Adhesion properties of BFRP reinforcement and steel-PVA hybrid ECC

-

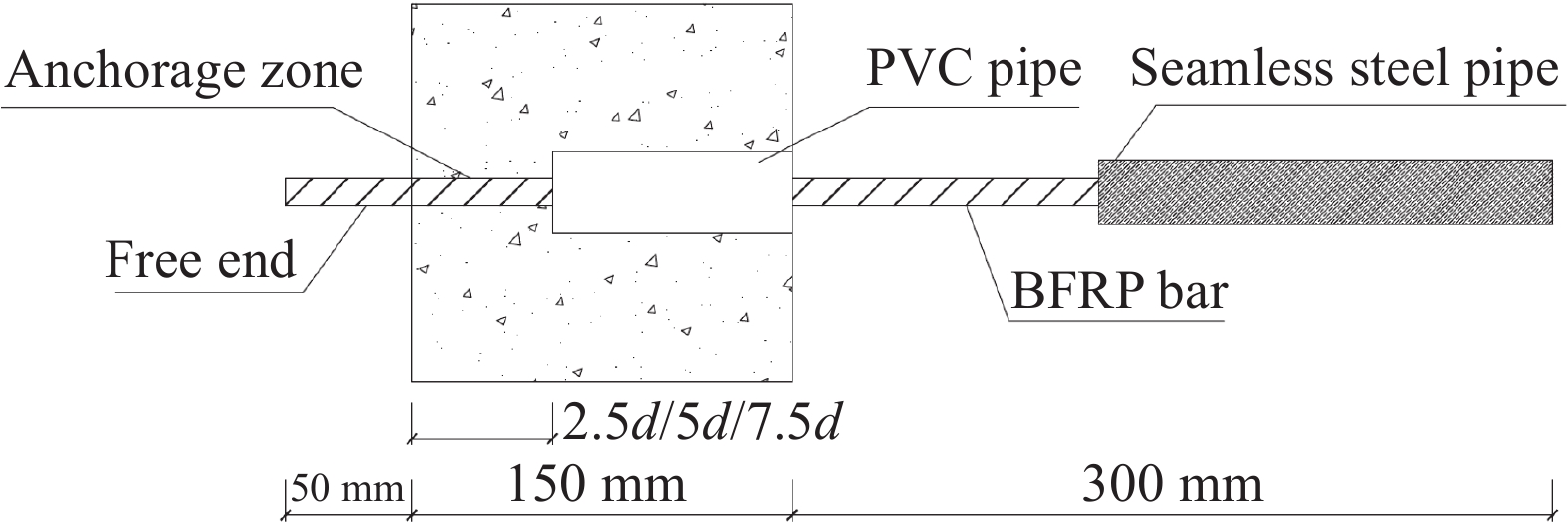

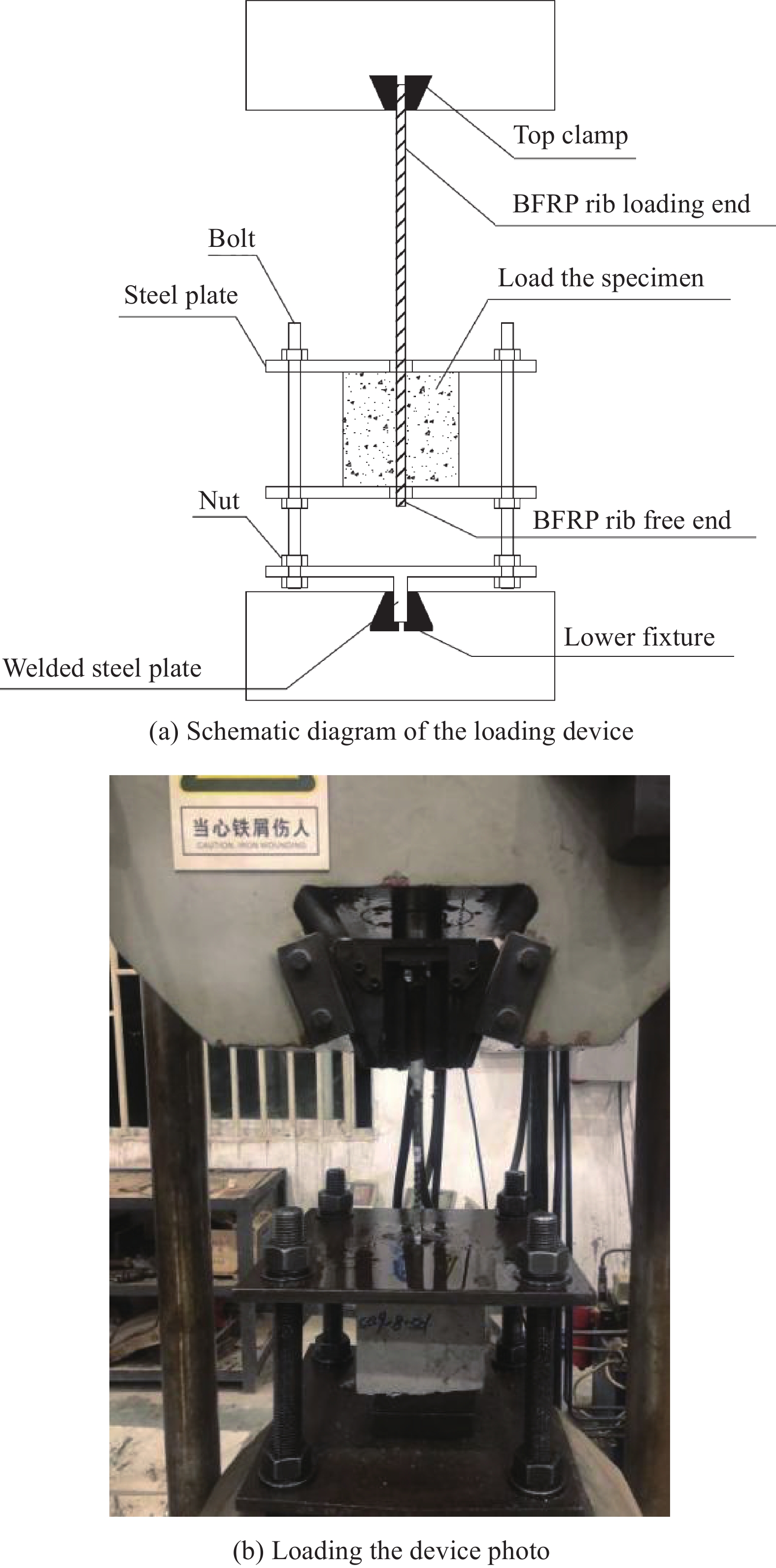

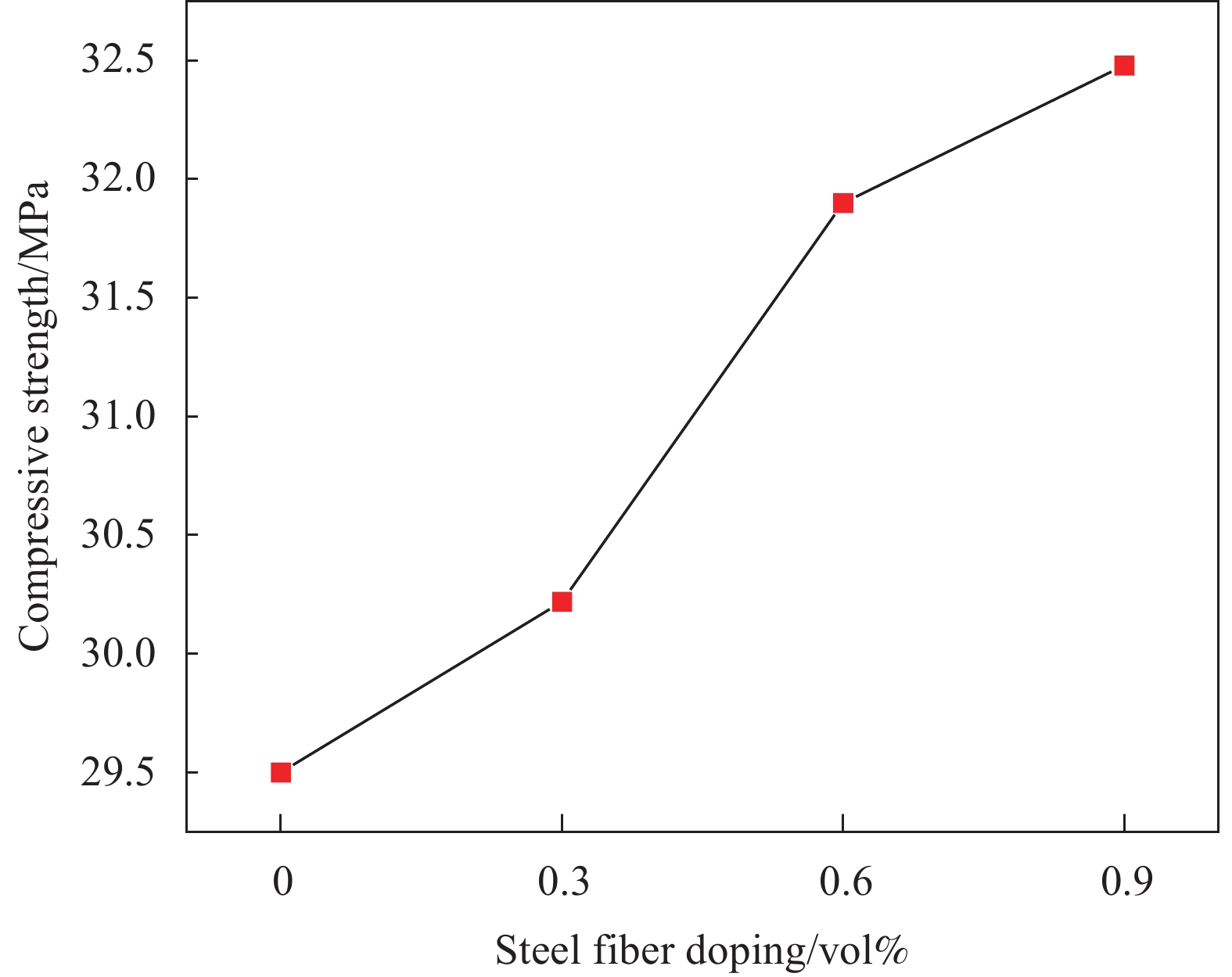

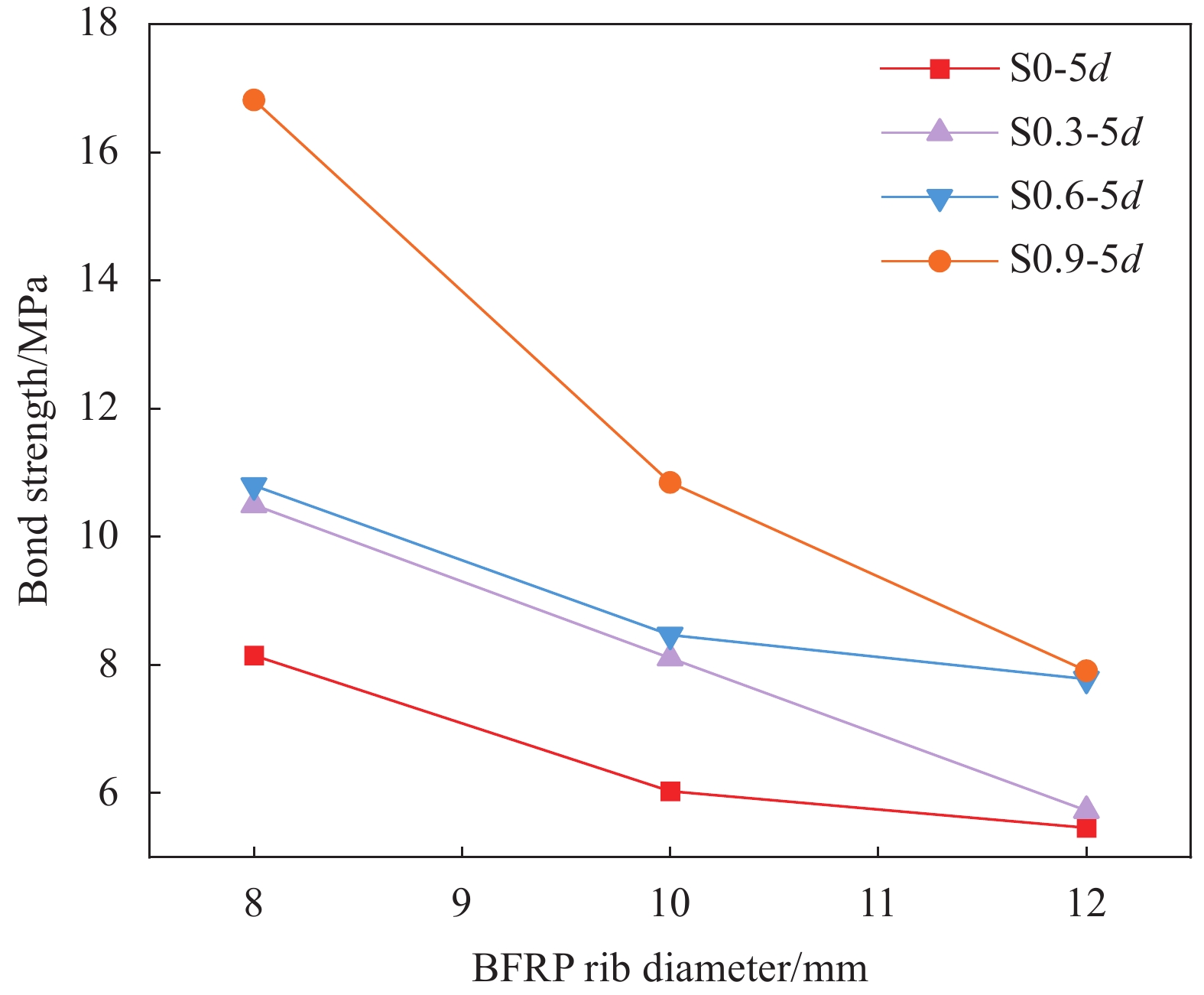

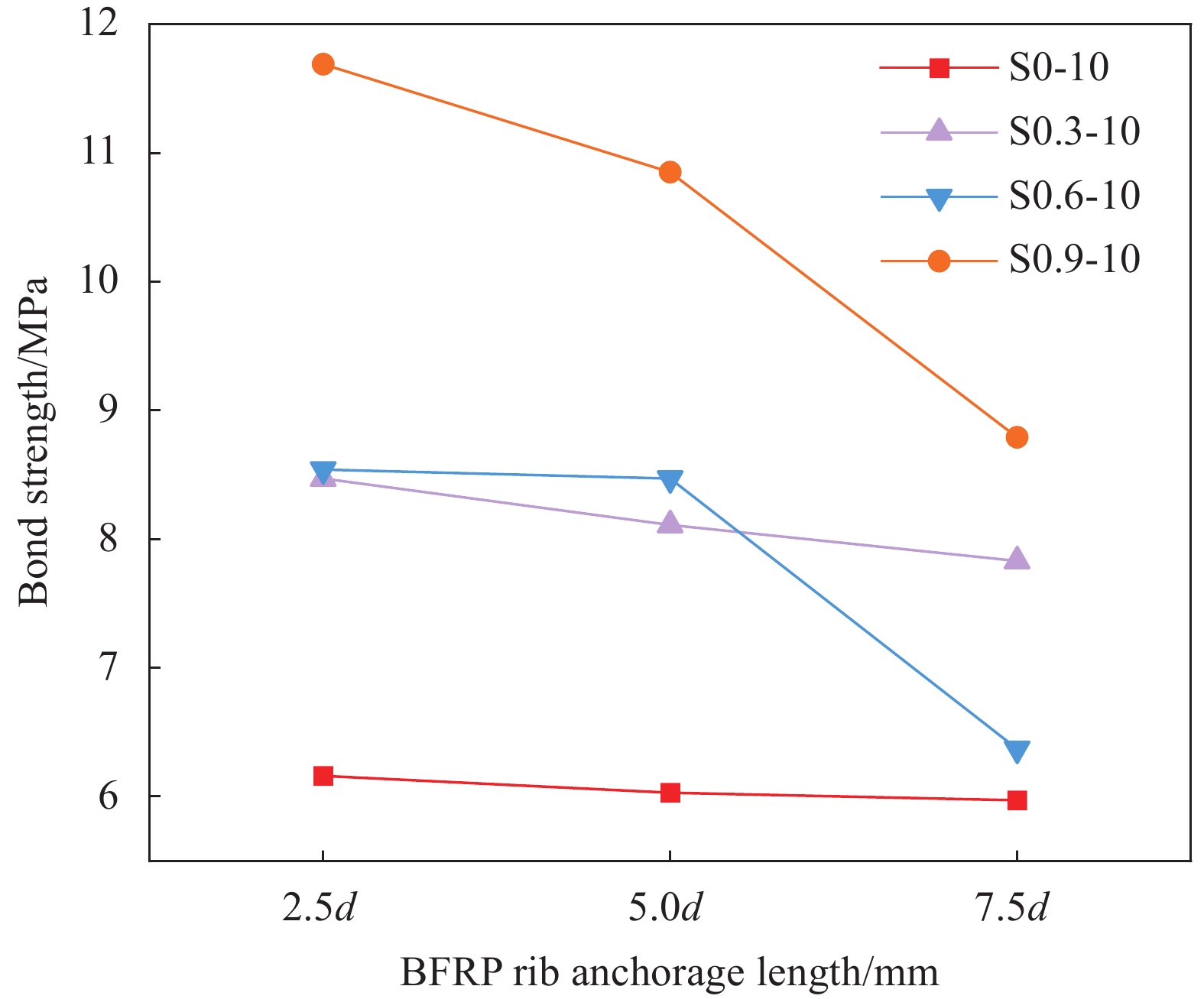

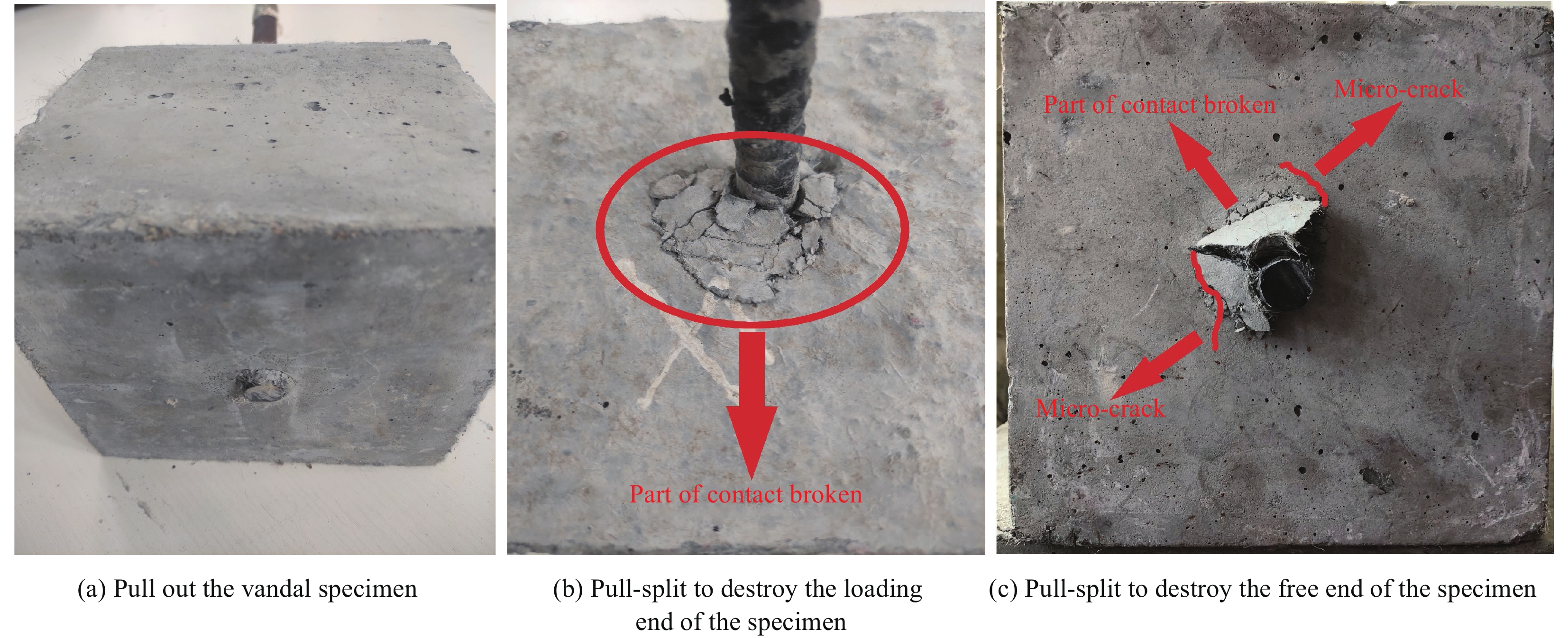

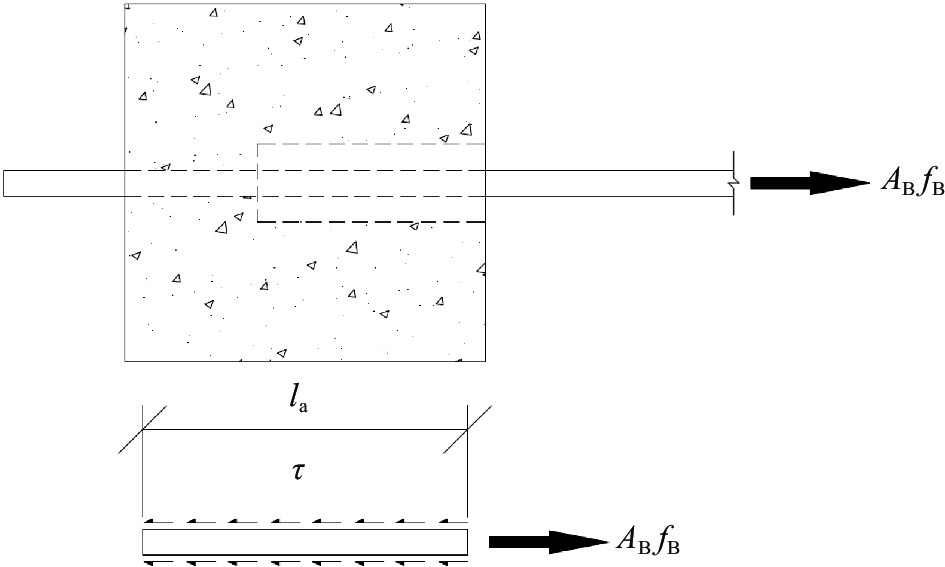

摘要: 为研究玄武岩纤维增强树脂复合材料(BFRP)筋与钢-聚乙烯醇混杂纤维增强水泥基复合材料(钢-PVA混杂ECC)的粘结性能,进行系列试验研究与分析。研究表明:在试验钢纤维掺量范围内,钢纤维掺量对试件的力学性能和界面粘结性能均为正面影响,钢-PVA混杂ECC试件的立方体抗压强度随钢纤维掺量增加而增大,增加钢纤维掺量可显著提高BFRP筋与钢-PVA混杂ECC的粘结强度;在试验BFRP筋直径及锚固长度范围内,BFRP筋直径及锚固长度对试件的界面粘结性能均为负面影响,增大BFRP筋直径及锚固长度,BFRP筋与钢-PVA混杂ECC试件的粘结强度均有不同程度的降低。中心拉拔试件粘结强度基本都在5~12 MPa之间。其中,采用0.9vol%钢纤维掺量,BFRP筋直径为8 mm及锚固长度为5d (d为 BFRP 筋的直径)的试件粘结强度最大,为16.82 MPa;而未掺加钢纤维,BFRP筋直径为12 mm及锚固长度为5d的试件粘结强度最小,为5.46 MPa。中心拉拔试件破坏模式分为BFRP筋拔出破坏和BFRP筋拔出-钢-PVA混杂ECC劈裂破坏(拔出-劈裂破坏),所有试件基本都为BFRP筋拔出破坏,仅有少量试件为拔出-劈裂破坏,且只有拔出-劈裂破坏的试件表面与BFRP筋接触部分出现破碎现象。采用四段式(微滑移段、滑移段、下降段和残余段)表达式建立的粘结-滑移模型可以较准确反映BFRP筋与钢-PVA混杂ECC的粘结滑移全过程。基于试验实测粘结强度和抗压强度值,建立了可计算BFRP筋基本锚固长度的表达式。Abstract: In order to study the adhesion properties of basalt fiber reinforced composites (BFRP) ribs and steel-polyvinyl alcohol hybrid fiber reinforced cement matrix composites (steel-PVA mixed ECC), a series of experimental studies and analysis were carried out. The results show that in the range of test steel fiber doping, the mechanical properties and interfacial adhesion properties of the steel fiber doping have a positive effect on the mechanical properties and interfacial adhesion properties of the specimen, and the cubic compressive strength of the steel-PVA hybrid ECC specimen increases with the increase of the amount of steel fiber, and the increase of the steel fiber doping can significantly improve the bonding strength of the BFRP rib and the steel-PVA hybrid ECC; In the test BFRP rib diameter and anchor length range, the diameter of the BFRP rib and the anchoring length have a negative impact on the interfacial bonding performance of the specimen, which increases the diameter of the BFRP rib and the anchoring length. The bond strength of BFRP ribs and steel-PVA hybrid ECC specimens has been reduced to varying degrees. The bond strength of the central pull specimen is basically between 5 and 12 MPa. Among them, the specimen with 0.9vol% steel fiber doping, BFRP rib diameter of 8 mm and anchor length of 5d has the largest bonding strength of 16.82 MPa, while the specimen with unaddressed steel fiber, BFRP rib diameter of 12 mm and anchor length of 5d has the smallest bonding strength, which is 5.46 MPa. The central pull specimen failure mode is divided into BFRP rib extraction failure and BFRP tendon extraction-steel-PVA mixed ECC cleavage failure (pulling-splitting failure), all specimens are basically BFRP rib extraction failure, only a small number of specimens are pulled out-cleavage failure, and only the surface of the specimen with the pull-split failure is broken in contact with the BFRP tendon. The bond-slip model established by using four-stage expressions (micro-slip section, slip section, descending section and residual section) expression can accurately reflect the bonding slip process of BFRP rib and steel-PVA mixed ECC. Based on the measured bond strength and compressive strength values of the test, an expression is established to calculate the basic anchor length of the BFRP rib.

-

Keywords:

- BFRP reinforcement /

- steel fibres /

- polyvinyl alcohol fibres /

- ECC /

- bonding performance /

- bonding-slip model

-

木材作为一种天然资源,兼具生态友好性和循环再生性,且因其高强度、高韧性、高模量及低密度、低导热性等优点,已经在家具建材、建筑用料、工艺品制作等方面得到广泛应用[1-3];而其天然定向微纤丝和管胞结构、纤维细胞壁之间明显的介孔结构[4]、细胞结构的多孔性及良好的生物相容性,均赋予木材更多的应用潜能。木材的多尺度分级孔隙结构在宏观层面主要为导管、管胞、纹孔、木纤维细胞腔等[5];而微观层面的孔隙主要为纤维素聚集而成的微纤丝在细胞壁各层的沉积形成[6],这些孔隙比表面积大、吸附能力强,且被木质素、半纤维素和抽提物填充。

近年来,研究者通过化学方法改性木材:先选择性地去除其木质素和半纤维素,保留以纤维素为主体的多维骨架结构,制成“高孔隙率三维结构材”,再分别采用不同方法制备出柔性木材、木材海绵、透明木材、木材水凝胶和碳化木材、致密化木材等各类木基功能复合材料。本文将综述其相关研究成果,为利用天然木材构建新型功能复合材料的深入研究提供参考,并为天然生物质资源的开发利用提供新思路。

1. 柔性木材

近年来,随着便携式储能设备[7]、传感器[8-9]、柔性电子器件[10-12]、三维生物载体[13-15]等的快速发展,传统的无机刚性材料已无法满足新型电子设备的要求[16],因此具备高柔性、生物相容性和多孔结构的材料引发更多关注。在各种无机物、聚合物、具有附加功能的生物材料中,天然生物材料因其固有的原料丰富性、生物相容性和可循环再生性脱颖而出。而三维结构木材具有孔隙率高、纤维排布规则、比表面积大等优点[17],兼具良好的生物相容性[13-15],因此用其制备柔性材料具有很大潜力。

基于“高孔隙率三维结构木材”在柔性多孔膜领域应用的尝试,Song等[18]将预先切割好的天然巴沙木片浸泡在NaOH和Na2SO3的混合溶液中处理,得到高孔隙率三维结构木片,再经去离子水洗涤、干燥后得到超柔性木片(图1)。通过磺化将亚硫酸盐基团接枝到木质素侧链中,使木质素在碱性溶液中快速溶解,经化学处理后该木片的模量由134 MPa降至116 MPa。这种利用高孔隙率三维结构木片通过“一步化学处理法”制备而成的柔性木片具有较好生物相容性、透气性、制备灵活性和取材便捷性等特点,为生物组织工程、柔性电子材料领域提供了新的思路。Jia等[19]将椴木沿垂直生长方向切片,经NaClO溶液脱木质素处理得到高孔隙率三维结构木材,再经乙醇多次漂洗后用玻璃杆在木片上以恒压滚动,引发强氢键作用使木材纤维被吸引,制备成工艺简单、耗时少、成本低的柔性纸(图2)。该柔结构纸具有独特的各向异性光散射和偏振效应,可实现在高透光率(约90%)和高雾度(约90%)间调节,为柔性电子、太阳能转换装置和其他柔性基材的应用开辟新的途径。

Wang等[20]利用NaOH和Na2SO3溶液脱木质素处理后得到高孔隙率三维结构巴沙木,再将其浸泡在氯化胆碱和丙烯酸制备的低共熔溶剂(PDES)中,在真空条件下反复浸润,并在主波长为365 nm的PDES下原位光聚合,制备出透明、可拉伸和导电的木质复合材料。经处理后,纤维素骨架结构表面高度缔合的羟基暴露,与PDES间发生强烈的氢键相互作用,提高了聚合物与木材基质的结合能力。此法更简便,且该材料作为触觉传感器时展现出优异的灵活性和灵敏度,有望替代传统材料[21-23],为智能电子、生物医学设备和其他相关领域提供新的选择。

然而,柔性木材的研究尚处起步阶段,仍需要充分利用木材的天然特点和高孔隙率三维结构木材的优势,对其制备工艺不断完善,使之符合现代材料需求的能力,从而有望在未来替代传统材料,在可穿戴设备、生物医药设备等领域发挥更大的优势。

2. 透明木材

自Fink[24]第一次提出“透明木材”的概念以来,科学家们对这种新型材料的研究就从未停止。木质素是木材中吸收光的组分,脱木质素后木材的特殊孔隙结构及富含木质素的细胞壁间空隙增大导致较大的光散射[25]及良好的生物相容性使木材以高孔隙率多层次三维结构材为骨架,进行化学改性和聚合物的填充,在细胞壁和空气的两相交界处,便能调节光学界面和减少光散射,以实现透明木材的低雾度[26]。

目前涌现出多种“透明木材”的制备方法,并利用不同试剂进行脱色处理和透明化处理,所得材料的光学和力学性能存在差异[27]。而将不同的纳米粒子添加到木材改性剂中,还可使木材具有发光性[28]、磁性[29]等功能化性质,进一步拓宽了透明木材在环保建筑[30]、光学器件[31]等方面的应用范围。

Zhu等[32]将椴木分别沿横向和径向裁切制备试件,在NaOH和Na2SO3的混合溶液中放置12 h后在H2O2中煮沸漂白得到高孔隙率三维结构木材,利于聚合物的快速渗透;随后浸渍在透明液态环氧树脂中,反复三次抽真空后干燥得到透明木复合材料。以上处理使填充的聚合物与纤维素骨架通过氢键和范德华力紧密贴合,经测试,这两类材料均具有较好的力学强度、延展性和透光率,但在光散射性上存在差异,此优势亦使透明木质复合材料应用更广。

Wang等[33]利用Na2SiO3、NaOH等将椴木脱木素,再用光致变色材料和甲基丙烯酸甲酯(MMA)混合溶液对高孔隙率三维结构椴木骨架进行填充,于75℃烘箱中聚合4 h,得到光致变色透明木质复合材料;其在可见光区的透射比和颜色均可调节,能在日照充足的情况下吸收紫外线而逐渐变色,降低室内房间的曝光度;而在太阳辐射较差的情况下回到透明状态,增加室内光线,还能利用光掩膜形成不同的图案(图3),因而在智能窗户领域彰显出很高的应用价值。

Montanari等[34]基于高孔隙率三维结构木材的高比表面积[35],在透明木材的基础上开发出一种兼具蓄热和可逆透光的新型透明木材,同样也可用在节能建筑领域。他们将白桦木木块放置在混合有NaClO2的CH3COOH缓冲液中进行脱木质素处理,用C2H5OH及C3H6O依次脱水后将样品放入聚乙二醇(PEG)和甲基丙烯酸甲酯(MMA)混合溶液中,在室温真空条件下反复浸渗,在70℃烘箱中聚合4 h。PEG与纤维素结构间的氢键作用保证了聚合效果,且给予透明木材良好潜热存储性能和可调透光率的新特性,可应用在包括温度传感器、储热和透光结构材料等诸多领域。

以上研究表明,透明木材在透光和储能两大领域,均表现出良好的材料特性,且有替代传统无机非金属材料的先天优势;但填充材料的环保性和化学稳定性将是其开发应用的主要挑战。

3. 木材海绵

随着各种三维多孔材料,如聚氨酯和三聚氰胺为代表的合成聚合物[36-38]、硅胶海绵[39-41]和碳气凝胶(如碳纳米管和石墨烯)[42-44]作为水油分离材料被逐渐开发应用,其制备工艺复杂、可重复利用率低、易造成二次污染、成本偏高等问题也逐渐凸显[45],阻碍其进一步应用。而由天然生物质材料制备的海绵因来源广泛、可循环再生、成本低、环境友好而受到更多关注。其中,木材由于其多层次的三维孔隙架构[46],可充分利用其纤维支架的方向性和延展性,设计制备具有高压缩性和高回弹率的木材;再对其进行化学改性,使之在水污染和有机物泄漏处理等环境修复领域[47]、可穿戴设备和可充电电池等电子设备领域彰显效用。

Wang等[48]首次提出“木材海绵”的概念。该研究以低密度巴沙木为原料,在100℃下利用NaClO2水溶液进行脱木素处理,并利用NaOH溶液去除半纤维素,得到具有波状堆叠层的高孔隙率三维结构木材;然后以甲基三甲氧基硅烷(MTMS)为硅化剂,通过化学气相沉积法(CVD)调节润湿性得到具有较高机械压缩性和弹性的高孔隙率疏水/亲油木材海绵(图4),可作为有效的吸油剂循环利用,在石油泄漏和有机污染物清理中发挥作用。

Chen等[49]受弹簧压缩结构[47]和蜂窝结构的启发,利用亚硫酸盐使木材木质素磺化,同时利用亚硫酸盐碱性溶液溶解半纤维素和部分纤维素,经H2O2溶液进一步化学处理后,木材薄细胞壁变得多孔直至完全破碎。冷冻干燥后,这些破裂的薄壁细胞就近附着在木射线上,形成具有多层堆叠和相连拱形层的高孔隙三维结构。在260℃下干燥6 h后,将海绵状高孔隙三维结构木材在Ar中以1 000℃碳化6 h,得到可高度压缩的木材碳海绵(WCS)(图5)。在原位扫描电镜和电导率的测试中发现该木材碳海绵表现出良好的可压缩性和各向异性。

木材海绵的制备充分利用高孔隙三维结构材纤维支架的方向性和延展性等天然优势,并结合其他化学处理方法,成为污染治理领域的新方向。而木材碳海绵则是在木材海绵的基础上再加工,在拥有碳化木材电导性的同时,具备独特的波状堆叠结构,使其有较高的压缩强度。但如何提高其稳定性和耐久性,还需进一步深入探究。

4. 碳化木材

碳化木材是指高温、无水、无氧条件下,经过深度碳化处理的木材,相较于木材碳海绵虽无层状堆叠结构,但孔隙率更高、抗变形更好。为顺应生态资源型社会的建设要求,石化能源的替代资源成为社会更加重视的发展方向,也存在着巨大的发展空间[50]。Li电池作为目前各类电子产品的主要电力供应方式,在日常生活中发挥着重要作用。Li以高理论容量和低化学电势著称,被看作是最好的阳极材料;但由于Li在剥离过程中体积不断变化及产生锂枝晶生长的问题,Li离子电池的安全性能和循环利用能力也还一直存在问题[51]。而“高孔隙率三维结构材”经碳化后,其三维多孔导电骨架结构(73%的孔隙率)是Li的理想载体,能够适应Li长期循环使用过程中的体积变化,并且其有序的孔道结构能有效梳理整个电化学过程,这为Li电池的发展开辟了新的发展方向[52]。

Zhang等[52]将天然椴木在260℃的空气中煅烧6 h后,在Ar中以1 000℃高温煅烧6 h得到高孔隙率三维结构碳化木。随后将覆盖有ZnO涂层的碳化木材浸入熔融Li中,使Li注入碳化木材的高孔隙三维孔道中,得到适合Li成核和生长的阳极(图6)。通过此方法改进的Li电池表现出稳定的循环性能,在高达250 h的循环测试后,碳化木Li电池的性能依旧优于传统Li电池。最近Yan等[53]利用相似的原理亦证实了三维多孔结构木材在经碳化后,其三维碳支架作为导电基质,确保磷在高质量负载情况下,也能抑制其合金化反应期间的体积变化,同时较大的比表面积也加快了电化学反应的效率,在多次循环后,仍能维持电极的完整性。因此,碳化木材可作为高质量的负载电极,用以开发高储能、高循环能力的Li离子电池。

Wang等[54]开发出一种低成本环保、具有开放通道和高比表面积的三维分级多孔电极结构,应用于全固态非对称超级电容器(ASC)的制备。他们选用杨木径向切片,在HCl溶液中浸泡1 h后反复冲洗,使木材呈中性,得到更利于电解质和离子运输渗透的高孔隙三维分层结构。之后样品被放置在500℃、N2氛围下碳化,通过简单的电沉积工艺得到三维分级多孔电极结构。采用该方法开发的超级电容器,相比于普通电容器,电化学性能和速率均得到显著提升,同时在10 000个循环中保持着85%的稳定性。

总之,碳化木材出色的三维多孔导电骨架结构,在能源材料的研究中有着良好的发展前景,但碳化木材脆性的增加和三维结构材弹性的丧失,在Li电池骨架的应用中如何去改善,还有待进一步探索。

5. 木材水凝胶

水凝胶是一种具有强亲水性三维网状结构的“湿水性材料”,主要由亲水性高分子通过物理化学方法交联而成[55]。由于良好的柔韧性、生物相容性和高含水量,水凝胶是生物医学和生物工程领域中模拟天然组织的良好选择,可用于药物传递[56-57]、软致动器[58-63]、电化学装置[64-68]和人造肌肉[69-70]等。目前,大多数以人造纤维素为基础制备的水凝胶存在组织结构无序、力学性能较差等诸多缺陷,阻碍其进一步开发应用[71-72]。因此,开发各向异性、高机械强度和强导电性的水凝胶具有重要意义。而“高孔隙率三维结构材”具有天然的抗拉伸强度高、纤维支架有序等优点,为其提供了更好的选择。

受到生物组织微观结构的启发,Kong等[73]充分利用天然木材的高抗拉强度和水凝胶的柔韧性及高含水量,制备出各向异性突出、导电性能和光学性能优异的木材水凝胶。他们首先将椴木样品在NaClO2溶液中脱木素制成高孔隙率三维结构木材,经漂洗后浸泡在丙烯酰胺(AM)单体、过硫酸铵(APS)引发剂和N,N-亚甲基双丙烯酰胺(MBA)交联剂的均相混合溶液中,放入模具并在60℃的烘箱内反应2 h得到木材水凝胶。该木材水凝胶和纤维素之间氢键的强力结合使其抗拉强度可达36 MPa,是大多数水凝胶的5~100倍;在低浓度下,其离子电导率为5×10−4 S/ cm,可与最好的纳米流体材料相媲美;同时该木材水凝胶具有类似肌肉的各向异性结构,可以实现可逆变形且不引起结构的明显变化(图7),这种材料的发明代表着高级水凝胶设计的新方向。

6. 致密化木材

木材在建筑领域的应用一直以原生木材的形态为主,难以满足现代建筑对材料刚性和韧性的要求。Hu等开发出“两步工艺法”,利用去除半纤维素和木质素后木材纤维支架各向异性的特点,经过化学处理使细胞壁破碎的方法,将木材改造成高强度、高韧性、轻质且高性能的结构材料。他们首先将天然木块在NaOH和Na2SO3混合沸腾水溶液中浸泡7 h,以去除半纤维素和木质素,得到高孔隙率三维结构木材;随后在100℃、5 MPa压力下压缩24 h,得到致密化木材(图8)。

由于纤维素分子链中有丰富的羟基,堆积在木材细胞壁间的部分纤维反复断裂并再生,涉及到大量氢键形成,使致密化木材有更好的硬度和韧性。这种致密化木材的抗压强度可达天然木材的5.5倍以上;抗拉强度可达587 MPa,为天然木材的10.6倍;且在弹道测试中,其弹道能量吸收达到天然木材的10倍左右。因此这种新型木质材料在建筑材料领域和装甲防护领域具备良好的应用空间。不同于柔性木材、木材海绵等松软形态,致密化木材证明了“高孔隙率三维结构材”亦可使木材物理性能得以加强。若能处理好木材各向异性强度差异的问题,即可在现有建筑等领域应用的基础上,发挥更大的作用。

7. 结论与展望

近年来利用“高孔隙率三维结构材”构建功能性木质复合材料被广泛研究,但由于此类研究尚处起步阶段,如何充分发挥木材的特性,开发出更高附加值的木基复合材料,还需从以下几个方面进一步研究。

(1)需探索出更高效、环保、低成本的“高孔隙率三维结构材”制备工艺。

(2)现阶段木质原料还局限于巴沙木、椴木等孔隙结构明显、胞间物质易除的树种,对木材的普适性不足,且缺乏广泛验证。后续研究需将范围扩展至更多树种和木材加工剩余物等,这对推广“高孔隙率三维结构材”的实际应用具有重要意义。

(3)现有研究中木材试件的尺寸尚无法达到实际生产的要求,当木材尺寸增加时,如何保持现有的组织架构及物理化学性能,是影响材料商业化应用的重要方面,应在此方面加大研究力度,更大程度地发挥其应用潜力。

-

表 1 纤维各项性能指标

Table 1 Fiber performance indicators

Fiber Type Length/

mmDiameter/

μmElastic modulus/

GPaTensile strength/

MPaElongation/

%Density/

(g·cm−3)PVA fiber Bundled 12 40 42 1600 7 1.3 Steel fiber Wave type 13 200 220 3000 3-5 7.5 Note: PVA—Polyvinyl alcohol. 表 2 玄武岩纤维增强树脂复合材料(BFRP)筋基本力学性能

Table 2 Basalt fiber reinforced plastics (BFRP) muscle basic mechanics performance

Diameter/mm Tensile strength/MPa Elastic modulus/GPa Elongation/% Density/(g·cm−3) 8 1462.24±61.52 57.61±1.08 2.64±0.75 1.98±0.58 10 1248.49±102.56 54.68±2.25 2.73±0.55 2.07±0.22 12 1294.46±82.53 56.52±1.52 2.81±0.14 2.01±0.45 表 3 工程水泥基复合材料(ECC)配合比

Table 3 Engineering cementitious composites (ECC) mix ratio

Cement/(kg·m−3) Fly ash/(kg·m−3) Sand/(kg·m−3) Water reducer/(kg·m−3) Water/(kg·m−3) PVA fiber/vol% 393 865 457 5 311 1.5 表 4 中心拉拔试件编号参数汇总

Table 4 Summary of central pull specimen number parameters

BFRP bar Steel fiber doping/vol% Diameter/mm Anchorage length/mm 0 0.3 0.6 0.9 8 5d S0-8-5d S0.3-8-5d S0.6-8-5d S0.9-8-5d 10 2.5d S0-10-2.5d S0.3-10-2.5d S0.6-10-2.5d S0.9-10-2.5d 5d S0-10-5d S0.3-10-5d S0.6-10-5d S0.9-10-5d 7.5d S0-10-7.5d S0.3-10-7.5d S0.6-10-7.5d S0.9-10-7.5d 12 5d S0-12-5d S0.3-12-5d S0.6-12-5d S0.9-12-5d Notes: S0, S0.3, S0.6 and S0.9—0vol%, 0.3vol%, 0.6vol% and 0.9vol% of the volume of the steel fiber, respectively; 8, 10 and 12—BFRP rib diameters of 8 mm, 10 mm and 12 mm, respectively; 2.5d, 5d and 7.5d—2.5 times, 5 times and 7.5 times the diameter d of the BFRP rib anchorage length, respectively. 表 5 BFRP筋增强钢-PVA混杂ECC粘结-滑移曲线拟合参数

Table 5 Bonding-slip curves fitting parameters of BFRP reinforced steel-PVA hybrid ECC

Specimen number CMR model BSP model GFRP model BSP model BSP model full curve α β R2 R2 α R2 R2 α β R2 S0-10-2.5d 1.686 2.080 0.963 0.973 0.346 0.943 0.989 0.760 1.372 0.976 S0-10-5d 2.388 1.364 0.971 0.968 0.614 0.928 0.973 0.721 1.319 0.972 S0-10-7.5d 2.730 1.212 0.975 0.977 0.924 0.950 0.962 0.692 1.146 0.975 S0-12-5d 2.651 1.041 0.943 0.981 0.658 0.941 0.939 0.873 1.111 0.966 S0-8-5d 1.827 0.846 0.973 0.985 0.352 0.990 0.988 0.697 1.002 0.983 S0.3-10-2.5d 1.921 1.559 0.961 0.979 0.719 0.961 0.953 0.792 1.082 0.975 S0.3-10-5d 1.806 0.855 0.972 0.984 0.360 0.994 0.982 0.600 0.874 0.982 S0.3-10-7.5d 5.054 1.362 0.975 0.982 1.210 0.934 0.938 0.804 1.042 0.962 S0.3-12-5d 2.146 1.355 0.974 0.954 0.677 0.981 0.959 0.683 0.896 0.960 S0.3-8-5d 1.816 1.230 0.970 0.982 0.617 0.993 0.979 0.684 0.897 0.968 S0.6-10-2.5d 1.132 1.080 0.983 0.979 0.622 0.954 0.943 0.577 1.062 0.954 S0.6-10-5d 1.995 1.516 0.953 0.959 0.389 0.946 0.986 0.753 0.726 0.955 S0.6-10-7.5d 1.926 1.691 0.957 0.962 0.516 0.947 0.943 0.750 0.967 0.960 S0.6-12-5d 2.527 2.351 0.972 0.972 1.247 0.937 0.935 0.810 0.950 0.966 S0.6-8-5d 2.370 1.343 0.981 0.986 0.836 0.957 0.951 0.679 0.956 0.973 S0.9-10-2.5d 1.693 1.391 0.961 0.974 0.511 0.973 0.966 0.639 1.037 0.973 S0.9-10-5d 1.812 1.174 0.974 0.963 0.405 0.929 0.957 0.605 1.264 0.964 S0.9-10-7.5d 2.933 1.302 0.984 0.974 0.596 0.958 0.973 0.604 1.075 0.963 S0.9-12-5d 1.863 1.128 0.963 0.979 0.440 0.940 0.975 0.764 1.274 0.976 S0.9-8-5d 1.765 2.118 0.968 0.969 0.700 0.944 0.970 0.769 1.187 0.969 Notes: α and β—Coefficients to be determined; R2—Correlation coefficient obtained by fitting the bond-slip model; CMR—Cosenza-Manfredi-Realfonzo; BSP—BFRP bars and steel-PVA hybrid ECC; GFRP—GFRP/steel strand fiber composite bars. 表 6 BFRP筋基本锚固长度粘结系数K

Table 6 Bonding coefficients K for the basic anchor length of BFRP ribs

Steel fiber doping/vol% Compressive strength/MPa K Average value 10-2.5d 8-5d 10-5d 12-5d 10-7.5d 0 29.50 0.00268 0.00385 0.00265 0.00210 0.00264 0.00278 0.3 30.22 0.00307 0.00427 0.00300 0.00210 0.00295 0.00308 0.6 31.90 0.00292 0.00470 0.00291 0.00232 0.00252 0.00307 0.9 32.48 0.00335 0.00503 0.00323 0.00233 0.00291 0.00337 Average value — 0.00300 0.00446 0.00295 0.00221 0.00275 — -

[1] 王吉忠, 杨俊龙, 崔文佳. 盐溶液干湿循环对CFRP-混凝土界面粘结性能的影响[J]. 复合材料学报, 2018, 35(8):2055-2064. DOI: 10.13801/j.cnki.fhclxb.20170829.003 WANG Jizhong, YANG Junlong, CUI Wenjia. Effect of wet and dry cycle of salt solution on bonding performance of CFRP-concrete interface[J]. Acta Materiae Compositea Sinica,2018,35(8):2055-2064(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20170829.003

[2] 肖时辉, 苏光明, 唐孟雄, 等. 氯盐和硫酸盐环境下混凝土耐久性研究综述[J]. 混凝土, 2022(1):41-45. DOI: 10.3969/j.issn.1002-3550.2022.01.010 XIAO Shihui, SU Guangming, TANG Mengxiong, et al. A review on the durability of concrete under chloride and sulfate environment[J]. Concrete,2022(1):41-45(in Chinese). DOI: 10.3969/j.issn.1002-3550.2022.01.010

[3] 缪昌文, 顾祥林, 张伟平, 等. 环境作用下混凝土结构性能演化与控制研究进展[J]. 建筑结构学报, 2019, 40(1):1-10. DOI: 10.14006/j.jzjgxb.2019.01.001 MIAO Changwen, GU Xianglin, ZHANG Weiping, et al. Research progress on performance evolution and control of concrete structures under environmental action[J]. Jour-nal of Building Structures,2019,40(1):1-10(in Chinese). DOI: 10.14006/j.jzjgxb.2019.01.001

[4] DO T D D, YEN K J, YEN C H, et al. Impact of tension stiffening on the tensile and flexural behavior of ECC ferrocement[J]. Construction and Building Materials,2022,329:127201. DOI: 10.1016/j.conbuildmat.2022.127201

[5] ZHU M Z, CHEN B, WU M, et al. Effects of different mixing ratio parameters on mechanical properties of cost-effective green engineered cementitious composites (ECC)[J]. Construction and Building Materials,2022,328:127093. DOI: 10.1016/j.conbuildmat.2022.127093

[6] HUANG B T, ZHU J X, WENG K F, et al. Ultra-high-strength engineered/strain-hardening cementitious composites (ECC/SHCC): Material design and effect of fiber hybridization[J]. Cement and Concrete Composites, 2022, 129: 104464.

[7] 管品武, 尚佳琦, 范家俊, 等. CFRP片材-ECC-混凝土复合界面单面剪切试验研究[J]. 复合材料学报, 2022, 39(6): 2810-2820. GUAN Pinwu, SHANG Jiaqi, FAN Jiajun, et al. Single-sided shear test study of CFRP sheet-ECC-concrete composite interface[J]. Acta Compositea Materiae Sinica, 2022, 39(6): 2810-2820(in Chinese).

[8] HU X L, XIAO J Z, ZHANG K J, et al. The state-of-the-art study on durability of FRP reinforced concrete with seawater and sea sand[J]. Journal of Building Engineering,2022,51:104294. DOI: 10.1016/j.jobe.2022.104294

[9] ZENG J J, ZHUGE Y, LIANG S D, et al. Durability assessment of PEN/PET FRP composites based on accelerated aging in alkaline solution/seawater with different temperatures[J]. Construction and Building Materials,2022,327:126992. DOI: 10.1016/j.conbuildmat.2022.126992

[10] ALI M, SOLIMAN A, NEHDI M. Hybrid-fiber reinforced engineered cementitious composite under tensile and impact loading[J]. Materials& Design,2017,117:139-149.

[11] NGUYEN W J, BANDELT M, TRONO W, et al. Mechanics and failure characteristics of hybrid fiber-reinforced concrete (HyFRC) composites with longitudinal steel reinforcement[J]. Engineering Structures,2019,183:243-254. DOI: 10.1016/j.engstruct.2018.12.087

[12] 郑宇宙, 杨星, 王文炜, 等. 纤维增强复合筋与混凝土黏结性能试验及黏结-滑移本构关系模型[J]. 工业建筑, 2015, 45(6):1-6. DOI: 10.13204/j.gyjz201506001 ZHENG Yuzhou, YANG Xing, WANG Wenwei, et al. Adhesion performance test of fiber reinforced composite rib and concrete and bonding-slip constitutive relationship model[J]. Industrial Construction,2015,45(6):1-6(in Chinese). DOI: 10.13204/j.gyjz201506001

[13] 刘生纬, 张家玮, 赵建昌, 等. 硫酸盐干湿交替对碳纤维增强环氧树脂-混凝土界面粘结性能的影响[J]. 复合材料学报, 2018, 35(1):16-23. DOI: 10.13801/j.cnki.fhclxb.20170315.003 LIU Shengwei, ZHANG Jiawei, ZHAO Jianchang, et al. Effect of alternating wet and dry sulfate on bonding performance of carbon fiber-reinforced epoxy resin-concrete interface[J]. Acta Composites Sinica Sinica,2018,35(1):16-23(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20170315.003

[14] HUANG H, YUAN Y J, ZHANG W, et al. Bond properties between GFRP bars and hybrid fiber-reinforced concrete containing three types of artificial fibers[J]. Construction and Building Materials,2020,250(C):118857.

[15] WANG H L, SUN X Y, PENG G Y, et al. Experimental study on bond behaviour between BFRP bar and engineered cementitious composite[J]. Construction and Building Materials,2015,95:448-456. DOI: 10.1016/j.conbuildmat.2015.07.135

[16] 滕晓丹, 姚淇耀, 陆宸宇, 等. BFRP筋与分级粒径河砂ECC粘结滑移性能试验研究[J]. 硅酸盐通报, 2022, 41(4):1264-1275. TENG Xiaodan, YAO Qiyao, LU Chenyu, et al. Experimental study on the adhesion slip performance of BFRP tendon and graded river sand ECC[J]. Bulletin of the Chinese Ceramic Society,2022,41(4):1264-1275(in Chinese).

[17] 单炜, 张绍逸. BFRP筋与混凝土的粘结-滑移本构关系[J]. 建筑科学与工程学报, 2013, 30(2):15-20. DOI: 10.3969/j.issn.1673-2049.2013.02.003 SHAN Wei, ZHANG Shaoyi. Bonding-slip constitutive relationship between BFRP reinforcement and concrete[J]. Journal of Building Science and Engineering,2013,30(2):15-20(in Chinese). DOI: 10.3969/j.issn.1673-2049.2013.02.003

[18] 吴智深, 汪昕, 史健喆. 玄武岩纤维复合材料性能提升及其新型结构[J]. 工程力学, 2020, 37(5):1-14. WU Zhishen, WANG Xin, SHI Jianzhe. Performance improvement of basalt fiber composites and their novel structures[J]. Engineering Mechanics,2020,37(5):1-14(in Chinese).

[19] ZHANG Z G, QIAN S Z, LIU H Z, et al. Ductile concrete material with self-healing capacity for jointless concrete pavement use[J]. Transportation Research Record,2017,2640(1):78-83. DOI: 10.3141/2640-09

[20] 赵军, 王帅斌, 王自柯, 等. BFRP筋与地聚物混凝土黏结性能试验研究[J]. 建筑结构学报, 2022, 43(6):245-256. ZHAO Jun, WANG Shuaibin, WANG Zike, et al. Experimental study on adhesion performance of BFRP reinforcement and ground polymer concrete[J]. Journal of Building Structures,2022,43(6):245-256(in Chinese).

[21] 全国水泥制品标准化技术委员会. 高延性纤维增强水泥基复合材料力学性能试验方法: JC/T 2461—2018[S]. 北京: 中国建材工业出版社, 2018. National Technical Committee for Standardization of Cement Products. Test method for mechanical properties of cement matrix composites reinforced with high ductility fiber: JC/T 2461—2018[S]. Beijing: China Building Materials Industry Press, 2018(in Chinese).

[22] 中华人民共和国住房和城乡建设部. 混凝土物理力学性能试验方法标准: GB/T 50081—2019[S]. 北京: 中国建筑工业出版社, 2019. Ministry of Housing and Urban-Rural Development of the People's Republic of China. Physical and mechanical properties test method standard for concrete: GB/T 50081—2019[S]. Beijing: China Architecture and Building Press, 2019(in Chinese).

[23] 全国纤维增强塑料标准化技术委员会土木工程用复合材料及纤维分技术委员会. 纤维增强复合材料筋基本力学性能试验方法: GB/T 30022—2013[S]. 北京: 中国标准出版社, 2013. National Technical Committee for Standardization of Fiber Reinforced Plastics Composites and Fibers Sub-technical Committee for Civil Engineering. Test method for basic mechanical properties of fiber reinforced composite reinforcement reinforcement: GB/T 30022—2013[S]. Beijing: China Standards Press, 2013(in Chinese).

[24] 全国试验机标准化技术委员会. 液压式万能试验机: GB/T 3159—2008[S]. 北京: 中国标准出版社, 2008. National Testing Machine Standardization Technical Committee. Hydraulic universal testing machine: GB/T 3159—2008[S]. Beijing: China Standards Press, 2008(in Chinese).

[25] HAMDI A, RAHIMAH M, PHILLIP V, et al. Mechanical properties and bond stress-slip behaviour of fly ash geopolymer concrete[J]. Construction and Building Materials,2022,327:126909. DOI: 10.1016/j.conbuildmat.2022.126909

[26] 赵秋红, 董硕, 谢萌. 钢纤维增强地聚物再生混凝土单轴受压全曲线试验[J]. 建筑结构学报, 2022, 43(11):255-265. ZHAO Qiuhong, DONG Shuo, XIE Meng. Uniaxial compression full curve test of steel fiber reinforced geopolymer regenerated concrete[J]. Journal of Building Structures,2022,43(11):255-265(in Chinese).

[27] LIU Y W, SHI C J, ZHANG Z H, et al. Mechanical and fracture properties of ultra-high performance geopolymer concrete: Effects of steel fiber and silica fume[J]. Cement and Concrete Composites, 2020, 112: 103665.

[28] ZHAO D B, ZHOU Y W, XING F, et al. Bond behavior and failure mechanism of fiber-reinforced polymer bar-engineered cementitious composite interface[J]. Engineering Structures,2021,243:112520. DOI: 10.1016/j.engstruct.2021.112520

[29] WANG W J, WANG Y, LI D D, et al. Bond-slip behavior between basalt fiber reinforced plastic bars and recycled aggregate concrete[J]. Construction and Building Materials,2021,302:124360. DOI: 10.1016/j.conbuildmat.2021.124360

[30] 高丹盈, BRAHIM B. 纤维聚合物筋与混凝土粘结性能的影响因素[J]. 工业建筑, 2001(2):9-14. DOI: 10.3321/j.issn:1000-8993.2001.02.004 GAO Danying, BRAHIM B. Influencing factors of bonding properties of fiber polymer ribs and concrete[J]. Industrial Construction,2001(2):9-14(in Chinese). DOI: 10.3321/j.issn:1000-8993.2001.02.004

[31] MARANAN G, MANALO A, KARUNASENA K, et al. Bond stress-slip behavior: Case of GFRP bars in geopolymer concrete[J]. Journal of Materials in Civil Engineering,2015,27(1):04014116. DOI: 10.1061/(ASCE)MT.1943-5533.0001046

[32] HOSSAIN K M A. Bond strength of GFRP bars embedded in engineered cementitious composite using RILEM beam testing[J]. International Journal of Concrete Structures and Materials,2018,12(1):101-115.

[33] 徐世烺, 王洪昌. 超高韧性水泥基复合材料与钢筋粘结本构关系的试验研究[J]. 工程力学, 2008(11):53-61. XU Shilang, WANG Hongchang. Experimental study on the constitutive relationship between ultra-high toughness cement matrix composites and steel reinforcement bonding[J]. Engineering Mechanics,2008(11):53-61(in Chinese).

[34] 潘宇, 刘锋. FRP筋与混凝土粘结性能研究综述 [C]//第十六届全国现代结构工程学术研讨会论文集. 聊城, 2016: 1255-1265. PAN Yu, LIU Feng. A review on the adhesion properties of FRP reinforcement and concrete[C]//Proceedings of the 16th National Symposium on Modern Structural Engineering. Liaocheng, 2016: 1255-1265(in Chinese).

[35] 李雨珊, 尹世平, 刘运超. FRP筋与全珊瑚骨料海水混凝土界面粘结-滑移本构关系[J]. 复合材料学报, 2022, 39(8): 3950-3964. LI Yushan, YIN Shiping, LIU Yunchao. Interfacial bonding-slip constitutive relationship between FRP rib and whole coral aggregate seawater concrete [J]. Acta Composites Materiae Sinica, 2022, 39(8): 3950-3964(in Chinese).

[36] 尤志国, 陶志强, 徐国强, 等. 混杂纤维自密实混凝土轴心抗拉强度试验研究[J]. 结构工程师, 2019, 35(1):198-204. DOI: 10.3969/j.issn.1005-0159.2019.01.026 YOU Zhiguo, TAO Zhiqiang, XU Guoqiang, et al. Experimental study on tensile strength of hybrid fiber self-compacting concrete[J]. Structural Engineer,2019,35(1):198-204(in Chinese). DOI: 10.3969/j.issn.1005-0159.2019.01.026

[37] 徐礼华, 邓方茜, 徐浩然, 等. 钢-聚丙烯混杂纤维混凝土柱抗震性能试验研究[J]. 土木工程学报, 2016, 49(1):3-13. DOI: 10.15951/j.tmgcxb.2016.01.002 XU Lihua, DENG Fangqian, XU Haoran, et al. Experimental study on seismic performance of steel-polypropylene hybrid fiber concrete column[J]. Chinese Journal of Civil Engineering,2016,49(1):3-13(in Chinese). DOI: 10.15951/j.tmgcxb.2016.01.002

[38] SAIKALI R E, PANTAZOPOULOU S J, PALERMO D. Local bond-slip behavior of reinforcing bars in high-performance steel fiber-reinforced concrete beams[J]. ACI Structural Journal,2022,119(2):139-153.

[39] FENG Q, WEI P, ZHAO K X, et al. Experimental investigation of stirrup confinement effects on bond-slip responses for corner and middle bars[J]. Construction and Building Materials,2022,314(PA):125629.

[40] 肖良丽, 刘彦, 雷梦琦, 等. 玻璃纤维复材筋与混杂纤维混凝土黏结性能研究[J]. 工业建筑, 2019, 49(3):18-23. DOI: 10.13204/j.gyjz201903004 XIAO Liangli, LIU Yan, LEI Mengqi, et al. Study on the adhesion properties of glass fiber composite reinforcement and mixed fiber concrete[J]. Industrial Construction,2019,49(3):18-23(in Chinese). DOI: 10.13204/j.gyjz201903004

[41] ROLLAND A, ARGOUL P, BENZARTI K, et al. Analytical and numerical modeling of the bond behavior between FRP reinforcing bars and concrete[J]. Construction and Building Materials,2020,231(C):117160.

[42] 郝庆多, 王言磊, 侯吉林, 等. GFRP/钢绞线复合筋与混凝土粘结滑移本构关系模型[J]. 工程力学, 2009, 26(5):62-72. HAO Qingduo, WANG Yanlei, HOU Jilin, et al. GFRP/steel strand composite rib and concrete bond slip constitutive relationship model[J]. Engineering Mechanics,2009,26(5):62-72(in Chinese).

[43] 尹世平, 华云涛, 徐世烺. FRP配筋混凝土结构研究进展及其应用[J]. 建筑结构学报, 2021, 42(1):134-150. DOI: 10.14006/j.jzjgxb.2019.0349 YIN Shiping, HUA Yuntao, XU Shilang. Research progress and application of FRP reinforced concrete structure[J]. Journal of Building Structures,2021,42(1):134-150(in Chinese). DOI: 10.14006/j.jzjgxb.2019.0349

-

期刊类型引用(3)

1. 崔双双,孟瑶,陈伟宏,孙浩. 高应变率荷载作用下钢筋与ECC的黏结滑移关系研究. 振动与冲击. 2024(01): 71-82 .  百度学术

百度学术

2. 邓朗妮,杨洲,钟锰军,雷丽贞,廖羚. FRP网格-工程用水泥基复合材料复合材料加固钢筋混凝土梁挠度. 复合材料学报. 2023(09): 5212-5224 .  本站查看

本站查看

3. 万聪聪,姜天华,余意. 基于正交试验的聚丙烯泡沫混凝土基本力学性能研究. 硅酸盐通报. 2023(10): 3518-3529 .  百度学术

百度学术

其他类型引用(3)

-

下载:

下载: