Microstructure, properties and cytocompatibility evaluation of hydroxyapatite/Ti-13Nb-13Zr composites

-

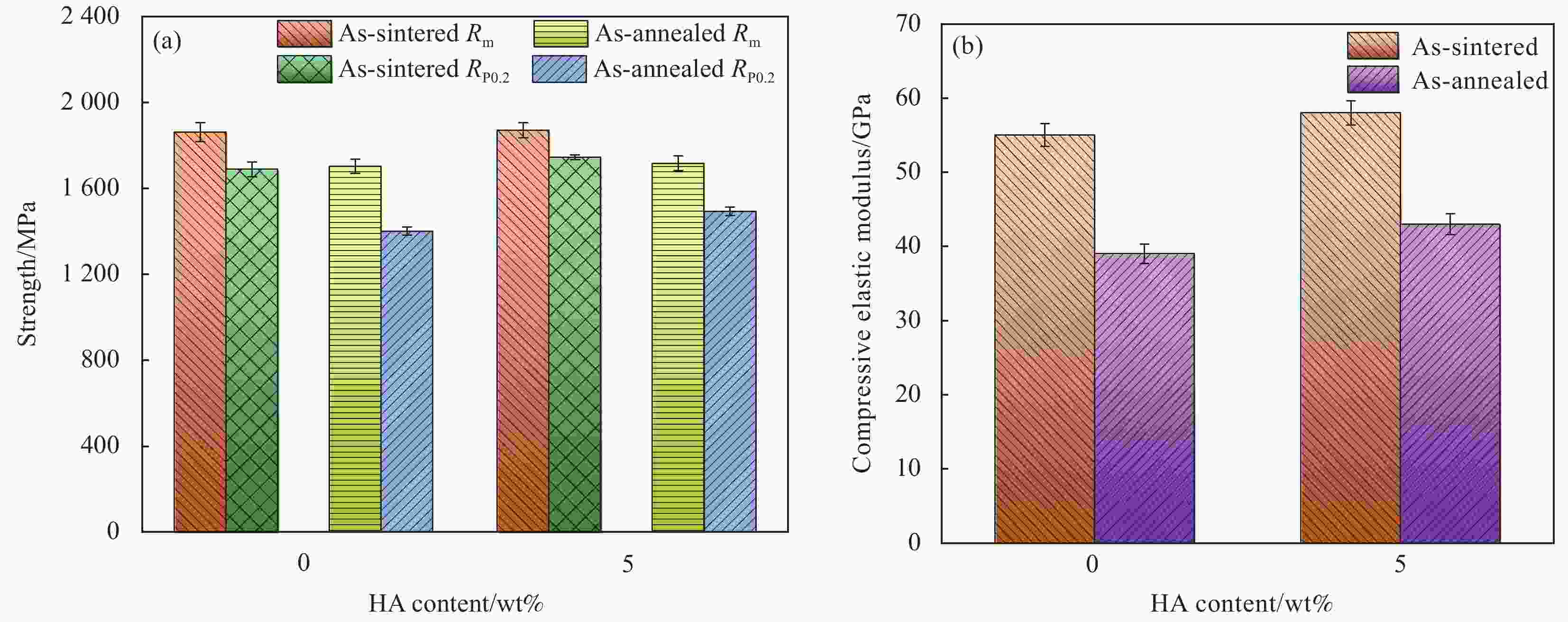

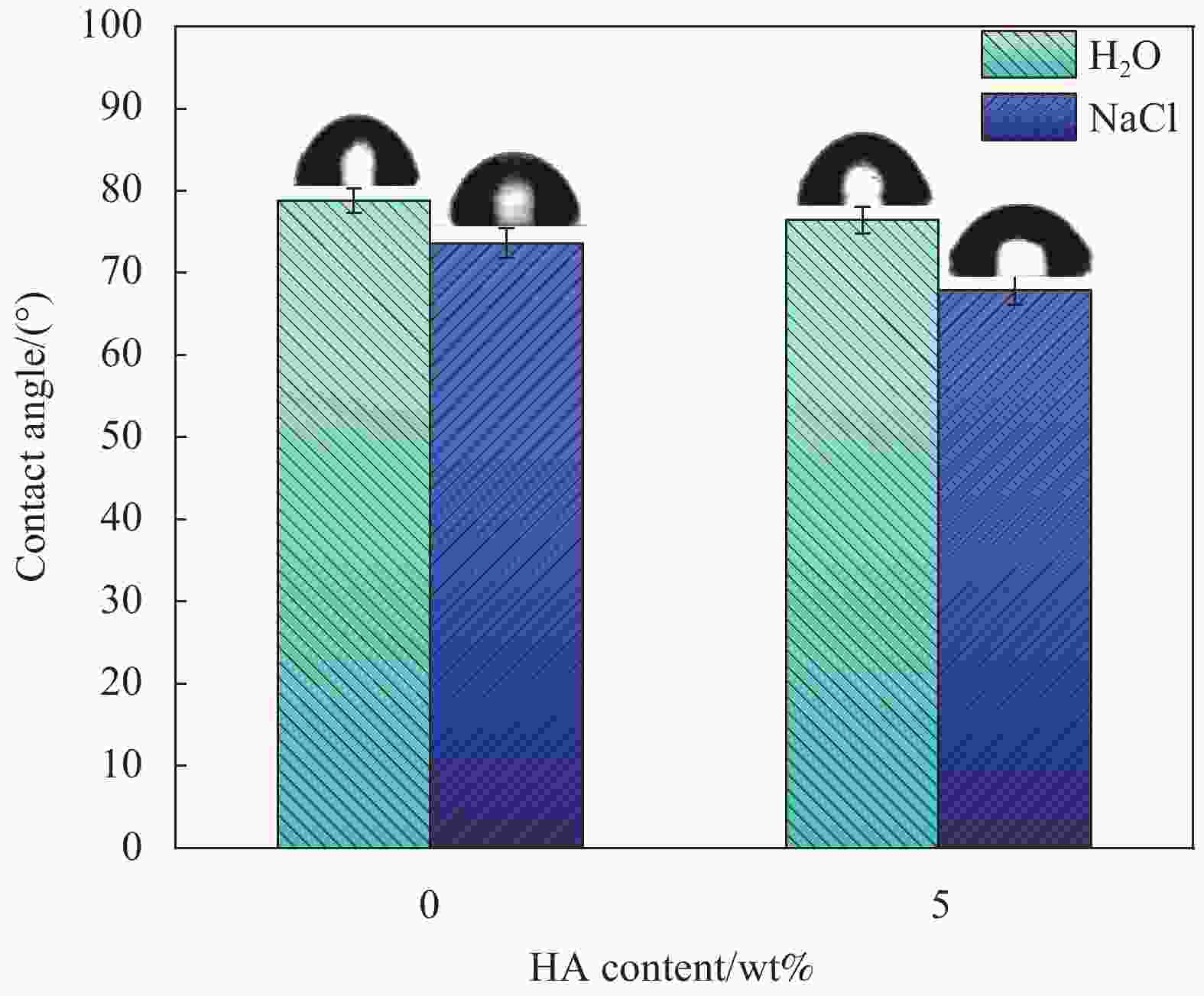

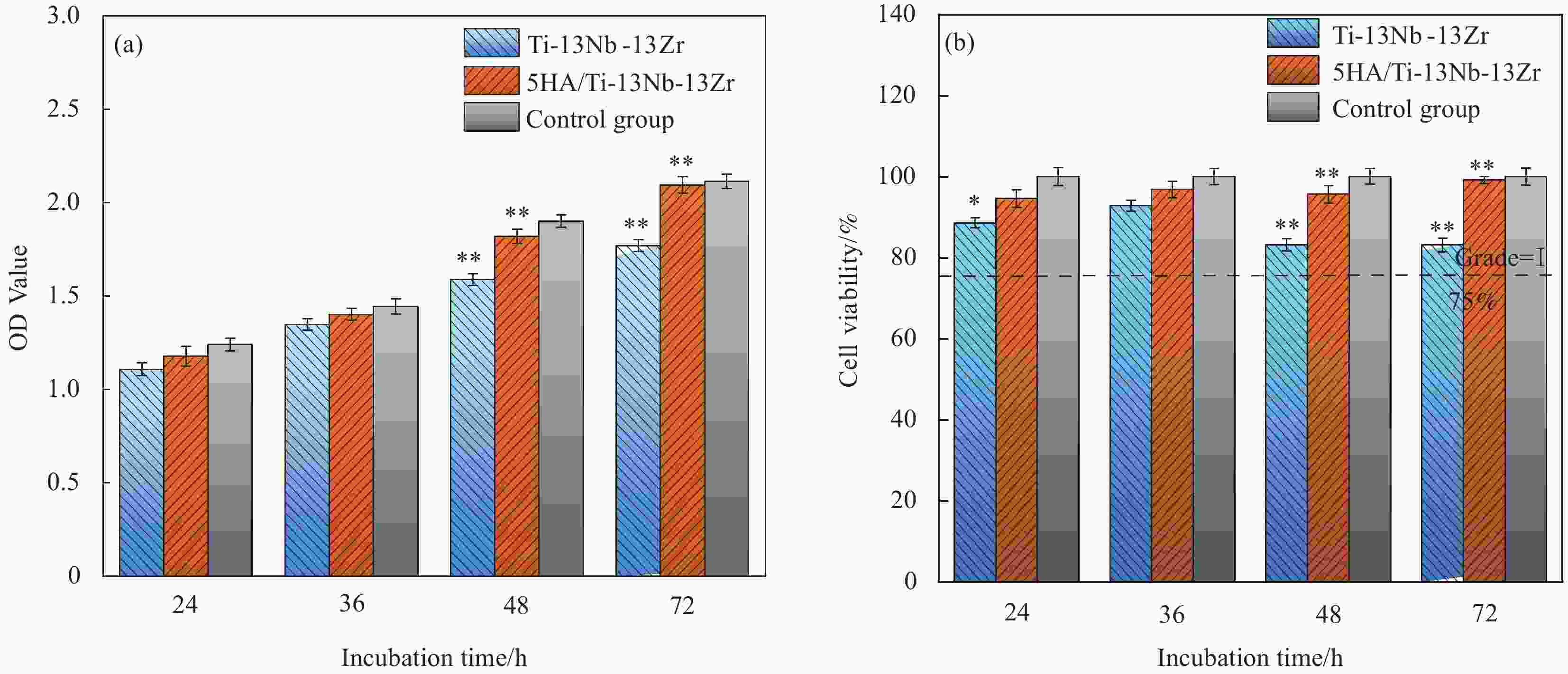

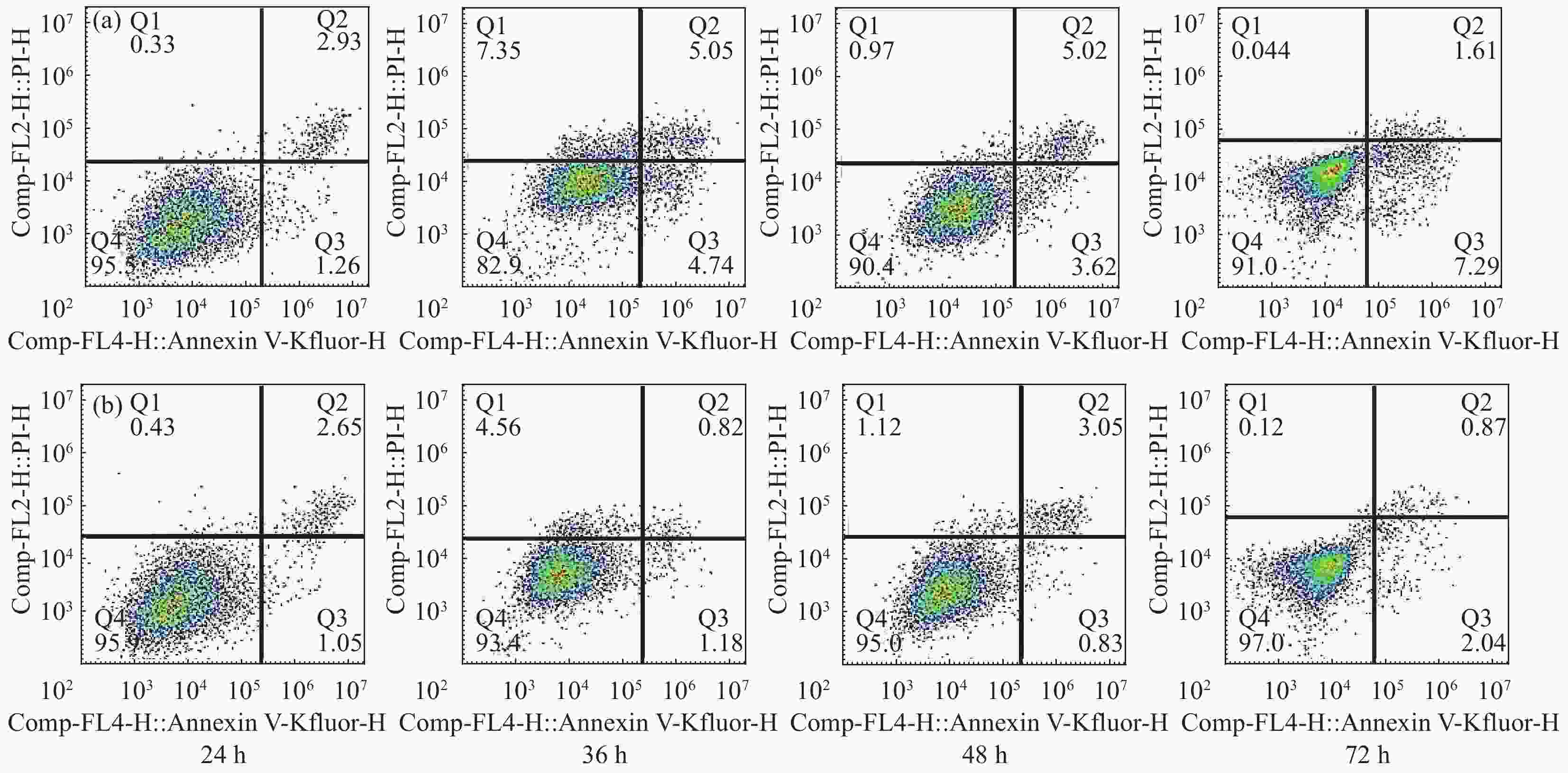

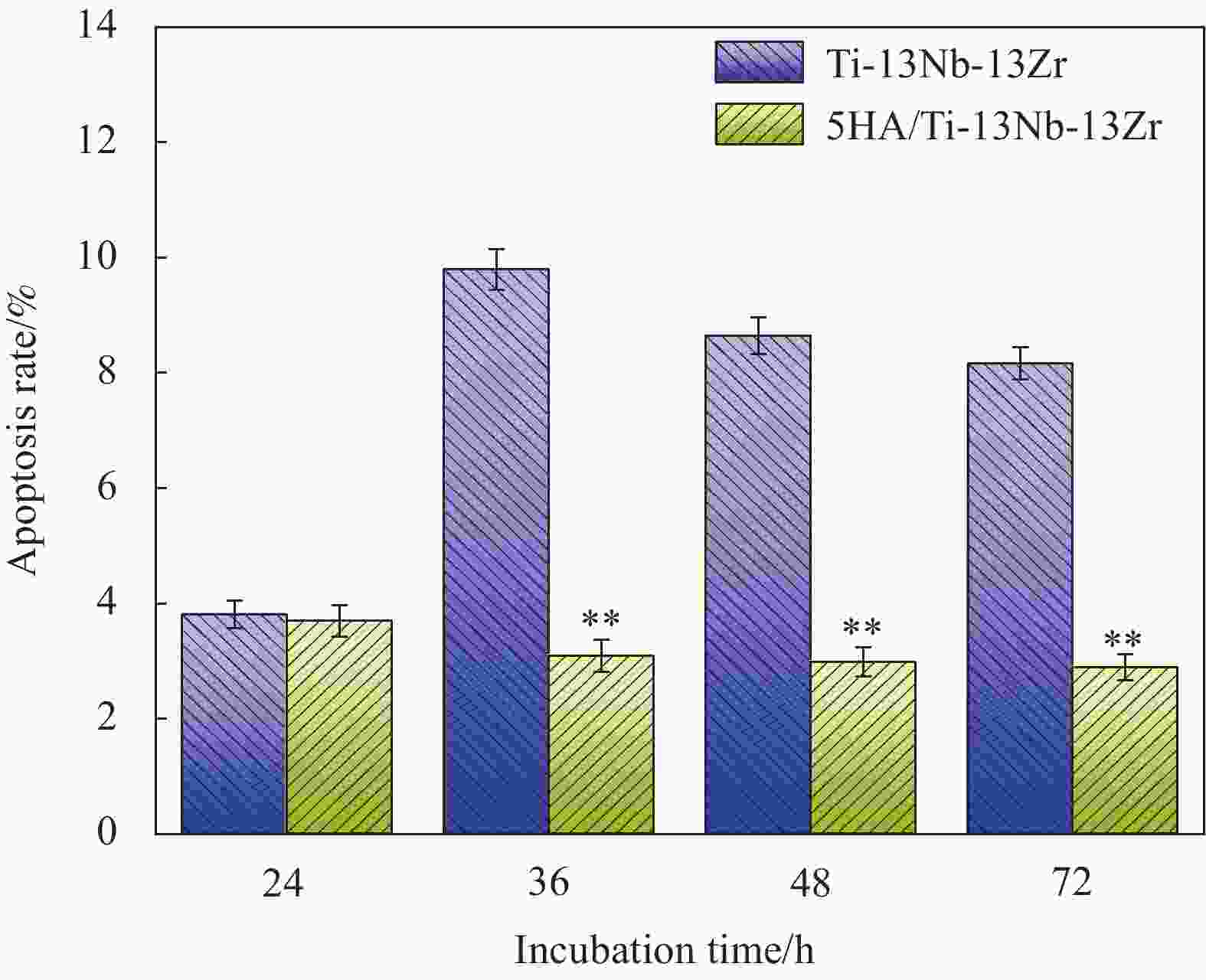

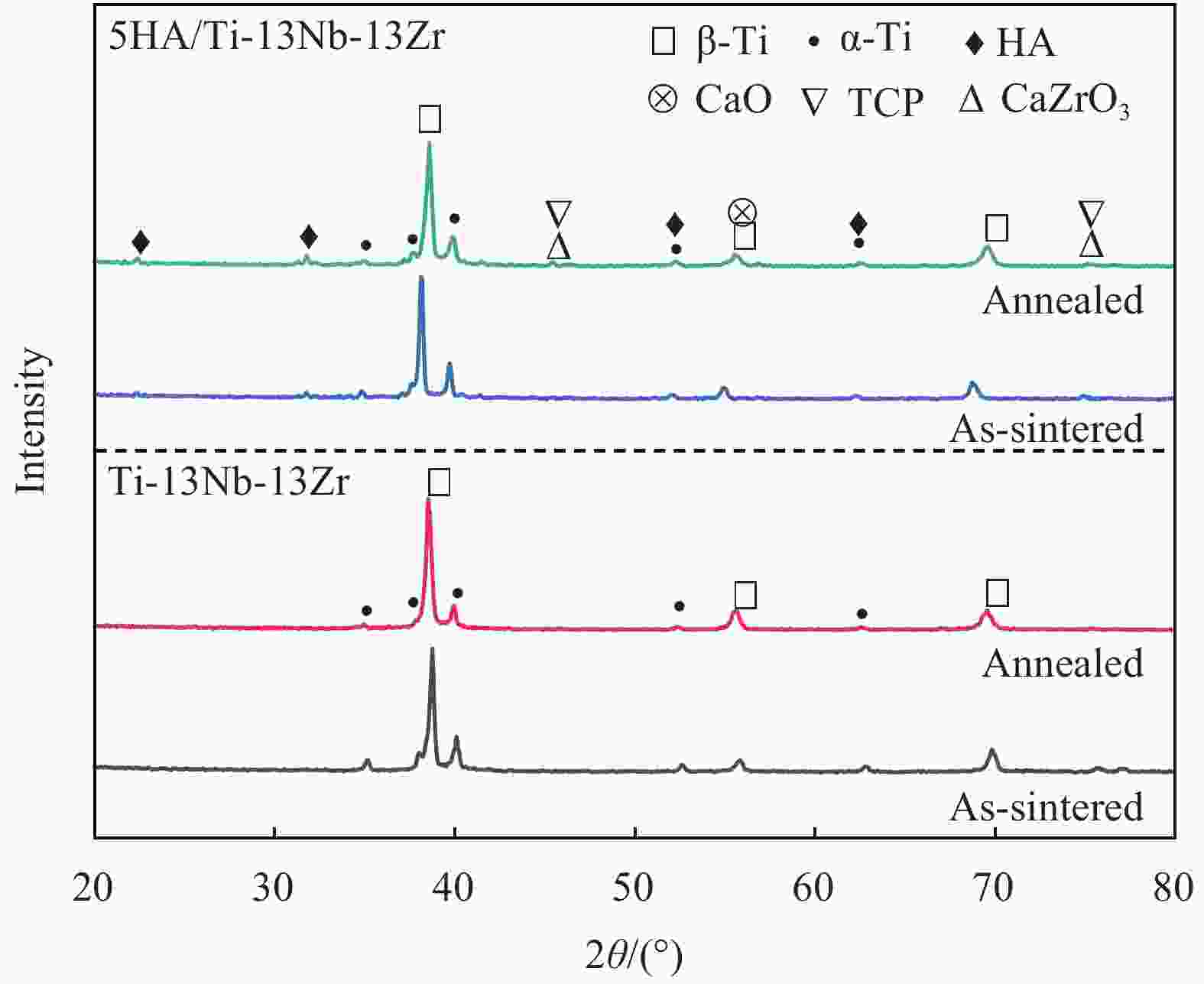

摘要: 为了改善Ti-13Nb-13Zr医用钛合金的生物活性与细胞相容性,利用放电等离子烧结(SPS)技术制备了Ti-13Nb-13Zr合金和羟基磷灰石(HA)含量5wt%的5HA/Ti-13Nb-13Zr复合材料并进行退火处理,研究了两种材料的显微组织、力学性能、表面润湿性、体外矿化行为及细胞增殖与凋亡等生物学性能。结果表明:合金主要由β-Ti和α-Ti相组成,复合材料由β-Ti、α-Ti、HA相及少量陶瓷反应相(Ca3(PO4)2、CaZrO3、CaO)组成,退火后部分初生α-Ti转变为β-Ti且组织更均匀,HA的加入会使得晶粒细化;退火后两种材料抗压强度、屈服强度、屈强比和弹性模量均略微下降;HA的加入提高了复合材料亲水性、类骨磷灰石形成能力、细胞增殖率并降低了细胞凋亡率;综合分析,退火后的5HA / Ti-13Nb-13Zr复合材料抗压强度、屈服强度和弹性模量分别为(1744±9) MPa、(1493±12) MPa和(43±1.6) GPa,具有优异的类骨磷灰石形成能力,同时细胞增殖率达到99.1%±0.8%,表明HA的加入明显提高了Ti-13Nb-13Zr合金的生物活性与细胞相容性。Abstract: In order to improve the bioactivity and cytocompatibility of Ti-13Nb-13Zr biomedical titanium alloy, Ti-13Nb-13Zr alloy and 5HA/Ti-13Nb-13Zr composite with hydroxyapatite (HA) content 5wt% were fabricated by spark plasma sintering (SPS) technique and then annealed. The microstructure, mechanical properties, surface wettability, in vitro mineralization behavior, cell proliferation and apoptosis of the two materials were investigated. The results show that the alloy is mainly composed of β-Ti and α-Ti phases, and the composite is mainly composed of β-Ti, α-Ti, HA phases and a small amount of ceramic reaction phases (Ca3(PO4)2, CaZrO3, CaO). After annealing, the part of α-Ti transforms to β-Ti and the microstructure is more uniform. The addition of HA can refine the grains to a certain extent. The compressive strength, yield strength, yield ratio and elastic modulus of the two materials decrease slightly after annealing. The HA not only strengthens the hydrophilicity and osteoapatite-like formation ability, but also increases cell viability rate and cell apoptosis rate of the composites. Comprehensive analysis, the compressive strength, yield strength and elastic modulus of the 5HA/Ti-13Nb-13Zr are (1744±9) MPa, (1493±12) MPa and (43±1.6) GPa, respectively. Moreover, the 5HA/Ti-13Nb-13Zr composite have excellent bone-like apatite formation ability and the cell viability reaches 99.1%±0.8%. It indicated that the addition of HA significantly improves the bioactivity and cytocompatibility of Ti-13Nb-13Zr alloy.

-

图 2 退火前后Ti-13Nb-13Zr合金和5HA/Ti-13Nb-13Zr复合材料的微观形貌:((a)、(b)) 烧结态合金;((c)、(d)) 退火态合金;((e)、(f)) 烧结态复合材料;((g)、(h)) 退火态复合材料

Figure 2. Microstructure of Ti-13Nb-13Zr alloy and 5HA/Ti-13Nb-13Zr composite before and after annealing: ((a), (b)) Sintered alloy; ((c), (d)) Annealed alloy; ((e), (f)) Sintered composite; ((g), (h)) Annealed composite

图 7 退火态Ti-13Nb-13Zr合金和5HA/Ti-13Nb-13Zr复合材料浸提液诱导人成骨肉瘤细胞(MG63 细胞)凋亡实验:(a)合金;(b)复合材料 (X轴、Y轴分别表示PI 和 Annexin V,一般认为PI单染的细胞是已经死亡的细胞,Annexin V单染的细胞是凋亡早期的细胞,而双染是凋亡中期的细胞;Q1区表示死细胞;Q2表示凋亡晚期细胞;Q3表示正常细胞;Q4表示凋亡早期细胞)

Figure 7. Apoptosis experiment of Human osteosarcoma cells (MG63 cells) induced by extraction of Ti-13Nb-13Zr alloy and 5HA/Ti-13Nb-13Zr composite after annealing: (a) Alloy; (b) Composite (X and Y axes indicate PI and annexin V respectively. It is generally accepted that the cells with PI mono-staining are dead cells, the cells with annexin V mono-staining are cells in the early apoptotic stage, and the cells with double staining are cells in the middle apoptotic stage; Q1 represents dead cells; Q2 represents late apoptotic cells; Q3 represents normal cells; Q4 represents early apoptotic cells)

表 1 两组材料在SBF溶液浸泡后的表面成分分析

Table 1. Surface composition analysis of two groups of materials soaked in SBF solution

Material Element/at% Ti O Na Ca P Cl K Point A 1.1 19.6 39.7 — — 38.3 1.1 Point B 0.6 46.6 15.7 10.1 6.8 13.3 7.5 -

[1] BOYER R, WELSCH G, COLLINGS E W. Materials properties handbook: Titanium alloys[M]. Ohio: ASM International, Materials Park, 1994. [2] GEETHA M, SINGH A K, ASOKAMANI R, et al. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review[J]. Progress in Materials Science,2009,54(3):397-425. doi: 10.1016/j.pmatsci.2008.06.004 [3] CHEN Q, THOUAS G A. Metallic implant biomaterials[J]. Materials Science and Engineering: R: Reports,2015,87:1-57. doi: 10.1016/j.mser.2014.10.001 [4] 王莉丽, 王秀峰, 丁旭, 等. Ti/HA生物复合材料的研究进展[J]. 材料导报, 2012, 26(17):80-82. doi: 10.3969/j.issn.1005-023X.2012.17.017WANG Lili, WANG Xiufeng, DING Xu, et al. Research progress of Ti/HA biocomposites[J]. Journal of Materials Review,2012,26(17):80-82(in Chinese). doi: 10.3969/j.issn.1005-023X.2012.17.017 [5] CHANG B S, LEE C K, HONG K S, et al. Osteoconduction at porous hydroxyapatite with various pore configurations[J]. Biomaterials,2000,21(12):1291-1298. doi: 10.1016/S0142-9612(00)00030-2 [6] 刘宣勇. 生物医用钛材料及其表面改性[M]. 北京: 化学工业出版社, 2009.LIU Xuanyong. Study on surface modification and selective biological effects of titanium implant materials[M]. Beijing: Publishing House of Chemical Industry, 2009(in Chinese). [7] 陈菲. 羟基磷灰石生物医用陶瓷材料的研究与发展[J]. 中国陶瓷, 2006, 42(4):8-10. doi: 10.3969/j.issn.1001-9642.2006.04.002CHEN Fei. Research and development of hydroxyapatite biomedical ceramic materials[J]. Chinese Ceramics,2006,42(4):8-10(in Chinese). doi: 10.3969/j.issn.1001-9642.2006.04.002 [8] MARDER R, ESTOURNES C, CHEVALLIER G, et al. Spark and plasma in spark plasma sintering of rigid ceramic nanoparticles: A model system of YAG[J]. Journal of the European Ceramic Society,2015,35(1):211-218. doi: 10.1016/j.jeurceramsoc.2014.08.001 [9] 何远怀. 羟基磷灰石/Ti-13Nb-13Zr生物材料的制备和性能研究[D]. 昆明: 昆明理工大学, 2018.HE Yuanhuai. Preparation and properties of hydroxyapatite/Ti-13Nb-13Zr biomaterials[D]. Kunming: Kunming University of Science and Technology, 2018(in Chinese). [10] 刘万理, 张玉勤, 蒋业华, 等. 固溶温度对SPS烧结Ti-24Nb-4Zr-8Sn合金组织和力学性能的影响[J]. 金属热处理, 2017, 42(4):99-103.LIU Wanli, ZHANG Yuqin, JIANG Yehua, et al. Effect of solution temperature on microstructure and mechanical properties of SPS sintered Ti-24Nb-4Zr-8Sn alloy[J]. Heat Treatment of Metals,2017,42(4):99-103(in Chinese). [11] 雷晓飞, 董利民, 张志强, 等. 退火工艺对TC6钛合金棒材显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2017, 46(S1):80-84.LEI Xiaofei, DONG Limin, ZHANG Zhiqiang, et al. Effect of annealing process on microstructure and mechanical properties of TC6 titanium alloy bars[J]. Rare Metal Materials and Engineering,2017,46(S1):80-84(in Chinese). [12] 雷雨涛, 朱斌, 张玉勤, 等. 退火温度对HA/Ti-24Nb-4Zr复合材料组织与性能的影响[J]. 金属热处理, 2020, 45(10):94-98.LEI Yutao, ZHU Bin, ZHANG Yuqin, et al. Effect of annealing temperature on microstructure and properties of HA/Ti-24Nb-4Zr composites[J]. Heat Treatment of Metals,2020,45(10):94-98(in Chinese). [13] 王海, 魏芬绒, 邓家彬, 等. 影响钛合金屈强比的因素及作用机理探讨[J]. 热加工工艺, 2016, 45(22):109-115.WANG Hai, WEI Fenrong, DENG Jiabin, et al. Discussion on the factors affecting the strength ratio of titanium alloy and the mechanism of action[J]. Hot Working Technology,2016,45(22):109-115(in Chinese). [14] 熊汉城, 黄海广, 李志敏, 等. 退火温度对大口径 TC4 合金无缝管组织与性能的影响[J]. 金属热处理, 2019, 44(12):107-111.XIONG Hancheng, HUANG Haiguang, LI Zhimin, et al. The effect of annealing temperature on the microstructure and properties of large-diameter TC4 alloy seamless pipes[J]. Heat Treatment of Metals,2019,44(12):107-111(in Chinese). [15] 中国国家标准化管理委员会. 钛及钛合金牌号和化学成分: GB/T 3620.1—2016[S]. 北京: 中国标准出版社, 2016.Standardization Administration of the People’s Republic of China. Designation and composition of titanium and titanium alloy: GB/T 3620.1—2016[S]. Beijing: China Standards Press, 2016(in Chinese). [16] 姜久仰, 刘宏宇, 徐吉林, 等. 医用Ti-6Al-4V合金表面超疏水涂层的制备及生物学性能[J]. 稀有金属材料与工程, 2019, 48(6): 1884-1891.JIANG Jiuyang, LIU Hongyu, XU Jilin, et al. Preparation and biological properties of the fluoroalkyl silane superhydrophobic coatings on biomedical Ti-6Al-4V alloy[J]. Rare Metal Materials and Engineering, 2019, 48(6): 1884-1891(in Chinese). [17] NING C Q, ZHOU Y. In vitro bioactivity of a biocomposite fabricated from HA and Ti powders by powder metallurgy method[J]. Biomaterials,2002,23(14):2909-2915. doi: 10.1016/S0142-9612(01)00419-7 [18] 吴泽恩, 胡锐, 张铁邦, 等. 间隙原子O对高Nb-TiAl合金显微组织与相转变的影响[J]. 金属学报, 2013, 49(11):1381-1386.WU Zeen, HU Rui, ZHANG Tiebang, et al. Effect of interstitial atom O on microstructure and phase transition of high Nb-TiAl alloy[J]. Journal of Metals,2013,49(11):1381-1386(in Chinese). [19] GIBSON L J. The mechanical behaviour of cancellous bone[J]. Journal of Biomechanics,1985,18(5):317-328. doi: 10.1016/0021-9290(85)90287-8 [20] MENZIES K L, JONES L. The impact of contact angle on the biocompatibility of biomaterials[J]. Optometry and Vision Science,2010,87(6):387-399. doi: 10.1097/OPX.0b013e3181da863e [21] OZASA K, NEMOTO S, LI Y Z, et al. Contact angle and biocompatibility of sol-gel prepared TiO2 thin films for their use as semiconductor based cell viability sensors[J]. Surface and Interface Analysis,2008,40(3-4):579-583. doi: 10.1002/sia.2729 [22] JIANG L, WANG R, YANG B, et al. Binary cooperative complementary nanoscale interfacial materials[J]. Pure and Applied Chemistry,2000,72(1-2):73-81. doi: 10.1351/pac200072010083 [23] CHA T G, YI J W, MOON M W, et al. Nanoscale patterning of microtextured surfaces to control superhydrophobic robustness[J]. Langmuir,2010,26(11):8319-8326. doi: 10.1021/la9047402 [24] CHAU T T, BRUKARD W J, KOH P T L, et al. A review of factors that affect contact angle and implications for flotation practice[J]. Advances in Colloid and Interface Science,2009,150(2):106-115. doi: 10.1016/j.cis.2009.07.003 [25] 杜晨光, 夏帆, 王树涛, 等. 仿生智能浸润性表面研究的新进展[J]. 高等学校化学学报, 2010, 31(3): 421-431.DU Chenguang, XIA Fan, WANG Shutao, et al, Advances in bio-inspired smart surfaces with special wettability[J]. Chemistry Journal of Chinese Universities, 2010, 31(3): 421-431(in Chinese). [26] KOKUBO T, KIM H M, KAWASHITA M. Novel bioactive materials with different mechanical properties[J]. Biomaterials,2003,24(13):2161-2175. doi: 10.1016/S0142-9612(03)00044-9 [27] HALLAB N J, BUNDY K J, O'CONNOR K, et al. Evaluation of metallic and polymeric biomaterial surface energy and surface roughness characterization for directed cell adhesion[J]. Tissue Engineering,2001,7(1):55-71. doi: 10.1089/107632700300003297 [28] TANAKA T, HIROSE M, KOTOBUKI N, et al. Nano-scaled hydroxyapatite/silk fibroin sheets support osteogenic differentiation of rat bone marrow mesenchymal cells[J]. Materials Science and Engineering: C,2007,27(4):817-823. doi: 10.1016/j.msec.2006.09.019 [29] LIU K, LIU P C, LIU R, et al. Dual AO/EB staining to detect apoptosis in osteosarcoma cells compared with flow cytometry[J]. Medical Scicence Monitor Basic Research,2015,21:15-20. doi: 10.12659/MSMBR.893327 [30] DU PLESSIS L H, HAMMAN J H. In vitro evaluation of the cytotoxic and apotogenic properties of aloe whole leaf and gel materials[J]. Drug and Chemical Tocicology,2014,37(2):169-177. doi: 10.3109/01480545.2013.834356 -

下载:

下载: