Bend capacity of continuous fiber GFRP stirrups with rectangular section

-

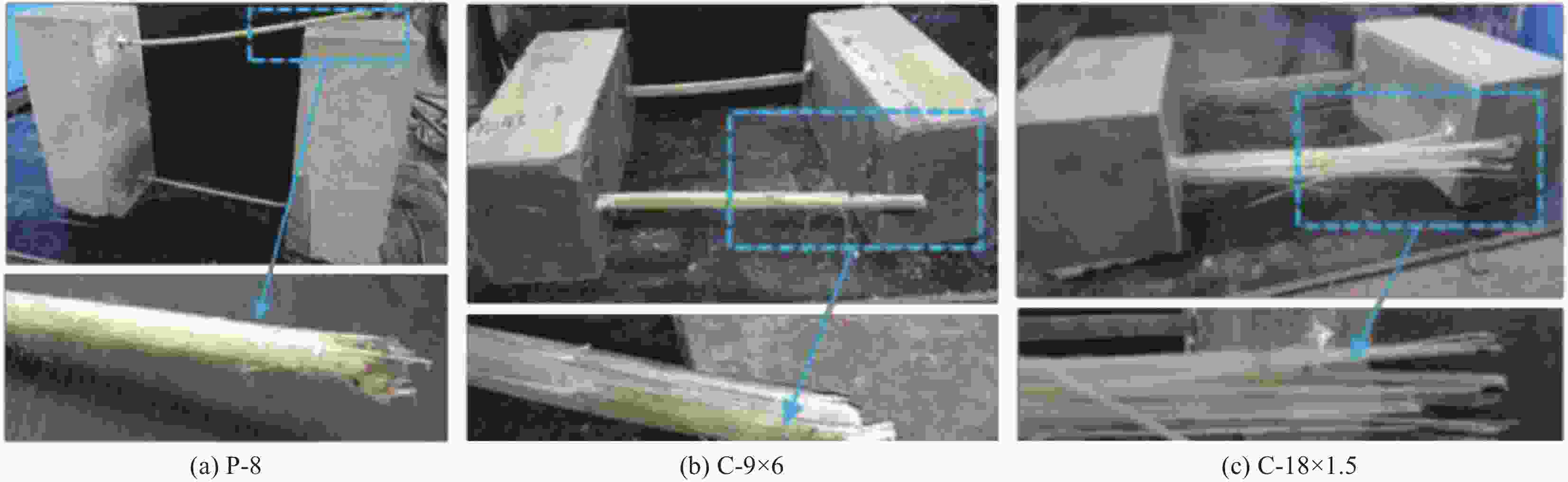

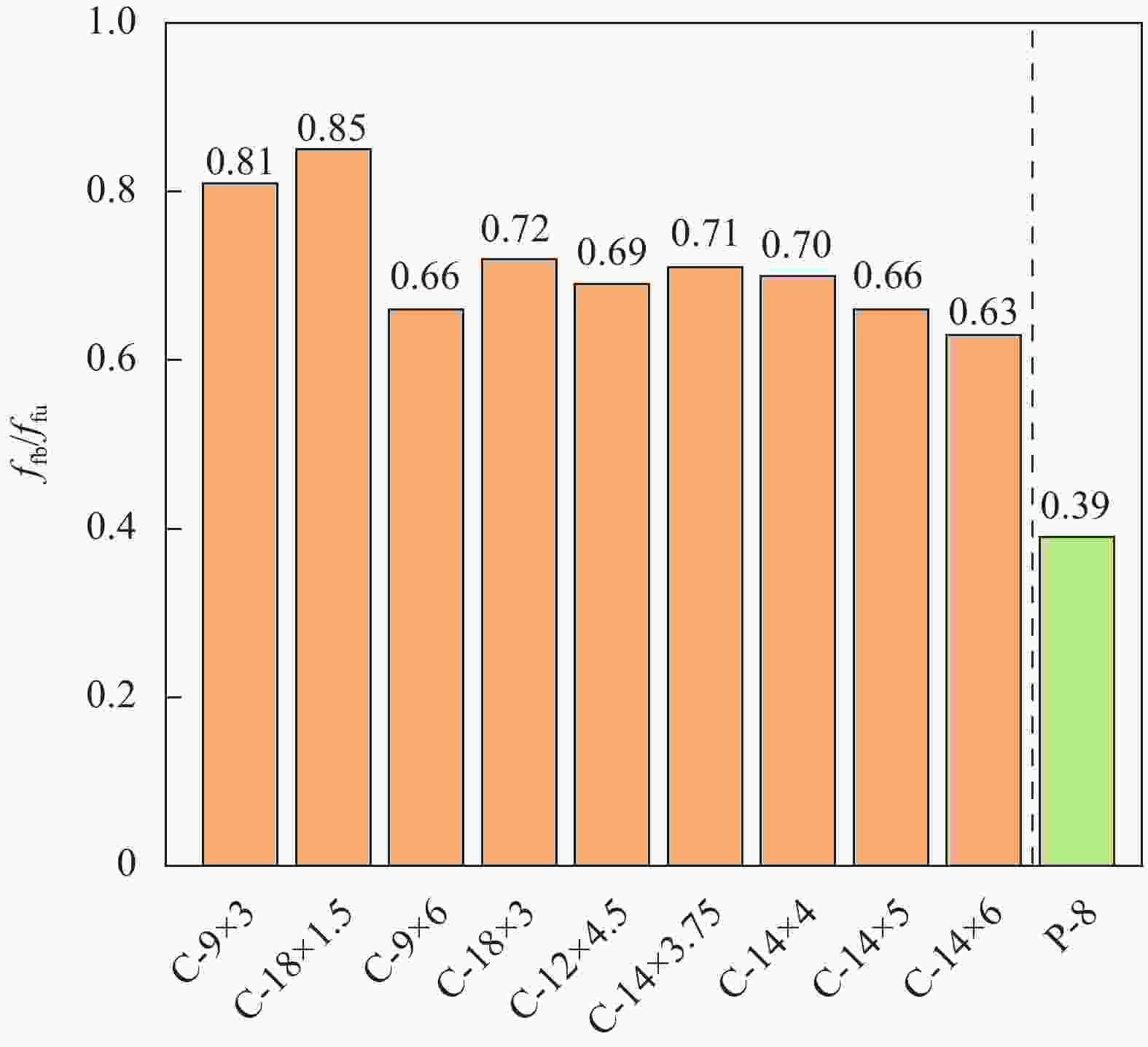

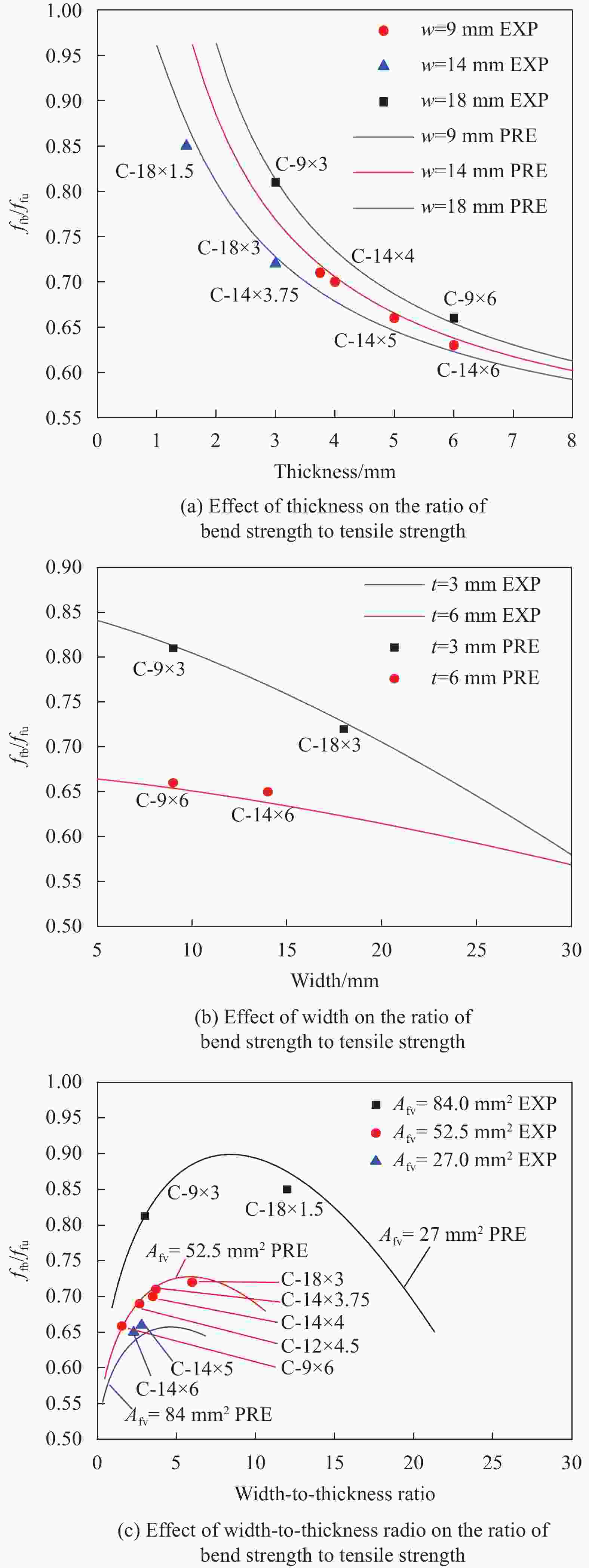

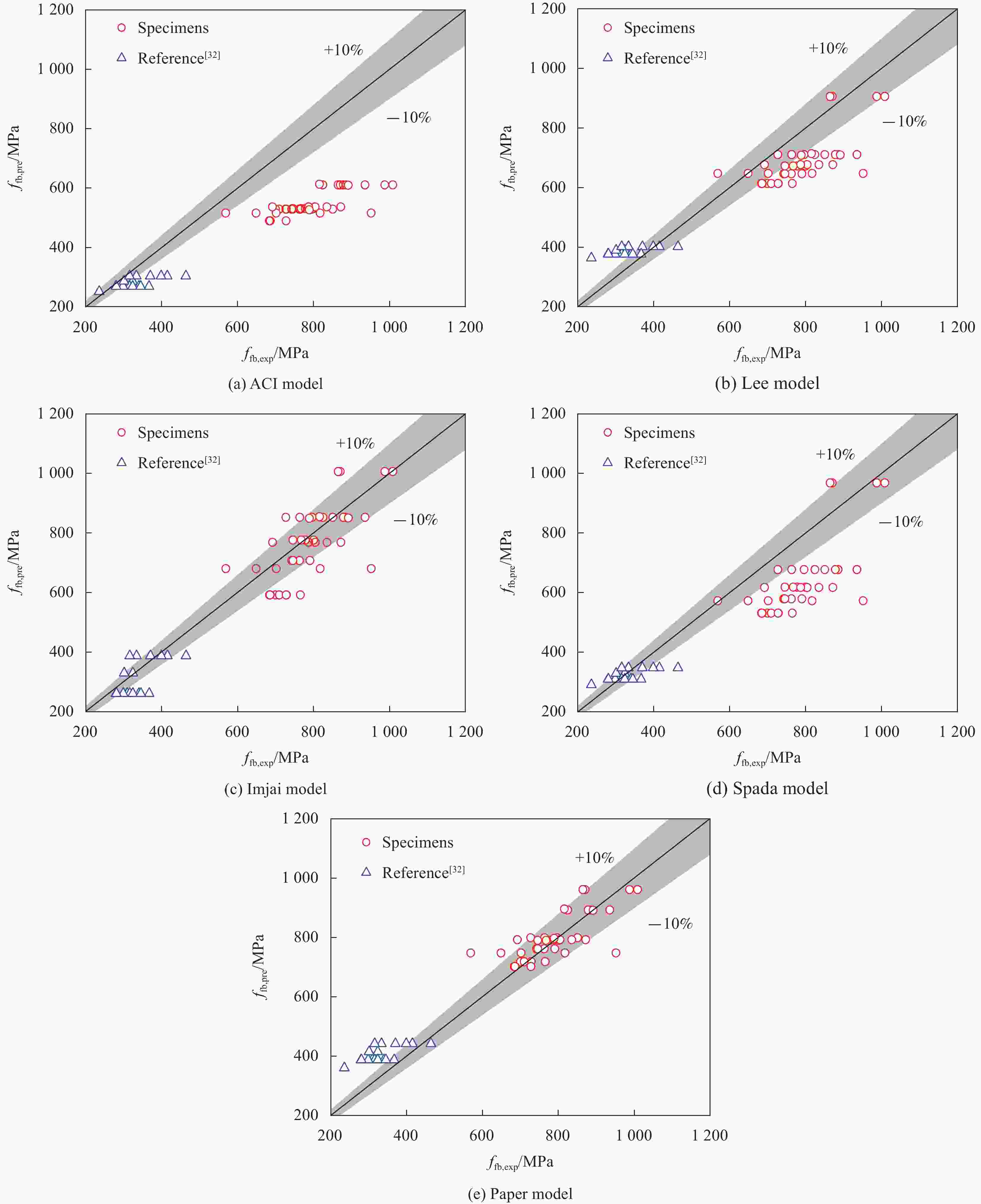

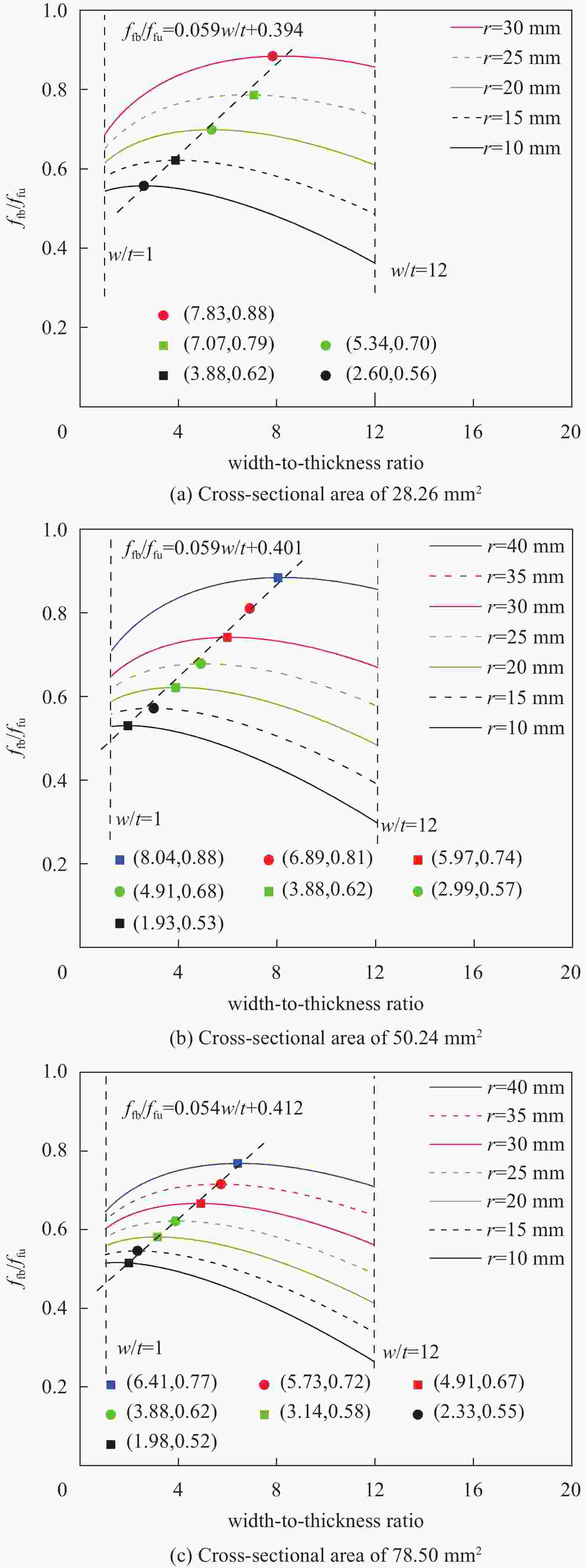

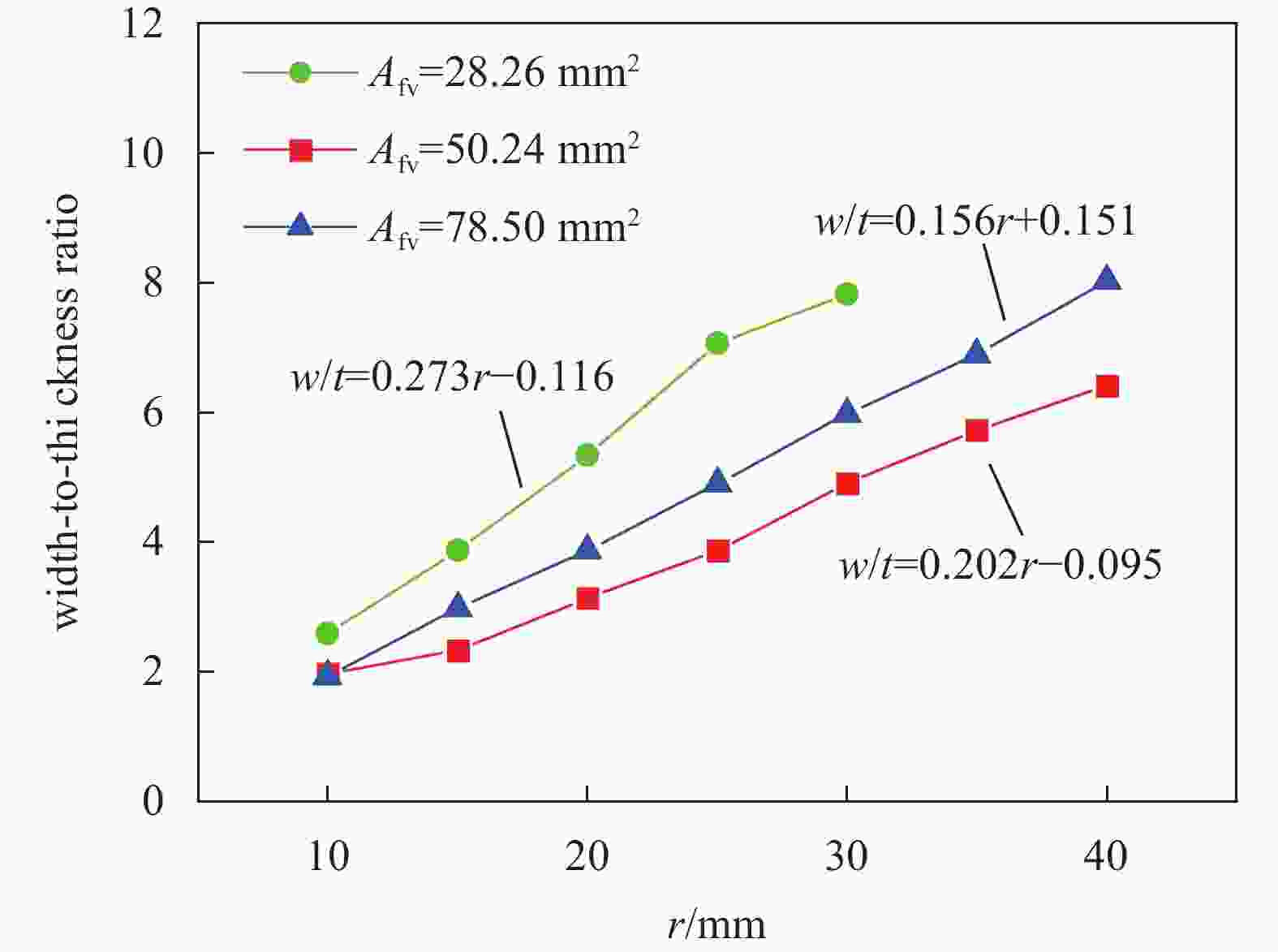

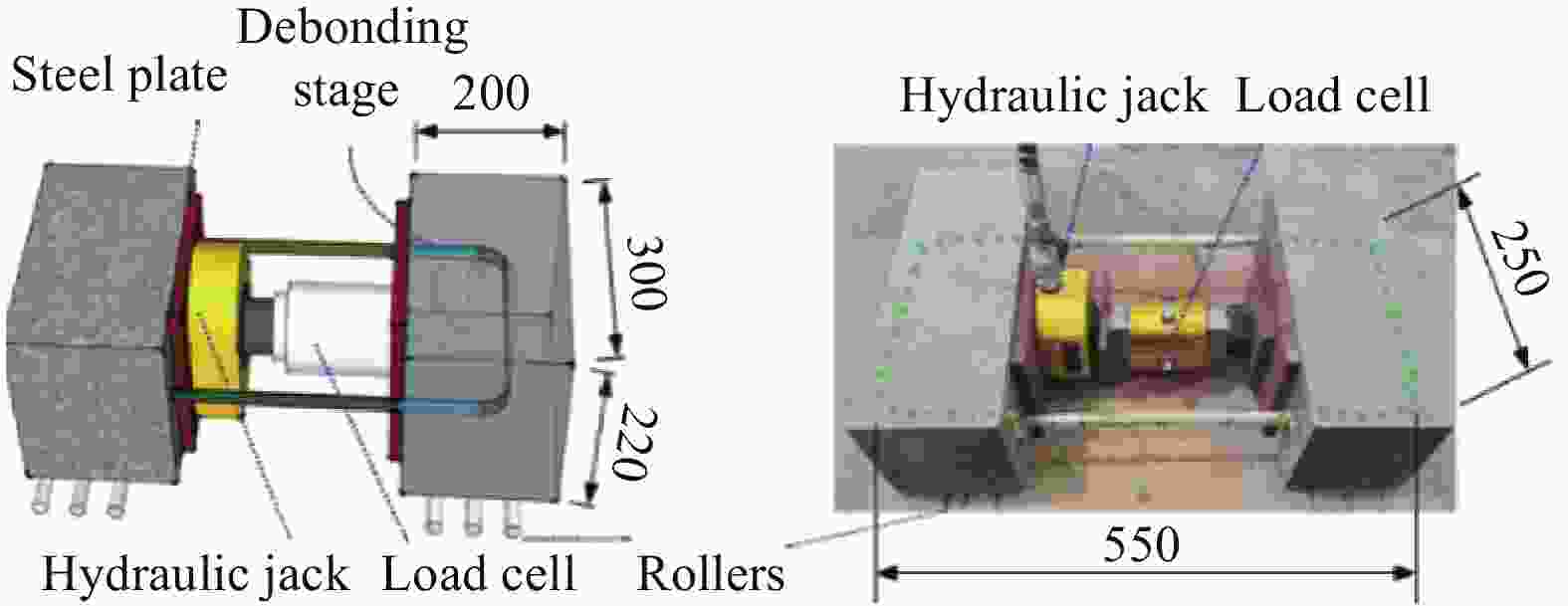

摘要: 纤维增强复合材料(FRP)箍筋角部弯曲段受拉强度是箍筋破坏的关键控制参数,为研究新型矩形截面连续纤维玻璃纤维增强树脂复合材料(GFRP)箍筋的弯曲段受拉性能,采用ACIB.5试验方法测试并得到了9种不同矩形截面GFRP箍筋与传统拉挤圆形截面箍筋的弯曲段受拉强度,考察了箍筋形式、截面宽度、厚度及宽厚比对GFRP箍筋弯曲段受拉性能的影响规律。试验结果表明,矩形截面连续纤维GFRP箍筋的弯曲段受拉强度与圆形截面拉挤箍筋相比有明显提高。弯曲段受拉强度与直线段受拉强度之比随矩形截面厚度的减小而增大,随截面宽度增加而减小。当截面面积一定时,随着宽厚比的增大,弯曲段受拉强度与直线段受拉强度之比呈增大趋势,但增长幅度逐渐减小。根据试验数据建立了考虑弯曲半径与截面宽厚比影响的矩形截面连续纤维GFRP箍筋弯曲段受拉强度预测模型,箍筋弯曲半径建议在25~40 mm范围内取值,依据不同的弯曲半径,连续纤维GFRP箍筋最优宽厚比的建议取值范围为2~8,为该类箍筋实际应用提供了设计依据。Abstract: The bend strength is a key control parameter for fiber-reinforced polymer (FRP) stirrup. To investigate the bend capacity of the new type of continuous fiber GFRP stirrups with a rectangular section, the bend strength of nine types of continuous fiber GFRP stirrups with different cross-section sizes and the traditional pultruded stirrups were tested using the ACIB.5 test method. The influences of the form of the stirrup, the width, the thickness, and the width-to-thickness ratio on the bend capacity of the continuous fiber GFRP stirrups with a rectangular section were investigated. The test results show that the bend strength of the new type of GFRP stirrup is significantly improved compared with that of the pultruded stirrup. The ratio of the bend strength to the tensile strength increases with the decrease of the thickness of the continuous fiber GFRP stirrup and decreases with the increase of the width. When the cross-sectional area is certain, the width-to-thickness ratio increases and the ratio of the bend strength to the tensile strength shows a tendency to increase, but the growth gradually decreases. Based on the experimental data, a bend strength prediction model for the GFRP stirrups with a rectangular section considering the effect of bend radius and width-to-thickness ratio was established. The bend radius of the continuous fiber GFRP stirrup is recommended to be taken in the range of 25-40mm. According to the different bend radii, the optimal width-to-thickness ratio of continuous fiber GFRP stirrup is recommended to be taken in the range of 2-8, which could be used in practical engineering.

-

Key words:

- GFRP /

- stirrup /

- rectangular section /

- bend strength /

- bend capacity

-

表 1 箍筋弯曲段受拉性能试件工况与试验结果

Table 1. Specimen design and test results of the bend test

Group Specimens Numbers N w/mm t/mm w/t Afv/mm2 ffb/MPa ffb,avg/MPa COV/% ffb/ffu υk/% Continuous fiber

GFRP rectangular

section stirrupsC-9×3 1 8 9 3 3 27.0 824.8 892.2 5.09 0.81 0.15 2 8 9 3 3 27.0 885.9 3 8 9 3 3 27.0 878.5 4 8 9 3 3 27.0 935.7 C-18×1.5 1 4 18 1.5 12 27.0 870.6 933.3 8.14 0.85 0.15 2 4 18 1.5 12 27.0 865.4 3 4 18 1.5 12 27.0 1009.1 4 4 18 1.5 12 27.0 988.3 C-9×6 1 16 9 6 1.5 54.0 765.8 726.5 3.96 0.66 0.14 2 16 9 6 1.5 54.0 700.5 3 16 9 6 1.5 54.0 728.9 4 16 9 6 1.5 54.0 710.5 C-18×3 1 8 18 3 6 54.0 727.2 784.6 6.68 0.72 0.15 2 8 18 3 6 54.0 796.4 3 8 18 3 6 54.0 763.9 4 8 18 3 6 54.0 850.8 C-12×4.5 1 12 12 4.5 2.7 54.0 742.5 760.6 2.90 0.69 0.15 2 12 12 4.5 2.7 54.0 763.2 3 12 12 4.5 2.7 54.0 790.6 4 12 12 4.5 2.7 54.0 745.8 C-14×3.75 1 10 14 3.75 3.7 52.5 778.3 773.3 2.92 0.71 0.15 2 10 14 3.75 3.7 52.5 800.5 3 10 14 3.75 3.7 52.5 768.2 4 10 14 3.75 3.7 52.5 746.1 C-14×4 1 10 14 4 3.5 56.0 787.5 768. 7 5.84 0.70 0.15 2 10 14 4 3.5 56.0 804.7 3 10 14 4 3.5 56.0 691.7 4 10 14 4 3.5 56.0 790.9 C-14×5 1 10 14 5 2.8 70.0 649.3 722.4 8.41 0.66 0.19 2 10 14 5 2.8 70.0 702.4 3 10 14 5 2.8 70.0 817.4 4 10 14 5 2.8 70.0 720.5 C-14×6 1 10 14 6 2.3 84.0 686.2 696.2 3.01 0.63 0.23 2 10 14 6 2.3 84.0 728.3 3 10 14 6 2.3 84.0 684.4 4 10 14 6 2.3 84.0 686.1 Pultruded stirrups P-8 1 — d=8 — 50.2 423.8 415.2 3.39 0.39 2.5 2 — d=8 — 50.2 398.6 3 — d=8 — 50.2 406.4 4 — d=8 — 50.2 392.0 Notes: N is the number of fiber winding layers of stirrups; w is the width of stirrups; t is the thickness of stirrups; d is the diameter of pultruded stirrups; Afv is the cross-sectional area of stirrups; ffb is the bend strength of stirrups; ffb,avg is the average value of the bend strength; COV is the coefficient of variation of the bend strength; υk is the volume fraction of the curling fibers. 表 2 基于本文试验的弯曲段受拉强度预测模型的比较

Table 2. Comparison of all prediction models for bend strength based on the tests in this paper

Paper ACI Lee Imjai Spada RMSE 63.38 255.92 123.59 91.98 163.78 Mean 0.99 1.45 1.15 1.05 1.25 SD 0.08 0.12 0.11 0.13 0.15 COV/% 8.15 8.53 9.28 12.11 12.09 Notes: RMSE is Root Mean Squared Error; SD is Standard Deviation; COV is Coefficient of Variation. -

[1] 叶列平, 冯鹏. FRP 在工程结构中的应用与发展[J]. 土木工程学报, 2006, 39(3): 24-36. doi: 10.3321/j.issn:1000-131X.2006.03.004YE Lieping, FENG Peng. Application and development of fiber-reinforced polymer in engineering structures[J]. China Civil Engineering Journal, 2006, 39(3): 24-36(in Chinese). doi: 10.3321/j.issn:1000-131X.2006.03.004 [2] 王自柯, 段建新, 赵军, 等. FRP 筋在不同腐蚀环境下的层间剪切性能劣化试验[J]. 复合材料学报, 2024, 41(4): 2031-2042.WANG Zike, DUAN Jianxin, ZHAO Jun, et al. Experimental study on the degradation of interlaminar shear performance of FRP bars in different corrosive environments[J]. Acta Materiae Compositae Sinica, 2024, 41(4): 2031-2042 (in Chinese). [3] FENG G, ZHU D, GUO S, et al. A review on mechanical properties and deterioration mechanisms of FRP bars under severe environmental and loading conditions[J]. Cement and Concrete Composites, 2022, 104758. [4] 邓宗才, 高伟男, 沈锋. 碱、盐环境下不同应力水平FRP筋抗压强度试验与理论研究[J]. 复合材料学报, 2017, 34(10): 2220-2231.DENG Zongcai, CAO Weinan, SHEN Feng. Experimental and theoretical study on compressive strength of FRP rebars under different stress levels in alkali and salt solution[J]. Acta Materiae Compositae Sinica, 2017, 34(10): 2220-2231 (in Chinese). [5] SUN Y, WU T, LIU X. Serviceability performance of fiber-reinforced lightweight aggregate concrete beams with CFRP bars[J]. Advances in Structural Engineering, 2022, 25(1): 117-132. doi: 10.1177/13694332211043333 [6] TENG J G, ZHANG B, ZHANG S, et al. Steel-free hybrid reinforcing bars for concrete structures[J]. Advances in Structural Engineering, 2018, 21(16): 2617-2622. doi: 10.1177/1369433218818772 [7] TOBBI H, FARGHALY A S, BENMOKRANE B. Behavior of Concentrically Loaded Fiber-Reinforced Polymer Reinforced Concrete Columns with Varying Reinforcement Types and Ratios[J], ACI Structural Journal, 2014, 111(2). [8] MARANAN G B, MANALO A C, BENMOKRANE B, et al. Shear Behavior of Geopolymer Concrete Beams Reinforced with Glass Fiber-Reinforced Polymer Bars[J]. ACI Structural Journal, 2017, 114(2): 337-348. [9] DONG H L, WANG D, WANG Z, et al. Axial compressive behavior of square concrete columns reinforced with innovative closed-type winding GFRP stirrups[J]. Composite Structures, 2018, 192: 115-125. doi: 10.1016/j.compstruct.2018.02.092 [10] PENG F, XUE W, Evaluation of bend strength calculation of fiber-reinforced polymer stirrups[C]. WU Z S. Joint Conference of the 12th International Symposium on Fiber Reinforced Polymers for Reinforced Concrete Structures (FRPRCS-12) & the 5th Asia Pacific Conference on Fiber Reinforced Polymers in Structures (APFIS-2015). Nanjing: Southeast University, 2015. [11] EL-SAYED A K, EL-SALAKAWY E, BENMOKRANE B. Mechanical and structural characterization of new carbon FRP stirrups for concrete members[J]. Journal of Composites for Construction, 2007, 11(4): 352-362. doi: 10.1061/(ASCE)1090-0268(2007)11:4(352) [12] AHMED E A, EL-SAYED A K, EL-SALAKAWY E, et al. Bend Strength of FRP Stirrups: Comparison and Evaluation of Testing Methods[J]. Journal of Composites for Construction, 2010, 14(1): 3-10. doi: 10.1061/(ASCE)CC.1943-5614.0000050 [13] A C. Guide Test Methods for Fiber-Reinforced Polymer (FRP) Composites for Reinforcing or Strengthening Concrete and Masonry Structures[S]. American Concrete Institute, 2012. [14] Currier J, Fogstad C, Walrath D, et al. Bond Development of Thermoplastic FRP Shear Reinforcement Stirrups[C] Infrastructure, ASCE, 2014. [15] Shehata E, Morphy R, Rizkalla S. Fibre reinforced polymer shear reinforcement for concrete members: behavior and design guidelines[J]. Canadian Journal of Civil Engineering, 2000, 27(5): 859-72. doi: 10.1139/l00-004 [16] 李彪, 杨勇新, 岳清瑞, 等. 复合材料箍筋力学性能试验研究[J]. 施工技术, 2018, 47(20): 22-25.LI Biao, YANG Yongxin, YUE Qingrui, et al. Experimental study on mechanical properties of composite stirrups[J]. Construction Technology, 2018, 47(20): 22-25(in Chinese). [17] 白浩阳, 薛伟辰, 江佳斐. 基于数据库的GFRP箍筋弯拉强度计算方法[J]. 哈尔滨工程大学学报, 2024, (2): 1-8.BAI Haoyang, XUE Weichen, JIANG Jiafei. Calculation approach for tensile strength of GFRP stirrup at bend based on database[J]. Journal of Harbin Engineering University, 2024, (2): 1-8(in Chinese). [18] LEE C, KO M, LEE Y. Bend strength of complete closed-type carbon fiber-reinforced polymer stirrups with rectangular section[J]. Journal of Composites for Construction, 2014, 18(1): 04013022. doi: 10.1061/(ASCE)CC.1943-5614.0000428 [19] LEE C, KIM J-Y, HEO S-Y. Experimental observation on the effectiveness of fiber sheet strip stirrups in concrete beams[J]. Journal of Composites for Construction, 2010, 14(5): 487-497. doi: 10.1061/(ASCE)CC.1943-5614.0000109 [20] SPADEA S, ORR J, IVANOVA K. Bend-strength of novel filament wound shear reinforcement[J]. Composite Structures, 2017, 176: 244-253. doi: 10.1016/j.compstruct.2017.05.032 [21] Zeng J J, Yan Z T, Jiang Y Y, et al. 3D printing of FRP grid and bar reinforcement for reinforced concrete plates: Development and effectiveness[J]. Composite Structures, 2024, 335: 117946. doi: 10.1016/j.compstruct.2024.117946 [22] Liu G, Xiong Y, Zhou LM. Additive manufacturing of continuous fiber reinforced polymer composites: Design opportunities and novel applications[J]. Composites Communications, 2021, 27: 100907. doi: 10.1016/j.coco.2021.100907 [23] Tian X Y, Liu T F, Yang C C, Wang QR, Li DC. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites[J]. Composites: Part A, 2016, 88: 198-205. doi: 10.1016/j.compositesa.2016.05.032 [24] Jeong S K, Lee S S, Kim C, et al. Flexural behavior of GFRP reinforced concrete members with CFRP grid shear reinforcements[J]. Key Engineering Materials, 2006, 306: 1361-1366. [25] Dong Z Q, Sun Y, Zhu H, et al. Shear behavior of hybrid seawater sea-sand concrete short beams reinforced with BFRP reinforcements[J]. Engineering Structures, 2022, 252: 113615. doi: 10.1016/j.engstruct.2021.113615 [26] 原野, 王震宇, 王代玉. 配置新型封闭缠绕式 GFRP 箍筋混凝土梁的受剪性能试验[J]. 复合材料学报, 2023, 39(11): 5074-5085.YUAN Ye, WANG Zhenyu, WANG Daiyu. Experimental study on the shear performance of concrete beams reinforced with new type closed winding GFRP stirrups[J]. Acta Materiae Compositae Sinica, 2023, 39(11): 5074-5085 (in Chinese). [27] TESTING A S F, MATERIALS. Standard test method for tensile properties of polymer matrix composite materials, ASTM D3039/D3039M-14[S]. American Society for Testing and Materials West Conshohocken, 2008. [28] 中国国家标准化管理委员会, 纤维增强复合材料筋基本力学性能试验方法(GB/T30022-2013))[S]. 北京: 中国标准出版社, 2013.Standardization Administration of China. Test method for basic mechanical properties of fiber reinforced polymer bar: GB/T 30022-2013[S]. Beijing: Standards Press of China, 2013(in Chinese). [29] 沈浩杰, 姚卫星, 吴义韬. 复合材料层合板宽度尺寸效应的混合模型[J]. 南京航空航天大学学报, 2014, 46(3): 371-376. doi: 10.3969/j.issn.1005-2615.2014.03.006SHEN Haojie, YAO Satellite, WU Yitao. Mixed model for size effect of FRP composite in width[J]. Journal of Nanjing University of Aeronautics and Astronautics, 2014, 46(3): 371-376(in Chinese). doi: 10.3969/j.issn.1005-2615.2014.03.006 [30] ACI, Guide for the design and construction of concrete reinforced with FRP bars[S]. Farmington Hills MI, 2015. [31] IMJAI T, GUADAGNINI M, PILAKOUTAS K, et al. A practical macro-mechanical model for the bend capacity of fibre-reinforced polymer bars[J]. Proceedings of the Institution of Civil Engineers-Structures and Buildings, 2021, 174(10): 824-835. doi: 10.1680/jstbu.19.00135 [32] Imjai T, Guadagnini M, Pilakoutas K. Bend Strength of FRP Bars: Experimental investigation and Bond Modelling[J]. Journal of Materials in Civil Engineering, 2017, 29(7): 04017024. doi: 10.1061/(ASCE)MT.1943-5533.0001855 -

点击查看大图

点击查看大图

计量

- 文章访问数: 36

- HTML全文浏览量: 26

- 被引次数: 0

下载:

下载: