Study on impermeability of polymer modified repair mortar based on low field nuclear magnetic resonance technology

-

摘要:

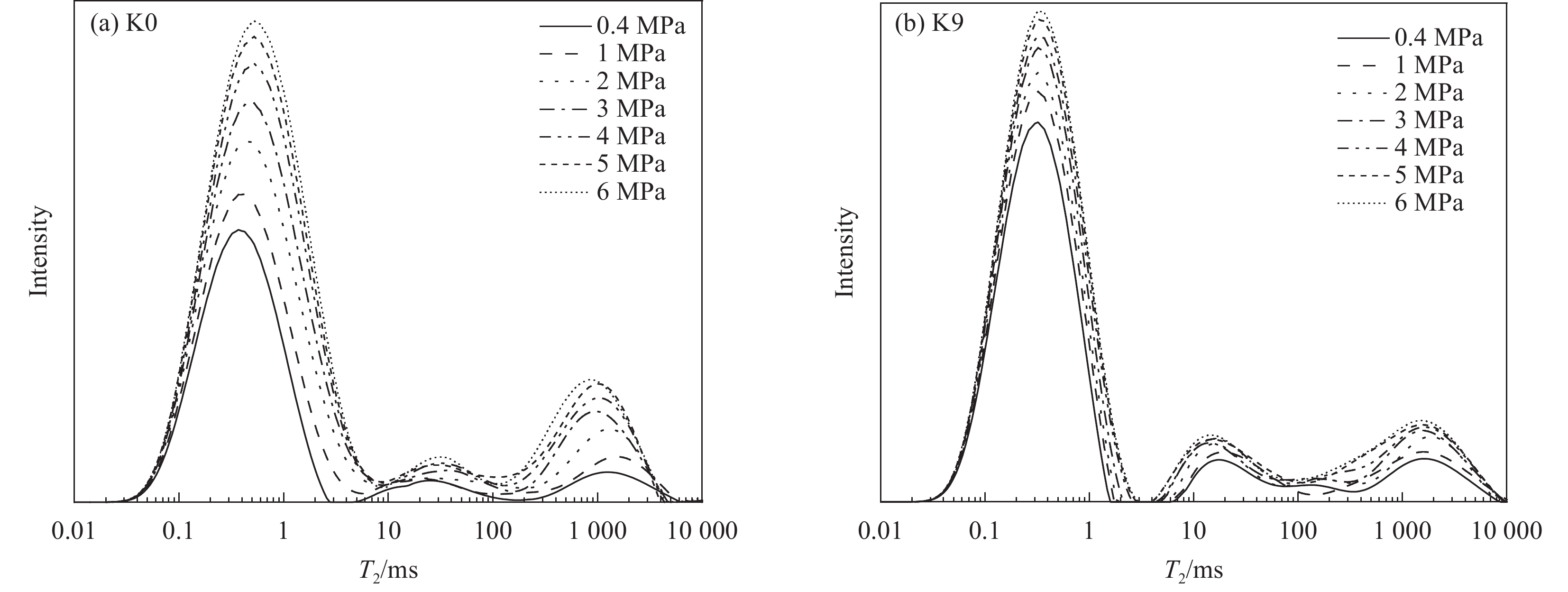

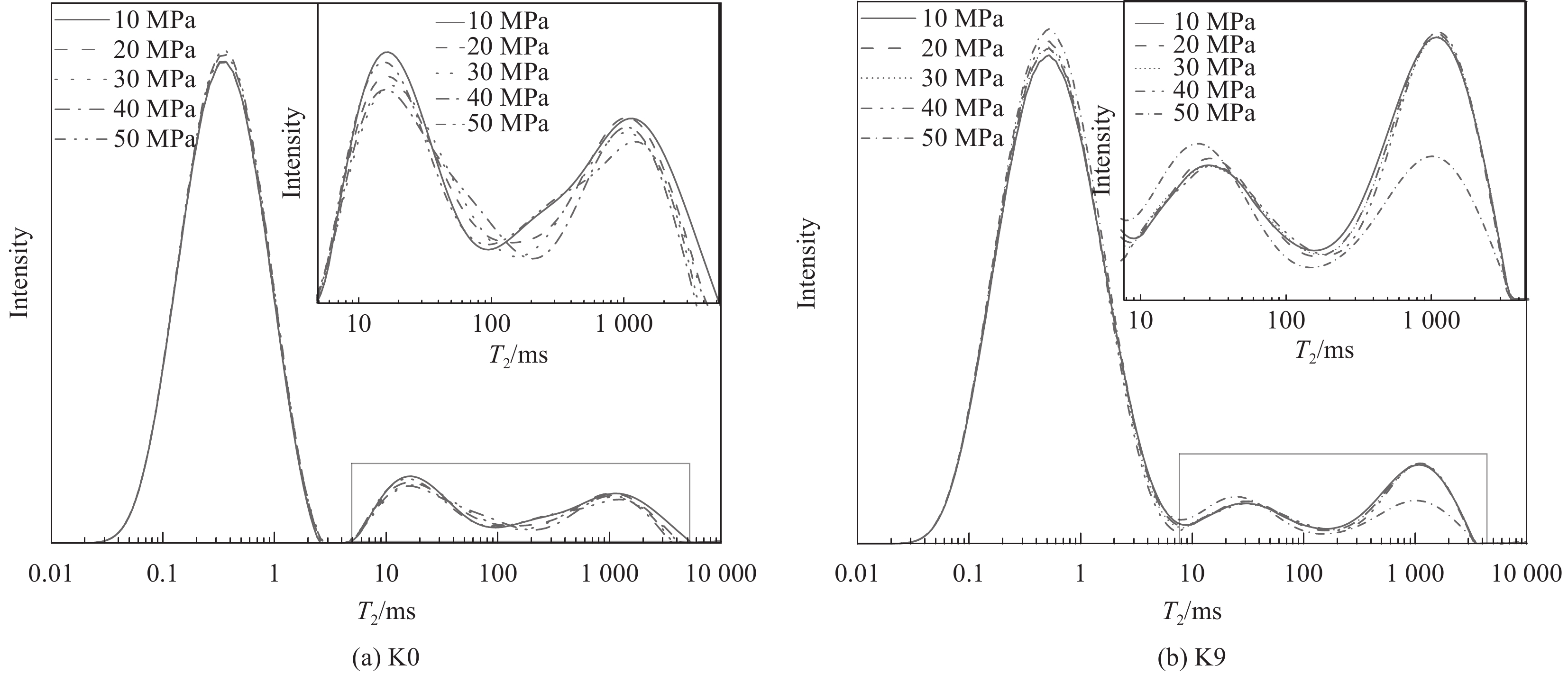

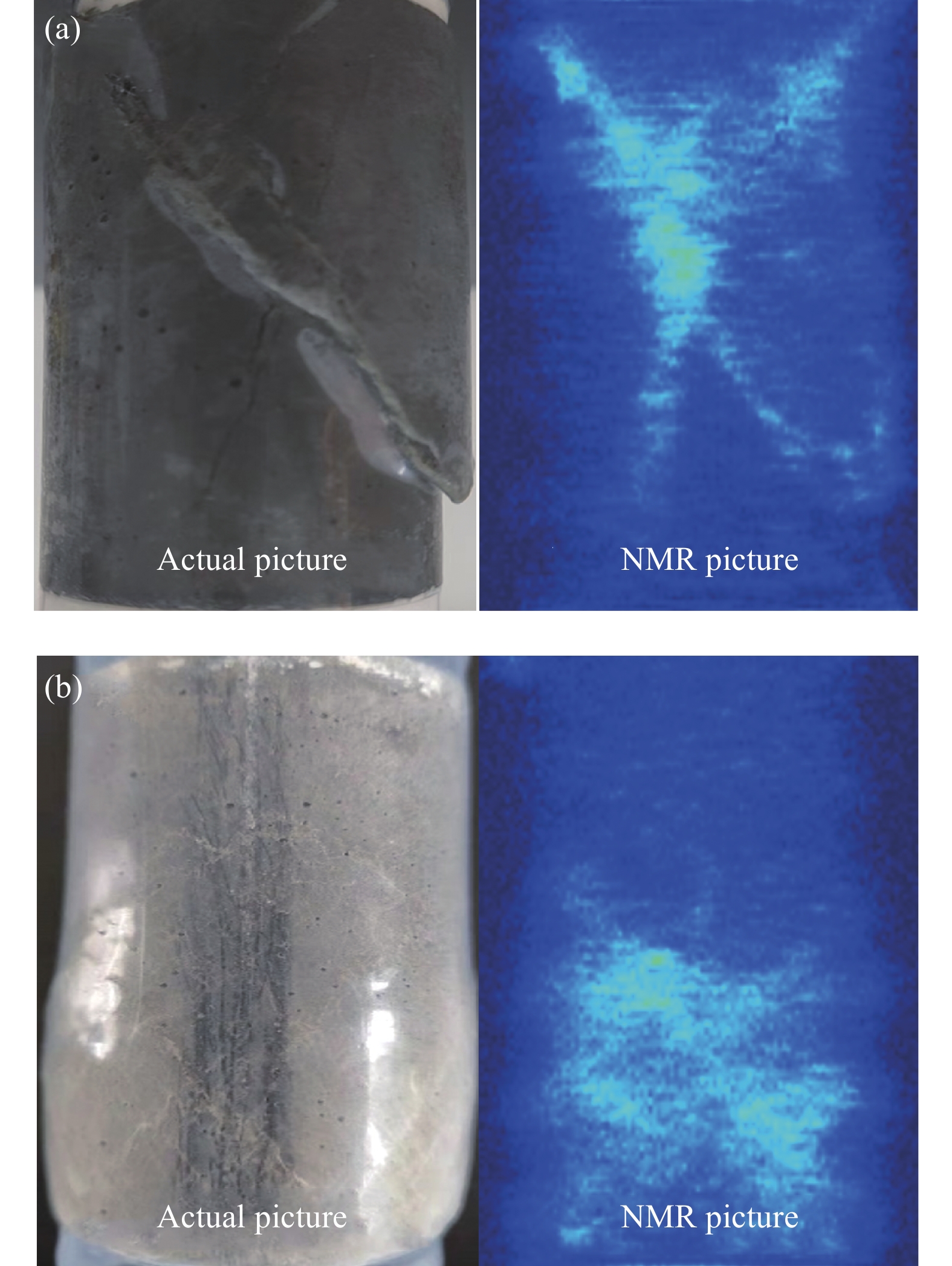

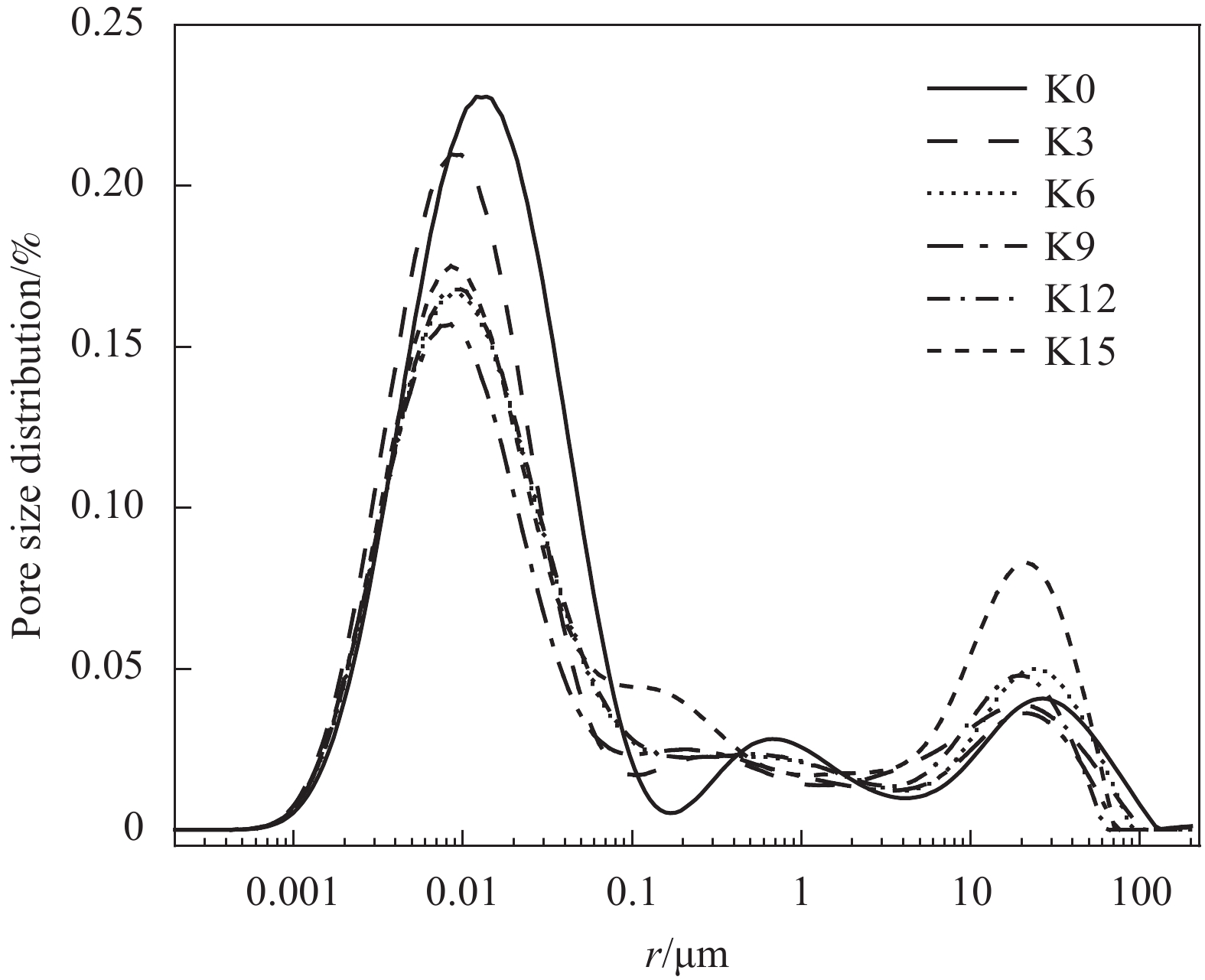

:1H低场核磁共振是通过氢原子能量变化分析水的分布和含量,一种快速、有效、无损的测试技术。通过三轴1H低场核磁共振获得了不同应力状态下可再分散乳胶粉(简称聚合物)改性修补砂浆中可蒸发水的横向弛豫时间(T2)和渗水量,据此分析了砂浆的抗渗性,并通过孔结构与微观形貌揭示了聚合物对砂浆可蒸发水横向弛豫特征的影响机制。研究表明:渗透压是修补砂浆横向弛豫时间和渗水量的主要影响因素,聚合物降低了不同渗透压下修补砂浆毛细孔和凝胶孔水的含量,6 MPa时渗水量降低57.3%,显著提升了修补砂浆的抗渗性能;聚合物提高了修补砂浆的韧性,三轴荷载作用下砂浆由交叉裂缝破坏变为压缩破坏,避免了砂浆在轴压作用下产生的抗渗性能突破。聚合物膜的阻隔和填充作用使砂浆孔隙率降低了3.28%,减弱了凝胶孔和毛细孔中的传输能力,从而降低了修补砂浆的横向弛豫强度和渗水量,提高了其抗渗性能。相较于传统的抗渗性检测方法,1H低场核磁共振可以表征水分的渗透过程,是一种切实可行的抗渗性检测方法。

Abstract:Low field 1H-nuclear magnetic resonance (NMR) is a quick, effective and nondestructive measuring technique to investigate the distribution and content of water by H-atom energy changes. Transverse relaxation time (T2) and seepage amount of redispersible polymer powder (polymer)-modified repair mortars were obtained by triaxial low field 1H-NMR, that was wont to analyze the permeability of the repair mortars. The mechanism of polymer influence on the transverse relaxation characteristics of repair mortars was explained by pore structure and micromorphology analysis. It’s shown that: Osmotic pressure is the main factor affecting the transverse relaxation time and seepage amount of mortar. Polymer reduces the water content in capillary and gel pores of repair mortar under different osmotic pressures, and the water seepage decreases by 57.3% at 6MPa, which significantly improves the impermeability of repair mortar. The polymer improves the toughness of the repair mortar, which makes the cross-cracking damage of mortar change into compression deterioration under three-axis loading conditions, thus avoiding the breakthrough of impermeability of the mortar under axial compression. The blocking and filling effect of polymer film reduces the porosity of mortar by 3.28%, and weakens the transmission ability in gel pores and capillary pores. Therefore, the transverse relaxation strength and water seepage of repair mortar are reduced, enhancing its impermeability. Compared with the traditional impermeability testing methods, low field 1H-NMR can characterize the water infiltration process and the seepage amount at different osmotic pressures, which is a practical impermeability testing method.

-

Keywords:

- low field NMR /

- transverse relaxation time /

- seepage amount /

- polymer /

- repair mortar /

- impermeability

-

表面活性剂是同时具有疏水基团和亲水基团的两亲性化合物,具有乳化、破乳、分散、絮凝、润湿、铺展、起泡、消泡、洗涤和杀菌等功能,被广泛应用于科学研究及石油开采、乳液聚合、食品、农业、纺织等工业领域[1-4]。出于合成角度考虑,一般希望得到结构稳定的表面活性剂,然而,在大多数实际应用中,表面活性剂往往只被需要在某一阶段发挥作用,当过程结束后,需要其失去活性或者从体系中轻易取出以减少残留导致的副作用[5-7]。另外,表面活性剂在用完后若直接排放到环境中,会造成巨大的资源浪费,还可能引起严重的环境污染而破坏生态平衡[8]。

解决这类问题的一个比较理想的办法就是采用刺激响应型表面活性剂取代传统的表面活性剂。刺激响应型表面活性剂在受到外界刺激时,其聚集形态、表面活性、溶解性、黏度和乳液稳定性会发生变化。如果这种变化可逆,即存在“开”与“关”两种状态,则该表面活性剂被认为具有开关性能[9-12]。与小分子表面活性剂相比,高聚物表面活性剂具有很好的乳化稳定性、在各种表/界面上有很好的吸附能力、优良的分散性和凝聚力,并且许多高聚物表面活性剂还具有良好的保水性、增稠性、成膜性及粘附性,更重要的是,大多数高分子表面活性剂是低毒的。

目前,开关型高聚物表面活性剂受到了普遍的关注[13-19]。研究结果表明,现有的表面活性剂还存在不少的问题,如pH开关型高分子表面活性剂在使用过程中需加入大量酸或碱,不仅会对环境造成污染,而且多次循环后也会因盐的累积而影响其性能;光开光型表面活性剂的应用受到了透明度的限制,因很多体系不透明,功能基团无法吸收特定波长的光做出响应或转变不彻底;热开光型表面活性剂需要较大的温度差,能耗大。因此,设计与开发成本低廉、工艺简单、性能优异的新型开关型高分子表面活性剂具有重大的意义。

CO2开关型高分子表面活性剂因其环境友好、可循环利用的优势而备受青睐[20-27]。但是,目前的研究发现,CO2开关型高分子表面活性剂存在合成复杂、价格昂贵且响应速度慢等缺点。此外,研究大多集中于探讨表面活性剂水溶液聚集结构的变化,而开关型乳液的研究较少;且多数高分子表面活性剂均采用嵌段等复杂的方式合成。

为了使操作简便,更适于实际应用,本实验采用廉价易得的单体甲基丙烯酸二乙氨基乙酯(DEAEMA)和乙烯基磺酸钠(SVS),通过简单的无规共聚的自由基聚合法制备出一种CO2开关型高分子表面活性剂,用于水/液体石蜡体系的乳化,研究了乳液的CO2开关性能和乳化机制,可为石油开采中利用开关型表面活性剂水溶液以乳液的形式提取石油并轻易破乳而分离得到石油提供借鉴。

1. 实验材料及方法

1.1 原材料

甲基丙烯酸二乙氨基乙酯(DEAEMA),AR,99%,阿拉丁试剂有限公司;乙烯基磺酸钠(SVS),25%水溶液,阿拉丁试剂有限公司;过硫酸铵(APS),AR,阿拉丁试剂有限公司;CO2,>99.999%,法国液化空气(中国)投资有限公司;N2,>99.999%,法国液化空气(中国)投资有限公司;液体石蜡,AR,国药集团试剂有限公司。

1.2 P(DEAEMA-SVS)聚合物粒子的合成

称取 20 mmol DEAEMA和20 mmol SVS置于干燥的100 mL三颈烧瓶中,加入20 mL去离子水,搅拌并升温至80℃,加入2wt%的APS,反应6 h。所得的粗产物用透析袋(MW 3500 Da)透析24 h,每6 h换一次水。将所得的水溶液冷冻干燥,得到最终产物P(DEAEMA-SVS)。改变单体DEAEMA和单体SVS的物料比例进行同样的实验步骤,得到不同投料比(摩尔比为4∶1,3∶1,2∶1,1∶1,1∶2,1∶3和1∶4)的产物作对比研究。

1.3 样品表征

利用JNM-ECA600 核磁共振仪(日本电子株式会社)测定聚合物粒子1H-NMR谱(C3D6O);采用18角激光光散射仪(DAMN HELEOSⅡ,美国Wyatt公司)测定聚合物的凝胶渗透色谱;采用Zetasizer Nano S90高灵敏纳米粒度分析仪(英国马尔文公司)通过动态光散射(DLS)的方法测聚合物粒径;用吊环法在KRUSS K100表面张力仪上测P(DEAEMA-SVS)水溶液的表面张力;用拉环法在KRUSS K100表面张力仪(德国克吕士科学仪器有限公司)上测定P(DEAEMA-SVS)水溶液与液体石蜡之间的界面张力。采用XPV-990E透反射偏光显微镜(上海长方光学仪器有限公司)和LSM780激光共聚焦显微镜(德国Zeiss公司)观察乳液液滴形态。

1.4 P(DEAEMA-SVS)乳液的制备

将聚合物P(DEAEMA-SVS)水溶液(1wt%)与液体石蜡按体积比1∶2两相混合,然后在超声细胞破碎仪(XC-CDS650,宁波市先倡电子科技有限公司)下超声乳化(450 W),其功率设置为60%,工作时间和间隔时间均设置为2 s,工作次数为8次。将制备好的乳液密封在室温下放置3周,通过直接观察法确定乳液的稳定性。通过液滴测试和电导率(DDSJ-308A电导率仪,上海精密科学仪器有限公司)测试确认乳液类型。

1.5 P(DEAEMA-SVS)乳液的开关性能测定

向P(DEAEMA-SVS)乳液中通入CO2(100 mL/min)30 min后静置30 min,观察乳液外观。在60℃下再向该体系通入N2(100 mL/min)30 min,待溶液降温至室温后,再用超声细胞破碎仪超声乳化。重复上述步骤4次,探究乳液的开关性能。同时探究不同P(DEAEMA-SVS)浓度对乳液稳定性及失稳的影响。

2. 结果与讨论

2.1 P(DEAEMA-SVS)的结构与分子量分布

将P(DEAEMA-SVS)聚合物溶解在氘代丙酮中,利用核磁共振仪测得其1H-NMR谱如图1所示:δ=1.8~2.1 ×10−6(1、2、3)处的化学位移为高分子主链上的C—CH2—C和C—CH—C;δ=4.00×10−6(4)处的化学位移为—COOCH2CH2中的O原子所连的亚甲基H;δ=2.75×10−6(5)处的化学位移为—COOCH2CH2中远离氧原子的亚甲基H;δ=2.55×10−6(6)处的化学位移为—N(CH2CH3)2中的亚甲基H;δ=1.1×10−6(7)处的化学位移为—N(CH2CH3)2中的甲基H;δ=0.9×10−6(8)处的化学位移为高分子主链上的甲基H。

P(DEAEMA-SVS)聚合物的凝胶渗透色谱(GPC)测试结果显示合成的该物质为高分子化合物,其数均分子量为5.262×104,均重分子量为3.857×103,Z均分子量为9.466×104。其分子量分布为:40000~45000(29.22%)、45 000~50 000(24.36%)、50 000~60 000(25.70%)、60 000~80 000(12.11%)、100 000~200 000(3.62%)、200 000~400 000(1.62%),如图2所示。

2.2 不同投料比对P(DEAEMA-SVS)乳液稳定性的影响

单体投料比例不同时,所合成的聚合物粒子粒径会有差别,而粒径过大会使形成的乳液不稳定,粒径过小会使所形成的乳液不易破乳,因此选择合适尺寸的聚合物显得尤为重要。利用动态光散射原理,测定频率位移,由Stokes-Einstein方程计算得出颗粒粒径及分布。图3为不同投料比(DEAEMA和SVS单体摩尔比为4∶1,3∶1,2∶1,1∶1,1∶2,1∶3和1∶4)所得产物的尺寸及粒径分布。当单体DEAEMA和单体SVS的投料摩尔比为1∶1时,聚合物粒子的粒径约为113 nm。随着单体SVS投料比的增加(2∶1→1∶4),聚合物粒径在一定的范围内(60~115 nm)稳定且粒径分布(PDI)较窄。

将不同摩尔比单体投料所合成的聚合物分别配置成质量比为1%的水溶液,测得这些物质的表面张力如图4所示。用该仪器测得纯水的表面张力为74 mN/m。可以发现,不同单体配比投料所合成的聚合物均具有表面活性,都能降低水的表面张力。其中单体DEAEMA和单体SVS比例为1∶1和1∶2合成的聚合物活性更强,能够明显地降低水的表面张力至37.279 mN/m 和35.820 mN/m。

除表面张力外,不同单体配比投料所合成的聚合物粒子对油水界面的吸附能力也是有很大的差别,而其在油水界面吸附的能力的大小会直接影响所形成乳液的稳定性。采用液体石蜡作为油相,研究不同单体配比投料所合成的聚合物水溶液与液体石蜡之间的界面张力(图4)。用该仪器测得纯水与液体石蜡直接的界面张力为66.231 mN/m。相对于其他单体配比,单体配比为1∶1和1∶2时,所得聚合物在油水界面上的吸附能力更强,能将界面张力降至5.492 mN/m和4.994 mN/m。这两种单体配比投料所得聚合物的界面张力值大幅下降,说明这两种聚合物具有很强的表面活性和界面活性,为形成稳定的乳液提供了可能,P(DEAEMA-SVS)聚合物能作为唯一乳化剂稳定乳液。

根据以上数据的分析,不同单体比例投料所合成的聚合物无论是粒径大小还是表面/界面活性都有着很大的差异。聚合物表面活性剂中所含亲/疏水单体基团比例的不同会导致HLB值存在差异,进而引起乳化性能的改变。当DEAEMA∶ SVS为2∶1时,所合成的聚合物粒子的表面张力和界面张力均略低于DEAEMA和SVS的投料摩尔比为1∶1时所合成的聚合物粒子,但作为唯一乳化剂制备的乳液在静置3周后会分出水层,而当DEAEMA∶ SVS=1∶1所合成聚合物粒子的乳液却更稳定。因此接下来选择DEAEMA∶ SVS=1∶1时所合成聚合物粒子形成的乳液进行乳化性能和开关性能的研究。

2.3 P(DEAEMA-SVS)的乳化性能

用P(DEAEMA-SVS)聚合物作为唯一乳化剂制备了水/液体石蜡的乳液,所制备的初始乳液的外观均一,没任何分层或分水分油现象。将得到的乳液取一滴滴入清水中,发现乳液滴能在水中迅速分散;并用电导率仪测得该乳液的电导率为120 μS/cm,其值远大于10 μS/cm,证明用P(DEAEMA-SVS)聚合物制备的水/液体石蜡乳液是水包油(O/W)型。将制备好的P(DEAEMA-SVS)乳液在室温下密封静置3周,发现乳液未出现分层现象,如图5所示。图6为乳液的显微镜照片。可以发现放置三周的乳液与原始乳液的乳液液滴大小并没有明显差别。由此说明P(DEAEMA-SVS) 是一种非常有效的高分子表面活性剂。

将不同浓度的P(DEAEMA-SVS)水溶液与液体石蜡混合形成乳液,将乳液静置一段时间后观察乳液的外观变化,如图7所示。当表面活性剂P(DEAEMA-SVS)浓度低于0.2wt%时,虽然也能形成乳液,但其乳液有明显的分层,这是由于浓度较低时形成的乳液液滴粒径较大,而液体石蜡的密度较小,引出液滴在浮力的作用下集中在上层,其水相也不是澄清的,说明仍有P(DEAEMA-SVS)颗粒存在于水相中;而当其浓度大于0.2wt%时,均能形成稳定均一的乳液。

不同的油水比例对乳液稳定性也存在影响。当液体石蜡与水的比例小于1∶1时,均能形成稳定的乳液。但当液体石蜡与水的比例超过1∶1时,虽然也能形成乳液,如图8(b)所示,但该乳液无法一直稳定为均一相,放置一段时间后液滴将上浮分层,下层水相不澄清(图8(a)),说明当液体石蜡的量大于50%时形成的乳液不稳定。

2.4 P(DEAEMA-SVS)乳液的开关性能

在室温下,向聚合物P(DEAEMA-SVS) 水/液体石蜡的乳液体系中通入CO2 10 min后,发现有明显的油层析出,继续通CO2至30 min后乳液完全破乳,溶液回到初始的两相状态,且油水界线清晰。CO2的加入使聚合物侧链上的叔胺基团质子化从而增加了聚合物的水溶性,使聚集缠绕的聚合物链快速分散并向水相中迅速迁移,因而无法吸附在油水界面上。由于P(DEAEMA-SVS)在发生质子化作用后,其水溶性增大使其在破乳后完全存在于水相中,因此不仅不会对油相造成污染而且更有利于回收和再次利用。

破乳后的体系在60℃温度下,通入N2 30 min后,发现油水两层的界面开始模糊,油相变浑浊。待体系降温至室温后,将该体系经细胞粉碎机乳化后又可再次获得稳定的乳液。N2的加入排出了CO2,使叔胺基团发生去质子化反应,分散的聚合物链再次形成聚集缠绕的结构并从水中析出,吸附在油水界面上。由此看出P(DEAEMA-SVS)粒子(1wt%)制备的水/液体石蜡乳液具有非常好的CO2开关性能,并且上述通CO2破乳/通N2再乳化的过程可重复多次,多次循环过程中制备的乳液完全相同,图9为P(DEAEMA-SVS)聚合物粒子(1wt%)制备的水/液体石蜡乳液对CO2/N2的刺激响应及3次破乳/再乳化过程。

图10为液体石蜡与水的比例对聚合物P(DEAEMA-SVS) 水/液体石蜡乳液失稳破乳的影响。由图10(a)可以看出,当油水比小于1∶1时乳液均具有良好的稳定性。向乳液中通入CO2 30 min后,乳液能快速破乳实现油水分离,表明乳液的破乳与液体石蜡与水的比例无关。

图11为在同一油水比例下不同浓度的P(DEAEMA-SVS)水溶液与液体石蜡形成的乳液破乳10 min时的情况。随着P(DEAEMA-SVS) 水溶液浓度的升高,其所含的聚合粒子增多,使乳液对CO2的响应速率及响应能力不同。可知,由不同浓度的P(DEAEMA-SVS)水溶液制备的乳液均能破乳实现油水分离(图11(b)),但破乳的速率不同。当向体系内通入CO2 10 min后,可以看到低浓度(0.025wt%)的乳液已经完全破乳,油水几乎完全分离。而高浓度的乳液需要更长的破乳时间。P(DEAEMA-SVS)浓度大于0.8wt%所形成的乳液需要通CO2 30 min才能完全破乳,并且破乳后水溶液的乳白色也比低浓度的深。实验结果表明,聚合物的浓度一定程度上会减慢乳液的破乳速率,但均可以实现完全破乳。由此说明,该聚合物P(DEAEMA-SVS) 表面活性剂能与水/液体石蜡形成CO2开关型乳液。

2.5 P(DEAEMA-SVS)乳液的乳化和破乳机制

图12为P(DEAEMA-SVS)水/液体石蜡乳液的乳化和破乳机制。聚合物P(DEAEMA-SVS)因其高分子侧链上的叔胺基团的疏水性,聚集缠绕成小球并能吸附在油水界面上,使液体石蜡以液滴的形式均匀地分散在水相中,形成稳定的水包油型(O/W型)乳液。

当向溶液中通入CO2,使水中产生大量的H+与叔胺基团发生质子化反应形成亲水的季铵盐,增大了聚合物的亲水性,改变了物质本身的水油平衡,降低了物质的表面活性,从而使高分子链在静电斥力的作用下分散并将高分子链迁移至水中,油水界面遭到破坏,乳液的液滴相互兼并,最终引起油水两相分离,使乳液破乳。在60℃温度下,通入N2可将CO2去除,这使聚合物侧链上的叔胺基团发生去质子化作用,重新回到原来疏水的状态,并聚集缠绕成球状再次吸附在油水界面上,再次形成稳定的乳液。

3. 结 论

(1) 制备了CO2开关型聚合物P(DEAEMA-SVS)表面活性剂,能有效降低水的表面张力和水/液体石蜡的界面张力。DEAEMA/SVS单体投料比为1∶1 (摩尔比)时,形成的聚合物粒子粒径分布窄,可将水的表面张力降低至37.279 mN/m,将水/液体石蜡的界面张力降低至5.492 mN/m,其表面活性和界面活性均很强,可作为唯一乳化剂稳定乳液。

(2) 聚合物P(DEAEMA-SVS)表面活性剂水溶液可与液体石蜡形成稳定且灵敏的CO2开关型乳液。通入CO2 30 min可使乳白色的P(DEAEMA-SVS) 乳液破乳变为澄清态;在60℃下通入N2能快速地去除CO2,使溶液变回原始状态再乳化。通CO2破乳/通N2再乳化的过程可重复进行。由P(DEAEMA-SVS)粒子(1wt%)制备的水/液体石蜡乳液具有非常好的CO2开关响应性能,且该开关性能是可循环的。

(3) P(DEAEMA-SVS)表面活性剂因其侧链上的叔胺基团的疏水性,可与水/液体石蜡形成水包油型乳液。在CO2的作用下,叔胺基团发生质子化作用形成亲水的季铵盐,乳液的油水界面遭破坏且两相分离而破乳。60℃温度下通入N2可去除CO2,使聚合物侧链上的叔胺基团去质子化重新形成疏水性聚集球体吸附在油水界面上,再次稳定乳液。

-

表 1 水泥的化学组成

Table 1 Chemical compositions of cement

SiO2 Al2O3 Fe2O3 CaO MgO SO3 Na2O f-CaO Loss 20.6 4.57 3.29 63.27 2.59 2.11 0.55 0.76 2.15 表 2 水泥物理力学性能

Table 2 Physical and mechanical properties of cement

Setting time/min Flexural strength/MPa Compressive strength/MPa Initial set Final set 3 d 7 d 28 d 3 d 7 d 28 d 128 196 5.3 6.4 8.5 26 35.9 45.6 表 3 聚合物改性修补砂浆配合比

Table 3 Mix proportion of polymer modified repair mortar

Specimen No. Cement/g Sand/g Superplasticizer/g Defoamer/g Water/g Polymer/g K0 100 200 0.2 0.5 35 0 K3 100 200 0.2 0.5 35 3 K6 100 200 0.2 0.5 35 6 K9 100 200 0.2 0.5 35 9 K12 100 200 0.2 0.5 35 12 K15 100 200 0.2 0.5 35 15 表 4 不同渗透时间修补砂浆渗水量

Table 4 Seepage amount of repaired mortar at different times

5 min 10 min 15 min 20 min 25 min 30 min K0 0.4% 0.71% 1.02% 1.29% 1.54% 1.72% K9 0.05% 0.13% 0.18% 0.22% 0.24% 0.27% 表 5 不同渗透压修补砂浆渗水量

Table 5 Seepage amount of repaired mortar at different infiltration times

1 MPa 2 MPa 3 MPa 4 MPa 5 MPa 6 MPa K0 1.59% 3.1% 3.9% 4.26% 4.68% 5.34% K9 0.57% 0.97% 1.48% 1.79% 2.02% 2.28% 表 6 不同轴压修补砂浆渗水量

Table 6 Seepage amount of repairing mortar under different coaxial pressure

20 MPa 30 MPa 40 MPa 50 MPa K0 0.03% −0.03% −0.11% −0.38% K9 −0.08% −0.13% −0.12% −0.03% 表 7 聚合物掺量对修补砂浆孔隙率的影响

Table 7 Influence of polymer content on porosity of repair mortar

K0 K3 K6 K9 K12 K15 Porosity/% 10.73 9.25 8.53 7.45 8.49 9.84 -

[1] 陈立军, 王永平, 尹新生, 等. 混凝土孔径尺寸对其抗渗性的影响[J]. 硅酸盐学报, 2005, (4): 500-505. DOI: 10.3321/j.issn:0454-5648.2005.04.017 CHEN Lijun, WANG Yongping, YIN Xinsheng, et. al. Effect of aperture size on impermeability of concrete[J]. Journal of the Chinese Ceramic Society, 2005, (4): 500-505(in Chinese). DOI: 10.3321/j.issn:0454-5648.2005.04.017

[2] 于琦, 万小梅, 赵铁军, 等. 碱激发矿渣混凝土抗氯离子渗透性及电测试验方法研究[J]. 材料导报, 2022, 36(5): 100-105. DOI: 10.11896/cldb.20120067 YU Qi, WAN Xiaomei, ZHAO Tiejun, et. al. Investigation on resistance of chloride penetration of alkali activated slag concrete and related electrical test methods[J]. Materials Review, 2022, 36(5): 100-105(in Chinese). DOI: 10.11896/cldb.20120067

[3] Valckenborg R M E, Pel L, Hazrati K. Pore water distribution in mortar during drying as determined by NMR[J]. Materials and Structures, 2001, 34(244): 599-604.

[4] Heijden G, Bijnen R, Pel L, et. al. Moisture transport in heated concrete, as studied by NMR, and its consequences for fire spalling[J]. Cement & Concrete Research, 2007, 37(6): 894-901.

[5] Bohris A J, Goerke U, Mcdonald P J, et. al. A broad line NMR and MRI study of water and water transport in Portland cement pastes[J]. Magnetic Resonance Imaging, 1998, 16(5-6): 455-461. DOI: 10.1016/S0730-725X(98)00072-1

[6] Zhang A, Yang W, Ge Y, et. al. Study on the hydration and moisture transport of white cement containing nanomaterials by using low field nuclear magnetic resonance[J]. Construction and Building Materials, 2020, 249: 118788. DOI: 10.1016/j.conbuildmat.2020.118788

[7] 程福周, 雷学文, 孟庆山, 等. 基于核磁共振技术的疏浚淤泥固化土孔隙水含量及分布研究[J]. 长江科学院院报, 2016, 33(10): 116-120. CHENG Fuzhou, Lei Xuewen, Meng Qingshan, et. al. Pore water content of solidified dredging silt and its distribution based on nuclear magnetic resonance[J]. Journal of Yangtze River Scientific Research Institute, 2016, 33(10): 116-120(in Chinese).

[8] Chen Shi, Xiwen Zou, Liu Yang, Ping Wang, et. al. Influence of humidity on the mechanical properties of polymer-modified cement-based repair materials[J]. Construction and Building Materials, 2020, 261(2): 119928.

[9] 阎培渝, 岳蕾, 代丹, 等. 无固化剂环氧树脂乳液对油井水泥早期水化的影响[J]. 硅酸盐学报, 2017, 45(5): 608-613. YAN Peiyu, YUE Lei, DAI Dan, et. al. Influence of epoxy resin emulsion without curing agent on hydration of oil well cement in early age[J]. Journal of the Chinese Ceramic Society, 2017, 45(5): 608-613(in Chinese).

[10] Peng Y, Zhao G, Qi Y, et. al. In-situ assessment of the water-penetration resistance of polymer modified cement mortars by μ-XCT, SEM and EDS[J]. Cement and Concrete Composites, 2020, 114: 103821. DOI: 10.1016/j.cemconcomp.2020.103821

[11] Nirrupama K I, Gujar P, Ashwin K N, et. al. Interfacial adhesion mechanism between organic polymer coating and hydrating cement paste[J]. Cement and Concrete Composites, 2020, 115.

[12] 梅军鹏, 徐智东, 李海南, 等. 纳米粒子/聚合物对水泥基材料强度和抗渗性的影响[J]. 功能材料, 2021, 52(12): 12184-12189. DOI: 10.3969/j.issn.1001-9731.2021.12.028 MEI Junpeng, XU Zhidong, LI Hainan, et. al. Effects of nanoparticle/polymer composites on strength and impermeability of cement-based materials[J]. Journal of Functional Materials, 2021, 52(12): 12184-12189(in Chinese). DOI: 10.3969/j.issn.1001-9731.2021.12.028

[13] 李国忠, 张水. 聚合物水泥基灌浆材料的性能研究[J]. 建筑材料学报, 2010, 13(6): 744-748. DOI: 10.3969/j.issn.1007-9629.2010.06.008 LI Guozhong, ZHANG Shui. Study on the property of polymer cement-based grouting material[J]. Journal of Building Materials, 2010, 13(6): 744-748(in Chinese). DOI: 10.3969/j.issn.1007-9629.2010.06.008

[14] 全国水泥标准化技术委员会. 水泥胶砂强度检验方法(ISO法)[J]. 2021. National Technical Committee for Cement Standardisa tion. Test method of cement mortar strength (ISO method)[J]. 2021(in Chinese).

[15] 李文郁, 尹健昊, 王健, 等. 低场核磁共振技术在水泥基材料中的理论模型及应用[J]. 硅酸盐学报, 2022, 50(11): 2992-3008. LI Wenyu, YIN Jianhao, WANG Jian, et. al. Principles and applications of low-field nuclear magnetic resonance in cementitious materials[J]. Journal of the Chinese Ceramic Society, 2022, 50(11): 2992-3008(in Chinese).

[16] 杨正宏, 高双双, 于龙, 等. 养护温度对陶粒内水分向水泥浆体中迁移行为的影响[J]. 建筑材料学报, 2020, 23(1): 138-144. DOI: 10.3969/j.issn.1007-9629.2020.01.021 YANG Zhenghong, YU Long, GAO Shuangshuan, et. al. Effect of curing temperature on migration of water from ceramsite to cement paste[J]. Journal of Building Materials, 2020, 23(1): 138-144(in Chinese). DOI: 10.3969/j.issn.1007-9629.2020.01.021

[17] 佘安明, 姚武. 基于低场核磁共振技术的水泥浆体孔结构与比表面积的原位表征[J]. 武汉理工大学学报, 2013, 35(10): 11-15. DOI: 10.3963/j.issn.1671-4431.2013.10.003 SHE An-ming, YAO Wu. Characterization of microstructure and specific surface area of pores in cement paste by low field nuclear magnetic resonance technique[J]. Journal of Wuhan University of Technology, 2013, 35(10): 11-15(in Chinese). DOI: 10.3963/j.issn.1671-4431.2013.10.003

[18] Xue S, Meng F, Zhang P, et. al. Influence of water re-curing on microstructure of heat-damaged cement mortar characterized by low-field NMR and MIP[J]. Construction and Building Materials, 2020, 262: 120532. DOI: 10.1016/j.conbuildmat.2020.120532

[19] 刘大智, 沈化荣, 储洪强, 等. 聚合物水泥砂浆的力学性能与微观机理研究[J]. 南京航空航天大学学报, 2010, 42(6): 802-805. DOI: 10.3969/j.issn.1005-2615.2010.06.025 Liu Dazhi, Shen Huarong, Chu Hongqiang, et. al. Mechanical properties and microscopic mechanism of polymer modified mortar[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2010, 42(6): 802-805(in Chinese). DOI: 10.3969/j.issn.1005-2615.2010.06.025

[20] 王茹, 许运东. 养护温度对丁苯乳液/硫铝酸盐水泥砂浆物理力学性能的影响[J]. 硅酸盐学报, 2017, 45(2): 227-234. WANG Ru, XU Yundong. Influence of curing temperature on physical and mechanical properties of styrene-butadiene rubber latex/sulphoaluminate cement mortar[J]. Journal of the Chinese Ceramic Society, 2017, 45(2): 227-234 (in Chinese).

[21] 王培铭, 赵国荣, 张国防. 可再分散乳胶粉在水泥砂浆中的作用机理[J]. 硅酸盐学报, 2018, 46(2): 256-262. WANG Peiming, ZHAO Guorong, ZHANG Guofang. Mechanism of redispersible polymer powder in cement mortar[J]. Journal of the Chinese Ceramic Society, 2018, 46(2): 256-262 (in Chinese).

[22] Mehta P K, Monteiro P J M. Concrete: Microstructure, Properties, and Material[M]. McGraw-Hill Publishing, 01.

[23] Pang Bo, Jia Yantao, Pang Sze Dai, et. al. The interpenetration polymer network in a cement paste–waterborne epoxy system[J]. Cement and Concrete Research, 2021, 139: 106236. DOI: 10.1016/j.cemconres.2020.106236

[24] 高乙博, 罗健林, 李治庆, 等. 正交优化纤维聚合物修补防护砂浆配比及其综合性能实现机制[J]. 复合材料学报, 2023, 40(9): 5258-5275. GAO Yibo, LUO Jianlin, LI Zhiqing, et. al. Orthogonal optimization mix ratio of fiber polymer repair protect mortar and its comprehensive performance realization mechanism[J]. Acta Materiae Compositae Sinica, 2023, 40(9: 5258-5275 (in Chinese)

-

期刊类型引用(10)

1. 翟兆阳,李欣欣,张延超,刘忠明,杜春华,张华明. 连续光纤激光切割金属薄壁材料工艺研究. 红外与激光工程. 2024(02): 33-43 .  百度学术

百度学术

2. 陶洋,李存静,逄增媛,张典堂. 展宽布/网胎针刺C/C复合材料制备及力学性能. 复合材料学报. 2024(04): 1934-1944 .  本站查看

本站查看

3. 董志刚,王中旺,冉乙川,鲍岩,康仁科. 碳纤维增强陶瓷基复合材料超声振动辅助铣削加工技术的研究进展. 机械工程学报. 2024(09): 26-56 .  百度学术

百度学术

4. 席翔,李海龙,陈友元,裴景奇,廖城坤,薛琳,储洪强,冉千平. 碳纤维增强碳基复合材料的介电性能对应力的自感知. 高分子材料科学与工程. 2024(05): 115-124 .  百度学术

百度学术

5. 钱奇伟,张昕,杨贞军,沈镇,校金友. 基于CT图像深度学习的三维编织C/C复合材料微观组分与缺陷智能识别. 复合材料学报. 2024(07): 3536-3543 .  本站查看

本站查看

6. 翟兆阳,李欣欣,张延超,刘忠明,杜春华,张华明. 基于正交试验的金属薄壁材料激光切割工艺优化. 中国机械工程. 2024(07): 1279-1289 .  百度学术

百度学术

7. 何金玲. 纤维复材浆料流变性能分析及矿混匀质量应用研究. 粘接. 2024(09): 87-90 .  百度学术

百度学术

8. 姚先龙. 碳基复合材料的应用及相关制备方法. 信息记录材料. 2023(01): 36-38 .  百度学术

百度学术

9. 石磊,罗浩,罗瑞盈. 胶层厚度对C/C复合材料剪切粘接性能的影响. 炭素技术. 2023(04): 22-26 .  百度学术

百度学术

10. 刘科众,陈舟,王泽鹏,韩保恒. C/C复合材料增密过程孔隙结构及演化研究. 机械设计与制造工程. 2022(10): 33-36 .  百度学术

百度学术

其他类型引用(10)

-

目的

水泥基材料渗透性和耐久性密切相关。目前,水泥基材料的抗渗测试有抗水渗透试验和抗氯离子渗透试验两种方法。这两种方法仅能测得水或离子的渗透结果,无法全面分析渗透过程,因此难以提供足够的数据分析水泥基材料抗渗性能。聚合物改性水泥基材料是一种有机-无机复合材料,具有高韧性、强粘结力和优异的抗渗性能。深入了解水在修补材料中的渗透过程,对揭示聚合物改性机理至关重要。H低场核磁共振是通过氢原子能量变化分析水的分布和含量,可快速、高效、无损的测试水在修补材料的渗透过程。相较于传统的抗渗性检测方法,H低场核磁共振可以表征水分的渗透过程和渗水量,是一种切实可行的抗渗性检测方法。

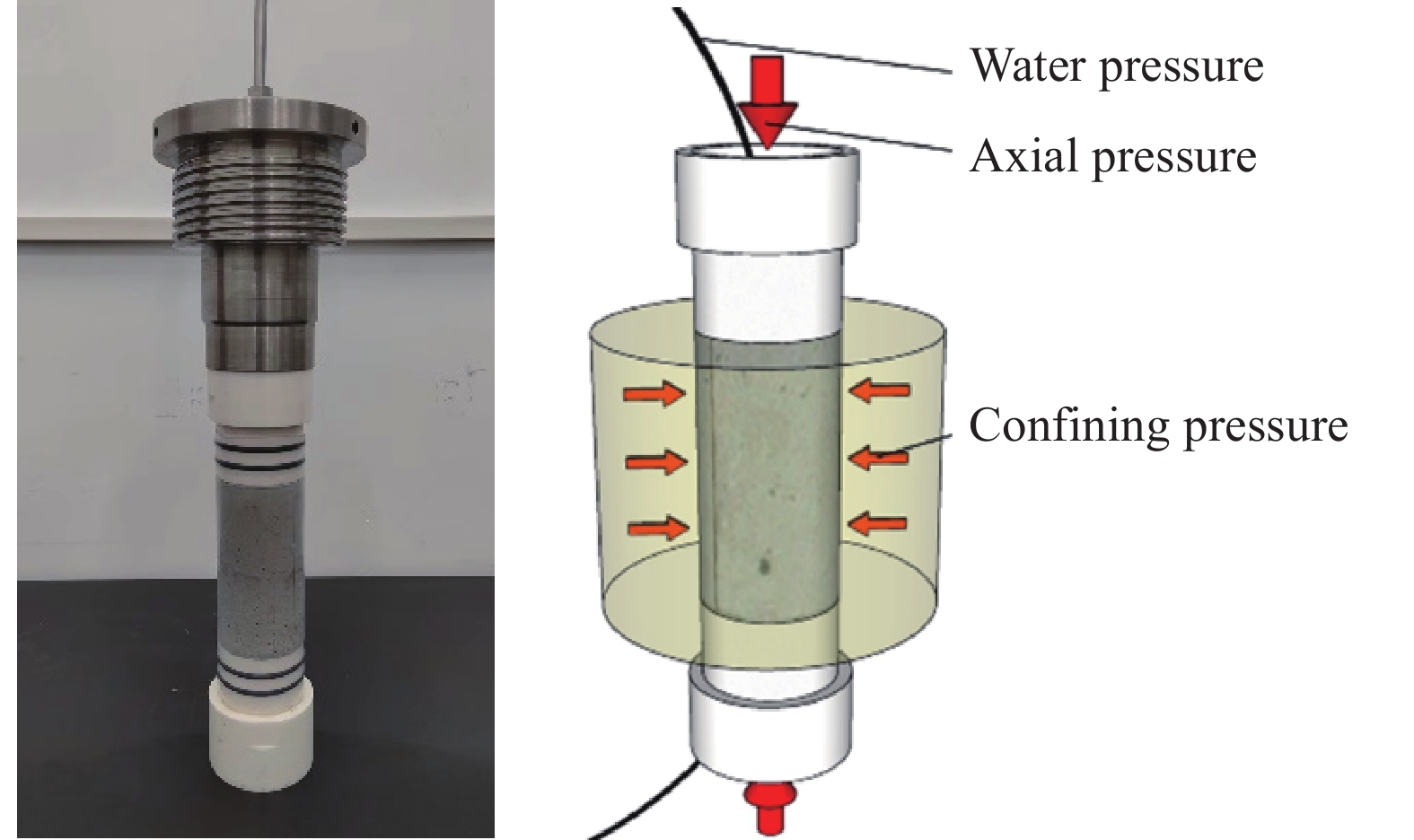

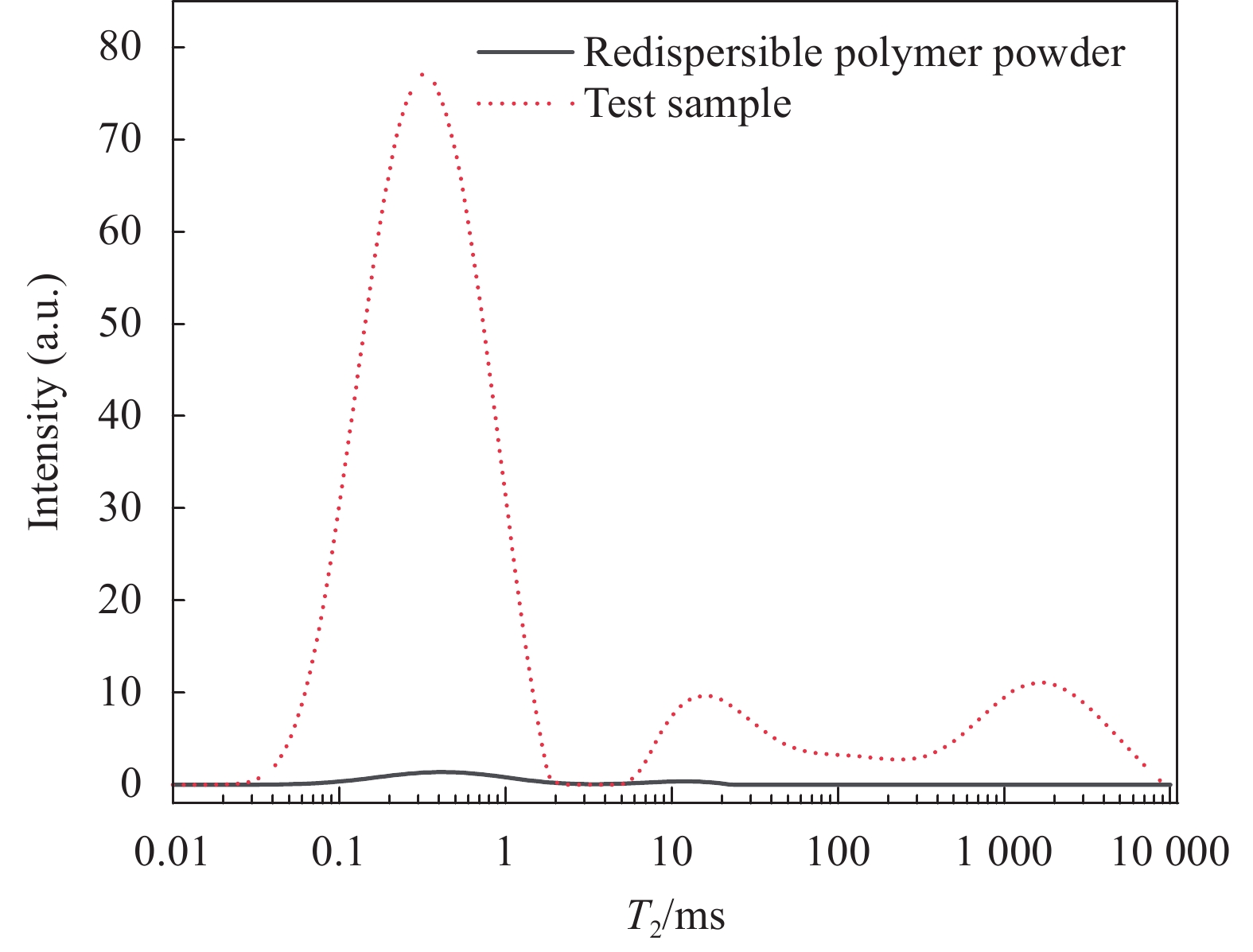

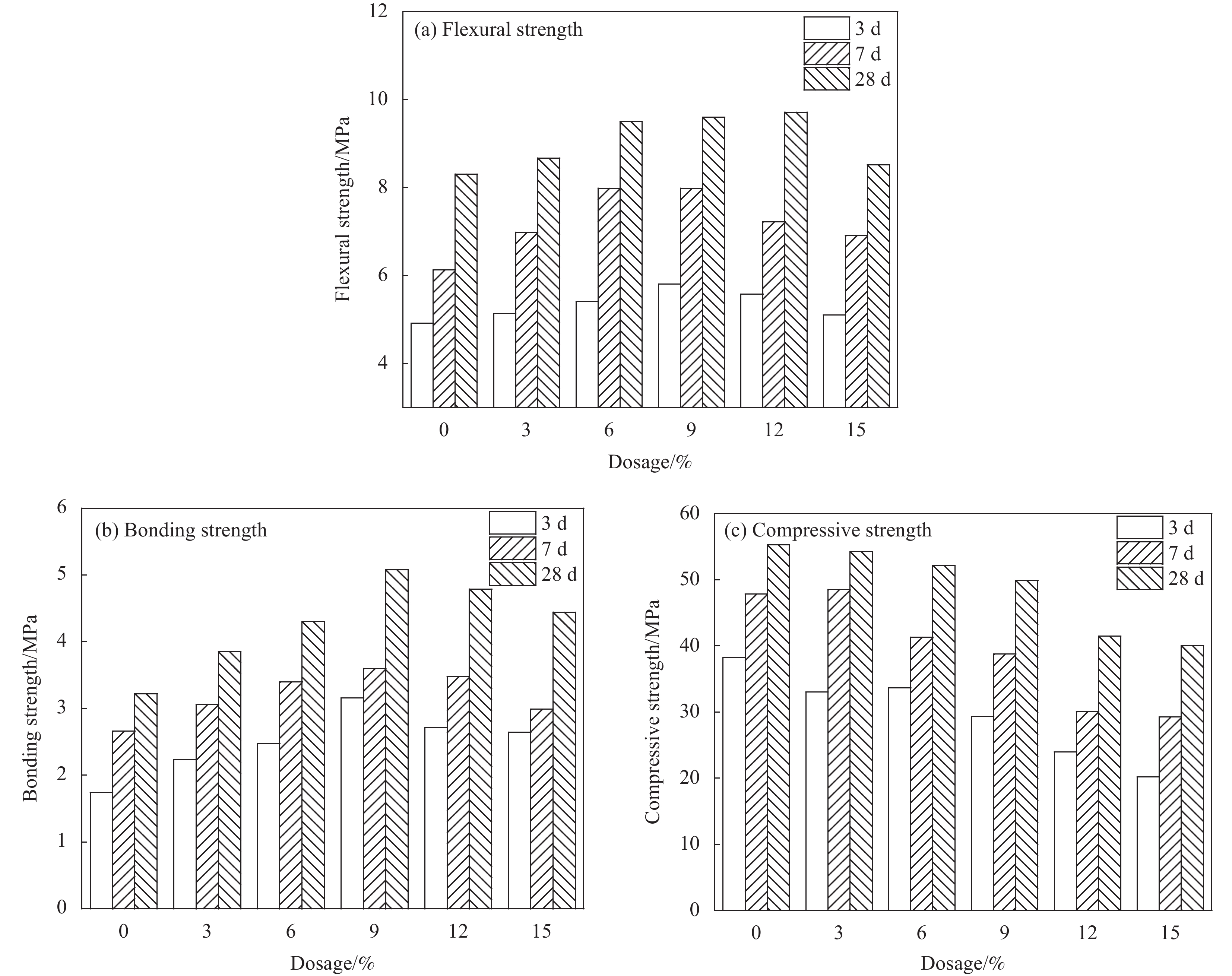

方法首先设计胶砂比为1:2,水灰比为0.35的修补砂浆,研究了0、3%、6%、9%、12%、15%水泥质量的聚合物对修补砂浆的抗折强度、抗压强度和粘结强度的影响。通过1H低场核磁共振技术测试了渗透压力、渗透时间和轴压对聚合物修补砂浆中可蒸发水的横向弛豫时间和渗水量的影响,并以此表征修补砂浆的抗渗性。最后,通过孔结构和微观形貌分析了聚合物对修补砂浆横向弛豫时间和渗水量的影响机理。

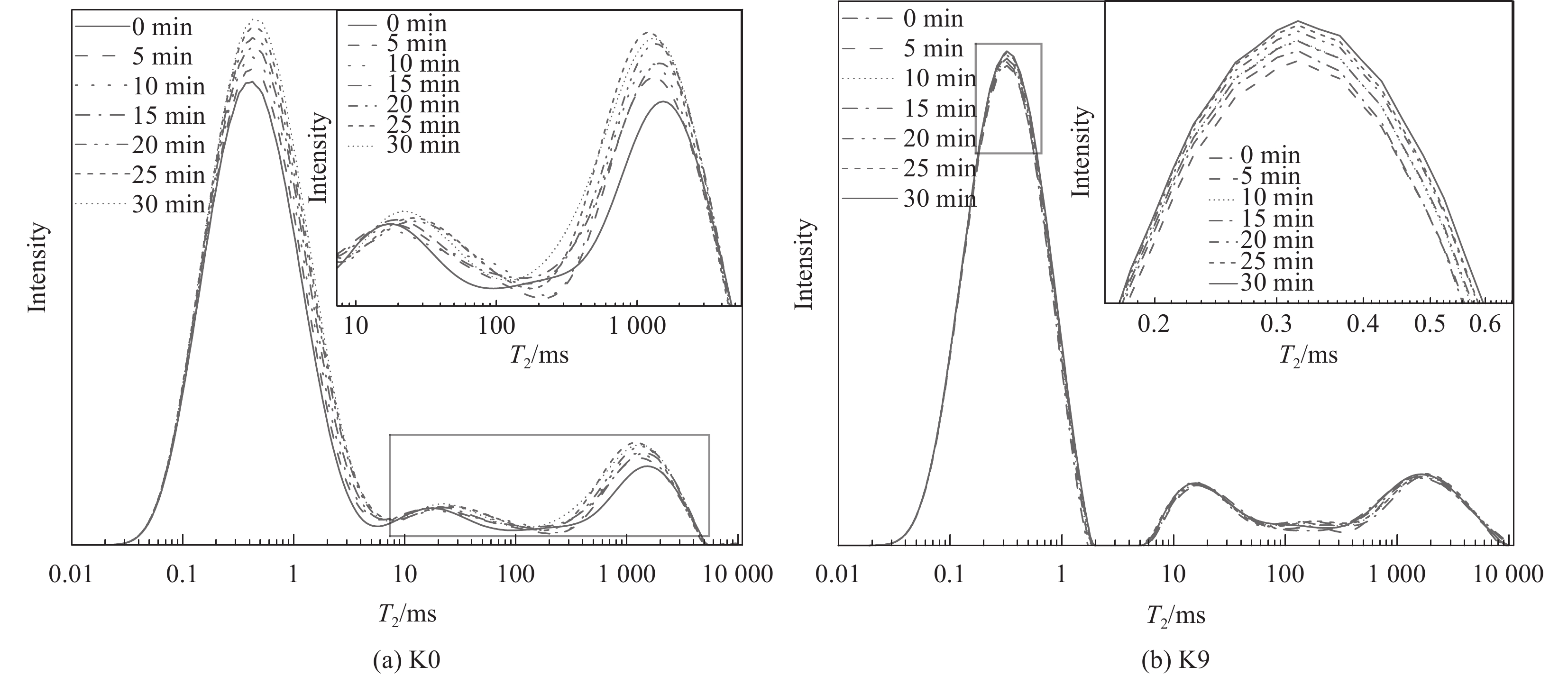

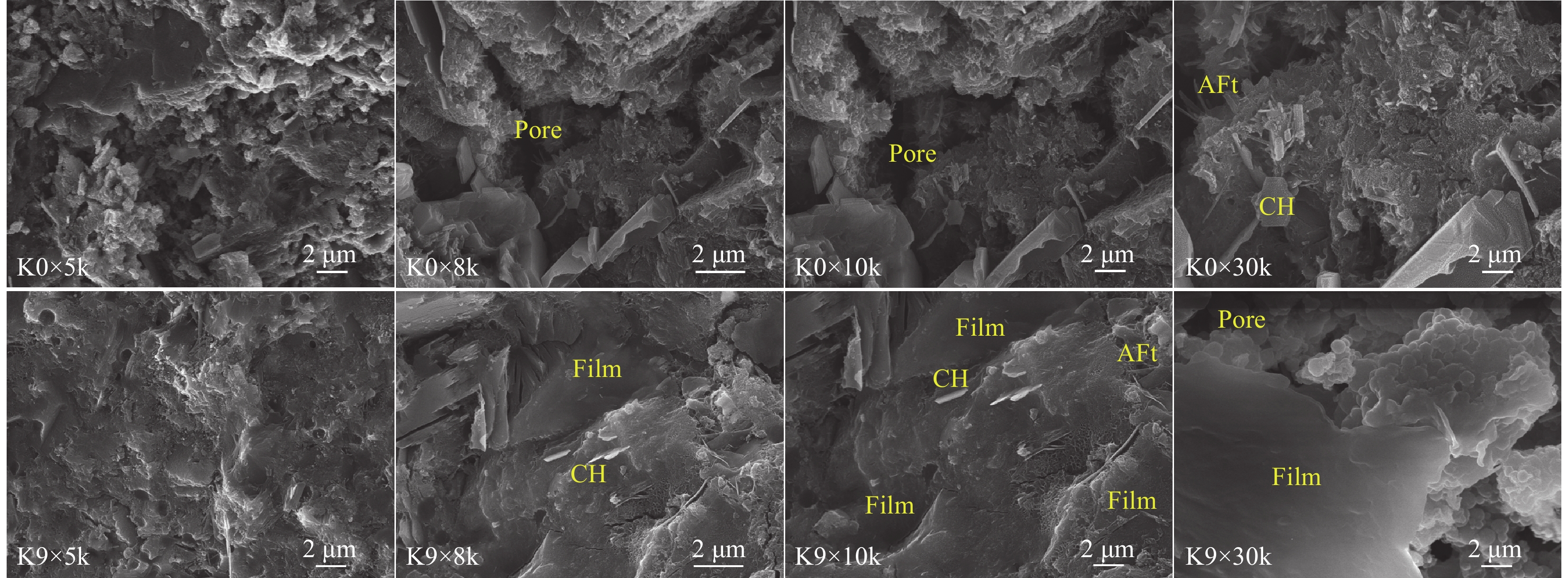

结果(1)聚合物提高了修补砂浆的力学性能,当掺量为9%时,砂浆的抗折强度和粘结强度分别增加了16.99%和57.45%,改善了修补砂浆的韧性和界面性能。(2)通过横向弛豫时间分布和渗水量可以有效的表征聚合物改性修补砂浆抗渗性能。随渗透压渗透时间的增加,水逐渐向修补砂浆凝胶孔隙和毛细孔隙中渗透,聚合物明显降低两者的增长趋势。(3)轴向压力作用下,修补砂浆中的孔隙被压缩,横向弛豫时间分布一个峰的峰值略有增加。当轴压增大到50MPa时,对照组试样横向弛豫时间分布突变,产生交叉裂缝破坏。聚合物改性修补砂浆产生明显的压缩变形未产生明显裂纹,试样的横向弛豫时间分布没有突变。(4)聚合物成膜后粘附在水化产物表面,分割、填充了水泥基材料的孔隙,孔隙率最大降低了3.28%,改善了修补砂浆的微观结构。

结论渗透压力是修补砂浆横向弛豫时间和渗水量的主要影响因素,聚合物降低了不同渗透压下修补砂浆毛细孔和凝胶孔水的含量,6MPa时渗水量降低57.3%,显著提升了修补砂浆的抗渗性能。聚合物提高了修补砂浆的韧性,三轴荷载作用下砂浆由交叉裂缝破坏变为压缩破坏,避免了砂浆在轴压作用下产生的抗渗性能突破。聚合物膜的阻隔和填充作用减弱了凝胶孔和毛细孔中的传输能力,从而降低了修补砂浆的横向弛豫强度和渗水量,提高了其抗渗性能。相较于传统的抗渗性检测方法,H低场核磁共振可以表征水分的渗透过程,是一种切实可行的抗渗性检测方法。

下载:

下载: