2021 Vol. 38, No. 12

2021, 38(12): 4247-4254.

doi: 10.13801/j.cnki.fhclxb.20210303.002

Abstract:

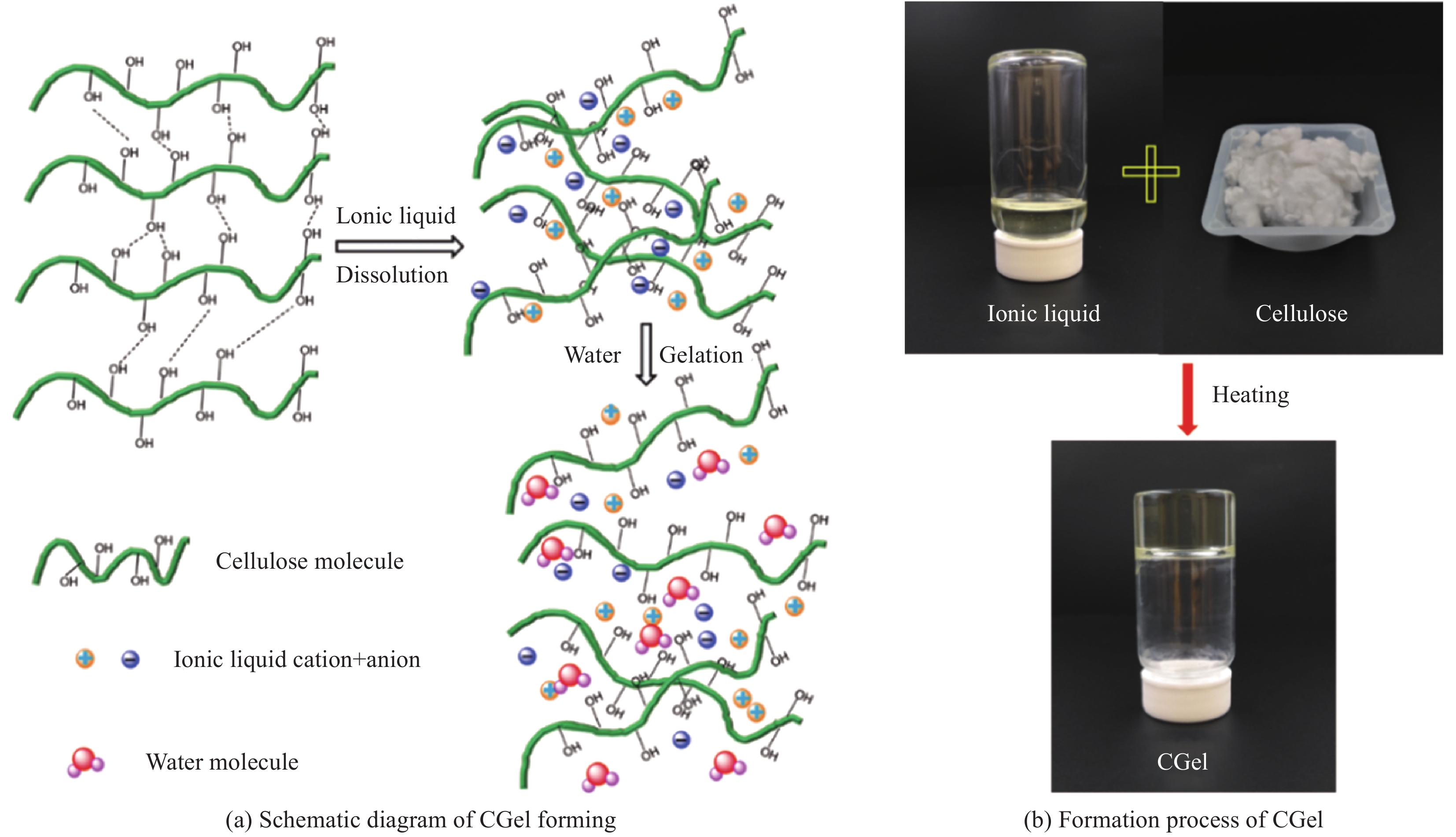

The development of high-performance ionic gel can significantly promote the flexible electronic devices. In this study, an environmentally friendly cellulose-based ionic gel (CGel) had been designed based on the heating-cooling process, where the natural cellulose functioned as the gel framework, and the ionic liquid worked as the conductive material. In the CGel, the cellulose possesses a 3D porous structure, which can effectively adsorb and reserve the ionic liquid. The CGel presents high modules (G′>G″), superior transparency of 88% and conductivity of 2.2 mS/cm, as well as desirable flexibility. In addition, the CGel system features a recycled and reproductive character based on a hot-temperature heating and cooling gelation process. More interestingly, the cellulose-based gel is extremely sensitive to the water molecules, where the conductivity of the CGel features a positive relationship with the humidity, leading to a promising potential for real-time monitoring the environmental humidity and human skin conditions.

The development of high-performance ionic gel can significantly promote the flexible electronic devices. In this study, an environmentally friendly cellulose-based ionic gel (CGel) had been designed based on the heating-cooling process, where the natural cellulose functioned as the gel framework, and the ionic liquid worked as the conductive material. In the CGel, the cellulose possesses a 3D porous structure, which can effectively adsorb and reserve the ionic liquid. The CGel presents high modules (G′>G″), superior transparency of 88% and conductivity of 2.2 mS/cm, as well as desirable flexibility. In addition, the CGel system features a recycled and reproductive character based on a hot-temperature heating and cooling gelation process. More interestingly, the cellulose-based gel is extremely sensitive to the water molecules, where the conductivity of the CGel features a positive relationship with the humidity, leading to a promising potential for real-time monitoring the environmental humidity and human skin conditions.

2021, 38(12): 4255-4264.

doi: 10.13801/j.cnki.fhclxb.20210304.001

Abstract:

Graphene oxide (GO) is a photothermal conversion material with good performance, which is widely used in seawater desalination, photoelectric conversion and solar energy utilization. In order to test the photothermal evaporation characteristics of GO supported non-woven fabric film (GO film) and polyvinyl alcohol-graphene oxide non-woven fabric composite film (PVA-GO composite film), GO was prepared by an improved Hummers method, and non-woven fabrics of cellulose and polyester were selected, and GO membranes and PVA-GO composite membranes were prepared by immersion-ultrasonic method. Ultraviolet-visible-near infrared spectrometer was used to analyze the light absorption properties of GO film and PVA-GO composite film, and the amount of evaporated water of GO film and PVA-GO composite film was measured by electronic balance. Because PVA has hydrophilicity and increases the water absorption of the membrane, the addition of PVA will increase the amount of evaporated water. The surface characteristics of GO membrane and PVA-GO composite membrane were analyzed by SEM. It is found that the GO membrane without PVA has a fibrous filament structure, and the fibers are clearly visible. After adding PVA, the fiber is wrapped by PVA, indicating that the light absorption capacity of the film is enhanced. When 6wt% PVA is added, the non-woven fibers are completely wrapped by PVA. When using a xenon lamp to conduct water evaporation experiments on the two films, the evaporation rate of the GO film reaches 1.67 kg/(m2·h), and the evaporation rate of the PVA-GO composite film reaches 1.85 kg/(m2·h). In addition, the layered structure of GO appears in the GO film, and the ultraviolet-visible-near-infrared spectroscopy shows a good light absorption ability, and it has a good photothermal conversion ability in the photothermal evaporation experiment. The PVA-GO composite film has better photothermal conversion performance and light absorption when the PVA mass concentration is 4wt%.

Graphene oxide (GO) is a photothermal conversion material with good performance, which is widely used in seawater desalination, photoelectric conversion and solar energy utilization. In order to test the photothermal evaporation characteristics of GO supported non-woven fabric film (GO film) and polyvinyl alcohol-graphene oxide non-woven fabric composite film (PVA-GO composite film), GO was prepared by an improved Hummers method, and non-woven fabrics of cellulose and polyester were selected, and GO membranes and PVA-GO composite membranes were prepared by immersion-ultrasonic method. Ultraviolet-visible-near infrared spectrometer was used to analyze the light absorption properties of GO film and PVA-GO composite film, and the amount of evaporated water of GO film and PVA-GO composite film was measured by electronic balance. Because PVA has hydrophilicity and increases the water absorption of the membrane, the addition of PVA will increase the amount of evaporated water. The surface characteristics of GO membrane and PVA-GO composite membrane were analyzed by SEM. It is found that the GO membrane without PVA has a fibrous filament structure, and the fibers are clearly visible. After adding PVA, the fiber is wrapped by PVA, indicating that the light absorption capacity of the film is enhanced. When 6wt% PVA is added, the non-woven fibers are completely wrapped by PVA. When using a xenon lamp to conduct water evaporation experiments on the two films, the evaporation rate of the GO film reaches 1.67 kg/(m2·h), and the evaporation rate of the PVA-GO composite film reaches 1.85 kg/(m2·h). In addition, the layered structure of GO appears in the GO film, and the ultraviolet-visible-near-infrared spectroscopy shows a good light absorption ability, and it has a good photothermal conversion ability in the photothermal evaporation experiment. The PVA-GO composite film has better photothermal conversion performance and light absorption when the PVA mass concentration is 4wt%.

2021, 38(12): 4265-4272.

doi: 10.13801/j.cnki.fhclxb.20210303.001

Abstract:

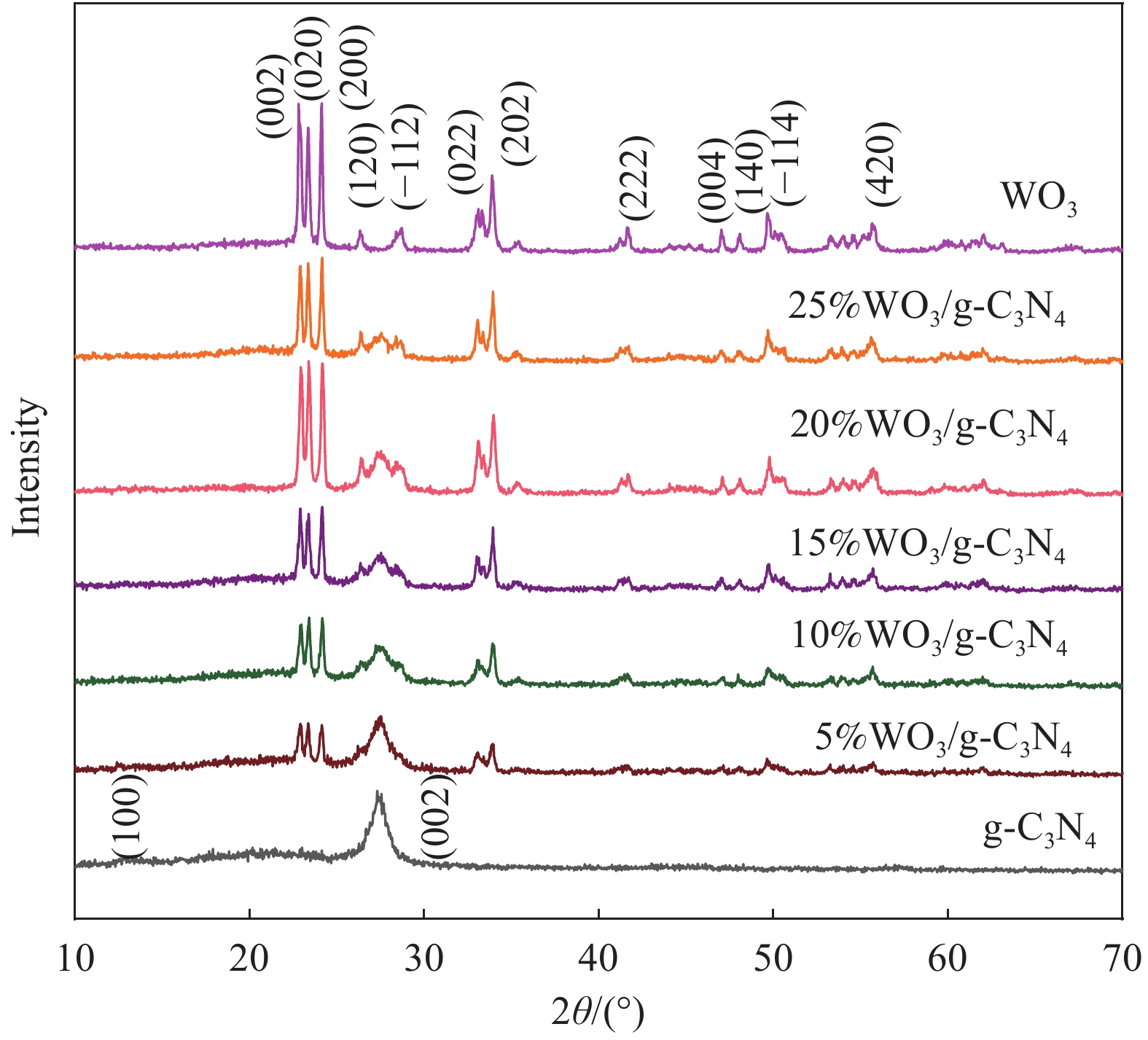

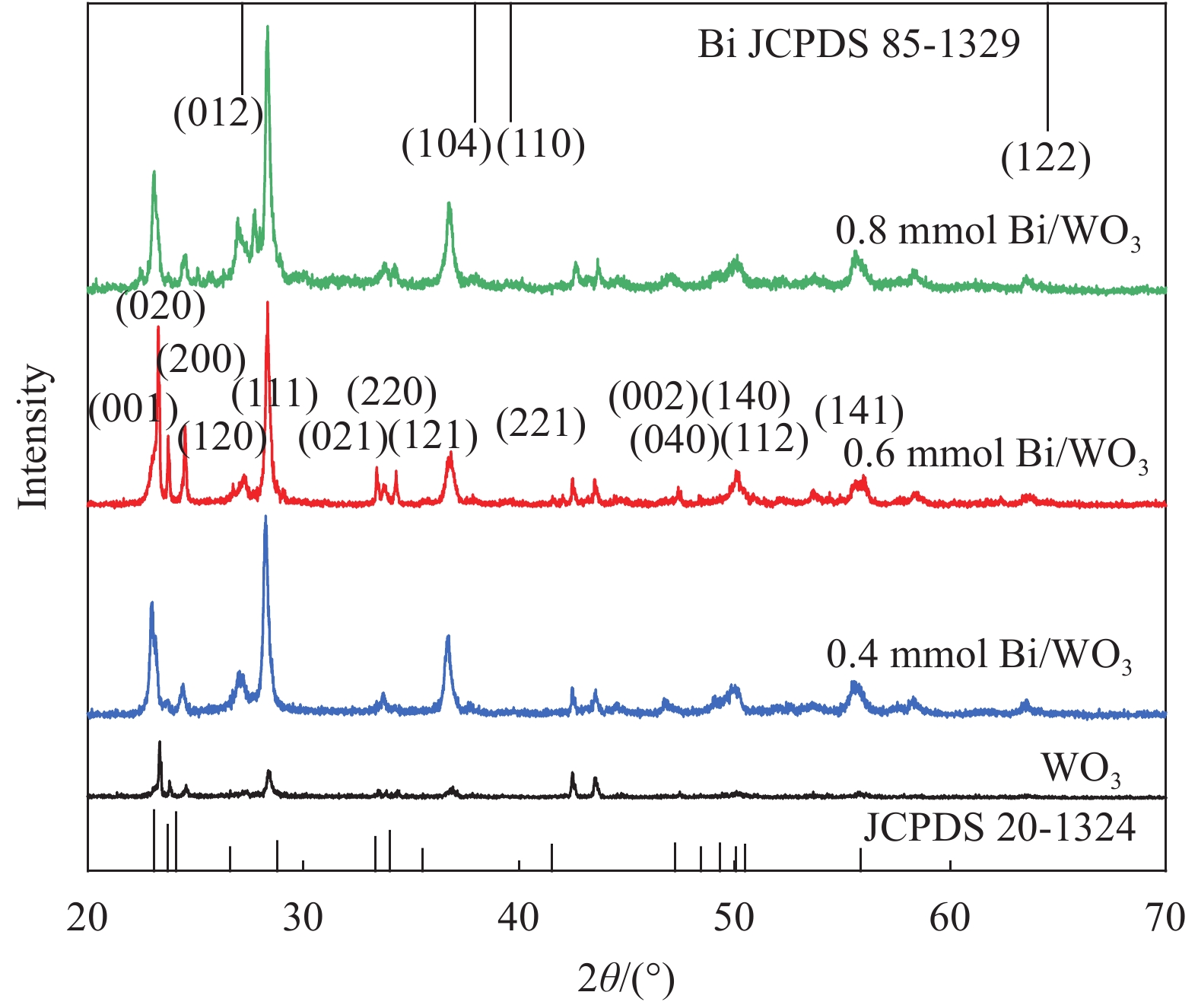

The WO3/graphite phase carbon nitride (g-C3N4) composites were prepared by mixing self-made layered g-C3N4 with WO3 nanoplates and afterward calcination process, and were characterized by XRD, SEM, TEM, UV-Vis DRS and PL. The results show that g-C3N4 presents graphene-like layered structure, and WO3 indicates nanoplate structure, and scatters on the surfaces of g-C3N4. After compounding with WO3, the absorption edge of UV-Vis spectrum shifts to red, which widens the response of g-C3N4 to visible light. The photocatalytic degradation properties of WO3/g-C3N4 were examined using rodamine B (RhB) as a simulated pollutant. When the mass ratio of WO3/g-C3N4 is 1∶5, the best photocatalytic activity is obtained. After 60 min of visible light irradiation, the degradation rate of RhB can reach 94.9%. The photocatalyst shows good stability, as the photodegradation rate of RhB reaches 88.9% after repeated use of the same photocatalyst for 6 times. The study of photocatalytic mechanism shows that superoxide radical (·O2−) is the main active species for photocatalytic degradation of RhB.

The WO3/graphite phase carbon nitride (g-C3N4) composites were prepared by mixing self-made layered g-C3N4 with WO3 nanoplates and afterward calcination process, and were characterized by XRD, SEM, TEM, UV-Vis DRS and PL. The results show that g-C3N4 presents graphene-like layered structure, and WO3 indicates nanoplate structure, and scatters on the surfaces of g-C3N4. After compounding with WO3, the absorption edge of UV-Vis spectrum shifts to red, which widens the response of g-C3N4 to visible light. The photocatalytic degradation properties of WO3/g-C3N4 were examined using rodamine B (RhB) as a simulated pollutant. When the mass ratio of WO3/g-C3N4 is 1∶5, the best photocatalytic activity is obtained. After 60 min of visible light irradiation, the degradation rate of RhB can reach 94.9%. The photocatalyst shows good stability, as the photodegradation rate of RhB reaches 88.9% after repeated use of the same photocatalyst for 6 times. The study of photocatalytic mechanism shows that superoxide radical (·O2−) is the main active species for photocatalytic degradation of RhB.

2021, 38(12): 4273-4281.

doi: 10.13801/j.cnki.fhclxb.20210310.002

Abstract:

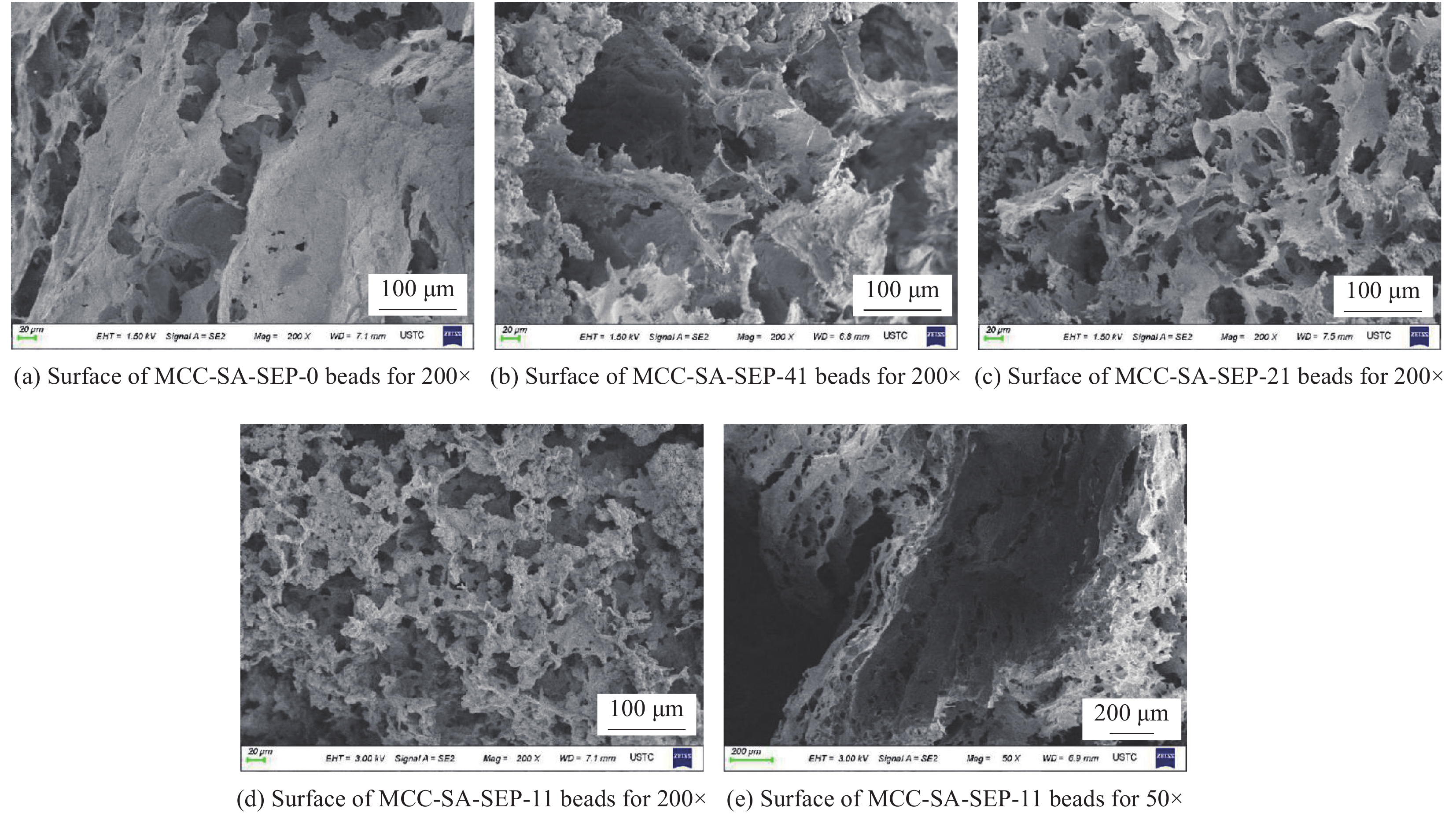

Double network composite beads (MCC-SA-SEP) were synthesized by a floating droplet method, in which microcrystalline cellulose (MCC) and sodium alginate (SA) worked as the network frameworks, and sepiolite (SEP) was a functional component. The microstructure and thermal properties of the as-prepared MCC-SA-SEP beads were characterized by SEM and TG, respectively, and the adsorption performance for methylene blue (MB) aqueous solution was studied. The results present that the MCC-SA-SEP beads have three-dimensional porous structures, and the thermal stability increases gradually with the increasing of SEP contents. The adsorption process of MCC-SA-SEP follows the pseudo-second-order kinetic model and Langmuir isotherm, with the maximum adsorption capacity of 333.3 mg/g for MB. After five regeneration cycles, the adsorption capacity could still retain 85.4% of the initial adsorption amount, demonstrating a novel organic-inorganic hybrid adsorbent for dye waste water treatment.

Double network composite beads (MCC-SA-SEP) were synthesized by a floating droplet method, in which microcrystalline cellulose (MCC) and sodium alginate (SA) worked as the network frameworks, and sepiolite (SEP) was a functional component. The microstructure and thermal properties of the as-prepared MCC-SA-SEP beads were characterized by SEM and TG, respectively, and the adsorption performance for methylene blue (MB) aqueous solution was studied. The results present that the MCC-SA-SEP beads have three-dimensional porous structures, and the thermal stability increases gradually with the increasing of SEP contents. The adsorption process of MCC-SA-SEP follows the pseudo-second-order kinetic model and Langmuir isotherm, with the maximum adsorption capacity of 333.3 mg/g for MB. After five regeneration cycles, the adsorption capacity could still retain 85.4% of the initial adsorption amount, demonstrating a novel organic-inorganic hybrid adsorbent for dye waste water treatment.

2021, 38(12): 4282-4293.

doi: 10.13801/j.cnki.fhclxb.20210309.002

Abstract:

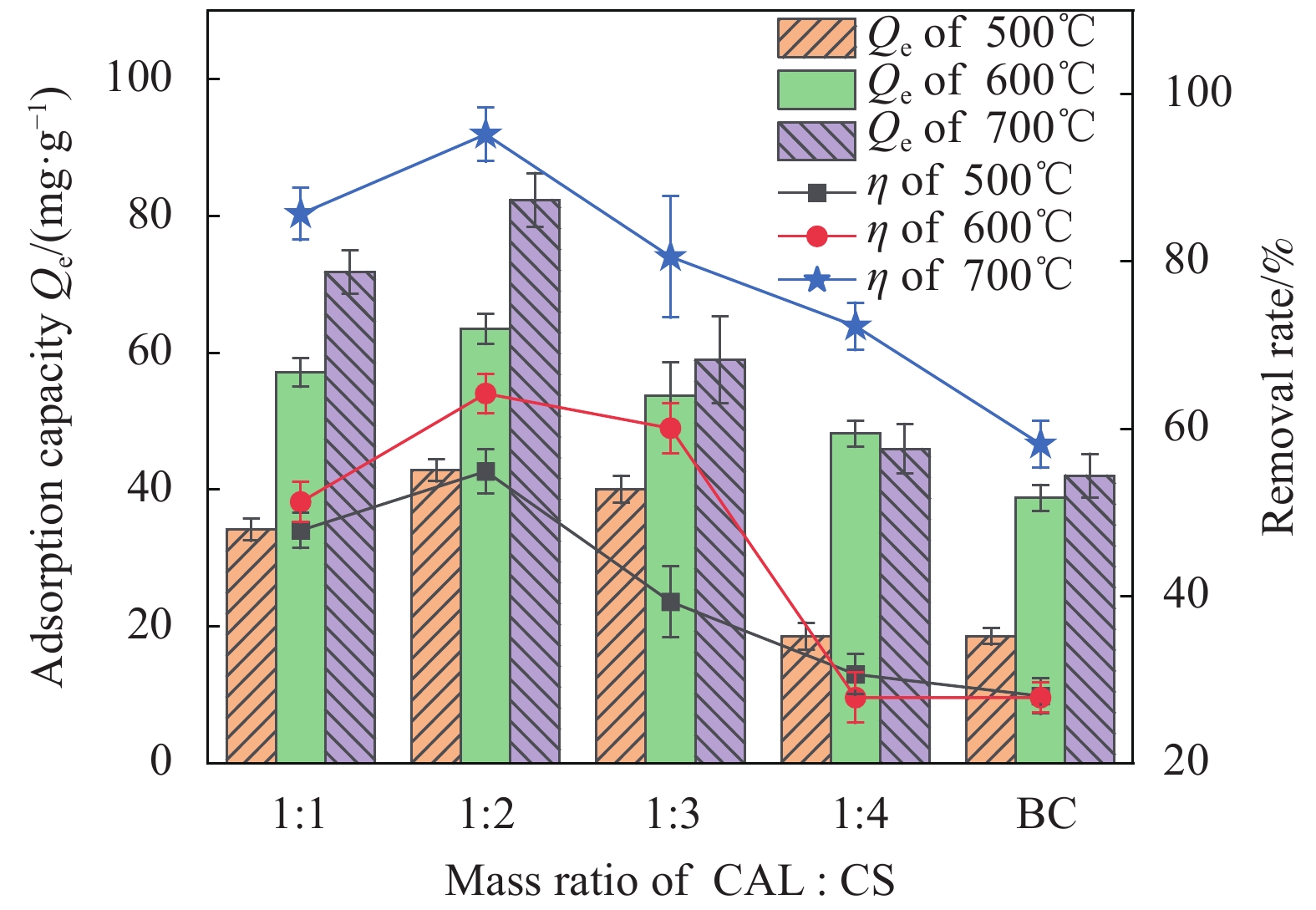

In order to obtain a biochar material which adsorbs PB (II) in wastewater efficiently, calcite/biochar (CAL/BC) composite was prepared by co-pyrolysis at 500℃, 600℃ and 700℃, using coconut shell (CS) and calcite (CAL) as raw materials. The surface morphology and structure of CAL/BC composites were characterized by SEM, ICP-MS, BET, XRD and FTIR. The results show that CAL and CS combine tightly under the three pyrolysis tempera-tures, and CAL/BC has a large specific surface area and a large number of functional groups. The maximum adsorption capacities of PB (II) on CAL/BC composite (CAL∶ CS=1∶ 2, mass ratio) prepared at 500℃, 600℃, and 700℃ are 95.24 mg·g−1, 99.01 mg·g−1, and 185.19 mg·g−1. The optimum adsorption condition is pH=5.5 and the amount of adsorbent is 1.5 g·L−1. The adsorption process conforms to the second-order kinetic model and Langmuir isotherm model. The mechanisms of adsorption of Pb(II) on CAL/BC composites are precipitation, ion exchange, cation-π action, pore filling and electrostatic gravitation. In addition, the removal rate of Pb(II) by CAL/BC composite remains high level after 4 adsorption-desorption cycles. Therefore, the CAL/BC composite prepared by co-pyrolysis has a excellent application prospect in the treatment of Pb(II) in wastewater.

In order to obtain a biochar material which adsorbs PB (II) in wastewater efficiently, calcite/biochar (CAL/BC) composite was prepared by co-pyrolysis at 500℃, 600℃ and 700℃, using coconut shell (CS) and calcite (CAL) as raw materials. The surface morphology and structure of CAL/BC composites were characterized by SEM, ICP-MS, BET, XRD and FTIR. The results show that CAL and CS combine tightly under the three pyrolysis tempera-tures, and CAL/BC has a large specific surface area and a large number of functional groups. The maximum adsorption capacities of PB (II) on CAL/BC composite (CAL∶ CS=1∶ 2, mass ratio) prepared at 500℃, 600℃, and 700℃ are 95.24 mg·g−1, 99.01 mg·g−1, and 185.19 mg·g−1. The optimum adsorption condition is pH=5.5 and the amount of adsorbent is 1.5 g·L−1. The adsorption process conforms to the second-order kinetic model and Langmuir isotherm model. The mechanisms of adsorption of Pb(II) on CAL/BC composites are precipitation, ion exchange, cation-π action, pore filling and electrostatic gravitation. In addition, the removal rate of Pb(II) by CAL/BC composite remains high level after 4 adsorption-desorption cycles. Therefore, the CAL/BC composite prepared by co-pyrolysis has a excellent application prospect in the treatment of Pb(II) in wastewater.

2021, 38(12): 4294-4304.

doi: 10.13801/j.cnki.fhclxb.20210202.005

Abstract:

The normal concrete (NC) and rubber/NC were prepared. The performance degradation process of concrete specimens within 60 salt freeze-thaw cycles was studied, which includes changes of apparent phenomenon, flaking amount and compressive strength loss. The adaptation of ultrasonic test in evaluating the performance of concrete after salt freeze-thaw cycles was investigated. The relationships between relative velocity, damage degree and compressive strength were comparative analyzed. The micro-structure changes of concrete specimens after salt freeze-thaw cycles were observed by SEM. The results show that the surface erosion of concrete becomes more obvious, the flaking amount, internal damage and strength loss gradually increase, with the increasing number of salt freeze-thaw cycles. It has good correlation between the ultrasonic parameters and compressive strength. After the concrete undergoing salt freeze-thaw damage, the internal structure becomes loose and flocculent, increasing pores and cracks appear, and the density decreases, which results in deterioration of macro-mechanical properties. However, the deterioration degree of rubber/concrete is better than that of normal concrete at all cycle stages, because the elastic rubber fine aggregate can effectively alleviate internal cracking and pore expansion caused by icing pressure. The rubber/concrete with 10% rubber content (mass ratio to cementitious material) (10%Rubber/NC) has the best performance indicators. After 60 salt freeze-thaw cycles, the compressive strength loss rates of normal concrete and 10%Rubber/NC are 58.5% and 48.0%, respectively.

The normal concrete (NC) and rubber/NC were prepared. The performance degradation process of concrete specimens within 60 salt freeze-thaw cycles was studied, which includes changes of apparent phenomenon, flaking amount and compressive strength loss. The adaptation of ultrasonic test in evaluating the performance of concrete after salt freeze-thaw cycles was investigated. The relationships between relative velocity, damage degree and compressive strength were comparative analyzed. The micro-structure changes of concrete specimens after salt freeze-thaw cycles were observed by SEM. The results show that the surface erosion of concrete becomes more obvious, the flaking amount, internal damage and strength loss gradually increase, with the increasing number of salt freeze-thaw cycles. It has good correlation between the ultrasonic parameters and compressive strength. After the concrete undergoing salt freeze-thaw damage, the internal structure becomes loose and flocculent, increasing pores and cracks appear, and the density decreases, which results in deterioration of macro-mechanical properties. However, the deterioration degree of rubber/concrete is better than that of normal concrete at all cycle stages, because the elastic rubber fine aggregate can effectively alleviate internal cracking and pore expansion caused by icing pressure. The rubber/concrete with 10% rubber content (mass ratio to cementitious material) (10%Rubber/NC) has the best performance indicators. After 60 salt freeze-thaw cycles, the compressive strength loss rates of normal concrete and 10%Rubber/NC are 58.5% and 48.0%, respectively.

2021, 38(12): 4305-4312.

doi: 10.13801/j.cnki.fhclxb.20210302.003

Abstract:

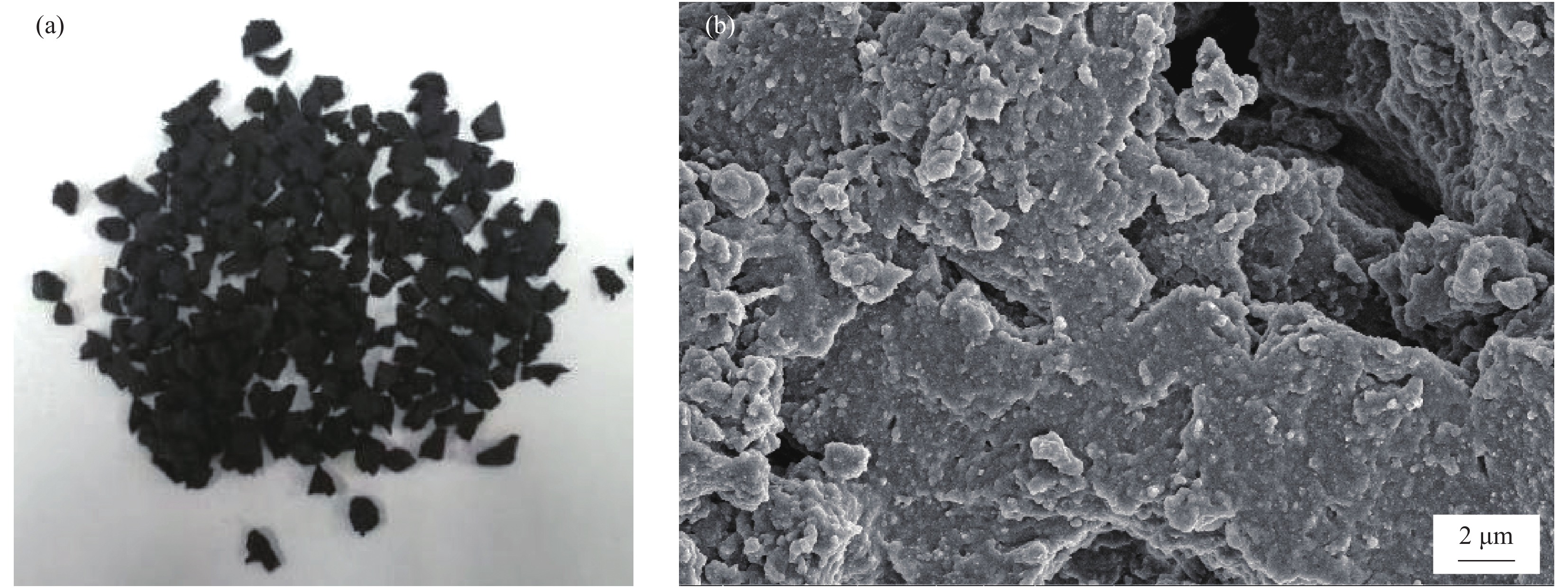

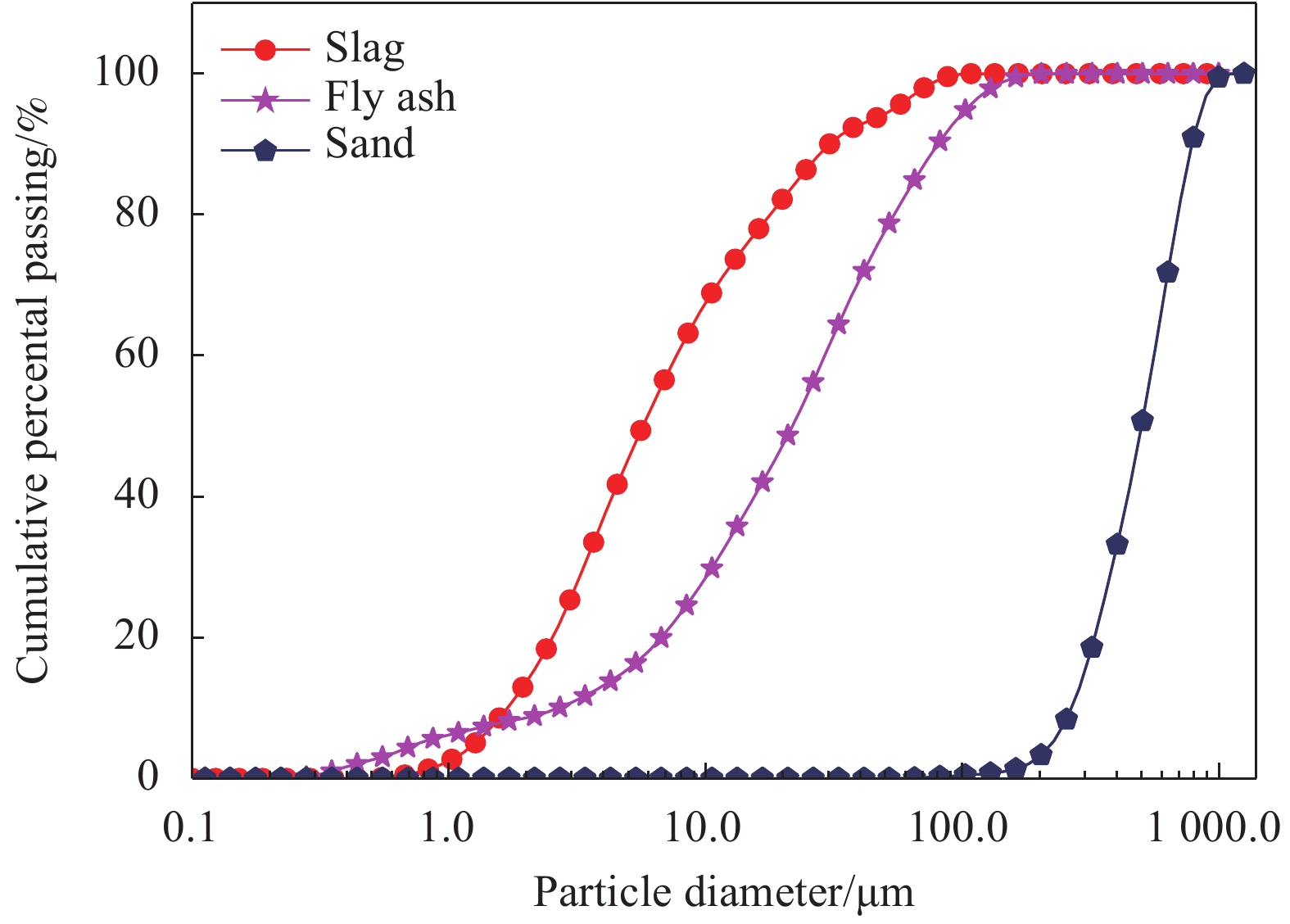

Activated by alkaline activator, polyethylene (PE) fiber reinforced high ductile alkali-activated slag composites were prepared using slag as the main raw material and fly ash as auxiliary material. The tensile and compressive properties of the composites under different curing ages (1 day, 3 days, 7 days, 28 days, 56 days and 120 days) were studied through uniaxial tensile and compressive tests, and the cracks were characterized by a digital image correlation technology (DIC). The results show that the alkali-activated slag owns a good high ductility and early strength. The strength value at 7 days can reach more than 84% of the ultimate strengths (the ultimate tensile and compressive strengths are 5.05 MPa and 91.24 MPa, respectively), 5.74% for the tensile strain, and the multi-cracking is basically saturated. After 28 days, the tensile and compressive properties become stable (tensile and compressive strengths and tensile strain keep around 6 MPa, 100 MPa and 6%, respectively). DIC analysis cloud maps visually describe the formation and propagation of cracks, which can be applied to predict reliably the direction and location of cracks to a certain extent.

Activated by alkaline activator, polyethylene (PE) fiber reinforced high ductile alkali-activated slag composites were prepared using slag as the main raw material and fly ash as auxiliary material. The tensile and compressive properties of the composites under different curing ages (1 day, 3 days, 7 days, 28 days, 56 days and 120 days) were studied through uniaxial tensile and compressive tests, and the cracks were characterized by a digital image correlation technology (DIC). The results show that the alkali-activated slag owns a good high ductility and early strength. The strength value at 7 days can reach more than 84% of the ultimate strengths (the ultimate tensile and compressive strengths are 5.05 MPa and 91.24 MPa, respectively), 5.74% for the tensile strain, and the multi-cracking is basically saturated. After 28 days, the tensile and compressive properties become stable (tensile and compressive strengths and tensile strain keep around 6 MPa, 100 MPa and 6%, respectively). DIC analysis cloud maps visually describe the formation and propagation of cracks, which can be applied to predict reliably the direction and location of cracks to a certain extent.

2021, 38(12): 4313-4324.

doi: 10.13801/j.cnki.fhclxb.20210210.003

Abstract:

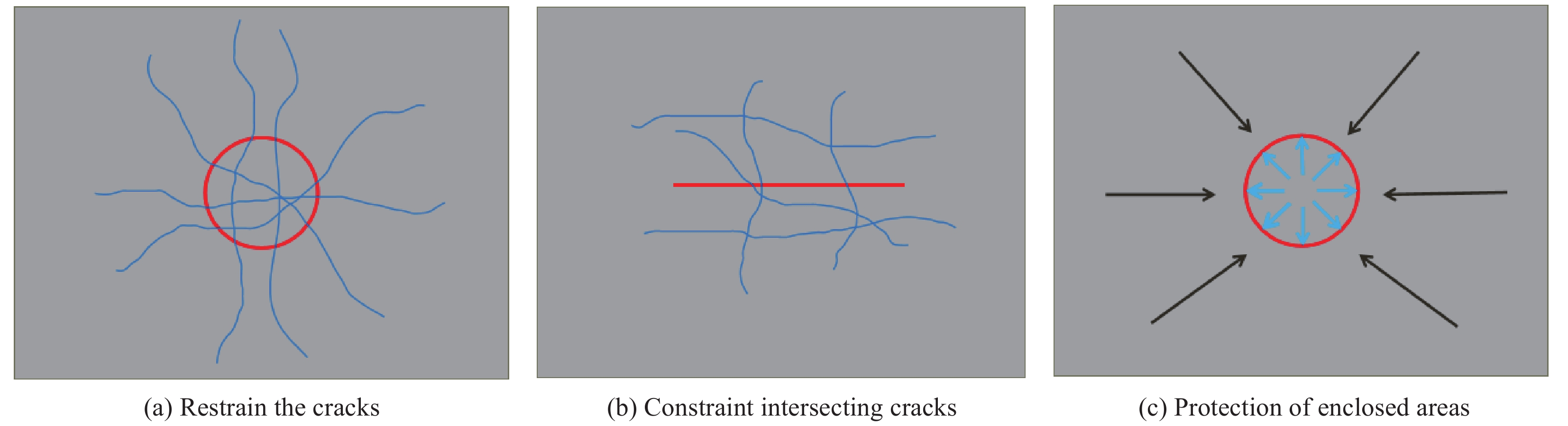

The influence of six kinds of steel fibers (SF) (short straight, long straight, half ring, triangular, rectangular, circular) with small length-diameter ratio on high-performance concrete was studied. The influence of SF on the fluidity, compressive strength and bending strength of concrete was discussed by changing the volume fraction of SF to change the number and area of the ring formed. The failure mode and mechanism of concrete were analyzed by studying the failure interface. The results show that: the number of closed SF and the area of fiber ring play a major role in the flow of concrete; the circular SF in the closed SF has the best effect on the bending and compressive strength of concrete than other closed SF. In the hybrid test of short straight SF and circular SF, when the volume fraction of circular SF is 1vol% and the volume fraction of short straight SF is 0.5vol%, the improvement on the compressive strength and bending strength of SF reinforced concrete is the best.

The influence of six kinds of steel fibers (SF) (short straight, long straight, half ring, triangular, rectangular, circular) with small length-diameter ratio on high-performance concrete was studied. The influence of SF on the fluidity, compressive strength and bending strength of concrete was discussed by changing the volume fraction of SF to change the number and area of the ring formed. The failure mode and mechanism of concrete were analyzed by studying the failure interface. The results show that: the number of closed SF and the area of fiber ring play a major role in the flow of concrete; the circular SF in the closed SF has the best effect on the bending and compressive strength of concrete than other closed SF. In the hybrid test of short straight SF and circular SF, when the volume fraction of circular SF is 1vol% and the volume fraction of short straight SF is 0.5vol%, the improvement on the compressive strength and bending strength of SF reinforced concrete is the best.

2021, 38(12): 4325-4336.

doi: 10.13801/j.cnki.fhclxb.20210223.002

Abstract:

Ultra high toughness cementitious composites (UHTCC) is a new material with ultra-high toughness and good durability. Its compressive toughness index is an important index to evaluate the toughness of UHTCC. 5 groups of UHTCC with different fiber contents were tested under uniaxial compression after ultra-low temperature, and the evaluation index of compressive toughness of UHTCC under ultra-low temperature was studied, and its deformation capacity was equivalent analyzed. The experimental results show that within a certain range, with the increase of fiber content, the compressive strength and toughness of UHTCC are significantly improved, but beyond the optimal content range, the performances are not improved, but are slightly decreased; ultra-low temperature has a certain improvement on the compressive strength of UHTCC, when the temperature is reduced to −196℃, the axial compressive strength can be increased by 74.42%, but it shows obvious fragility.

Ultra high toughness cementitious composites (UHTCC) is a new material with ultra-high toughness and good durability. Its compressive toughness index is an important index to evaluate the toughness of UHTCC. 5 groups of UHTCC with different fiber contents were tested under uniaxial compression after ultra-low temperature, and the evaluation index of compressive toughness of UHTCC under ultra-low temperature was studied, and its deformation capacity was equivalent analyzed. The experimental results show that within a certain range, with the increase of fiber content, the compressive strength and toughness of UHTCC are significantly improved, but beyond the optimal content range, the performances are not improved, but are slightly decreased; ultra-low temperature has a certain improvement on the compressive strength of UHTCC, when the temperature is reduced to −196℃, the axial compressive strength can be increased by 74.42%, but it shows obvious fragility.

2021, 38(12): 4337-4348.

doi: 10.13801/j.cnki.fhclxb.20210310.001

Abstract:

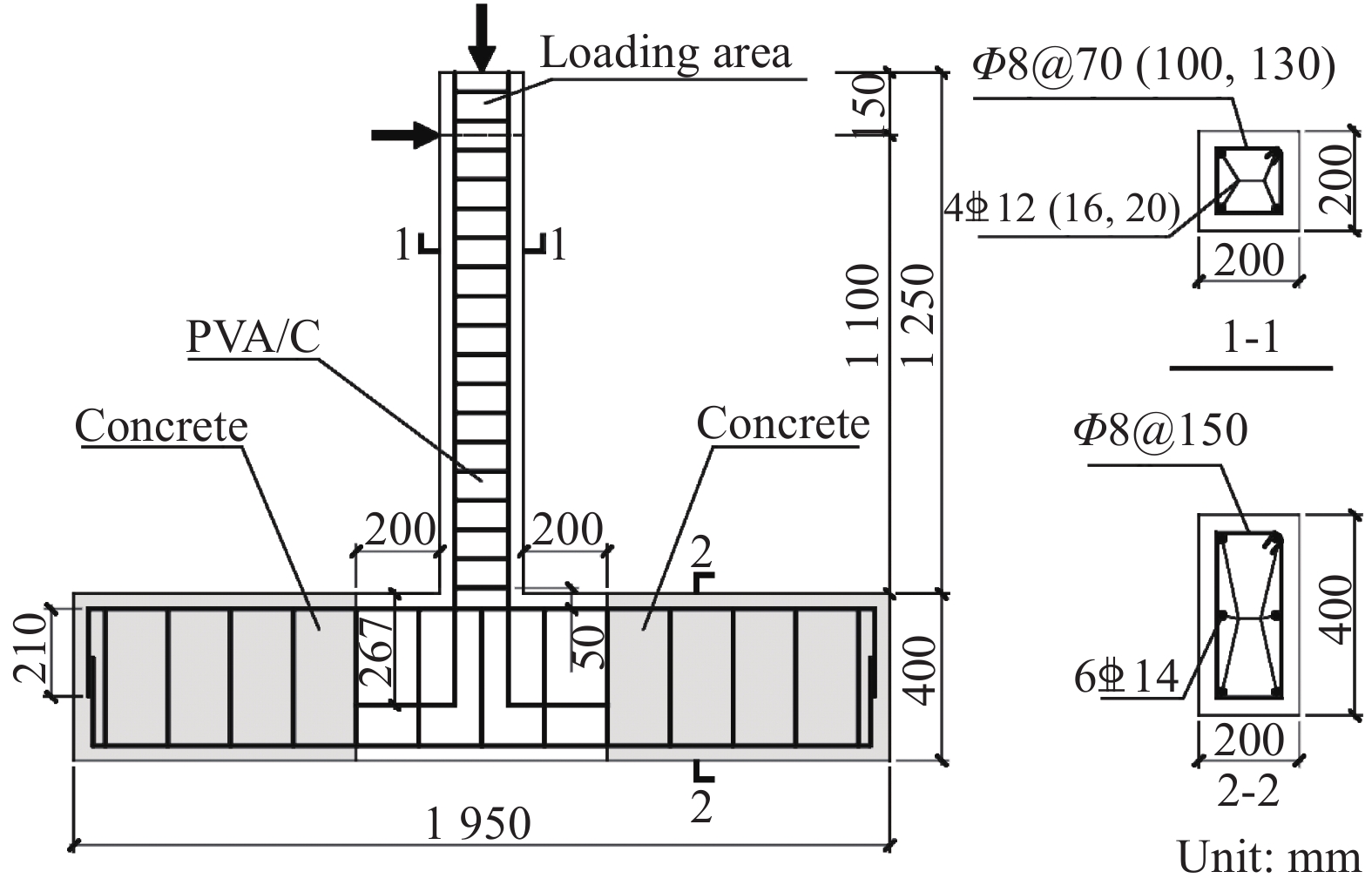

Previous studies on the seismic performance of polyvinyl alcohol fiber reinforced cementitious compo-site (PVA/C) columns mostly focused on short columns, and PVA/C was usually set locally in the joint and its adjacent parts. Based on this, low-cycle reversed loading tests on medium-length PVA/C columns with low axial pressure ratio were carried out, and PVA/C was set along the full height of the column. Test variation parameters are fiber volume fraction ρf and volume-stirrup ratio ρv. The following conclusions can be drawn through the test: Bending failure occurs in all specimens. When ρf and ρv increase within the test condition range respectively, the crack controlling ability, ductility, section rotation ability and energy dissipation ability of specimens are improved. While the rate of stiffness degradation and decay of bearing capacity are decreased. The increase of ρf can greatly improve the cracking load of specimens, but has little effect on the peak load. When ρf increases from 0 vol% to 2 vol%, the displacement ductility coefficient, the energy consumption ratio and the cracking load increase 52.9%, 112.3% and 51.1%, respectively. The PVA/C columns can maintain good seismic performance and crack morphology even if the stirrup ratio is reduced. According to the experimental data of this paper and other relevant literature, the relationship between displacement ductility coefficient and ρf and ρv is obtained. Differences of seismic performance of various PVA/C columns were summarized.

Previous studies on the seismic performance of polyvinyl alcohol fiber reinforced cementitious compo-site (PVA/C) columns mostly focused on short columns, and PVA/C was usually set locally in the joint and its adjacent parts. Based on this, low-cycle reversed loading tests on medium-length PVA/C columns with low axial pressure ratio were carried out, and PVA/C was set along the full height of the column. Test variation parameters are fiber volume fraction ρf and volume-stirrup ratio ρv. The following conclusions can be drawn through the test: Bending failure occurs in all specimens. When ρf and ρv increase within the test condition range respectively, the crack controlling ability, ductility, section rotation ability and energy dissipation ability of specimens are improved. While the rate of stiffness degradation and decay of bearing capacity are decreased. The increase of ρf can greatly improve the cracking load of specimens, but has little effect on the peak load. When ρf increases from 0 vol% to 2 vol%, the displacement ductility coefficient, the energy consumption ratio and the cracking load increase 52.9%, 112.3% and 51.1%, respectively. The PVA/C columns can maintain good seismic performance and crack morphology even if the stirrup ratio is reduced. According to the experimental data of this paper and other relevant literature, the relationship between displacement ductility coefficient and ρf and ρv is obtained. Differences of seismic performance of various PVA/C columns were summarized.

2021, 38(12): 4349-4361.

doi: 10.13801/j.cnki.fhclxb.20210203.003

Abstract:

The cracking of reinforced concrete pipe during pipe jacking construction seriously affects the project quality and subsequent operation. In view of the role of polypropylene fiber in improving the crack resistance and tensile properties of concrete, this paper adopted two types of fine polypropylene fibers and one type of crude polypropylene fiber, designing 3 groups of reinforced concrete pipe specimens, which were reinforced with plain concrete, single-scale crude fiber and hybrid three-scale fibers. The three-edge-bearing test was carried out. The cracking failure patterns, load-deflection responses and ductility indexes after cracking of these pipes were comparatively analyzed. A finite element numerical model was developed for reproducing the three-edge-bearing test to investigate the influence law of polypropylene fiber content on the mechanical properties of reinforced concrete pipe. The results show that the crack resistance and load-bearing capacities of concrete pipe are improved by adding crude polypropylene fiber, and the higher service and ultimate strength of pipe are achieved under the synergistic action of fine and crude polypropylene fibers. Compared with the pipe without fiber, the hybrid multi-scale fibers increase the service and ultimate strength by 28.7% and 36.4%. In addition, using this numerical simulation method, the load-deflection responses of fiber reinforced concrete pipe can be reasonably predicted, and the optimum contents of crude fiber when incorporating single-scale and three-scale fibers are obtained, aiming to the higher ultimate strength of concrete pipe.

The cracking of reinforced concrete pipe during pipe jacking construction seriously affects the project quality and subsequent operation. In view of the role of polypropylene fiber in improving the crack resistance and tensile properties of concrete, this paper adopted two types of fine polypropylene fibers and one type of crude polypropylene fiber, designing 3 groups of reinforced concrete pipe specimens, which were reinforced with plain concrete, single-scale crude fiber and hybrid three-scale fibers. The three-edge-bearing test was carried out. The cracking failure patterns, load-deflection responses and ductility indexes after cracking of these pipes were comparatively analyzed. A finite element numerical model was developed for reproducing the three-edge-bearing test to investigate the influence law of polypropylene fiber content on the mechanical properties of reinforced concrete pipe. The results show that the crack resistance and load-bearing capacities of concrete pipe are improved by adding crude polypropylene fiber, and the higher service and ultimate strength of pipe are achieved under the synergistic action of fine and crude polypropylene fibers. Compared with the pipe without fiber, the hybrid multi-scale fibers increase the service and ultimate strength by 28.7% and 36.4%. In addition, using this numerical simulation method, the load-deflection responses of fiber reinforced concrete pipe can be reasonably predicted, and the optimum contents of crude fiber when incorporating single-scale and three-scale fibers are obtained, aiming to the higher ultimate strength of concrete pipe.

2021, 38(12): 4362-4370.

doi: 10.13801/j.cnki.fhclxb.20210202.002

Abstract:

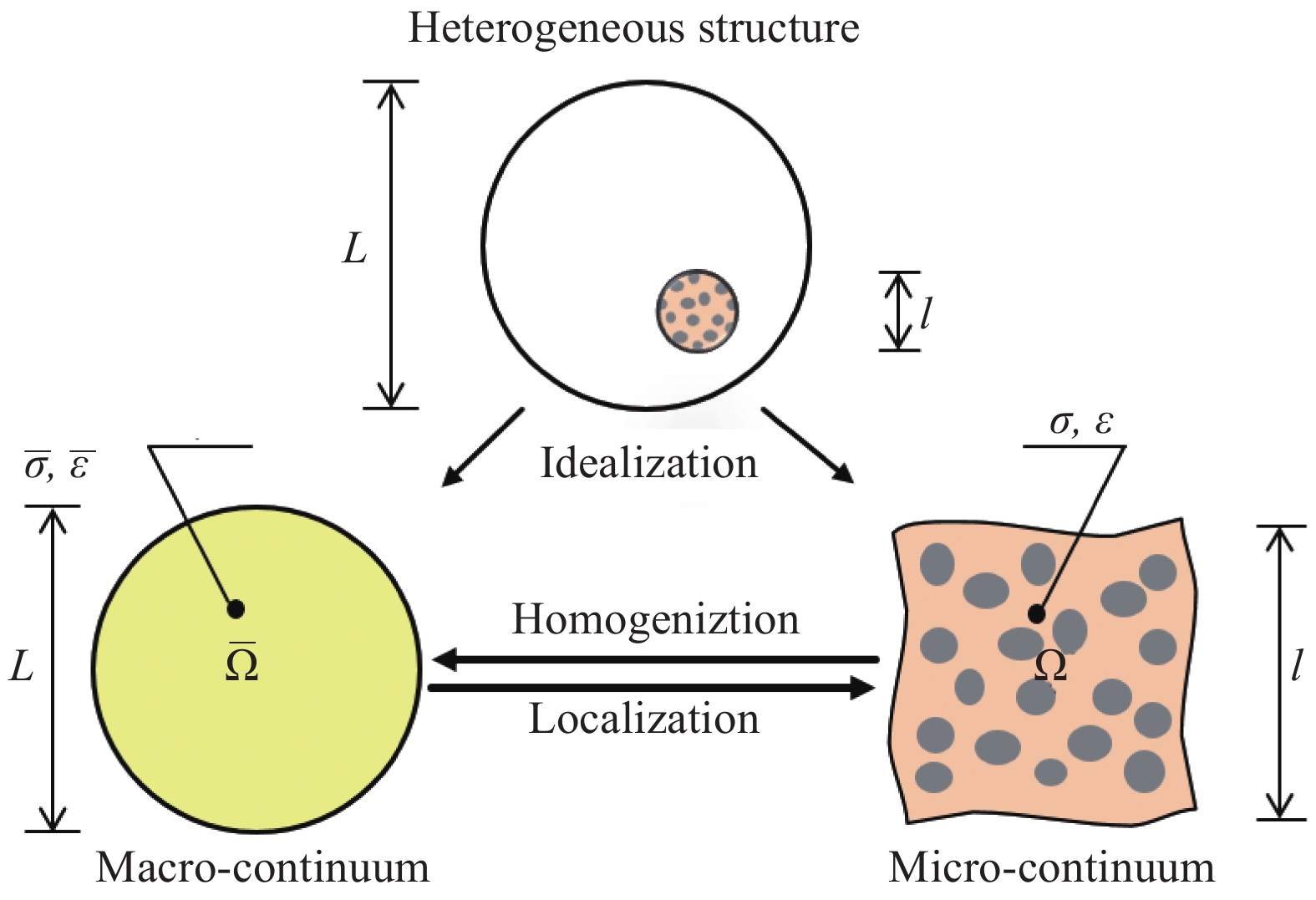

A three-dimensional finite element modeling for graphene nanocomposites usually requires very fine meshes. In case of plasticity, the computational efficiency of a micro representative volume element model is extremely low. For a remedy, based on the theory of nonuniform transformation field analysis, a reduced order homogenization method for graphene nanocomposites was proposed. First, we performed a pre-analysis for different loading paths to extract micro plastic strain fields; then a proper orthogonal decomposition of those field information was performed to obtain several plastic modes, which were used as basis functions for model order reduction. A constitutive model of reduced variables was derived from the equivalence of macro and micro dissipation power. The offline analysis of this method was implemented in MATLAB. For engineering computations, the online analysis was implemented by the user subroutine interface UMAT of the commercial finite element software ABAQUS. The effectiveness of the proposed method was illustrated by three-dimensional numerical examples. The results show that the acceleration rate for 3D representative volume element computations is of the order of 103~104, while maintaining a sufficient accuracy level.

A three-dimensional finite element modeling for graphene nanocomposites usually requires very fine meshes. In case of plasticity, the computational efficiency of a micro representative volume element model is extremely low. For a remedy, based on the theory of nonuniform transformation field analysis, a reduced order homogenization method for graphene nanocomposites was proposed. First, we performed a pre-analysis for different loading paths to extract micro plastic strain fields; then a proper orthogonal decomposition of those field information was performed to obtain several plastic modes, which were used as basis functions for model order reduction. A constitutive model of reduced variables was derived from the equivalence of macro and micro dissipation power. The offline analysis of this method was implemented in MATLAB. For engineering computations, the online analysis was implemented by the user subroutine interface UMAT of the commercial finite element software ABAQUS. The effectiveness of the proposed method was illustrated by three-dimensional numerical examples. The results show that the acceleration rate for 3D representative volume element computations is of the order of 103~104, while maintaining a sufficient accuracy level.

2021, 38(12): 4371-4378.

doi: 10.13801/j.cnki.fhclxb.20210210.002

Abstract:

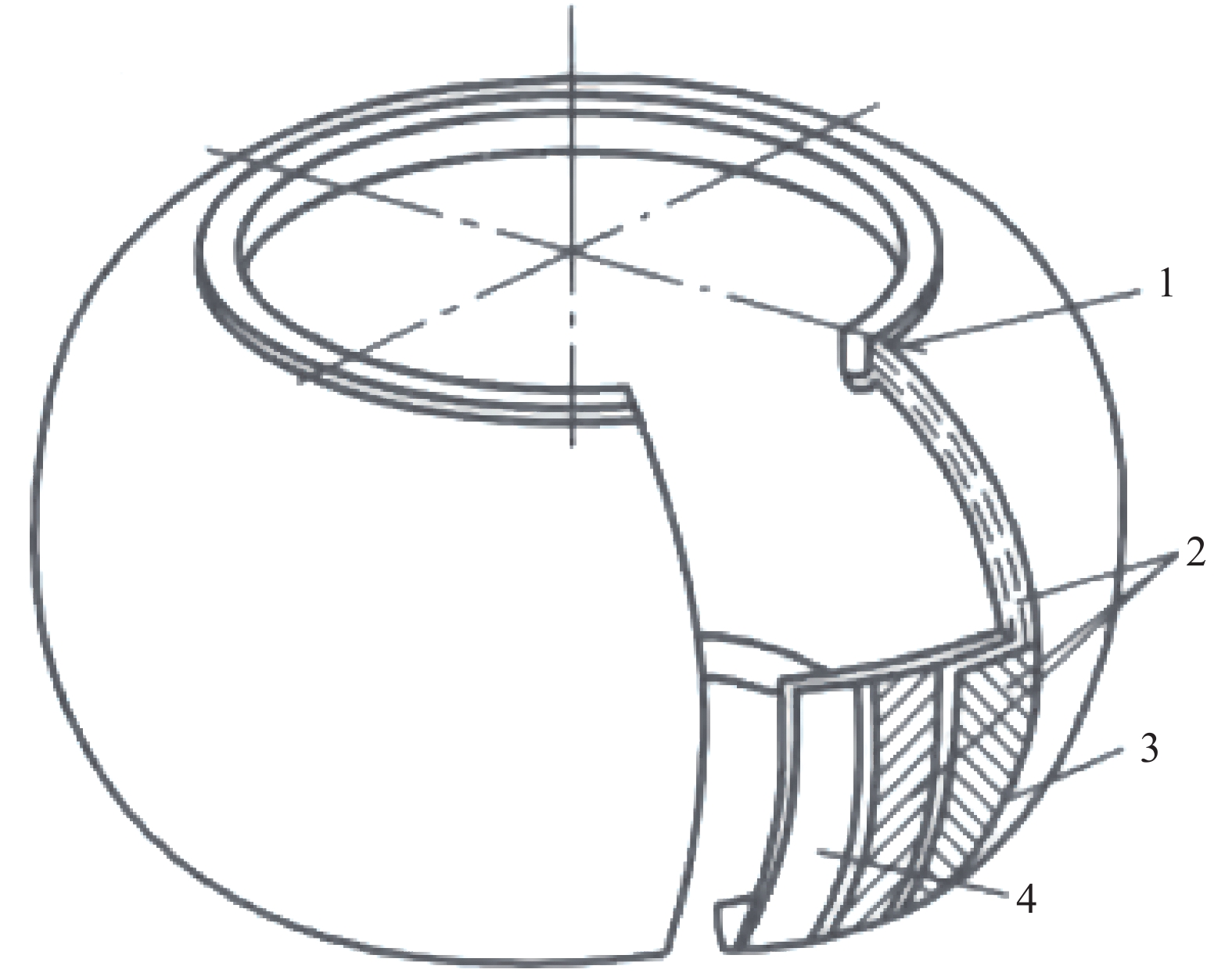

Air springs with cord-rubber structure have the advantages of variable stiffness, lightweighting and better isolating effect, which have become the highlights of vehicle research in the current of new developing trends of automobile. However, as an important parameter, the effective area of air spring is lack of thorough predictive theory. A predictive analytical method for effective area of rolling lobe air spring for vehicles was put forward based on composite material mechanics and the geometrical characteristics of air spring bellow. A predictive formula of air spring effective area was given manifesting the influence of various parameters especially pressure inside bellow and air spring height on effective area. Experiments were conducted using mechanical test rig with certain air spring and the results of test fit the theory well. The errors of theoretical prediction can be less than 1% compared with experiment data. The method is useful for effective area prediction and accurate modeling as well as the height control of air suspension.

Air springs with cord-rubber structure have the advantages of variable stiffness, lightweighting and better isolating effect, which have become the highlights of vehicle research in the current of new developing trends of automobile. However, as an important parameter, the effective area of air spring is lack of thorough predictive theory. A predictive analytical method for effective area of rolling lobe air spring for vehicles was put forward based on composite material mechanics and the geometrical characteristics of air spring bellow. A predictive formula of air spring effective area was given manifesting the influence of various parameters especially pressure inside bellow and air spring height on effective area. Experiments were conducted using mechanical test rig with certain air spring and the results of test fit the theory well. The errors of theoretical prediction can be less than 1% compared with experiment data. The method is useful for effective area prediction and accurate modeling as well as the height control of air suspension.

2021, 38(12): 4379-4392.

doi: 10.13801/j.cnki.fhclxb.20210207.003

Abstract:

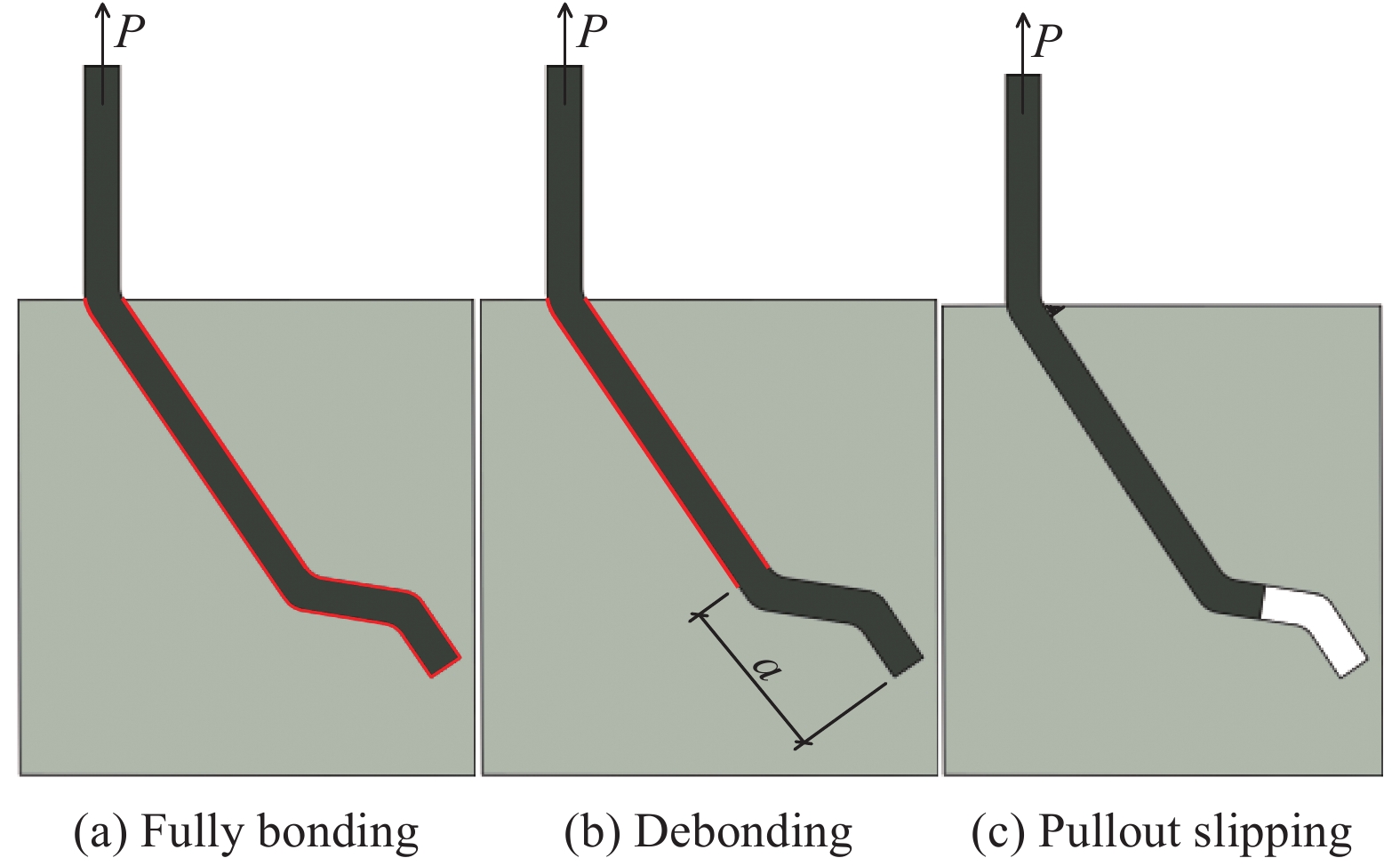

It is well-known that the hooked-end steel fiber is one of the most widely-used type of steel fiber in structural engineering, and the pullout behavior of a single steel fiber is significant for determining the tensile constitutive and the tensile toughness of steel fiber reinforced concrete. In order to obtain a theoretical analysis method which can effectively predict the pullout load-end displacement curves of inclined hooked-end steel fiber, the inclined pullout process of the hooked-end steel fiber was divided into three states: fully bonding stage, debonding stage and pullout slipping stage. A novel bond shear stresses-end displacement model was established considering the different steel fiber pullout stages and the damage of the matrix hole. A theoretical analysis model that can predict the load-slip curve of the pullout behavior of inclined hooked-end steel fiber was proposed by considering the plastic deformation of the steel fiber, the additional friction, spalling and snubbing effects of the matrix caused by the fiber pullout inclination. A simplified model was also proposed based on the theoretical model. The existing experimental data were selected to verify and evaluate the proposed calculation model. The results show that the two models proposed in this paper can effectively predict the process of hooked-end steel fiber inclined pullout. And the two models have high calculation accuracy and low coefficient of variation, which provide a theoretical reference for further analysis of the effect of steel fiber on the enhancement of tensile properties of cement-based materials.

It is well-known that the hooked-end steel fiber is one of the most widely-used type of steel fiber in structural engineering, and the pullout behavior of a single steel fiber is significant for determining the tensile constitutive and the tensile toughness of steel fiber reinforced concrete. In order to obtain a theoretical analysis method which can effectively predict the pullout load-end displacement curves of inclined hooked-end steel fiber, the inclined pullout process of the hooked-end steel fiber was divided into three states: fully bonding stage, debonding stage and pullout slipping stage. A novel bond shear stresses-end displacement model was established considering the different steel fiber pullout stages and the damage of the matrix hole. A theoretical analysis model that can predict the load-slip curve of the pullout behavior of inclined hooked-end steel fiber was proposed by considering the plastic deformation of the steel fiber, the additional friction, spalling and snubbing effects of the matrix caused by the fiber pullout inclination. A simplified model was also proposed based on the theoretical model. The existing experimental data were selected to verify and evaluate the proposed calculation model. The results show that the two models proposed in this paper can effectively predict the process of hooked-end steel fiber inclined pullout. And the two models have high calculation accuracy and low coefficient of variation, which provide a theoretical reference for further analysis of the effect of steel fiber on the enhancement of tensile properties of cement-based materials.

2021, 38(12): 3971-3985.

doi: 10.13801/j.cnki.fhclxb.20210309.001

Abstract:

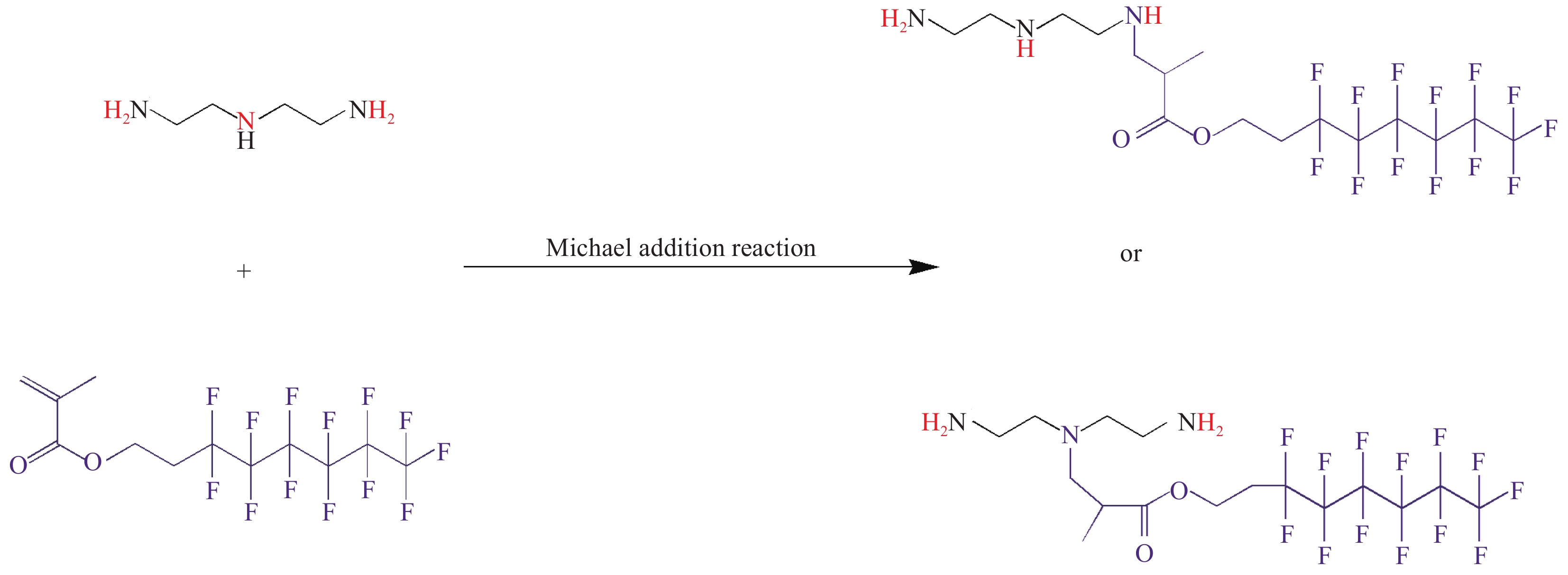

Superhydrophobic materials have great potential application prospects in the field of metal anticorrosion. In order to obtain TiO2/epoxy resin composite coating material with excellent corrosion resistance, firstly, the surface of nano-TiO2 was modified with trimethoxy heptafluorodecyl silane and γ-aminopropyltriethoxysilane (KH550), and then the diethylenetriamine (DETA) as curing agent was fluorinated with perfluorooctyl methacrylate. Finally, two kinds of composite coatings were prepared by blending method and two-step method respectively. The phase composition and microstructure of fluorinated curing agent (F-DETA) and fluorinated nano TiO2 (f-TiO2) were analyzed by FTIR, XPS and 1HNMR. The contact angle tester and static test show that when the molar ratio of trimethoxyheptafluorodecyl silane to γ-aminopropyltriethoxysilane is 1∶15, the performance of f-TiO2 is the best. The contact angle of the composite coating reaches 164.9°. SEM was used to characterize the micro-morphology of the coating surface and cross-section. The results show that the f-TiO2/epoxy resin composite coating prepared by two-step method has uniform rough surface, low porosity inside the coating, and gradient structure between epoxy resin layer and f-TiO2 layer. The friction experiment proves that the super hydrophobicity of f-TiO2/epoxy resin composite coating prepared by two-step method has certain mechanical stability. Tafel polarization curve and electrochemical impedance spectroscopy (EIS) show that the f-TiO2/epoxy resin composite coating prepared by two-step method has excellent corrosion resistance, and its corrosion inhibition efficiency is as high as 99.99%.

Superhydrophobic materials have great potential application prospects in the field of metal anticorrosion. In order to obtain TiO2/epoxy resin composite coating material with excellent corrosion resistance, firstly, the surface of nano-TiO2 was modified with trimethoxy heptafluorodecyl silane and γ-aminopropyltriethoxysilane (KH550), and then the diethylenetriamine (DETA) as curing agent was fluorinated with perfluorooctyl methacrylate. Finally, two kinds of composite coatings were prepared by blending method and two-step method respectively. The phase composition and microstructure of fluorinated curing agent (F-DETA) and fluorinated nano TiO2 (f-TiO2) were analyzed by FTIR, XPS and 1HNMR. The contact angle tester and static test show that when the molar ratio of trimethoxyheptafluorodecyl silane to γ-aminopropyltriethoxysilane is 1∶15, the performance of f-TiO2 is the best. The contact angle of the composite coating reaches 164.9°. SEM was used to characterize the micro-morphology of the coating surface and cross-section. The results show that the f-TiO2/epoxy resin composite coating prepared by two-step method has uniform rough surface, low porosity inside the coating, and gradient structure between epoxy resin layer and f-TiO2 layer. The friction experiment proves that the super hydrophobicity of f-TiO2/epoxy resin composite coating prepared by two-step method has certain mechanical stability. Tafel polarization curve and electrochemical impedance spectroscopy (EIS) show that the f-TiO2/epoxy resin composite coating prepared by two-step method has excellent corrosion resistance, and its corrosion inhibition efficiency is as high as 99.99%.

2021, 38(12): 3986-3995.

doi: 10.13801/j.cnki.fhclxb.20210205.001

Abstract:

Aramid nanofiber (ANF) is an ideal building block for fabricating high-strength composite materials because of its large aspect ratio, high specific area, a plenty of amide group on the surface, and excellent mechanical properties. In this work, a novel hydrogel processing strategy was developed to prepare ANF-reinforced poly(vinyl alcohol) (PVA) composite films. The loading of ANF, pre-stretching ratio of ANF/PVA hydrogel and chemical crosslinking of PVA component were optimized step by step. The dispersion and orientation of ANF, the crosslinking form of PVA, and the interfacial hydrogen bond between ANF and PVA were characterized and analyzed. It is confirmed that the mechanical properties reach maximum values when ANF loading, pre-stretching ratio and the used crosslinking agent are 25wt%, 55% and CuCl2, respectively. The Young’s modulus and tensile strength of the resultant composite film are as high as (14.6±0.3) GPa and (496.5±10.0) MPa, far superior to previously reported ANF-reinforced polymer composites. Moreover, the high-strength composite film has good transparency and excellent UV light shielding property. Its transmittance is larger than 72.1%, while it can shield more than 99.98% UV light. We believe that the transparent yet UV light-blocking composite film can be applied as advanced packaging materials.

Aramid nanofiber (ANF) is an ideal building block for fabricating high-strength composite materials because of its large aspect ratio, high specific area, a plenty of amide group on the surface, and excellent mechanical properties. In this work, a novel hydrogel processing strategy was developed to prepare ANF-reinforced poly(vinyl alcohol) (PVA) composite films. The loading of ANF, pre-stretching ratio of ANF/PVA hydrogel and chemical crosslinking of PVA component were optimized step by step. The dispersion and orientation of ANF, the crosslinking form of PVA, and the interfacial hydrogen bond between ANF and PVA were characterized and analyzed. It is confirmed that the mechanical properties reach maximum values when ANF loading, pre-stretching ratio and the used crosslinking agent are 25wt%, 55% and CuCl2, respectively. The Young’s modulus and tensile strength of the resultant composite film are as high as (14.6±0.3) GPa and (496.5±10.0) MPa, far superior to previously reported ANF-reinforced polymer composites. Moreover, the high-strength composite film has good transparency and excellent UV light shielding property. Its transmittance is larger than 72.1%, while it can shield more than 99.98% UV light. We believe that the transparent yet UV light-blocking composite film can be applied as advanced packaging materials.

2021, 38(12): 3996-4003.

doi: 10.13801/j.cnki.fhclxb.20210531.004

Abstract:

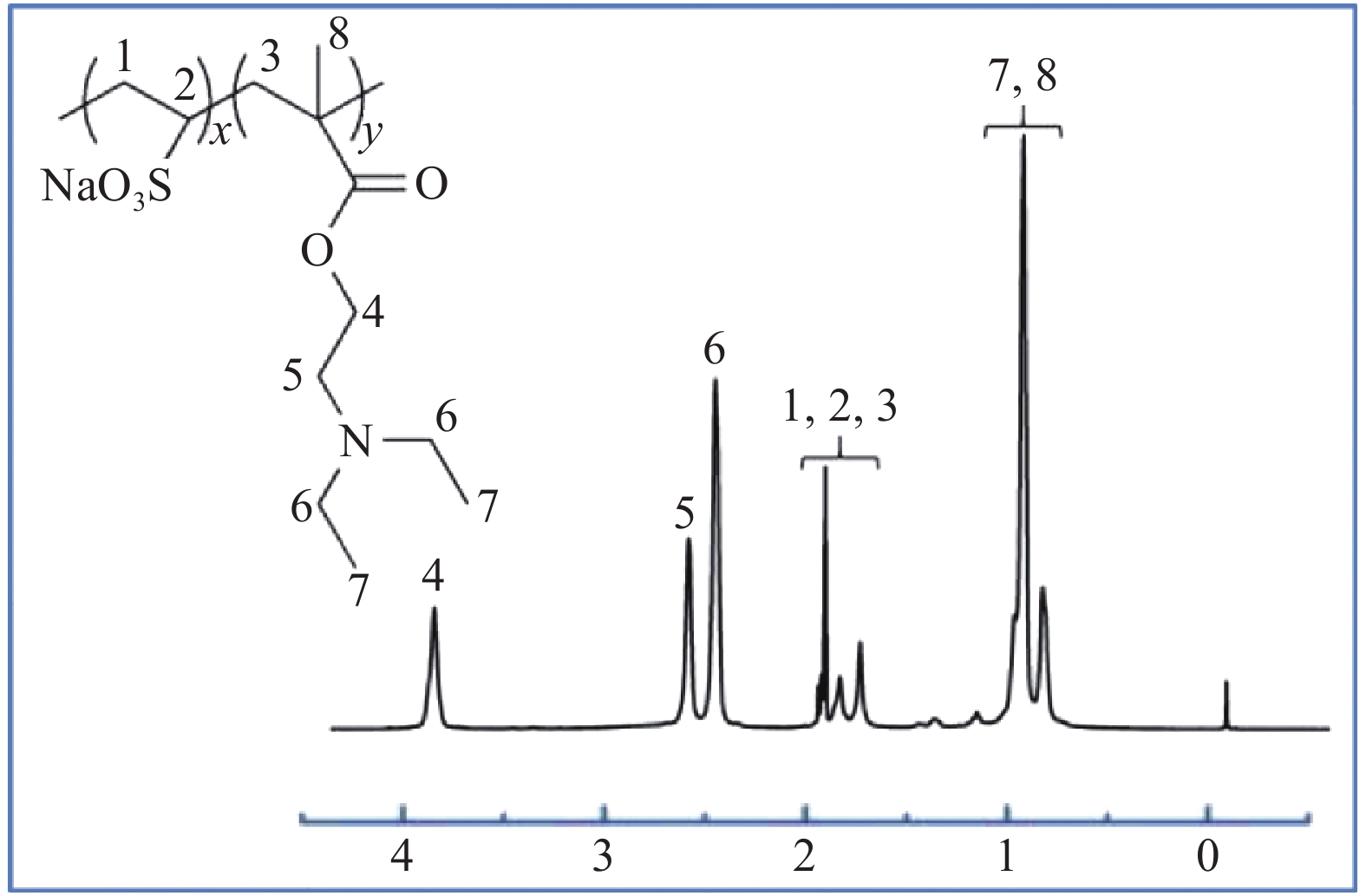

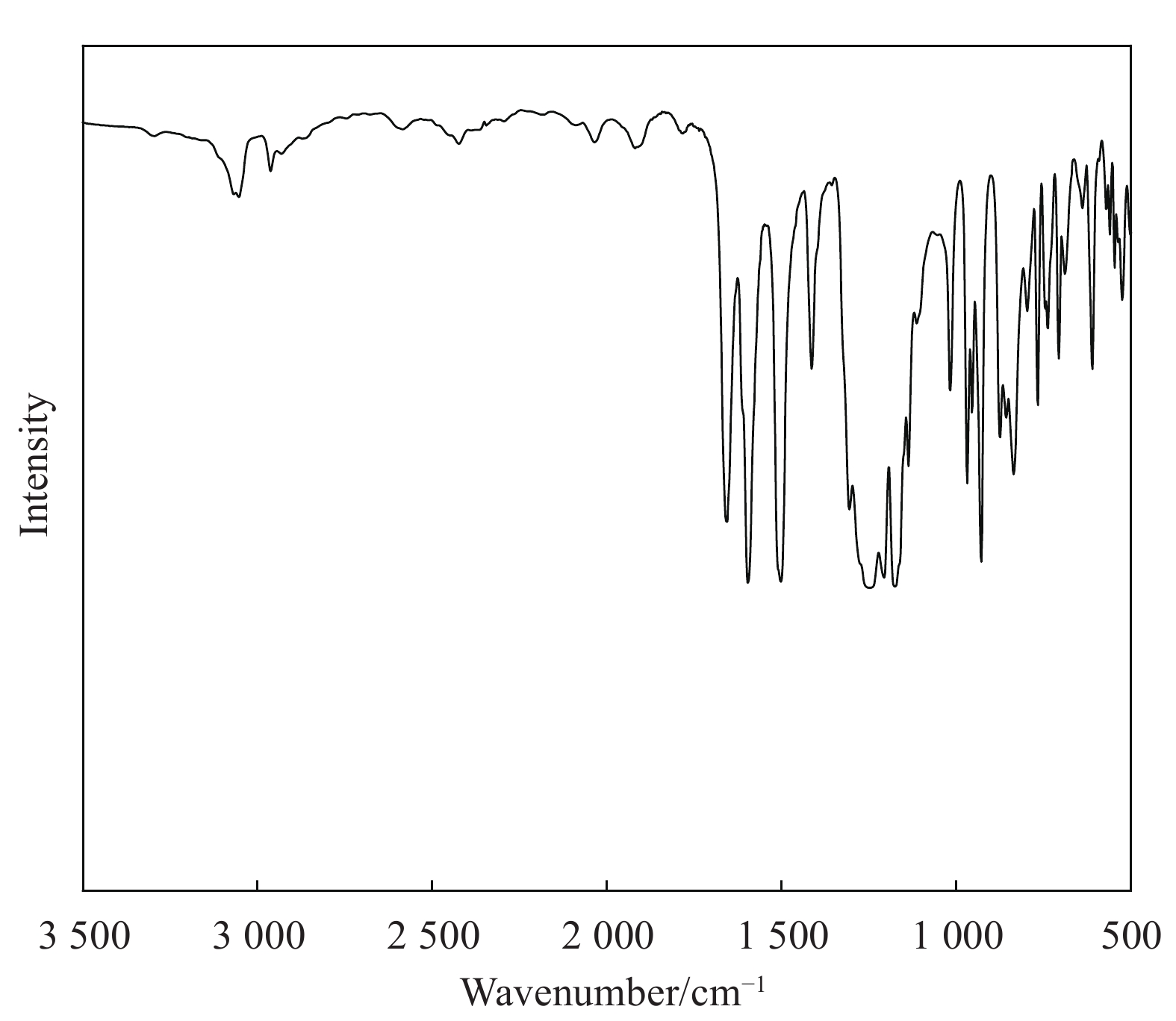

Polymer surfactants are widely used in scientific research and industrial fields such as food, agriculture and spanning. In order to reduce the side effect caused by the residual of the inactive polymer after most of the practical application process, designing and developing switchable polymer surfactants is of great significance and application value. A CO2-switchable surfactant Poly(N, N-Diethylaminoethyl methacrylate-sodium vinylsulfonate) (P(DEAEMA-SVS)) has been synthesized by free radical polymerization. The structure and molecular weight distribution of P(DEAEMA-SVS) were characterized by 1H-NMR and GPC spectra. The stability of P(DEAEMA-SVS) emulsion was studied by the surface tension and interfacial tension. The polymer P(DEAEMA-SVS) with the size of about 113 nm and the narrow particle size distribution form via N, N-Diethylaminoethyl methacrylate (DEAEMA) and sodium vinylsulfonate (SVS) of 1∶1 mole ratio as reaction monomers, which decrease the surface tension of water to 37.279 mN/m and the interfacial tension of water/paraffin wax to 5.492 mN/m. It is indicated that P(DEAEMA-SVS) polymer is an effective CO2-switchable O/W surfactant to stabilize emulsion as a only emulsifier. The surface activity and CO2 response of the polymer were evaluated by mixing the aqueous solution (1wt%) with paraffin wax. Bubbling CO2 for 30 min to the milky emulsion, it turns into clear and bubbling N2 for 30 min at 60℃, and converts to its original state, showing excellent cyclic performance of de-emulsification and re-emulsification process. The research results of emulsification mechanism show that the side-electron mobility and photogenerated electron-hole pairs separation. Chained tertiary amino groups of P(DEAEMA-SVS) polymer protonize and turn into hydrophilic quatemary ammonium salt to destroy the oil/water balance of the emulsion with bubbling CO2, while quatemary ammonium salt deprotonizes and returns into hydrophobic tertiary aminogroups with bubbling N2 at 60℃.

Polymer surfactants are widely used in scientific research and industrial fields such as food, agriculture and spanning. In order to reduce the side effect caused by the residual of the inactive polymer after most of the practical application process, designing and developing switchable polymer surfactants is of great significance and application value. A CO2-switchable surfactant Poly(N, N-Diethylaminoethyl methacrylate-sodium vinylsulfonate) (P(DEAEMA-SVS)) has been synthesized by free radical polymerization. The structure and molecular weight distribution of P(DEAEMA-SVS) were characterized by 1H-NMR and GPC spectra. The stability of P(DEAEMA-SVS) emulsion was studied by the surface tension and interfacial tension. The polymer P(DEAEMA-SVS) with the size of about 113 nm and the narrow particle size distribution form via N, N-Diethylaminoethyl methacrylate (DEAEMA) and sodium vinylsulfonate (SVS) of 1∶1 mole ratio as reaction monomers, which decrease the surface tension of water to 37.279 mN/m and the interfacial tension of water/paraffin wax to 5.492 mN/m. It is indicated that P(DEAEMA-SVS) polymer is an effective CO2-switchable O/W surfactant to stabilize emulsion as a only emulsifier. The surface activity and CO2 response of the polymer were evaluated by mixing the aqueous solution (1wt%) with paraffin wax. Bubbling CO2 for 30 min to the milky emulsion, it turns into clear and bubbling N2 for 30 min at 60℃, and converts to its original state, showing excellent cyclic performance of de-emulsification and re-emulsification process. The research results of emulsification mechanism show that the side-electron mobility and photogenerated electron-hole pairs separation. Chained tertiary amino groups of P(DEAEMA-SVS) polymer protonize and turn into hydrophilic quatemary ammonium salt to destroy the oil/water balance of the emulsion with bubbling CO2, while quatemary ammonium salt deprotonizes and returns into hydrophobic tertiary aminogroups with bubbling N2 at 60℃.

2021, 38(12): 4004-4013.

doi: 10.13801/j.cnki.fhclxb.20210210.005

Abstract:

Superhydrophobic coatings were prepared by a facilespraying process from a fluorinated poly(aryl ether ketone) (FPAEK) solution containing hydrophobic fumed SiO2 and carbon nanotube (CNT) as inorganicdopants. The FPAEK was polymerized from 4,4′-(hexafluoroisopropylidene)diphenol and 4,4-difluorophenophenone. It has been found that when the doping amounts of SiO2 and CNT are both 1wt%, the water contact angle WCA of the SiO2-CNT/FPAEK coating is 167° and the sliding angle SA is 4°. The glass transition temperature and initial decomposition temperature of the SiO2-CNT/FPAEK coating are 170℃ and 480℃, respectively, demonstrating its excellent thermal stability. After immersing in pH=1 of HCl solution, pH=13 of NaOH solution, and 3.5wt% mass fraction of NaCl solution for 13 days, the SiO2-CNT/FPAEK coating maintains its WCA above 150°, demonstrating its excellent chemical stability. After 80 friction testing cycles, the SiO2-CNT/FPAEK coating maintains the WCA at 151°, demonstrating its good mechanical stability. In the electrochemical tests, the corrosion voltage Ecorr of the steel plate is increased from −0.538 V to −0.112 V and the corrosion current Jcorr is decreased from 2.105×10−5 A to 1.94×10−7 A after coating with the SiO2-CNT/FPAEK, demonstrating its good anti-corrosion property. Replacing the substrate with iron plate, cement plate, glass plate and polyethyleneplate, the superhydrophobic coatings are also obtained. The dust and other contaminants can be easily removed from the superhydrophobic coatings by the falling water droplets, demonstrating its good self-cleaning property. Therefore, the SiO2-CNT/FPAEK superhydrophobic coating has prospect applications.

Superhydrophobic coatings were prepared by a facilespraying process from a fluorinated poly(aryl ether ketone) (FPAEK) solution containing hydrophobic fumed SiO2 and carbon nanotube (CNT) as inorganicdopants. The FPAEK was polymerized from 4,4′-(hexafluoroisopropylidene)diphenol and 4,4-difluorophenophenone. It has been found that when the doping amounts of SiO2 and CNT are both 1wt%, the water contact angle WCA of the SiO2-CNT/FPAEK coating is 167° and the sliding angle SA is 4°. The glass transition temperature and initial decomposition temperature of the SiO2-CNT/FPAEK coating are 170℃ and 480℃, respectively, demonstrating its excellent thermal stability. After immersing in pH=1 of HCl solution, pH=13 of NaOH solution, and 3.5wt% mass fraction of NaCl solution for 13 days, the SiO2-CNT/FPAEK coating maintains its WCA above 150°, demonstrating its excellent chemical stability. After 80 friction testing cycles, the SiO2-CNT/FPAEK coating maintains the WCA at 151°, demonstrating its good mechanical stability. In the electrochemical tests, the corrosion voltage Ecorr of the steel plate is increased from −0.538 V to −0.112 V and the corrosion current Jcorr is decreased from 2.105×10−5 A to 1.94×10−7 A after coating with the SiO2-CNT/FPAEK, demonstrating its good anti-corrosion property. Replacing the substrate with iron plate, cement plate, glass plate and polyethyleneplate, the superhydrophobic coatings are also obtained. The dust and other contaminants can be easily removed from the superhydrophobic coatings by the falling water droplets, demonstrating its good self-cleaning property. Therefore, the SiO2-CNT/FPAEK superhydrophobic coating has prospect applications.

2021, 38(12): 4014-4022.

doi: 10.13801/j.cnki.fhclxb.20210215.002

Abstract:

Fluorinated hyperbranched polyurethane (FHPU) was first prepared, and then combined with Prussian blue (PB) nanoparticles with photothermal conversion function to obtain PB/FHPU superhydrophobic anti-icing composite with photothermal conversion function coating material. The structure and performance of FHPU and PB/FHPU superhydrophobic anti-icing composite coating materials were analyzed by FTIR, TGA and DSC tests, and the excellent photothermal performance of the composite coating materials was proved through the photothermal conversion experiment; The effect of the amount of PB nanoparticles added on the surface properties and photothermal conversion performance of composite coating materials was deeply explored. The results show that when the PB mass accounts for 13% of the FHPU, the composite coating material can form a composite coating with a micro-nano structure. The maximum contact angle of the coating surface is 157° and the rolling angle is 1.8°. At the same time, the temperature of the coating can rise by 78.1°C within 10 s under 808 nm laser irradiation, and the maximum temperature reaches to 148.7°C. Therefore, the light-to-heat conversion functional superhydrophobic anti-icing composite coating material has good hydrophobic and anti-icing properties.

Fluorinated hyperbranched polyurethane (FHPU) was first prepared, and then combined with Prussian blue (PB) nanoparticles with photothermal conversion function to obtain PB/FHPU superhydrophobic anti-icing composite with photothermal conversion function coating material. The structure and performance of FHPU and PB/FHPU superhydrophobic anti-icing composite coating materials were analyzed by FTIR, TGA and DSC tests, and the excellent photothermal performance of the composite coating materials was proved through the photothermal conversion experiment; The effect of the amount of PB nanoparticles added on the surface properties and photothermal conversion performance of composite coating materials was deeply explored. The results show that when the PB mass accounts for 13% of the FHPU, the composite coating material can form a composite coating with a micro-nano structure. The maximum contact angle of the coating surface is 157° and the rolling angle is 1.8°. At the same time, the temperature of the coating can rise by 78.1°C within 10 s under 808 nm laser irradiation, and the maximum temperature reaches to 148.7°C. Therefore, the light-to-heat conversion functional superhydrophobic anti-icing composite coating material has good hydrophobic and anti-icing properties.

2021, 38(12): 4023-4030.

doi: 10.13801/j.cnki.fhclxb.20210312.005

Abstract:

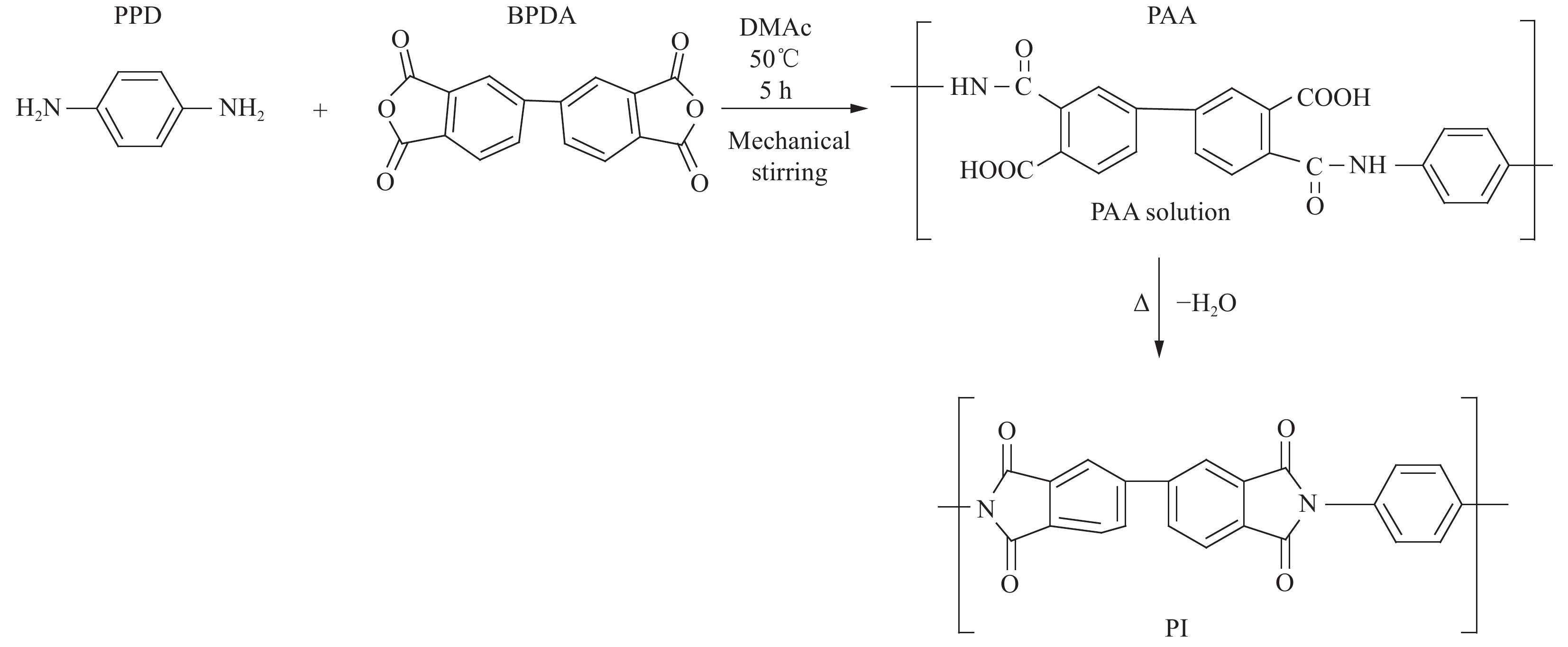

The colorless polyimide (PI) used for the flexible display field is required to have high transparency and low thermal expansion coefficient CTE. However, the CTE value of commercial colorless PI film is above 40×10−6/℃. In the study, nanofiber self-filled PI film was prepared by embedding the PI nanofiber-net in thermoplastic fluorinated polyimide solution (PI-F). The nanofiber-net self-filled PI film demonstrates high transparency retention, much CTE and excellent tensile property. The results show that the fiber of nanosize avoids light scattering, therefore the high transparency of the film is retained. When the PI fiber mass fraction is 10%, the transparency of the film is 80.5%. In comparison to the pure PI-F film, the CTE of composite film is reduced by 40.3% and reaches 28.3×10−6/℃; The tensile strength and the tensile modulus of the composite film are increased by 132.9% and 89.5%, respectively and are 107.6 MPa and 1152.2 MPa correspondingly.

The colorless polyimide (PI) used for the flexible display field is required to have high transparency and low thermal expansion coefficient CTE. However, the CTE value of commercial colorless PI film is above 40×10−6/℃. In the study, nanofiber self-filled PI film was prepared by embedding the PI nanofiber-net in thermoplastic fluorinated polyimide solution (PI-F). The nanofiber-net self-filled PI film demonstrates high transparency retention, much CTE and excellent tensile property. The results show that the fiber of nanosize avoids light scattering, therefore the high transparency of the film is retained. When the PI fiber mass fraction is 10%, the transparency of the film is 80.5%. In comparison to the pure PI-F film, the CTE of composite film is reduced by 40.3% and reaches 28.3×10−6/℃; The tensile strength and the tensile modulus of the composite film are increased by 132.9% and 89.5%, respectively and are 107.6 MPa and 1152.2 MPa correspondingly.

Mechanical properties of CFRP bar and bond-type anchorage system after elevated temperature exposure

2021, 38(12): 4031-4041.

doi: 10.13801/j.cnki.fhclxb.20210215.005

Abstract:

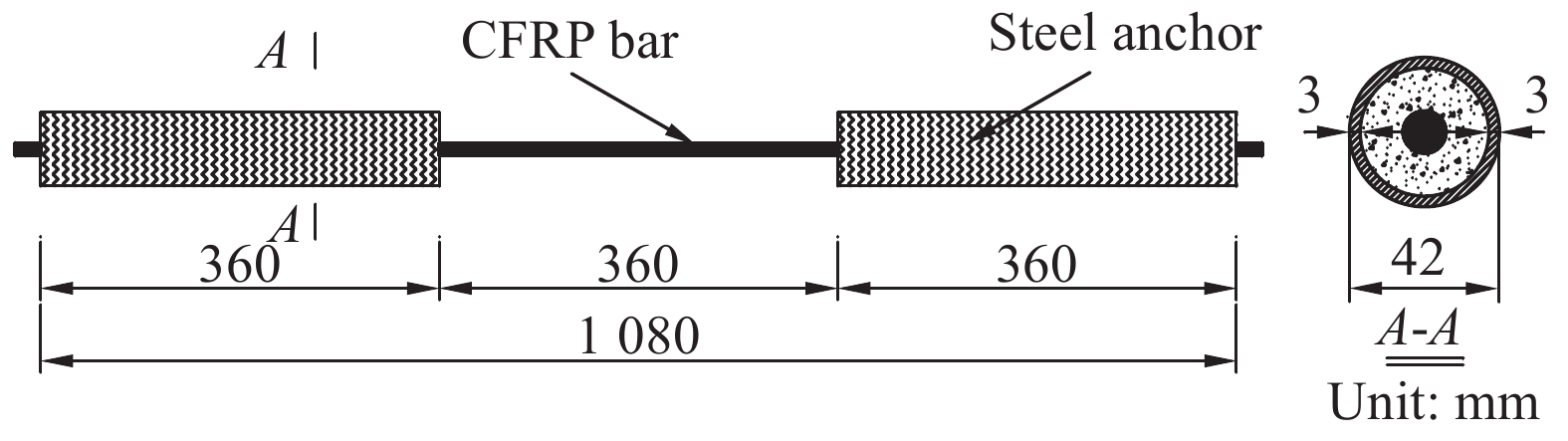

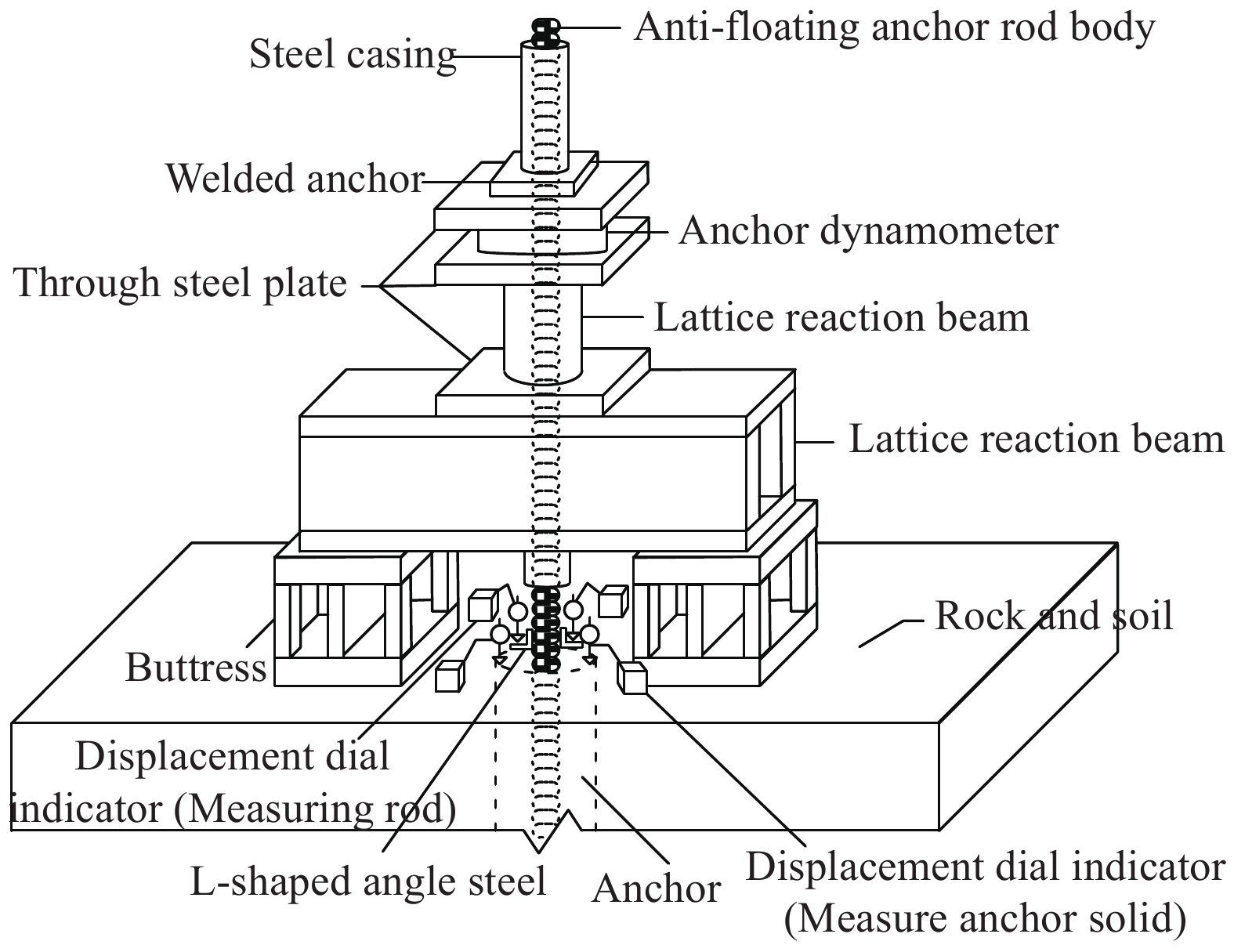

To investigate the mechanical properties of carbon fiber reinforced polymer (CFRP) bar and bond-type anchorage system after different elevated temperature exposures, the axial tensile tests and anchorage perfor-mance tests were conducted on 12 specimens and 36 specimens with different elevated temperatures and bond lengths, respectively. The results demonstrate that the static performance of CFRP bar exposed to elevated temperature of 100℃ degenerates slightly compared with the specimen at room temperature in the axial tensile tests. The tensile strength, elastic modulus and ultimate strain of specimens exposed to the elevated temperature of 200℃ and 300℃ decrease by 6.4%, 8.2%, 3.8% and 16.6%, 18.3%, 8.3%, respectively, compared with the specimen at room temperature. In the anchorage performance tests, the bond strength of the specimens decreases with the increase of elevated temperature and bond length. Compared with the specimen at room temperature, the bond strengths of the specimens exposed to the elevated temperature of 200℃ and 300℃ decrease by 31.5%-36.3% and 44.2%-47.4%, respectively, while the bonding length is fixed. The practical formulas with high accuracy for determining the axial tensile performance of CFRP bars, bond strength and critical anchorage length of the bond-type anchorage system after elevated temperature exposure were developed.

To investigate the mechanical properties of carbon fiber reinforced polymer (CFRP) bar and bond-type anchorage system after different elevated temperature exposures, the axial tensile tests and anchorage perfor-mance tests were conducted on 12 specimens and 36 specimens with different elevated temperatures and bond lengths, respectively. The results demonstrate that the static performance of CFRP bar exposed to elevated temperature of 100℃ degenerates slightly compared with the specimen at room temperature in the axial tensile tests. The tensile strength, elastic modulus and ultimate strain of specimens exposed to the elevated temperature of 200℃ and 300℃ decrease by 6.4%, 8.2%, 3.8% and 16.6%, 18.3%, 8.3%, respectively, compared with the specimen at room temperature. In the anchorage performance tests, the bond strength of the specimens decreases with the increase of elevated temperature and bond length. Compared with the specimen at room temperature, the bond strengths of the specimens exposed to the elevated temperature of 200℃ and 300℃ decrease by 31.5%-36.3% and 44.2%-47.4%, respectively, while the bonding length is fixed. The practical formulas with high accuracy for determining the axial tensile performance of CFRP bars, bond strength and critical anchorage length of the bond-type anchorage system after elevated temperature exposure were developed.

2021, 38(12): 4042-4051.

doi: 10.13801/j.cnki.fhclxb.20210526.004

Abstract:

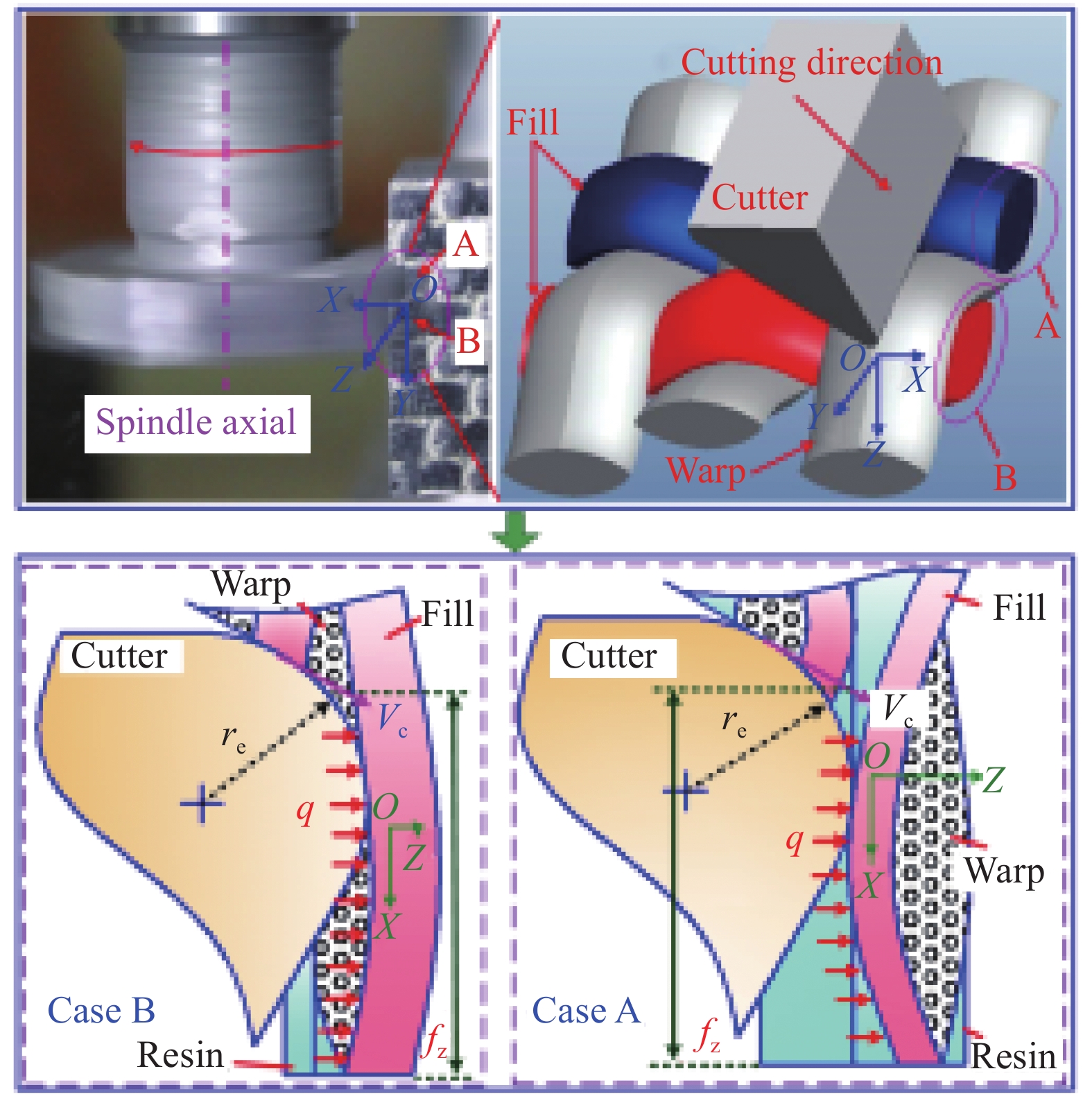

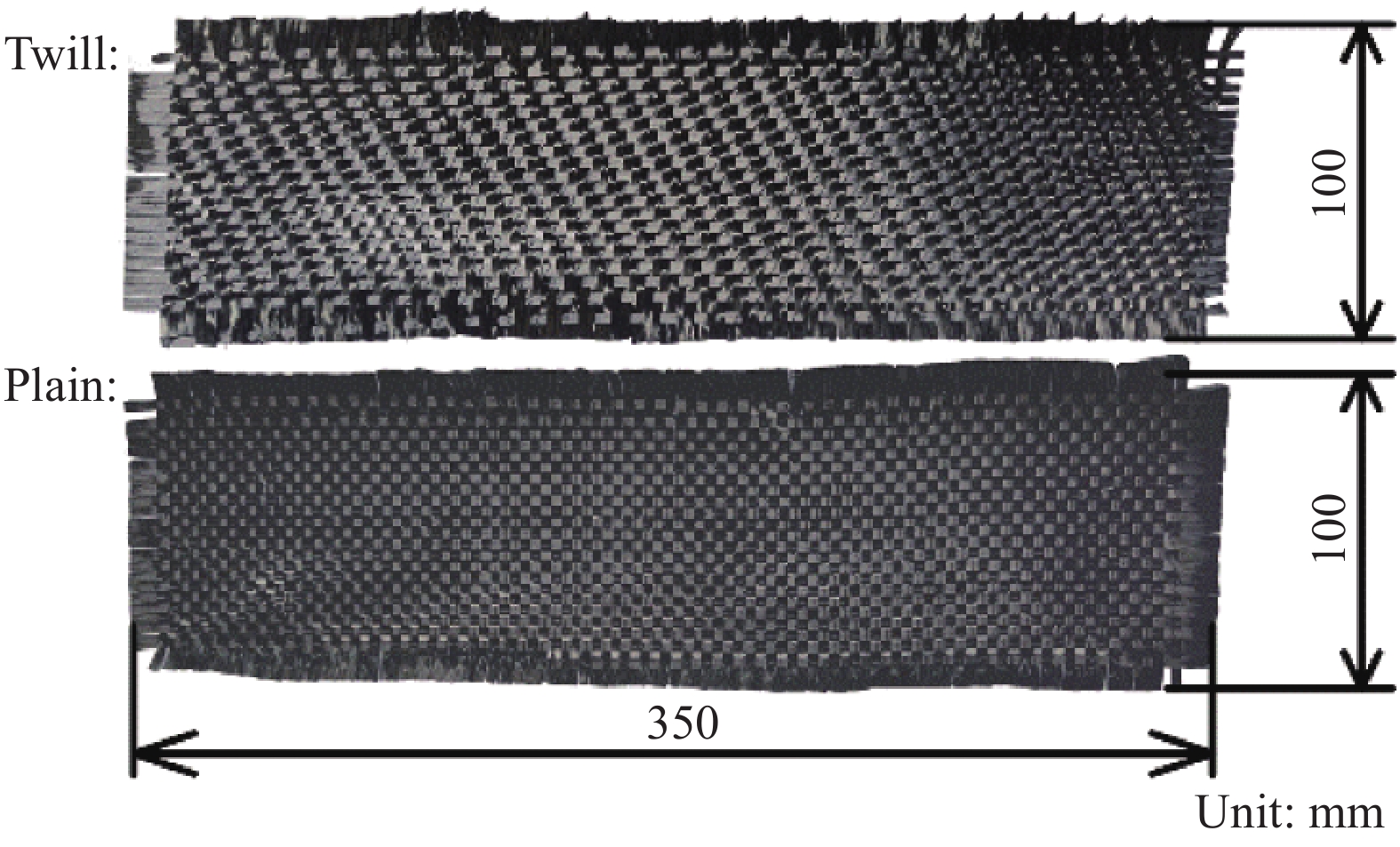

In view of the problem that the delamination was easily occurred during the carbon fiber-reinforced plastic (CFRP) slotting, especially the exit side was the most serious, according to the formation process of the slotting delamination, the onset critical force models of the exit outermost layer delamination for CFRP slotting were emphatically established. The slotting tests, using the T-slot cutter, were carried out on the plain weave CFRP. Then, the formation mechanisms of the delamination were revealed from the view mechanics. The results show that the delaminations of the warp fibers on both up and down sides are small. The onset critical forces of the case A (supported) and case B (unsupported) for the fill fibers are small, then, the delaminations of these two cases easily occur, especially the case B. The critical forces of these two cases are large near the edge of a single fiber bundle, and their changes are small in the central of a single fiber bundle. Additionally, the deformations of these two cases are all large in the center of a single fiber bundle and are small near the edge of a single fiber bundle. As a result, in the boundary of a single bundle of fibers, the delaminations of the case A or case B are all shaped as a half-moon arc “wave peak”. The delaminations of these two cases increase with the increasing feed per tooth fz and the cutting speed Vc. The experimental results are in good agreement with the theoretical derivation results of the critical forces.

In view of the problem that the delamination was easily occurred during the carbon fiber-reinforced plastic (CFRP) slotting, especially the exit side was the most serious, according to the formation process of the slotting delamination, the onset critical force models of the exit outermost layer delamination for CFRP slotting were emphatically established. The slotting tests, using the T-slot cutter, were carried out on the plain weave CFRP. Then, the formation mechanisms of the delamination were revealed from the view mechanics. The results show that the delaminations of the warp fibers on both up and down sides are small. The onset critical forces of the case A (supported) and case B (unsupported) for the fill fibers are small, then, the delaminations of these two cases easily occur, especially the case B. The critical forces of these two cases are large near the edge of a single fiber bundle, and their changes are small in the central of a single fiber bundle. Additionally, the deformations of these two cases are all large in the center of a single fiber bundle and are small near the edge of a single fiber bundle. As a result, in the boundary of a single bundle of fibers, the delaminations of the case A or case B are all shaped as a half-moon arc “wave peak”. The delaminations of these two cases increase with the increasing feed per tooth fz and the cutting speed Vc. The experimental results are in good agreement with the theoretical derivation results of the critical forces.

2021, 38(12): 4052-4059.

doi: 10.13801/j.cnki.fhclxb.20210203.001

Abstract:

Based on the demand of new generation advanced composites characterized by the balance of com-pressive and tensile strength, the compressive strength of carbon fiber/epoxy composites with various cross section characteristics of carbon fibers was studied by finite element simulation and experiment. Results show that the compressive strength of carbon fiber/epoxy composite increases with the increasing fiber diameter, and round is better than ellipse regarding to the fiber cross section shape.

Based on the demand of new generation advanced composites characterized by the balance of com-pressive and tensile strength, the compressive strength of carbon fiber/epoxy composites with various cross section characteristics of carbon fibers was studied by finite element simulation and experiment. Results show that the compressive strength of carbon fiber/epoxy composite increases with the increasing fiber diameter, and round is better than ellipse regarding to the fiber cross section shape.

2021, 38(12): 4060-4072.

doi: 10.13801/j.cnki.fhclxb.20210311.004

Abstract:

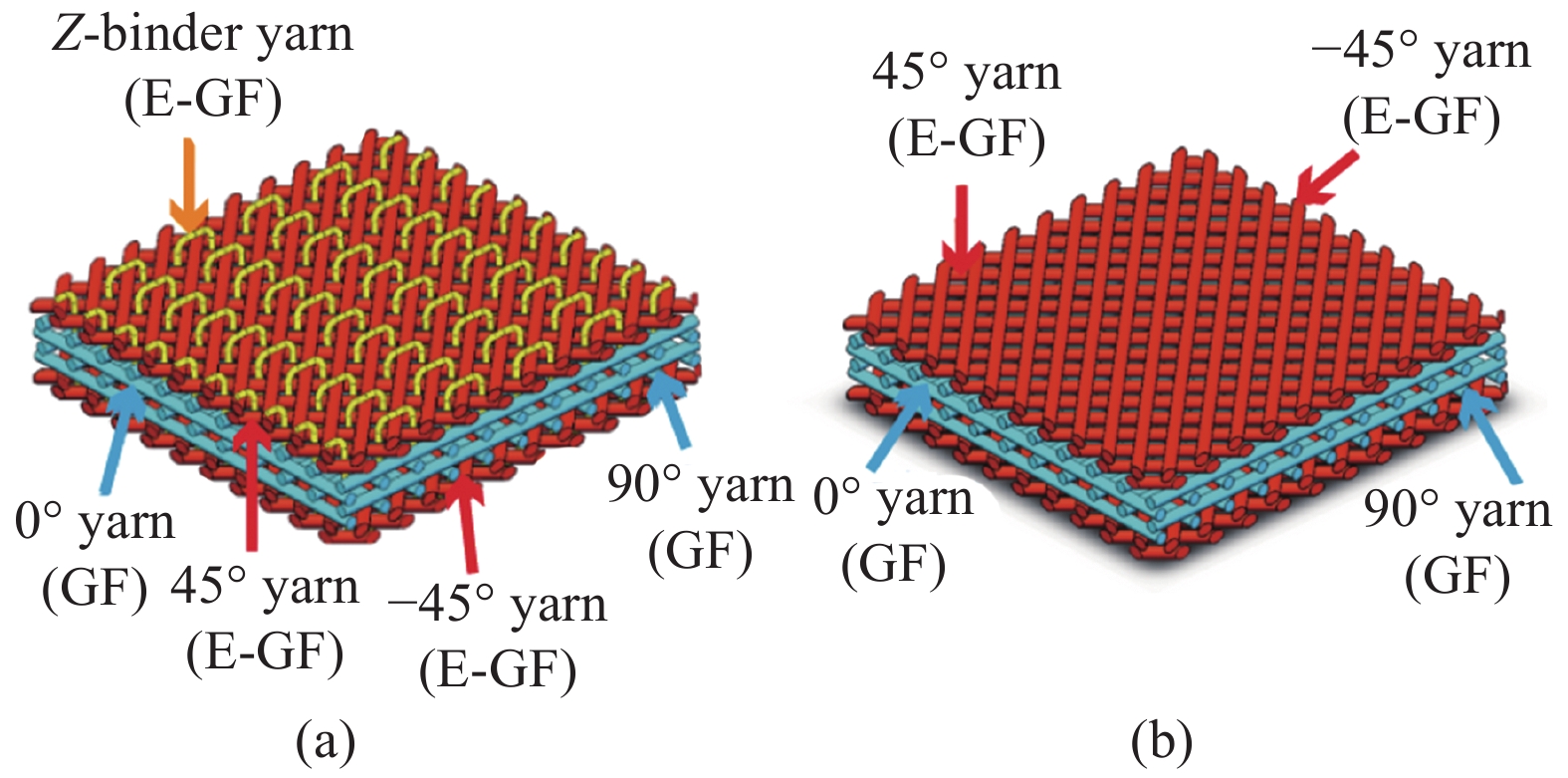

The bending and shear properties of the three-dimensional braided carbon fiber-glass fiber/bismaleimide composite and the laminated carbon fiber-glass fiber/bismaleimide composite were investigated aging at 200℃ and 250℃ for 10, 30, 90, 120, and 180 days, respectively. The results show that the interfacial performance of the fiber/matrix decreases significantly with the prolonged aging time in a hot oxygen environment, and the bending and shear retention rates of braided composite are better than the laminated composite. This is because Z-binder yarns in the thickness direction of braided composite bundle all yarns into an integral structure to resist external load, and the existence of Z-binder yarns can prevent the expansion of cracks and slow down the aging rate of composites when cracks occur between composites due to thermal-oxidative aging. This means that the integrated structure of braided composite can compensate the mechanical performance degradation caused by hot oxygen aging compared with the laminated composite.

The bending and shear properties of the three-dimensional braided carbon fiber-glass fiber/bismaleimide composite and the laminated carbon fiber-glass fiber/bismaleimide composite were investigated aging at 200℃ and 250℃ for 10, 30, 90, 120, and 180 days, respectively. The results show that the interfacial performance of the fiber/matrix decreases significantly with the prolonged aging time in a hot oxygen environment, and the bending and shear retention rates of braided composite are better than the laminated composite. This is because Z-binder yarns in the thickness direction of braided composite bundle all yarns into an integral structure to resist external load, and the existence of Z-binder yarns can prevent the expansion of cracks and slow down the aging rate of composites when cracks occur between composites due to thermal-oxidative aging. This means that the integrated structure of braided composite can compensate the mechanical performance degradation caused by hot oxygen aging compared with the laminated composite.

2021, 38(12): 4073-4089.

doi: 10.13801/j.cnki.fhclxb.20210311.005

Abstract:

Aiming at the shortcoming that it is difficult for a single curing agent to simultaneously meet the requirements of heat resistance and toughness, the influence of the mixing of two curing agents (Condensationamine 105 with excellent heat resistance and amino-terminated polyoxypropylene D230 with good toughness) on the glass transition temperature Tg and basic mechanical properties of the nano-SiO2 epoxy adhesive at elevated temperature was analyzed. According to certain curing conditions, a total of 30 adhesive tensile test pieces and 21 carbon fiber reinforced polymer (CFRP) plate-steel double lap test pieces were fabricated, and quasi-static tensile tests and shear tensile tests were performed at elevated and room temperatures. The dynamic thermodynamic properties of the corresponding adhesives were tested and compared with the heat resistance and mechanical properties of commonly used commercial adhesives. The results show that the preferred ratio of the two curing agents of condensationamine 105 and amino-terminated polyoxypropylene D230 is 1∶2. With the increase of the curing temperature, the Tg of the adhesive with the preferred ratio of two mixed curing agent is increased. Based on comprehensive technical and economic factors, the recommended (preferred) curing condition is 90℃ for 2 h. The tensile strength and toughness of the nano-SiO2 epoxy adhesive with the recommended ratio and the recommended curing conditions between ambient temperature 20~70℃ are better than the commonly used commercial adhesives. The load-displacement curve of CFRP plate-steel lap joint based on nano-SiO2 adhesive with recommended ratio and recommended curing process has a yield section at the service temperature of 70℃, and the bearing capacity (Compared with the lap joint based on nano-SiO2 adhesive with a single condensationamine 105 and a single amino-terminated polyoxypropylene 230 curing agent, the bearing capacity of the lap joint has been increased by 104.03% and 64.43%, respectively) and ductility (It is more than 2.5 times of the lap joints using a single amine 105 curing agent) are greatly improved. The bond-slip constitutive can be simplified as a trilinear quadrilateral model at elevated temperature and room temperature. Under the premise of satisfying heat resistance, the toughness of the adhesive needs to be improved as much as possible to effectively enhance the bonded behavior of the CFRP-steel lap interface. The recommended adhesive-bonded CFRP plate-steel lap joint has much superior load-bearing capacity and interface fracture energy compared with commonly used commercial adhesives.

Aiming at the shortcoming that it is difficult for a single curing agent to simultaneously meet the requirements of heat resistance and toughness, the influence of the mixing of two curing agents (Condensationamine 105 with excellent heat resistance and amino-terminated polyoxypropylene D230 with good toughness) on the glass transition temperature Tg and basic mechanical properties of the nano-SiO2 epoxy adhesive at elevated temperature was analyzed. According to certain curing conditions, a total of 30 adhesive tensile test pieces and 21 carbon fiber reinforced polymer (CFRP) plate-steel double lap test pieces were fabricated, and quasi-static tensile tests and shear tensile tests were performed at elevated and room temperatures. The dynamic thermodynamic properties of the corresponding adhesives were tested and compared with the heat resistance and mechanical properties of commonly used commercial adhesives. The results show that the preferred ratio of the two curing agents of condensationamine 105 and amino-terminated polyoxypropylene D230 is 1∶2. With the increase of the curing temperature, the Tg of the adhesive with the preferred ratio of two mixed curing agent is increased. Based on comprehensive technical and economic factors, the recommended (preferred) curing condition is 90℃ for 2 h. The tensile strength and toughness of the nano-SiO2 epoxy adhesive with the recommended ratio and the recommended curing conditions between ambient temperature 20~70℃ are better than the commonly used commercial adhesives. The load-displacement curve of CFRP plate-steel lap joint based on nano-SiO2 adhesive with recommended ratio and recommended curing process has a yield section at the service temperature of 70℃, and the bearing capacity (Compared with the lap joint based on nano-SiO2 adhesive with a single condensationamine 105 and a single amino-terminated polyoxypropylene 230 curing agent, the bearing capacity of the lap joint has been increased by 104.03% and 64.43%, respectively) and ductility (It is more than 2.5 times of the lap joints using a single amine 105 curing agent) are greatly improved. The bond-slip constitutive can be simplified as a trilinear quadrilateral model at elevated temperature and room temperature. Under the premise of satisfying heat resistance, the toughness of the adhesive needs to be improved as much as possible to effectively enhance the bonded behavior of the CFRP-steel lap interface. The recommended adhesive-bonded CFRP plate-steel lap joint has much superior load-bearing capacity and interface fracture energy compared with commonly used commercial adhesives.

2021, 38(12): 4090-4105.

doi: 10.13801/j.cnki.fhclxb.20210317.003

Abstract:

Mode II debonding is one of the most typical failure modes on carbon fiber reinforce polymer (CFRP) plate-to-steel interface. In order to elucidate the interfacial debonding mechanism of CFRP-strengthened steel structures, single- and double-lap shear tests were conducted to investigate the mechanical behavior and debonding failure process at the FRP-to-steel plate interface. The technique of digital image correlation (DIC) was applied to measure the normal strain distribution on the surface of CFRP. Comparing the failure modes between these two joints, it can be found that a mode II fracture occurs on the interface of double-lap joint, which is caused by shear stresses. While the interface of single-lap joint subjected to eccentric loading is governed by mixed-mode I/II behavior, with the failure attributed to the combination of shear stress and bending moment. Additionally, the ultimate load and bond slip of the double-lap joints in mode II increase with the increment of bond length until an effective bond length is reached, beyond which the ultimate load remains unchanged. However, for single-lap joints subjected to eccentric loading, the ultimate loads with different bond lengths are almost the same. Based on bilinear bond-slip law obtained from experiment results, finite element model can be established to analysis the mode II interfacial debonding process of CFRP-strengthened steel structures, which shows an excellent agreement with the experimental results.

Mode II debonding is one of the most typical failure modes on carbon fiber reinforce polymer (CFRP) plate-to-steel interface. In order to elucidate the interfacial debonding mechanism of CFRP-strengthened steel structures, single- and double-lap shear tests were conducted to investigate the mechanical behavior and debonding failure process at the FRP-to-steel plate interface. The technique of digital image correlation (DIC) was applied to measure the normal strain distribution on the surface of CFRP. Comparing the failure modes between these two joints, it can be found that a mode II fracture occurs on the interface of double-lap joint, which is caused by shear stresses. While the interface of single-lap joint subjected to eccentric loading is governed by mixed-mode I/II behavior, with the failure attributed to the combination of shear stress and bending moment. Additionally, the ultimate load and bond slip of the double-lap joints in mode II increase with the increment of bond length until an effective bond length is reached, beyond which the ultimate load remains unchanged. However, for single-lap joints subjected to eccentric loading, the ultimate loads with different bond lengths are almost the same. Based on bilinear bond-slip law obtained from experiment results, finite element model can be established to analysis the mode II interfacial debonding process of CFRP-strengthened steel structures, which shows an excellent agreement with the experimental results.

2021, 38(12): 4106-4122.

doi: 10.13801/j.cnki.fhclxb.20210317.002

Abstract:

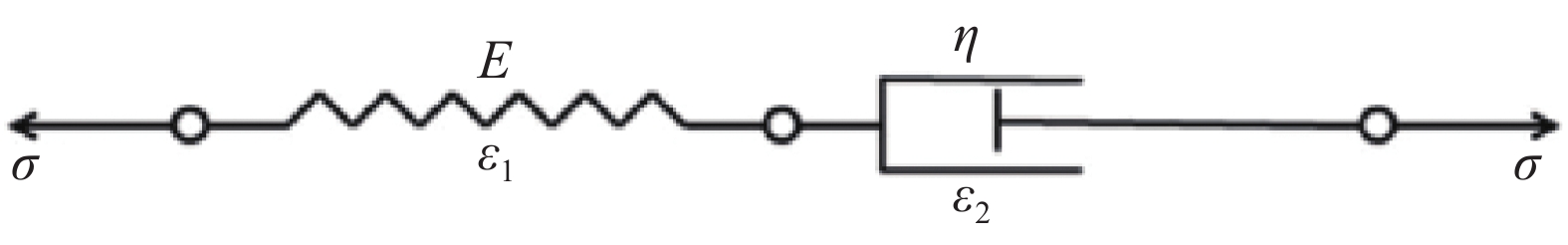

To reduce costs, increase environmental friendliness, and obtain a good wood feeling, ultra-highly filled polypropylene-based wood plastic composites (UH-WPCs) were successfully prepared by extrusion technology using poplar wood fiber and bamboo fiber as raw materials. Based on pronounced reduction in polypropylene matrix content, the effect of filling content and fiber species on mechanical properties and creep resistance at high and low temperatures, thermal expansion, dimensional stability, and water uptake behavior of the UH-WPCs were investigated. The results show that as the filling content increases from 75wt% to 90wt%, the linear thermal expansion coefficient of the UH-WPCs decreases drastically, creep strain decreases gradually but increases at 90wt% filling content, and the tensile and flexural moduli increase firstly and then decrease at 90wt% filling content. The tensile strength, flexural strength and impact strength decrease gradually with the increasing filling content. The UH-WPCs show higher tensile and flexural properties at −30℃, while the impact toughness is higher at 60℃. The variation of temperature, humidity and moisture content can lead to the dimensional change of UH-WPCs. The UH-WPCs exhibite obvious anisotropy in dimensional change. The largest change in dimension was observed in the thickness direction, followed by width and length direction. The effect of humidity on the dimensional stability of UH-WPCs is more significant than that of temperature. The UH-WPCs prepared with wood fiber show better comprehensive properties than that with bamboo fiber, which is attributed to the larger aspect ratio of wood fiber and better interface adhesion of wood fiber-filled UH-WPCs. The research of UH-WPCs provides a theoretical basis for reducing cost of WPCs and broadening its application scenarios.

To reduce costs, increase environmental friendliness, and obtain a good wood feeling, ultra-highly filled polypropylene-based wood plastic composites (UH-WPCs) were successfully prepared by extrusion technology using poplar wood fiber and bamboo fiber as raw materials. Based on pronounced reduction in polypropylene matrix content, the effect of filling content and fiber species on mechanical properties and creep resistance at high and low temperatures, thermal expansion, dimensional stability, and water uptake behavior of the UH-WPCs were investigated. The results show that as the filling content increases from 75wt% to 90wt%, the linear thermal expansion coefficient of the UH-WPCs decreases drastically, creep strain decreases gradually but increases at 90wt% filling content, and the tensile and flexural moduli increase firstly and then decrease at 90wt% filling content. The tensile strength, flexural strength and impact strength decrease gradually with the increasing filling content. The UH-WPCs show higher tensile and flexural properties at −30℃, while the impact toughness is higher at 60℃. The variation of temperature, humidity and moisture content can lead to the dimensional change of UH-WPCs. The UH-WPCs exhibite obvious anisotropy in dimensional change. The largest change in dimension was observed in the thickness direction, followed by width and length direction. The effect of humidity on the dimensional stability of UH-WPCs is more significant than that of temperature. The UH-WPCs prepared with wood fiber show better comprehensive properties than that with bamboo fiber, which is attributed to the larger aspect ratio of wood fiber and better interface adhesion of wood fiber-filled UH-WPCs. The research of UH-WPCs provides a theoretical basis for reducing cost of WPCs and broadening its application scenarios.

2021, 38(12): 4123-4137.

doi: 10.13801/j.cnki.fhclxb.20210210.001

Abstract:

A method dealing with stacking sequence optimization of composite stiffened panel considering buckling was proposed. Based on the energy-based method in calculating buckling loads of composite stiffened panels, the explicit formulations in calculating local buckling loads of skin and stiffener of composite stiffened panel were proposed systematically. The influences of each elastic supporting panel element and stiffener’s foot were taken into account during the calculation of the local buckling loads of skin and stiffener. Engineering method was introduced to calculate the global buckling load. Based on the homemade HAJIF’s composite stacking engineering library, the stacking parameters were regarded as design variables and the proposed explicit formulations in calculating buckling loads were used to build an optimization progress of composite stiffened panels’ stacking sequence and its program implementation. The least square method was applied to choose the most closed staking parameter of optimized and engineering-library laminates automatically. A higher accuracy and efficiency of the proposed formulations in calculating the buckling loads of composite stiffened panels was obtained in comparison with the traditional FEA method. The numerical optimization examples of the composite stiffened panel show that the stiffened panel’s buckling load increases by 17% with an almost unchanged weight. And the optimal stacking sequence results can be extracted from the composite stacking engineering library and be used in practical structure directly.