Effect of graphene reinforcement on strengthening of grapheme/Al composites at different compression stages

-

摘要: 利用分子动力学(MD)方法探究了石墨烯纳米片(GNs)层数和每层片数对GNs/Al复合材料不同压缩阶段力学增强效果的影响。结果发现:GNs层和片数越多,复合材料弹性模量、屈服强度和最大应力强度的增强效果越显著,且增强层由3片及以上GNs构成时,压缩曲线会出现双最大应力峰值。压缩后期,GNs的断裂造成复合材料的各向异性,使复合材料在GNs锯齿形方向上的横向变形大于扶手椅方向。与MD结果对比分析发现,当金属层厚不足3 nm时,限制层滑模型不再适用。

-

关键词:

- 分子动力学 /

- 石墨烯/Al复合材料 /

- 压缩阶段 /

- 位错结构 /

- 限制层滑模型

Abstract: Molecular dynamics (MD) method was used to investigate the effect of the number of graphene nanosheets (GNs) layers and the number of sheets in each layer on the mechanical reinforcement of GNs/Al composite at different compression stages. The results show that the increase of GNs layers and the number of GNs sheets increases the enhancement effect of elastic modulus, yield strength and maximum stress strength of the composite. When the reinforcement layer is composed of 3 or more GNs sheets, double maximum stress peaks appear in the compression curve. At the late compression stage, the fracture of GNs results in the anisotropy of the composite, and the transverse deformation of the composite in the zigzag direction of GNs is larger than that in the armchair direction. When the thickness of metal layer is less than 3 nm, the confined layer slip model is not applicable. -

复合材料的可设计性满足实际需求,充分利用各材料的优异特性而成为各学科发展的新趋势,其中Al及其合金凭借质轻、制造成本低、加工性能好等特点而被广泛应用。早期金属基复合材料的增强体主要以微米尺度的纤维或陶瓷颗粒物为主,力学性能相比于纯金属基质显著提升,但复合材料的塑性、延展性和断裂韧性大幅度降低[1-2]。随着纳米科技的发展,广大学者在研究复合材料时,将兴趣转到了纳米尺度。大量研究[3-6]表明,纳米尺度的增强体能极大地提升金属基复合材料的强度且保持良好的塑性和延展性。近年来,碳纳米材料[7-11]因其独特的力学特性和高自润滑性而被广泛关注,石墨烯纳米片(GNs)以极高的杨氏模量、断裂强度及比表面积和延展性[12-15]脱颖而出,为金属基复合材料的研究打开了新世界[16-18]。

Zhao等[19]、Boostani等[20]和Rashad等[21]分别通过拉伸实验研究了在2wt%以下的GNs含量对Ni基、Al基和Mg基复合材料强度与韧性的影响,观察材料断口,发现其断裂行为主要是韧窝和撕裂棱特征。这说明增强体的加入使材料的应力状况更加复杂,界面结合处往往会造成严重的应力集中现象。Liu等[22]采用原位化学气相沉积的方法合成了一种超细Ni纳米粒子(NPs)修饰的GNs异质材料(NPs-GNP),然后将NPs-GNP散入铝合金颗粒中,得到NPs-GNP/Al复合粉末。结果发现,在加入GNs为1wt%之前,复合材料的强度随着增强体含量的增加而增加,超过后,复合材料的强度反而开始下降。产生这一现象的原因是高含量的NPs-GNP在相同的球磨分散工艺下由于集聚效应而分散不均匀。该实验表明Ni纳米粒子能大大提高GNs和Al基体的界面结合强度,改善GNs在Al基质中的分散性。这为优化界面结合,制备高性能的金属基复合材料提供了重要参考。

将二维纳米材料GNs作为金属基的增强体,尽管可通过实验观测到复合材料的模量和变形等宏观表现及电镜透射和原位分析技术[23-28]表征增强体在金属基质中的存在形式,但复合材料结构的塑性演变、材料界面间的变形机制等微观机制及强化机制与影响因素之间的联系仍不明确。鉴于微观尺度的实验研究的困难性,原子尺度上的理论和模拟探索[29-30]提供了可行办法。通过理论与模拟手段展示复合材料变形特征,进而有效预测材料的力学行为,可为工程实际和材料设计与制备提供有益借鉴。关于增强体和基质界面的结合,主要通过第一性原理[31-33]进行研究。Dong等[34]利用第一性原理计算了GNs与12种金属界面之间的相互作用。在增强体和强化效果的联系上,Peng等[35]采用分子动力学方法(MD)研究了GNs对Cu基复合材料单轴拉伸力学性能的影响,并发现强度的提高与GNs的手性和层间厚度有关,扶手椅型GNs的界面应力比锯齿型GNs更明显。Lin等[36]在c面(0001)蓝宝石纳米压痕下的MD模拟中发现,菱形面滑移激活产生了三次对称堆积,r面和A面的孪晶/滑移系统为c面蓝宝石上的裂纹形成提供了成核条件,弥补了实验方法难以观察动态变形过程的不足。

随着计算机技术的发展,MD方法在复合材料的拉伸[37-42]、压缩[43-44]、剪切[45]和纳米压痕[46-47]等微观机制方面已进行大量研究。而对于GNs增强金属基复合材料压缩时的结构演化研究仍然处于探索阶段,GNs的几何尺寸如层数及每层GNs片数对复合材料的力学行为影响规律研究仍然较少。本文采用MD方法,模拟了垂直GNs平面方向上GNs/Al复合材料的压缩,分析GNs增强层数量状态对各个阶段结构演化的影响,尤其是压缩后期的塑性流动阶段。同时将MD得到的增强体对GNs/Al复合材料力学性能的影响结果与混和法则[48-50](ROM)和限制层滑模型[51-53](CLS)等常见预测复合材料力学性能的数学模型的计算结果进行比较,分析计算偏差产生的原因,并验证了CLS模型的使用范围。

1. MD模型与模拟步骤

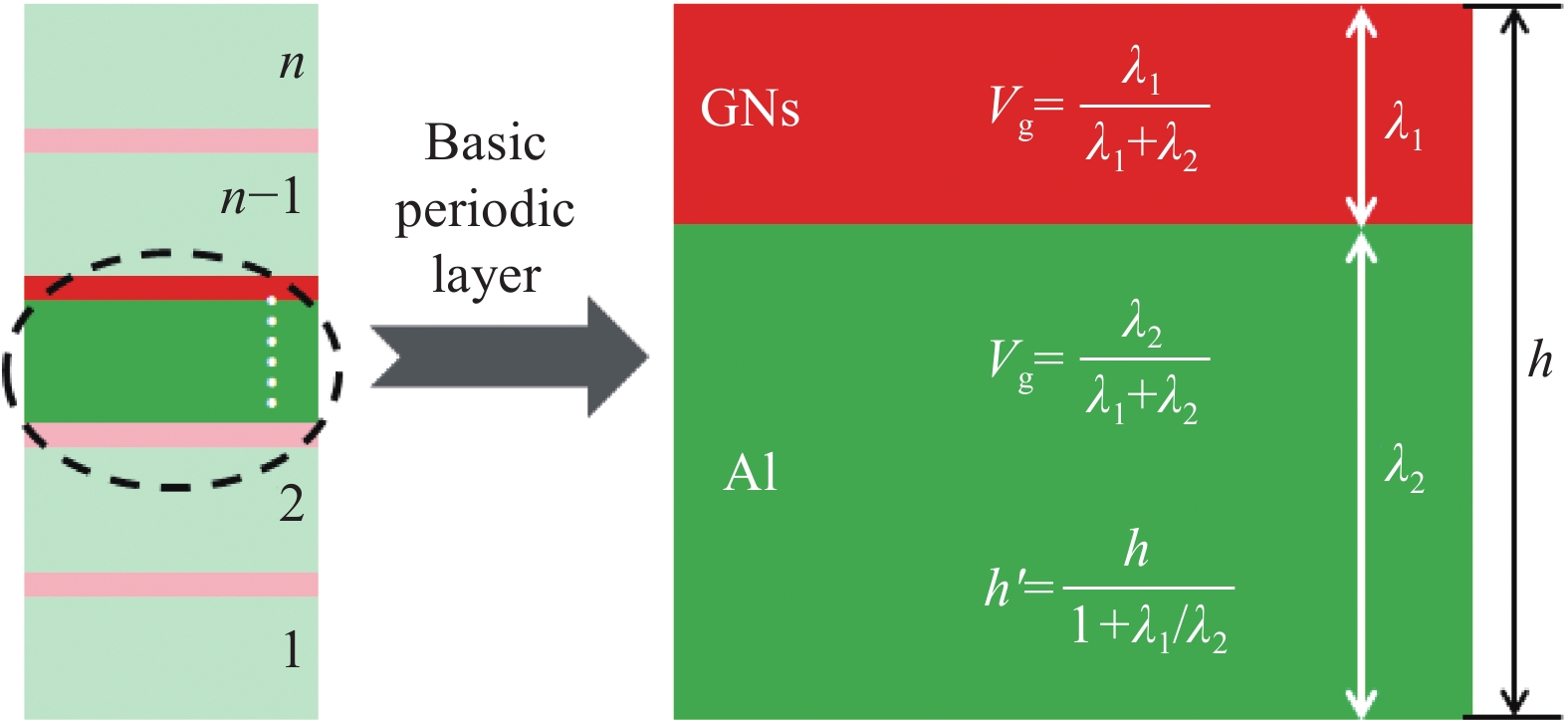

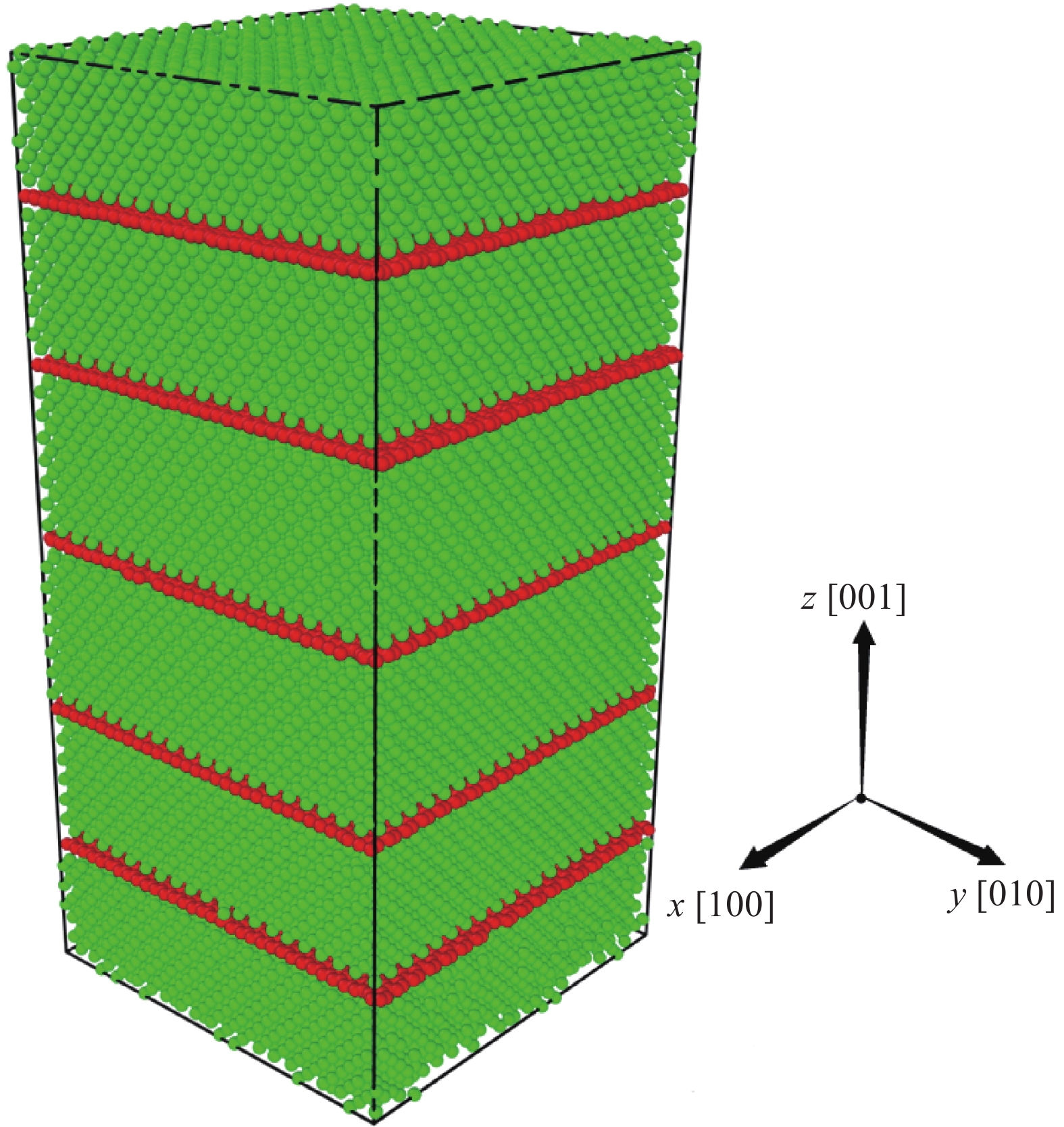

本文GNs/Al复合材料的MD模型如图1(以5层为例),由8.1 nm×8.1 nm×16.2 nm的纯Al柱中等距离加入不同层数(1~5层)的GNs构成。GNs的大小均约为8.1 nm×8.1 nm。每个Al柱约64000个粒子,每片GNs含2470个粒子。

分别采用EAM势[54]、AIREBO势[55]和L-J势[56]来描述Al原子、C原子和Al-C原子之间的相互作用。其中L-J势函数出现最早,形式也最简单,如下式:

Uij(r)=4εij[(σijrij)12−(σijrij)6] (1) 其中:rij为i和j两个粒子的间距;势阱深度ε和零势距离σ两个参数分别取0.03457 eV和0.30135 nm[57-59]。整个模拟过程中,模拟步长设定为1 fs,并在300 K,NPT系宗下驰豫200 ps以使构型平衡。许多研究[60-62]发现,在通常使用的MD加载速率中,拉伸和压缩的应变率对相关MD模型的力学性能影响较小,因此为考虑计算时效,在300 K和NPT系宗下,保持沿z[001]方向上压缩的应变率为0.005 ps−1恒定。x[100]、y[010]和z[001]3个方向都设置为周期性边界条件,并维持横向上压力为0。

2. 结果与讨论

2.1 GNs/Al复合材料的分子动力学性能

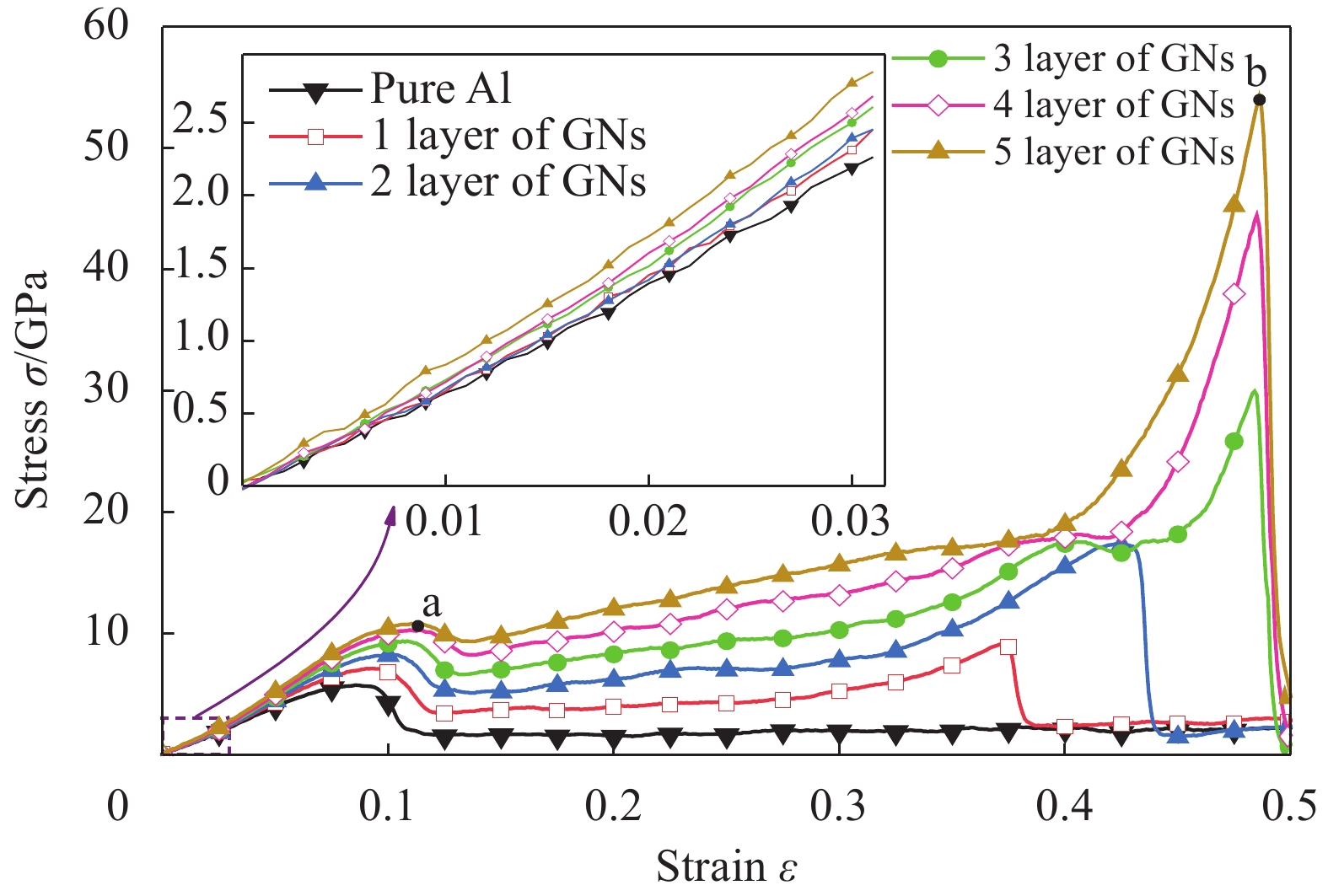

压缩变形的应力-应变结果如图2所示,可见GNs的加入能明显提高复合材料垂直GNs平面方向上的压缩性能,且随GNs层数的增加而增加。此次拉伸模拟中,纯Al的弹性模型为69.9 GPa,屈服强度为5.41 GPa,在之前研究报道[60,62]的62.8~79.8 GPa和2.96~6.75 GPa之间,说明本次模拟结果可被接受。

比较各模型的压缩曲线,纯Al仅有一个极大值点,即材料的屈服点[61-62]。超过屈服点后,应力出现大幅度的下降,最后进入稳定的塑性应力平台阶段。GNs/Al复合材料的压缩模拟同样存在与纯Al相同的阶段特性,屈服极限随着GNs层数的增加而明显增大。超过屈服极限后,GNs/Al复合材料的应力降低的程度随着层数的增加变得越来越轻(a点)。此外,不同于纯Al材料的应力平台特征,GNs/Al复合材料的应力随着应变的增大持续增长,并最后出现显著的峰值(b点)。当加入的GNs超过3层后,虽然强化的b点应力值依然随着GNs层的增加而增加,但对应的应变几乎趋于一致,Weng等[44]研究GNs/Cu力学性能及Zhang等[49]研究Cu/Cr纳米结构的塑性和屈服强度的比例关系时也出现这一情况。实际上,尺寸相同的模型中,GNs层数的增加即是层间Al基厚度的减小,从而对压缩变形由Al主导的GNs/Al复合材料的形变能力有所影响。当GNs少于3层时,金属层仍能产生足量位错随着加载变形继续而缠结强化(具体强化过程接下来讨论),且多层GNs提供更多位错形核点,使更多层GNs材料能通过更大的压缩应变令缠结强化更显著。

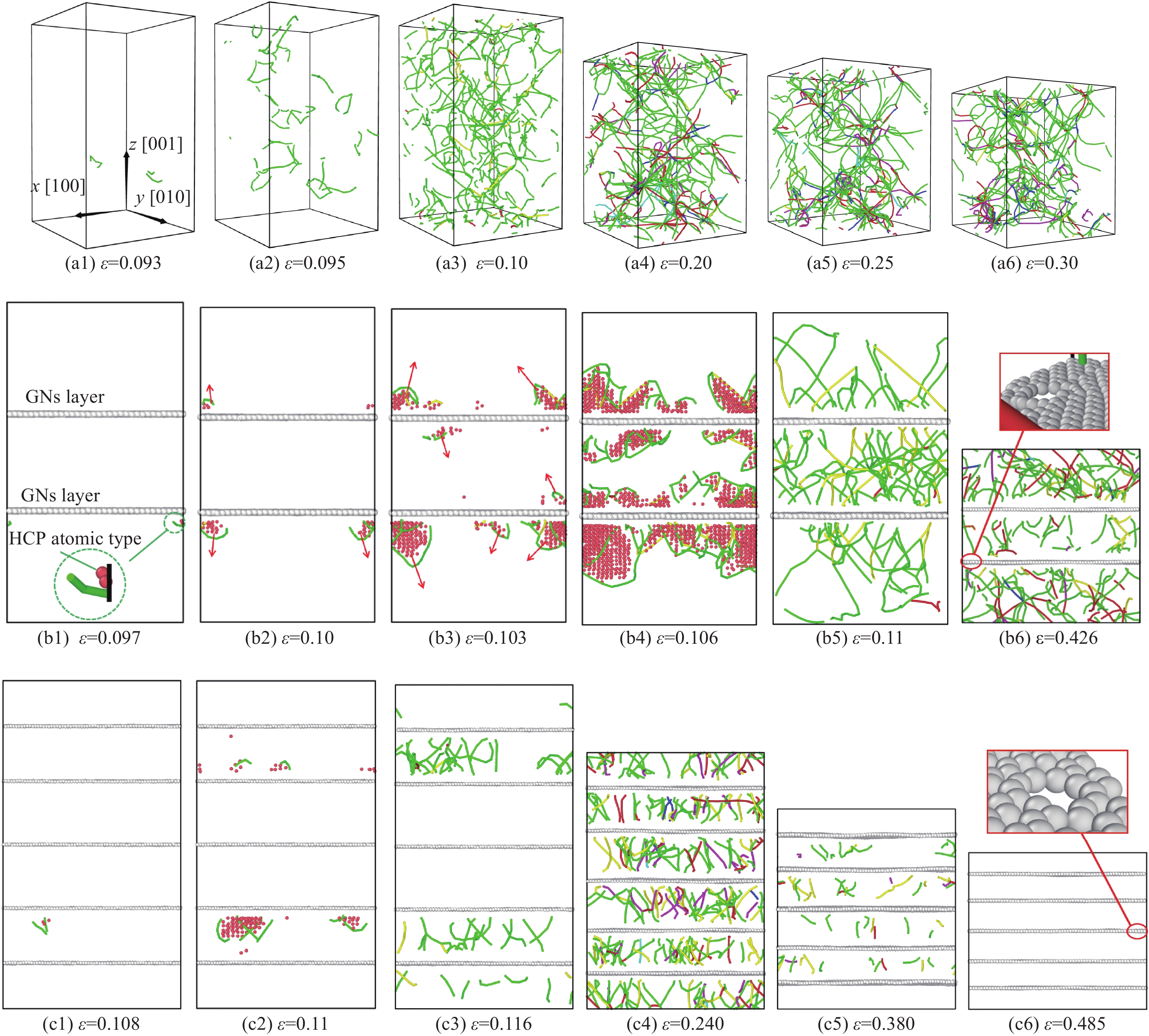

欲明确GNs的加入对GNs/Al复合材料的强化机制,须从微观变形机制入手。众多研究[35,63-65]表明,位错等原子缺陷的传播和反应状况是材料强化的关键因素。在1~5层GNs的各个复合材料模型中,位错的形核和传播及相互缠结作用具有相同特点。因此图3仅以2层和5层GNs的复合材料模型的微观演化快照作为代表,并以纯Al作为参照。为清晰展示位错结构,快照中不显示FCC等原子结构。

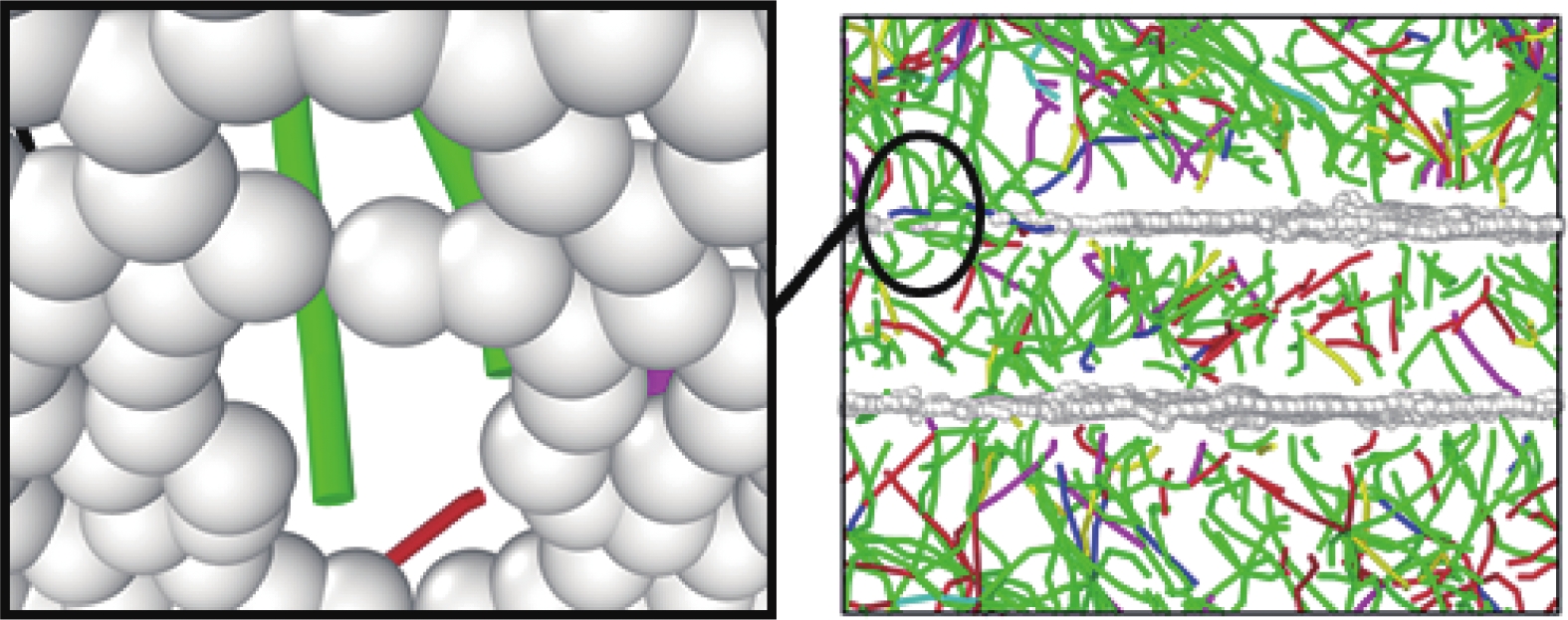

所有模型都在屈服点a首次出现位错,且都在{111}晶面族上传播和滑移。对于纯Al材料,屈服后随着应变的持续,位错密度也随之增加,新的位错在体内随机均匀产生。然而对于GNs/Al复合材料,位错都在GNs/Al的边界上形核和生长,并向远离GNs的方向移动。图3(b)显示了含两层GNs的复合材料的位错演化过程:材料经过a点(图3(b1))进入塑性变形后,不断有新的位错在界面处产生并远离GNs移动,箭头示意位错的移动方向。两层GNs之间的位错相向而移,最终相互交织缠结,并且不断有新的位错以相同形式运动,使位错密度大大增加,位错运动变得更加困难。同时,GNs平面上强共价键的存在阻挡了位错在整个材料体内的贯穿,界面处位错形核过程不断修改,所需形核应力增加,从而材料抵抗塑性变形的能力也就大大增加,直至GNs层破坏(图3(b6)),位错与界面的应力释放,如图4所示。此即GNs对金属基复合材料的强化机制。

5层GNs的模型也表现出相同过程,但值得注意的是,该模型内的位错密度没有两层GNs的高,而且在变形后期,位错明显减少(图3(c5)~3(c6))。这是由于GNs层数的增加,使层间金属Al占比减小。许多研究[49,52-53,64]指出,位错堆积可作为连续体,但在亚微米尺度下,位错堆积太少并不能视为连续体,且尺度越小,位错越难发生。模型中加入5层GNs使层间Al基厚度大大减小。先产生的位错不断运动至边界,构成位错线的原子相对于晶体另一部分发生滑动,位错线内的原子滑移到表面后使表面不平整而形成滑移台阶,如图5所示。继续压缩让Al厚度越来越小,难以产生新的位错而使压缩后期复合材料体内位错越来越少。界面对位错的运动起强烈抑制作用,从而对复合材料力学性能起到强化效果;同时由于金属层厚的降低,复合材料位错的产生及变形能力受到较大影响。

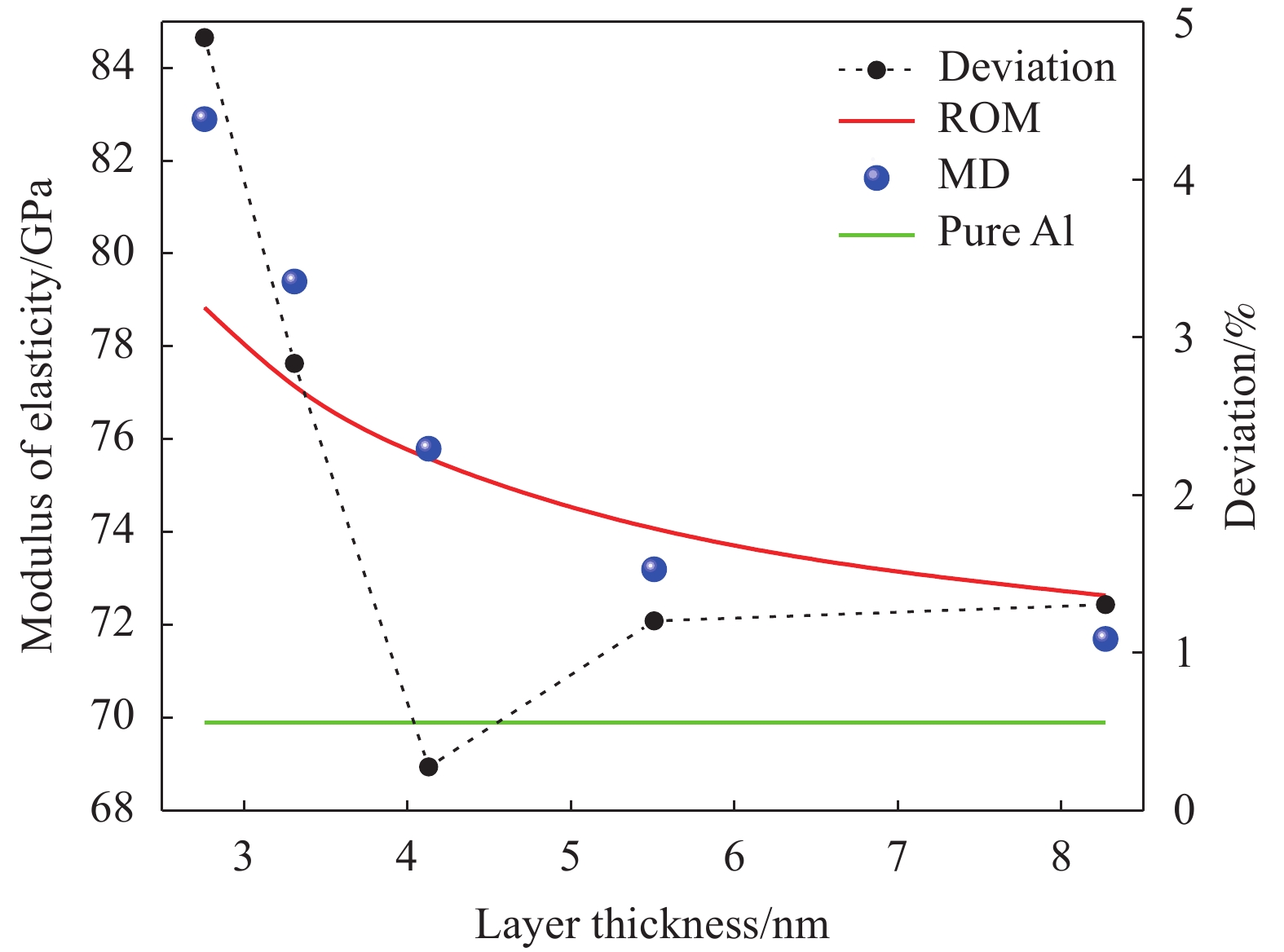

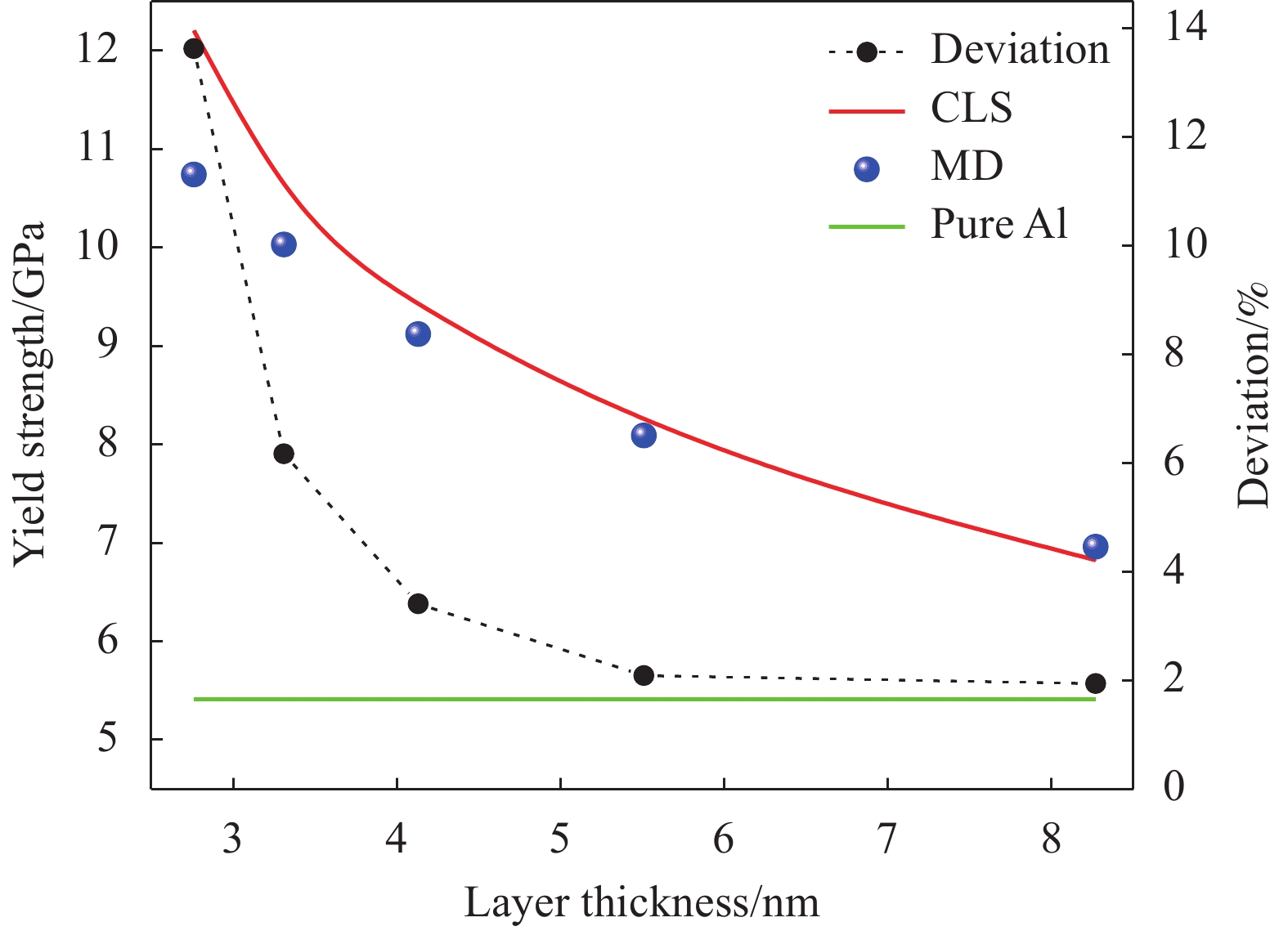

GNs的加入,显著提高了GNs/Al复合材料在垂直GNs平面方向上压缩的力学性能,如提高屈服强度和最大应力强度等。图2的内嵌图表明复合材料的弹性模量也得到了一定程度的提高。关于不同GNs层数的复合材料在垂直GNs平面方向上压缩的弹性模量、屈服强度和最大应力强度列于表1中。

表 1 不同GNs层数复合材料的弹性模量、屈服强度和最大应力强度Table 1. Elastic modulus, yield strength and maximum stress strength of composites with different GNs layersNumber

of GNs

layersThickness of periodic layer/nm Elasticity modulus/

GPaYield strength/GPa Maximum stress/

GPa0 16.20 69.9 5.41 − 1 8.27 71.7 6.96 9.08 2 5.51 72.2 8.09 17.49 3 4.13 75.8 9.12 30.05 4 3.31 79.4 10.03 44.46 5 2.76 82.9 10.74 54.21 2.2 ROM和CLS模型

MD方法能够获得实验在原子动态和细节上难以发现的底层变形机制,通过模拟数据的处理,可以直观地认识到复合材料各个阶段的力学特性,进而对相应的宏观实际做出科学合理的判断和预测。与此同时,许多分析计算的数学模型也发展地十分成熟,便捷又实用地对复合材料进行性能设计和预测。如混和法则[48-50](ROM)和限制层滑模型[51-53](CLS)等。

ROM的基本原理是通过增强体和基体体积的加权特性来预测复合材料的性质。其基本形式为

P=∑PiVi ,其中P为材料的任意性质,V为各层(块)材料的体积分数。在此基础上,利用Hirsch模型得到的下式[66]被广泛使用于弹性模量的计算:1Ec=VmEm+VgEg (2) 式中:E为弹性模量;V为体积分数;下角标m表示基体;g表示增强体;c表示复合材料。

CLS模型则普遍运用于位错受相界面或晶界约束材料的强度计算。对于塑性阶段,在伯氏矢量b限于材料一层内的滑移回路所需的剪切应力τcls由以下平衡式得到[52]:

τcls=μ∗b8πh∗(4−ν1−ν)lnαh∗b (3) 其中:

μ∗=μmμg/(μmVg+μgVm) ;μ和ν是对应材料的剪切模量和基质的泊松比;α代表岩心截止参数;h*表示材料内基质厚度;b是一个位错伯氏矢量的长度。剪切应力τcls与泰勒因子M相乘[52]即可得到法向屈服应力σcls。压缩加载时,界面应力f与界面能的单位(J/m2)相同,因此将其与层厚归一化得到应力单位,式(3)可修改为[44,49,67-69]σcls=Mμ∗b8πh∗(4−ν1−ν)lnαh∗b−fh+μ∗bL(1−ν) (4) 式中:

L=bm/(εVg) 表征了滑移阵的平均剪切距离;ε为给定的塑性应变;m为0.5级的应变分辨系数;h为周期层厚度。图6示意了模型结构分层。通过式(2)计算材料弹性模量;指定塑性变形阶段的平均应变[44]ε=0.35,代入式(4)计算材料的屈服强度,最后与分子动力学结果比较,如图7和图8所示。计算时,α取0.8,M取3[53];b为0.2864 nm;GNs的厚度取0.335 nm,剪切模量取280 GPa,弹性模量取1 TPa[44];Al的剪切模量和泊松比分别取32.5 GPa和0.34[70-71]。ROM和CLS模型计算复合材料的弹性模量和屈服强度与MD结果基本吻合,但复合材料内GNs超过4层(周期层厚度在3 nm及以下)时,结果偏差都会增大。MD的动态模拟较准静态ROM模型所得到的结果难免会有较小波动,结果显示ROM与MD关于弹性模量的预测结果最大偏差在5%内(图7),误差在可接受范围内。参照ROM模型,MD模型给出的数据在置信水平95%时的置信区间为[ROM−0.85, ROM+0.85]。相比于ROM对复合材料弹性模量的预测,CLS模型对屈服强度的计算结果与MD结果偏差更大。CLS模型的计算式中包含了滑移位错环传播的应力及界面位错阵列对约束层滑移应力的贡献[44],而在层厚较薄时,MD模拟显示(图3(c))金属内位错发展受到明显影响,这是造成MD模型与CLS模型在层厚较薄时有较大偏差的原因。Misra等[52]在长度尺度对多层复合材料相关变形机制的研究中也指出,材料厚度过小会影响CLS模型的适用性。

2.3 多片GNs层对GNs/Al复合材料压缩性能的影响

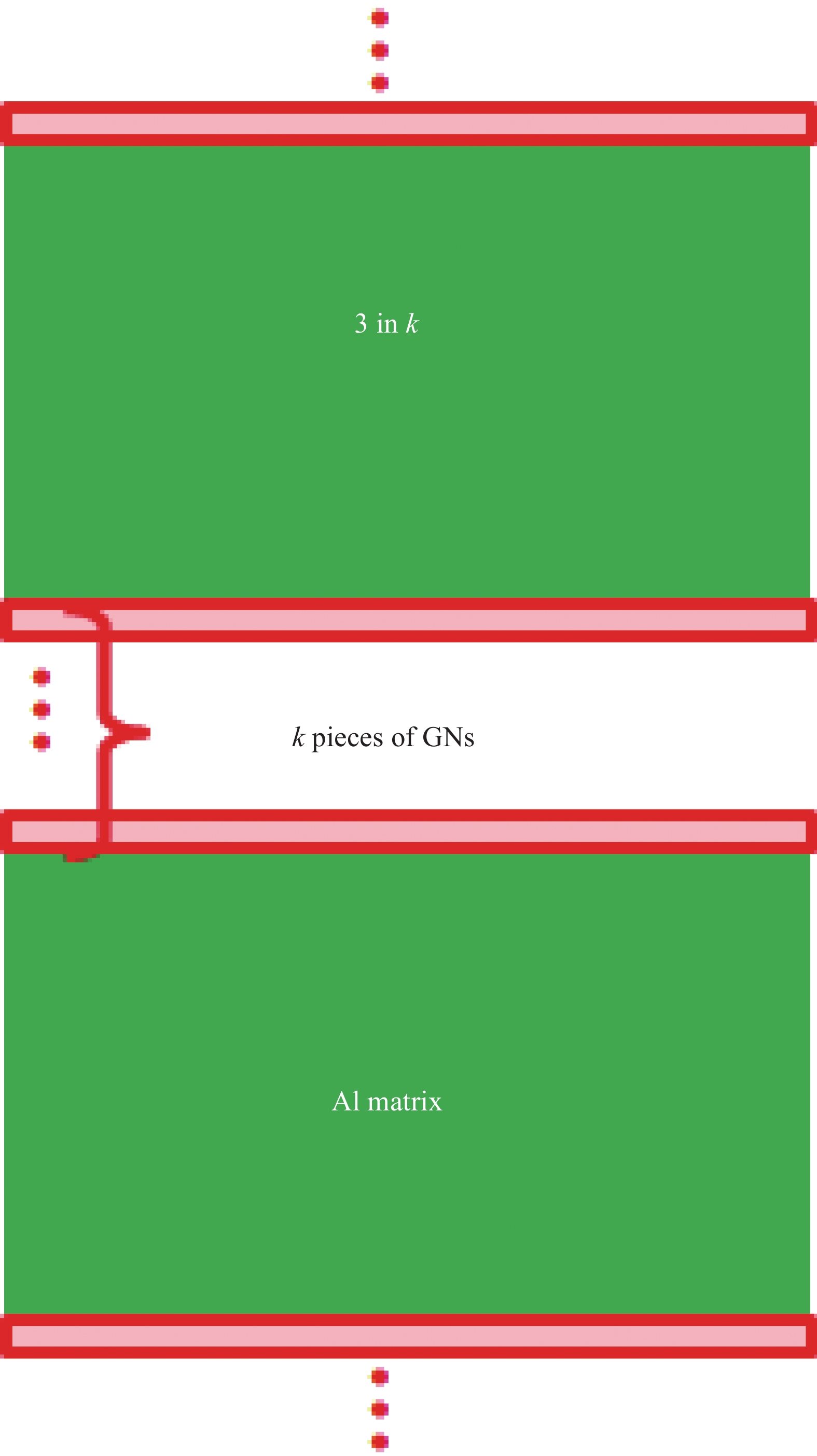

图2的垂直GNs平面压缩的应力-应变曲线说明GNs层的加入能有效提高GNs/Al复合材料的压缩性能。虽然GNs层越多,压缩性能的强化效果越好,但每个GNs层只有一片GNs。现以3层GNs为例,建立如图9示意的每个GNs层由1~4片GNs组成的模型(3 in 1~3 in 4),相应位错形态及应力-应变曲线如图10所示。

相同GNs层数下,增加GNs的片数(加厚GNs层)能提高复合材料压缩的强化效果,而GNs层厚的增加会减小Al基的厚度,使材料位错产生和变形困难。有趣的是,当GNs层片数超过两片时,压缩后期出现了两个最大应力峰值。这是由于GNs层阻塞位错扩展效应是GNs/金属复合材料力学性能增强的原因,Al与GNs之间的晶格和剪切模量失配导致界面高应力集中,位错在传播过程中受到GNs不可穿透界面的约束,导致位错与界面之间产生强烈相互作用。因此接触Al基的GNs片会首先破坏失效,致使应力有所下降,但很快内片GNs开始起到增强作用,且受到相同形式的作用力。由于内层GNs已经承受了持续压缩传递来的应力作用,因此很快也会破坏失效,使上升的应力值再次下降。此即多片GNs层(k≥3)出现双最大应力峰值的原因,过程示意如图11所示。

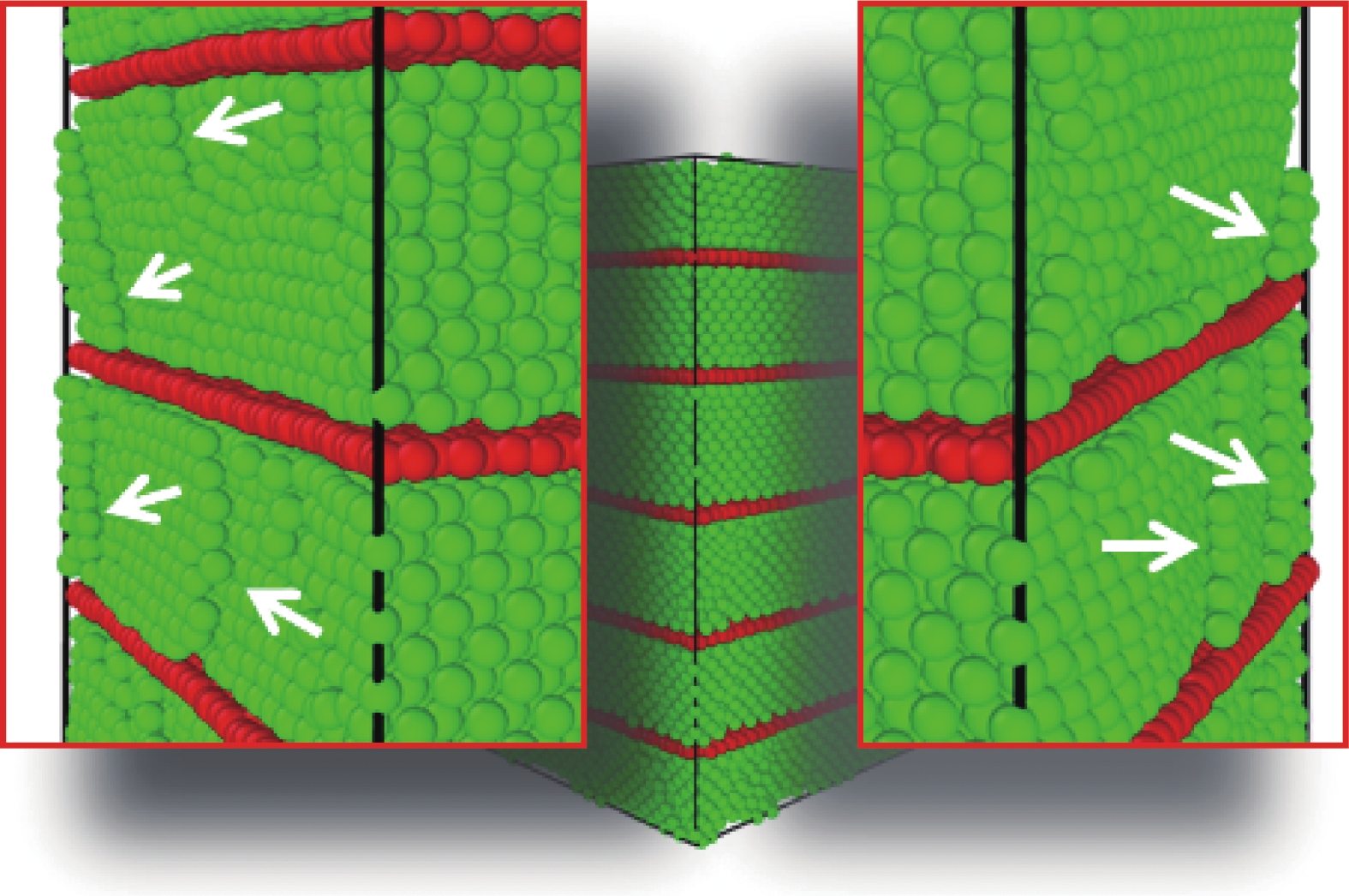

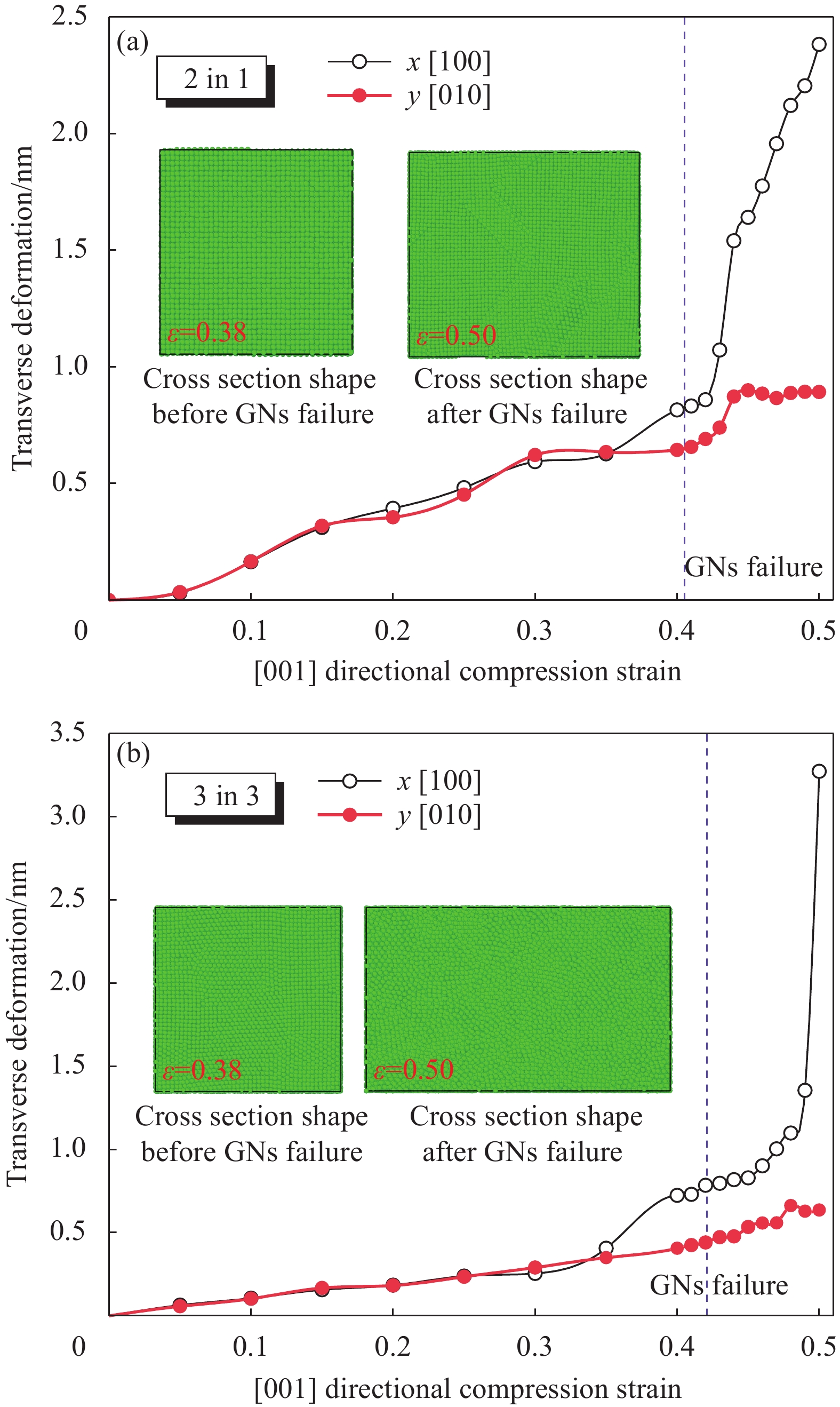

其实在所有模型压缩过程中,复合材料两个横向(x[100]和y[010])上的变形在GNs断裂破坏前基本一致,而GNs破坏后,垂直GNs断裂线方向的横向变形会立即远大于另一横向变形。以2 in 1和3 in 3模型为例,两个横向变形的具体情况如图12所示。

许多研究[72-73]表明GNs扶手椅方向的杨氏模量和抗拉强度要强于锯齿形方向,因此压缩GNs/Al复合材料的应力传递到GNs上时,锯齿形方向(x[100])的变形大于扶手椅方向(y[010])而首先产生破坏,最后垂直锯齿形方向的裂纹扩大将GNs“扯断”,如图13所示。GNs层的不同形态造成复合材料的各向异性,使GNs断裂失效后复合材料在锯齿形方向的横向变形大于扶手椅方向。

3. 结 论

(1) 加入石墨烯纳米片(GNs)能强化GNs/Al复合材料在垂直GNs平面方向上的压缩力学性能,且弹性模量、屈服强度及最大应力强度随着GNs层数的增加而提升。但GNs层数和片数的增加会降低Al基厚度,影响位错形核和运动,使位错密度减少,从而降低了材料的塑性变形能力。

(2) 每个GNs层的GNs超过2片时,由于GNs/Al界面间的强相互作用,使外侧GNs片(贴近Al基)首先破坏,继而作用力传入内片,直至内片GNs破坏,使复合材料在压缩时产生双最大应力峰值。

(3) 混和法则(ROM)能很好地运用于纳米领域;限制层滑模型(CLS)包含了滑移位错环传播的应力及界面位错阵列对约束层滑移应力的贡献,而厚度较低的金属层影响了位错的发生与运动,因此金属层厚不足3 nm时,CLS模型不再适用。

(4) 压缩后期GNs垂直锯齿形方向断裂,造成GNs/Al复合材料的各向异性,使材料在GNs锯齿形方向的横向变形大于扶手椅方向的横向变形。

-

表 1 不同GNs层数复合材料的弹性模量、屈服强度和最大应力强度

Table 1 Elastic modulus, yield strength and maximum stress strength of composites with different GNs layers

Number

of GNs

layersThickness of periodic layer/nm Elasticity modulus/

GPaYield strength/GPa Maximum stress/

GPa0 16.20 69.9 5.41 − 1 8.27 71.7 6.96 9.08 2 5.51 72.2 8.09 17.49 3 4.13 75.8 9.12 30.05 4 3.31 79.4 10.03 44.46 5 2.76 82.9 10.74 54.21 -

[1] MORTENSEN A, LLORCA J. Metal matrix composites[J]. Annual Review of Materials Research,2010,40:243-270. DOI: 10.1146/annurev-matsci-070909-104511

[2] CHAWLA N, SHEN Y L. Mechanical behavior of particle reinforced metal matrix composites[J]. Advanced Engineering Materials,2001,3(6):357-370. DOI: 10.1002/1527-2648(200106)3:6<357::AID-ADEM357>3.0.CO;2-I

[3] CASATI R, VEDANI M. Metal matrix composites reinforced by nano-particles—A review[J]. Metals,2014,4(1):65-83. DOI: 10.3390/met4010065

[4] ZHANG Z, CHEN D L. Contribution of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites[J]. Materials Science and Engineering: A,2008,483:148-152.

[5] ZHANG Z, CHEN D. Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength[J]. Scripta Materialia,2006,54(7):1321-1326. DOI: 10.1016/j.scriptamat.2005.12.017

[6] SANATY-ZADEH A. Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall-Petch effect[J]. Materials Science and Engineering: A,2012,531:112-118. DOI: 10.1016/j.msea.2011.10.043

[7] BARTOLUCCI S F, PARAS J, RAFIEE M A, et al. Graphene–aluminum nanocomposites[J]. Materials Science and Engi-neering: A,2011,528(27):7933-7937. DOI: 10.1016/j.msea.2011.07.043

[8] HU Z, TONG G, LIN D, et al. Graphene-reinforced metal matrix nanocomposites–A review[J]. Materials Science and Technology,2016,32(9):930-953. DOI: 10.1080/02670836.2015.1104018

[9] DIXIT S, MAHATA A, MAHAPATRA D R, et al. Multi-layer graphene reinforced aluminum-manufacturing of high strength composite by friction stir alloying[J]. Composites Part B: Engineering,2018,136:63-71. DOI: 10.1016/j.compositesb.2017.10.028

[10] 王娟, 张法明, 商彩云, 等. 石墨烯/钛基复合材料的界面反应控制、微观组织和压缩性能[J]. 复合材料学报, 2020, 37(12):3137-3148. DOI: 10.13801/j.cnki.fhclxb.20200421.001 WANG J, ZHANG F M, SHANG C Y, et al. Interfacial reaction control, microstructure and compression properties of graphene/titanium matrix composites[J]. Acta Materiae Compositae Sinica,2020,37(12):3137-3148(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20200421.001

[11] 冯俊俊, 张会, 李亚鹏, 等. 石墨烯负载铜增强铜基块体复合材料制备及其性能[J]. 复合材料学报, 2023, 40(1):485-498. DOI: 10.13801/j.cnki.fhclxb.20220307.003 FENG J J, ZHANG H, LI Y P, et al. Preparation and properties of graphene-supported copper reinforced copper matrix composites[J]. Acta Materiae Compositae Sinica,2023,40(1):485-498(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20220307.003

[12] NOVOSELOV K S, GEIM A K, MOROZOV S V, et al. Electric field effect in atomically thin carbon films[J]. Science,2004,306(5696):666-669. DOI: 10.1126/science.1102896

[13] TJONG S C. Recent progress in the development and pro-perties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets[J]. Materials Science and Engineering: R: Reports,2013,74(10):281-350. DOI: 10.1016/j.mser.2013.08.001

[14] LEE C, WEI X, KYSAR J W, et al. Measurement of the elastic properties and intrinsic strength of monolayer graphene[J]. Science,2008,321(5887):385-388. DOI: 10.1126/science.1157996

[15] CHAE H K, SIBERIO-PÉREZ D Y, JAHEON K, et al. A route to high surface area, porosity and inclusion of large molecules in crystals[J]. Nature,2004,427(6974):523-527. DOI: 10.1038/nature02311

[16] MORTAZAVI B, RÉMOND Y, AHZI S, et al. Thickness and chirality effects on tensile behavior of few-layer graphene by molecular dynamics simulations[J]. Computational Materials Science,2012,53(1):298-302. DOI: 10.1016/j.commatsci.2011.08.018

[17] 程有亮, 赵维娜, 方长青, 等. 石墨烯量子点/纤维素复合气凝胶材料的制备及其吸附性能研究[J]. 包装工程, 2020, 41(5):114-120. DOI: 10.19554/j.cnki.1001-3563.2020.05.016 CHENG Y L, ZHAO W N, FANG C Q, et al. Preparation and adsorption properties of graphene quantum dots/cellulose composite aerogels[J]. Packaging Engineering,2020,41(5):114-120(in Chinese). DOI: 10.19554/j.cnki.1001-3563.2020.05.016

[18] 陈鹏, 徐朝阳. 对苯二酚增强纤维素/石墨烯电极的制备[J]. 包装工程, 2019, 40(15):92-97. DOI: 10.19554/j.cnki.1001-3563.2019.15.015 CHEN P, XU C Y. Preparation of hydroquinone reinforced cellulose/graphene electrode[J]. Packaging Engineering,2019,40(15):92-97(in Chinese). DOI: 10.19554/j.cnki.1001-3563.2019.15.015

[19] ZHAO C. Enhanced strength in reduced graphene oxide/nickel composites prepared by molecular-level mixing for structural applications[J]. Applied Physics A,2015,118(2):409-416. DOI: 10.1007/s00339-014-8909-y

[20] BOOSTANI A F, TAHAMTAN S, JIANG Z, et al. Enhanced tensile properties of aluminium matrix composites reinforced with graphene encapsulated SiC nanoparticles[J]. Composites Part A: Applied Science and Manufacturing,2015,68:155-163. DOI: 10.1016/j.compositesa.2014.10.010

[21] RASHAD M, PAN F, HU H, et al. Enhanced tensile properties of magnesium composites reinforced with graphene nanoplatelets[J]. Materials Science and Engineering: A,2015,630:36-44. DOI: 10.1016/j.msea.2015.02.002

[22] LIU G, ZHAO N, SHI C, et al. In-situ synthesis of graphene decorated with nickel nanoparticles for fabricating reinforced 6061 Al matrix composites[J]. Materials Science and Engineering: A,2017,699:185-193.

[23] ZENG X, YU J, FU D, et al. Wear characteristics of hybrid aluminum-matrix composites reinforced with well-dispersed reduced graphene oxide nanosheets and silicon carbide particulates[J]. Vacuum,2018,155:364-375. DOI: 10.1016/j.vacuum.2018.06.033

[24] ZARE Y. Study of nanoparticles aggregation/agglomeration in polymer particulate nanocomposites by mechanical properties[J]. Composites Part A: Applied Science and Manufacturing,2016,84:158-164. DOI: 10.1016/j.compositesa.2016.01.020

[25] ALGUL H, TOKUR M, OZCAN S, et al. The effect of graphene content and sliding speed on the wear mecha-nism of nickel-graphene nanocomposites[J]. Applied Surface Science,2015,359:340-348. DOI: 10.1016/j.apsusc.2015.10.139

[26] QI S, LI X, ZHANG Z, et al. Fabrication and characterisation of electro-brush plated nickel-graphene oxide nano-composite coatings[J]. Thin Solid Films,2017,644:106-114. DOI: 10.1016/j.tsf.2017.06.064

[27] ZHANG H, XU C, XIAO W, et al. Enhanced mechanical properties of Al5083 alloy with graphene nanoplates prepared by ball milling and hot extrusion[J]. Materials Science and Engineering: A,2016,658:8-15. DOI: 10.1016/j.msea.2016.01.076

[28] 张家宝, 李志鹏, 杨鲁岩, 等. FCC金属中位错与孪晶界交互作用的原子机制[J]. 电子显微学报, 2020, 39(6):731-743. DOI: 10.3969/j.issn.1000-6281.2020.06.016 ZHANG J B, LI Z P, YANG L Y, et al. Atomic mechanism of interaction between dislocation and twin boundary in FCC metal[J]. Journal of Chinese Electron Microscopy Society,2020,39(6):731-743(in Chinese). DOI: 10.3969/j.issn.1000-6281.2020.06.016

[29] 陈玉丽, 马勇, 潘飞, 等. 多尺度复合材料力学研究进展[J]. 固体力学学报, 2018, 39(1):1-68. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2017.030 CHEN Y L, MA Y, PAN F, et al. Advances in mechanics research of multi-scale composites[J]. Chinese Journal of Solid Mechanics,2018,39(1):1-68(in Chinese). DOI: 10.19636/j.cnki.cjsm42-1250/o3.2017.030

[30] 俞洋, 苏益士, YANN B, 等. 颗粒增强金属基复合材料的结构建模与力学模拟研究进展[J]. 中国材料进展, 2020, 39(3):214-225. DOI: 10.7502/j.issn.1674-3962.201811010 YU Y, SU Y S, YANN B, et al. Progress in structural modeling and mechanical simulation of particle reinforced metal matrix composites[J]. Materials China,2020,39(3):214-225(in Chinese). DOI: 10.7502/j.issn.1674-3962.201811010

[31] RAO L, LIU H, LIU S, et al. Interface relationship between TiN and Ti substrate by first-principles calculation[J]. Computational Materials Science,2018,155:36-47. DOI: 10.1016/j.commatsci.2018.08.028

[32] LIU R, YIN X, FENG K, et al. First-principles calculations on Mg/TiB2 interfaces[J]. Computational Materials Science,2018,149:373-378. DOI: 10.1016/j.commatsci.2018.03.045

[33] WANG F, LI J, SHI C, et al. Orientation relationships and interface structure in MgAl2O4 and MgAlB4 co-reinforced Al matrix composites[J]. ACS Applied Materials & Interfaces,2019,11(45):42790-42800.

[34] DONG A, FU Q, WEI M, et al. Graphene-metal interaction and its effect on the interface stability under ambient conditions[J]. Applied Surface Science,2017,412:262-270. DOI: 10.1016/j.apsusc.2017.03.240

[35] PENG W, SUN K. Effects of Cu/graphene interface on the mechanical properties of multilayer Cu/graphene compo-sites[J]. Mechanics of Materials,2020,141:103270. DOI: 10.1016/j.mechmat.2019.103270

[36] LIN J, JIANG F, XU X, et al. Molecular dynamics simulation of nanoindentation on c-plane sapphire[J]. Mechanics of Materials,2021,154:103716. DOI: 10.1016/j.mechmat.2020.103716

[37] MA Y, ZHANG S, XU Y, et al. Effects of temperature and grain size on deformation of polycrystalline copper-graphene nanolayered composites[J]. Physical Chemistry Chemical Physics,2020,22(8):4741-4748. DOI: 10.1039/C9CP06830A

[38] TANG W, ZHANG J, WU J, et al. Mechanical properties and enhancement mechanisms of titanium-graphene nanocomposites[J]. Acta Mechanica Sinica,2020,36(4):855-865. DOI: 10.1007/s10409-020-00968-x

[39] 郭俊贤, 王波, 杨振宇. 石墨烯/Cu复合材料力学性能的分子动力学模拟[J]. 复合材料学报, 2014, 31(1):152-157. DOI: 10.3969/j.issn.1000-3851.2014.01.022 GUO J X, WANG B, YANG Z Y. Molecular dynamics simulation of mechanical properties of graphene/Cu composites[J]. Acta Materiae Compositae Sinica,2014,31(1):152-157(in Chinese). DOI: 10.3969/j.issn.1000-3851.2014.01.022

[40] 湛家铭, 姚小虎, 李旺辉, 等. 基于分子动力学的石墨烯/碳化硅复合材料力学性能研究[J]. 华南理工大学学报:自然科学版, 2017, 45(5):135-140. ZHAN J M, YAO X H, LI W H, et al. Mechanical properties of graphene/Silicon carbide composites based on molecular dynamics[J]. Journal of South China University of Technology (Natural Science Edition),2017,45(5):135-140(in Chinese).

[41] 陈生辉, 吕强, 郭继成, 等. 石墨烯/聚乙烯复合材料及其拉伸性能的分子动力学模拟[J]. 高分子学报, 2017(4):716-726. DOI: 10.11777/j.issn1000-3304.2017.16201 CHEN S H, LV Q, GUO J C, et al. Molecular dynamics simulation of graphene/polyethylene composites and their tensile properties[J]. Acta Polymerica Sinica,2017(4):716-726(in Chinese). DOI: 10.11777/j.issn1000-3304.2017.16201

[42] 魏宁, 赵思涵, 李志辉, 等. 石墨烯尺寸和分布对石墨烯/铝基复合材料裂纹扩展的影响[J]. 物理学报, 2022, 71(13):134702. WEI N, ZHAO S H, LI Z H, et al. Effects of graphene size and distribution on crack propagation in graphene/aluminum matrix composites[J]. Acta Physica Sinica,2022,71(13):134702(in Chinese).

[43] SHUANG F, AIFANTIS K E. Dislocation-graphene interactions in Cu/graphene composites and the effect of boundary conditions: A molecular dynamics study[J]. Carbon,2021,172:50-70. DOI: 10.1016/j.carbon.2020.09.043

[44] WENG S, NING H, FU T, et al. Molecular dynamics study of strengthening mechanism of nanolaminated graphene/Cu composites under compression[J]. Scientific Reports,2018,8(1):1-10.

[45] 华军, 宋郴, 段志荣, 等. 石墨烯/铜复合材料剪切性能的分子动力学模拟[J]. 复合材料学报, 2018, 35(3):632-639. DOI: 10.13801/j.cnki.fhclxb.20170504.001 HUA J, SONG C, DUAN Z R, et al. Molecular dynamics simulation of shear properties of graphene/copper composites[J]. Acta Materiae Compositae Sinica,2018,35(3):632-639(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20170504.001

[46] PENG W, SUN K, ZHANG M, et al. Effects of graphene coating on the plastic deformation of single crystal copper nano-cuboid under different nanoindentation modes[J]. Materials Chemistry and Physics,2019,225:1-7. DOI: 10.1016/j.matchemphys.2018.12.028

[47] GAO Y, RUESTES C J, URBASSEK H M. Nanoindentation and nanoscratching of iron: Atomistic simulation of dislocation generation and reactions[J]. Computational Materials Science,2014,90:232-240. DOI: 10.1016/j.commatsci.2014.04.027

[48] LIU X, WANG F, WANG W, et al. Interfacial strengthening and self-healing effect in graphene-copper nanolayered composites under shear deformation[J]. Carbon,2016,107:680-688. DOI: 10.1016/j.carbon.2016.06.071

[49] ZHANG J, ZHANG X, LIU G, et al. Scaling of the ductility with yield strength in nanostructured Cu/Cr multilayer films[J]. Scripta Materialia,2010,63(1):101-104. DOI: 10.1016/j.scriptamat.2010.03.024

[50] SONG H, XU J, ZHANG Y, et al. Molecular dynamics study of deformation behavior of crystalline Cu/amorphous Cu50Zr50 nanolaminates[J]. Materials & Design,2017,127:173-182.

[51] EMBURY J, HIRTH J. On dislocation storage and the mechanical response of fine scale microstructures[J]. Acta Metallurgica et Materialia,1994,42(6):2051-2056. DOI: 10.1016/0956-7151(94)90030-2

[52] MISRA A, HIRTH J, HOAGLAND R. Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites[J]. Acta Materialia,2005,53(18):4817-4824. DOI: 10.1016/j.actamat.2005.06.025

[53] ZHU Y, LI Z, HUANG M, et al. Strengthening mechanisms of the nanolayered polycrystalline metallic multilayers assisted by twins[J]. International Journal of Plasticity,2015,72:168-184. DOI: 10.1016/j.ijplas.2015.05.014

[54] DAW M S, BASKES M I. Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals[J]. Physical Review B, 1984, 29(12): 6443-6453.

[55] STUART S, HARRISON J, TUTEIN A. A reactive potential for hydrocarbons with intermolecular interactions[J]. The Journal of Chemical Physics,2000,112(14):6472-6486. DOI: 10.1063/1.481208

[56] LENNARD-JONES J E. Cohesion[J]. Proceedings of the Physical Society (1926-1948),1931,43(5):461. DOI: 10.1088/0959-5309/43/5/301

[57] SILVESTRE N, FARIA B, LOPES J N C. Compressive behavior of CNT-reinforced aluminum composites using molecular dynamics[J]. Composites Science and Technology,2014,90:3842-3844.

[58] KUTANA A, GIAPIS K P. Transient deformation regime in bending of single-walled carbon nanotubes[J]. Physical Review Letters,2006,97(24):245-501.

[59] MUNILLA J, CASTRO M, CARNICERO A. Surface effects in atomistic mechanical simulations of Al nanocrystals[J]. Physical Review B,2009,80(2):024109. DOI: 10.1103/PhysRevB.80.024109

[60] LI Z, GAO Y, ZHAN S, et al. Molecular dynamics study on temperature and strain rate dependences of mechanical properties of single crystal Al under uniaxial loading[J]. AIP Advances,2020,10(7):075321. DOI: 10.1063/1.5086903

[61] LIU Y, SHAO D, ZENG Y, et al. Molecular dynamics study of the tensile deformation on aluminum nanorod[J]. Advanced Intelligent Systems,2016,136:139-146.

[62] REZAEI R, TAVAKOLI-ANBARAN H, SHARIATI M. Mechanical characteristics and failure mechanism of nano-single crystal aluminum based on molecular dynamics simulations: Strain rate and temperature effects[J]. Jour-nal of Solid Mechanics,2017,9(4):794-801.

[63] GRAVELL J D, RYU I. Latent hardening/softening behavior in tension and torsion combined loadings of single crystal FCC micropillars[J]. Acta Materialia,2020,190:58-69. DOI: 10.1016/j.actamat.2020.02.030

[64] YAMAKOV V, WOLF D, PHILLPOT S R, et al. Dislocation processes in the deformation of nanocrystalline aluminium by molecular-dynamics simulation[J]. Nature Materials,2002,1(1):45-49. DOI: 10.1038/nmat700

[65] WANG X, XIAO W, WANG L, et al. Investigation on mechanical behavior of multilayer graphene reinforced aluminum composites[J]. Physica E: Low-Dimensional Systems and Nanostructures,2020,123:114172. DOI: 10.1016/j.physe.2020.114172

[66] KALAPRASAD G, JOSEPH K, THOMAS S, et al. Theoretical modelling of tensile properties of short sisal fibre-reinforced low-density polyethylene composites[J]. Journal of Materials Science,1997,32(16):4261-4267. DOI: 10.1023/A:1018651218515

[67] HOAGLAND R G, KURTZ R J, HENAGER J R C. Slip resistance of interfaces and the strength of metallic multilayer composites[J]. Scripta Materialia,2004,50(6):775-779. DOI: 10.1016/j.scriptamat.2003.11.059

[68] BAKER S P, ZHANG L, GAO H. Effect of dislocation core spreading at interfaces on strength of thin-films[J]. Jour-nal of Materials Research,2002,17(7):1808-1813. DOI: 10.1557/JMR.2002.0268

[69] CAMMARATA R, SIERADZKI K, SPAEPEN F. Simple model for interface stresses with application to misfit dislocation generation in epitaxial thin films[J]. Journal of Applied Physics,2000,87(3):1227-1234. DOI: 10.1063/1.372001

[70] REINHART W, ASAY J, CHHABILDAS L, et al. Investigation of 6061-T6 aluminum strength pproperties to 160 GPa[C]//APS Shock Compression of Condensed Matter Meeting Abstracts. Nashville: American Institute of Physics, 2009: 977-980.

[71] 侯日立, 彭建祥, 经福谦. 一种计算金属剪切模量的本构模型: 以Al为例[J]. 物理学报, 2009, 58(9):6413-6418. DOI: 10.3321/j.issn:1000-3290.2009.09.086 HOU R L, PENG J X, JING F Q. A constitutive model for calculating shear modulus of metal: A case study of Al[J]. Acta Physica Sinica,2009,58(9):6413-6418(in Chinese). DOI: 10.3321/j.issn:1000-3290.2009.09.086

[72] GAO Y, HAO P. Mechanical properties of monolayer graphene under tensile and compressive loading[J]. Physica E: Low-dimensional Systems and Nanostructures,2009,41(8):1561-1566. DOI: 10.1016/j.physe.2009.04.033

[73] SAKHAEE-POUR A. Elastic properties of single-layered graphene sheet[J]. Solid State Communications,2009,149(1-2):91-95. DOI: 10.1016/j.ssc.2008.09.050

-

期刊类型引用(2)

1. 荣誉,孙树堂,王智鹏,郝嘉欣,张煜航,连一仁,朱业明,闫津,牛江宇. 不同加载方式下减震器填充材料力学性能实验研究. 包装工程. 2025(03): 263-271 .  百度学术

百度学术

2. 程超,颜建伟,朱兆铭,谭鑫. 横向和纵向荷载下石墨烯/Al层状梁的弯曲特性. 复合材料学报. 2023(12): 6897-6909 .  本站查看

本站查看

其他类型引用(1)

-

下载:

下载: