used in wastewater treatment as a new type of adsorption material. In this paper, first, the working principle of electrospinning is briefly introduced. Then, the latest research progress of electrospun nano-fiber membrane as adsorbents in wastewater treatment is reviewed, mainly including the removal of organic pollutants, inorganic anions and heavy metal ions, as well as the application of desalination. Besides, the adsorption mechanisms are summarized. Finally, the challenges and prospects of electrospun nanofiber membrane in wastewater treatment are discussed. This review may help researchers have a deeper understanding of electrospun nanofiber membrane materials, whether in the design and synthesis of nanofibers at the macro level or the adsorption mechanisms microscopically .

Electrospun nanofiber membrane has a unique network structure and connected micropores. With the advantages of large specific surface area, high porosity, easy modification, easy recycling and good chemical stability, it has been widely used in wastewater treatment as a new type of adsorption material. In this paper, first, the working principle of electrospinning is briefly introduced. Then, the latest research progress of electrospun nano-fiber membrane as adsorbents in wastewater treatment is reviewed, mainly including the removal of organic pollutants, inorganic anions and heavy metal ions, as well as the application of desalination. Besides, the adsorption mechanisms are summarized. Finally, the challenges and prospects of electrospun nanofiber membrane in wastewater treatment are discussed. This review may help researchers have a deeper understanding of electrospun nanofiber membrane materials, whether in the design and synthesis of nanofibers at the macro level or the adsorption mechanisms microscopically .

2022, 39(4): 1395-1410.

doi: 10.13801/j.cnki.fhclxb.20211115.002

Abstract:

Due to its excellent thermal physical properties such as good fatigue resistance, high specific strength and good heat resistance, carbon fiber reinforced plastic composites (CFRP) have been widely used in rail transportation, aerospace, aircraft, etc. industries. As the main load-bearing parts, a large number of assembly holes need to be machined for the mechanical connection between CFRP plates. However, as a hard-to-machining material with high hardness and anisotropy, traditional mechanical drilling has many disadvantages, such as many drilling procedures, serious tool wear and so on. Compared with the traditional mechanical drilling process, the laser can machine any hardness materials, and laser drilling shows the advantages such as no tool wear, good economy and easy to realize automatic control. First, this paper summarized the laser drilling technology of CFRP plates, and the common processes of laser drilling CFRP were emphatically analyzed. Then, the research status of defects and their suppression in CFRP laser drilling was analyzed. Subsequently, the influences of laser processing parameters on CFRP processing quality and efficiency were discussed. Aiming to reveal the material removal mechanism of laser drilling CFRP, the numerical simulation and dynamic process observation based on high-speed camera were emphatically analyzed. Finally, the development trends of CFRP laser drilling technology were forecasted.

Due to its excellent thermal physical properties such as good fatigue resistance, high specific strength and good heat resistance, carbon fiber reinforced plastic composites (CFRP) have been widely used in rail transportation, aerospace, aircraft, etc. industries. As the main load-bearing parts, a large number of assembly holes need to be machined for the mechanical connection between CFRP plates. However, as a hard-to-machining material with high hardness and anisotropy, traditional mechanical drilling has many disadvantages, such as many drilling procedures, serious tool wear and so on. Compared with the traditional mechanical drilling process, the laser can machine any hardness materials, and laser drilling shows the advantages such as no tool wear, good economy and easy to realize automatic control. First, this paper summarized the laser drilling technology of CFRP plates, and the common processes of laser drilling CFRP were emphatically analyzed. Then, the research status of defects and their suppression in CFRP laser drilling was analyzed. Subsequently, the influences of laser processing parameters on CFRP processing quality and efficiency were discussed. Aiming to reveal the material removal mechanism of laser drilling CFRP, the numerical simulation and dynamic process observation based on high-speed camera were emphatically analyzed. Finally, the development trends of CFRP laser drilling technology were forecasted.

2022, 39(4): 1411-1424.

doi: 10.13801/j.cnki.fhclxb.20211022.001

Abstract:

Reverse osmosis is an operation that uses osmotic pressure as the driving force to separate solvent from solution. It has become the mainstream technology in the field of desalination due to its advantages of low energy consumption, low cost and environmental friendliness, leading the global seawater/brackish water desalination market. As the core of reverse osmosis technology, reverse osmosis membranes still have some problems of water flux, salt rejection and insufficient durability to meet the increasing demand. The development of mixed matrix reverse osmosis membranes based on inorganic nanomaterial has injected new vitality into solving this problem, and there have been many research reports. This paper reviewed the current research progress of inorganic nanohybrid matrix reverse osmosis membrane, focusing on the research status and progress, problems and challenges of zero-dimensional, one-dimensional and two-dimensional inorganic nanohybrid matrix and inorganic nanocomposite hybrid matrix reverse osmosis membranes. Finally, the future research directions of mixed matrix reverse osmosis membrane filled with inorganic nanomaterials were also analyzed and prospected.

Reverse osmosis is an operation that uses osmotic pressure as the driving force to separate solvent from solution. It has become the mainstream technology in the field of desalination due to its advantages of low energy consumption, low cost and environmental friendliness, leading the global seawater/brackish water desalination market. As the core of reverse osmosis technology, reverse osmosis membranes still have some problems of water flux, salt rejection and insufficient durability to meet the increasing demand. The development of mixed matrix reverse osmosis membranes based on inorganic nanomaterial has injected new vitality into solving this problem, and there have been many research reports. This paper reviewed the current research progress of inorganic nanohybrid matrix reverse osmosis membrane, focusing on the research status and progress, problems and challenges of zero-dimensional, one-dimensional and two-dimensional inorganic nanohybrid matrix and inorganic nanocomposite hybrid matrix reverse osmosis membranes. Finally, the future research directions of mixed matrix reverse osmosis membrane filled with inorganic nanomaterials were also analyzed and prospected.

2022, 39(4): 1425-1445.

doi: 10.13801/j.cnki.fhclxb.20211223.002

Abstract:

Cellulose and chitin are polysaccharides that abundantly exist in nature and have similar structures. Cellulose and chitin nanofibers prepared by using 2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO) oxidization, not only have good hydrophilicity, biodegradability, biocompatibility and the active chemical properties brought by various functional groups (hydroxyl, carboxyl, acetyl, amino, etc.), but also have the characteristics of large specific surface area, chiral liquid crystal phase, high crystallinity, high transparency and specific nano effect caused by nano size. These natural polysaccharide nanofibers have become one of the research focuses in the field of biomass nanomaterials. In this review, the TEMPO oxidation methods used for the preparation of natural polysaccharide nanofibers, as well as the nanofiber extraction mechanism, were comprehensive summarized. At the same time, the up to now research progress on the as-prepared polysaccharide nanofibers-based composites, such as film, gel, conductive, medical, electromagnetic shielding and environmental materials, with focusing on its mechanical enhancement and function upgradation performance were reviewed. Specific focus is giving to the contributions of the functional groups and nano size of cellulose and chitin nanofibers on the performance improvements of the composites. Finally, the development direction of natural polysaccharide nanofibers and the opportunities and challenges of their applications in various fields are prospected.

Cellulose and chitin are polysaccharides that abundantly exist in nature and have similar structures. Cellulose and chitin nanofibers prepared by using 2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO) oxidization, not only have good hydrophilicity, biodegradability, biocompatibility and the active chemical properties brought by various functional groups (hydroxyl, carboxyl, acetyl, amino, etc.), but also have the characteristics of large specific surface area, chiral liquid crystal phase, high crystallinity, high transparency and specific nano effect caused by nano size. These natural polysaccharide nanofibers have become one of the research focuses in the field of biomass nanomaterials. In this review, the TEMPO oxidation methods used for the preparation of natural polysaccharide nanofibers, as well as the nanofiber extraction mechanism, were comprehensive summarized. At the same time, the up to now research progress on the as-prepared polysaccharide nanofibers-based composites, such as film, gel, conductive, medical, electromagnetic shielding and environmental materials, with focusing on its mechanical enhancement and function upgradation performance were reviewed. Specific focus is giving to the contributions of the functional groups and nano size of cellulose and chitin nanofibers on the performance improvements of the composites. Finally, the development direction of natural polysaccharide nanofibers and the opportunities and challenges of their applications in various fields are prospected.

2022, 39(4): 1446-1456.

doi: 10.13801/j.cnki.fhclxb.20211101.002

Abstract:

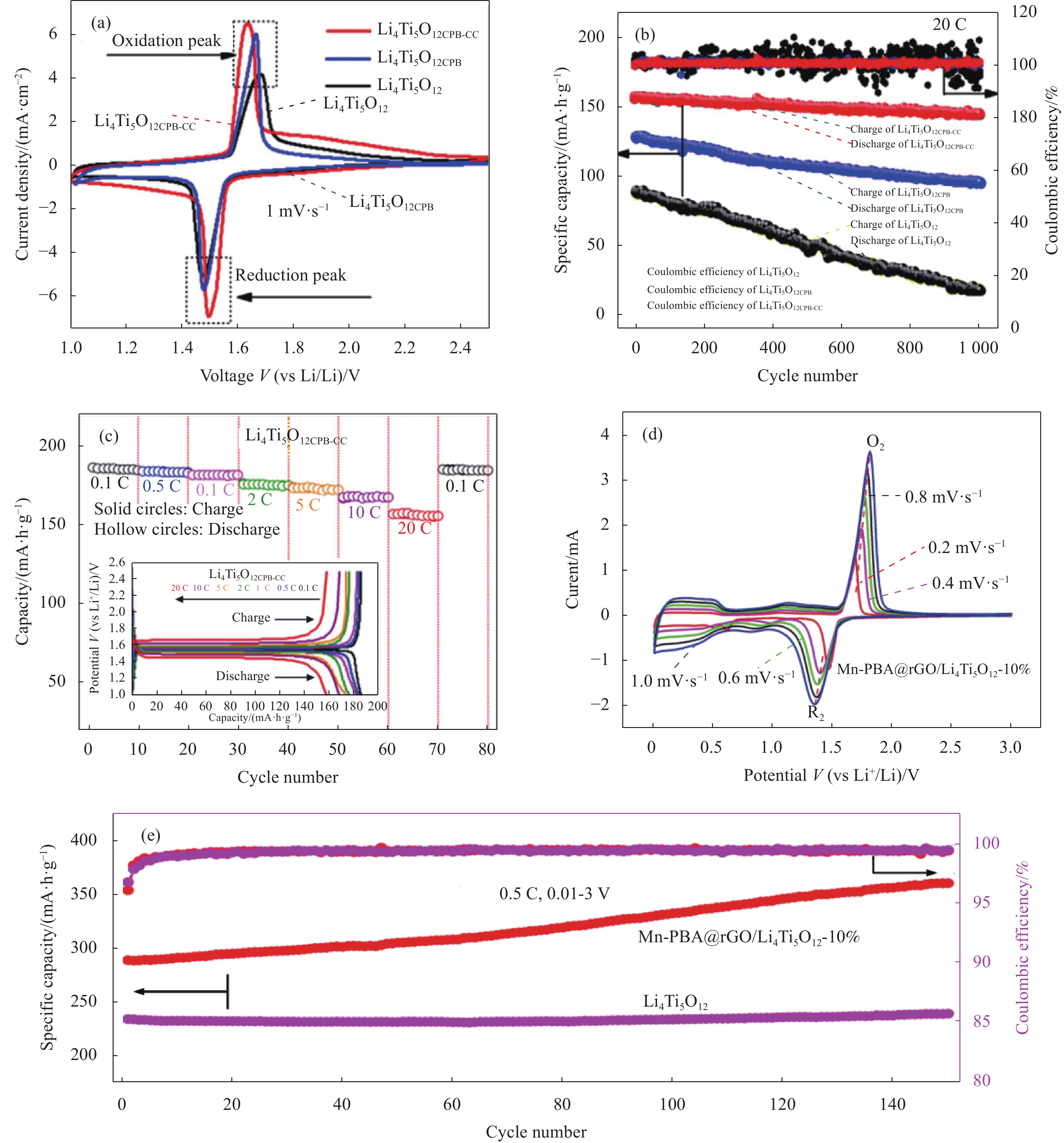

Lithium-ion batteries (LIBs) have attracted the attention of related researchers because of their excellent performance such as no memory effects, environmental-friendly and small self-discharge. The development of information electronics, electric vehicles and smart grids has created a huge demand for high energy density, long cycle life and low cost LIBs. As one of the important components of LIBs, the performance of anodes has an important impact on the overall indicators of the battery, the material used as anode is required to have high specific capacity and excellent cycling performance and other characteristics. Lithium metal is easy to form dendrites in the reaction process, and its commercial application is limited. The carbon base anode, lithium titanate (Li4Ti5O12) and silicon carbon anode are also difficult to meet the requirements of practical applications, the research of new anode materials has become a new hotspot. In this paper, the research status of anode materials for LIB was reviewed, the advantages and disadvantages of anode materials such as carbon based anode, Li4Ti5O12, silicon carbon anode and new anode material were summarized and analyzed. Besides that, the research direction of anode materials for LIB was pointed out, and the prospect of anode materials was prospected.

Lithium-ion batteries (LIBs) have attracted the attention of related researchers because of their excellent performance such as no memory effects, environmental-friendly and small self-discharge. The development of information electronics, electric vehicles and smart grids has created a huge demand for high energy density, long cycle life and low cost LIBs. As one of the important components of LIBs, the performance of anodes has an important impact on the overall indicators of the battery, the material used as anode is required to have high specific capacity and excellent cycling performance and other characteristics. Lithium metal is easy to form dendrites in the reaction process, and its commercial application is limited. The carbon base anode, lithium titanate (Li4Ti5O12) and silicon carbon anode are also difficult to meet the requirements of practical applications, the research of new anode materials has become a new hotspot. In this paper, the research status of anode materials for LIB was reviewed, the advantages and disadvantages of anode materials such as carbon based anode, Li4Ti5O12, silicon carbon anode and new anode material were summarized and analyzed. Besides that, the research direction of anode materials for LIB was pointed out, and the prospect of anode materials was prospected.

2022, 39(4): 1457-1468.

doi: 10.13801/j.cnki.fhclxb.20210830.002

Abstract:

As a novel two-dimensional layered nano material, MXene has large specific surface area and rich surface functional groups. When used as a filler in polymer composites, it can significantly improve the performance or broaden the application of polymer. Therefore, it has been widely studied at present. In this paper, the preparation methods of MXene and MXene/polymer composites are briefly summarized. The mechanical, thermal, tribological and electromagnetic shielding properties of MXene/polymer composites are described, and the latest research progress has been summarized. Finally, the prospects are made on the main problems and for its future development orientation.

As a novel two-dimensional layered nano material, MXene has large specific surface area and rich surface functional groups. When used as a filler in polymer composites, it can significantly improve the performance or broaden the application of polymer. Therefore, it has been widely studied at present. In this paper, the preparation methods of MXene and MXene/polymer composites are briefly summarized. The mechanical, thermal, tribological and electromagnetic shielding properties of MXene/polymer composites are described, and the latest research progress has been summarized. Finally, the prospects are made on the main problems and for its future development orientation.

Research progress on preparation and aging resistance of carbon-based wood electrothermal composites

2022, 39(4): 1469-1485.

doi: 10.13801/j.cnki.fhclxb.20211123.001

Abstract:

Carbon-based wood electrothermal composite is an innovative wooden functional composite that fabricated by carbon material as heating element embedded in wood matrix, which can be widely used to produce electrothermal wooden floor, electrothermal wooden wall panel and electrothermal wooden wardrobe etc. The carbon-based wood electrothermal composites show an integrated function of heating and decoration, and have excellent application prospects in the field of clean heating. In this review, the preparation method and application of carbon fiber heating paper, carbon nanotube heating composite, graphene heating composite, carbon fiber heating wire, carbon black heating composite and carbon crystal heating composite were introduced. Furthermore, the effects of process parameter and structure on the physical and chemical properties, electrical conductivity and electrothermal performances of electrothermal engineered wood composite, electrothermal fiberboard composite and electrothermal bamboo-wood composite were analyzed, as well as the current development of the influence of electrothermal and hygrothermal behaviour on the aging resistance and electric safety were also summarized. Finally, the future development directions of carbon-based wood electrothermal composites were prospected.

Carbon-based wood electrothermal composite is an innovative wooden functional composite that fabricated by carbon material as heating element embedded in wood matrix, which can be widely used to produce electrothermal wooden floor, electrothermal wooden wall panel and electrothermal wooden wardrobe etc. The carbon-based wood electrothermal composites show an integrated function of heating and decoration, and have excellent application prospects in the field of clean heating. In this review, the preparation method and application of carbon fiber heating paper, carbon nanotube heating composite, graphene heating composite, carbon fiber heating wire, carbon black heating composite and carbon crystal heating composite were introduced. Furthermore, the effects of process parameter and structure on the physical and chemical properties, electrical conductivity and electrothermal performances of electrothermal engineered wood composite, electrothermal fiberboard composite and electrothermal bamboo-wood composite were analyzed, as well as the current development of the influence of electrothermal and hygrothermal behaviour on the aging resistance and electric safety were also summarized. Finally, the future development directions of carbon-based wood electrothermal composites were prospected.

2022, 39(4): 1486-1497.

doi: 10.13801/j.cnki.fhclxb.20210925.001

Abstract:

With the rapid development of semiconductor manufacturing technology, the miniaturization and integration of electronic equipment make the heat dissipation becoming a key factor restricting the development of electronic components, and higher requirements have been placed on the thermal conductivity of thermal interface and packaging materials. Simple blending between thermally conductive filler and polymer matrix is difficult to achieve high thermal conductivity at low filling levels. Orientation of thermally conductive fillers in polymer matrix is favorable for achieving anisotropic thermal conductivity and reducing the thermally conductive permeation threshold, therefore, how to construct an oriented structure of thermally conductive filler in the polymer matrix to form an efficient thermally conductive network at low filling levels is becoming a research hotspot. In the process of promoting the orientation of thermally conductive fillers, especially fillers with nonspherical characteristics (flaky, rod-shaped or fibrous, etc.), external force plays a vital role. This article is classified according to the main driving forces that induce the orientation of thermally conductive fillers, and summarizes the latest technology and research progress in the preparation of anisotropic polymer matrix composites with high thermal conductivity, using magnetic field induction, electric field induction and mechanical force induction in the past 5 years. The conditions, mechanism of forming oriented structure of conducting filler under the action of external forces, and the structure-property relationship are mainly introduced. The characteristics, advantages and disadvantages of each method are analyzed. The bottlenecks in constructing an oriented structure of thermally conductive filler in the polymer matrix are analyzed simultaneously so far. Finally, the future development direction of thermally conductive polymer composites is forecasted. This review provides a reference for the development and application of highly thermally conductive, anisotropic polymer composites at a low filler loading level.

With the rapid development of semiconductor manufacturing technology, the miniaturization and integration of electronic equipment make the heat dissipation becoming a key factor restricting the development of electronic components, and higher requirements have been placed on the thermal conductivity of thermal interface and packaging materials. Simple blending between thermally conductive filler and polymer matrix is difficult to achieve high thermal conductivity at low filling levels. Orientation of thermally conductive fillers in polymer matrix is favorable for achieving anisotropic thermal conductivity and reducing the thermally conductive permeation threshold, therefore, how to construct an oriented structure of thermally conductive filler in the polymer matrix to form an efficient thermally conductive network at low filling levels is becoming a research hotspot. In the process of promoting the orientation of thermally conductive fillers, especially fillers with nonspherical characteristics (flaky, rod-shaped or fibrous, etc.), external force plays a vital role. This article is classified according to the main driving forces that induce the orientation of thermally conductive fillers, and summarizes the latest technology and research progress in the preparation of anisotropic polymer matrix composites with high thermal conductivity, using magnetic field induction, electric field induction and mechanical force induction in the past 5 years. The conditions, mechanism of forming oriented structure of conducting filler under the action of external forces, and the structure-property relationship are mainly introduced. The characteristics, advantages and disadvantages of each method are analyzed. The bottlenecks in constructing an oriented structure of thermally conductive filler in the polymer matrix are analyzed simultaneously so far. Finally, the future development direction of thermally conductive polymer composites is forecasted. This review provides a reference for the development and application of highly thermally conductive, anisotropic polymer composites at a low filler loading level.

2022, 39(4): 1498-1510.

doi: 10.13801/j.cnki.fhclxb.20211009.002

Abstract:

The interface is a bridge connecting different two phases inside the composite material, which greatly affects the thermal, electrical, mechanical and other properties of the composites. As a new branch in the field of composite materials, thermal conductive composites have attracted more and more attention in recent years due to the rapid development of electronic and electrical appliances. However, it is found that the thermal conductivity of the composites is difficult to reach a few percent of the thermal conductivity of the conductive filler even if the high packing scheme is adopted, and the interfacial thermal resistance is the key factor affecting the improvement of the thermal conductivity of the composites. This paper analyzes the reasons for the thermal resistance of the internal interface inside the composites from the perspective of the interface layer and the heat transfer effect of the interface. In addition, the influence of interface effects on the heat conduction of functional composites was discussed in terms of theoretical research methods, experimental characterization techniques, and interface factors that affect the internal heat conduction behavior of materials. Finally, the development of interface and interfacial heat transfer research were summarized and prospected.

The interface is a bridge connecting different two phases inside the composite material, which greatly affects the thermal, electrical, mechanical and other properties of the composites. As a new branch in the field of composite materials, thermal conductive composites have attracted more and more attention in recent years due to the rapid development of electronic and electrical appliances. However, it is found that the thermal conductivity of the composites is difficult to reach a few percent of the thermal conductivity of the conductive filler even if the high packing scheme is adopted, and the interfacial thermal resistance is the key factor affecting the improvement of the thermal conductivity of the composites. This paper analyzes the reasons for the thermal resistance of the internal interface inside the composites from the perspective of the interface layer and the heat transfer effect of the interface. In addition, the influence of interface effects on the heat conduction of functional composites was discussed in terms of theoretical research methods, experimental characterization techniques, and interface factors that affect the internal heat conduction behavior of materials. Finally, the development of interface and interfacial heat transfer research were summarized and prospected.

2022, 39(4): 1511-1533.

doi: 10.13801/j.cnki.fhclxb.20210820.001

Abstract:

Textile composites are widely used in aerospace field because of its advantages of light weight, high strength and strong designability.The fiber structure of textile preform determines the final mechanical properties of composites. However, the fiber structure of preform inevitably undergoes macro-scale and micro-structure deformation during the weaving process, and even wrinkle defects. The preform is a flexible skeleton, and its deformation mechanism is very complicated. Test is the most direct method to characterize the mechanical properties of preform, and it is also the basis of establishing theoretical and numerical analysis model. In this paper, the basic test methods of textile composite preform, such as tensile test, compression test, bending test, shear test and forming test, are reviewed. The advantages, disadvantages and applicable conditions of different test methods are discussed, and the future research work is prospected. The work in this paper will provide theoretical guidance for the improvement of preform mechanics testing technology, the establishment of testing standards and the accurate control of shape during the forming process. It will promote the structural design and engineering application of textile composites.

Textile composites are widely used in aerospace field because of its advantages of light weight, high strength and strong designability.The fiber structure of textile preform determines the final mechanical properties of composites. However, the fiber structure of preform inevitably undergoes macro-scale and micro-structure deformation during the weaving process, and even wrinkle defects. The preform is a flexible skeleton, and its deformation mechanism is very complicated. Test is the most direct method to characterize the mechanical properties of preform, and it is also the basis of establishing theoretical and numerical analysis model. In this paper, the basic test methods of textile composite preform, such as tensile test, compression test, bending test, shear test and forming test, are reviewed. The advantages, disadvantages and applicable conditions of different test methods are discussed, and the future research work is prospected. The work in this paper will provide theoretical guidance for the improvement of preform mechanics testing technology, the establishment of testing standards and the accurate control of shape during the forming process. It will promote the structural design and engineering application of textile composites.

2022, 39(4): 1534-1546.

doi: 10.13801/j.cnki.fhclxb.20210719.001

Abstract:

Traditional wastewater treatment methods, such as physical, chemical and biological methods, still have many shortcomings in the treatment efficiency, human health and environmental protection, etc. However, the use of bio-nanocomposites can effectively solve the problems existing in the traditional wastewater treatment methods, which is a new material with great application prospects in wastewater treatment. This review described the synthesis mechanism of bio-nanocomposites, analyzed bio-nano composites for adsorption, photocatalytic and antibacterial mechanism of water treatment, and heavy metals in the water, organic dyes, drugs, inorganic salt and other contaminants removal applications, including hydroxyl groups on the surface of the material replaced by fluorine ion adsorption, chromium ions are adsorbed by electrostatic interaction and ion interaction. The biological part of the composite material can reduce the band gap and increase the adsorption area by absorbing the energy of a specific spectrum and catalyzing the oxidation of the pollutants adsorbed on the surface, which will eventually degrade or mineralize them. The material can directly interact with microbial cells to interrupt transmembrane electron transfer, destroy/penetrate cell envelope or oxidize cell components, or produce secondary products such as reactive oxygen species. The problems existing in controlling the morphology and particle size of nanoparticles, rapidly increasing the yield of nanoparticles and clarifying the toxicity of some sizes of nanoparticles were analyzed. In this paper the future development direction of bio-nanocomposites was put forward, achieving efficient control of green bio-nanocomposites production technology was expected. The next step is to focus on the precise mechanism of cellular and biochemical process, optimize the reaction parameters, improve the stability of the nanoparticles, explore the biological materials range of nano composite and form a mature synthesis technology scheme of bio-nanocomposites.

Traditional wastewater treatment methods, such as physical, chemical and biological methods, still have many shortcomings in the treatment efficiency, human health and environmental protection, etc. However, the use of bio-nanocomposites can effectively solve the problems existing in the traditional wastewater treatment methods, which is a new material with great application prospects in wastewater treatment. This review described the synthesis mechanism of bio-nanocomposites, analyzed bio-nano composites for adsorption, photocatalytic and antibacterial mechanism of water treatment, and heavy metals in the water, organic dyes, drugs, inorganic salt and other contaminants removal applications, including hydroxyl groups on the surface of the material replaced by fluorine ion adsorption, chromium ions are adsorbed by electrostatic interaction and ion interaction. The biological part of the composite material can reduce the band gap and increase the adsorption area by absorbing the energy of a specific spectrum and catalyzing the oxidation of the pollutants adsorbed on the surface, which will eventually degrade or mineralize them. The material can directly interact with microbial cells to interrupt transmembrane electron transfer, destroy/penetrate cell envelope or oxidize cell components, or produce secondary products such as reactive oxygen species. The problems existing in controlling the morphology and particle size of nanoparticles, rapidly increasing the yield of nanoparticles and clarifying the toxicity of some sizes of nanoparticles were analyzed. In this paper the future development direction of bio-nanocomposites was put forward, achieving efficient control of green bio-nanocomposites production technology was expected. The next step is to focus on the precise mechanism of cellular and biochemical process, optimize the reaction parameters, improve the stability of the nanoparticles, explore the biological materials range of nano composite and form a mature synthesis technology scheme of bio-nanocomposites.

2022, 39(4): 1547-1558.

doi: 10.13801/j.cnki.fhclxb.20210607.002

Abstract:

Metal-organic framework (MOFs) was an organic-inorganic hybrid material with porous structure formed by self-assembly of metal ions or clusters and organic ligands through coordination bonds. They have the advantages of adjustable frame structure, high porosity, good chemical stability, reproducibility and simple synthesis process. Therefore, it was widely used in adsorption and separation of small molecules, catalytic chemical reaction, catalytic degradation, enrichment of substances, REDOX reaction, drug dilution and other fields. Magnetic metal organic framework (MMOFs) introduces magnetic metal particles on the basis of metal organic framework, greatly improves and optimizes its original performance, enriches the research content of metal organic framework, and widens the application of metal organic framework in food, pesticide and biology analysis. In this paper, the application of magnetic metal-organic framework in bioanalysis was systematically discussed. On this basis, the limitations of current MMOFs materials in this field were summarized, and the new trend of research was proposed.

Metal-organic framework (MOFs) was an organic-inorganic hybrid material with porous structure formed by self-assembly of metal ions or clusters and organic ligands through coordination bonds. They have the advantages of adjustable frame structure, high porosity, good chemical stability, reproducibility and simple synthesis process. Therefore, it was widely used in adsorption and separation of small molecules, catalytic chemical reaction, catalytic degradation, enrichment of substances, REDOX reaction, drug dilution and other fields. Magnetic metal organic framework (MMOFs) introduces magnetic metal particles on the basis of metal organic framework, greatly improves and optimizes its original performance, enriches the research content of metal organic framework, and widens the application of metal organic framework in food, pesticide and biology analysis. In this paper, the application of magnetic metal-organic framework in bioanalysis was systematically discussed. On this basis, the limitations of current MMOFs materials in this field were summarized, and the new trend of research was proposed.

2022, 39(4): 1559-1569.

doi: 10.13801/j.cnki.fhclxb.20210616.005

Abstract:

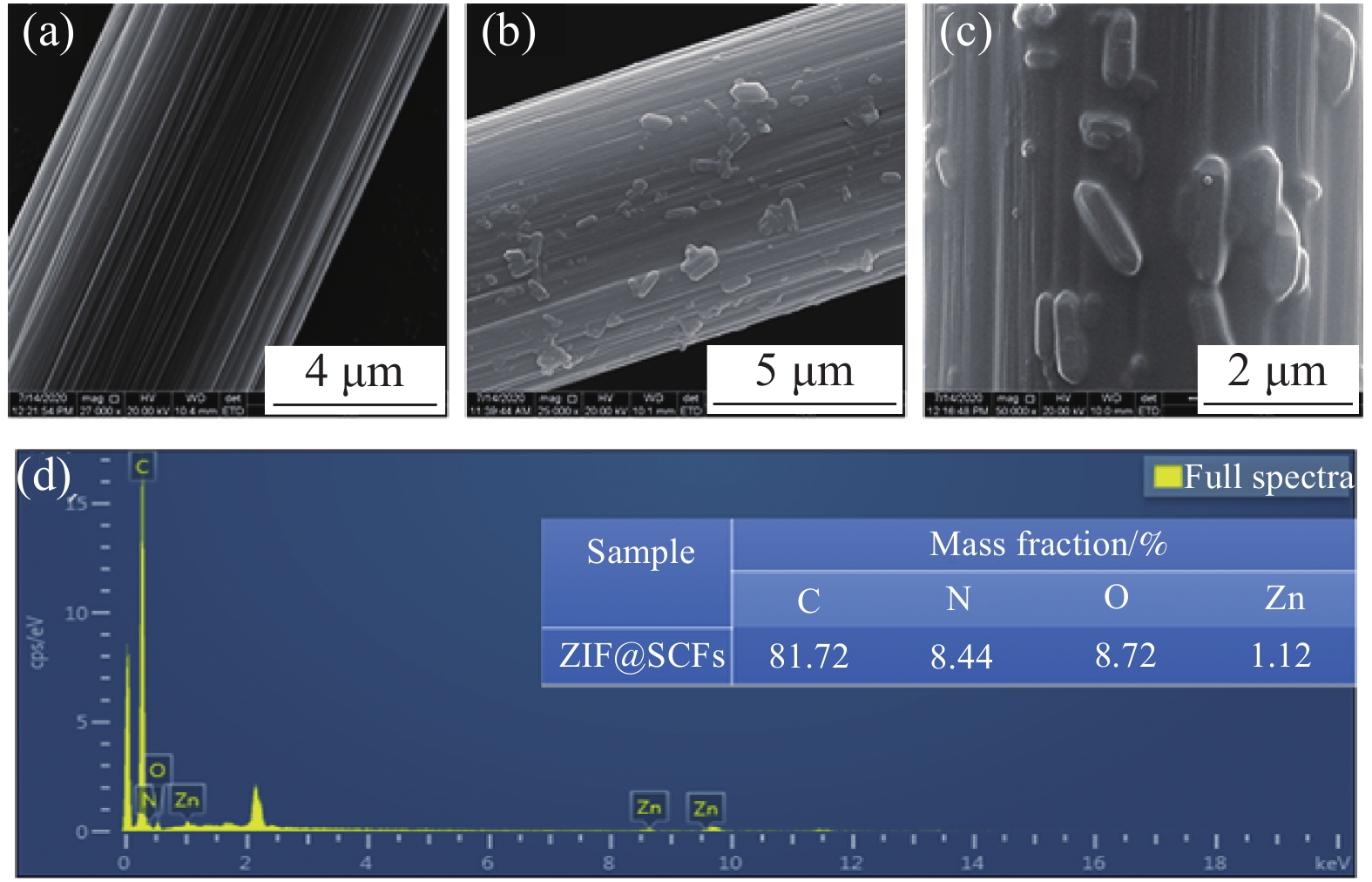

The nano ZIF-8 on short carbon fibers (ZIF-8@SCFs) were prepared in situ growth. The composites were manufactured using ZIF-8@SCFs, ammonium polyphosphate (APP) and epoxy resin (EP) to improve the flame retardant and mechanical properties. Oxygen index tester, horizontal and vertical combustion tester, cone calorimeter and universal electronic tensile machine were used to investigate the flame retardant and mechanical properties of EP composite materials. The experimental results show that when the addition amount of ZIF-8@SCFs is 1wt% (the mass ratio of APP to ZIF-8@SCFs is 4∶1), the limiting oxygen index of the composite material increases from 25.7% to 28.1%, and UL-94 reaches V-1 level. The peak heat release rate (pHRR) and total smoke production (TSP) are reduced evidently compared with the sample with only 5wt% of APP. Besides, the tensile strength, flexural strength, elastic modulus and elongation at break of the composite material are increased by 86%, 81%, 20% and 75%, respectively, which solves the problem that the addition of inorganic flame-retardant destroys the mechanical properties of EP. The prepared composites could be applied in practice.

The nano ZIF-8 on short carbon fibers (ZIF-8@SCFs) were prepared in situ growth. The composites were manufactured using ZIF-8@SCFs, ammonium polyphosphate (APP) and epoxy resin (EP) to improve the flame retardant and mechanical properties. Oxygen index tester, horizontal and vertical combustion tester, cone calorimeter and universal electronic tensile machine were used to investigate the flame retardant and mechanical properties of EP composite materials. The experimental results show that when the addition amount of ZIF-8@SCFs is 1wt% (the mass ratio of APP to ZIF-8@SCFs is 4∶1), the limiting oxygen index of the composite material increases from 25.7% to 28.1%, and UL-94 reaches V-1 level. The peak heat release rate (pHRR) and total smoke production (TSP) are reduced evidently compared with the sample with only 5wt% of APP. Besides, the tensile strength, flexural strength, elastic modulus and elongation at break of the composite material are increased by 86%, 81%, 20% and 75%, respectively, which solves the problem that the addition of inorganic flame-retardant destroys the mechanical properties of EP. The prepared composites could be applied in practice.

2022, 39(4): 1570-1581.

doi: 10.13801/j.cnki.fhclxb.20210518.011

Abstract:

Three kinds of thermoplastic resin, waterborne rubber, waterborne polyester and waterborne polyurethane, were used as resin matrix, and ultra-high molecular weight polyethylene (UHMWPE) fiber was worked as reinforcement. The unidirectional cross-ply structure bulletproof advanced composite laminates were prepared by hot-pressing process. The influences of thermoplastic resin matrix on mechanical behavior and ballistic response of bulletproof advanced composites were studied through ballistic impact test and mechanical test. The results show that: compared with the single thermoplastic resin system, UHMWPE fiber composite, which was fabricated with the thermoplastic resin mixed system, has better anti-penetration performance, higher tensile strength at break and higher interlaminar shear strength at break. This phenomenon is due to the higher utilization efficiency of UHMWPE fiber in the mixed resin system. Moreover, according to indirect tension mechanism induced by transverse compression together with membrane force effect caused by the larger deformation under ballistic impact, the anti-penetration performance of UHMWPE fiber composite is positively correlated with mechanical properties under quasi-static state, including tensile strength at break and interlaminar shear strength.

Three kinds of thermoplastic resin, waterborne rubber, waterborne polyester and waterborne polyurethane, were used as resin matrix, and ultra-high molecular weight polyethylene (UHMWPE) fiber was worked as reinforcement. The unidirectional cross-ply structure bulletproof advanced composite laminates were prepared by hot-pressing process. The influences of thermoplastic resin matrix on mechanical behavior and ballistic response of bulletproof advanced composites were studied through ballistic impact test and mechanical test. The results show that: compared with the single thermoplastic resin system, UHMWPE fiber composite, which was fabricated with the thermoplastic resin mixed system, has better anti-penetration performance, higher tensile strength at break and higher interlaminar shear strength at break. This phenomenon is due to the higher utilization efficiency of UHMWPE fiber in the mixed resin system. Moreover, according to indirect tension mechanism induced by transverse compression together with membrane force effect caused by the larger deformation under ballistic impact, the anti-penetration performance of UHMWPE fiber composite is positively correlated with mechanical properties under quasi-static state, including tensile strength at break and interlaminar shear strength.

2022, 39(4): 1582-1591.

doi: 10.13801/j.cnki.fhclxb.20210518.001

Abstract:

For effectively enhancing the interlaminar fracture toughness of carbon fiber epoxy resin composite laminates (CF/EP), a modification method of nanofiber veils intercalation cooperating nanoparticles was proposed. First, the needle-like FeOOH nanoparticles were uniformly loaded on the surface of the carbon fiber cloth by spraying method, and then the prepared electrospun polyvinylidene fluoride (PVDF) nanofiber veils was interleaved between the layers of the FeOOH loaded carbon fiber cloth, and the modified composite laminate PVDF&FeOOH-CF/EP was prepared by manual laying-vacuum hot pressing method, and the effective effect and mechanism of FeOOH with different areal densities in enhancing the interlaminar fracture toughness of CF/EP with the PVDF were studied. The results show that FeOOH is evenly distributed on the carbon fiber cloth. When the areal density is 2 g/m2, the PVDF&FeOOH-CF/EP laminate has the best toughening effect. Compared with that of CF/EP, the mode-I interlaminar fracture toughness GIC is increased by 118% and mode-II interlaminar fracture toughness GIIC is increased by 97%, while the GIC and GIIC of PVDF-CF/EP only are increased by 70% and 44%, respectively. SEM analysis shows that the addition of FeOOH not only improves the fracture toughness of the matrix, but also enhances the interface between the PVDF fiber and the matrix epoxy resin, thereby enhancing the toughening behavior of PVDF fiber.

For effectively enhancing the interlaminar fracture toughness of carbon fiber epoxy resin composite laminates (CF/EP), a modification method of nanofiber veils intercalation cooperating nanoparticles was proposed. First, the needle-like FeOOH nanoparticles were uniformly loaded on the surface of the carbon fiber cloth by spraying method, and then the prepared electrospun polyvinylidene fluoride (PVDF) nanofiber veils was interleaved between the layers of the FeOOH loaded carbon fiber cloth, and the modified composite laminate PVDF&FeOOH-CF/EP was prepared by manual laying-vacuum hot pressing method, and the effective effect and mechanism of FeOOH with different areal densities in enhancing the interlaminar fracture toughness of CF/EP with the PVDF were studied. The results show that FeOOH is evenly distributed on the carbon fiber cloth. When the areal density is 2 g/m2, the PVDF&FeOOH-CF/EP laminate has the best toughening effect. Compared with that of CF/EP, the mode-I interlaminar fracture toughness GIC is increased by 118% and mode-II interlaminar fracture toughness GIIC is increased by 97%, while the GIC and GIIC of PVDF-CF/EP only are increased by 70% and 44%, respectively. SEM analysis shows that the addition of FeOOH not only improves the fracture toughness of the matrix, but also enhances the interface between the PVDF fiber and the matrix epoxy resin, thereby enhancing the toughening behavior of PVDF fiber.

2022, 39(4): 1592-1600.

doi: 10.13801/j.cnki.fhclxb.20210609.004

Abstract:

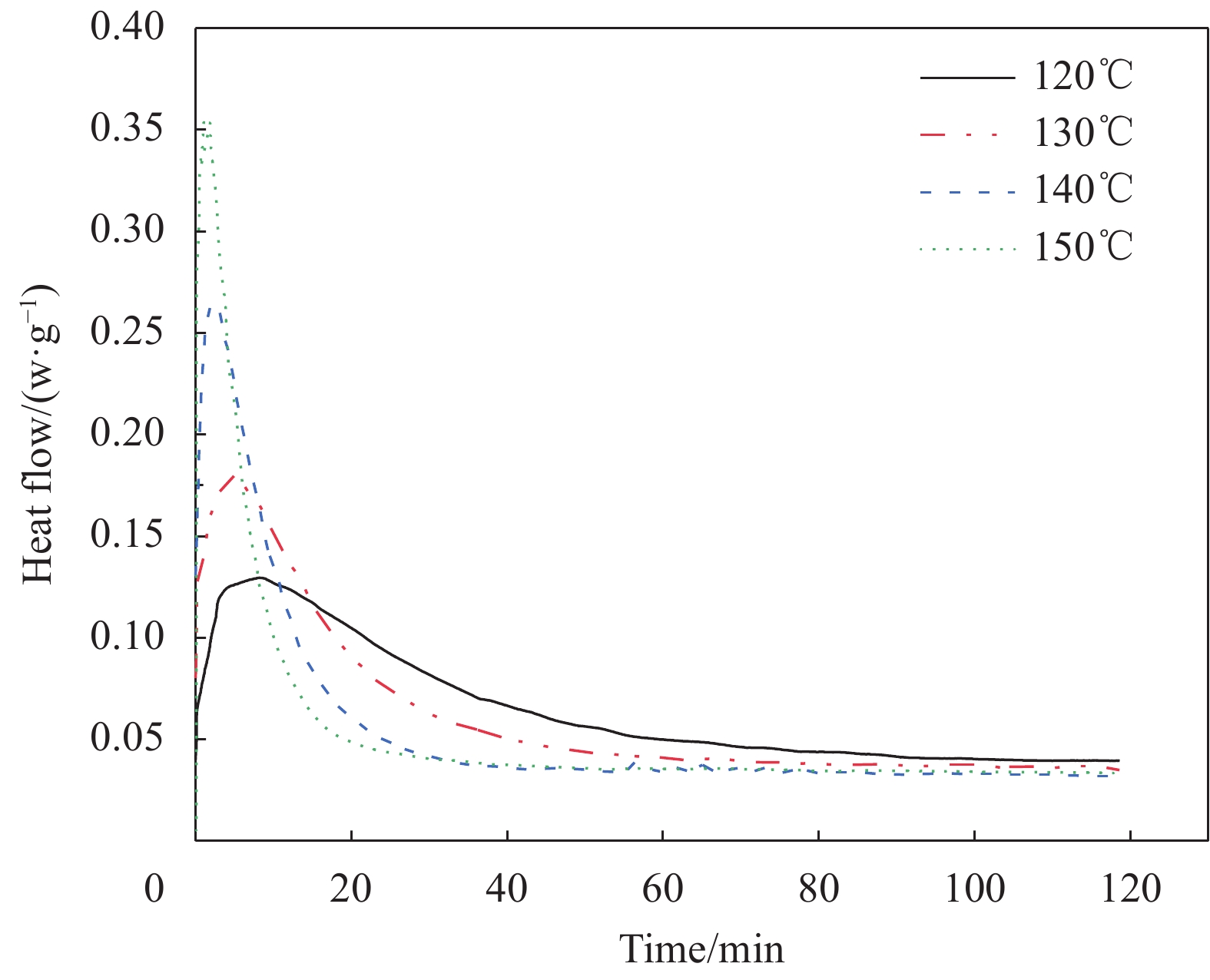

SIFEL 3705 is a kind of liquid fluoroelastomer developed by Shinyue company, Janpan, which can resist many chemicals and strong reducing media. It has been widely used in military, electronic, petrochemical and other fields overseas. It can scientifically guide the selection of sealing materials, give full play to the high performance of the material so as to meet the harsh sealing conditions when the structure and performance characteristics of SIFEL 3705 are mastered. The chemical structure and low temperature resistance of the liquid fluoroelastomer SIFEL 3705A and 3705B premixed were analyzed by FTIR, nuclear magnetic resonance spectroscopy (NMR) and differential scanning calorimetry (DSC) analyses. For the fluoroelastomer prepared by vulcanization of two-component premix, DSC, dynamic thermo-mechanical analysis (DMA), mechanical properties, low temperature flexibility, compression set, heat resistance and chemical medium resistance were tested and analyzed. The results show that the chemical structure of the main compound in SIFEL 3705A and 3705B premix is similar, which is fluororubber with ether bond C—O—C bond in the main chain. The glass transition temperature Tg of the fluoroelastomer is −52.5℃, and it still own resilience at −50℃. The fluoroelastomer has good mechanical properties and heat resis-tance with Shore A hardness of 66, tensile strength of 8.98 MPa, elongation at break of 289%, and initial degradation (mass loss of 5wt%) temperature as 476.8℃. The constant compression set is no more than 20% after compressing at 130℃ for 120 days. Meanwhile, the fluoroelastomer has excellent resistance to chemical media. The performance changes are unconspicuous in anhydrous ethanol and synthetic oil. The properties are changed quickly and then reach equilibrium in strong polar solvent of N, N-dimethylhydrazine. The results show that SHIN-ETSU fluoroelastomer as a sealing material is applicable for harsh environment such as low temperature of −50℃ and strong corrosive solvent.

SIFEL 3705 is a kind of liquid fluoroelastomer developed by Shinyue company, Janpan, which can resist many chemicals and strong reducing media. It has been widely used in military, electronic, petrochemical and other fields overseas. It can scientifically guide the selection of sealing materials, give full play to the high performance of the material so as to meet the harsh sealing conditions when the structure and performance characteristics of SIFEL 3705 are mastered. The chemical structure and low temperature resistance of the liquid fluoroelastomer SIFEL 3705A and 3705B premixed were analyzed by FTIR, nuclear magnetic resonance spectroscopy (NMR) and differential scanning calorimetry (DSC) analyses. For the fluoroelastomer prepared by vulcanization of two-component premix, DSC, dynamic thermo-mechanical analysis (DMA), mechanical properties, low temperature flexibility, compression set, heat resistance and chemical medium resistance were tested and analyzed. The results show that the chemical structure of the main compound in SIFEL 3705A and 3705B premix is similar, which is fluororubber with ether bond C—O—C bond in the main chain. The glass transition temperature Tg of the fluoroelastomer is −52.5℃, and it still own resilience at −50℃. The fluoroelastomer has good mechanical properties and heat resis-tance with Shore A hardness of 66, tensile strength of 8.98 MPa, elongation at break of 289%, and initial degradation (mass loss of 5wt%) temperature as 476.8℃. The constant compression set is no more than 20% after compressing at 130℃ for 120 days. Meanwhile, the fluoroelastomer has excellent resistance to chemical media. The performance changes are unconspicuous in anhydrous ethanol and synthetic oil. The properties are changed quickly and then reach equilibrium in strong polar solvent of N, N-dimethylhydrazine. The results show that SHIN-ETSU fluoroelastomer as a sealing material is applicable for harsh environment such as low temperature of −50℃ and strong corrosive solvent.

2022, 39(4): 1601-1609.

doi: 10.13801/j.cnki.fhclxb.20210525.001

Abstract:

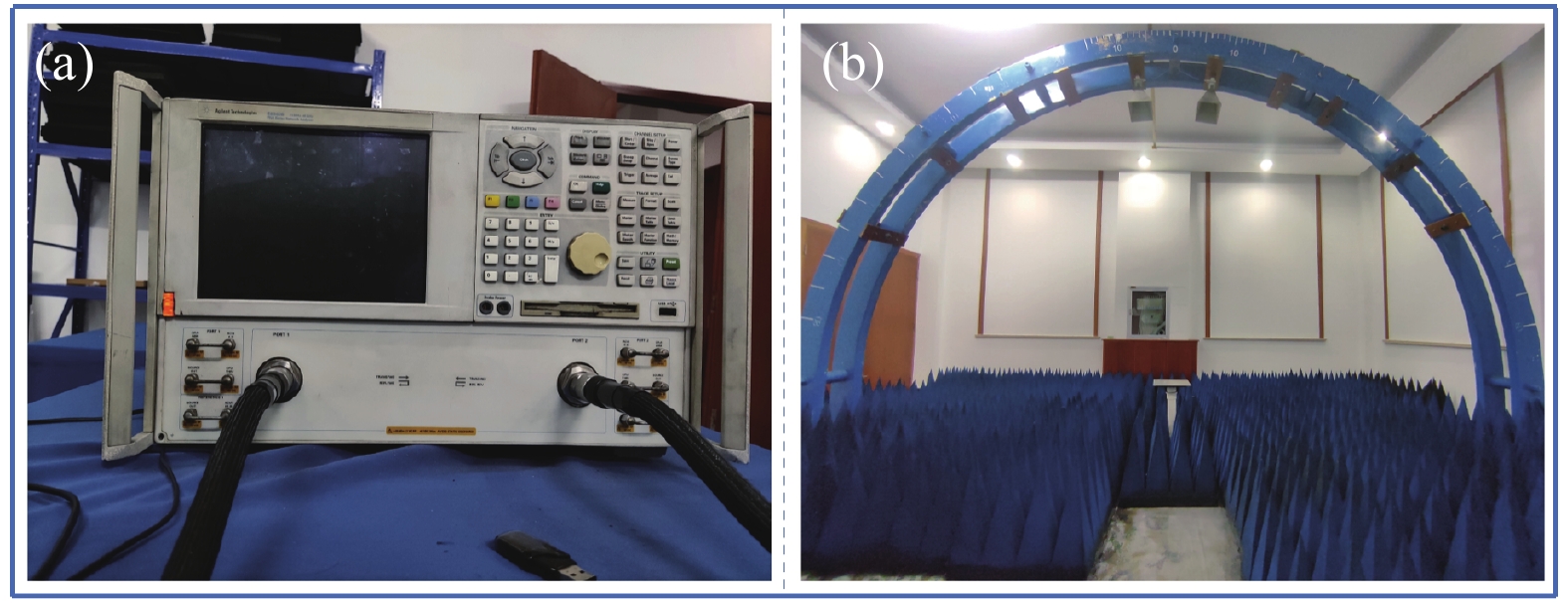

As a new type of artificial composite material, metamaterials have attracted numerous attentions in the fields of physics, materials science and electromagnetics for its unique electromagnetic properties. A transparent and flexible metamaterial with wideband microwave absorption properties was proposed in this work. The reflection-type metamaterial was composed of a microwave absorption layer, a dielectric substrate and a reflective backplane. The impedance matching curves of the microwave absorption layer was deduced based on the impedance matching theory to improve the accuracy and efficiency of the wideband optimization design. Simulated results show that absorption higher than 90% can be achieved in the frequency band ranging from 8.2-22 GHz, corresponding to a total wideband of 13.8 GHz. The relative bandwidth reaches up to 91.4%, realizing wideband absorption while the thickness of the metamaterial is only 0.091 times the upper-cutoff wavelength. In addition, the metamaterial absorber is insensitive to polarization angle since its unit cell is symmetrical. Moreover, by rationally selecting materials of polyvinyl chloride (PVC) and indium tin oxide (ITO), the metamaterial absorber in this work is optically transparent and flexible, thus quite suitable for window radar stealth and equipment conformal stealth.

As a new type of artificial composite material, metamaterials have attracted numerous attentions in the fields of physics, materials science and electromagnetics for its unique electromagnetic properties. A transparent and flexible metamaterial with wideband microwave absorption properties was proposed in this work. The reflection-type metamaterial was composed of a microwave absorption layer, a dielectric substrate and a reflective backplane. The impedance matching curves of the microwave absorption layer was deduced based on the impedance matching theory to improve the accuracy and efficiency of the wideband optimization design. Simulated results show that absorption higher than 90% can be achieved in the frequency band ranging from 8.2-22 GHz, corresponding to a total wideband of 13.8 GHz. The relative bandwidth reaches up to 91.4%, realizing wideband absorption while the thickness of the metamaterial is only 0.091 times the upper-cutoff wavelength. In addition, the metamaterial absorber is insensitive to polarization angle since its unit cell is symmetrical. Moreover, by rationally selecting materials of polyvinyl chloride (PVC) and indium tin oxide (ITO), the metamaterial absorber in this work is optically transparent and flexible, thus quite suitable for window radar stealth and equipment conformal stealth.

2022, 39(4): 1610-1616.

doi: 10.13801/j.cnki.fhclxb.20210526.005

Abstract:

Bi2MoO6/WO3 composite photocatalysts with various Bi2MoO6 amounts were successfully synthesized by hydrothermal method. The microstructure, morphologies, optical absorption properties and spectral response of Bi2MoO6/WO3 composites were measured and characterized by XRD, SEM, UV-Vis, EIS and PL. Moreover, the photocatalytic activities of the samples were further investigated. The results show that the photocatalytic activity of the 15%Bi2MoO6/WO3 composite is obviously higher than that of the pure WO3 and Bi2MoO6: the photocatalytic oxygen production efficiency of the Bi2MoO6/WO3 is 2.3 times that of the pure WO3. The oxygen production efficiency of composite catalyst obtained 107 μmol/(g·h) after introducing Fe(NO3)3·9H2O assacrificial agent and exhibited good cycling stability. It is inferred that the Bi2MoO6 nanoparticle-WO3 nanorod heterojunction structure improves the transport and transfer efficiency of photo-generated carriers, reduces the recombination probability of electron-hole pairs, which is helpful to enhance the photocatalytic activity.

Bi2MoO6/WO3 composite photocatalysts with various Bi2MoO6 amounts were successfully synthesized by hydrothermal method. The microstructure, morphologies, optical absorption properties and spectral response of Bi2MoO6/WO3 composites were measured and characterized by XRD, SEM, UV-Vis, EIS and PL. Moreover, the photocatalytic activities of the samples were further investigated. The results show that the photocatalytic activity of the 15%Bi2MoO6/WO3 composite is obviously higher than that of the pure WO3 and Bi2MoO6: the photocatalytic oxygen production efficiency of the Bi2MoO6/WO3 is 2.3 times that of the pure WO3. The oxygen production efficiency of composite catalyst obtained 107 μmol/(g·h) after introducing Fe(NO3)3·9H2O assacrificial agent and exhibited good cycling stability. It is inferred that the Bi2MoO6 nanoparticle-WO3 nanorod heterojunction structure improves the transport and transfer efficiency of photo-generated carriers, reduces the recombination probability of electron-hole pairs, which is helpful to enhance the photocatalytic activity.

2022, 39(4): 1617-1627.

doi: 10.13801/j.cnki.fhclxb.20210609.001

Abstract:

Aiming at the low utilization rate of low-grade palygorskite in Linze area, MnOx/purifing palygorskite clay rich iron (PPCI) hybrid catalysts were prepared by the redox reaction method between KMnO4 and (NH4)2C2O4 via using low-grade PPCI from Linze as the support. The δ-MnO2/PPCI catalyst with Mn loading of 33.6wt% has excellent performance for formaldehyde oxidation at room temperature, which maintains more than effective 99% formaldehyde removal rate within 720 minutes. In contrast, the effective formaldehyde removal rate of the unloaded δ-MnO2 sample is only 87% after 720 min. Also, the removal rate of formaldehyde with initial concentration of 146.6 mg/m3 is more than 95% in 1h. The above results reveal that the introduction of palygorskite clay as the support greatly improves the efficiency of the MnOx/PPCI hybrid catalysts at room temperature. The formaldehyde oxidation kinetics results follow the second-order kinetics. Manganese oxide was highly distributed on the surface of palygorskite, resulting in a larger specific surface area (73.2 m2/g) and expose more Mn3+/Mn4+ couples, which improves the redox capacity and electrochemical activity of the composite catalyst and contributes to the process of formaldehyde degradation eventually. Based on the analysis results of in-situ DRFTS, the formation and conversion of formaldehyde on the surface of catalysts were revealed. Formaldehyde is first converted to dioxymethylene (DOM) by surface hydroxyl groups (–OH), and then oxidized to formate species (HCOO−) by surface active oxygen, HCOO− is finally oxidized to CO2 and H2O. The consumed -OH groups can be compensated from the activation of O2 via water and surface-active oxygen species reaction. This work paves a new road to utilizing low-grade palygorskite clay as compo-site catalysts for air purification at room temperature.

Aiming at the low utilization rate of low-grade palygorskite in Linze area, MnOx/purifing palygorskite clay rich iron (PPCI) hybrid catalysts were prepared by the redox reaction method between KMnO4 and (NH4)2C2O4 via using low-grade PPCI from Linze as the support. The δ-MnO2/PPCI catalyst with Mn loading of 33.6wt% has excellent performance for formaldehyde oxidation at room temperature, which maintains more than effective 99% formaldehyde removal rate within 720 minutes. In contrast, the effective formaldehyde removal rate of the unloaded δ-MnO2 sample is only 87% after 720 min. Also, the removal rate of formaldehyde with initial concentration of 146.6 mg/m3 is more than 95% in 1h. The above results reveal that the introduction of palygorskite clay as the support greatly improves the efficiency of the MnOx/PPCI hybrid catalysts at room temperature. The formaldehyde oxidation kinetics results follow the second-order kinetics. Manganese oxide was highly distributed on the surface of palygorskite, resulting in a larger specific surface area (73.2 m2/g) and expose more Mn3+/Mn4+ couples, which improves the redox capacity and electrochemical activity of the composite catalyst and contributes to the process of formaldehyde degradation eventually. Based on the analysis results of in-situ DRFTS, the formation and conversion of formaldehyde on the surface of catalysts were revealed. Formaldehyde is first converted to dioxymethylene (DOM) by surface hydroxyl groups (–OH), and then oxidized to formate species (HCOO−) by surface active oxygen, HCOO− is finally oxidized to CO2 and H2O. The consumed -OH groups can be compensated from the activation of O2 via water and surface-active oxygen species reaction. This work paves a new road to utilizing low-grade palygorskite clay as compo-site catalysts for air purification at room temperature.

2022, 39(4): 1628-1637.

doi: 10.13801/j.cnki.fhclxb.20210707.001

Abstract:

MnO2 is considered as a promising electrode material for supercapacitors because of its low cost, high abundance, large theoretical specific capacitance and environmentally friendly nature. How to obtain high-performance MnO2 electrode material with high mass loading via a low-cost synthesis method has attracted considerable attention and still remained a huge challenge. Herein, nitrided TiO2 nanorod arrays (N-TiO2) were successfully prepared on carbon fiber paper (CFP) by a novel seeded hydrothermal synthesis and thermal nitridation, and then hierarchical porous α-MnO2 nanoflowers entwined with nanoribbons were grown on the nitrided TiO2/CFP electrode. Hierarchical porous nanoflowers entwined with nanoribbons and nanorod arrays provide appropriate geometries and electronic structures, helping suppress stack tendency at high mass loading and improve the specific capacitance of electrode. The α-MnO2@N-TiO2/CFP electrode with high mass-loading of 20.9 mg·cm−2 shows a high areal capacitance of 3.0 F·cm−2 at 1 mA·cm−2 and excellent cycling stability with no capacitance reduction after 5000 cycles. The high performance makes the α-MnO2@N-TiO2/CFP electrode a promising electrode material for supercapacitor applications.

MnO2 is considered as a promising electrode material for supercapacitors because of its low cost, high abundance, large theoretical specific capacitance and environmentally friendly nature. How to obtain high-performance MnO2 electrode material with high mass loading via a low-cost synthesis method has attracted considerable attention and still remained a huge challenge. Herein, nitrided TiO2 nanorod arrays (N-TiO2) were successfully prepared on carbon fiber paper (CFP) by a novel seeded hydrothermal synthesis and thermal nitridation, and then hierarchical porous α-MnO2 nanoflowers entwined with nanoribbons were grown on the nitrided TiO2/CFP electrode. Hierarchical porous nanoflowers entwined with nanoribbons and nanorod arrays provide appropriate geometries and electronic structures, helping suppress stack tendency at high mass loading and improve the specific capacitance of electrode. The α-MnO2@N-TiO2/CFP electrode with high mass-loading of 20.9 mg·cm−2 shows a high areal capacitance of 3.0 F·cm−2 at 1 mA·cm−2 and excellent cycling stability with no capacitance reduction after 5000 cycles. The high performance makes the α-MnO2@N-TiO2/CFP electrode a promising electrode material for supercapacitor applications.

2022, 39(4): 1638-1647.

doi: 10.13801/j.cnki.fhclxb.20210611.001

Abstract:

The development of superhydrophobic materials in practical applications has been severely hindered by the complexity of manufacturing and the sensitivity to mechanical contact. In order to prepare a mechanically durable flexible super-hydrophobic surface on the surface of a flexible substrate (vulcanized silicone rubber), using the reversible characteristics of the swelling process of vulcanized silicone rubber and the improved sol-gel method, the silicone rubber sheet was swelled with a n-butylamine aqueous solution in advance, and then immersed in zinc nitrate/ethanol solution. Due to the cross-diffusion, contact and reaction between zinc nitrate and n-butylamine aqueous solution on the surface of silicone rubber, ZnO nanoflowers were grown in-situ on the rubber surface. The construction of the superhydrophobic rough structure came from the synergistic effect of zinc nitrate and n-butylamine, with static contact angle and rolling angle being (158±1.5)° and (4.5±0.5)° respectively. SEM images show that ZnO nanosheets of 100-200 nm in thickness are generated and the ZnO nanosheets are “embedded”, not just “deposited” on the rubber surface, which improves the mechanical durability. By adding a silane coupling agent γ-aminopropyltriethoxysilane (KH550) to the silicone rubber compounds, the interface interaction between the ZnO nanosheets and the rubber matrix is further improved. Even with 300 times of linear wear, it could still maintain superhydrophobic and exhibit excellent mechanical stability. Moreover, after 500 cycles of bending deformation, its hydrophobicity hardly changes, which solves the problem of superhydrophobic coating falling off when the substrate is bent and deformed. High mechanical stability and simple preparation process endow the superhydrophobic rubber a high application prospect.

The development of superhydrophobic materials in practical applications has been severely hindered by the complexity of manufacturing and the sensitivity to mechanical contact. In order to prepare a mechanically durable flexible super-hydrophobic surface on the surface of a flexible substrate (vulcanized silicone rubber), using the reversible characteristics of the swelling process of vulcanized silicone rubber and the improved sol-gel method, the silicone rubber sheet was swelled with a n-butylamine aqueous solution in advance, and then immersed in zinc nitrate/ethanol solution. Due to the cross-diffusion, contact and reaction between zinc nitrate and n-butylamine aqueous solution on the surface of silicone rubber, ZnO nanoflowers were grown in-situ on the rubber surface. The construction of the superhydrophobic rough structure came from the synergistic effect of zinc nitrate and n-butylamine, with static contact angle and rolling angle being (158±1.5)° and (4.5±0.5)° respectively. SEM images show that ZnO nanosheets of 100-200 nm in thickness are generated and the ZnO nanosheets are “embedded”, not just “deposited” on the rubber surface, which improves the mechanical durability. By adding a silane coupling agent γ-aminopropyltriethoxysilane (KH550) to the silicone rubber compounds, the interface interaction between the ZnO nanosheets and the rubber matrix is further improved. Even with 300 times of linear wear, it could still maintain superhydrophobic and exhibit excellent mechanical stability. Moreover, after 500 cycles of bending deformation, its hydrophobicity hardly changes, which solves the problem of superhydrophobic coating falling off when the substrate is bent and deformed. High mechanical stability and simple preparation process endow the superhydrophobic rubber a high application prospect.

2022, 39(4): 1648-1656.

doi: 10.13801/j.cnki.fhclxb.20210518.010

Abstract:

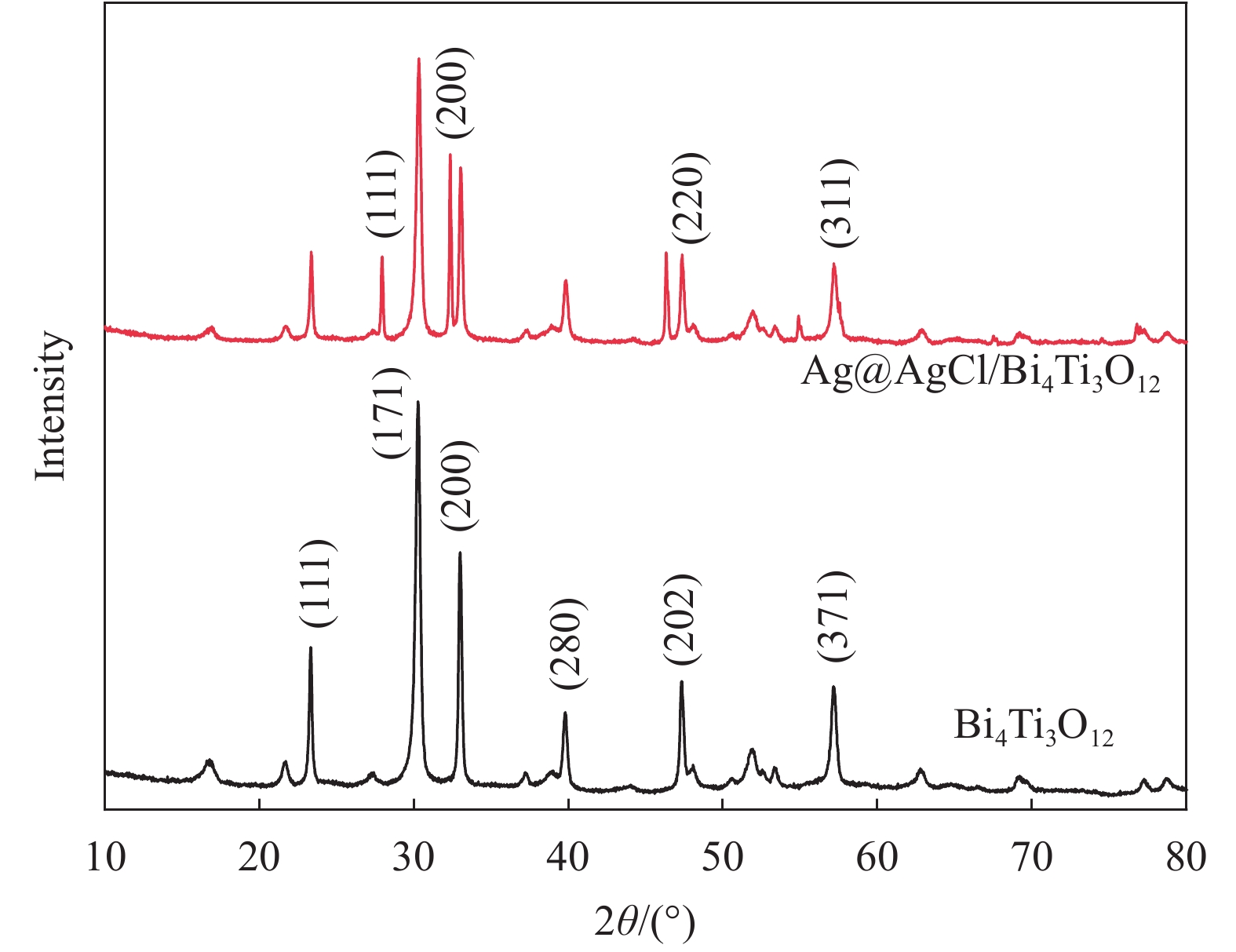

The Bi4Ti3O12was prepared by hydrothermal method using bismuth nitrate as the bismuth source and tetrabutyl titanate as the titanium source, and then the Bi4Ti3O12 was reduced by light to obtain Ag@AgCl/Bi4Ti3O12 nanocomposites using silver nitrate as the silver source and hydrochloric acid as the chlorine source. The compo-sition and structure of the as-prepared nanocomposites were characterized by XRD, UV-Vis DRS, SEM, TEM, BET and XPS, etc. Taking the decolorization rate of methyl orange (MO) as an evaluation standard, the visible light catalytic performance and active substances of the as-prepared catalyst were investigated. The results show that the prepared Bi4Ti3O12 has a stacked curd-shaped nanosheets structure and Ag@AgCl particles deposite between the sheets, the specific surface area of Ag@AgCl/Bi4Ti3O12 increases to 14.30 m2/g, and the absorption of visible light is enhanced. The decolorization rate can attain 96.71% when the 80 mL 10 mg/L MO solutions were irradiated under the 300 W xenon lamp for 30 min using 0.5 g/L Ag@AgCl/Bi4Ti3O12, which is 38.28% higher than that of pure Bi4Ti3O12. The degradation experiment has strong cycle stability and superoxide radicals (•O2−) plays a decisive role in the degradation process.

The Bi4Ti3O12was prepared by hydrothermal method using bismuth nitrate as the bismuth source and tetrabutyl titanate as the titanium source, and then the Bi4Ti3O12 was reduced by light to obtain Ag@AgCl/Bi4Ti3O12 nanocomposites using silver nitrate as the silver source and hydrochloric acid as the chlorine source. The compo-sition and structure of the as-prepared nanocomposites were characterized by XRD, UV-Vis DRS, SEM, TEM, BET and XPS, etc. Taking the decolorization rate of methyl orange (MO) as an evaluation standard, the visible light catalytic performance and active substances of the as-prepared catalyst were investigated. The results show that the prepared Bi4Ti3O12 has a stacked curd-shaped nanosheets structure and Ag@AgCl particles deposite between the sheets, the specific surface area of Ag@AgCl/Bi4Ti3O12 increases to 14.30 m2/g, and the absorption of visible light is enhanced. The decolorization rate can attain 96.71% when the 80 mL 10 mg/L MO solutions were irradiated under the 300 W xenon lamp for 30 min using 0.5 g/L Ag@AgCl/Bi4Ti3O12, which is 38.28% higher than that of pure Bi4Ti3O12. The degradation experiment has strong cycle stability and superoxide radicals (•O2−) plays a decisive role in the degradation process.

2022, 39(4): 1657-1666.

doi: 10.13801/j.cnki.fhclxb.20210622.001

Abstract:

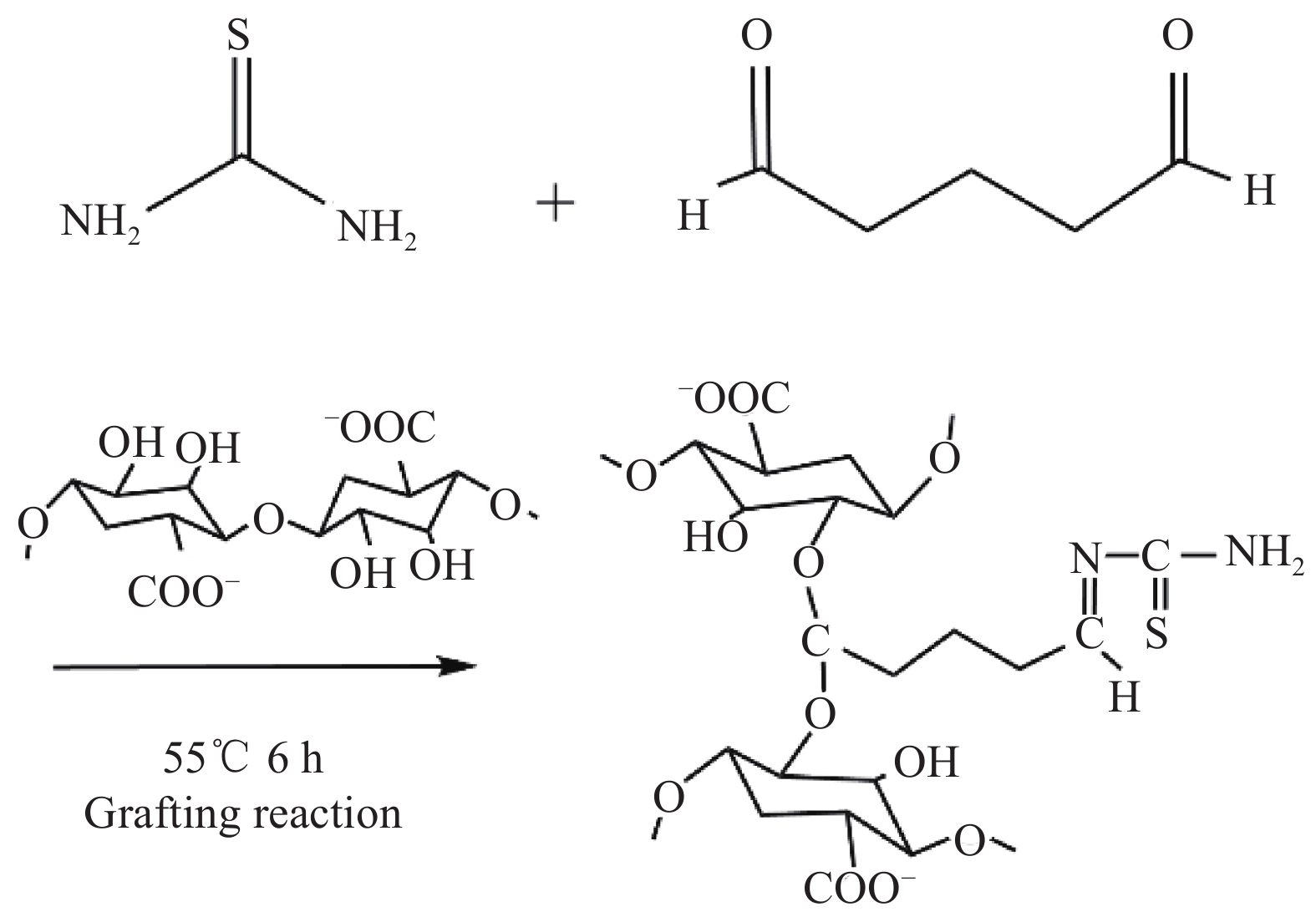

The photocatalysis is an efficient method to remove Cr(VI) from aqueous solution. Compared with adsorption, which can reduce Cr(VI) to Cr(III) in a short time. Glutaraldehyde was used as a crosslinking agent to graft thiourea onto sodium alginate (SA) for the synthesis of thiourea/sodium alginate beads (GTSA), the adsorption and reduction mechanism of Cr(VI) in solution under light condition was investigated. Compared with SA, the light absorbance of GTSA is greatly increased, as well as the ability to adsorb and reduce Cr(VI). Under the irradiation of ultraviolet mercury lamp at pH=1, the removal rate of Cr(VI) reaches 99%, and the reduction rate reaches 79%. The mechanism of Cr(VI) adsorption reduction by GTSA was analyzed by FTIR, SEM, UV-DRS and XPS, which indicated that the removal process of Cr(VI) is a synergistic effect of electrostatic adsorption and photocatalytic reduction.

The photocatalysis is an efficient method to remove Cr(VI) from aqueous solution. Compared with adsorption, which can reduce Cr(VI) to Cr(III) in a short time. Glutaraldehyde was used as a crosslinking agent to graft thiourea onto sodium alginate (SA) for the synthesis of thiourea/sodium alginate beads (GTSA), the adsorption and reduction mechanism of Cr(VI) in solution under light condition was investigated. Compared with SA, the light absorbance of GTSA is greatly increased, as well as the ability to adsorb and reduce Cr(VI). Under the irradiation of ultraviolet mercury lamp at pH=1, the removal rate of Cr(VI) reaches 99%, and the reduction rate reaches 79%. The mechanism of Cr(VI) adsorption reduction by GTSA was analyzed by FTIR, SEM, UV-DRS and XPS, which indicated that the removal process of Cr(VI) is a synergistic effect of electrostatic adsorption and photocatalytic reduction.

2022, 39(4): 1667-1677.

doi: 10.13801/j.cnki.fhclxb.20210617.004

Abstract:

The hydrogen production from hydrogen evolution reaction (HER) in electrochemical water splitting is considered to be one of the most promising energy conversion methods, which can simultaneously obtain high purity hydrogen and realize energy storage and conversion. The key depends on the development of HER electrocatalysts with high efficiency, high stability and low price. A series of NiOOH/polyaniline (NiOOH/PANI) catalyst precursors were prepared via one-pot hydrothermal method. After pyrolysis at 800°C, the Ni-NiO/N-C electrocatalysts were obtained and applied to HER. The XRD, SEM, TEM, BET, XPS and Raman spectroscopy were conducted to analyze the physical and chemical properties of the catalysts. Results show that the catalysts are present in the nanosheet morphology, the nickel and nickel oxide are coexisted and highly dispersed in the carbon support. The results of HER tests demonstrate that the catalytic performance is closely related with the content of nickel in the catalyst, and the Ni-NiO/N-C-0.6 catalyst with the aniline addition of 0.6 mL exhibits the best performance for HER, which has an overpotential of only 168 mV at a current density of 10 mA·cm−2. Besides, the catalyst also has good catalytic stability with almost no detectable activity decay after 16 h HER test or 1000 times of cyclic voltammetry measurements, demonstrating broad application prospects.

The hydrogen production from hydrogen evolution reaction (HER) in electrochemical water splitting is considered to be one of the most promising energy conversion methods, which can simultaneously obtain high purity hydrogen and realize energy storage and conversion. The key depends on the development of HER electrocatalysts with high efficiency, high stability and low price. A series of NiOOH/polyaniline (NiOOH/PANI) catalyst precursors were prepared via one-pot hydrothermal method. After pyrolysis at 800°C, the Ni-NiO/N-C electrocatalysts were obtained and applied to HER. The XRD, SEM, TEM, BET, XPS and Raman spectroscopy were conducted to analyze the physical and chemical properties of the catalysts. Results show that the catalysts are present in the nanosheet morphology, the nickel and nickel oxide are coexisted and highly dispersed in the carbon support. The results of HER tests demonstrate that the catalytic performance is closely related with the content of nickel in the catalyst, and the Ni-NiO/N-C-0.6 catalyst with the aniline addition of 0.6 mL exhibits the best performance for HER, which has an overpotential of only 168 mV at a current density of 10 mA·cm−2. Besides, the catalyst also has good catalytic stability with almost no detectable activity decay after 16 h HER test or 1000 times of cyclic voltammetry measurements, demonstrating broad application prospects.

2022, 39(4): 1678-1691.

doi: 10.13801/j.cnki.fhclxb.20210617.003

Abstract:

In order to investigate the seismic performance of prestressed carbon fiber reinforced polymer (CFRP) tendons and rebars-steel reinforced concrete (SRC) eccentrically tensioned member, the low reversed cyclic loading tests of four members of prestressed CFRP tendons-SRC eccentric tension, 4 members of prestressed rebar-SRC eccentric tension and 3 members of ordinary SRC tension were conducted. The test parameters include eccentricity, prestressed tension level, vertical force and the types of prestressed tendon. The results show that the failure modes of all the members are bending shear failure, and the hysteretic curves of all the members are full and the ductility is good. With the increase of eccentricity, the bearing capacity, ductility and energy dissipation capacity of each component decrease accordingly. With the increase of the prestress tensile level, the bearing capacity of the component increases to a certain extent, but the energy dissipation capacity decreases, and the ductility coefficient increases first and then decreases, and the increase range is greater than the decrease range. With the increase of vertical tensile force, the bearing capacity, ductility and energy dissipation capacity of the prestressed CFRP tendons-SRC eccentric tensile member decrease correspondingly. Compared with the ordinary SRC tensile member, the prestressed CFRP tendons-SRC eccentric tensile member has better bearing capacity, stiffness, ductility and crack resistance, but lower energy consumption capacity. Compared with the prestressed rebar-SRC eccentric tensile member, the prestressed CFRP tendons-SRC eccentric tensile member has lower bearing capacity and ductility, but higher energy dissipation capacity.

In order to investigate the seismic performance of prestressed carbon fiber reinforced polymer (CFRP) tendons and rebars-steel reinforced concrete (SRC) eccentrically tensioned member, the low reversed cyclic loading tests of four members of prestressed CFRP tendons-SRC eccentric tension, 4 members of prestressed rebar-SRC eccentric tension and 3 members of ordinary SRC tension were conducted. The test parameters include eccentricity, prestressed tension level, vertical force and the types of prestressed tendon. The results show that the failure modes of all the members are bending shear failure, and the hysteretic curves of all the members are full and the ductility is good. With the increase of eccentricity, the bearing capacity, ductility and energy dissipation capacity of each component decrease accordingly. With the increase of the prestress tensile level, the bearing capacity of the component increases to a certain extent, but the energy dissipation capacity decreases, and the ductility coefficient increases first and then decreases, and the increase range is greater than the decrease range. With the increase of vertical tensile force, the bearing capacity, ductility and energy dissipation capacity of the prestressed CFRP tendons-SRC eccentric tensile member decrease correspondingly. Compared with the ordinary SRC tensile member, the prestressed CFRP tendons-SRC eccentric tensile member has better bearing capacity, stiffness, ductility and crack resistance, but lower energy consumption capacity. Compared with the prestressed rebar-SRC eccentric tensile member, the prestressed CFRP tendons-SRC eccentric tensile member has lower bearing capacity and ductility, but higher energy dissipation capacity.

2022, 39(4): 1692-1700.

doi: 10.13801/j.cnki.fhclxb.20210601.004

Abstract:

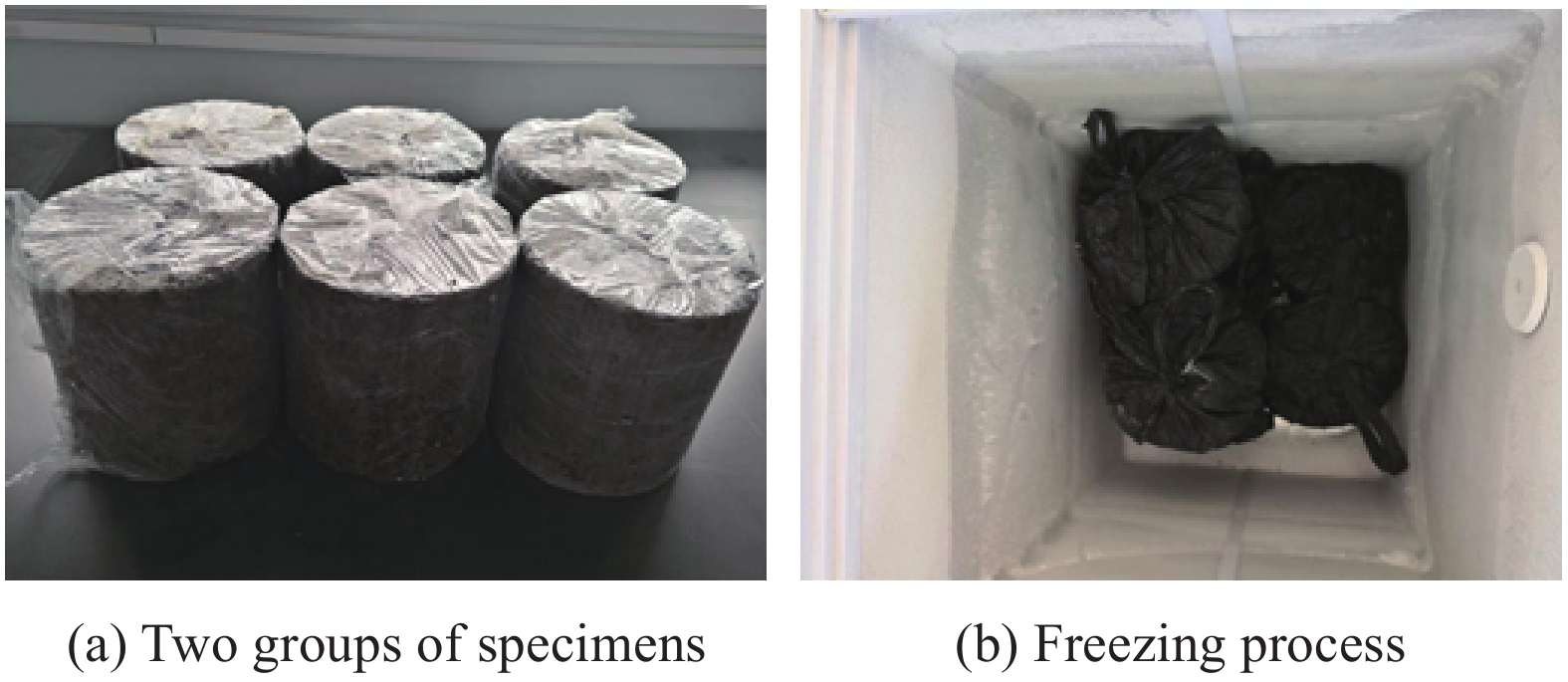

The development of meso-damage of cement stabilized cold recycled mixture under freeze-thaw environment was revealed by indoor test, and the effects of cement and recycled asphalt pavement material (RAP) on its damage in different freeze-thaw cycles were analyzed. The specimen after freeze-thaw cycle was scanned by CT machine, and the batch of 2D slice images were obtained. The cross section was analyzed by using the image processing technology, and the damage variable was introduced based on the change of the CT mean value in the image. The results show that with the increase of the number of freeze-thaw cycles, the average CT of mixture cross section increases at first and then decreases. On the other hand, the damage variable first decreases and then increases, which reflects the whole process of cement stable cold recycled mixture from initial meso damage to macroscopic damage in freeze-thaw environment, which can be divided into four stages, i.e.\begin{document}$N \leqslant 1$\end{document} ![]()

![]()

\begin{document}$1 <N \leqslant 3$\end{document} ![]()

![]()

\begin{document}$3 < N \leqslant 7$\end{document} ![]()

![]()

\begin{document}$7 < N \leqslant 9$\end{document} ![]()

![]()

The development of meso-damage of cement stabilized cold recycled mixture under freeze-thaw environment was revealed by indoor test, and the effects of cement and recycled asphalt pavement material (RAP) on its damage in different freeze-thaw cycles were analyzed. The specimen after freeze-thaw cycle was scanned by CT machine, and the batch of 2D slice images were obtained. The cross section was analyzed by using the image processing technology, and the damage variable was introduced based on the change of the CT mean value in the image. The results show that with the increase of the number of freeze-thaw cycles, the average CT of mixture cross section increases at first and then decreases. On the other hand, the damage variable first decreases and then increases, which reflects the whole process of cement stable cold recycled mixture from initial meso damage to macroscopic damage in freeze-thaw environment, which can be divided into four stages, i.e.

2022, 39(4): 1701-1714.

doi: 10.13801/j.cnki.fhclxb.20210702.001

Abstract:

In order to study the mechanical modification effect of nano-SiO2 on coastal cement soil at short age, unconfined compression test, splitting tensile test, pH test and SEM test of cement soil with nano-SiO2 content (mass ratio to cement) of 0%, 1.5%, 3.0%, 4.5% and 6.0% were carried out. Mechanical tests show that nano-SiO2 can improve the unconfined compressive strength, splitting tensile strength and elastic modulus of cement soil, but aggravate its brittleness; the compressive strength of nano-SiO2 modified soil is about 10 times of its tensile strength. The pH test shows that nano-SiO2 can improve the alkaline environment of cement soil. SEM micro test shows that the change law of cement soil particle morphology and pore characteristics is closely related to the strength development law. With the increase of nano-SiO2 content, the distribution of soil particle morphology changes from loose to aggregate, and the pores decrease. In conclusion, when the nano-SiO2 content is 4.5%, the strength improvement effect is the best, the micro pores are the least, and 4.5% is the best content. Finally, the quadratic polynomial model between mechanical strength and micro porosity of nano-SiO2 modified cement soil is established.

In order to study the mechanical modification effect of nano-SiO2 on coastal cement soil at short age, unconfined compression test, splitting tensile test, pH test and SEM test of cement soil with nano-SiO2 content (mass ratio to cement) of 0%, 1.5%, 3.0%, 4.5% and 6.0% were carried out. Mechanical tests show that nano-SiO2 can improve the unconfined compressive strength, splitting tensile strength and elastic modulus of cement soil, but aggravate its brittleness; the compressive strength of nano-SiO2 modified soil is about 10 times of its tensile strength. The pH test shows that nano-SiO2 can improve the alkaline environment of cement soil. SEM micro test shows that the change law of cement soil particle morphology and pore characteristics is closely related to the strength development law. With the increase of nano-SiO2 content, the distribution of soil particle morphology changes from loose to aggregate, and the pores decrease. In conclusion, when the nano-SiO2 content is 4.5%, the strength improvement effect is the best, the micro pores are the least, and 4.5% is the best content. Finally, the quadratic polynomial model between mechanical strength and micro porosity of nano-SiO2 modified cement soil is established.

2022, 39(4): 1715-1724.

doi: 10.13801/j.cnki.fhclxb.20210629.001

Abstract: