Effect of mesoporous SiO2 on the mechanical properties of epoxy resin at ultra-low temperature and the interface properties of resin/carbon fiber

-

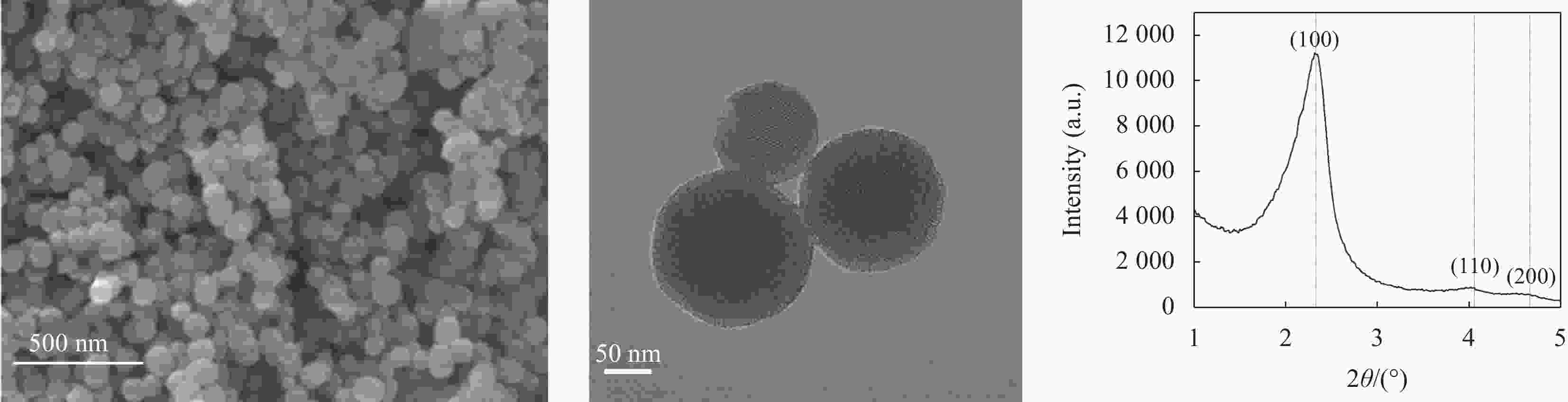

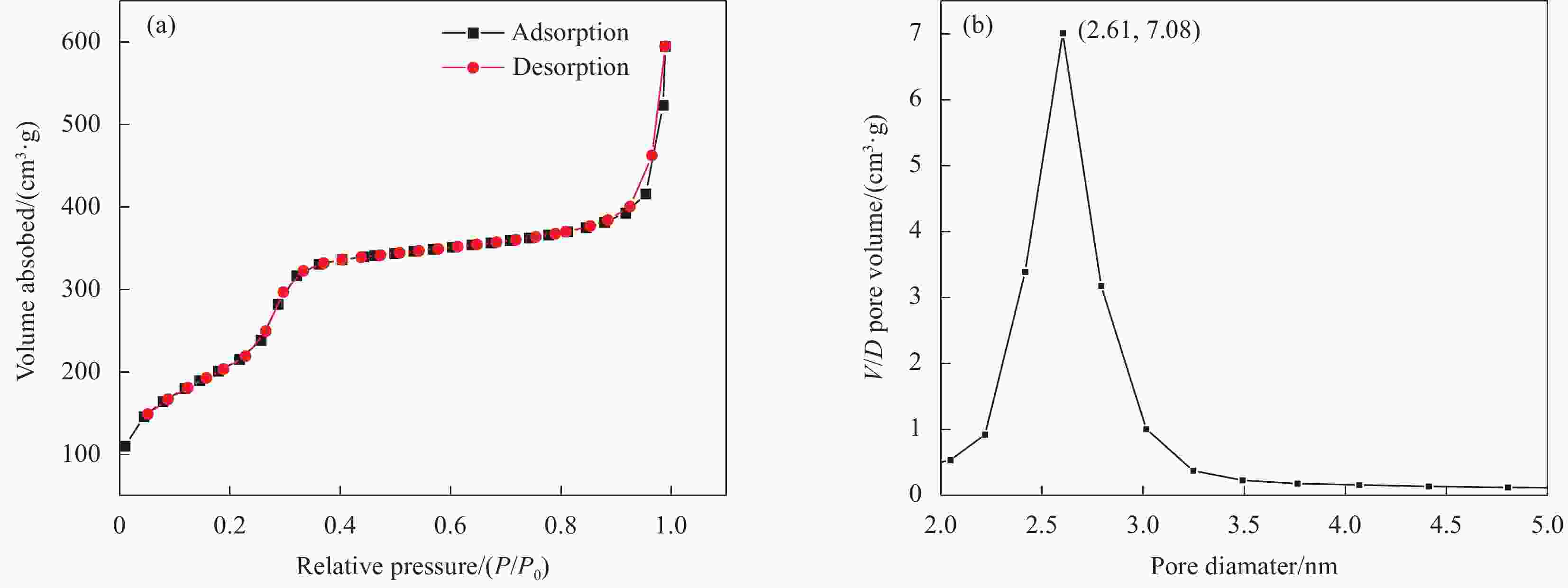

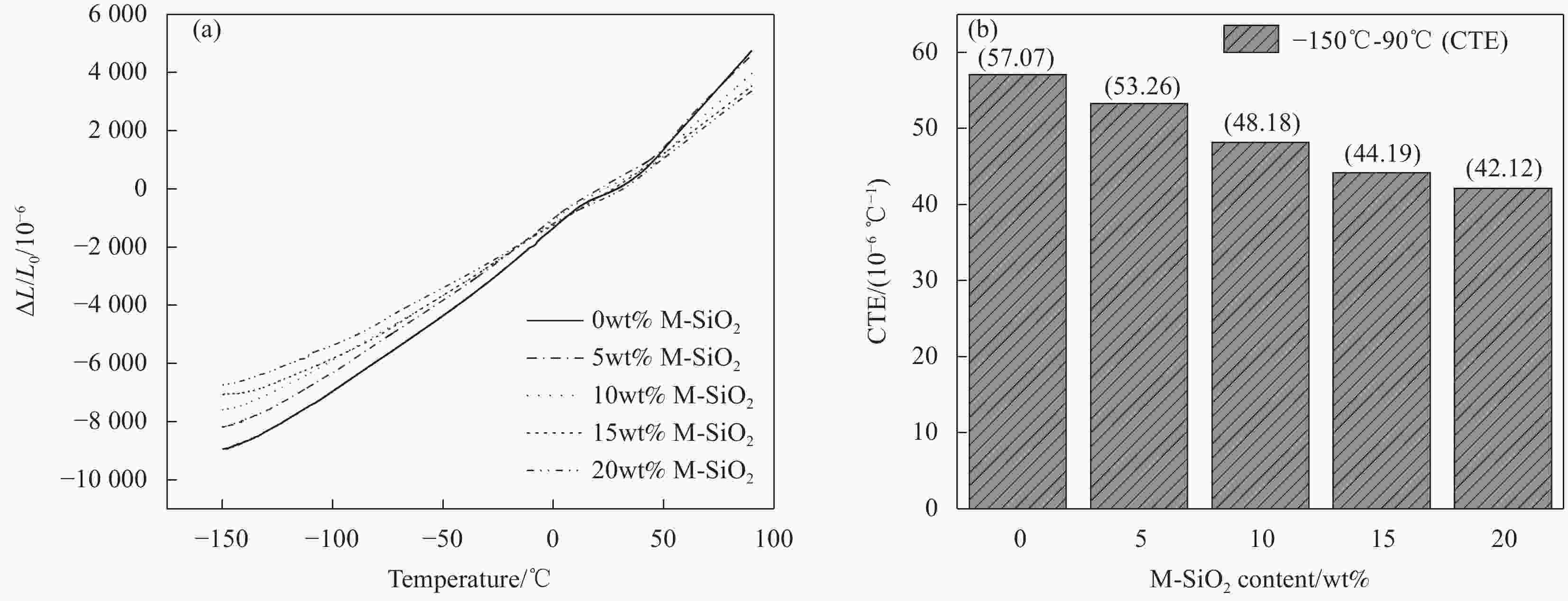

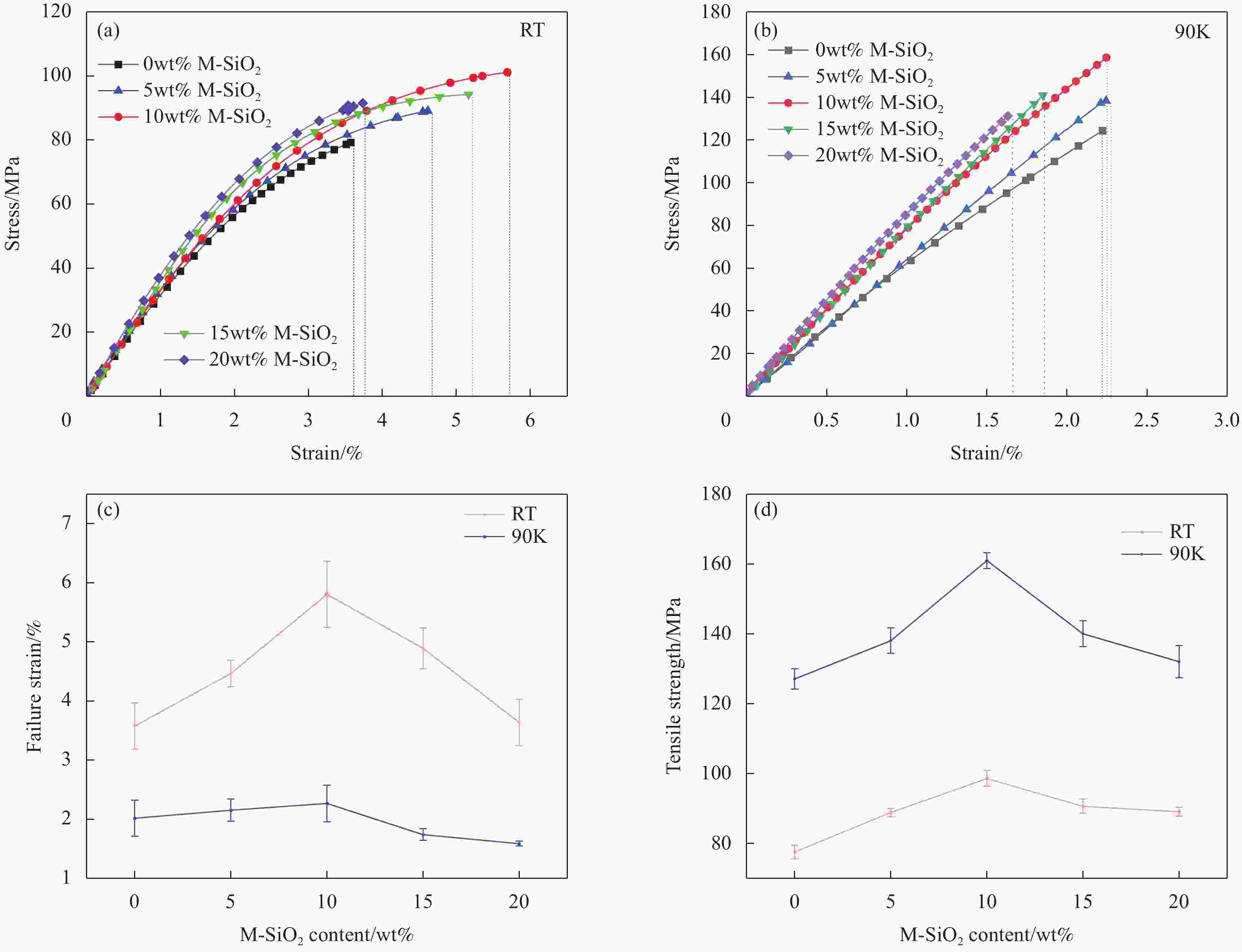

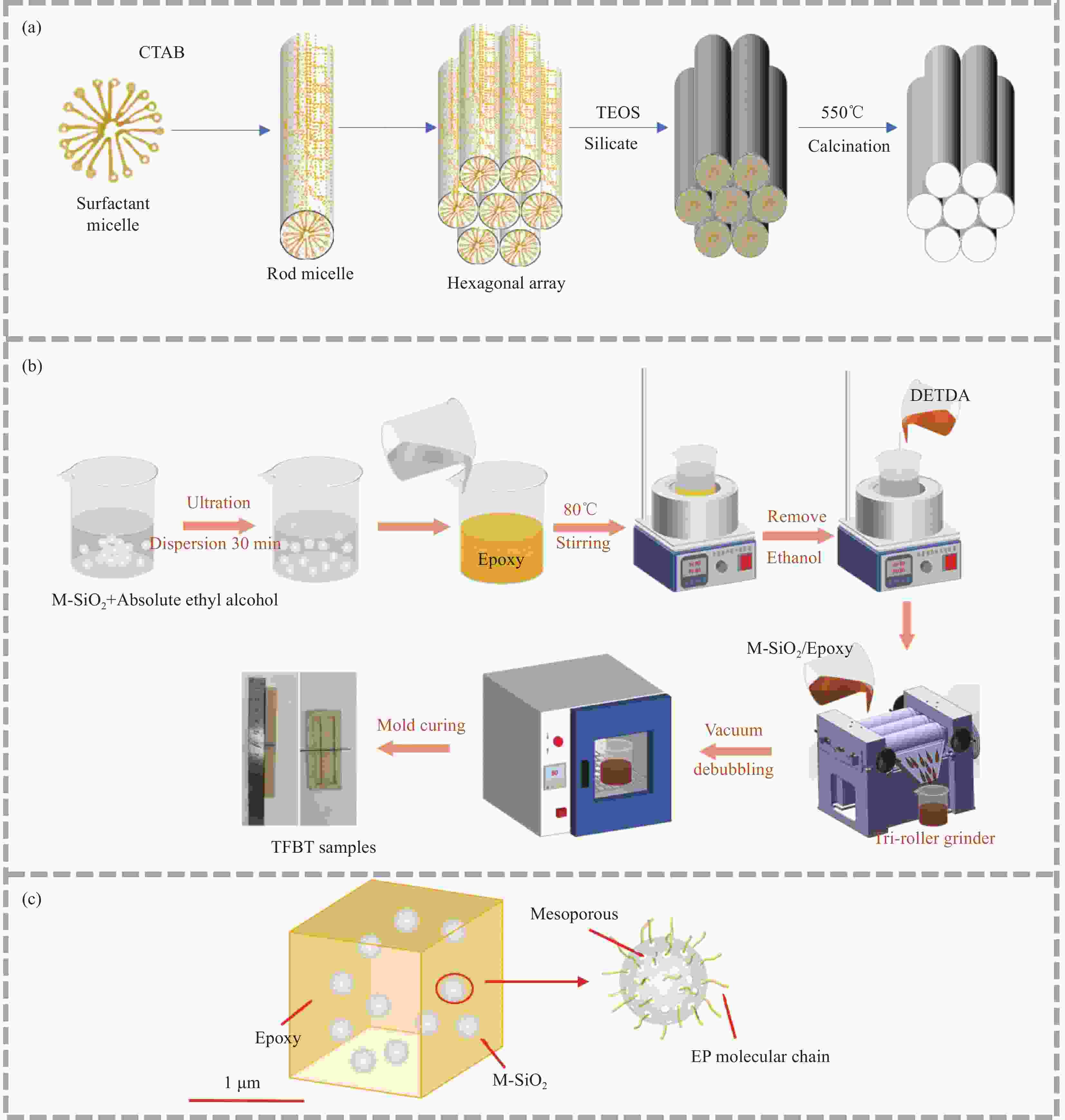

摘要: 碳纤维增强环氧树脂基复合材料在超低温环境下的应用日益广泛。然而,由于环氧树脂基体与碳纤维之间的热膨胀系数不匹配,导致碳纤维复合材料在超低温环境下产生显著的温度应力,从而影响其服役性能。本文采用溶胶-凝胶法成功制备了粒径为100至160 nm、平均孔径为4.24 nm的介孔SiO2,并通过三辊研磨法将其加入到环氧树脂中制备出介孔SiO2/环氧树脂复合材料。测试结果表明:介孔SiO2的添加有效降低了环氧树脂的热膨胀系数,并提高了其力学性能。具体来说,在室温和90 K下,添加10wt.%含量介孔SiO2的环氧树脂抗拉强度分别达到约98 MPa和160 MPa,相比纯环氧树脂分别提高27.07%和26.02%。此外,随着介孔SiO2含量的增加,环氧树脂的热膨胀系数逐渐降低,当添加20wt.%介孔SiO2时,介孔SiO2/环氧树脂复合材料的热膨胀系数相比于纯环氧树脂的热膨胀系数下降26.31%。TFBT测试结果表明:添加5wt.% 含量介孔SiO2的环氧树脂的TFBT强度比纯环氧树脂提高了41.07%,这说明介孔SiO2可以有效改善树脂/碳纤维的界面结合性能。

-

关键词:

- 介孔SiO2纳米粒子 /

- 环氧树脂 /

- 复合材料 /

- 热膨胀系数 /

- 界面强度

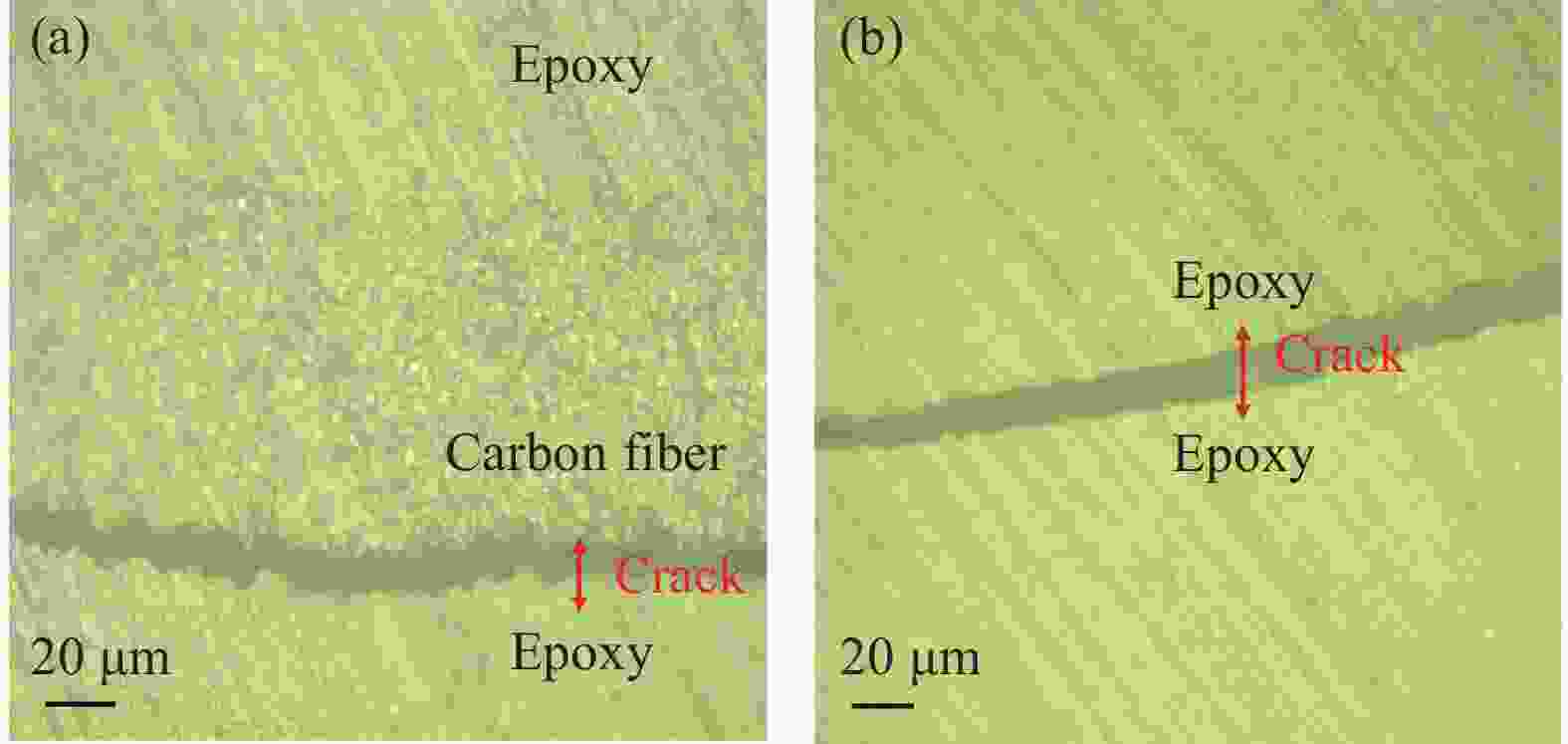

Abstract: Carbon fiber reinforced epoxy matrix composites are increasingly used in ultra-low temperature environments. However, due to the mismatch of the thermal expansion coefficient between the epoxy resin matrix and the carbon fiber, the carbon fiber composite material will produce significant temperature stress in the ultra-low temperature environment, which will affect its service performance. Mesoporous SiO2 with a particle size of 100 to 160 nm and an average pore size of 4.24 nm was successfully prepared by sol-gel method, and mesoporous SiO2/epoxy resin composites were prepared by adding them to epoxy resin by three-roller grinding method. The test results show that the addition of mesoporous SiO2 effectively reduces the thermal expansion coefficient of epoxy resin and improves its mechanical properties. Specifically, at room temperature and 90 K, the tensile strength of epoxy resin with 10 wt.% mesoporous SiO2 reached about 98 MPa and 160 MPa, respectively, which was 27.07% and 26.02% higher than that of pure epoxy resin, respectively. In addition, with the increase of mesoporous SiO2 content, the thermal expansion coefficient of epoxy resin decreases gradually, and when 20wt.% mesoporous SiO2 is added, the thermal expansion coefficient of mesoporous SiO2/epoxy resin composites decreases by 26.31% compared with that of pure epoxy resin. The TFBT test results showed that the TFBT strength of epoxy resin with 5 wt.% mesoporous SiO2 content was increased by 41.07% compared with that of pure epoxy resin, indicating that mesoporous SiO2 could effectively improve the interfacial bonding properties of resin/carbon fiber. -

图 4 (a)不同介孔SiO2/环氧树脂复合材料的热膨胀率随温度的变化关系;(b)不同介孔SiO2/环氧树脂复合材料在不同温度区间的热膨胀系数

Figure 4. (a) The relationship between the thermal expansion rate of mesoporous SiO2/epoxy resin composites with different mass fractions and temperature;(b) the thermal expansion coefficient of mesoporous SiO2/epoxy resins with different mass fractions in different temperature ranges

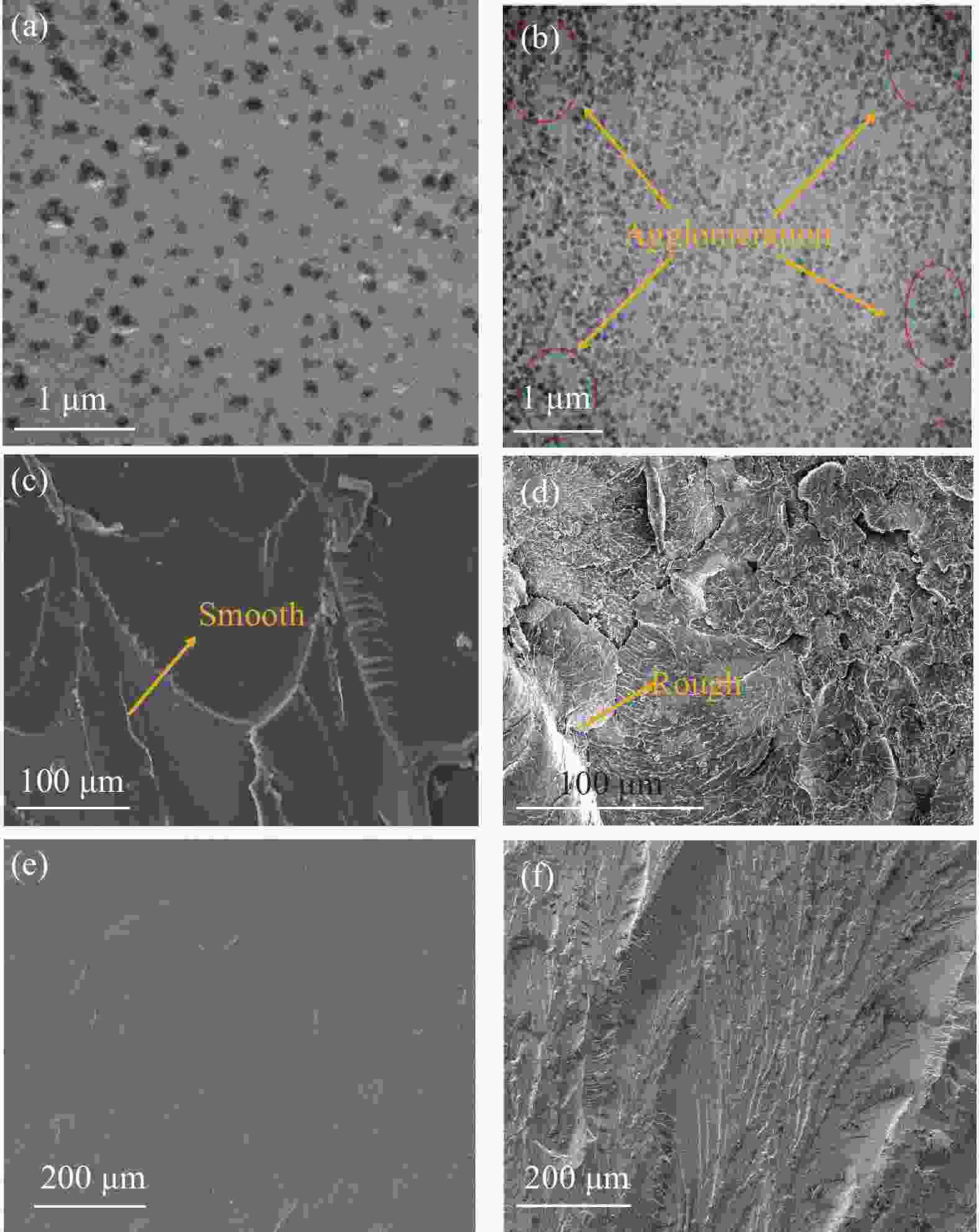

图 6 添加(a)10 wt.%和(b)20 wt.%介孔SiO2的环氧树脂复合材料的TEM图;RT下,(c) 纯环氧树脂和(d)添加10 wt.%介孔 SiO2的环氧树脂复合材料断面SEM图;90 K下,(e) 纯环氧树脂和(f)添加10 wt.%介孔 SiO2的环氧树脂复合材料断面SEM图

Figure 6. Transmission electron microscopy images of (a) solidified epoxy composites with 10.0 wt.% and (b) 20.0 wt.% mesoporous SiO2;(c) Scanning electron microscopy of RT fracture sections of epoxy composites with 0 wt.% and (d) 10.0 wt.% mesoporous SiO2; (e) Scanning electron microscopy of 90 K fracture cross-section of epoxy composites with 0 wt.% and (f) 10.0 wt.% mesoporous SiO2

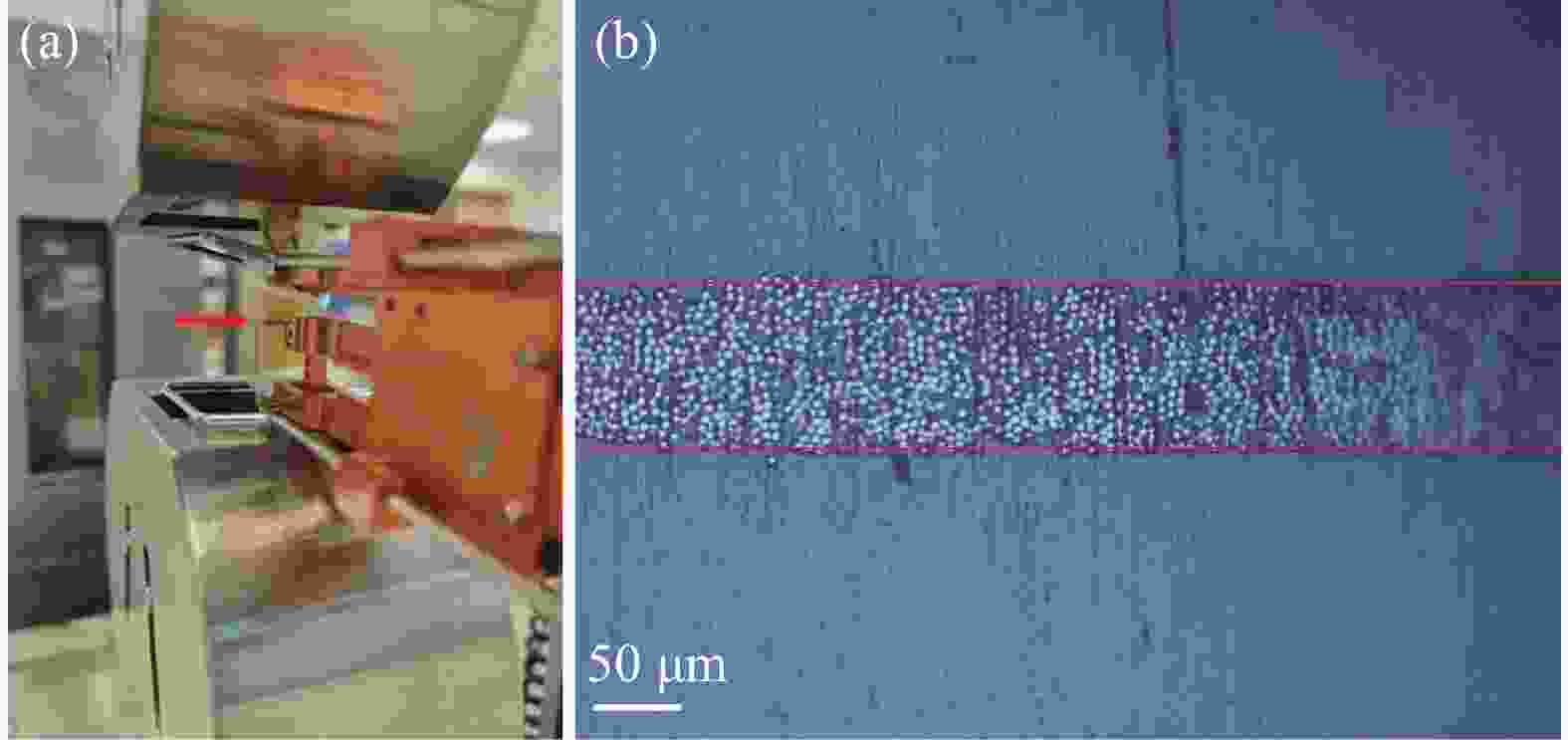

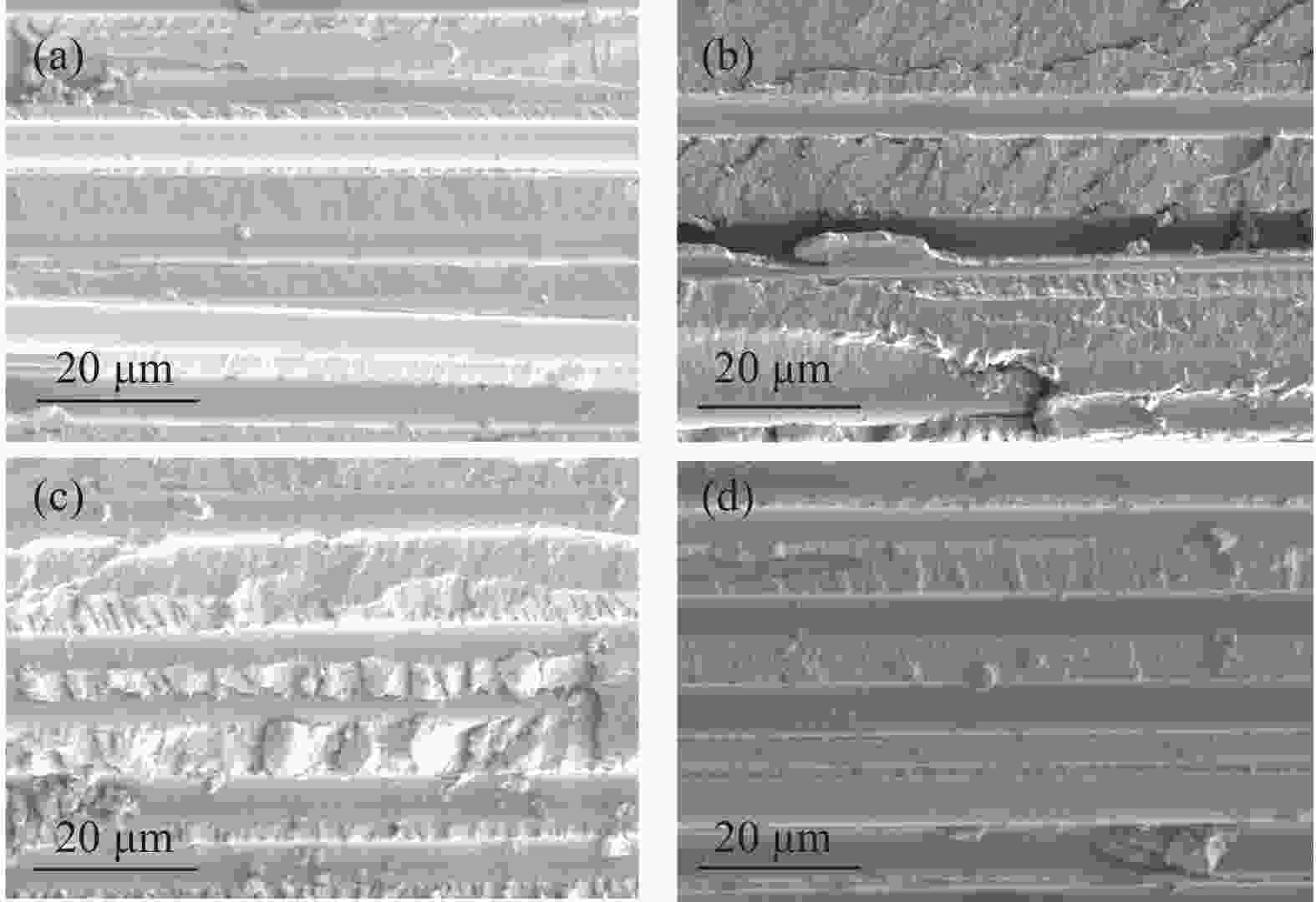

图 10 未经热循环处理的介孔 SiO2/环氧树脂复合材料TFBT样品断面SEM图:(a) 0 wt.%介孔SiO2 ;(b) 5 wt.%介孔SiO2; (c) 10 wt.%介孔SiO2 ;(d) 20 wt.%介孔SiO2

Figure 10. Cross-sections of mesoporous SiO2 modified epoxy/carbon fiber TFBT samples: (a) 0 wt.% mesoporous SiO2; (b) 5 wt.% mesoporous SiO2; (c) 10 wt.% mesoporous SiO2; (d) 20 wt.% mesoporous SiO2

表 1 介孔SiO2/环氧复合材料制备配比

Table 1. Preparation ratio of mesoporous SiO2/epoxy composites

Sample name M-SiO2/

g830

epoxy/gDETDA/

gPure epoxy resin 0 80 20 5 wt.%M-SiO2/Epoxy composite 4 80 20 10 wt.%M-SiO2/Epoxy composite 8 80 20 15 wt.%M-SiO2/Epoxy composite 12 80 20 20 wt.%M-SiO2/Epoxy composite 16 80 20 表 2 制备的介孔SiO2比表面积、孔容孔径分布参数

Table 2. The specific surface area and pore size distribution parameters of mesoporous SiO2

M-SiO2 Specific surface

area/(m2·g)Pore

volume/(cm3·g)The most pore

size distribution/nmAverage pore

size distribution/nmMCM-41 758.54 0.64 2.61 4.24 表 3 添加不同含量介孔SiO2/环氧树脂复合材料RT和90 K抗拉强度以及断裂应变。

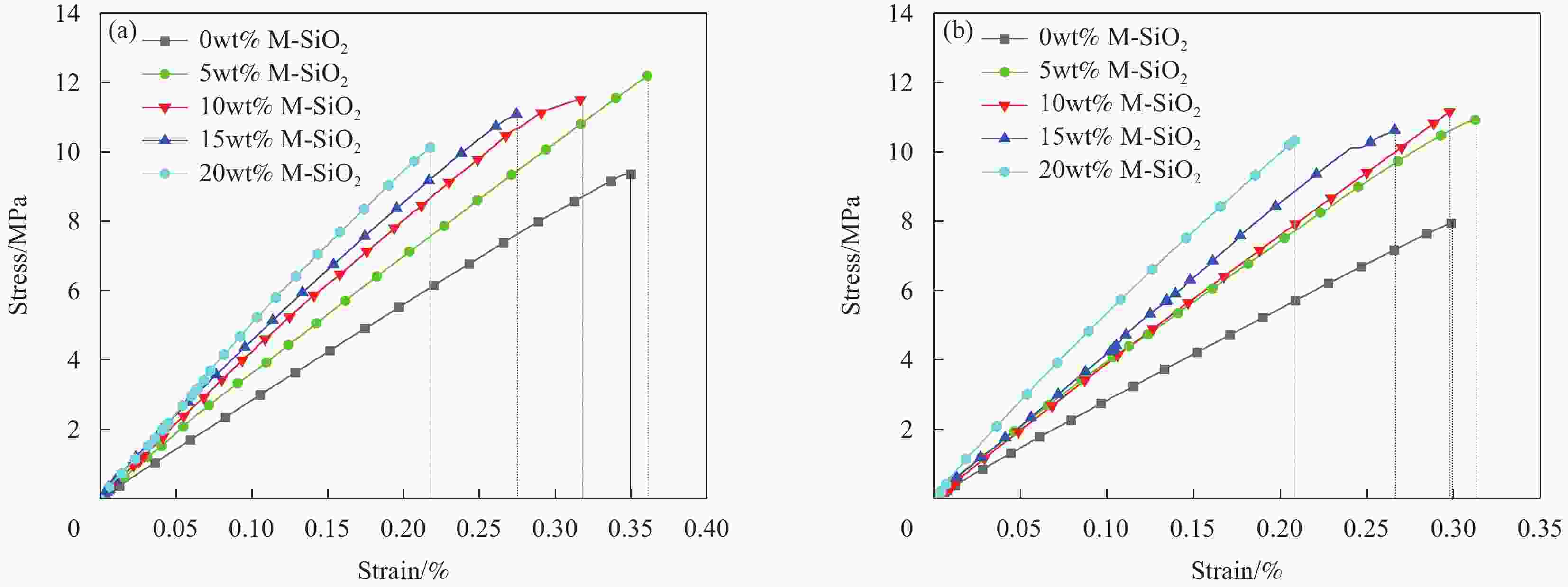

Table 3. Tensile strength and breaking strain of mesoporous SiO2/epoxy composites with different amounts of RT(a) and 90 K(b) are added.

Temperature RT 90 K Mesoporous SiO2 content/wt.% Tensile strength/MPa Strain at break/% Tensile strength/MPa Strain at break/% 0 77.56±1.92 3.57±0.39 127.09±2.89 2.01±0.30 5 88.86±1.16 4.46±0.22 138.05±3.62 2.15±0.18 10 98.56±2.26 5.80±0.55 160.97±2.24 2.26±0.31 15 90.64±2.02 4.89±0.34 140.01±3.72 1.74±0.10 20 89.05±1.27 3.63±0.39 132.04±4.61 1.58±0.04 表 4 添加不同含量介孔SiO2的TFBT试样热循环处理前后的强度

Table 4. Strength of mesoporous SiO2TFBT with different contents before and after thermal cycling

Before thermal cycling treatment 50 thermal cycles Mesoporous SiO2 content/wt.% TFBT

Strength/MPaTFBT

Strength/MPa0 9.30±0.23 7.63±0.41 5 12.72±0.51 11.1±0.47 10 11.72±0.17 11.3±0.15 15 11.21±0.13 10.78±0.17 20 10.31±0.39 10.24±0.12 -

[1] 湛利华, 关成龙, 黄诚, 等. 航天低温复合材料贮箱国内外研究现状分析[J]. 航空制造技术, 2019, 62(16): 79-87.ZHAN L, GUAN C, HUANG C, et al. Analysis of the research status of aerospace cryogenic composite tanks at home and abroad[J]. Aeronautical Manufacturing Technology, 2019, 62(16): 79-87 (in Chinese). [2] 张辰威, 张博明. 复合材料贮箱在航天飞行器低温推进系统上的应用与关键技术[J]. 航空学报, 2014, 35(10): 2747-2755.ZHANG C, ZHANG B. Application and key technology of composite tank in cryogenic propulsion system of space vehicle[J]. Journal of Aeronautics and Astronautic, 2014, 35(10): 2747-2755 (in Chinese). [3] TIWARI S, MICHAEL J, JOHN J, et al. A review of liquid hydrogen aircraft and propulsion technologies[J]. International Journal of Hydrogen Energy, 2024, 57: 1174-1196. doi: 10.1016/j.ijhydene.2023.12.263 [4] MORKAVUK S, KOKLU U, GEMI L, et al. Cryogenic machining of carbonfiber reinforced plastic (CFRP) composites and the effects of cryogenic treatment on tensile properties: a comparative study[J]. Composites Part B, 2018, 147: 1-11. doi: 10.1016/j.compositesb.2018.04.024 [5] KARA M, KIRICI M, TATAR A, et al. Impact behavior of carbon fiber/epoxy composite tubes reinforced with multi-walled carbon nanotubes at cryogenic environment[J]. Composites Part B, 2018, 145: 145-154. doi: 10.1016/j.compositesb.2018.03.027 [6] 李泽. 环氧树脂及其复合材料低温热膨胀性能研究 [D]. 哈尔滨工业大学, 2022.002020.LI Z. Study on low-temperature thermal expansion properties of epoxy resin and its composites [D]. Harbin Institute of Technology, 2022.002020 (in Chinese). [7] YU B, JIANG Z, TANG X, et al. Enhanced interphase between epoxy matrix and carbon fiber with carbon nanotube-modified silane coating[J]. Composites Science and Technology, 2014, 99(4): 131-140. [8] SONG B, WANG T, SUN H, etal. Graphitic carbon nitride (g-C3N4) Interfacially Strengthened carbon fiber epoxy composites[J]. Composites Science and Technology, 2018, 167: 515-521. doi: 10.1016/j.compscitech.2018.08.031 [9] CHEN W, YU Y, LI P, et al. Effect of new epoxy matrix for T800 carbon fiber/epoxy filament wound composites[J]. Composites Science and Technology, 2007, 67(11-12): 2261-2270. doi: 10.1016/j.compscitech.2007.01.026 [10] ZHANG Q, WU J, GAO L, et al. Dispersion stability of functionalized MWCNT in the epoxy–amine system and itseffects on mechanical and interfacial properties of carbon fiber composites[J]. Mater. Des, 2016, 94: 392-402. doi: 10.1016/j.matdes.2016.01.062 [11] GAO B, ZHANG R, HE M, et al. Effect of amultiscale reinforcement by carbon fiber surface treatment with graphene oxide/carbon nanotubes on the mechanical properties of reinforced carbon/carbon composites[J]. Composites Part A, 2016, 90: 433-440. doi: 10.1016/j.compositesa.2016.08.012 [12] LEE G, KO K, YU Y, et al. A facile method for preparing CNT-grafted carbon fibers and improved tensile strength of their composites[J]. CompositesPart A, 2015, 69: 132-138. doi: 10.1016/j.compositesa.2014.11.015 [13] GAO B, ZHANG R, WANG C, et al. Enhanced mechanical properties of carbon fibercomposites by grafting different structural poly(amido amine) onto fiber surface[J]. Polym. Test, 2016, 56: 192-199 doi: 10.1016/j.polymertesting.2016.10.019 [14] K A, PATHAK, BORAH M, et al. Improved mechanicalproperties of carbon fiber/graphene oxide-epoxy hybrid composites[J]. Composites Science and Technology, 2016, 135: 28-38. doi: 10.1016/j.compscitech.2016.09.007 [15] THITSARTARN W, FAN X, YANG S, et al. Simultaneous enhancement of strength and toughness of epoxy using POSS-Rubber core-shell nanoparticles[J]. Composites Science and Technology, 2015, 118: 63-71. doi: 10.1016/j.compscitech.2015.06.011 [16] POUR Z, GHAEMY M. Polymer grafted graphene oxide: for improved dispersion in epoxy resin and enhancement of mechanical properties of nanocomposite[J]. Composites Science and Technology, 2016, 136: 145-157. doi: 10.1016/j.compscitech.2016.10.014 [17] CAROLAN D, A J, Kinloch A, et al. Mechanical and fracture performance of carbon fiber reinforced composites with nanoparticle modified matrices[J]. Procedia Structural Integrity, 2016, 2: 096-103. doi: 10.1016/j.prostr.2016.06.013 [18] KOTHMAN M, ZEILER R, ANDA A, et al. Fatigue crack propagation behaviour of epoxy resins modified with silica-nanoparticles[J]. Polymer 2015, 60: 157–163. [19] GUPTA M, S A, SYDLIK J, et al. The effect of mixing methods on the dispersion of carbon nanotubes duringthe solvent-free processing of multiwalled carbon nanotube/epoxy composites[J]. Polym. Sci. Pol, 2013, 51(6): 410-420. doi: 10.1002/polb.23225 [20] WANG N, SHAO Y, SHI W, et al. Preparation and characterization of epoxy composites filled with functionalized nano-sized MCM-41 particles[J]. Mater Sci, 2008, 43: 3683-3688 doi: 10.1007/s10853-008-2591-4 [21] American Society of Testing Materials. Standard Test Method For Tensile properties of Plasticsv: ASTM-D638[S]. Philadelphia: ASTM, 2022. [22] ZHAO D, HUO Q, FENG J, etal. Nonionic Triblock and Star Diblock Copolymer and Oligomeric Surfactant Syntheses of Highly Ordered, Hydrothermally Stable, Mesoporous Silica Structures[J]. American Chemical Society, 1998, 120: 5024-6036 doi: 10.1021/ja972017w [23] ZhAO D, FENG J, HUO Q, et al. Triblock copolymer syntheses of mesoporous silica with periodic 50 to 300 angstrom pores.[J]. Science, 1998, 279(5350): 548-552 doi: 10.1126/science.279.5350.548 [24] CAI Q, LUO Z, PANG W, et al. Dilute solution routes to various controllable morphologies of MCM-4l silica with a basic medium[J]. Chemistry of Materials, 2001, 13(2): 258-263 doi: 10.1021/cm990661z [25] WU T, LIU Y, LI N, et al. Cryogenic mechanica properties of epoxy resin toughened by hydroxyl-terminated polyurethane[J]. Polym. Test, 2019, 74: 45-56. doi: 10.1016/j.polymertesting.2018.11.048 [26] YAO D, PENG N, ZHENG Y. Enhanced mechanical and thermal performances epoxy resin by oriented solvent-free graphene/carbon nanotube/Fe3O4 composite nanofluid[J]. Composites Science and Technology, 2018, 67: 234-242. [27] DITTANET P, A R, PEARSON. Effect of silica nanoparticle size on tougheningmechanisms of filled epoxy[J]. Polymer, 2012, 3(9): 1890-1905. [28] ZHANG J, Deng S, WANG Y, et al. Effect of nanoparticles on interfacial properties of carbon fiber epoxy composites[J]. Compos. Part A Appl. Sci. Manuf, 2013, 55: 35-44. doi: 10.1016/j.compositesa.2013.08.005 [29] FENG Q, DENG Y, XIAO H, et al. Enhanced cryogenic interfacial normal bond property between carbon fibers and epoxy matrix by carbon nanotubes[J]. Compos. Sci. Technol, 2014, 104: 59-65. doi: 10.1016/j.compscitech.2014.09.006 [30] DRESCHER P, THOMAS J, BORRIS J, et al. Strengthening fiber/matrix interphase by fiber surface modification and nanoparticle incorporation into the matrix[J]. Compos. Sci. Technol, 2013, 74: 60-66. doi: 10.1016/j.compscitech.2012.10.004 [31] 李稳, 陈蔚, 汤立群, 等, 基于纤维束增强树脂基复合材料测试的单向层合板层间剪切性能的预估方法[J]. 复合材料学报, 2018, 5(10): 2793-2803.LI W, CHEN W, TANG L, et al. A prediction method of interlaminar shear strength of unidirectional laminates based on fiber bundle reinforced polymer composites[J]. Acta Materiae Compositae Sinica, 2018, 35(10): 2793-2803(in Chinese). [32] MOHAMMAD S, PEARCE G, WANG C, et al. Toughening carbon fibre composites at cryogenic temperatures using low-thermal expansion nanoparticles[J]. Composites Part A: Applied Science and Manufacturing, 2021, 150: 106613. doi: 10.1016/j.compositesa.2021.106613 -

点击查看大图

点击查看大图

计量

- 文章访问数: 24

- HTML全文浏览量: 12

- 被引次数: 0

下载:

下载: