Preparation and characterization on carbon fiber composites with high thermal conductivity based on multifunctional intercalation structures

-

摘要: 随着碳纤维增强树脂基复合材料在航天领域中的广泛应用,结构/功能一体化碳纤维(CF)复合材料将发挥出重要作用。本文采用功能化层间技术(Functional interlayer technology,FIT)制备了高导热沥青基碳纤维增强氰酸酯复合材料。在短切碳纤维薄膜表面电泳沉积石墨烯片(GNPs)和Al2O3制备薄膜材料GNPs-Al2O3/CF作为多功能插层结构,以其取代纤维层之间的富树脂层区域。后者表现出良好的导热性能,正交铺层复合材料的面内热导率和面外热导率分别提高了123.1%和77.5%,准各向同性铺层复合材料的面内热导率和面外热导率分别提高了119.0%和50.0%。此外,多功能插层结构的加入可以阻碍裂纹的扩展,改善复合材料层间韧性。因此,多功能插层结构既能在层间形成有效的导热网络结构,改善复合材料面内和面外热导率,又能提高层间区域的增韧效率。Abstract: With the extensive application of carbon fiber reinforced resin matrix composites in aerospace field, structure/function integrated composites will play a crucial part. In this paper, asphalt based carbon fiber (CF) reinforced cyanate ester composites with high thermal conductivity were prepared by functional interlayer technology (FIT). The film material graphene sheets (GNPs)-Al2O3/CF prepared by electrophoretic deposition of GNPs and Al2O3 on the surface of the short-cut carbon fiber film was used as the functional interlayer film to replace the resin-rich layer region between the fiber layers. The in-plane thermal conductivity and through-plane thermal conductivity of orthogonal lamination composites are increased by 123.1% and 77.5%. The in-plane thermal conductivity and through-plane thermal conductivity of quasi-anisotropic lamination composites are increased by 119.0% and 50.0%, respectively. In addition, the addition of multifunctional intercalation structure can prevent the propagation of cracks and improve the interlaminar toughness of composites. Therefore, the multifunctional intercalation structure can not only form an effective thermal network structure between the layers to improve the in-plane and out-of-plane thermal conductivity of the composite, but also improve the toughening efficiency of the interlayer region.

-

近年来,随着我国航天技术不断向微型化、集成化、轻量化和多功能化方向发展,航天器的集成度、工作频率和功率密度不断提高,过高的功率密度会使小范围内的热量堆积,使器件的温度偏离正常工作温度[1-3]。在卫星天线和电子系统中,非均匀的温度分布会引发较严重的热变形,造成载荷运行状态的不稳定性,严重的受热不均匀甚至引发材料的结构性破坏,进而影响航天器的探测任务和使用寿命[4-5]。因此不断改善材料和结构的导热性能是航天领域不断发展的迫切需求[6]。

沥青基碳纤维因其优异的导热性能已成为先进复合材料中的重要增强材料[7-8]。碳纤维增强聚合物复合材料(Carbon fiber reinforced polymer,CFRP)具有优异的力学性能、灵活的可设计性及空间环境稳定性,在卫星结构制造领域受到了广泛的关注[9-10]。

沥青基碳纤维具有较高的固有导热系数及复合材料优异的面内导热性能[11]。然而,树脂基体的导热性能较差,只有0.2~0.4 W/(m·K)[12-13]。由于厚度方向没有连续的纤维,层间界面中树脂基体相对丰富,阻断了声子在厚度方向的传输,导致复合材料贯穿厚度方向的导热系数较低,通常低于1 W/(m·K),也严重限制了其在特殊热扩散领域的应用。

为了提高高分子材料的导热性能,高导热填料成为众多研究者关注的焦点。然而,除了填料的界面修饰和排列方式外,填料的本征导热系数、形状、尺寸和负载量都对聚合物复合材料的导热系数有较大的影响。碳基填料及其杂化物具有较高的固有热导率,特别是短切碳纤维、碳纳米管和石墨烯[13],具备高纵横比和易于功能化的特点[14],可以同时实现从纳米到微米尺度的大尺寸分布。由于各种填料通过交联网络的协同作用形成导热网络结构,能够有效提高热导率[14-15]。因此,包括通过磁场、电场、应力场等技术来研究填料在特定方向上的取向改善面外热导率[16-18]。

通过诱导三维有序石墨结构也为高导热、高性能碳纤维复合材料的制备和生产提供了理论指导。中科院宁波所Hao等[19]以氧化石墨烯(GO)作为接枝桥梁,在碳纤维表面均匀接枝高取向度和结晶度的聚对苯撑苯丙双噁唑(PBO)层。再通过进一步石墨化,制备了同轴的聚丙烯腈(PAN)/PBO复合基碳纤维,所得单向PAN/PBO-碳纤维(CF)环氧树脂基复合材料的面内导热系数提高50%以上,厚度方向导热系数的提高率可达137%,导热系数达2.54 W/(m·K)。相关研究也以简单的工艺实现了低成本短碳纤构筑高导热取向三维网络结构。Jiao等[20]经过简单的“擀饼”工艺,使碳纤维沿擀制方向排列,且让导热填料结合紧密,除去缺陷,导热系数会进一步提升。Niu等[21]提出了膨胀流辅助取向的方法,用于一维/二维填料在热塑性/热固性复合材料中垂直取向结构的构筑。所制备的复合材料具有高面外取向度和高面外热导率。

针对碳纤维复合材料受高热阻树脂基体阻隔及碳纤维各向异性影响所致的厚度方向导热系数较低的问题,本文在沥青基碳纤维复合材料铺层过程中设置了短切碳纤维表面电泳沉积石墨烯片(GNPs)和Al2O3的薄膜材料。以GNPs和Al2O3为导热填料,在复合材料层间构筑三维导热网络结构,以短切碳纤维(CF)衬底为骨架结构,增强层间相互作用,以期同时达到改善复合材料的导热性能和层间力学性能的目的。

1. 实验部分

1.1 原材料

沥青基碳纤维(TC-HC-600),陕西天策科技新材料有限公司;氰酸酯树脂(Cyanate ester,CE),实验室自制;石墨烯片(GNPs),梯希爱(上海)化成工业发展有限公司;Al2O3,天津市致远化学试剂有限公司;阴离子聚丙烯酰胺(Anionic polyacrylamide,APAM)、聚氨酯(Polyurethane,PU),阿拉丁试剂(上海)有限公司。

所用沥青基碳纤维热导率为614 W/(m·K)。氰酸酯树脂为本实验室自制树脂,具有低挥发、低质损、高玻璃化转变温度(220℃)的特点,满足航天结构用树脂材料的要求。GNPs厚度为5~18 nm,厚度小于20层。Al2O3粒径在30~60 nm之间。APAM分子量在600万至

2500 万之间,在此区间内能够与水任意比例相容。1.2 薄膜的制备

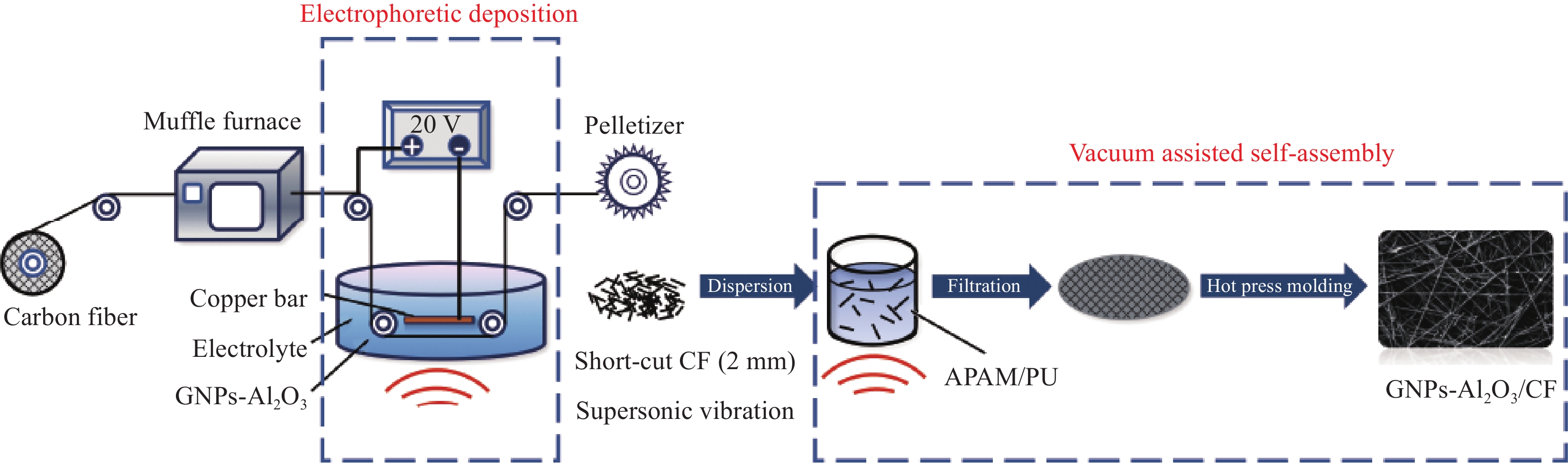

首先在480℃下加热除去沥青基碳纤维表面的上浆剂。将 2 mg GNPs和2 mg Al2O3 分散于 100 mL 蒸馏水中,利用NaOH将混合溶液的pH值调节至10,超声处理 30 min,形成电泳沉积电解液。将处理后的碳纤维丝束浸渍在配制完成的电解液中,以丝束为阳极,铜棒为阴极,在碳纤维表面电泳沉积GNPs和Al2O3。其中电泳电源采用 IT6872 A,施加电压为6 V,电极间的距离固定为4 cm,电泳沉积时间为1 min。

随后将表面电泳沉积后的碳纤维经过清洗、烘干、径向切割成2 mm的短切碳纤维。将一定比例短切碳纤维加入到去离子水中,每100 mL去离子水中加入5 g APAM和2 g PU复配型分散剂,超声振动分散20 min后,通过滤纸过滤溶液后再经去离子水冲洗3遍,在室温下干燥12 h。最后,在25℃和2.5 MPa下对所得薄膜进行热压5 min,得到50~80 μm厚度的薄膜材料(GNPs-Al2O3/CF)。技术路线如图1所示。为了对比差异性,按表1制备了5种不同的薄膜试样。每种薄膜试样电泳沉积工艺参数相同。不同之处在于沥青基碳纤维表面上浆剂的存在与否及电泳沉积无机粒子的种类。

表 1 用于对比实验的薄膜材料Table 1. Thin film materials for comparative experimentsSample Sizing agent Electrophoretic deposition CF Yes None CF-1 None None Al2O3/CF None Al2O3 GNPs/CF None GNPs GNPs-Al2O3/CF None GNPs/Al2O3 1.3 复合材料层合板的制备

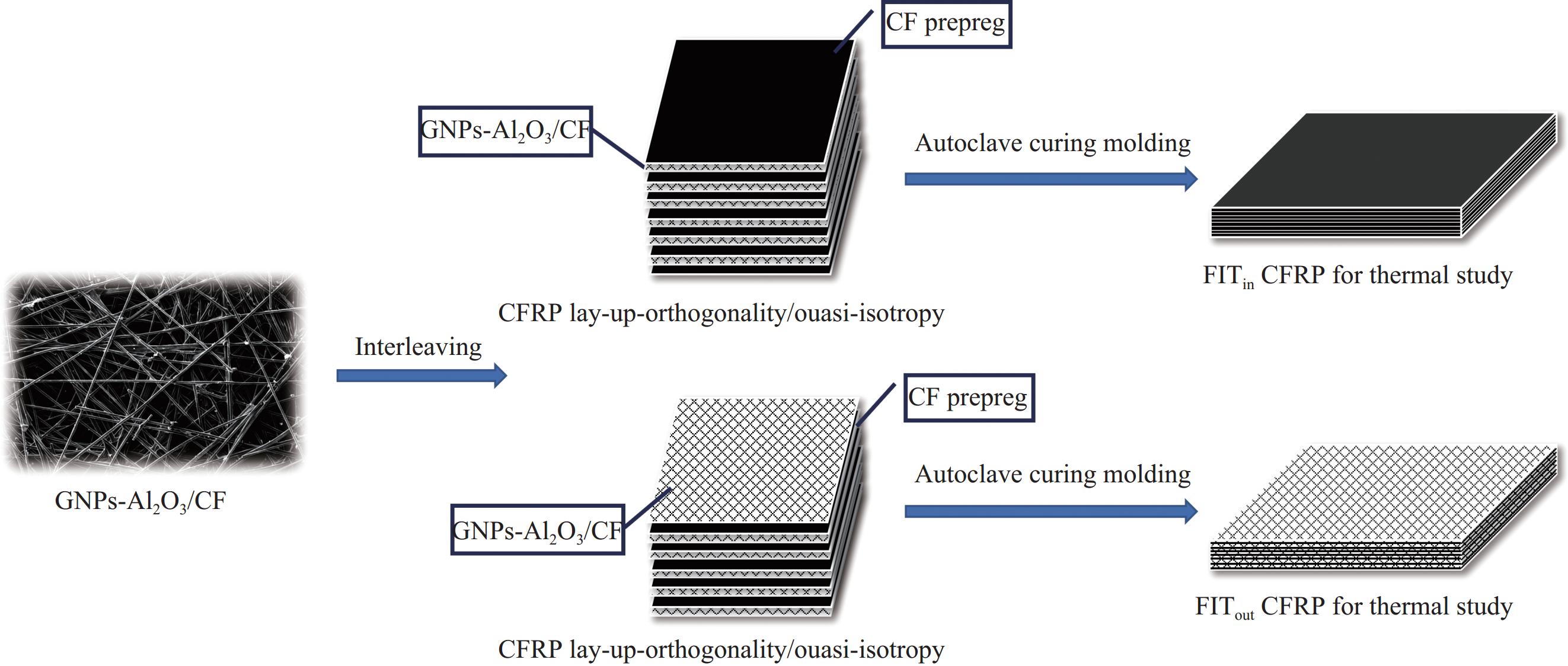

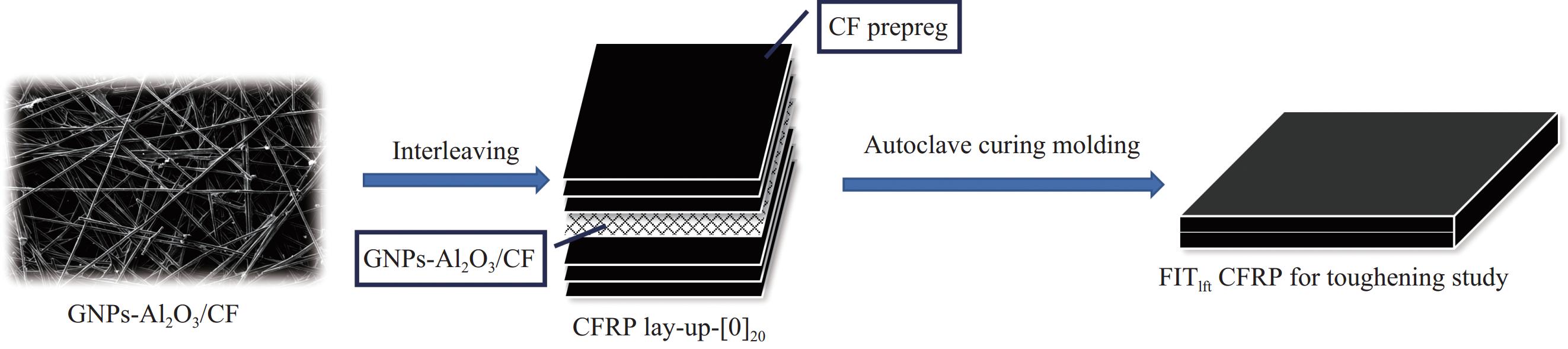

首先通过湿法缠绕制备0.08 mm厚度的TC-HC-600/CE预浸料,纤维体积含量65vol%±3vol%,然后将其裁剪成300 mm×300 mm的方块。采用正交铺层[0/90]n和准各向同性铺层[0/+45/90/−45]n制备碳纤维复合材料,并且按照图2和图3所示的方式,在铺层过程中设置不同插层形式,采用图4所示的热压罐固化成型工艺制备复合材料FITin(面外一层为碳纤维)、FITout(面外一层为多功能插层结构)及FITlft(层间增韧测试试样),以此来研究多功能插层结构对复合材料导热性能和层间韧性的作用效果。

![]() 图 2 复合材料导热性能测试试样制备示意图FIT—Functional interlayer technology; CFRP—Carbon fiber reinforced polymer;FITin—The outermost layer of the specimen is CF; FITout—The outermost layer of the specimen is GNPs-Al2O3/CFFigure 2. Schematic diagram of sample preparation for thermal conductivity testing of composite materials

图 2 复合材料导热性能测试试样制备示意图FIT—Functional interlayer technology; CFRP—Carbon fiber reinforced polymer;FITin—The outermost layer of the specimen is CF; FITout—The outermost layer of the specimen is GNPs-Al2O3/CFFigure 2. Schematic diagram of sample preparation for thermal conductivity testing of composite materials1.4 结构与性能表征

采用场发射扫描电子显微镜(SEM,S-4700, 日本日立)和DMFASTSCAN2-SYS的原子力显微镜(AFM,德国布鲁克)对薄膜的形貌进行表征。复合材料导热性能依据《闪光法测量热扩散系数或导热系数》(GB/T 22588—2008)[22],采用激光闪光测试仪(Nano Flash,LFA 467,Netzsch)表征。层间性能依据《纤维增强塑料复合材料单向增强材料I型层间断裂韧性GIc的测定》(GB/T 28891—2012)[23]在万能试验机(UTM5205SYXL,深圳三思纵横科技股份有限公司)上进行层间断裂韧性试验。

2. 结果与讨论

2.1 薄膜的表面形貌

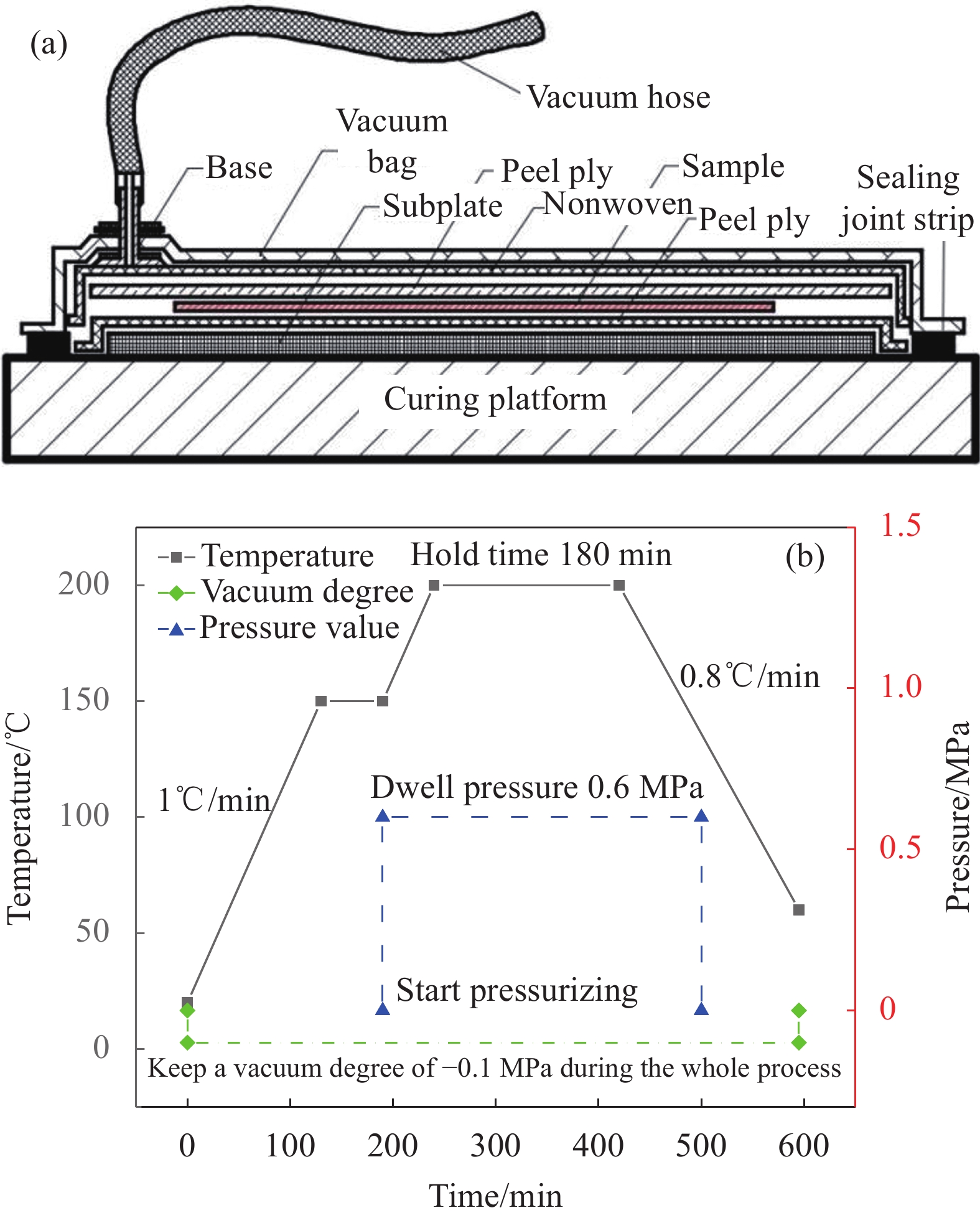

图5展现了TC-HC-600碳纤维表面微观形貌。通过SEM可以观察到表面含有上浆剂、不含上浆剂及电泳沉积修饰GNPs-Al2O3/CF纤维的表面形貌。可以看出,含有上浆剂的CF表面非常平整光滑,去除上浆剂后纤维表面存在许多沟槽。通过电泳沉积的方法,GNPs和Al2O3成功附着在了纤维表面,这预计将在复合材料层与层之间厚度方向上形成有效的导热结构,确保薄膜材料对导热性能的改善作出贡献。同时随着GNPs及Al2O3的沉积,使碳纤维表面变得更加粗糙,也将有助于改善碳纤维复合材料层间性能。

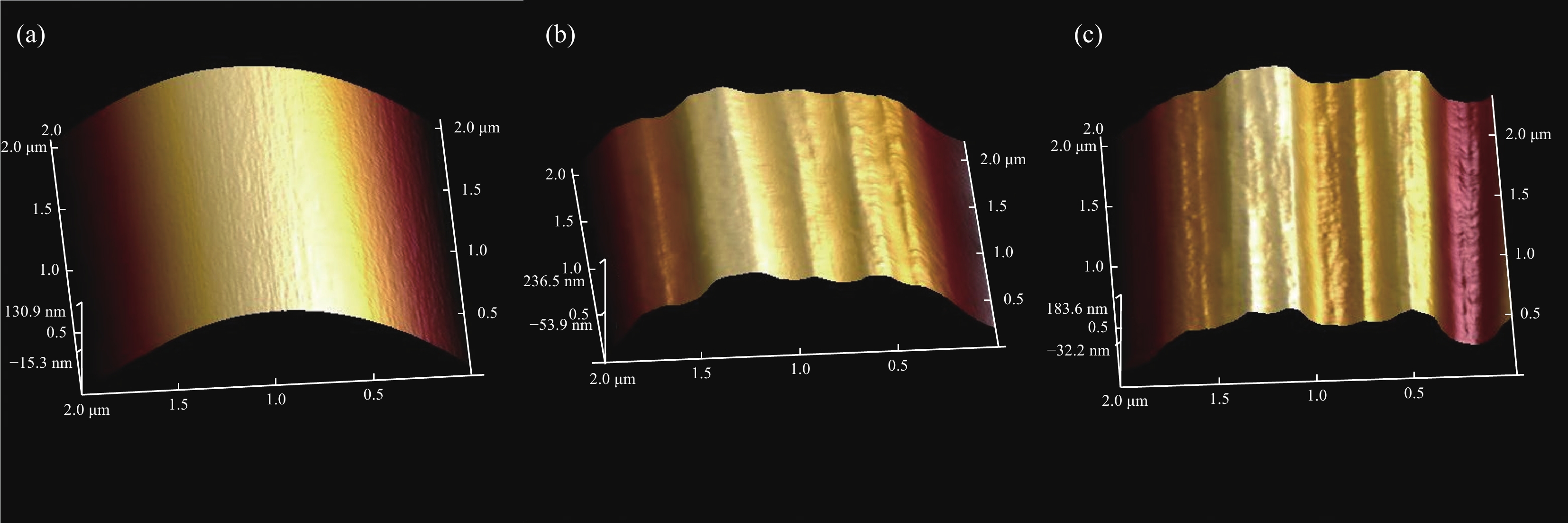

为了确认氧化石墨烯沉积后CF表面变得更加粗糙,使用原子力显微镜对表面含有上浆剂、表面不含上浆剂、表面电泳沉积GNPs和Al2O3的试样进行表面粗糙度测量,该技术可以为各种尺寸和形状的样品提供灵活的、非接触式的3D真实表面表征。

从图6的TC-HC-600碳纤维AFM图谱中可以看出,含有上浆剂的碳纤维表面光滑平整,未上浆的碳纤维表面存较浅且细小的沟槽,粗糙度大于含有上浆剂的碳纤维。而电泳沉积后的碳纤维表面由于附着了GNPs和Al2O3而变得更加粗糙,使纤维的比表面积增大,进而增强了纤维与树脂之间的物理锚定作用,表现为纤维增强体与树脂基体之间的结合力的改善。

2.2 薄膜材料的表面润湿性

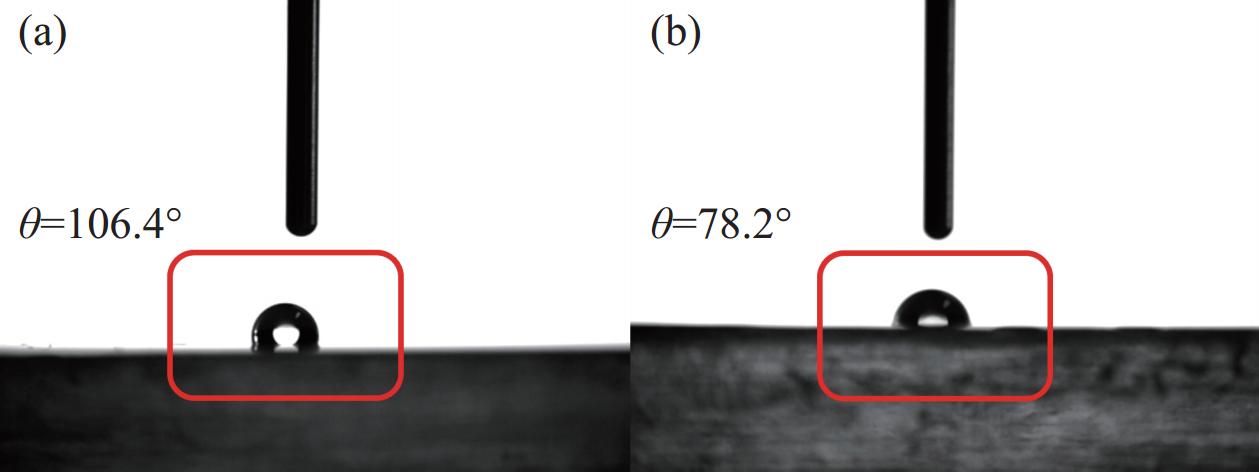

碳纤维表面极性基团数量相对较少,在宏观上表现为化学惰性,进而使碳纤维与树脂无法紧密结合,因此复合材料容易发生分层,导致力学性能大幅下降。本文采用接触角测试仪(JGW-360B,成惠试验机有限公司)测量CF和GNPs-Al2O3/CF薄膜的表面润湿性,根据相似相溶的原理,以纤维与水滴的接触角来反映其润湿性,如图7所示。从图7(a)可以看出,水滴保持圆形,接触角较大,平均接触角为106.4°,说明CF 润湿性较低。而GNPs-Al2O3/CF薄膜由于GNPs和Al2O3的加入及真空辅助自组装的过程中对其进行了表面改性,其接触角显著减小至78.2°。由于在GNPs-Al2O3/CF薄膜材料表面引入了更多的极性基团,润湿性有较强的改善,接触点较多的GNPs-Al2O3/CF薄膜表面更容易与水连接。因此,通过电泳沉积的方法,GNPs-Al2O3/CF薄膜有望加强纤维与树脂基体之间的物理化学相互作用,对改善复合材料层间韧性具有很大潜力。

2.3 薄膜材料的导热性能

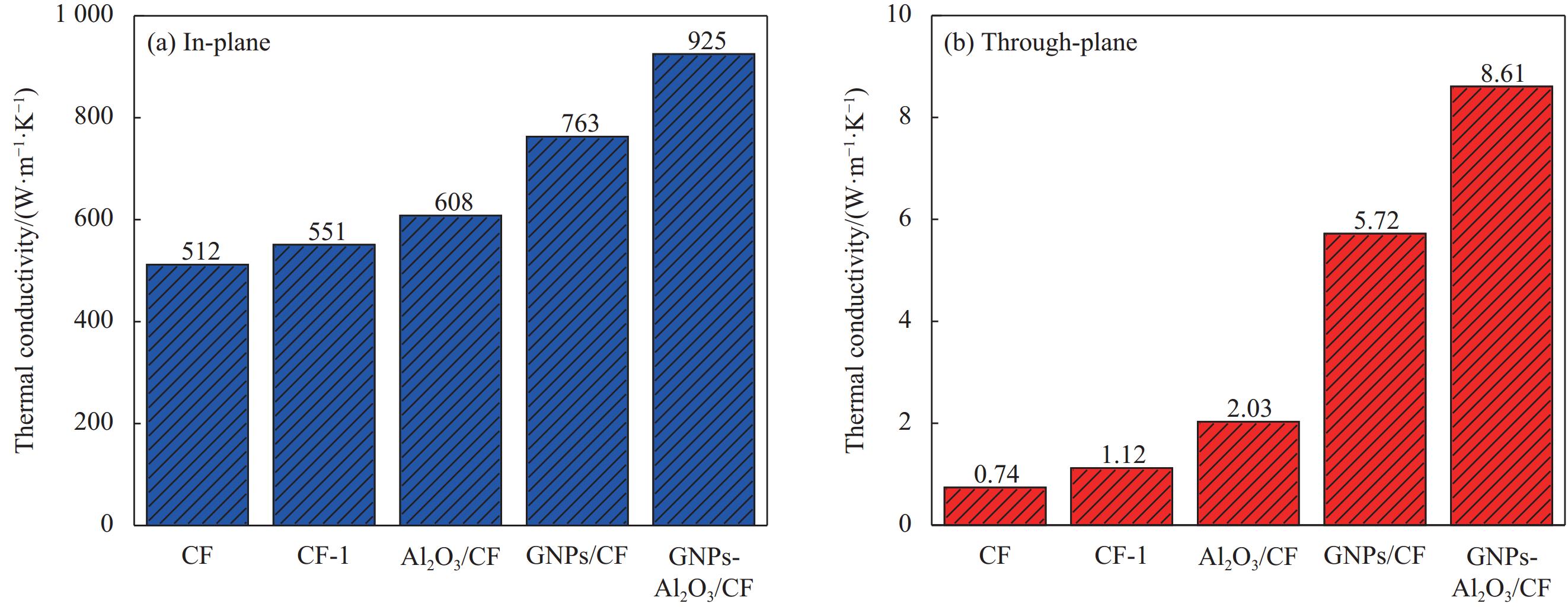

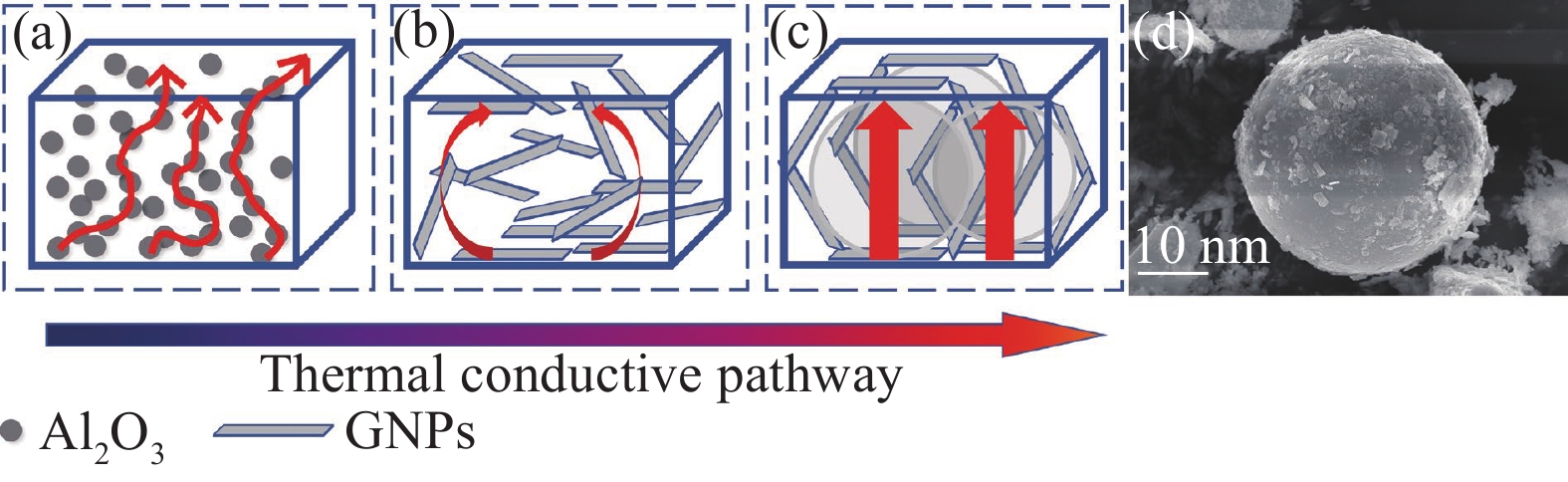

图8分别为表1所示5种薄膜材料的面内和面外热导率。可以看出,GNPs-Al2O3/CF薄膜的面内和面外热导率达到最大,分别为925 W/(m·K)和8.61 W/(m·K)。比未表面改性的CF薄膜提高了80.6%和406.5%。CF-1薄膜比CF薄膜的热导率略高,这主要是由于上浆剂作为一种高分子材料,本征热导率是非常低的,通常情况下小于0.5 W/(m·K),阻碍了纤维之间热量的传输。Al2O3/CF在厚度方向热导率比CF提高了19.0%,是由于 Al2O3颗粒相互连接,形成了热输运结构,可以充分利用Al2O3的本征热导率k (30 W/(m·K))[24],但是改善效果并不明显,这主要是由于单纯依靠颗粒改善导热性能时,形成的导热结构热界面多、传热能力低,因此面外k值的改善非常有限。GNPs/CF在厚度方向的热导率提高了236.0%,改善作用显著,主要是由于GNPs同样可以通过相互接触建立有效的导热结构,并且GNPs具有超过

3000 W/(m·K)的本征热导率(图9)[25]。但是两种薄膜材料的厚度方向热导率还是没有达到最大值,这是由于Al2O3和GNPs自身还是具有较低的面外k值。总的来说,在基体中构建二维填料的垂直排列是提高复合材料厚度方向k值的有效策略。引入GNPs片状结构到颗粒中, GNPs薄片覆盖在Al2O3颗粒表面,降低了Al2O3直接接触所形成的界面热阻,同时能够充分利用GNPs的超高面内k值,提高复合材料热传输效率。![]() 图 9 不同薄膜结构热传输路径示意图:(a) Al2O3热传输路径;(b) GNPs热传输路径;(c) GNPs-Al2O3热传输路径;(d)基于SEM的GNPs-Al2O3微观结构示意图Figure 9. Schematic diagram of heat transfer paths for different thin film structures: (a) Heat transfer paths of Al2O3; (b) Heat transfer paths of GNPs; (c) Heat transfer paths of GNPs-Al2O3; (d) Microstructure diagram of GNPs-Al2O3 based on SEM

图 9 不同薄膜结构热传输路径示意图:(a) Al2O3热传输路径;(b) GNPs热传输路径;(c) GNPs-Al2O3热传输路径;(d)基于SEM的GNPs-Al2O3微观结构示意图Figure 9. Schematic diagram of heat transfer paths for different thin film structures: (a) Heat transfer paths of Al2O3; (b) Heat transfer paths of GNPs; (c) Heat transfer paths of GNPs-Al2O3; (d) Microstructure diagram of GNPs-Al2O3 based on SEM2.4 复合材料导热性能

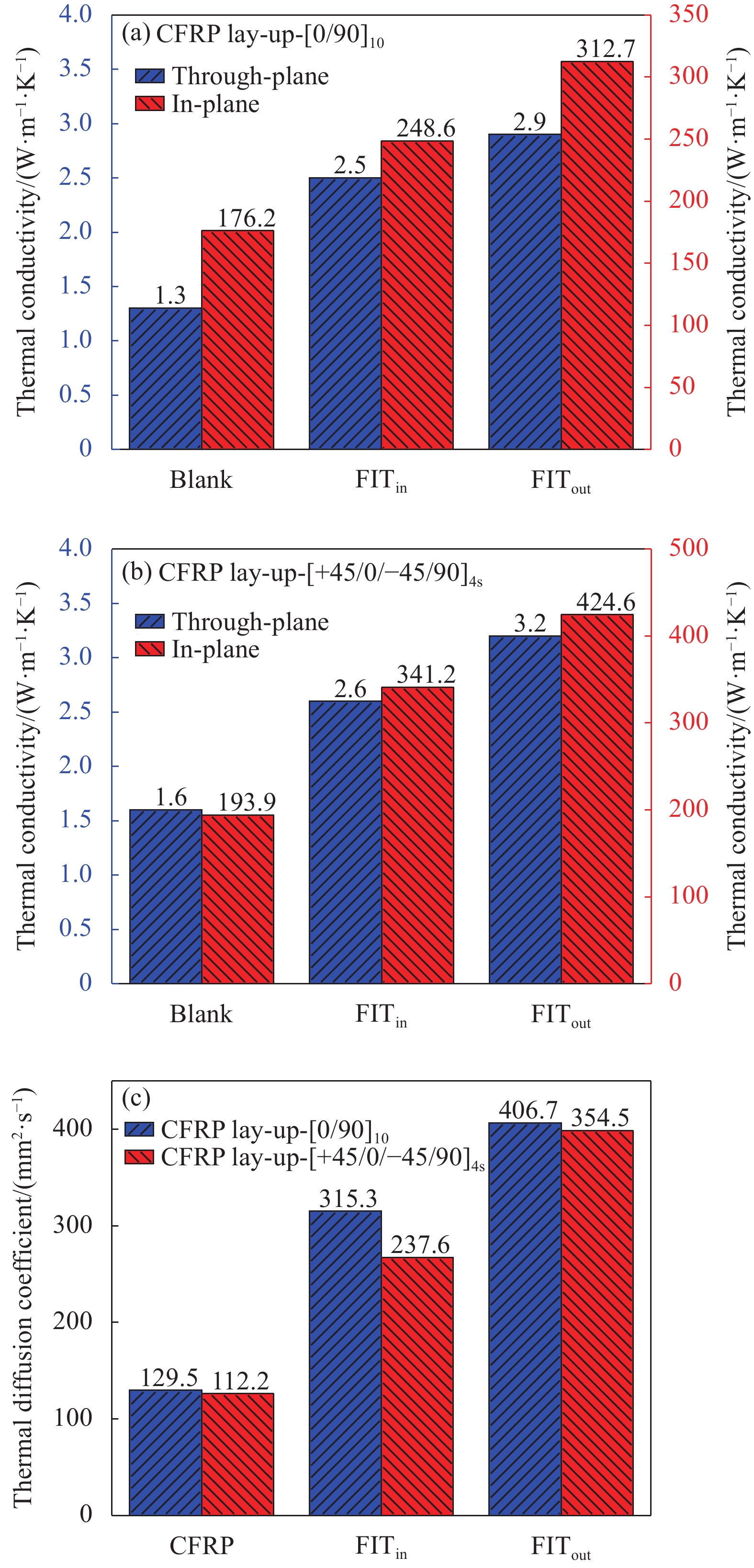

图10为各组试样的面内热导率和面外热导率。本文内容设置了正交铺层和准各向同性铺层。正交铺层层合板的面内和面外热导率最大分别为312.7 W/(m·K)和2.9 W/(m·K),比未改性正交铺层层合板的176.2 W/(m·K)和1.3 W/(m·K)提高了77.5%和123.1%。准各向同性铺层层合板的面内和面外热导率最大分别为424.6 W/(m·K)和3.2 W/(m·K),比未改性准各向同性铺层层合板的193.9 W/(m·K)和1.6 W/(m·K)增加了119.0%和50.0%。热能主要以晶格振动形式传递,而填料/填料界面和填料/聚合物界面的振动模式耦合不良导致热阻较大,这是阻碍聚合物基复合材料热传输的决定性因素。在这里,理想的热传输结构有效地降低了填料/填料界面和填料/聚合物界面的界面热阻。多功能夹层结构有规律地平铺于碳纤维预浸料层与层之间,形成周期性的层状结构,通过堆叠连接形成了许多导热单元。这些导热单元取代了传统的富树脂层间区,从而打破了厚度方向上的隔热屏障。此外,由于多功能插层结构的连续性,复合材料的面内热导率也有了显著的改善。

纤维方向对面内热导率也有较大的影响。根据图10所示结果可以看出,准各向同性铺层的复合材料热导率高于正交铺层。主要是由于准各向同性铺层的复合材料中具有与热流方向垂直关系的纤维含量较少。垂直热流方向的纤维传热基体是聚合物,会阻碍热流的传输。

正交层合板和准各向同性层合板的FITout的面内和面外热导率都高于FITin。正交铺层层合板FITout的面内和面外热导率比FITin分别提高了16.0%和25.8%。准各向同性层合板FITout的面内和面外热导率比FITin分别提高了23.0%和24.4%。这主要是由于层合板外表面额外增加的多功能插层结构进一步增大了表面传热效率,将为进一步优化材料导热结构设计的研究提供依据。

2.5 复合材料的层间断裂韧性

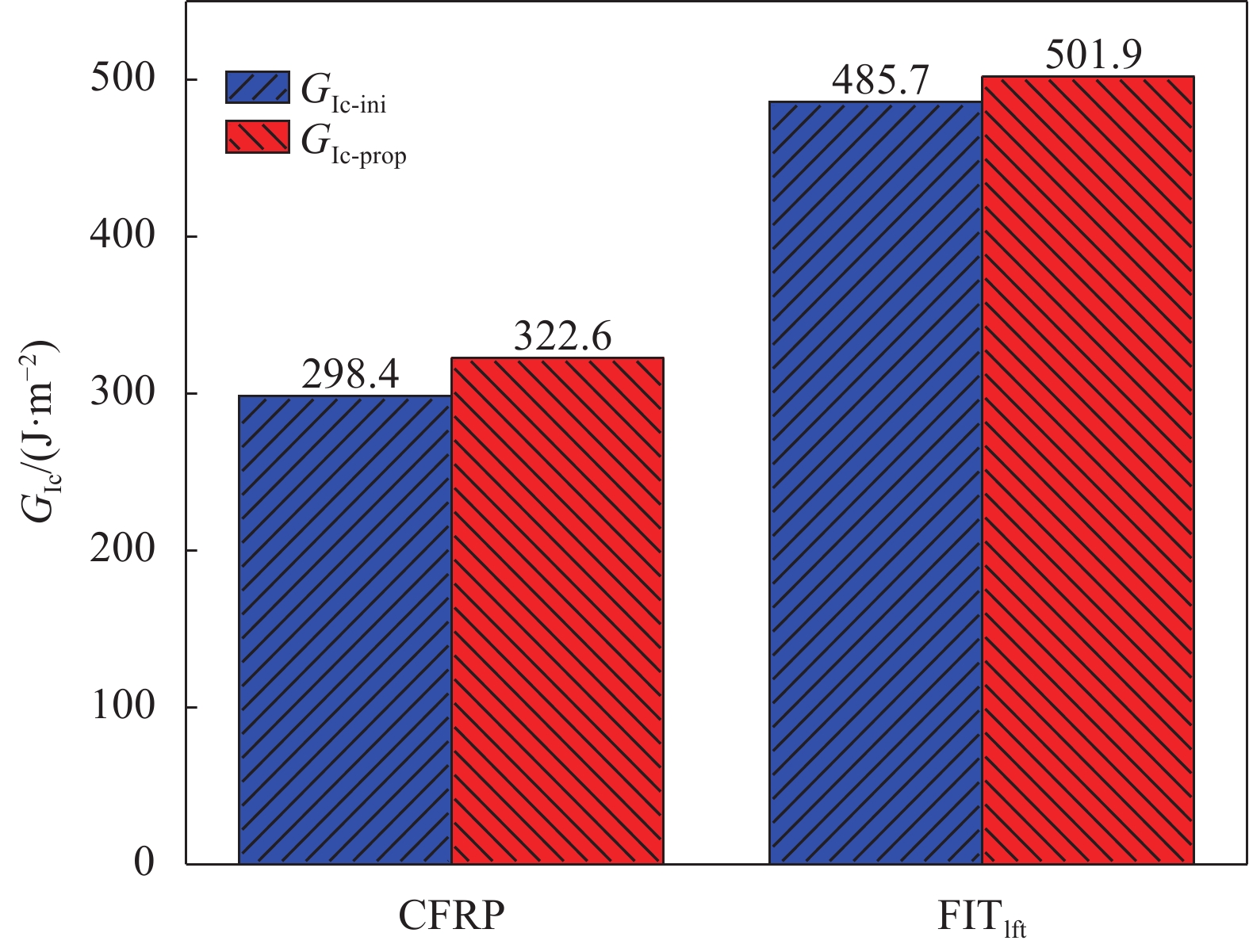

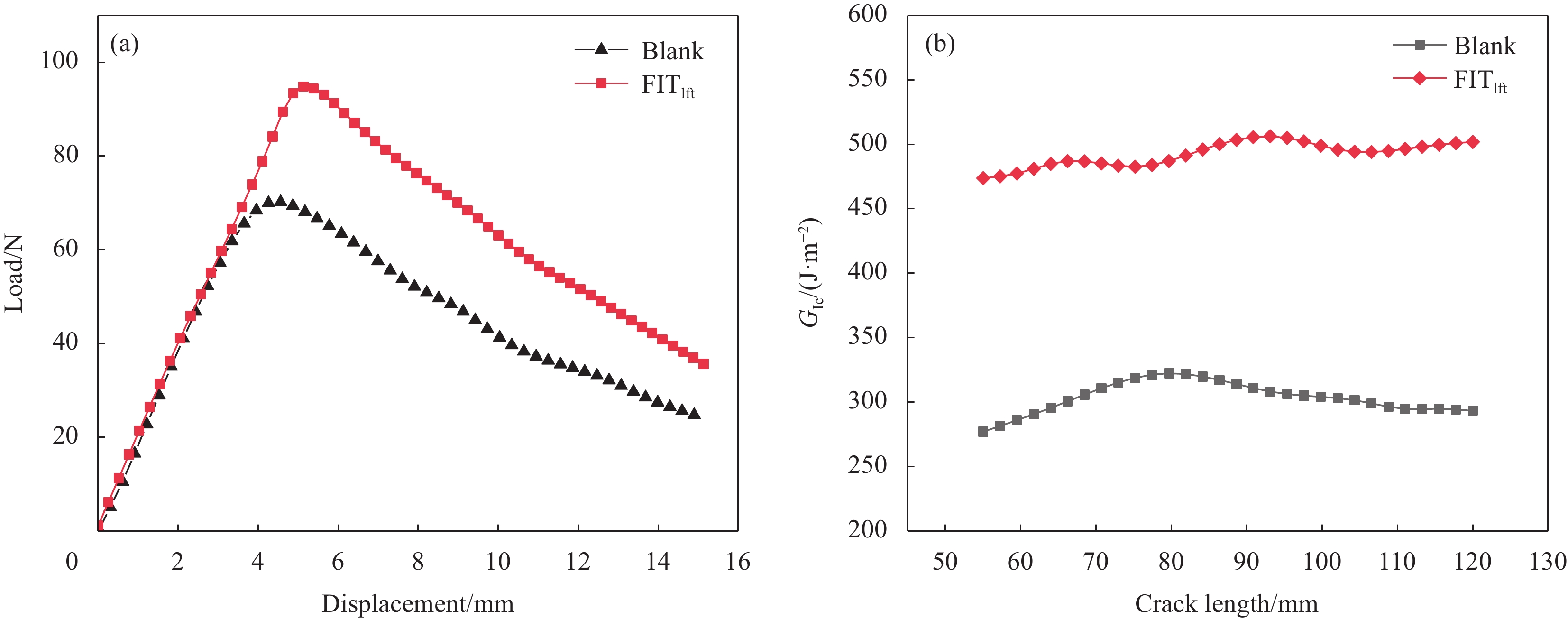

FITlft试样的I型断裂初始能GIc-ini和I型断裂扩展能GIc-prop如图11所示。与未设置多功能插层结构的空白组试样相比,FITlft的平均GIc-ini和GIc-prop分别从298.4 J/m2和322.6 J/m2增加到485.7 J/m2和501.9 J/m2,对应分别增加了62.8%和55.6%。典型I型力-位移曲线如图12(a)所示。在初始加载过程中,FITlft试样在较高的载荷和位移下观察到裂纹萌生。多功能插层结构的加入延缓了裂纹的萌生,增加了裂纹扩展需要的载荷。图12(b)为I型试件典型的R曲线。两条曲线均显示裂纹扩展稳定,且GIc-prop随裂纹长度的增加而增大。FITlft各点的GIc-prop均高于空白组试样,同样说明FITlft试样裂纹扩展需要更大的能量。

3. 结 论

通过功能化层间技术,石墨烯片-Al2O3/碳纤维(GNPs-Al2O3/CF)薄膜材料提供了双功能特性,同时提高了沥青基碳纤维层合板的面内、面外热导率和层间韧性。薄膜可以很好地渗透到树脂基体中,在碳纤维层间区域形成连续导热结构。针对两种不同的铺层方式:

(1)正交铺层层合板的面内和面外热导率最大分别为312.7 W/(m·K)和2.9 W/(m·K),增加了77.5%和123.1%;

(2)准各向铺层层合板的面外和面内热导率最大分别为3.2 W/(m·K)和424.6 W/(m·K),增加了50.0%和119.0%;

(3) GNPs-Al2O3/CF薄膜材料增大了复合材料裂纹扩展所需的能量,达到层间增韧的作用。

-

图 2 复合材料导热性能测试试样制备示意图

FIT—Functional interlayer technology; CFRP—Carbon fiber reinforced polymer;FITin—The outermost layer of the specimen is CF; FITout—The outermost layer of the specimen is GNPs-Al2O3/CF

Figure 2. Schematic diagram of sample preparation for thermal conductivity testing of composite materials

图 9 不同薄膜结构热传输路径示意图:(a) Al2O3热传输路径;(b) GNPs热传输路径;(c) GNPs-Al2O3热传输路径;(d)基于SEM的GNPs-Al2O3微观结构示意图

Figure 9. Schematic diagram of heat transfer paths for different thin film structures: (a) Heat transfer paths of Al2O3; (b) Heat transfer paths of GNPs; (c) Heat transfer paths of GNPs-Al2O3; (d) Microstructure diagram of GNPs-Al2O3 based on SEM

表 1 用于对比实验的薄膜材料

Table 1 Thin film materials for comparative experiments

Sample Sizing agent Electrophoretic deposition CF Yes None CF-1 None None Al2O3/CF None Al2O3 GNPs/CF None GNPs GNPs-Al2O3/CF None GNPs/Al2O3 -

[1] WU X, TANG B, CHEN J, et al. Epoxy composites with high cross-plane thermal conductivity by constructing all-carbon multidimensional carbon fiber/graphite networks[J]. Composites Science and Technology, 2021, 203: 108610. DOI: 10.1016/j.compscitech.2020.108610

[2] HAN S, CHUANG D. Increasing the through-thickness thermal conductivity of carbon fiber polymer-matrix composite by curing pressure increase and filler incorporation[J]. Composites Science & Technology, 2011, 71(16): 1944-1952.

[3] 雷智博, 曹建光, 董丽宁, 等. 航天器热管理高导热材料应用研究[J]. 中国材料进展, 2018, 37(12): 1039-1047. DOI: 10.7502/j.issn.1674-3962.2018.12.12 LEI Zhibo, CAO Jianguang, DONG lining, et al. Application of high thermal conductivity materials for spacecraft thermal management[J]. Materials Development in China, 2018, 37(12): 1039-1047(in Chinese). DOI: 10.7502/j.issn.1674-3962.2018.12.12

[4] LIANG X, CHEN W, JI J, et al. Synergistic effect of carbon fiber and alumina in improving the thermal conductivity of polydimethylsiloxane composite[J]. Thermochimica Acta, 2021, 703: 178980. DOI: 10.1016/j.tca.2021.178980

[5] ZHANG G, XUE S, CHEN F, et al. An efficient thermal interface material with anisotropy orientation and high through plane thermal conductivity[J]. Composites Science and Technology, 2023, 231: 109784. DOI: 10.1016/j.compscitech.2022.109784

[6] 王函, 孙新阳, 张建岗, 等. 石墨烯/碳纤维混杂复合材料的结构功能一体化研究进展[J]. 固体火箭技术, 2021, 44(6): 737-746. WANG Han, SUN Xinyang, ZHANG Jiangang, et al. Progress in structural and functional integration of graphene/carbon fiber hybrid composites[J]. Solid Rocket Technology, 2021, 44(6): 737-746(in Chinese).

[7] 张媛媛, 初人庆, 郭丹, 等. 高性能沥青基碳纤维发展现状及制备工艺[J]. 当代化工, 2023, 52(2): 457-460. DOI: 10.3969/j.issn.1671-0460.2023.02.041 ZHANG Yuanyuan, CHU Renqing, GUO Dan, et al. Development status and preparation technology of high performance asphalt-based carbon fiber[J]. Contemporary Chemical Industry, 2023, 52(2): 457-460(in Chinese). DOI: 10.3969/j.issn.1671-0460.2023.02.041

[8] 田雨华, 王象东, 王辉, 等. 中间相沥青基碳纤维与T800H碳纤维复合材料性能对比[J]. 高科技纤维与应用, 2022, 47(3): 30-34. TIAN Yuhua, WANG Xiangdong, WANG Hui, et al. Comparison of properties of mesophase asphaltic carbon fiber and T800H carbon fiber composites[J]. High-Tech Fiber and Application, 2022, 47(3): 30-34(in Chinese).

[9] 江文剑, 姜恒坤, 梁云, 等. 高精确度碳纤维复合材料反射器研究进展与展望[J]. 太赫兹科学与电子信息学报, 2022, 20(10): 1064-1072. DOI: 10.11805/TKYDA2021380 JIANG Wenjian, JIANG Hengkun, LIANG Yun, et al. Research progress and prospect of high precision carbon fiber composite reflectors[J]. Journal of Terahertz Science and Electronic Information, 2022, 20(10): 1064-1072(in Chinese). DOI: 10.11805/TKYDA2021380

[10] 杨燕宁, 张亮儒, 董经经, 等. 高模量碳纤维复合材料在卫星结构上的应用[J]. 高科技纤维与应用, 2022, 47(4): 11-15. DOI: 10.3969/j.issn.1007-9815.2022.04.001 YANG Yanning, ZHANG Liangru, DONG Jingjing, et al. Application of high-modulus carbon fiber composites to satellite structures[J]. High-Tech Fiber and Application, 2022, 47(4): 11-15(in Chinese). DOI: 10.3969/j.issn.1007-9815.2022.04.001

[11] ABBAS F A, ALHAMDO M H. Thermal performance of asphalt solar colctor by improving tube and slab characteristics[J]. International Journal of Thermofluid, 2023, 17: 100293. DOI: 10.1016/j.ijft.2023.100293

[12] FENG C P, CHEN L B, TIAN G L, et al. Robust polymer-based paper-like thermal interface materials with a through-plane thermal conductivity over 9 W·m−1·K−1[J]. Chemical Engineering Journal, 2020, 392: 123784. DOI: 10.1016/j.cej.2019.123784

[13] 葛瑛, 杨东元, 高超锋, 等. 高导热石墨烯复合材料研究进展[J]. 上海塑料, 2022, 50(5): 1-7. GE Ying, YANG Dongyuan, GAO Chaofeng, et al. Research progress of graphene composites with high thermal conductivity[J]. Shanghai Plastic, 2022, 50(5): 1-7(in Chinese).

[14] ZHANG X, ZHANG J, XIA L, et al. Achieving high-efficiency and robust 3D thermally conductive while electrically insulating hybrid filler network with high orientation and ordered distribution[J]. Chemical Engineering Journal, 2018, 334: 247-256. DOI: 10.1016/j.cej.2017.10.037

[15] LI M, ALI Z, WEI X, et al. Stress induced carbon fiber orientation for enhanced thermal conductivity of epoxy composites[J]. Composites Part B: Engineering, 2021, 208: 108599. DOI: 10.1016/j.compositesb.2020.108599

[16] GUO H, LI X, LI B, et al. Thermal conductivity of graphene/poly(vinylidene fluoride) nanocomposite membrane[J]. Materials & Design, 2017, 114: 355-363.

[17] YUAN J, QIAN X, MENG Z, et al. Highly thermally conducting polymer-based films with magnetic field-assisted vertically aligned hexagonal boron nitride for flexible electronic encapsulation[J]. ACS Applied Materials & Interfaces, 2019, 11(19): 17915-17924.

[18] 陈海斌, 陈瑞, 刘美琪, 等. 基于外力诱导取向的高导热聚合物基复合材料研究进展[J]. 复合材料学报, 2022, 39(4): 1486-1497. CHEN Haibin, CHEN Rui, LIU Meiqi, et al. Research progress of polymer matrix composites with high thermal conductivity based on external force induced orientation[J]. Acta Materiae Compositae Sinica, 2022, 39(4): 1486-1497(in Chinese).

[19] HAO M, HU Z, HUANG Y, et al. Enhanced both in-plane and through-thickness thermal conductivity of carbon fiber/epoxy composites by fabricating high thermal conductive coaxial PAN/PBO carbon fibers[J]. Composites Part B: Engineering, 2022, 229: 109468. DOI: 10.1016/j.compositesb.2021.109468

[20] JIAO T, HAN B, ZHAO L, et al. Pie-rolling-inspired construction of vertical carbon fiber high thermal conductivity hybrid networks[J]. Applied Surface Science, 2023, 618: 156711. DOI: 10.1016/j.apsusc.2023.156711

[21] NIU H, GUO H, KANG L, et al. Vertical alignment of anisotropic fillers assisted by expansion flow in polymer composites[J]. Nano-Micro Letters, 2022, 14(9): 153.

[22] 全国耐火材料标准化技术委员会. 闪光法测量热扩散系数或导热系数: GB/T 22588—2008[S]. 北京: 中国标准出版社, 2008. Refractory. Determination of thermal conductivity by the flash method: GB/T 22588—2008[S]. Beijing: Standards Press of China, 2008(in Chinese).

[23] 全国纤维增强塑料标准化技术委员会. 纤维增强塑料复合材料单向增强材料I型层间断裂韧性GIc的测定: GB/T 28891—2012[S]. 北京: 中国标准出版社, 2012. National Fiber Reinforced Plastics. Fiber-reinforced plastic composite—Determination of mode I interlaminar fracture toughness GIc for unidirectionally reinforced materials: GB/T 28891—2012[S]. Beijing: Standards Press of China, 2012(in Chinese).

[24] CHEN H, GINZBURG V V, YANG J, et al. Thermal conductivity of polymer-based composites: Fundamentals and applications[J]. Progress in Polymer Science, 2016, 59: 41-85.

[25] FENG C P, WAN S S, WU W C, et al. Electrically insulating, layer structured SiR/GNPs/BN thermal management materials with enhanced thermal conductivity and breakdown volage[J]. Composites Science and Technology, 2018, 167(20): 456-462.

-

目的

随着碳纤维增强树脂基复合材料在航天领域中的广泛应用,结构/功能一体化碳纤维复合材料将发挥出重要作用。本文采用功能化层间技术(FIT)制备了高导热沥青基碳纤维增强氰酸酯复合材料。以GNPs和AlO为导热填料,在复合材料层间构筑三维导热网络结构。以短切碳纤维CF为骨架结构,增强层间相互作用,探索微观导热结构对复合材料宏观热性能的影响与作用机制。

方法在短切碳纤维薄表面电泳沉积GNPs和AlO制备薄膜材料GNPs-AlO/CF作为多功能插层结构。采用正交铺层[0/90]和准各向同性铺层[0/+45/90/-45]制备碳纤维复合材料,并且在铺层过程中将制备的多功能插层结构设置在预浸料层与层之间,最后采用热压罐固化成型工艺制备复合材料。通过扫描电镜、原子力显微镜、激光闪光测试仪和万能试验机对多功能插层结构及碳纤维复合材料的导热性能和力学性能进行表征。

结果由扫描电镜和原子力显微镜图像可以得出结论,GNPs和AlO成功附着在了纤维表面,这预计将在复合材料层与层之间厚度方向上形成有效的导热结构,确保薄膜材料对导热性能的改善做出贡献。同时使碳纤维表面变得更加粗糙,也将有助于改善碳纤维复合材料层间性能。GNPs-AlO/CF薄膜的面内和面外热导率达到最大,分别为925 W/(m·K)和8.61 W/(m·K)。比未表面改性的CF薄膜提高了80.6%和406.5%。引入GNPs片状结构到颗粒中,降低了AlO直接接触所形成的界面热阻,同时能够充分利用GNPs的超高面内值,提高复合材料热传输效率。正交铺层层合板的面内和面外热导率最大分别为312.7 W/(m·K)和2.9 W/(m·K),比未改性正交铺层层合板的176.2 W/(m·K)和1.3 W/(m·K)提高了77.5%和123.1%。准各向同性铺层层合板的面内和面外热导率最大分别为424.6 W/(m·K)和3.2 W/(m·K),比未改性准各向同性铺层层合板的193.9 W/(m·K)和1.6 W/(m·K)增加了119.0%和50.0%。理想的热传输结构有效地降低了填料/填料界面和填料/聚合物界面的界面热阻。多功能夹层结构有规律地平铺于碳纤维预浸料层与层之间,形成周期性的层状结构,通过堆叠连接形成了许多导热单元。此外,与未设置多功能插层结构的空白组试样相比,的平均ini Ic和prop Ic分别从298.J/m和322.6J/m增加到485.7J/m和501.9J/m,对应分别增加了62.8%和55.6%。多功能插层结构的加入延缓了裂纹的萌生,增加了裂纹扩展需要的载荷。

结论通过功能化层间技术,GNPs-AlO/CF薄膜材料提供了双功能特性,同时提高了沥青基碳纤维层合板的面内、面外热导率和层间韧性。薄膜可以很好地渗透到树脂基体中,在碳纤维层间区域形成连续导热结构。针对两种不同的铺层方式:正交铺层层合板的面内和面外热导率最大分别为312.7 W/(m·K)和2.9 W/(m·K),增加了77.5%和123.1%。准各向铺层层合板的面外和面内热导率最大分别为3.2 W/(m·K)和424.6 W/(m·K),增加了50.0%和119.0%。通过增韧机理研究,GNPs-AlO/CF薄膜材料增大了裂纹扩展所需的能量,达到层间增韧的作用。

下载:

下载: