2022 Vol. 39, No. 5

2022, 39(5): 1847-1858.

doi: 10.13801/j.cnki.fhclxb.20220302.001

Abstract:

Solar energy is a clean and pollution-free renewable energy, and its efficient development and utilization can significantly promote national “dual carbon” work. Using photovoltaic cells to convert solar energy into electricity is one of the ways to use solar energy. In this review, the research progress, industry policies, business models and development and application prospects of photovoltaic cell materials were summarized. First of all, the efficiency, cost, advantages and disadvantages of various photovoltaic cells and the impact of material factors on application scenarios were clarified, and combined with the latest research progress, the future development direction of various photovoltaic cells was analyzed. Secondly, combined with the business model and supporting policies of the photovoltaic industry, the influence of policy driving mechanisms on the development of photovoltaic cell materials and industry was discussed. Finally, based on the research progress of photovoltaic cell materials and the development direction of the photovoltaic industry, this field was summarized and prospected. The way that photovoltaic industry contributes to the national "dual carbon" work under the "dual carbon" vision was analyzed.

Solar energy is a clean and pollution-free renewable energy, and its efficient development and utilization can significantly promote national “dual carbon” work. Using photovoltaic cells to convert solar energy into electricity is one of the ways to use solar energy. In this review, the research progress, industry policies, business models and development and application prospects of photovoltaic cell materials were summarized. First of all, the efficiency, cost, advantages and disadvantages of various photovoltaic cells and the impact of material factors on application scenarios were clarified, and combined with the latest research progress, the future development direction of various photovoltaic cells was analyzed. Secondly, combined with the business model and supporting policies of the photovoltaic industry, the influence of policy driving mechanisms on the development of photovoltaic cell materials and industry was discussed. Finally, based on the research progress of photovoltaic cell materials and the development direction of the photovoltaic industry, this field was summarized and prospected. The way that photovoltaic industry contributes to the national "dual carbon" work under the "dual carbon" vision was analyzed.

2022, 39(5): 1859-1869.

doi: 10.13801/j.cnki.fhclxb.20220120.003

Abstract:

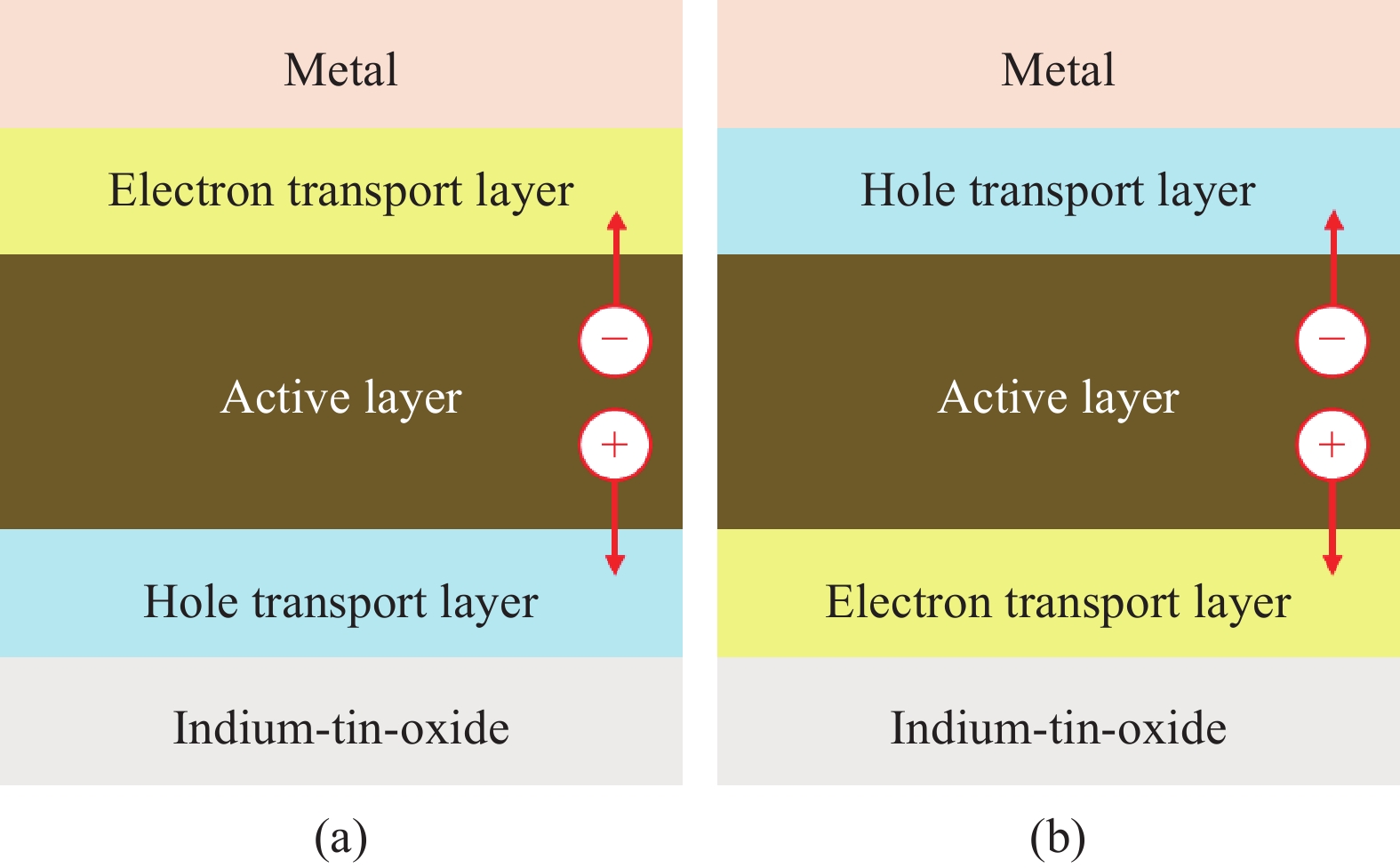

In recent years, cesium based inorganic perovskites (CsPbX3) are of great interest due to their high thermal resistance, low cost and tunable bandgap, which have been used as absorbers to for the development of novel thin-film solar cells. Currently, the photovoltaic performance of inverted perovskite solar cells (PSC) still leg behind that of regular solar cells, though the inverted solar cells are more stable and more promising as top layer of tandem solar cells. Therefore, the device structure of inverted solar cell remains to be further optimized. To approach this aim, researchers have developed a series of organic and inorganic interfacial layers, including hole-transport-layer and electron-transport-layer, with the aim of optimizing the inverted inorganic perovskite solar cells. Herein, we address the recent progress of organic and inorganic interfacial layers from the perspective of materials and processing techniques. A variety of material systems are compared to summarize their features. This work also discuss their bottlenecks and try to provide potential solutions for achieving ideal interfacial layers.

In recent years, cesium based inorganic perovskites (CsPbX3) are of great interest due to their high thermal resistance, low cost and tunable bandgap, which have been used as absorbers to for the development of novel thin-film solar cells. Currently, the photovoltaic performance of inverted perovskite solar cells (PSC) still leg behind that of regular solar cells, though the inverted solar cells are more stable and more promising as top layer of tandem solar cells. Therefore, the device structure of inverted solar cell remains to be further optimized. To approach this aim, researchers have developed a series of organic and inorganic interfacial layers, including hole-transport-layer and electron-transport-layer, with the aim of optimizing the inverted inorganic perovskite solar cells. Herein, we address the recent progress of organic and inorganic interfacial layers from the perspective of materials and processing techniques. A variety of material systems are compared to summarize their features. This work also discuss their bottlenecks and try to provide potential solutions for achieving ideal interfacial layers.

2022, 39(5): 1870-1889.

doi: 10.13801/j.cnki.fhclxb.20220422.002

Abstract:

New-generation solar cells, including organic solar cells, perovskite solar cells and quantum dot solar cells, are pretty promising photovoltaic devices. At present, the energy conversion efficiency of organic solar cells and perovskite solar cells exceeds 19% and 25.6% respectively. Fullerenes are widely used in organic solar cells active layer and interface layer, perovskite solar cells active layer and intermediate layer due to their high electron mobility and good electronic properties. In organic solar cells, fullerenes act as the active layer receptors to improve the electron transport capacity of devices. As an interface modification layer, it can effectively reduce the contact resistance and inhibit the recombination of carriers. In perovskite solar cells, fullerene materials act as active layer additive to passivate perovskite defect and restrain hysteresis effect. As an intermediate layer, the interface morphology can be optimized and charge extraction and transport can be promoted. In this paper, the research progress of fullerene materials in each component is reviewed, and the development prospect of fullerene materials in each component is prospected, and the future research direction is proposed.

New-generation solar cells, including organic solar cells, perovskite solar cells and quantum dot solar cells, are pretty promising photovoltaic devices. At present, the energy conversion efficiency of organic solar cells and perovskite solar cells exceeds 19% and 25.6% respectively. Fullerenes are widely used in organic solar cells active layer and interface layer, perovskite solar cells active layer and intermediate layer due to their high electron mobility and good electronic properties. In organic solar cells, fullerenes act as the active layer receptors to improve the electron transport capacity of devices. As an interface modification layer, it can effectively reduce the contact resistance and inhibit the recombination of carriers. In perovskite solar cells, fullerene materials act as active layer additive to passivate perovskite defect and restrain hysteresis effect. As an intermediate layer, the interface morphology can be optimized and charge extraction and transport can be promoted. In this paper, the research progress of fullerene materials in each component is reviewed, and the development prospect of fullerene materials in each component is prospected, and the future research direction is proposed.

2022, 39(5): 1890-1906.

doi: 10.13801/j.cnki.fhclxb.20211118.001

Abstract:

To achieve green and sustainable development, reducing CO2 emissions, it is deemed necessary to continue to promote and develop clean energy technologies, such as photovoltaics solar cell technology. Among of photovoltaic technologies, the organic-inorganic hybrid perovskite solar cells have the characteristics of low-cost, light weight, and simple manufacturing, which are more suitable for the requirements of future development. Perovskite materials are direct bandgap semiconductors with adjustable bandgap, which have lower exciton binding energy, longer carrier lifetime and diffusion length, and higher defect tolerance. The current maximum efficiency has exceeded 25%. However, the inherent instability of the material and sensitivity to environmental factors, such as water, heat, oxygen, and ultraviolet light, have become the primary problems limiting its further development. Recently, two-dimensional (2D) halide perovskite has attracted the attention of researchers around the world due to its ultra-high humidity stability. However, the efficiency of two-dimensional halide perovskite cells is still far behind that of traditional three-dimensional halide perovskite cells. Therefore, improving the efficiency of solar cells while maintaining excellent stability is a key problem in the research of 2D perovskite solar cells. In this paper, we mainly focus on the 2D halide perovskite film preparation and device structure, as well as efficiency and stability, and other issues to provide guidance for the development of efficient and stable 2D halide perovskite solar cells.

To achieve green and sustainable development, reducing CO2 emissions, it is deemed necessary to continue to promote and develop clean energy technologies, such as photovoltaics solar cell technology. Among of photovoltaic technologies, the organic-inorganic hybrid perovskite solar cells have the characteristics of low-cost, light weight, and simple manufacturing, which are more suitable for the requirements of future development. Perovskite materials are direct bandgap semiconductors with adjustable bandgap, which have lower exciton binding energy, longer carrier lifetime and diffusion length, and higher defect tolerance. The current maximum efficiency has exceeded 25%. However, the inherent instability of the material and sensitivity to environmental factors, such as water, heat, oxygen, and ultraviolet light, have become the primary problems limiting its further development. Recently, two-dimensional (2D) halide perovskite has attracted the attention of researchers around the world due to its ultra-high humidity stability. However, the efficiency of two-dimensional halide perovskite cells is still far behind that of traditional three-dimensional halide perovskite cells. Therefore, improving the efficiency of solar cells while maintaining excellent stability is a key problem in the research of 2D perovskite solar cells. In this paper, we mainly focus on the 2D halide perovskite film preparation and device structure, as well as efficiency and stability, and other issues to provide guidance for the development of efficient and stable 2D halide perovskite solar cells.

2022, 39(5): 1907-1923.

doi: 10.13801/j.cnki.fhclxb.20210609.002

Abstract:

Integrating sustainable cellulose materials into electronic devices is a hot research topic in academic communities. Highly transparent cellulose film with high transmission haze is a kind of paper with special optical properties. In addition to the advantages (degradability, low cost, flexibility, light weight, etc.) of ordinary paper, it also presents high transparency and strong light scattering behavior (high transmission haze), and has the potential to use in solar cells as a green optical transparent material to improve the power conversion efficiency. In this review, the development process of highly hazy and transparent cellulose film was first introduced. Then, the preparation and properties (such as optical properties, mechanical properties, thermal stability and water resistance) of highly transparent and hazy cellulose films were summarized in detail. After that, the progress in the use of transparent and hazy cellulose film in solar cells was discussed. Finally, scientific and technical problems of highly transparent and hazy cellulose films for solar cells were summarized, and their challenges and future research direction were provided as well.

Integrating sustainable cellulose materials into electronic devices is a hot research topic in academic communities. Highly transparent cellulose film with high transmission haze is a kind of paper with special optical properties. In addition to the advantages (degradability, low cost, flexibility, light weight, etc.) of ordinary paper, it also presents high transparency and strong light scattering behavior (high transmission haze), and has the potential to use in solar cells as a green optical transparent material to improve the power conversion efficiency. In this review, the development process of highly hazy and transparent cellulose film was first introduced. Then, the preparation and properties (such as optical properties, mechanical properties, thermal stability and water resistance) of highly transparent and hazy cellulose films were summarized in detail. After that, the progress in the use of transparent and hazy cellulose film in solar cells was discussed. Finally, scientific and technical problems of highly transparent and hazy cellulose films for solar cells were summarized, and their challenges and future research direction were provided as well.

2022, 39(5): 1924-1936.

doi: 10.13801/j.cnki.fhclxb.20211215.001

Abstract:

Recent years, perovskite solar cells have been developing rapidly because of the high efficiency, ease of preparation and low cost. To the preparation and optimization of multilayer structures for perovskite devices, researchers always pay most attention on the perovskite light absorber and charge-transporting layers. While in the case of the top electrode, evaporated Au electrodes can work well as a standard method at the current laboratory stage. Therefore, the top electrode issue is easily overlooked by researchers. However, the high cost of equipments and raw materials for evaporated precious metal electrodes will not be ignored in the large-area devices manufacturing and large-scale applications of perovskite solar cells. Several non-evaporation processes such as conductive film transferring or conductive paste coating have been developed to solve these problems. Herein, we addresses the current progress of transfer methods top electrodes from the perspective of process techniques. A variety of material systems including metals, polymers and carbon are compared to summarize some general principles. Also, the shortcomings of the transfer method, and bottlenecks of materials and potential solutions for ideal transfer electrodes are discussed.

Recent years, perovskite solar cells have been developing rapidly because of the high efficiency, ease of preparation and low cost. To the preparation and optimization of multilayer structures for perovskite devices, researchers always pay most attention on the perovskite light absorber and charge-transporting layers. While in the case of the top electrode, evaporated Au electrodes can work well as a standard method at the current laboratory stage. Therefore, the top electrode issue is easily overlooked by researchers. However, the high cost of equipments and raw materials for evaporated precious metal electrodes will not be ignored in the large-area devices manufacturing and large-scale applications of perovskite solar cells. Several non-evaporation processes such as conductive film transferring or conductive paste coating have been developed to solve these problems. Herein, we addresses the current progress of transfer methods top electrodes from the perspective of process techniques. A variety of material systems including metals, polymers and carbon are compared to summarize some general principles. Also, the shortcomings of the transfer method, and bottlenecks of materials and potential solutions for ideal transfer electrodes are discussed.

2022, 39(5): 1937-1955.

doi: 10.13801/j.cnki.fhclxb.20220303.001

Abstract:

Lead halide perovskite solar cells have attracted extensive attention on account of their excellent photoelectric conversion efficiency and relatively low fabrication cost. However, the poor long-term stability becomes a barrier that hinders the commercialization of lead halide perovskite solar cells. It is reported that interfacial non-radiative recombination in lead halide perovskite solar cells is the main cause that leads to energy loss, affects device stability and then deteriorates the device performance. To solve this issue, interface engineering is applied as a valid strategy to suppress interfacial non-radiative recombination and fabricate efficient and stable lead halide perovskite solar cells, achieving tangible results. In this review, the working principle of lead halide perovskite solar cells and interfacial non-radiactive recombination process are explained in detail. The origin of interfacial non-radiative recombination is also analyzed, which highlights the important role of interface engineering for lead halide perovskite solar cells. Meanwhile, the recent research advances of interface engineering in lead halide perovskite solar cells with normal n-i-p structure are summarized with the discussion of the modification mechanism. What’s more, based on the development status of the interface engineering in lead halide perovskite solar cells, we prospect the development directions for the interface engineering in lead halide perovskite solar cells in the future.

Lead halide perovskite solar cells have attracted extensive attention on account of their excellent photoelectric conversion efficiency and relatively low fabrication cost. However, the poor long-term stability becomes a barrier that hinders the commercialization of lead halide perovskite solar cells. It is reported that interfacial non-radiative recombination in lead halide perovskite solar cells is the main cause that leads to energy loss, affects device stability and then deteriorates the device performance. To solve this issue, interface engineering is applied as a valid strategy to suppress interfacial non-radiative recombination and fabricate efficient and stable lead halide perovskite solar cells, achieving tangible results. In this review, the working principle of lead halide perovskite solar cells and interfacial non-radiactive recombination process are explained in detail. The origin of interfacial non-radiative recombination is also analyzed, which highlights the important role of interface engineering for lead halide perovskite solar cells. Meanwhile, the recent research advances of interface engineering in lead halide perovskite solar cells with normal n-i-p structure are summarized with the discussion of the modification mechanism. What’s more, based on the development status of the interface engineering in lead halide perovskite solar cells, we prospect the development directions for the interface engineering in lead halide perovskite solar cells in the future.

2022, 39(5): 1956-1966.

doi: 10.13801/j.cnki.fhclxb.20211209.001

Abstract:

The preparation of porous carbon materials by high-temperature pyrolysis/activation of biomass under the protection of inert gas has the advantages of low cost, simple process, etc., and is an effective way to use waste and reduce environmental pollution. In this study, three different biomass materials were prepared by high-tempe-rature pyrolysis/activation to prepare porous carbon materials, which were combined with commercially conduc-tive carbon paste to make composite carbon paste and applied to the counter electrodes of perovskite solar cells (PSCs). The morphology, structure and specific surface area of different biomass porous carbon materials affect the photoelectric performance of the device. The results show that the photoelectric performance of PSCs based on different biomass porous carbon materials depends on the morphology, crystallinity, specific surface area and morphology of the biomass porous carbon materials and the interface contact between the perovskite/carbon electrode. The carbon-based PSCs prepared by the composite carbon electrode based on biomass porous carbon combined with the grinding process can obtain the highest photoelectric conversion efficiency (PCE) of 10.18% due to its good interface performance (the PCE of the PSCs without composite biomass carbon is 6.39%). After the best device is stored in air conditions for 60 days, 96% of the initial PCE was still retained.

The preparation of porous carbon materials by high-temperature pyrolysis/activation of biomass under the protection of inert gas has the advantages of low cost, simple process, etc., and is an effective way to use waste and reduce environmental pollution. In this study, three different biomass materials were prepared by high-tempe-rature pyrolysis/activation to prepare porous carbon materials, which were combined with commercially conduc-tive carbon paste to make composite carbon paste and applied to the counter electrodes of perovskite solar cells (PSCs). The morphology, structure and specific surface area of different biomass porous carbon materials affect the photoelectric performance of the device. The results show that the photoelectric performance of PSCs based on different biomass porous carbon materials depends on the morphology, crystallinity, specific surface area and morphology of the biomass porous carbon materials and the interface contact between the perovskite/carbon electrode. The carbon-based PSCs prepared by the composite carbon electrode based on biomass porous carbon combined with the grinding process can obtain the highest photoelectric conversion efficiency (PCE) of 10.18% due to its good interface performance (the PCE of the PSCs without composite biomass carbon is 6.39%). After the best device is stored in air conditions for 60 days, 96% of the initial PCE was still retained.

2022, 39(5): 1967-1975.

doi: 10.13801/j.cnki.fhclxb.20210426.001

Abstract:

Functional inorganic material nickel oxide (NiOx) as one of the most promising hole transport materials in perovskite solar cells, it has the advantages of high hole mobility, good stability, easy processing and suitable Fermi level. However, due to the inherent low conductivity of NiOx itself, the ionization energy of Ni vacancies is quite large, and the hole density in undoped NiOx is greatly restricted. In addition, the accumulation of holes increases the possibility of carrier recombination, thereby reducing the effective charge collection. Therefore, opti-mizing the quality of NiOx film formation is the key to solving the above problems. In this paper, DME-NiOx, EA-NiOx and NCs-NiOx films were prepared by solution method using ethylene glycol methyl ether (MEA), ethanol (EA) and deionized water as solutions. And optimized the NiOx-based perovskite device within the concentration adjustment range. In the end, the best device with a photoelectric conversion efficiency (PCE) of 18.50%, an open circuit voltage (Voc) of 1.034 V, a short circuit current (Jsc) of 22.94 mA/cm2 and a fill factor (FF) of 78% is obtained.

Functional inorganic material nickel oxide (NiOx) as one of the most promising hole transport materials in perovskite solar cells, it has the advantages of high hole mobility, good stability, easy processing and suitable Fermi level. However, due to the inherent low conductivity of NiOx itself, the ionization energy of Ni vacancies is quite large, and the hole density in undoped NiOx is greatly restricted. In addition, the accumulation of holes increases the possibility of carrier recombination, thereby reducing the effective charge collection. Therefore, opti-mizing the quality of NiOx film formation is the key to solving the above problems. In this paper, DME-NiOx, EA-NiOx and NCs-NiOx films were prepared by solution method using ethylene glycol methyl ether (MEA), ethanol (EA) and deionized water as solutions. And optimized the NiOx-based perovskite device within the concentration adjustment range. In the end, the best device with a photoelectric conversion efficiency (PCE) of 18.50%, an open circuit voltage (Voc) of 1.034 V, a short circuit current (Jsc) of 22.94 mA/cm2 and a fill factor (FF) of 78% is obtained.

2022, 39(5): 1976-1985.

doi: 10.13801/j.cnki.fhclxb.20220428.001

Abstract:

The preparation of large-area organic solar cells through coating or printing is the key to realizing the industrialization of organic photovoltaics. In the organic solar cells, ZnO is a commonly used material as an electron transporting layer. However, the self-aggregation of ZnO nanoparticles and the uneven drying of films during printing cause large numbers of defects and poor uniformity in large-area films, which seriously affects the perfor-mance of large-area printed organic photovoltaic devices. In this work, a ZnO nanoink suitable for large-area slot-die coating was developed by regulating solvent and introducing an ink dispersion stabilizer. The rheological pro-perties of ZnO nanoink were regulated by using a mixed solvent, which solved the issue of edge effect in the coated film. The introduction of ethanolamine additives solves the problem of ink aggregation during storage and printing, allowing the ink to maintain long-term stability during 18 months of storage. With this nanoink, large-area films with a size of 100×100 mm2 were obtained by slot-die coating. Such a film shows excellent film uniformity. Using the printed large-area ZnO films as electron transporting layer, an efficiency of higher than 14% is obtained for 1 cm2 flexible organic solar cells.

The preparation of large-area organic solar cells through coating or printing is the key to realizing the industrialization of organic photovoltaics. In the organic solar cells, ZnO is a commonly used material as an electron transporting layer. However, the self-aggregation of ZnO nanoparticles and the uneven drying of films during printing cause large numbers of defects and poor uniformity in large-area films, which seriously affects the perfor-mance of large-area printed organic photovoltaic devices. In this work, a ZnO nanoink suitable for large-area slot-die coating was developed by regulating solvent and introducing an ink dispersion stabilizer. The rheological pro-perties of ZnO nanoink were regulated by using a mixed solvent, which solved the issue of edge effect in the coated film. The introduction of ethanolamine additives solves the problem of ink aggregation during storage and printing, allowing the ink to maintain long-term stability during 18 months of storage. With this nanoink, large-area films with a size of 100×100 mm2 were obtained by slot-die coating. Such a film shows excellent film uniformity. Using the printed large-area ZnO films as electron transporting layer, an efficiency of higher than 14% is obtained for 1 cm2 flexible organic solar cells.

2022, 39(5): 1986-1994.

doi: 10.13801/j.cnki.fhclxb.20220222.001

Abstract:

The morphology of the active layer has an important influence on the device efficiency of organic solar cells. Tuning the molecular orientation in the active layer is one of the ways to optimize its morphology. This paper aims to use a Layer-by-Layer (LbL) method to regulate the orientation of molecules in the active layer of organic solar cells, thereby improving the efficiency of cell devices. By adding different additives to the electron acceptor, the orientation of acceptor molecule (Y6) in the active layer is adjusted, and the energy conversion efficiency of the optimized device reaches 16.2%. The active layer films were characterized by ellipsometry and grazing incidence wide-angle X-ray scattering (GIWAXS). The results show that after adding 1,8-diiooctane (DIO) as an additive to the receptor, Y6 molecules in the active layer tend to be horizontally oriented, and after adding chloronaphthalene (CN) as an additive to the receptor, Y6 molecules tend to be vertically oriented. The electrical and optical characterization results show that the horizontal orientation of Y6 increases the exciton separation efficiency, and then improves the energy conversion efficiency of the device.

The morphology of the active layer has an important influence on the device efficiency of organic solar cells. Tuning the molecular orientation in the active layer is one of the ways to optimize its morphology. This paper aims to use a Layer-by-Layer (LbL) method to regulate the orientation of molecules in the active layer of organic solar cells, thereby improving the efficiency of cell devices. By adding different additives to the electron acceptor, the orientation of acceptor molecule (Y6) in the active layer is adjusted, and the energy conversion efficiency of the optimized device reaches 16.2%. The active layer films were characterized by ellipsometry and grazing incidence wide-angle X-ray scattering (GIWAXS). The results show that after adding 1,8-diiooctane (DIO) as an additive to the receptor, Y6 molecules in the active layer tend to be horizontally oriented, and after adding chloronaphthalene (CN) as an additive to the receptor, Y6 molecules tend to be vertically oriented. The electrical and optical characterization results show that the horizontal orientation of Y6 increases the exciton separation efficiency, and then improves the energy conversion efficiency of the device.

2022, 39(5): 1995-2013.

doi: 10.13801/j.cnki.fhclxb.20210922.001

Abstract:

The nickel-rich lithium transition metal oxide cathode is an ideal high-energy power battery material due to its high capacity and high working voltage. Its performance is mainly affected by the structure, morphology, particle size and other factors of its hydroxide precursor. The spherical hydroxide precursor with controllable morphology and size of primary grain and secondary particles is the key for the preparation of nickel-rich cathode materials with excellent electrochemical performance. During the precipitation and crystallization process of hydroxide precursor, the process parameters will affect the performance of the precursor, and its growth mecha-nism has guiding significance for regulating the precipitation and crystallization. This paper reviews the basic theories related to precipitation crystallization, then discusses the growth mechanism of precipitation crystallization for hydroxide precursors of nickel-rich cathode materials and the influence of precipitation reaction factors on the physical and chemical properties of hydroxide. At last, the precursors for the synthesis of nickel-rich cathode materials with special structures such as single crystal, radial and core-shell structures are introduced.

The nickel-rich lithium transition metal oxide cathode is an ideal high-energy power battery material due to its high capacity and high working voltage. Its performance is mainly affected by the structure, morphology, particle size and other factors of its hydroxide precursor. The spherical hydroxide precursor with controllable morphology and size of primary grain and secondary particles is the key for the preparation of nickel-rich cathode materials with excellent electrochemical performance. During the precipitation and crystallization process of hydroxide precursor, the process parameters will affect the performance of the precursor, and its growth mecha-nism has guiding significance for regulating the precipitation and crystallization. This paper reviews the basic theories related to precipitation crystallization, then discusses the growth mechanism of precipitation crystallization for hydroxide precursors of nickel-rich cathode materials and the influence of precipitation reaction factors on the physical and chemical properties of hydroxide. At last, the precursors for the synthesis of nickel-rich cathode materials with special structures such as single crystal, radial and core-shell structures are introduced.

Research and discussion on processing technology of carbon fiber reinforced carbon matrix composites

2022, 39(5): 2014-2033.

doi: 10.13801/j.cnki.fhclxb.20211106.001

Abstract:

Carbon fiber reinforced carbon matrix composites (C/C) have the characteristics of low thermal expansion coefficient, corrosion resistance, thermal shock resistance, and wear resistance, which are widely used in military equipment, aerospace, automobile manufacturing and other fields. But it is difficult to achieve high precision machining of C/C composites by traditional processing technology. Laser processing technology has low requirements for the size, material and shape. It is easy to combine with other advanced processing technologies and has the characteristics that other methods do not have. This paper mainly reviews the preparation, application and processing methods of C/C composites, elaborates the mechanism and process characteristics of laser processing of C/C composites and the selection strategy of processing technology in different applications. Through the comparison of traditional processing methods and special processing methods, the problems and challenges faced by the processing of C/C composites are summarized, and the development trend of the combination of laser processing of C/C composites and other advanced manufacturing technologies is proposed.

Carbon fiber reinforced carbon matrix composites (C/C) have the characteristics of low thermal expansion coefficient, corrosion resistance, thermal shock resistance, and wear resistance, which are widely used in military equipment, aerospace, automobile manufacturing and other fields. But it is difficult to achieve high precision machining of C/C composites by traditional processing technology. Laser processing technology has low requirements for the size, material and shape. It is easy to combine with other advanced processing technologies and has the characteristics that other methods do not have. This paper mainly reviews the preparation, application and processing methods of C/C composites, elaborates the mechanism and process characteristics of laser processing of C/C composites and the selection strategy of processing technology in different applications. Through the comparison of traditional processing methods and special processing methods, the problems and challenges faced by the processing of C/C composites are summarized, and the development trend of the combination of laser processing of C/C composites and other advanced manufacturing technologies is proposed.

2022, 39(5): 2034-2048.

doi: 10.13801/j.cnki.fhclxb.20210824.001

Abstract:

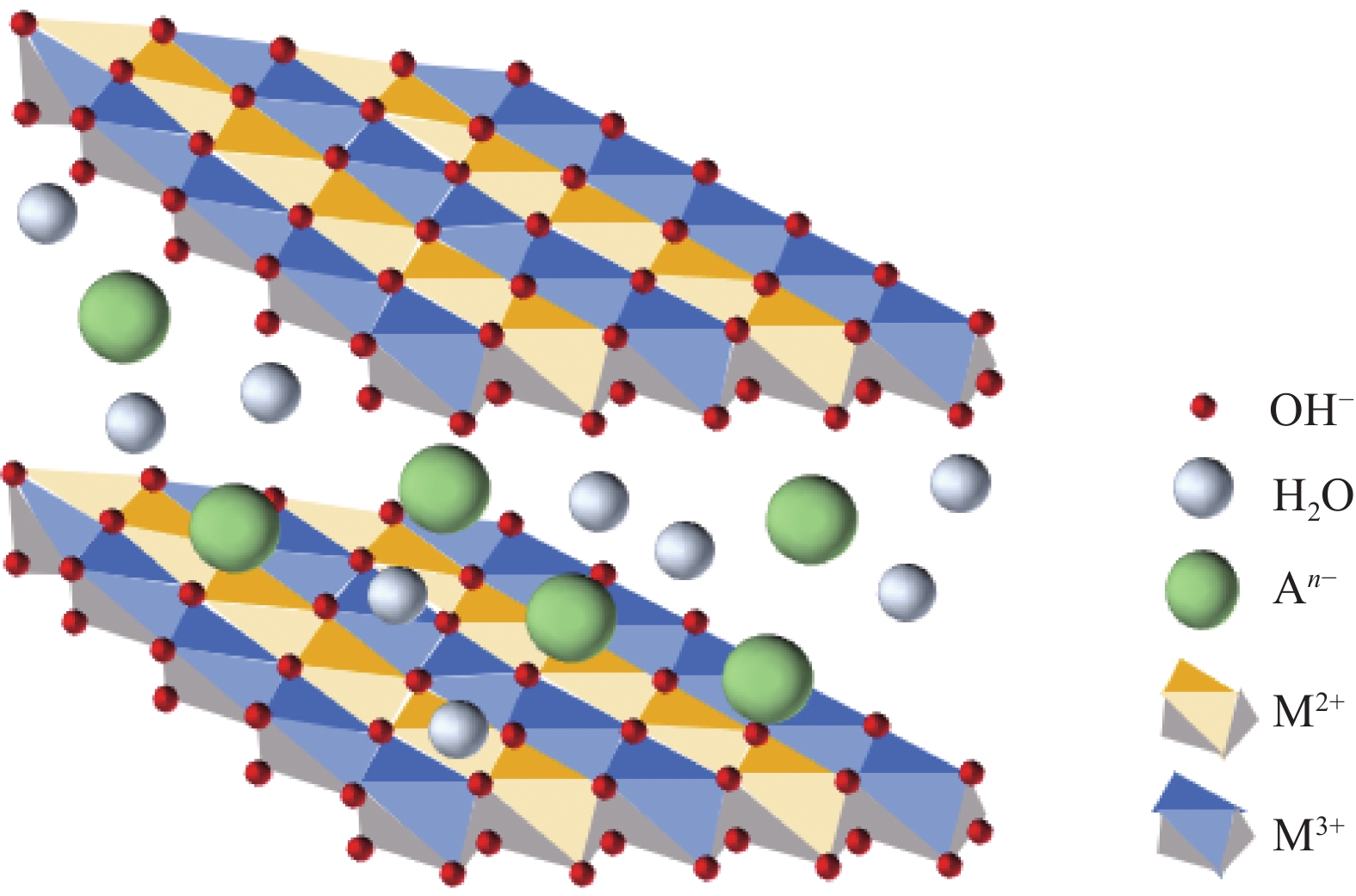

The rapid development of modern industry has caused a large number of refractory organic pollutants to enter the water body, there is an urgent need for economic and efficient pollution control and reduction technologies for refractory organic pollutants. In recent years, advanced oxidation technologies (SR-AOPs) based on sulfate radicals (SO4•–) have attracted much attention because of their strong oxidizing properties, wide pH tolerance, and ease of operation. Different types of metal oxygen/sulfide, carbon-based materials, metal-non-metal composite materials and organic metal materials are used to activate persulfate to generate active oxygen, thereby achieving oxidative degradation and further mineralization of organic pollutants. Among them, layered double hydroxides (LDHs) show excellent reactivity and catalytic advantages in activating persulfate due to their unique layered structure advantages, anion exchangeability and guest molecule adjustability. This article reviews the current research status of LDHs and their composites as heterogeneous catalysts to activate persulfate from the aspects of catalyst type, catalytic performance and mechanism, and degradation system influencing factors, and proposes relevant prospects for the continuous improvement of the catalytic system and future development.

The rapid development of modern industry has caused a large number of refractory organic pollutants to enter the water body, there is an urgent need for economic and efficient pollution control and reduction technologies for refractory organic pollutants. In recent years, advanced oxidation technologies (SR-AOPs) based on sulfate radicals (SO4•–) have attracted much attention because of their strong oxidizing properties, wide pH tolerance, and ease of operation. Different types of metal oxygen/sulfide, carbon-based materials, metal-non-metal composite materials and organic metal materials are used to activate persulfate to generate active oxygen, thereby achieving oxidative degradation and further mineralization of organic pollutants. Among them, layered double hydroxides (LDHs) show excellent reactivity and catalytic advantages in activating persulfate due to their unique layered structure advantages, anion exchangeability and guest molecule adjustability. This article reviews the current research status of LDHs and their composites as heterogeneous catalysts to activate persulfate from the aspects of catalyst type, catalytic performance and mechanism, and degradation system influencing factors, and proposes relevant prospects for the continuous improvement of the catalytic system and future development.

2022, 39(5): 2049-2059.

doi: 10.13801/j.cnki.fhclxb.20211009.001

Abstract:

Two-dimensional nanomaterials are the best choice for anticorrosive coatings because of their lamellar structure, dense hexagonal lattice, large specific surface area and excellent thermochemical stability. In this paper, the applications of two-dimensional nanomaterials in corrosion protection composite coatings are reviewed. The barrier protection, inhibition protection and sacrifice protection of two-dimensional nanomaterials in epoxy resin anticorrosive coatings are introduced firstly, and then the application ways and methods of common two-dimensional nanomaterials in epoxy resin anticorrosive coatings are expounded. In addition, the problems of dispersion, orientation and adhesion to metal substrate in the application of two-dimensional nanomaterials in anticorrosive coatings and their solutions are also summarized. Finally, the application of two-dimensional nanomaterials in epoxy anticorrosive coatings is summarized and prospected.

Two-dimensional nanomaterials are the best choice for anticorrosive coatings because of their lamellar structure, dense hexagonal lattice, large specific surface area and excellent thermochemical stability. In this paper, the applications of two-dimensional nanomaterials in corrosion protection composite coatings are reviewed. The barrier protection, inhibition protection and sacrifice protection of two-dimensional nanomaterials in epoxy resin anticorrosive coatings are introduced firstly, and then the application ways and methods of common two-dimensional nanomaterials in epoxy resin anticorrosive coatings are expounded. In addition, the problems of dispersion, orientation and adhesion to metal substrate in the application of two-dimensional nanomaterials in anticorrosive coatings and their solutions are also summarized. Finally, the application of two-dimensional nanomaterials in epoxy anticorrosive coatings is summarized and prospected.

2022, 39(5): 2060-2072.

doi: 10.13801/j.cnki.fhclxb.20210901.001

Abstract:

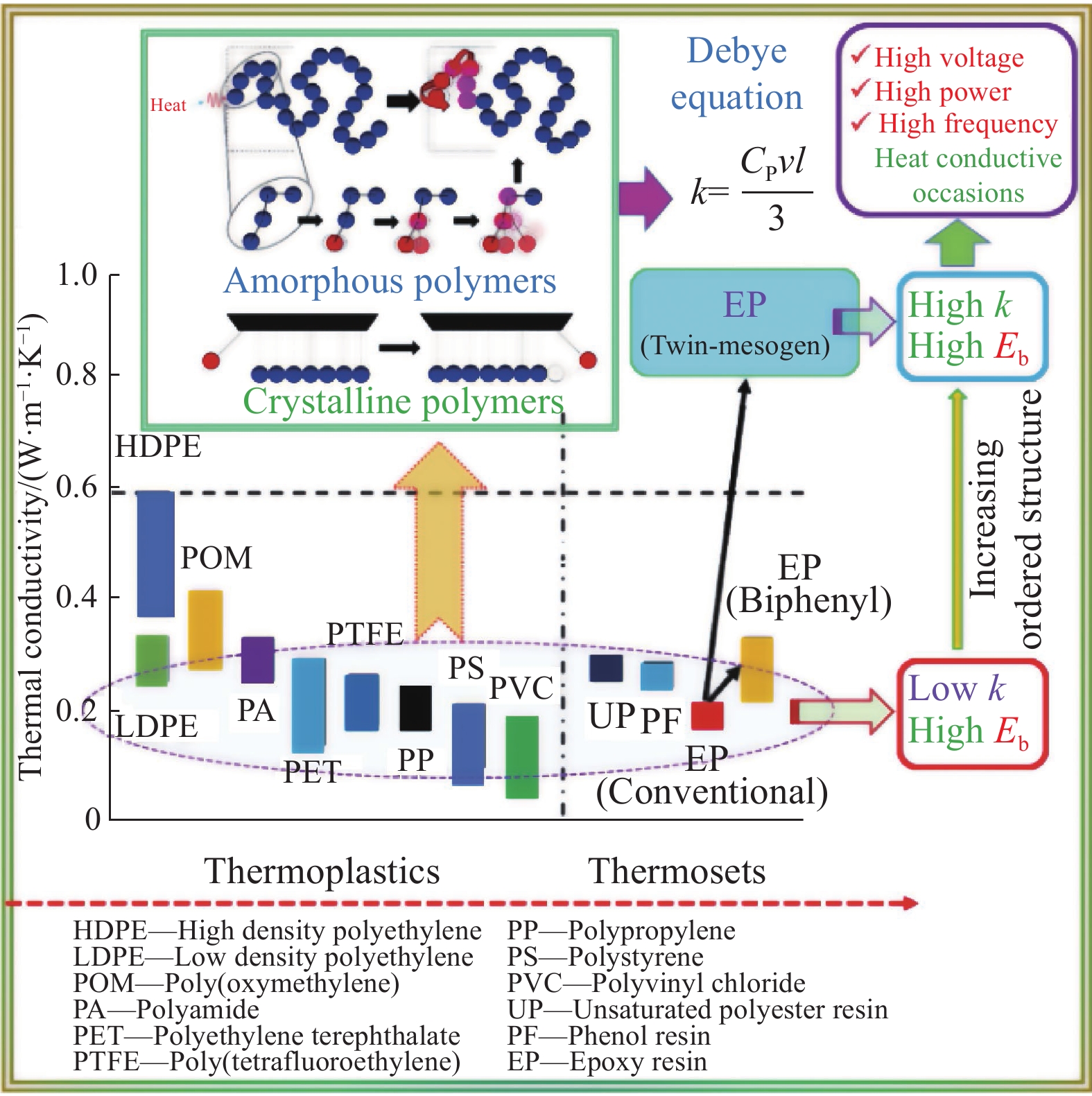

Difficulty in prompting heat dissipation has emerged as a critical issue and technical bottleneck restricting further miniaturization of microelectronic devices and electrical insulation equipment. Traditional heat conductive epoxy composites are not qualified for meeting the heat dissipation requirements of high-power, ultra-high-frequency and high-voltage insulating packaging because the thermal conductivity (k) and dielectric strength (Eb) cannot be regulated and improved synergistically. Intrinsically thermal conductive epoxy (ITCE), whose k can be enhanced by regulating ordered structure of cross-linked network containing liquid crystal epoxy (LCE) units, simultaneously exhibits high k and Eb. This paper analyzes the microstructure and intrinsic heat conduction mecha-nism of LCE, and summarizes the latest research progress in ITCE based on different LCE structures. The present work systematically analyzes the influencing factors on k of ITCE, such as structures of LCE and curing agent, temperature, LCE content, grain size, and external field-assisted processing, and expounds the way to improve the ordered structure of LCE and the intrinsic k. Finally, it summarizes the existing problems in current ITCE research and points to the future development direction. ITCE with excellent comprehensive performances represents the future development direction of ITCE, and the ITCE based composites has significant potential applications in high-density packaging microelectronics, high-voltage and high-power power equipment.

Difficulty in prompting heat dissipation has emerged as a critical issue and technical bottleneck restricting further miniaturization of microelectronic devices and electrical insulation equipment. Traditional heat conductive epoxy composites are not qualified for meeting the heat dissipation requirements of high-power, ultra-high-frequency and high-voltage insulating packaging because the thermal conductivity (k) and dielectric strength (Eb) cannot be regulated and improved synergistically. Intrinsically thermal conductive epoxy (ITCE), whose k can be enhanced by regulating ordered structure of cross-linked network containing liquid crystal epoxy (LCE) units, simultaneously exhibits high k and Eb. This paper analyzes the microstructure and intrinsic heat conduction mecha-nism of LCE, and summarizes the latest research progress in ITCE based on different LCE structures. The present work systematically analyzes the influencing factors on k of ITCE, such as structures of LCE and curing agent, temperature, LCE content, grain size, and external field-assisted processing, and expounds the way to improve the ordered structure of LCE and the intrinsic k. Finally, it summarizes the existing problems in current ITCE research and points to the future development direction. ITCE with excellent comprehensive performances represents the future development direction of ITCE, and the ITCE based composites has significant potential applications in high-density packaging microelectronics, high-voltage and high-power power equipment.

2022, 39(5): 2073-2088.

doi: 10.13801/j.cnki.fhclxb.20211011.001

Abstract:

The increasingly serious energy exhaustion and environmental pollution accelerates the development of clean hydrogen energy. Water splitting via photocatalysis technology provides an economical and clean way for the hydrogen production, converting solar energy into chemical energy through photocatalytic means is also a promising technical means. The rational selection of photocatalyst is the critical step for obtaining hydrogen energy in an efficient and economical way. Featuring the traits of large specific surface area, adjustable pore size, easy structure modification and abundant active sites, metal-organic frameworks (MOFs) are ideal candidates for photocatalytic hydrogen production scientists from domestic and foreign have carried out numerous researches on the water splitting with MOF-based photocatalysts. Currently, fruitful progresses have been achieved. In this paper, the state-of-the-art advances for the MOF-based materials as catalysts in the field of hydrogen production from splitting water was reviewed, and the advantages and limitations of MOFs as catalysts were summarized. The development prospect of MOFs and related materials in the field of photocatalytic hydrogen production was proposed, providing a valuable guideline for developing future photocatalysts.

The increasingly serious energy exhaustion and environmental pollution accelerates the development of clean hydrogen energy. Water splitting via photocatalysis technology provides an economical and clean way for the hydrogen production, converting solar energy into chemical energy through photocatalytic means is also a promising technical means. The rational selection of photocatalyst is the critical step for obtaining hydrogen energy in an efficient and economical way. Featuring the traits of large specific surface area, adjustable pore size, easy structure modification and abundant active sites, metal-organic frameworks (MOFs) are ideal candidates for photocatalytic hydrogen production scientists from domestic and foreign have carried out numerous researches on the water splitting with MOF-based photocatalysts. Currently, fruitful progresses have been achieved. In this paper, the state-of-the-art advances for the MOF-based materials as catalysts in the field of hydrogen production from splitting water was reviewed, and the advantages and limitations of MOFs as catalysts were summarized. The development prospect of MOFs and related materials in the field of photocatalytic hydrogen production was proposed, providing a valuable guideline for developing future photocatalysts.

2022, 39(5): 2089-2105.

doi: 10.13801/j.cnki.fhclxb.20211106.002

Abstract:

The composite materials prepared based on the titanium dioxide (TiO2) nanoparticles as additives have excellent heat resistance, aging resistance, etc. The TiO2 nanoparticles have special photocatalytic activity, such as, it has strong antibacterial and bactericidal ability after absorbing ultraviolet energy. Currently, TiO2 nanoparticles have a wide range of applications in various fields of coatings, cosmetics and medicine. However, affected by the nano-dimensional effect, the TiO2 nanoparticles in the polymer matrix have the disadvantages of being easy to agglomerate and difficult to disperse, which limits its application. Therefore, it is necessary to regulate the surface properties of nano-TiO2 by various surface modification methods to enhance its compatibility with the polymer matrix. This paper first described the preparation, surface modification method and mechanism of TiO2 nanoparticles in detail, subsequently, and the research progress on the TiO2 nanoparticles modified polymer compound composite material is reviewed in the recent years. Finally, this paper discussed the TiO2 nanoparticles exist problems in the research of polymer composites, and prospected its development direction in the future.

The composite materials prepared based on the titanium dioxide (TiO2) nanoparticles as additives have excellent heat resistance, aging resistance, etc. The TiO2 nanoparticles have special photocatalytic activity, such as, it has strong antibacterial and bactericidal ability after absorbing ultraviolet energy. Currently, TiO2 nanoparticles have a wide range of applications in various fields of coatings, cosmetics and medicine. However, affected by the nano-dimensional effect, the TiO2 nanoparticles in the polymer matrix have the disadvantages of being easy to agglomerate and difficult to disperse, which limits its application. Therefore, it is necessary to regulate the surface properties of nano-TiO2 by various surface modification methods to enhance its compatibility with the polymer matrix. This paper first described the preparation, surface modification method and mechanism of TiO2 nanoparticles in detail, subsequently, and the research progress on the TiO2 nanoparticles modified polymer compound composite material is reviewed in the recent years. Finally, this paper discussed the TiO2 nanoparticles exist problems in the research of polymer composites, and prospected its development direction in the future.

2022, 39(5): 2106-2120.

doi: 10.13801/j.cnki.fhclxb.20210701.002

Abstract:

With the widespread promotion of new energy electric vehicles for lithium batteries worldwide, the demand for lithium is surging. And the industry chain of lithium is in the process of technological transformation and upgrading, the extraction of lithium from salt lake brine is becoming the main source. Comprehensively compare the precipitation method, adsorption method, calcining leaching method, extraction method, and other processes used in the extraction of lithium from brine, membrane separation is a high-efficiency and energy-saving separation and purification technology without phase change at room temperature, and it has become the most promising energy-saving and environmentally-friendly new technology in the lithium extraction industry. At present, the research on membrane processes with lithium separation effect mainly includes membrane-adsorption, membrane-solvent extraction and membrane-electrodialysis, etc. And membrane-electrodialysis technology has been successfully applied to extract lithium from salt lake brine in industry. However, the existing shortcomings of organic membranes, such as membrane blockage, organic matter dissolution loss, and environmental pollution, limit the promotion of membrane-electrodialysis in the lithium extraction industry. Inorganic ceramic membranes are divided into microfiltration, ultrafiltration and nanofiltration according to the pore size. The separation process is mainly based on the “physical screening” theory, and the inorganic ceramic membrane material has stable chemical structure, good mechanical properties, simple preparation process, high temperature resistance, uniform pore size, It has many advantages such as narrow pore size distribution range and long life. Therefore, the development of new inorganic membrane materials has attracted widespread attention from the academic community and has become a hot issue in the study of lithium extraction by membrane methods.

With the widespread promotion of new energy electric vehicles for lithium batteries worldwide, the demand for lithium is surging. And the industry chain of lithium is in the process of technological transformation and upgrading, the extraction of lithium from salt lake brine is becoming the main source. Comprehensively compare the precipitation method, adsorption method, calcining leaching method, extraction method, and other processes used in the extraction of lithium from brine, membrane separation is a high-efficiency and energy-saving separation and purification technology without phase change at room temperature, and it has become the most promising energy-saving and environmentally-friendly new technology in the lithium extraction industry. At present, the research on membrane processes with lithium separation effect mainly includes membrane-adsorption, membrane-solvent extraction and membrane-electrodialysis, etc. And membrane-electrodialysis technology has been successfully applied to extract lithium from salt lake brine in industry. However, the existing shortcomings of organic membranes, such as membrane blockage, organic matter dissolution loss, and environmental pollution, limit the promotion of membrane-electrodialysis in the lithium extraction industry. Inorganic ceramic membranes are divided into microfiltration, ultrafiltration and nanofiltration according to the pore size. The separation process is mainly based on the “physical screening” theory, and the inorganic ceramic membrane material has stable chemical structure, good mechanical properties, simple preparation process, high temperature resistance, uniform pore size, It has many advantages such as narrow pore size distribution range and long life. Therefore, the development of new inorganic membrane materials has attracted widespread attention from the academic community and has become a hot issue in the study of lithium extraction by membrane methods.

2022, 39(5): 2121-2132.

doi: 10.13801/j.cnki.fhclxb.20210707.002

Abstract:

The development of polymer dielectric materials with low dielectric constant, low dielectric loss, temperature resistance and high mechanical strength is of great significance to meet the requirements of high performance dielectric materials in 5G field. The hollow SiO2 nanoparticles (HS) were modified by 1H, 2H, 2H-perfluorooctyltriethoxysilane (PTES), and two kinds of low dielectric poly (aryl ether nitrile) composites (HS@PTES/PEN-F) were prepared by solution casting and phase conversion methods based on fluorinated poly (aryl ether nitrile) copolymer (PEN-F). The successful synthesis of fluorinated poly (aryl ether nitrile) copolymer was confirmed by FTIR and 1H NMR; the structure and morphology of PTES modified HS were characterized by FTIR, TGA and XPS. At the same time, the dielectric properties, mechanical strength and thermal stability of the HS@PTES/PEN-F composites were studied. The results show that the HS modified by PTES exhibit good dispersion and interface compa-tibility in the PEN-F matrix resin. In terms of dielectric properties, when the content of modified SiO2 nanoparticles reaches 7wt%, the dielectric constant and the dielectric loss of the HS@PTES/PEN-F composite film prepared by solution casting method are 2.88 and 0.0198 at 1 kHz; the dielectric constant and dielectric loss of the HS@PTES/PEN-F composite film prepared by phase conversion method are 1.19 and 0.0043, respectively. In the aspect of mechanical properties, taking the phase conversion method as an example, when the content of modified SiO2 nanoparticles reaches 5wt%, the tensile strength and elasticity modulus increase to 10.34 MPa and 365.32 MPa, respectively. In addition, the glass transition temperature of HS@PTES/PEN-F composite film can reach 160℃, which shows good thermal stability.

The development of polymer dielectric materials with low dielectric constant, low dielectric loss, temperature resistance and high mechanical strength is of great significance to meet the requirements of high performance dielectric materials in 5G field. The hollow SiO2 nanoparticles (HS) were modified by 1H, 2H, 2H-perfluorooctyltriethoxysilane (PTES), and two kinds of low dielectric poly (aryl ether nitrile) composites (HS@PTES/PEN-F) were prepared by solution casting and phase conversion methods based on fluorinated poly (aryl ether nitrile) copolymer (PEN-F). The successful synthesis of fluorinated poly (aryl ether nitrile) copolymer was confirmed by FTIR and 1H NMR; the structure and morphology of PTES modified HS were characterized by FTIR, TGA and XPS. At the same time, the dielectric properties, mechanical strength and thermal stability of the HS@PTES/PEN-F composites were studied. The results show that the HS modified by PTES exhibit good dispersion and interface compa-tibility in the PEN-F matrix resin. In terms of dielectric properties, when the content of modified SiO2 nanoparticles reaches 7wt%, the dielectric constant and the dielectric loss of the HS@PTES/PEN-F composite film prepared by solution casting method are 2.88 and 0.0198 at 1 kHz; the dielectric constant and dielectric loss of the HS@PTES/PEN-F composite film prepared by phase conversion method are 1.19 and 0.0043, respectively. In the aspect of mechanical properties, taking the phase conversion method as an example, when the content of modified SiO2 nanoparticles reaches 5wt%, the tensile strength and elasticity modulus increase to 10.34 MPa and 365.32 MPa, respectively. In addition, the glass transition temperature of HS@PTES/PEN-F composite film can reach 160℃, which shows good thermal stability.

2022, 39(5): 2133-2140.

doi: 10.13801/j.cnki.fhclxb.20210812.001

Abstract:

Reduced graphene oxide(RGO) modified carbon fiber/polyphenylene sulfide composites (RGO-CF/PPS) were prepared by powder lamination methodand hot pressing process. Interlaminar shear properties and micromorphology of the RGO-CF/PPS composites at room temperature and hygrothermal environment were investi-gated. Meanwhile, the effect of RGO on the interface performance of the composites was analyzed. Results show that the interlaminar shear strength (ILSS) of the 0.1%RGO-CF/PPS composites in the dry state at room tempera-ture is 18.4% higher than that of the CF/PPS composites. After hygrothermal treatment, the ILSS of the RGO-CF/PPS composites are decreased and the ILSS strength retention rate of the RGO-CF/PPS composites is lower than that of the CF/PPS composites. Dynamic thermomechanical behavior results of the composites show that the RGO is helpful to enhance the interface bonding performance of the RGO-CF/PPS composites. Micromorphology shows that the RGO effectively improves the ILSS of the RGO-CF/PPS composites in the dry state at room temperature.

Reduced graphene oxide(RGO) modified carbon fiber/polyphenylene sulfide composites (RGO-CF/PPS) were prepared by powder lamination methodand hot pressing process. Interlaminar shear properties and micromorphology of the RGO-CF/PPS composites at room temperature and hygrothermal environment were investi-gated. Meanwhile, the effect of RGO on the interface performance of the composites was analyzed. Results show that the interlaminar shear strength (ILSS) of the 0.1%RGO-CF/PPS composites in the dry state at room tempera-ture is 18.4% higher than that of the CF/PPS composites. After hygrothermal treatment, the ILSS of the RGO-CF/PPS composites are decreased and the ILSS strength retention rate of the RGO-CF/PPS composites is lower than that of the CF/PPS composites. Dynamic thermomechanical behavior results of the composites show that the RGO is helpful to enhance the interface bonding performance of the RGO-CF/PPS composites. Micromorphology shows that the RGO effectively improves the ILSS of the RGO-CF/PPS composites in the dry state at room temperature.

2022, 39(5): 2141-2152.

doi: 10.13801/j.cnki.fhclxb.20210805.003

Abstract:

Polymer/inorganic nanocomposites have attracted extensive research interests due to their unique properties. In order to obtain SiC composite coating material with excellent hydrophobic and anticorrosive performance, silicon carbide (SiC) nanoparticles were ammoniated by silane coupling agent (KH-550), and then the covalently functionalized SiC-sulfonated polyaniline (SiC-NH2-SPANI) composites were synthesized by one-step oxidative polymerization of aniline, aminobenzenesulfonic acid and aminated SiC nanoparticles, the microstructure and morphology of the composites were characterizated by FT-IR, UV-vis, XRD and SEM. Finally, the SiC-NH2-SPANI epoxy coating was coated on the substrate by spraying method and the hydrophobic and anticorrosion performance of the prepared coating was studied. The effects of the amount of different SiC nanoparticle, ammonium persulfate and the amount of the composite materials on the covalently functionalized silicon carbide-sulfonated polyaniline/epoxy resin anticorrosive composite coating (SiC-NH2-SPANI/EP) was investigated. The results of hydrophobic property show that the contact angle value of the composite coating with 3wt%SiC-NH2-SPANI reaches 99.87°, which is higher than that of the composite coating that used the pristine SiC substituted for SiC-NH2. With regard to the influence of different reaction amount of SiC and ammonium persulfate, the anticorrosion performance of SiC-NH2-SPANI/EP is the best when the mass ratio of 15wt%SiC-NH2 to ammonium persulfate (APS) is 1 : 1. Among the composite coatings doped with different materials (SiC/EP, SiC-NH2/EP and SiC-NH2-SPANI/EP), the SiC-NH2/EP coating has the largest contact angle, the best hydrophobic performance and anticorrosion performance. It also shows that there is a relationship between hydrophobic property and anticorrosion pro-perty and the hydrophobic performance is directly proportional to anticorrosive performance. With regard to the influence of the content of composite coatings, the long-term stability and corrosion resistance are more excellent when the addition of SiC-NH2-SPANI/EP is 3wt%.

Polymer/inorganic nanocomposites have attracted extensive research interests due to their unique properties. In order to obtain SiC composite coating material with excellent hydrophobic and anticorrosive performance, silicon carbide (SiC) nanoparticles were ammoniated by silane coupling agent (KH-550), and then the covalently functionalized SiC-sulfonated polyaniline (SiC-NH2-SPANI) composites were synthesized by one-step oxidative polymerization of aniline, aminobenzenesulfonic acid and aminated SiC nanoparticles, the microstructure and morphology of the composites were characterizated by FT-IR, UV-vis, XRD and SEM. Finally, the SiC-NH2-SPANI epoxy coating was coated on the substrate by spraying method and the hydrophobic and anticorrosion performance of the prepared coating was studied. The effects of the amount of different SiC nanoparticle, ammonium persulfate and the amount of the composite materials on the covalently functionalized silicon carbide-sulfonated polyaniline/epoxy resin anticorrosive composite coating (SiC-NH2-SPANI/EP) was investigated. The results of hydrophobic property show that the contact angle value of the composite coating with 3wt%SiC-NH2-SPANI reaches 99.87°, which is higher than that of the composite coating that used the pristine SiC substituted for SiC-NH2. With regard to the influence of different reaction amount of SiC and ammonium persulfate, the anticorrosion performance of SiC-NH2-SPANI/EP is the best when the mass ratio of 15wt%SiC-NH2 to ammonium persulfate (APS) is 1 : 1. Among the composite coatings doped with different materials (SiC/EP, SiC-NH2/EP and SiC-NH2-SPANI/EP), the SiC-NH2/EP coating has the largest contact angle, the best hydrophobic performance and anticorrosion performance. It also shows that there is a relationship between hydrophobic property and anticorrosion pro-perty and the hydrophobic performance is directly proportional to anticorrosive performance. With regard to the influence of the content of composite coatings, the long-term stability and corrosion resistance are more excellent when the addition of SiC-NH2-SPANI/EP is 3wt%.

2022, 39(5): 2153-2160.

doi: 10.13801/j.cnki.fhclxb.20210716.002

Abstract:

Plant fiber reinforced composites are being applied to various fields of life. The interfacial incompatibility between hydrophilic reinforcement and hydrophobic matrix limits the mechanical properties of composites. In this paper, the kenaf fiber was modified by carboxylated carbon nanotubes (c-MWCNTs) to explore the interface improvement mechanism of kenaf fiber/epoxy resin composites. Firstly, the kenaf fiber was pretreated by water and NaOH. The effects of different pretreatment methods on the grafting of c-MWCNTs by kenaf fiber were investigated by observing the changes of fiber diameter, infrared spectrum and fiber bundle fracture strength. Then the kenaf fibers were modified with 0.5wt%, 1wt% and 3wt% c-MWCNTs, respectively. Interfacial shear strength (IFSS) of kenaf fiber/epoxy composites was investigated by single fiber pull-out test. The results show that the diameter variation, the removal of non-cellulose components and the decrease of fiber bundle fracture strength of kenaf fiber after alkali treatment are the smallest and the dimensional stability of composite is higher. Through single fiber pull-out test, IFSS of the kenaf fiber/epoxy resin composite increases gradually, but the effectiveness decreases gradually. When the mass fraction of c-MWCNTs is 0.5wt%, the effectiveness is the highest, and the improvement effect reaches 45.09%. The interfacial properties of kenaf fiber/epoxy resin composites modified by c-MWCNTs are improved. Due to the existence of c-MWCNTs, the mechanical lock between fiber and resin matrix is strengthened.

Plant fiber reinforced composites are being applied to various fields of life. The interfacial incompatibility between hydrophilic reinforcement and hydrophobic matrix limits the mechanical properties of composites. In this paper, the kenaf fiber was modified by carboxylated carbon nanotubes (c-MWCNTs) to explore the interface improvement mechanism of kenaf fiber/epoxy resin composites. Firstly, the kenaf fiber was pretreated by water and NaOH. The effects of different pretreatment methods on the grafting of c-MWCNTs by kenaf fiber were investigated by observing the changes of fiber diameter, infrared spectrum and fiber bundle fracture strength. Then the kenaf fibers were modified with 0.5wt%, 1wt% and 3wt% c-MWCNTs, respectively. Interfacial shear strength (IFSS) of kenaf fiber/epoxy composites was investigated by single fiber pull-out test. The results show that the diameter variation, the removal of non-cellulose components and the decrease of fiber bundle fracture strength of kenaf fiber after alkali treatment are the smallest and the dimensional stability of composite is higher. Through single fiber pull-out test, IFSS of the kenaf fiber/epoxy resin composite increases gradually, but the effectiveness decreases gradually. When the mass fraction of c-MWCNTs is 0.5wt%, the effectiveness is the highest, and the improvement effect reaches 45.09%. The interfacial properties of kenaf fiber/epoxy resin composites modified by c-MWCNTs are improved. Due to the existence of c-MWCNTs, the mechanical lock between fiber and resin matrix is strengthened.

2022, 39(5): 2161-2171.

doi: 10.13801/j.cnki.fhclxb.20210722.001

Abstract:

Negative stiffness honeycomb cell structures were fabricated by fused filament fabrication (FFF) based on chopped carbon fiber reinforced nylon composites (MarkForged Onyx). In order to analyze the printing properties and compression properties, compression tests for negative stiffness honeycomb cell structure specimens were carried out. The influence mechanism of three process parameters, including building directions, fill patterns and wall layers, on the printing properties and compression properties of the structure was analyzed. The results show that the combination of flat building directions, hexagonal fill pattern and one wall layer can effectively reduce the printing time and cost of the structure. The compression properties of the flat building directions are superior to that of the on-edge and up-right. Compared with quadrilateral and hexagonal fill pattern, triangular fill pattern improves the energy absorption capacity of the structure significantly. Two wall layers have a great impact on the compressive strength of the structure. Cell structures show pronounced negative stiffness behavior during the loading process with percent energy absorbed up to 70%, and force threshold of about 185 N. Through the cycle tests, there is only 6% of the compression deformation, realizing the recoverable energy absorption of negative stiffness honeycomb core structures based on Markforged Onyx chopped carbon fiber reinforced nylon composites.

Negative stiffness honeycomb cell structures were fabricated by fused filament fabrication (FFF) based on chopped carbon fiber reinforced nylon composites (MarkForged Onyx). In order to analyze the printing properties and compression properties, compression tests for negative stiffness honeycomb cell structure specimens were carried out. The influence mechanism of three process parameters, including building directions, fill patterns and wall layers, on the printing properties and compression properties of the structure was analyzed. The results show that the combination of flat building directions, hexagonal fill pattern and one wall layer can effectively reduce the printing time and cost of the structure. The compression properties of the flat building directions are superior to that of the on-edge and up-right. Compared with quadrilateral and hexagonal fill pattern, triangular fill pattern improves the energy absorption capacity of the structure significantly. Two wall layers have a great impact on the compressive strength of the structure. Cell structures show pronounced negative stiffness behavior during the loading process with percent energy absorbed up to 70%, and force threshold of about 185 N. Through the cycle tests, there is only 6% of the compression deformation, realizing the recoverable energy absorption of negative stiffness honeycomb core structures based on Markforged Onyx chopped carbon fiber reinforced nylon composites.

2022, 39(5): 2172-2182.

doi: 10.13801/j.cnki.fhclxb.20210615.001

Abstract:

Graphene oxide (GO) and multi-walled carbon nanotubes (MWCNTs) are widely used in rubber fillers due to their good mechanical properties and thermal conductivity. In order to increase the vulcanization efficiency and improve the physical properties of natural rubber, a GO/MWCNTs rubber composite was prepared by mixing graphene oxide and multi-walled carbon nanotubes with rubber in different proportions. Through testing the phy-sical properties of the rubber compound and the vulcanized rubber, it is concluded that there is a synergistic effect between MWCNTs filler and GO filler, and different ratios of GO and MWCNTs have different effects on the performance of the rubber compound. When MWCNTs filler is added quantitatively at 6wt%, with the increase of GO content: the maximum torque MH of the vulcanized rubber and the crosslinking density ΔM value increased; the scorch time tc10 and the normal vulcanization time tc90 decreased first, and tc90 rose slightly after 3wt%. When the content of GO and MWCNTs are 3wt% and 6wt%, the improvement of vulcanization efficiency is most obvious; when the two are added at 6wt% at the same time, the thermal conductivity of the compound and the vulcanized rubber are increased by 25.1% and 23.3% respectively; the 100% of the vulcanized rubber is fixed. Tensile stress and 300% constant elongation stress have a rising trend, and slightly decrease after 3wt%. Taken together, when GO and MWCNTs are added at 3wt% and 6wt%, respectively, the filler particles have the best reinforcement effect on the rubber. Its good thermal conductivity enhances the uniformity of the vulcanization reaction and realizes energy saving and consumption reduction in the vulcanization process.

Graphene oxide (GO) and multi-walled carbon nanotubes (MWCNTs) are widely used in rubber fillers due to their good mechanical properties and thermal conductivity. In order to increase the vulcanization efficiency and improve the physical properties of natural rubber, a GO/MWCNTs rubber composite was prepared by mixing graphene oxide and multi-walled carbon nanotubes with rubber in different proportions. Through testing the phy-sical properties of the rubber compound and the vulcanized rubber, it is concluded that there is a synergistic effect between MWCNTs filler and GO filler, and different ratios of GO and MWCNTs have different effects on the performance of the rubber compound. When MWCNTs filler is added quantitatively at 6wt%, with the increase of GO content: the maximum torque MH of the vulcanized rubber and the crosslinking density ΔM value increased; the scorch time tc10 and the normal vulcanization time tc90 decreased first, and tc90 rose slightly after 3wt%. When the content of GO and MWCNTs are 3wt% and 6wt%, the improvement of vulcanization efficiency is most obvious; when the two are added at 6wt% at the same time, the thermal conductivity of the compound and the vulcanized rubber are increased by 25.1% and 23.3% respectively; the 100% of the vulcanized rubber is fixed. Tensile stress and 300% constant elongation stress have a rising trend, and slightly decrease after 3wt%. Taken together, when GO and MWCNTs are added at 3wt% and 6wt%, respectively, the filler particles have the best reinforcement effect on the rubber. Its good thermal conductivity enhances the uniformity of the vulcanization reaction and realizes energy saving and consumption reduction in the vulcanization process.

2022, 39(5): 2183-2191.

doi: 10.13801/j.cnki.fhclxb.20210903.003

Abstract:

Phenolic epoxy resin (EP) is widely used in electronics because of its excellent electrical insulating pro-perties. The thermal conductivity of EP is low, and filling the highly conductive thermal inorganic fillers is an effec-tive way to construct the thermal conductive pathway of the thermal transport frame to improve the thermal conductivity of polymer composites. In this paper, the hexagonal boron nitride (h-BN)-four needle zinc oxide whisker (T-ZnOw)/EP composite was prepared by solution blended and hot-compaction process. The microstructures aspects, phase structures, thermal conductivity and electric insulating propertis of composites were systematically characterized and analyzed. The results show the h-BN-T-ZnOw/EP composite has good thermal conductivity and electrical insulating properties. When h-BN-T-ZnOw loading is 30wt%/5wt%, the thermal conductivity at 25℃ is 0.55 W/(m·K), which is 2.9 times higher than that of EP, and its volume resistivity is greater than 1015 Ω·m.

Phenolic epoxy resin (EP) is widely used in electronics because of its excellent electrical insulating pro-perties. The thermal conductivity of EP is low, and filling the highly conductive thermal inorganic fillers is an effec-tive way to construct the thermal conductive pathway of the thermal transport frame to improve the thermal conductivity of polymer composites. In this paper, the hexagonal boron nitride (h-BN)-four needle zinc oxide whisker (T-ZnOw)/EP composite was prepared by solution blended and hot-compaction process. The microstructures aspects, phase structures, thermal conductivity and electric insulating propertis of composites were systematically characterized and analyzed. The results show the h-BN-T-ZnOw/EP composite has good thermal conductivity and electrical insulating properties. When h-BN-T-ZnOw loading is 30wt%/5wt%, the thermal conductivity at 25℃ is 0.55 W/(m·K), which is 2.9 times higher than that of EP, and its volume resistivity is greater than 1015 Ω·m.

2022, 39(5): 2192-2200.

doi: 10.13801/j.cnki.fhclxb.20210726.002

Abstract:

Polybutylene terephthalate (PBT) is a semi-crystalline thermoplastic polymer with excellent dimensional stability, high stiffness and hardness, good chemical resistance, mechanical properties and processability. But its impact resistance is low and toughness is poor. PBT was melt blended with poly(butylene succinate-co-butylene diphenyl ether dicarboxylate) (PBSO), which has excellent toughness, to improve the toughness of PBT. Firstly, PBSO was synthesized by a two-step method of esterification and polycondensation, using diphenyl ether dicarboxylic acid (OBBA), succinic acid (SA) and butanediol (BDO) as monomers, and tetrabutyl titanate as catalyst. Then, PBSO/PBT with different mass ratios of PBSO and PBT were blended by melt-extrusion to study the toughening effect of PBSO on PBT. The mechanical toughness of blends, the compatibility of PBSO and PBT, crystallization behavior, thermal stability and rheological properties were studied. The structure of PBSO was characterized by FT-IR, 1H NMR and GPC. The mechanical performance test show that the tensile strength of the 20wt%PBSO/PBT composite material is 40.3 MPa, the elongation at break reach to 82.1%, the breaking energy increas to 24.70 MPa, and the impact strength is 23.2 kJ/m2, indicating a higher tensile strength and good toughness. Dynamic mechanical analysis (DMA) and SEM results indicate that PBSO has a compatibilizing effect on PBT, and PBSO/PBT is a partially compatible blend system. DSC and wide-angle X-ray diffraction (WAXD) results show that the addition of amorphous polymer PBSO reduce the crystallinity of PBT, but do not change the crystal structure of PBT. Thermogravimetric analysis (TGA) analysis demonstrated that the PBSO/PBT composite has a good processing thermal stability.

Polybutylene terephthalate (PBT) is a semi-crystalline thermoplastic polymer with excellent dimensional stability, high stiffness and hardness, good chemical resistance, mechanical properties and processability. But its impact resistance is low and toughness is poor. PBT was melt blended with poly(butylene succinate-co-butylene diphenyl ether dicarboxylate) (PBSO), which has excellent toughness, to improve the toughness of PBT. Firstly, PBSO was synthesized by a two-step method of esterification and polycondensation, using diphenyl ether dicarboxylic acid (OBBA), succinic acid (SA) and butanediol (BDO) as monomers, and tetrabutyl titanate as catalyst. Then, PBSO/PBT with different mass ratios of PBSO and PBT were blended by melt-extrusion to study the toughening effect of PBSO on PBT. The mechanical toughness of blends, the compatibility of PBSO and PBT, crystallization behavior, thermal stability and rheological properties were studied. The structure of PBSO was characterized by FT-IR, 1H NMR and GPC. The mechanical performance test show that the tensile strength of the 20wt%PBSO/PBT composite material is 40.3 MPa, the elongation at break reach to 82.1%, the breaking energy increas to 24.70 MPa, and the impact strength is 23.2 kJ/m2, indicating a higher tensile strength and good toughness. Dynamic mechanical analysis (DMA) and SEM results indicate that PBSO has a compatibilizing effect on PBT, and PBSO/PBT is a partially compatible blend system. DSC and wide-angle X-ray diffraction (WAXD) results show that the addition of amorphous polymer PBSO reduce the crystallinity of PBT, but do not change the crystal structure of PBT. Thermogravimetric analysis (TGA) analysis demonstrated that the PBSO/PBT composite has a good processing thermal stability.

2022, 39(5): 2201-2214.

doi: 10.13801/j.cnki.fhclxb.20210702.003

Abstract:

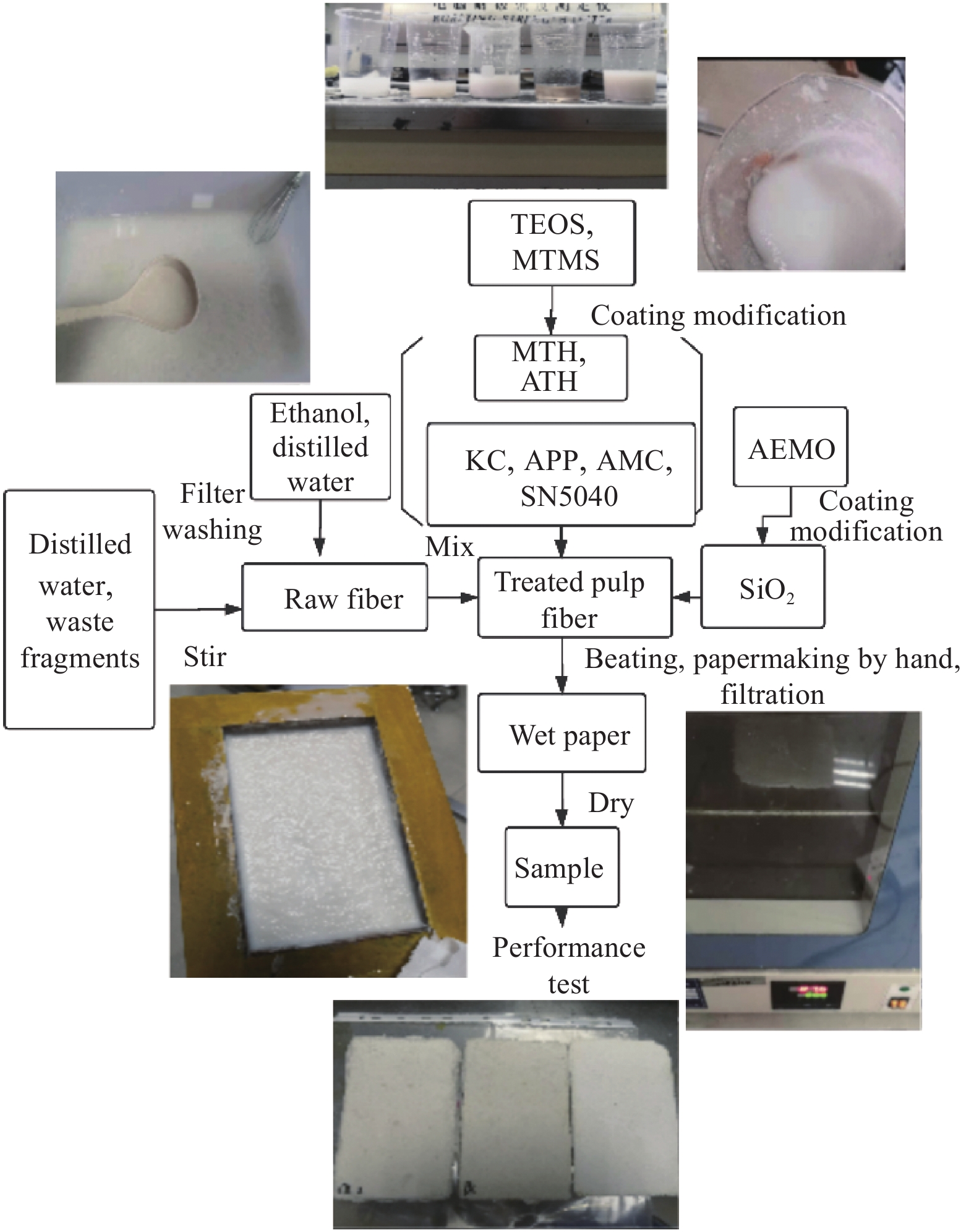

The purpose of this paper is to study and prepare a kind of renewable composite paperboard with both flame retardancy and hydrophobicity, and to explore its flame retardancy, hydrophobicity and mechanical properties. The intumescent flame retardant system (IFR) was constructed with ammonium polyphosphate (APP)-carrageenan (KC), tetraethylorthosilicate(TEOS)-methyltrimethoxysilane (MTMS)@magnesium aluminum hydro-xide(MAH) as synergistic flame retardant, silane coupling agent KH550 (AEMO)@SiO2 as hydrophobic filler. The flame retardant, hydrophobic and mechanical properties of APP-KC-[(TEOS-MTMS)@MAH]-(AEMO@SiO2) composite paperboard were tested. According to the national standard, the main physical properties of corrugated board were measured. The flame retardant effect of corrugated board was tested by vertical combustion test and limiting oxygen index (LOI). The microstructure was characterized by FE-SEM. FTIR was used to study the changes of functional groups before and after combustion. Its thermal stability was analyzed by thermogravimetry (TG). Contact angle (CA) test, rolling angle (SA) test and water absorption test were used to determine its hydrophobicity. The water absorption of composite paperboard is 1.78 g·m−2, the puncture strength is 6.4 J, the edge pressure strength is 8.3 kN·m−1, and the compressive strength is 360 kPa. The optimal formula is adopted (the mass ratio of APP, KC, MTH and ATH was 3∶2∶1∶1). The limiting oxygen index (LOI) reaches 32% at the same time. After the combustion experiment, the carbonization length is 19 mm, the flame duration is 0.5 s, and the ignition time is 3 s. TG results show that the carbon residue of APP-KC-[(TEOS-MTMS)@MAH]-[AEMO@SiO2] composite paperboard is 37.5%. SEM results show that there is a foamed carbon layer on the surface of the composite board after combustion, and the fiber is still intact. The contact angle is 110.2°. The moisture content is 232% lower than that of base paper. APP-KC-[(TEOS-MTMS)@MAH]-(AEMO@SiO2) composite paperboard has good flame retardancy, hydrophobicity and mechanical properties.