Review of process defects and failure behaviors of continuous fiber-reinforced composite materials via 3D printing

-

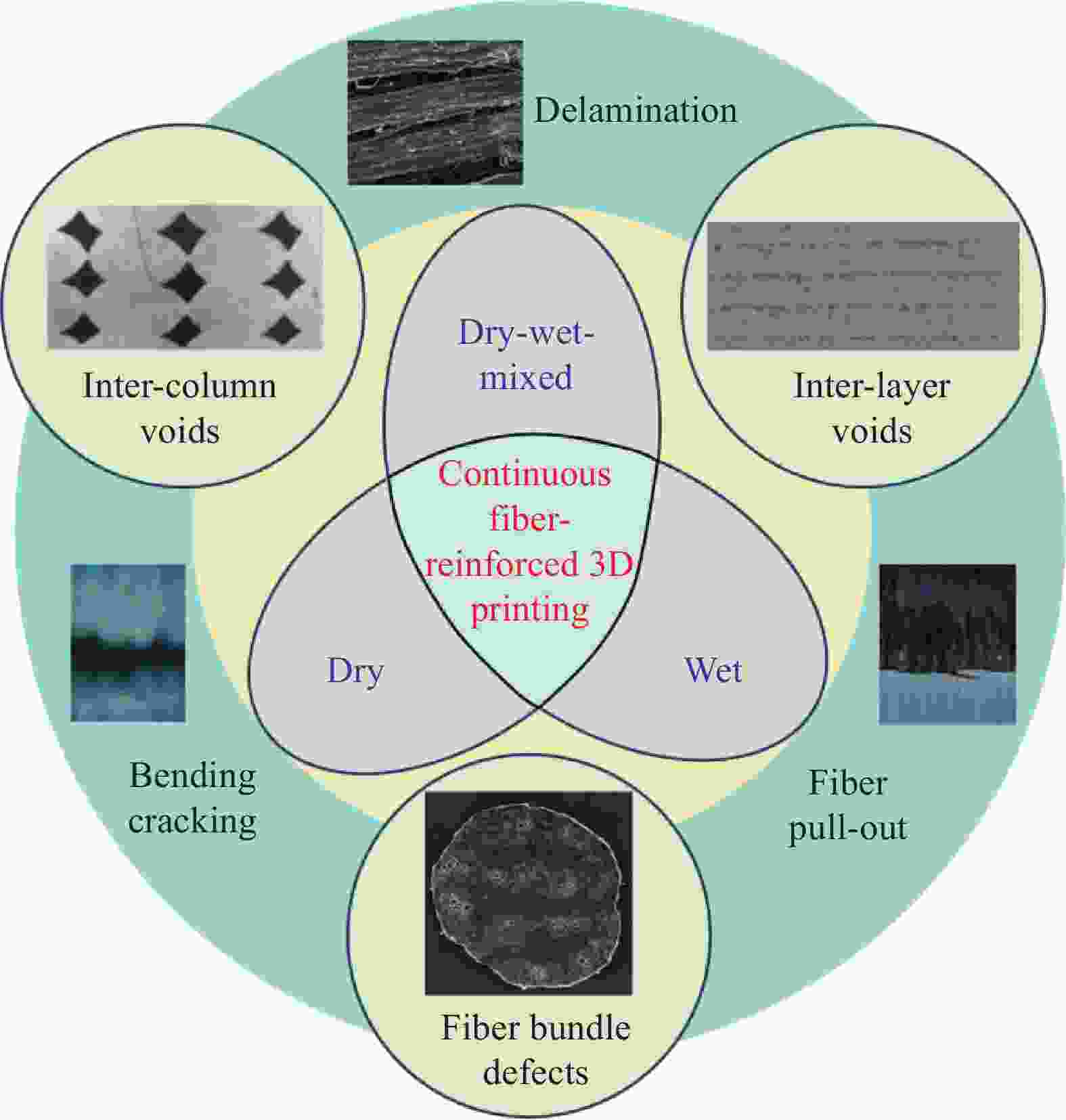

摘要: 因设计自由度高、无需模具和快速制造等优点,连续纤维增强3D打印已成为当今最具创新性的先进复合材料成型技术之一。本文综述了连续纤维增强3D打印复合材料工艺缺陷及失效行为的最新研究进展,引入了“干/湿/干湿-混合”的概念对打印工艺进行了系统性分类阐述,重点介绍了由于工艺过程引入的三种缺陷及其特点。随后,归纳了连续纤维增强3D打印复合材料的失效力学行为,并分析了引发失效的主要原因。最后,针对如何减少工艺缺陷、改善失效模式和降本增效对连续纤维增强复合材料3D打印技术的未来进行了展望。Abstract: Constraint-free design, rapid production, and the absence of mold requirements are just a few of the reasons why continuous fiber-reinforced 3D printing (CFR3DP) has emerged as one of the most innovative advanced composite manufacturing technologies nowadays. This study examines the recent developments in research concerning process defects and the failure behaviors of CFR3DP. In order to systematically categorize the printing process, the notion of “dry/wet/dry-wet-mixed” has been introduced, with an emphasis on the three distinct groups of defects that may be introduced during the additive manufacturing process. Following this, an analysis was conducted to summarize the failure behaviors of CFR3DP while also identifying the primary causes of failure. In conclusion, we propose the prospect of CFR3DP with respect to cost reduction, efficiency, the mitigation of process defects, and improvement of failure mode.

-

Key words:

- 3D Printing /

- Continuous Fiber /

- Process Defects /

- Failure Modes /

- Composite Materials

-

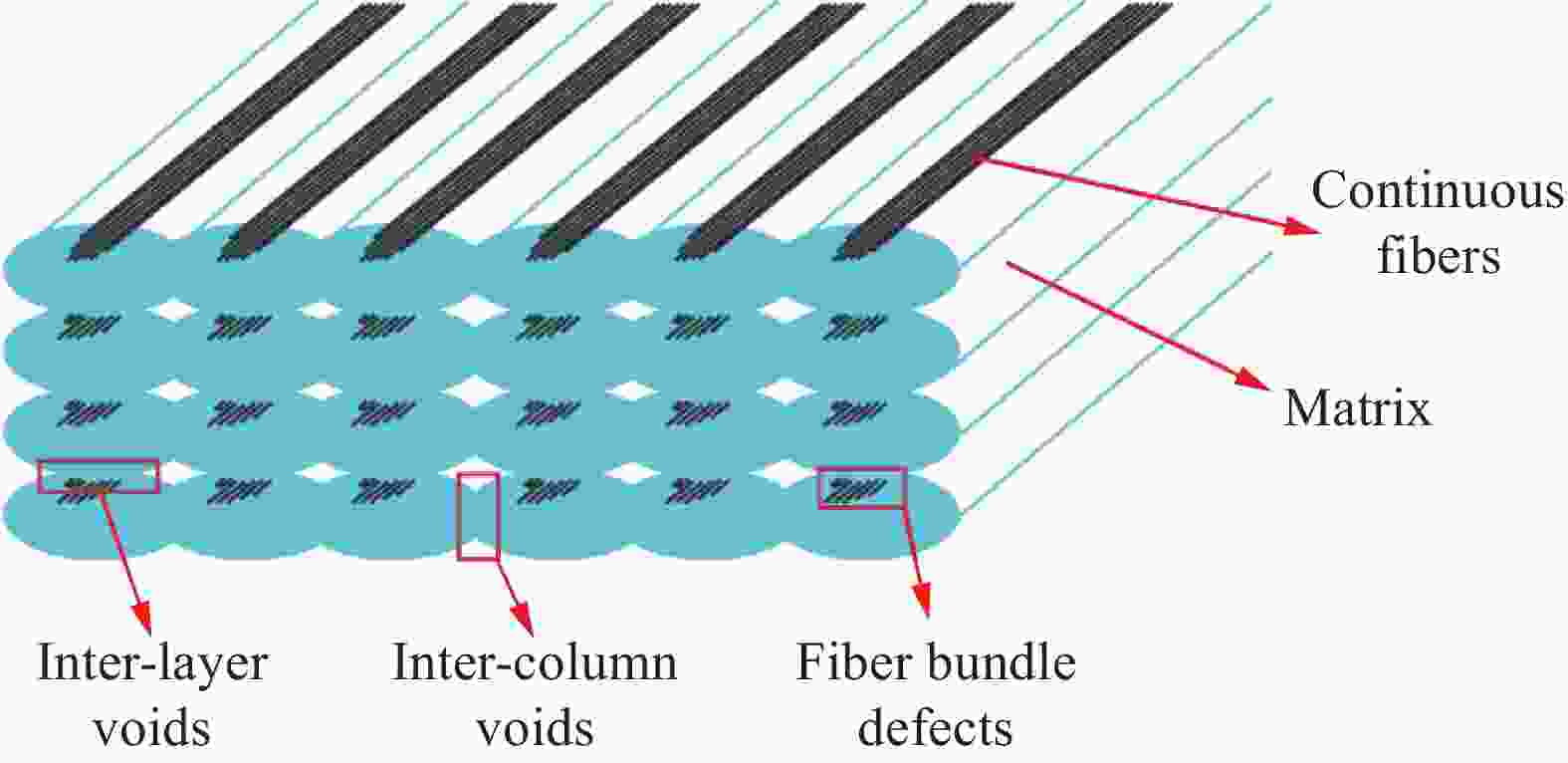

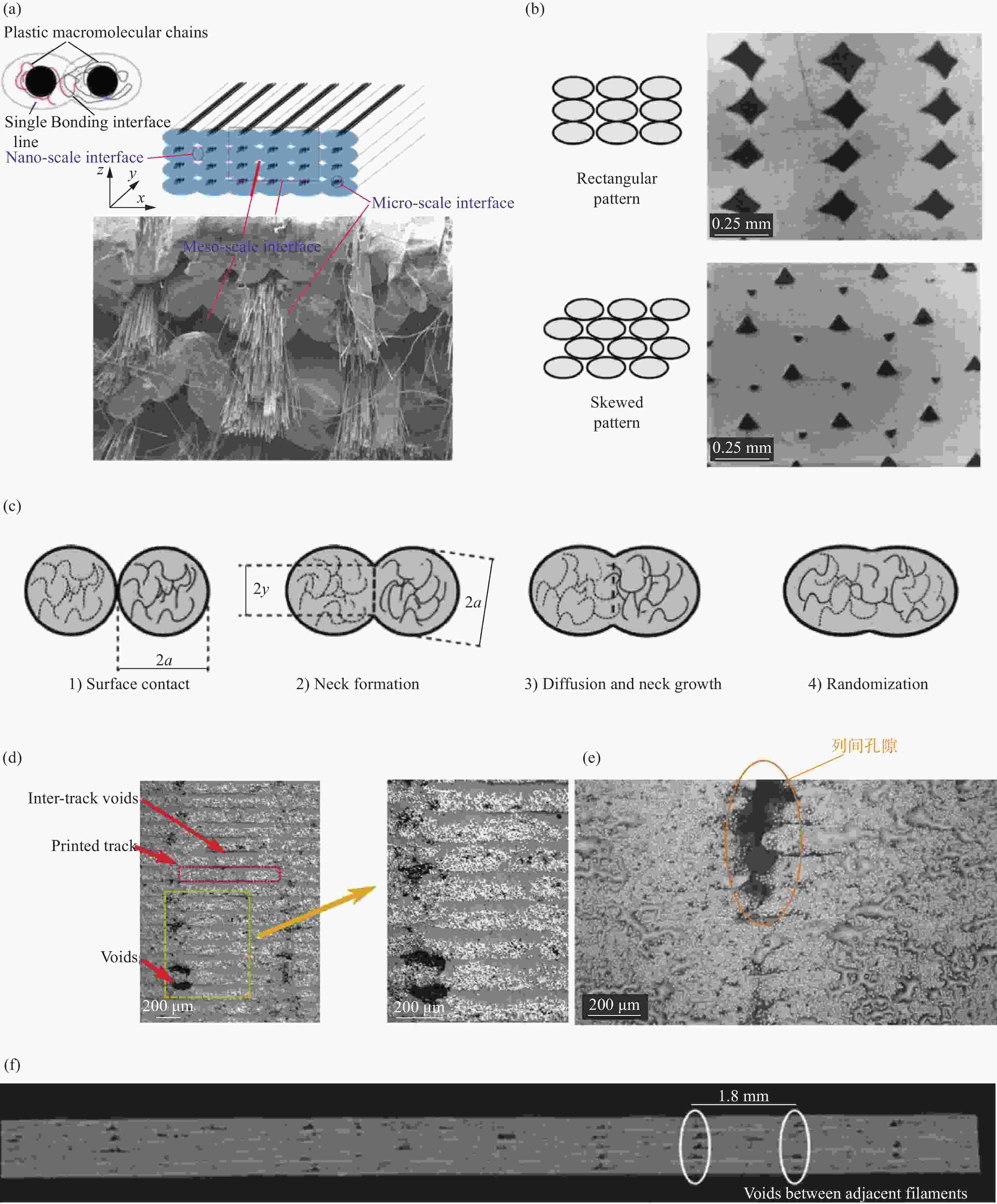

图 6 层间孔隙的微观形貌:(a)典型的层间孔隙SEM照片[87],(b)不同纤维体积含量构件的SEM照片[88],(c)典型的层间孔隙显微CT照片[86]和(d)编织多层复合材料中的层间孔隙显微CT照片[89]

Figure 6. Microscopic morphology of inter-layer voids: (a) the typical SEM picture of interlayer voids [87]; (b) the SEM photo of parts with different fiber volume contents [88]; (c) the typical micro-CT of interlayer voids snapshot [86]; and (d) the micro-CT photo of inter-layer voids in woven multilayer composites [89]

图 7 列间孔隙的微观形貌:(a)含典型列间孔隙的横截面和界面特征[92];(b)不同的堆叠方式形成不同列间孔隙形貌[93],(c)相邻两列之间树脂的合并过程原理[93];(d)MarkForged打印机制造弯曲测试样本横截面[93];(e)3D打印连续玻璃纤维增强尼龙的样品的显微照片[94] 和(f)多列样本的横截面[95]

Figure 7. Microscopic morphology of inter-column voids: (a) the cross-section and interface characteristics of typical inter-column voids [92]; (b) the different inter-column pore morphologies formed by two kinds of stacking methods[93]; (c) the merging process of resin between two adjacent columns [93]; (d) the cross section of a bending test sample manufactured by MarkForged printer [93]; (e) the micrograph of a 3D printed continuous glass fiber-reinforced nylon sample [94] ; and (f) the cross-section of multi-column sample[95]

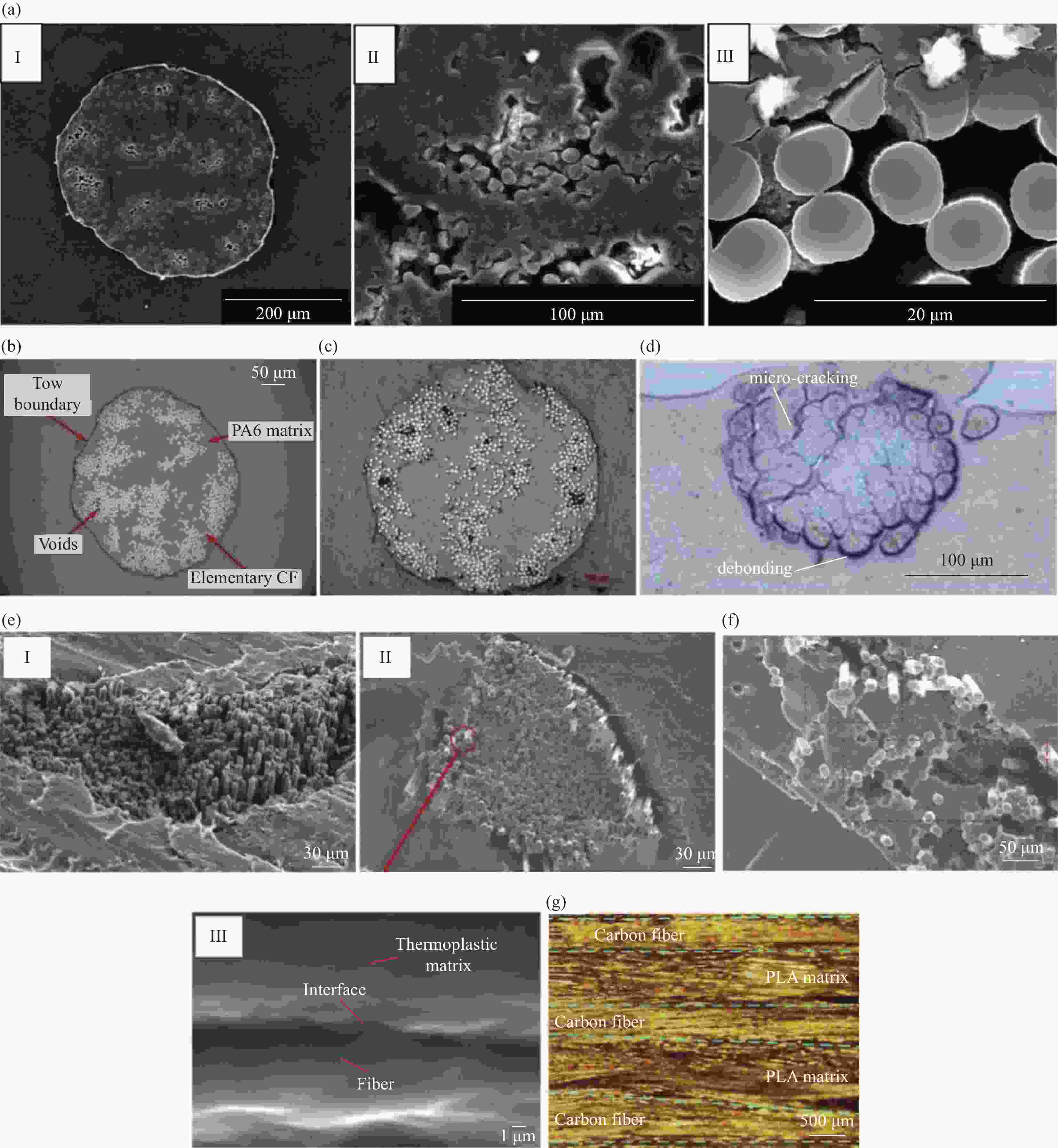

图 8 纤维束缺陷的微观形貌:(a)一个丝束在不同放大倍数下的SEM照片[86];(b)-(d)纤维束横断面显微照片[86, 93, 96],(e)纤维束边界上的弱界面[92];(f)纤维束内部不规则孔隙[91]和(g)碳纤维和PLA树脂之间的弱界面[97]

Figure 8. Microscopic morphology of fiber bundle defects: (a) the SEM photos of a fiber bundle at different magnifications [86]; (b)-(d) the micrographs of fiber bundle cross-sections [86, 93, 96]; (e) the weak interface on the fiber bundle boundary [92]; (f) the irregular voids inside the fiber bundle [91]; and (g) the weak interface between carbon fiber and PLA resin [97]

图 9 纤维拔出失效模式:(a)界面性能和断裂模式的演变 [95];(b)损伤演化过程和失效机制[96];(c)纤维束边界上的弱界面[89];(d)断口的光学显微照片[96]和(e)断口的SEM照片[97]

Figure 9. Fiber pull-out failure mode: (a) the evolution of interface properties and fracture modes [95]; (b) the damage evolution process and failure mechanism [96]; (c) the weak interface at fiber bundle boundary [89]; (d) the optical micrograph of the fracture surface [96]; and (e) the SEM photograph of the fracture surface [97]

图 10 纤维束缺陷的形成与纤维拔出的改善:(a)纤维束缺陷和其导致的弱界面 [101];(b)一维流动达西定律的主要参数[102-104];(c)宏观和微观浸渍现象[103];和(d)湿法和干法连续纤维3D打印的单束纱线的破坏断口[105]

Figure 10. Formation of fiber bundle defects and improvement of fiber pull-out: (a) fiber bundle defects and the resulting weak interfaces [101]; (b) Main parameters of Darcy’s law for one-dimensional flow [102-104]; (c) macroscopic and microscopic impregnation phenomena [103]; and (d) failure fractures of single bundle yarns for wet and dry continuous fiber 3D printing [105]

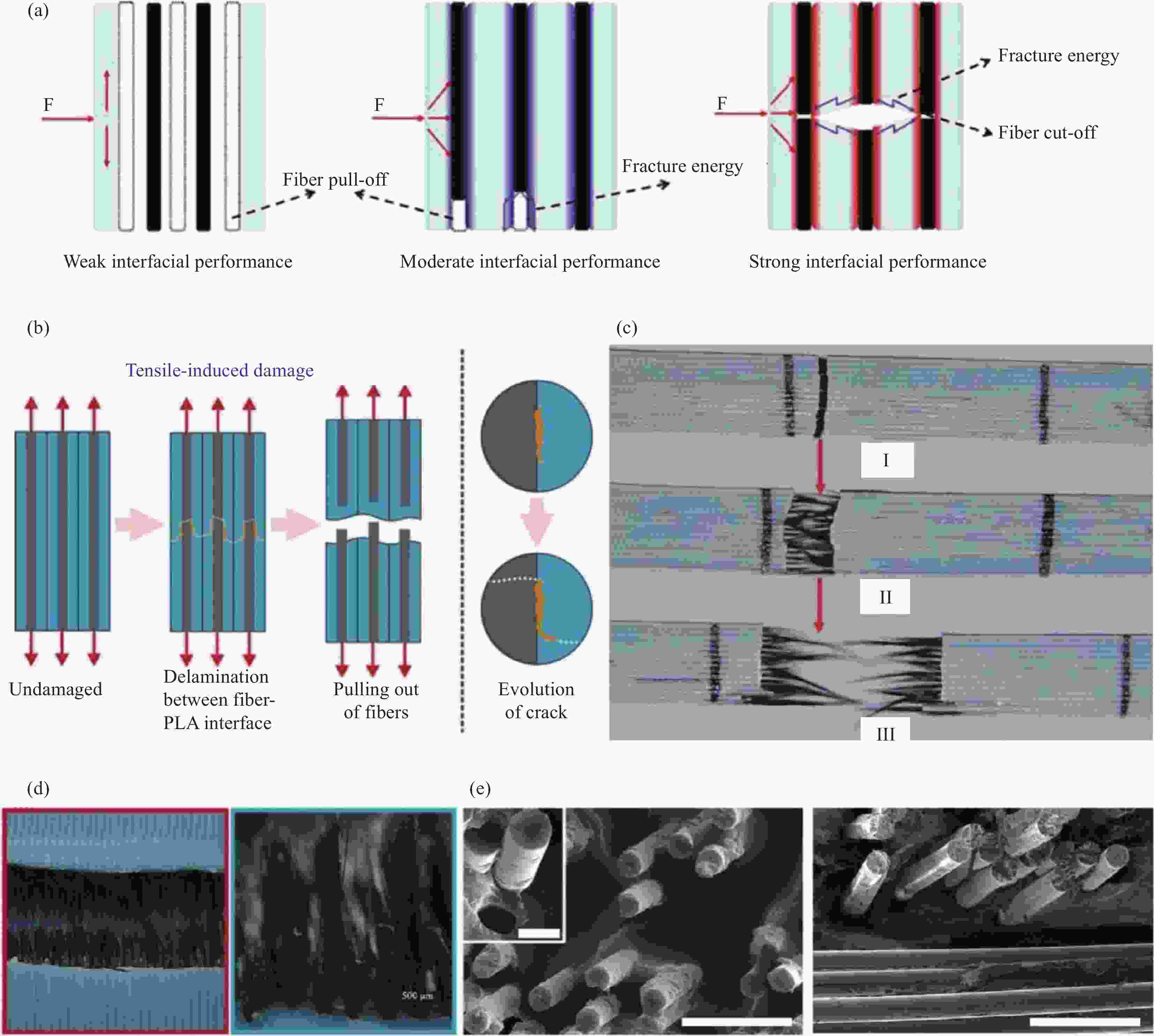

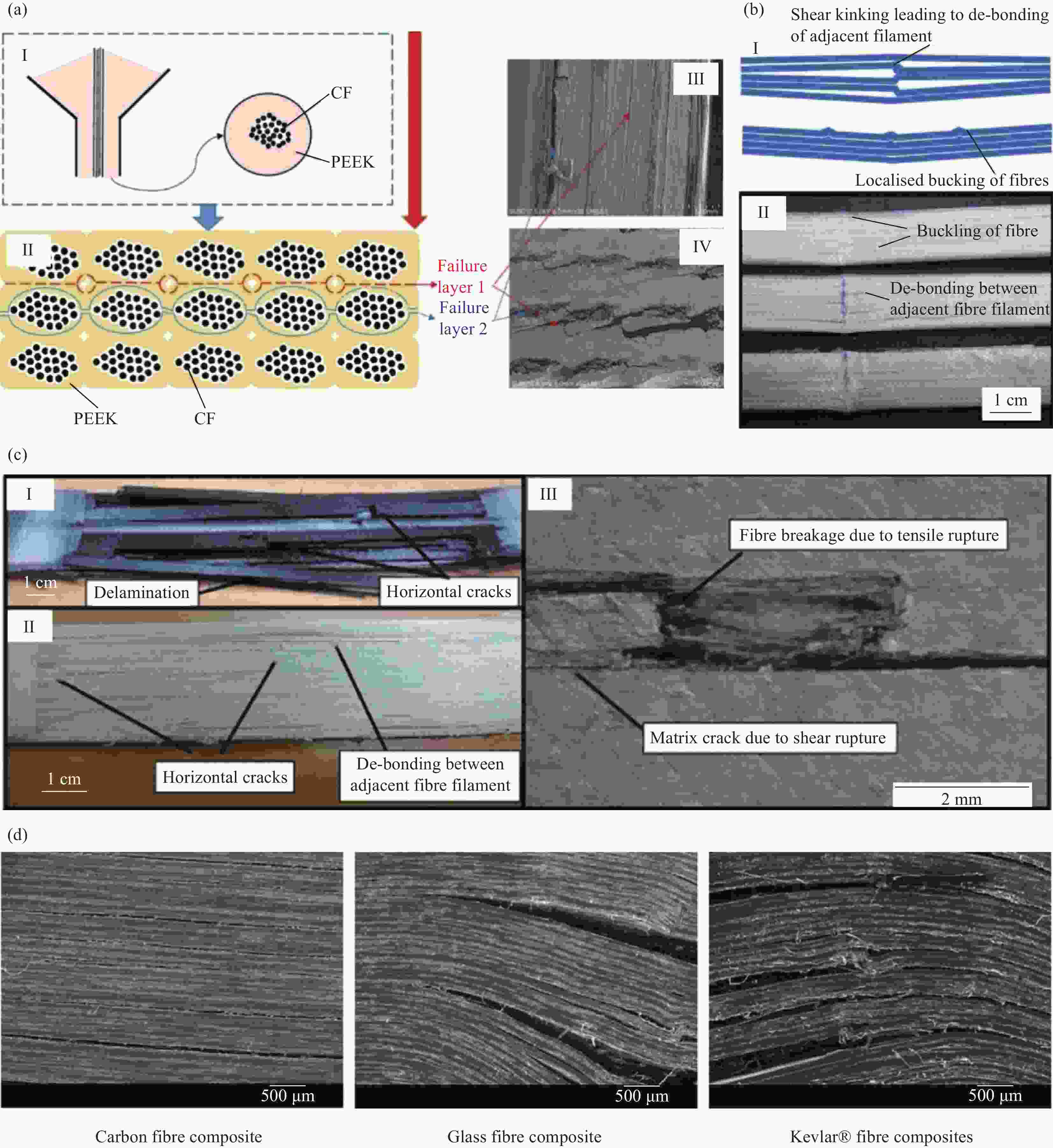

图 11 分层失效模式:(a)演化方式与微观形貌 [107];(b)弯曲载荷下的失效模式和宏观形貌[95];(c)拉伸载荷下的失效模式、宏观和微观形貌[95]和(d)不同种类纤维增强复合材料的分层微观形貌[108]

Figure 11. Delamination failure mode: (a) the evolution mode and microscopic morphology [107]; (b) the failure mode and macroscopic morphology under the bending load [95]; (c) the failure mode, macroscopic and microscopic morphology under tensile loads [95]; and (d) the delamination micromorphology of different types of fiber-reinforced composite materials [108]

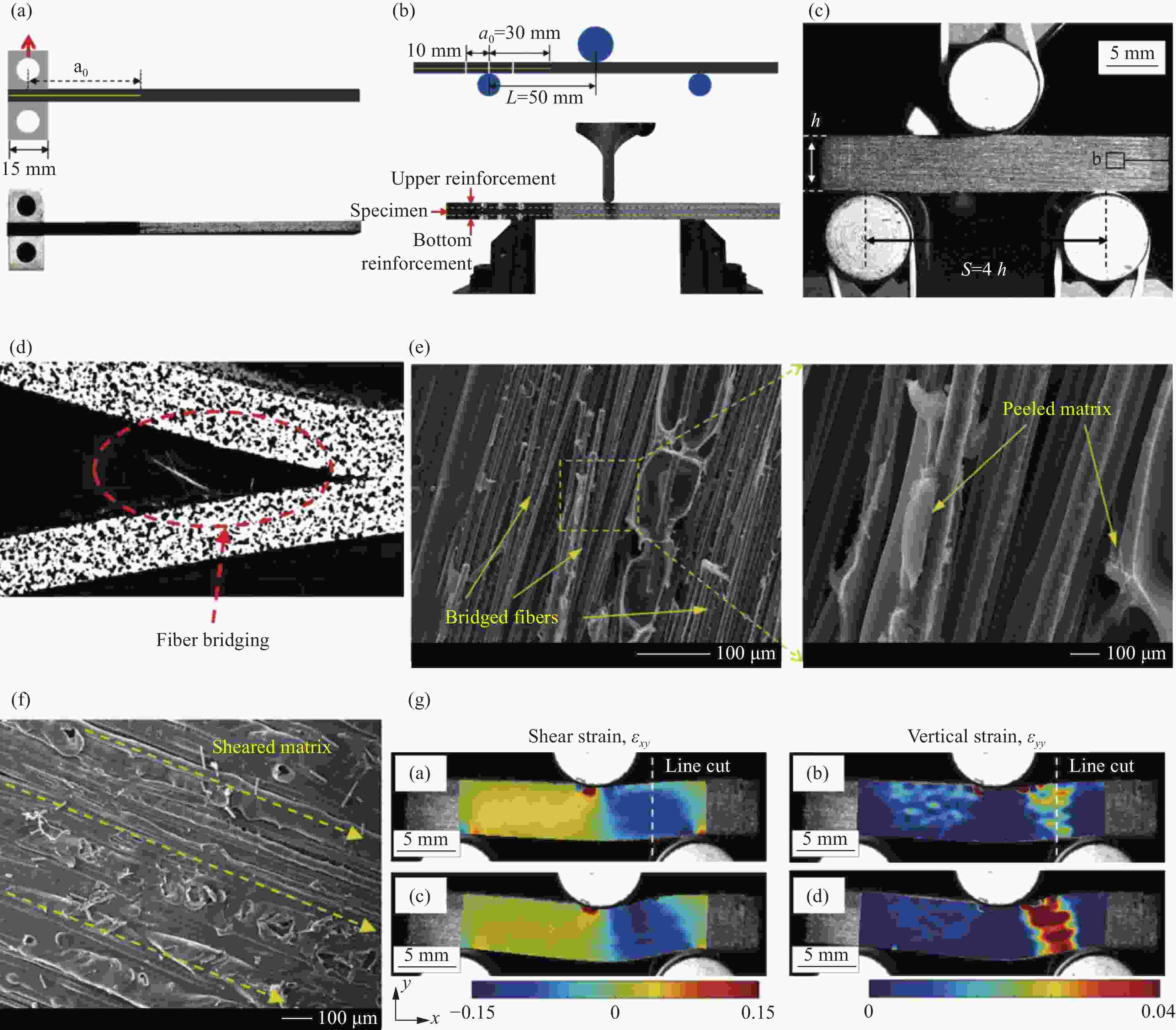

图 12 层间力学性能的表征:(a) DCB试验 [109-112];(b) ENF试验 [109];(c) ILSS试验 [113];(d)纤维桥联现象[109];(e) DCB试验剥离表面的SEM照片[108];(f)ENF试验后断裂表面的SEM照片[109] ;和(g)ILSS试验中分层损伤演化的DIC云图[113]

Figure 12. Characterization of interlayer mechanical properties: (a) DCB testing [109-112]; (b) ENF testing [109]; (c) ILSS testing [113]; (d) fiber bridging phenomenon [109]; (e) SEM photo of peeling surface in DCB testing [108]; (f) SEM photo of fracture surface after ENF testing [109]; and (g) DIC cloud image of delamination damage evolution in ILSS testing [113]

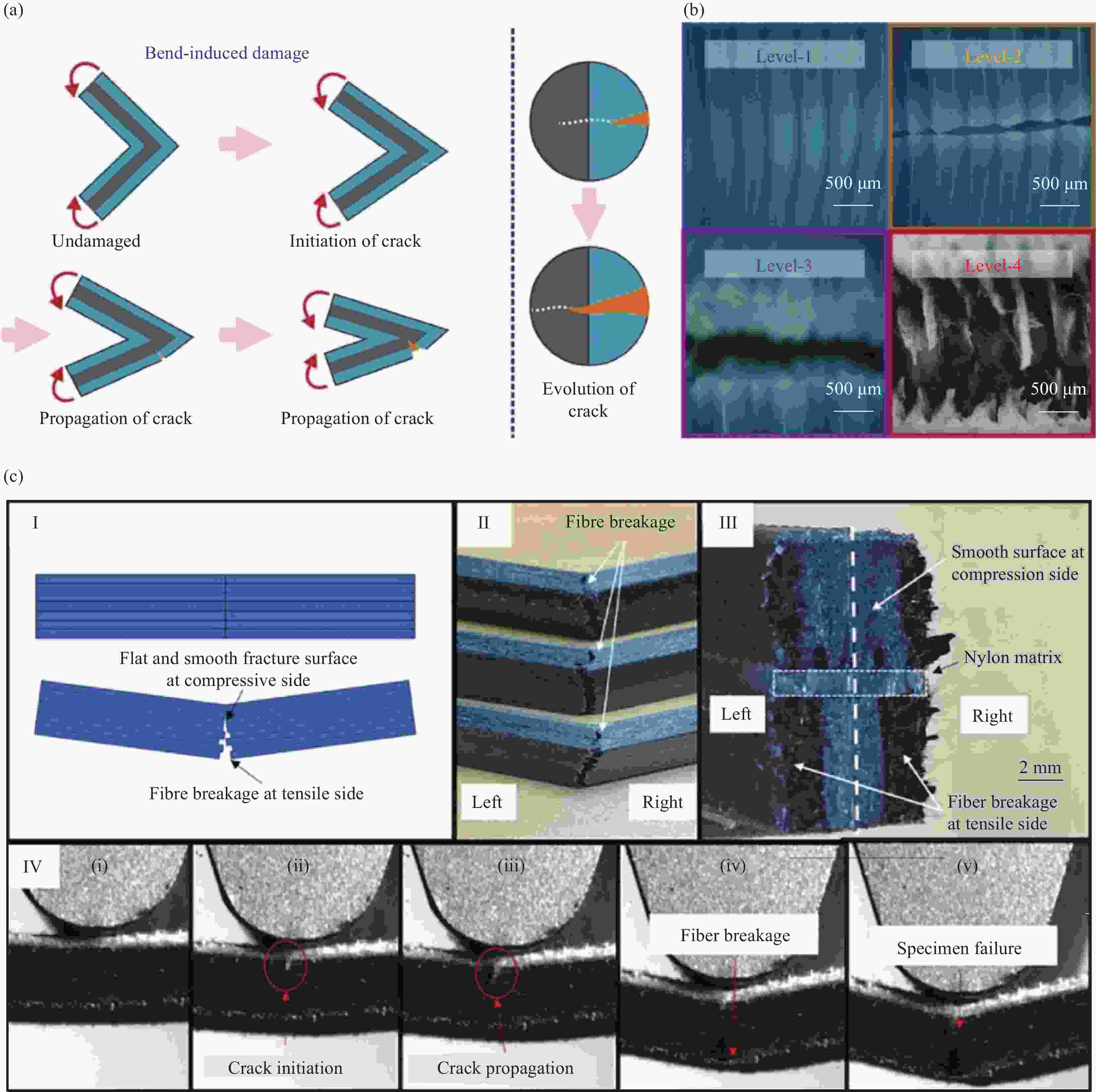

图 13 弯曲开裂失效模式:(a)裂纹的产生和演化过程原理 [99];(b)四级演化过程的微观照片[99]和(c)弯曲载荷下的裂纹萌生和发展过程[95]

Figure 13. Bending cracking failure mode: (a) the crack generation and evolution process [99]; (b) the microscopic of the fourth-level evolution process [99]; and (c) the crack initiation and development process under bending loads [95]

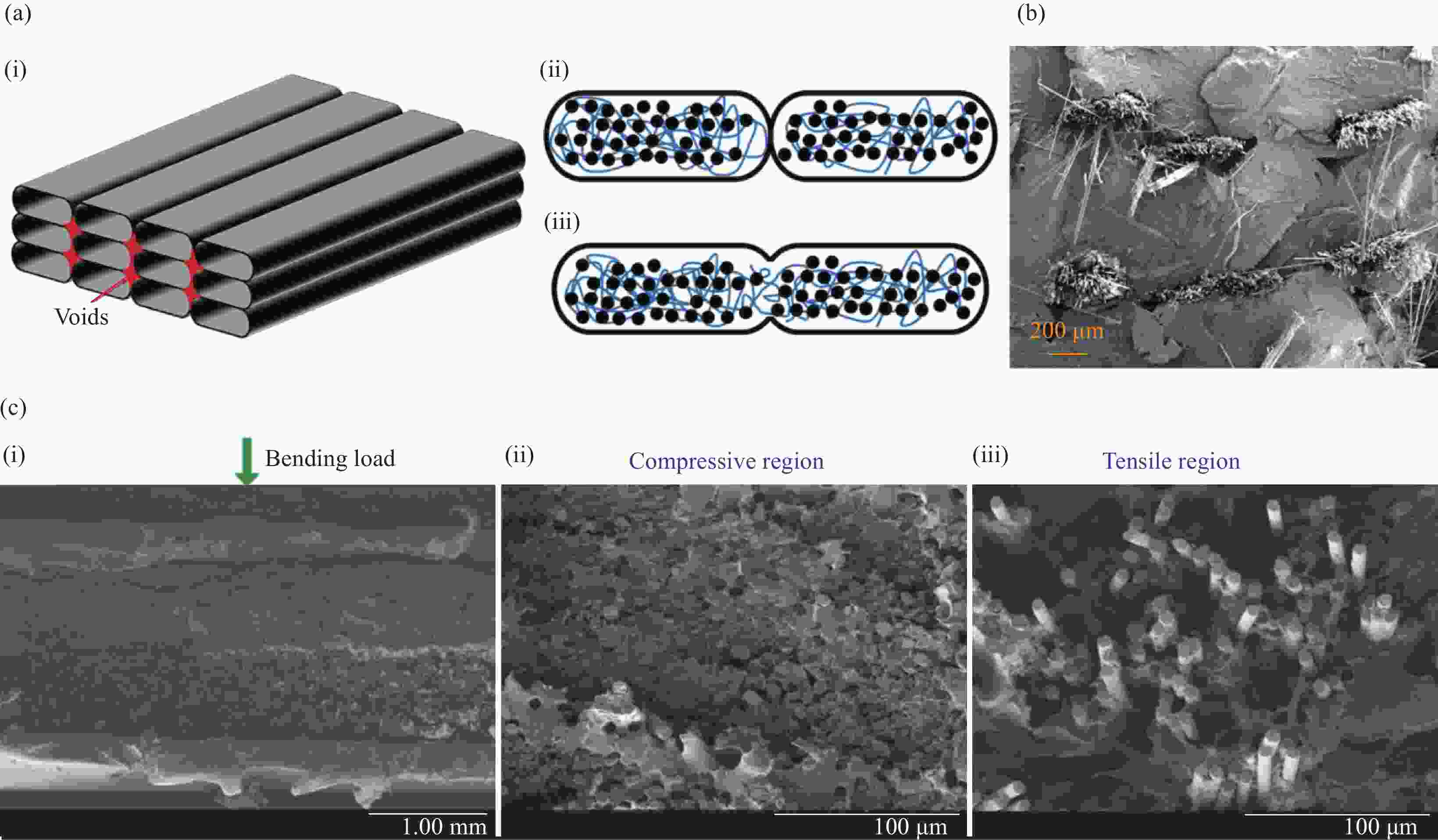

图 14 工艺缺陷与弯曲开裂断口:(a)列间孔隙形成过程 [86];(b)弯曲开裂断口的SEM照片 [117];和(c)弯曲载荷下压缩区与拉伸区的SEM照片 [118]

Figure 14. Process defects and bending cracking fractures: (a) formation process of inter-column pores [86]; (b) SEM photos of bending cracking fractures [117]; and (c) SEM photos of compression zone and tensile zone under bending load [118]

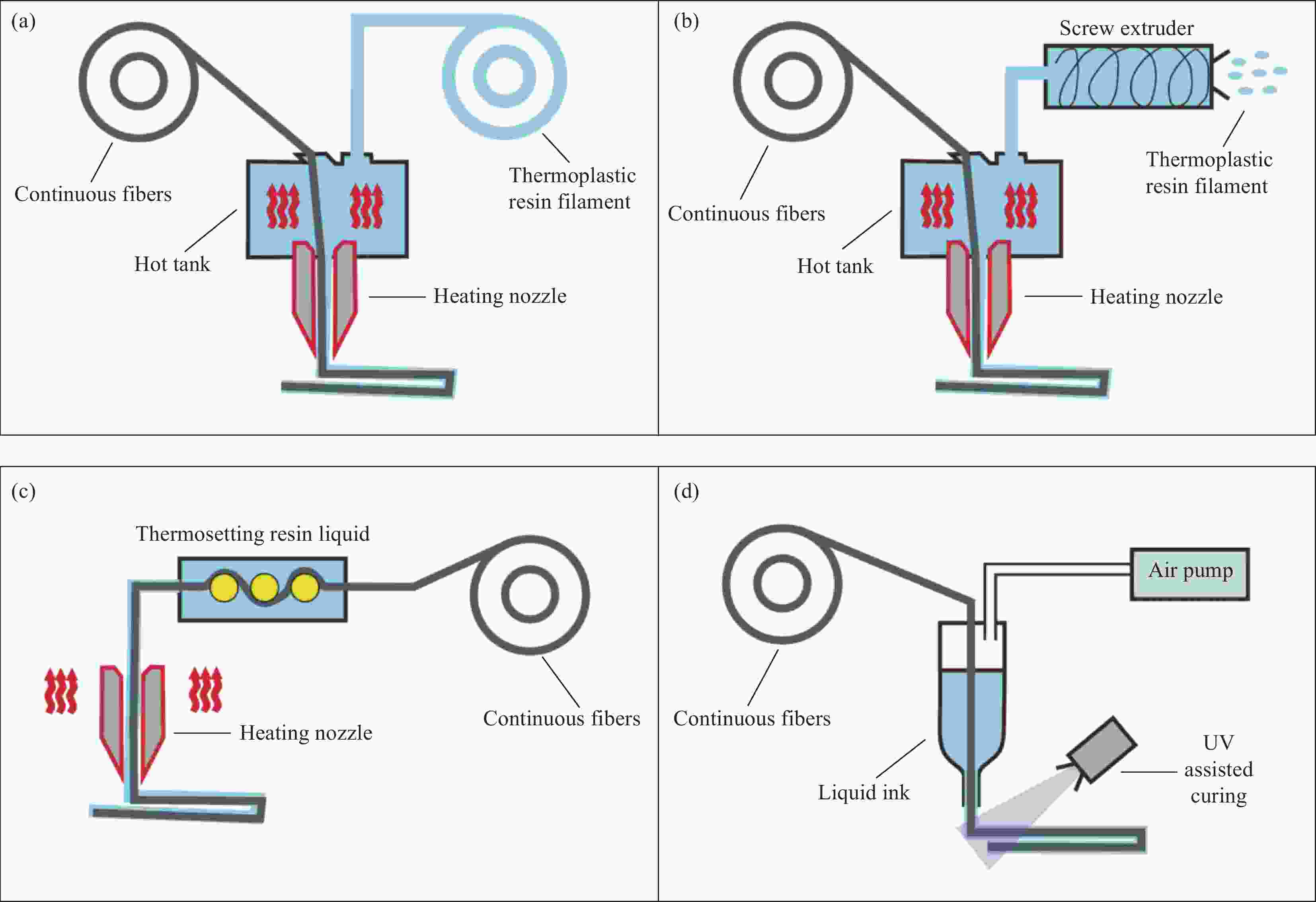

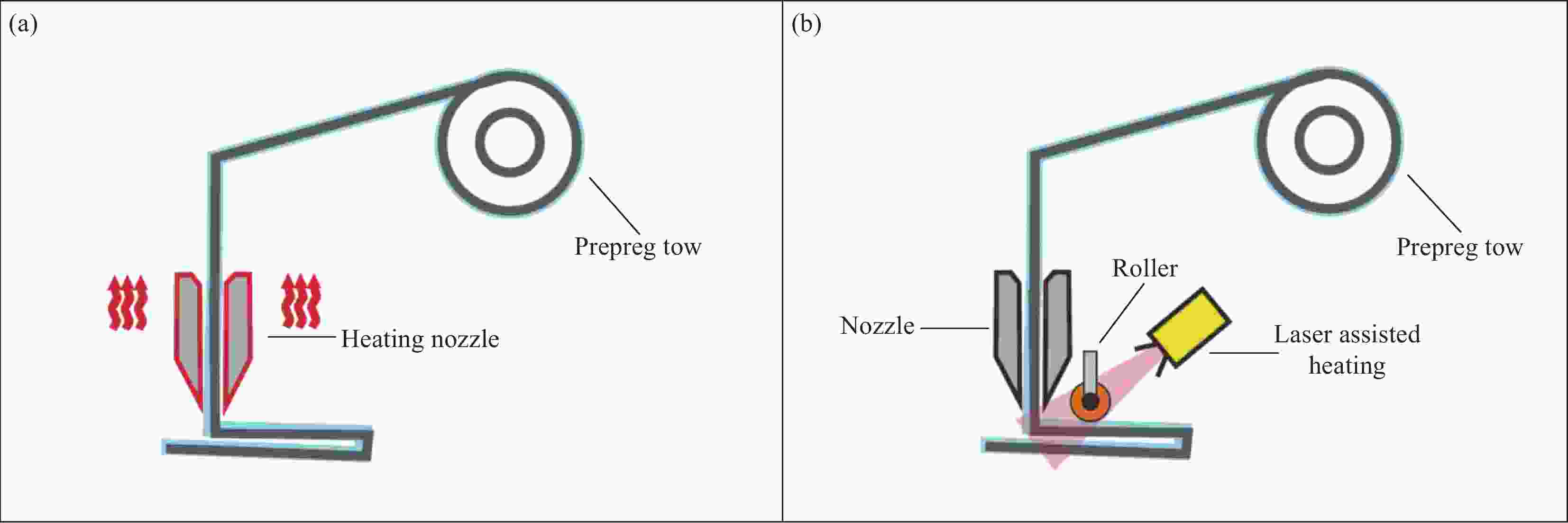

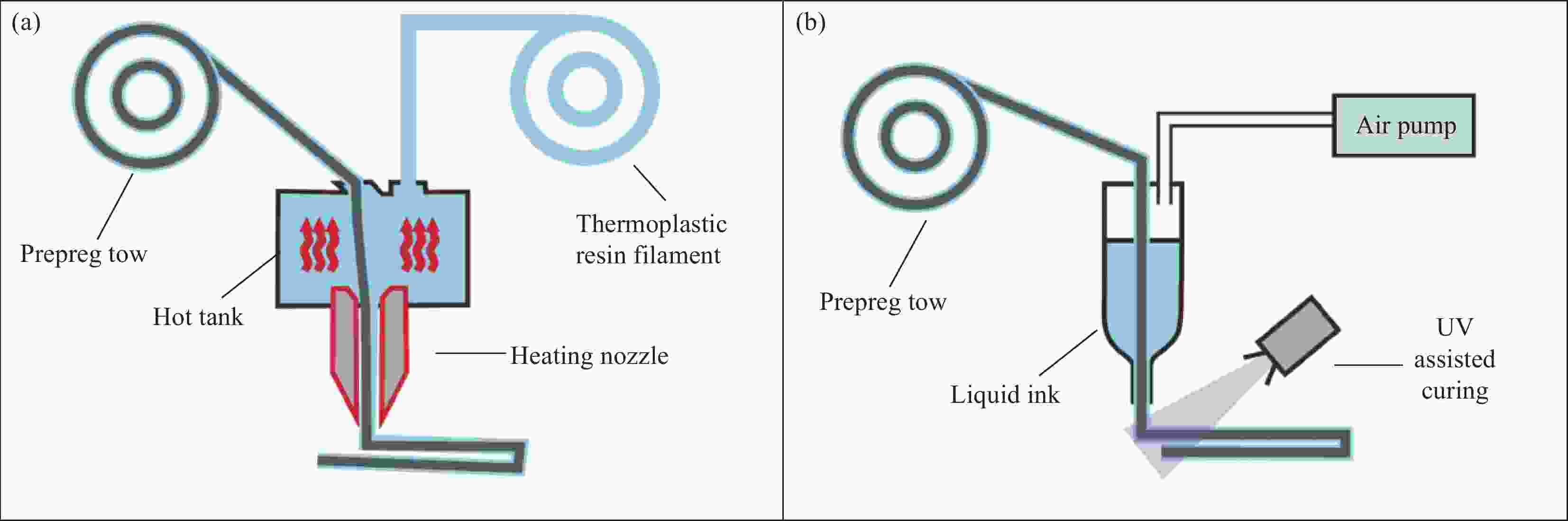

表 1 根据“干/湿/干湿-混合”概念分类的连续纤维增强3D打印复合材料的制备工艺

Table 1. Manufacturing processes of continuous fiber-reinforced 3D printing composites classified according to the concept of“dry/wet/dry-wet-mixed”

Classification Manufacturing processes Fibers/Reinforcement Consumables/Matrix Wet method In-situ impregnation fused

deposition [35-38]High-performance continuous dry

fibers: carbon fibers [45], glass fibers [46], Aramid fibers [47], basalt fibers [48];

Natural dry fibers: flax fibers [49], pineapple leave fibers [50]Thermoplastic resin: Polyetheretherketone [52], Polyphenylene sulfide [53], Polyamides [54], Polypropylene [55], Polycarbonate [56], Polylactic acid [57];

Thermoplastic resins with discontinuous fibrous reinforcements [58-59]Liquid deposition molding [46-48] Epoxy resin [46-48] Direct ink writing [49-51] Acrylic ink [50];

Liquid crystal elastomer [51]Dry method Material extrusion fused

deposition [72, 75-76]Continuous fiber thermoplastic [67-71];

Thermoset prepreg [72-73]/ Laser-Assisted Consolidation [77-78] Wet-dry-mixed method Prepreg tow co-extrusion [26, 79-81] Continuous fiber thermoplastic [70-71];

Thermoset prepreg [72-73]Thermoplastic resin [52-57];

Thermoplastic resins with discontinuous fibrous reinforcements [58-59]UV-Assisted Consolidation [74, 84] Continuous fiber light-cured prepreg [74] Light curing resins [74];

Light-thermal dual-cure resins [84]表 2 连续纤维增强3D打印复合材料的失效行为、相关工艺缺陷、失效机制与改善方式

Table 2. Failure behavior, related process defects, failure mechanisms, and improvement methods of continuous fiber-reinforced 3D printing composite materials

Failure behavior Related process defects Failure mechanisms Improvement methods Fiber pull-out [92, 98-100] Fiber bundle

defects [86, 91, 96-97]The crack initiates at the weak interface between the fiber and the matrix and then propagates until the fiber is pulled out [99] Pre-impregnating the fibers [104], print using dry method [104], increase molding pressure [98] and fiber pretreatment using sizing agents [105] Delamination [95, 106-107] Inter-layer voids [87-89],

inter-column voids [92-95],

and fiber bundle

defects [86, 91, 96-97]Weak interfaces sprout and expand rapidly along periodic distributions [106] Reduce process defects: improve

nozzles [113], vacuum printing [90] and laser-assisted heating [77]

Change the distribution of defects and weak interfaces to prevent rapid crack growth [114]Bending cracking [95, 99] Inter-column voids [92-95,115] and fiber bundle

defects [ 96-97,116-117]Cracks initiate from the upper surface of the tensile side and gradually expand toward the neutral axis until the structure is completely broken [95, 99] Perform hot pressing post-processing [91], adjust printing parameter settings [117] and adopt variable stiffness structural

design [118] -

[1] HSISSOU R, SEGHIRI R, BENZEKRI Z, et al. Polymer composite materials: A comprehensive review[J]. Composite structures, 2021, 262: 113640. doi: 10.1016/j.compstruct.2021.113640 [2] PINHEIRO MELO S, BARKE A, CERDAS F, et al. Sustainability assessment and engineering of emerging aircraft technologies—Challenges, methods and tools[J]. Sustainability, 2020, 12(14): 5663. doi: 10.3390/su12145663 [3] 冯志海, 李俊宁, 田跃龙, 等. 航天先进复合材料研究进展[J]. 复合材料学报, 2022, 39(9): 9.FENG Z, LI J, TIAN Y, et al. Research progress of aerospace advanced composite materials[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 9(in Chinese). [4] PARVEEZ B, KITTUR M I, BADRUDDIN I A, et al. Scientific advancements in composite materials for aircraft applications: a review[J]. Polymers, 2022, 14(22): 5007. doi: 10.3390/polym14225007 [5] TRZEPIECIŃSKI T, BATU T, KIBRETE F, et al. Application of Composite Materials for Energy Generation Devices[J]. Journal of Composites Science, 2023, 7(2): 55. doi: 10.3390/jcs7020055 [6] ZHANG J, LIN G, VAIDYA U, et al. Past, present and future prospective of global carbon fibre composite developments and applications[J]. Composites Part B: Engineering, 2022: 110463. [7] HALL W, JAVANBAKHT Z, HALL W, et al. How to make a composite—wet layup[J]. Design and Manufacture of Fibre-Reinforced Composites, 2021: 33-53. [8] HAN S H, OH H J, KIM S S. Evaluation of the impregnation characteristics of carbon fiber-reinforced composites using dissolved polypropylene[J]. Composites science and technology, 2014, 91: 55-62. doi: 10.1016/j.compscitech.2013.11.021 [9] MOHAMED M, SELIM M M, NING H, et al. Effect of fiber prestressing on mechanical properties of glass fiber epoxy composites manufactured by vacuum-assisted resin transfer molding[J]. Journal of Reinforced Plastics and Composites, 2020, 39(1-2): 21-30. doi: 10.1177/0731684419868841 [10] WANG Y, LI L, HOFMANN D, et al. Structured fabrics with tunable mechanical properties[J]. Nature, 2021, 596(7871): 238-243. doi: 10.1038/s41586-021-03698-7 [11] GU D, SHI X, POPRAWE R, et al. Material-structure-performance integrated laser-metal additive manufacturing[J]. Science, 2021, 372(6545): eabg1487. doi: 10.1126/science.abg1487 [12] CHEN J, LIU X, TIAN Y, et al. 3D-Printed anisotropic polymer materials for functional applications[J]. Advanced Materials, 2022, 34(5): 2102877. doi: 10.1002/adma.202102877 [13] PARANDOUSH P, LIN D. A review on additive manufacturing of polymer-fiber composites[J]. Composite Structures, 2017, 182: 36-53. doi: 10.1016/j.compstruct.2017.08.088 [14] WANG X, JIANG M, ZHOU Z, et al. 3D printing of polymer matrix composites: A review and prospective[J]. Composites Part B:Engineering, 2017, 110: 442-458. doi: 10.1016/j.compositesb.2016.11.034 [15] BRENKEN B, BAROCIO E, FAVALORO A, et al. Fused filament fabrication of fiber-reinforced polymers: A review[J]. Additive Manufacturing, 2018, 21: 1-16. doi: 10.1016/j.addma.2018.01.002 [16] 潘利剑. 先进复合材料成型工艺图解[M]. 化学工业出版社, 2016.PAN L. Advanced composite material forming process diagram[M]. Chemical Industry Publishing House, 2016. (in Chinese) [17] CHENG P, PENG Y, LI S, et al. 3D printed continuous fiber reinforced composite lightweight structures: a review and outlook[J]. Composites Part B: Engineering, 2022: 110450. [18] CHENG P, WANG K, LE DUIGOU A, et al. A novel dual-nozzle 3D printing method for continuous fiber reinforced composite cellular structures[J]. Composites Communications, 2023, 37: 101448. doi: 10.1016/j.coco.2022.101448 [19] DONG K, LIU L, HUANG X, et al. 3D printing of continuous fiber reinforced diamond cellular structural composites and tensile properties[J]. Composite Structures, 2020, 250: 112610. doi: 10.1016/j.compstruct.2020.112610 [20] DICKSON A N, BARRY J N, MCDONNELL K A, et al. Fabrication of continuous carbon, glass and Kevlar fibre reinforced polymer composites using additive manufacturing[J]. Additive Manufacturing, 2017, 16: 146-152. doi: 10.1016/j.addma.2017.06.004 [21] WANG Y, ZHANG G, REN H, et al. Fabrication strategy for joints in 3D printed continuous fiber reinforced composite lattice structures[J]. Composites Communications, 2022, 30: 101080. doi: 10.1016/j.coco.2022.101080 [22] ZHUO P, LI S, ASHCROFT I A, et al. Material extrusion additive manufacturing of continuous fibre reinforced polymer matrix composites: A review and outlook[J]. Composites Part B:Engineering, 2021, 224: 109143. doi: 10.1016/j.compositesb.2021.109143 [23] AZEEM M, YA H H, ALAM M A, et al. Application of filament winding technology in composite pressure vessels and challenges: a review[J]. Journal of Energy Storage, 2022, 49: 103468. doi: 10.1016/j.est.2021.103468 [24] 占冬至. 纤维湿法缠绕过程中在线自动配胶-浸胶系统研究[D]. 南京航空航天大学, 2019.ZHAN D. Research on on-line automatic gluing-dipping system in wet filament winding process[D]. Nanjing University of Aeronautics and Astronautics, 2019. (in Chinese) [25] 余木火, 王昊, 余许多等. 干法缠绕用预浸纱制备工艺优化及其性能[J]. 复合材料学报, 2022, 39(12): 5688-5698.YU M, WANG H, YU X, et al. Preparation process optimization and properties of prepreg yarn for dry winding[J]. Acta Materiae Compositae Sinica, 2022, 39(12): 5688-5698(in Chinese). [26] 龙昱, 李岩, 付昆昆. 3D打印纤维增强复合材料工艺和力学性能研究进展[J]. 复合材料学报, 2022, 39(9): 4196-4212.LONG Y, LI Y, FU K. Recent advances in 3D printed fiber reinforced composites: Processing technique and mechanical performance[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4196-4212(in Chinese). [27] 邢悦, 何鹏飞, 李竞龙, 等. 连续纤维增强聚合物复合材料增材制造工艺研究进展[J]. 复合材料学报, 2023, 40(7): 3703-3721. doi: 10.13801/j.cnki.fhclxb.20230224.001XING Y, HE P, LI J, et al. Additive manufacturing for continuous fiber-reinforced polymer composites: A review on processing technique[J]. Acta Materiae Compositae Sinica, 2023, 40(7): 3703-3721. doi: 10.13801/j.cnki.fhclxb.20230224.001 [28] 赵煜, 胡海洋, 药天运, 等. 3D打印GFRP层内失效力学行为的理论模型及细观机制[J]. 复合材料学报, 2023, 41(0): 1-19.ZHAO Y, HU H, YAO T, et al. Theoretical models and meso-scale mechanism of in-layer failure mechanicalbehaviours of 3D printing GFRP[J]. Acta Materiae Compositae Sinica [29] 孟云聪, 周光明, 蔡登安. 连续碳纤维3D打印圆形增强蜂窝的面内压缩性能[J]. 复合材料学报, 2023, 41(0): 1-12.MENG Y, ZHOU G, CAI D. In-plane compression properties of 3D printed continuous carbon fiber circular improved honeycomb[J]. Acta Materiae Compositae Sinica. [30] 周子彦, 范天翔, 张慧颖, 等. 3D打印连续碳纤维/聚醚酮酮复合材料工艺及其性能调控[J]. 复合材料学报, 2023, 40(9): 5070-5084. doi: 10.13801/j.cnki.fhclxb.20221215.002ZHOU Z, FAN T, ZHANG H, et al. Process and performance control of 3D printed continuous carbon fiber/poly(ether ketone ketone) composites[J]. Acta Materiae Compositae Sinica, 2023, 40(9): 5070-5084. doi: 10.13801/j.cnki.fhclxb.20221215.002 [31] 齐田宇, 杨建军, 赵佳伟, 等. 基于多材料3D打印和约束牺牲层连续功能梯度材料-结构一体化制造与性能[J]. 复合材料学报, 2022, 39(3): 1055-1067.QI T, YANG J, ZHAO J, et al. Integrated manufacturing and performance study of continuous functionally graded materials-structures based on multi-material 3D printing and constraint sacrifice layer[J]. Acta Materiae Compositae Sinica, 2022, 39(3): 1055-1067. [32] WICKRAMASINGHE S, DO T, TRAN P. FDM-based 3D printing of polymer and associated composite: A review on mechanical properties, defects and treatments[J]. Polymers, 2020, 12(7): 1529. doi: 10.3390/polym12071529 [33] FICO D, RIZZO D, CASCIARO R, et al. A review of polymer-based materials for fused filament fabrication (FFF): focus on sustainability and recycled materials[J]. Polymers, 2022, 14(3): 465. doi: 10.3390/polym14030465 [34] LI S, CHENG P, AHZI S, et al. Advances in hybrid fibers reinforced polymer-based composites prepared by FDM: A review on mechanical properties and prospects[J]. Composites Communications, 2023: 101592. [35] NAMIKI M, UEDA M, TODOROKI A, et al. 3D printing of continuous fiber reinforced plastic[C]//SAMPE Tech Seattle 2014 Conference. Soc. for the Advancement of Material and Process Engineering, 2014. [36] MATSUZAKI R, UEDA M, NAMIKI M, et al. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation[J]. Scientific reports, 2016, 6(1): 23058. doi: 10.1038/srep23058 [37] 冉旭东. 面向点阵结构的连续纤维3D打印成型技术研究[D]. 哈尔滨工业大学, 2021.RAN X. Reasearch On Technologies Of Continuous Fiber-Reinforced Composites 3D Printing For Lattice Structure Manufacturing[D]. Harbin Institute of Technology, 2021. (in Chinese) [38] 张海强, 陈晓佳, 杜俊斌, 等. 螺杆式连续纤维增强材料3D打印挤出头及使用方法: CN202011074956.8[P]. CN112477111A[2023-11-18].ZHANG H, CHEN X, DU J, et al. Screw continuous fiber reinforced material 3D printing extrusion head and use method: CN202011074956.8[P]. CN112477111A [2023-11-18]. (in Chinese) [39] MALAKHOV A V, TIAN X, ZHENG Z, et al. Three-dimensional printing of biomimetic variable stiffness composites with controlled orientations and volume fraction of fibers[J]. Composite Structures, 2022, 299: 116091. doi: 10.1016/j.compstruct.2022.116091 [40] CHENG Y, LI J, QIAN X, et al. 3D printed recoverable honeycomb composites reinforced by continuous carbon fibers[J]. Composite Structures, 2021, 268: 113974. doi: 10.1016/j.compstruct.2021.113974 [41] HOU Z, TIAN X, ZHANG J, et al. 3D printed continuous fibre reinforced composite corrugated structure[J]. Composite Structures, 2018, 184: 1005-1010. doi: 10.1016/j.compstruct.2017.10.080 [42] ZENG C, LIU L, BIAN W, et al. Bending performance and failure behavior of 3D printed continuous fiber reinforced composite corrugated sandwich structures with shape memory capability[J]. Composite Structures, 2021, 262: 113626. doi: 10.1016/j.compstruct.2021.113626 [43] WANG Z, LUAN C, LIAO G, et al. Mechanical and self-monitoring behaviors of 3D printing smart continuous carbon fiber-thermoplastic lattice truss sandwich structure[J]. Composites Part B:Engineering, 2019, 176: 107215. doi: 10.1016/j.compositesb.2019.107215 [44] LIU S, LI Y, LI N. A novel free-hanging 3D printing method for continuous carbon fiber reinforced thermoplastic lattice truss core structures[J]. Materials & Design, 2018, 137: 235-244. [45] DOU H, YE W, ZHANG D, et al. Three-Point Bending Properties of 3D-Printed Continuous Carbon Fiber Reinforced Heterogeneous Composites Based on Fiber Content Gradients[J]. Advanced Engineering Materials, 2023, 25(1): 2200829. doi: 10.1002/adem.202200829 [46] FARROKHABADI A, VEISI H, GHAREHBAGHI H, et al. Investigation of the energy absorption capacity of foam-filled 3D-printed glass fiber reinforced thermoplastic auxetic honeycomb structures[J]. Mechanics of Advanced Materials and Structures, 2023, 30(4): 758-769. doi: 10.1080/15376494.2021.2023919 [47] SHI K, YAN Y, MEI H, et al. 3D printing Kevlar fiber layer distributions and fiber orientations into nylon composites to achieve designable mechanical strength[J]. Additive Manufacturing, 2021, 39: 101882. doi: 10.1016/j.addma.2021.101882 [48] ZHANG H, SUN W. Mechanical properties and failure behavior of 3D printed thermoplastic composites using continuous basalt fiber under high-volume fraction[J]. Defence Technology, 2023, 27: 237-250. doi: 10.1016/j.dt.2022.07.010 [49] LE DUIGOU A, BARBÉ A, GUILLOU E, et al. 3D printing of continuous flax fibre reinforced biocomposites for structural applications[J]. Materials & Design, 2019, 180: 107884. [50] SUTEJA J, FIRMANTO H, SOESANTI A, et al. Properties investigation of 3D printed continuous pineapple leaf fiber-reinforced PLA composite[J]. Journal of Thermoplastic Composite Materials, 2022, 35(11): 2052-2061. doi: 10.1177/0892705720945371 [51] BALLA V K, KATE K H, SATYAVOLU J, et al. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects[J]. Composites Part B:Engineering, 2019, 174: 106956. doi: 10.1016/j.compositesb.2019.106956 [52] WANG P, ZOU B, DING S, et al. Functionally graded polyetheretherketone-based composites additively manufactured by material extrusion using a transition interface design method[J]. Composites Part A:Applied Science and Manufacturing, 2022, 158: 106977. doi: 10.1016/j.compositesa.2022.106977 [53] SHUTO R, NORIMATSU S, AROLA D D, et al. Effect of the nozzle temperature on the microstructure and interlaminar strength in 3D printing of carbon fiber/polyphenylene sulfide composites[J]. Composites Part C:Open Access, 2022, 9: 100328. doi: 10.1016/j.jcomc.2022.100328 [54] PENG Y, WU Y, LI S, et al. Tailorable rigidity and energy-absorption capability of 3D printed continuous carbon fiber reinforced polyamide composites[J]. Composites Science and Technology, 2020, 199: 108337. doi: 10.1016/j.compscitech.2020.108337 [55] KABIRI A, LIAGHAT G, ALAVI F, et al. Glass fiber/polypropylene composites with potential of bone fracture fixation plates: manufacturing process and mechanical characterization[J]. Journal of Composite Materials, 2020, 54(30): 4903-4919. doi: 10.1177/0021998320940367 [56] SHUTO R, NORIMATSU S, AROLA D D, et al. Effect of the nozzle temperature on the microstructure and interlaminar strength in 3D printing of carbon fiber/polyphenylene sulfide composites[J]. Composites Part C:Open Access, 2022, 9: 100328. doi: 10.1016/j.jcomc.2022.100328 [57] LI N, LI Y, LIU S. Rapid prototyping of continuous carbon fiber reinforced polylactic acid composites by 3D printing[J]. Journal of Materials Processing Technology, 2016, 238: 218-225. doi: 10.1016/j.jmatprotec.2016.07.025 [58] PENG Y, WU Y, WANG K, et al. Synergistic reinforcement of polyamide-based composites by combination of short and continuous carbon fibers via fused filament fabrication[J]. Composite Structures, 2019, 207: 232-239. doi: 10.1016/j.compstruct.2018.09.014 [59] DONG K, PANAHI-SARMAD M, CUI Z, et al. Electro-induced shape memory effect of 4D printed auxetic composite using PLA/TPU/CNT filament embedded synergistically with continuous carbon fiber: A theoretical & experimental analysis[J]. Composites Part B:Engineering, 2021, 220: 108994. doi: 10.1016/j.compositesb.2021.108994 [60] VALINO A D, DIZON J R C, ESPERA JR A H, et al. Advances in 3D printing of thermoplastic polymer composites and nanocomposites[J]. Progress in Polymer Science, 2019, 98: 101162. doi: 10.1016/j.progpolymsci.2019.101162 [61] HAO W, LIU Y, ZHOU H, ET AL. Preparation and characterization of 3D printed continuous carbon fiber reinforced thermosetting composites[J]. Polymer Testing, 2018, 65: 29-34. doi: 10.1016/j.polymertesting.2017.11.004 [62] MING Y, ZHANG S, HAN W, et al. Investigation on process parameters of 3D printed continuous carbon fiber-reinforced thermosetting epoxy composites[J]. Additive Manufacturing, 2020, 33: 101184. doi: 10.1016/j.addma.2020.101184 [63] MING Y, DUAN Y, ZHANG S, et al. Self-heating 3D printed continuous carbon fiber/epoxy mesh and its application in wind turbine deicing[J]. Polymer Testing, 2020, 82: 106309. doi: 10.1016/j.polymertesting.2019.106309 [64] SAADI M, MAGUIRE A, POTTACKAL N T, et al. Direct ink writing: a 3D printing technology for diverse materials[J]. Advanced Materials, 2022, 34(28): 2108855. doi: 10.1002/adma.202108855 [65] ABDULLAH A M, DING Y, HE X, et al. Direct-write 3D printing of UV-curable composites with continuous carbon fiber[J]. Journal of Composite Materials, 2023, 57(4): 851-863. doi: 10.1177/00219983221127182 [66] WANG Q, TIAN X, ZHANG D, et al. Programmable spatial deformation by controllable off-center freestanding 4D printing of continuous fiber reinforced liquid crystal elastomer composites[J]. Nature Communications, 2023, 14(1): 3869. doi: 10.1038/s41467-023-39566-3 [67] WANG Y, ZHANG Q, WANG Q, et al. Preparation of Continuous Glass Fiber Reinforced Polylactic Acid by Means of a Melt Impregnation Method and Application as a 3D Printing Consumable[J]. Chemistry Select, 2021, 6(35): 9535-9539. [68] YU L, CHEN K, XUE P, et al. Impregnation modeling and preparation optimization of continuous glass fiber reinforced polylactic acid filament for 3D printing[J]. Polymer Composites, 2021, 42(11): 5731-5742. doi: 10.1002/pc.26255 [69] 杨来侠, 刘波, 刘腾飞, 等. 3D打印连续纤维增强聚碳酸酯复合材料预浸丝制备与性能[J]. 复合材料学报, 2023, 40(10): 5654-5665.YANG L, LIU B, LIU T, et al. Preparation and properties of 3D printing continuous fiber reinforced polycarbonate composite prepreg filaments[J]. Acta Materiae Compositae Sinica, 2023, 40(10): 5654-5665(in Chinese). [70] KIM H, OH Y, HWANG J Y, et al. High-performance continuous carbon fiber composite filament via solution process[J]. Journal of Industrial and Engineering Chemistry, 2022, 115: 466-475. doi: 10.1016/j.jiec.2022.08.033 [71] 张帆, 陈港, 贵树峰, 等. PC/CCF制备工艺对浸渍程度的影响及3D打印性能分析[J]. 工程塑料应用, 2023, 51(3): 7.ZHANG F, CHEN G, GUI S, et al. Influence of PC/CCF Preparation Process on Impregnation Degree and 3D Printing Performance Analysis[J]. Engineering Plastics Application, 2023, 51(3): 7(in Chinese). [72] MING Y, DUAN Y, WANG B, et al. A novel route to fabricate high-performance 3D printed continuous fiber-reinforced thermosetting polymer composites[J]. Materials, 2019, 12(9): 1369. doi: 10.3390/ma12091369 [73] ZHANG H, ZHANG K, LI A, et al. 3D printing of continuous carbon fibre reinforced powder-based epoxy composites[J]. Composites Communications, 2022, 33: 101239. doi: 10.1016/j.coco.2022.101239 [74] RAHMAN M A, ISLAM M Z, GIBBON L, et al. 3D printing of continuous carbon fiber reinforced thermoset composites using UV curable resin[J]. Polymer Composites, 2021, 42(11): 5859-5868. doi: 10.1002/pc.26266 [75] CHEN Y, YE L. Topological design for 3D-printing of carbon fibre reinforced composite structural parts[J]. Composites Science and Technology, 2021, 204: 108644. doi: 10.1016/j.compscitech.2020.108644 [76] WANG B, MING Y, ZHOU J, et al. Fabrication of triangular corrugated structure using 3D printed continuous carbon fiber-reinforced thermosetting epoxy composites[J]. Polymer Testing, 2022, 106: 107469. doi: 10.1016/j.polymertesting.2021.107469 [77] PARANDOUSH P, TUCKER L, ZHOU C, et al. Laser assisted additive manufacturing of continuous fiber reinforced thermoplastic composites[J]. Materials & Design, 2017, 131: 186-195. [78] EICHENHOFER M, WONG J C H, ERMANNI P. Continuous lattice fabrication of ultra-lightweight composite structures[J]. Additive Manufacturing, 2017, 18: 48-57. doi: 10.1016/j.addma.2017.08.013 [79] ZHUO P, LI S, ASHCROFT I A, et al. Continuous fibre composite 3D printing with pultruded carbon/PA6 commingled fibres: Processing and mechanical properties[J]. Composites Science and Technology, 2022, 221: 109341. doi: 10.1016/j.compscitech.2022.109341 [80] NAKAGAWA Y, MORI K, MAENO T. 3D printing of carbon fibre-reinforced plastic parts[J]. The International Journal of Advanced Manufacturing Technology, 2017, 91: 2811-2817. doi: 10.1007/s00170-016-9891-7 [81] ZHANG Y, QIAO J, ZHANG G, et al. Prediction of deformation and failure behavior of continuous fiber reinforced composite fabricated by additive manufacturing[J]. Composite Structures, 2021, 265: 113738. doi: 10.1016/j.compstruct.2021.113738 [82] FEDULOV B, FEDORENKO A, KHAZIEV A, et al. Optimization of parts manufactured using continuous fiber three-dimensional printing technology[J]. Composites Part B:Engineering, 2021, 227: 109406. doi: 10.1016/j.compositesb.2021.109406 [83] AZAROV A V, ANTONOV F K, GOLUBEV M V, et al. Composite 3D printing for the small size unmanned aerial vehicle structure[J]. Composites Part B:Engineering, 2019, 169: 157-163. doi: 10.1016/j.compositesb.2019.03.073 [84] INVERNIZZI M, NATALE G, LEVI M, et al. UV-assisted 3D printing of glass and carbon fiber-reinforced dual-cure polymer composites[J]. Materials, 2016, 9(7): 583. doi: 10.3390/ma9070583 [85] KABIR S M F, MATHUR K, SEYAM A F M. A critical review on 3D printed continuous fiber-reinforced composites: History, mechanism, materials and properties[J]. Composite Structures, 2020, 232: 111476. doi: 10.1016/j.compstruct.2019.111476 [86] HE Q, WANG H, FU K, et al. 3D printed continuous CF/PA6 composites: Effect of microscopic voids on mechanical performance[J]. Composites Science and Technology, 2020, 191: 108077. doi: 10.1016/j.compscitech.2020.108077 [87] van de WERKEN N, HURLEY J, KHANBOLOUKI P, et al. Design considerations and modeling of fiber reinforced 3D printed parts[J]. Composites Part B:Engineering, 2019, 160: 684-692. doi: 10.1016/j.compositesb.2018.12.094 [88] UŞUN A, GÜMRÜK R. The mechanical performance of the 3D printed composites produced with continuous carbon fiber reinforced filaments obtained via melt impregnation[J]. Additive Manufacturing, 2021, 46: 102112. doi: 10.1016/j.addma.2021.102112 [89] DICKSON A N, DOWLING D P. Enhancing the bearing strength of woven carbon fibre thermoplastic composites through additive manufacturing[J]. Composite Structures, 2019, 212: 381-388. doi: 10.1016/j.compstruct.2019.01.050 [90] LI H, LIU B, GE L, et al. Mechanical performances of continuous carbon fiber reinforced PLA composites printed in vacuum[J]. Composites Part B:Engineering, 2021, 225: 109277. doi: 10.1016/j.compositesb.2021.109277 [91] MEI H, ALI Z, YAN Y, et al. Influence of mixed isotropic fiber angles and hot press on the mechanical properties of 3D printed composites[J]. Additive Manufacturing, 2019, 27: 150-158. doi: 10.1016/j.addma.2019.03.008 [92] YANG C, TIAN X, LIU T, et al. 3D printing for continuous fiber reinforced thermoplastic composites: mechanism and performance[J]. Rapid Prototyping Journal, 2017, 23(1): 209-215. doi: 10.1108/RPJ-08-2015-0098 [93] BLOK L G, LONGANA M L, YU H, et al. An investigation into 3D printing of fibre reinforced thermoplastic composites[J]. Additive Manufacturing, 2018, 22: 176-186. doi: 10.1016/j.addma.2018.04.039 [94] JUSTO J, TÁVARA L, GARCÍA-GUZMÁN L, et al. Characterization of 3D printed long fibre reinforced composites[J]. Composite Structures, 2018, 185: 537-548. doi: 10.1016/j.compstruct.2017.11.052 [95] GOH G D, DIKSHIT V, NAGALINGAM A P, et al. Characterization of mechanical properties and fracture mode of additively manufactured carbon fiber and glass fiber reinforced thermoplastics[J]. Materials & Design, 2018, 137: 79-89. [96] TEREKHINA S, EGOROV S, TARASOVA T, et al. In-nozzle impregnation of continuous textile flax fiber/polyamide 6 composite during FFF process[J]. Composites Part A:Applied Science and Manufacturing, 2022, 153: 106725. doi: 10.1016/j.compositesa.2021.106725 [97] LIU S, LI Y, LI N. A novel free-hanging 3D printing method for continuous carbon fiber reinforced thermoplastic lattice truss core structures[J]. Materials & Design, 2018, 137: 235-244. [98] LIU T, TIAN X, ZHANG M, et al. Interfacial performance and fracture patterns of 3D printed continuous carbon fiber with sizing reinforced PA6 composites[J]. Composites Part A:Applied Science and Manufacturing, 2018, 114: 368-376. doi: 10.1016/j.compositesa.2018.09.001 [99] ZHANG X, ZHENG X, SONG L, et al. Compressive properties and failure mechanisms of 3D-printed continuous carbon fiber-reinforced auxetic structures[J]. Composites Communications, 2023, 43: 101744. doi: 10.1016/j.coco.2023.101744 [100] PARANDOUSH P, ZHOU C, LIN D. 3D printing of ultrahigh strength continuous carbon fiber composites[J]. Advanced Engineering Materials, 2019, 21(2): 1800622. doi: 10.1002/adem.201800622 [101] MOSLEH N, REZADOUST A M, DARIUSHI S. Determining process-window for manufacturing of continuous carbon fiber-reinforced composite Using 3D-printing[J]. Materials and Manufacturing Processes, 2021, 36(4): 409-418. doi: 10.1080/10426914.2020.1843664 [102] GAROFALO J, WALCZYK D. In situ impregnation of continuous thermoplastic composite prepreg for additive manufacturing and automated fiber placement[J]. Composites Part A:Applied Science and Manufacturing, 2021, 147: 106446. doi: 10.1016/j.compositesa.2021.106446 [103] MAYER C, WANG X, NEITZEL M. Macro-and micro-impregnation phenomena in continuous manufacturing of fabric reinforced thermoplastic composites[J]. Composites Part A:Applied Science and Manufacturing, 1998, 29(7): 783-793. doi: 10.1016/S1359-835X(98)00056-6 [104] KACZMAREK D, WALCZYK D, GAROFALO J, et al. An investigation of in situ impregnation for additive manufacturing of thermoplastic composites[J]. Journal of Manufacturing Processes, 2021, 64: 972-981. doi: 10.1016/j.jmapro.2021.02.018 [105] AEGERTER N, VOLK M, MAIO C, et al. Pultrusion of hybrid bicomponent fibers for 3D printing of continuous fiber reinforced thermoplastics[J]. Advanced Industrial and Engineering Polymer Research, 2021, 4(4): 224-234. doi: 10.1016/j.aiepr.2021.07.004 [106] 张曼玉, 刘腾飞, 田小永, 等. 面向3D打印的连续碳纤维上浆工艺及其对复合材料性能的影响[J]. 中国材料进展, 2020, 39(5): 7.ZHANG M, LIU T, TIAN X, et al. Sizing Process of Continuous Carbon Fiber for 3D Printing and Its Influence on the Properties of Composites[J]. MATERIALS CHINA, 2020, (05): 349-355. [107] LUO M, TIAN X, SHANG J, et al. Impregnation and interlayer bonding behaviours of 3D-printed continuous carbon-fiber-reinforced poly-ether-ether-ketone composites[J]. Composites Part A:Applied Science and Manufacturing, 2019, 121: 130-138. doi: 10.1016/j.compositesa.2019.03.020 [108] CAMINERO M A, CHACÓN J M, GARCÍA-MORENO I, et al. Interlaminar bonding performance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling[J]. Polymer Testing, 2018, 68: 415-423. doi: 10.1016/j.polymertesting.2018.04.038 [109] KONG X, LUO J, LUO Q, et al. Experimental study on interface failure behavior of 3D printed continuous fiber reinforced composites[J]. Additive Manufacturing, 2022, 59: 103077. doi: 10.1016/j.addma.2022.103077 [110] DANG Z, CAO J, PAGANI A, et al. Fracture toughness determination and mechanism for mode-I interlaminar failure of 3D-printed carbon-Kevlar composites[J]. Composites Communications, 2023, 39: 101532. doi: 10.1016/j.coco.2023.101532 [111] POLYZOS E, KATALAGARIANAKIS A, VAN HEMELRIJCK D, et al. Delamination analysis of 3D-printed nylon reinforced with continuous carbon fibers[J]. Additive Manufacturing, 2021, 46: 102144. doi: 10.1016/j.addma.2021.102144 [112] TOUCHARD F, CHOCINSKI-ARNAULT L, FOURNIER T, et al. Interfacial adhesion quality in 3D printed continuous CF/PA6 composites at filament/matrix and interlaminar scales[J]. Composites Part B:Engineering, 2021, 218: 108891. doi: 10.1016/j.compositesb.2021.108891 [113] YAVAS D, ZHANG Z, LIU Q, et al. Interlaminar shear behavior of continuous and short carbon fiber reinforced polymer composites fabricated by additive manufacturing[J]. Composites Part B:Engineering, 2021, 204: 108460. doi: 10.1016/j.compositesb.2020.108460 [114] WANG Y, WANG Q, KONG D, et al. Research on Heating Zone Length of Continuous Fiber Reinforced Composites 3D Printing Nozzle[J]. ChemistrySelect, 2021, 6(41): 11293-11298. doi: 10.1002/slct.202103230 [115] DAMODARAN V, CASTELLANOS A G, MILOSTAN M, et al. Improving the Mode-II interlaminar fracture toughness of polymeric matrix composites through additive manufacturing[J]. Materials & Design, 2018, 157: 60-73. [116] WANG F, MING Y, YANG F, et al. Improving delamination resistance of 3D printed continuous fiber-reinforced thermoset composites by multi-scale synergistic toughening of mono-component polyetherketone-cardo[J]. Composites Science and Technology, 2024, 245: 110358. doi: 10.1016/j.compscitech.2023.110358 [117] WU S, SHAN Z, CHEN K, et al. Investigation of bending performance of printed continuous carbon fiber reinforced polylactic acid using acoustic emission[J]. Polymer Composites, 2023, 44(2): 863-872. doi: 10.1002/pc.27137 [118] LI L, LIU W, SUN L. Mechanical characterization of 3D printed continuous carbon fiber reinforced thermoplastic composites[J]. Composites Science and Technology, 2022, 227: 109618. doi: 10.1016/j.compscitech.2022.109618 [119] TIAN X, LIU T, YANG C, et al. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites[J]. Composites Part A:Applied Science and Manufacturing, 2016, 88: 198-205. doi: 10.1016/j.compositesa.2016.05.032 [120] YIN B, HE Q, YE L. Effects of deposition speed and extrusion temperature on fusion between filaments in single-layer polymer films printed with FFF[J]. Advanced Industrial and Engineering Polymer Research, 2021, 4(4): 270-276. doi: 10.1016/j.aiepr.2021.07.002 [121] DOU H, YE W, ZHANG D, et al. Three-Point Bending Properties of 3D-Printed Continuous Carbon Fiber Reinforced Heterogeneous Composites Based on Fiber Content Gradients[J]. Advanced Engineering Materials, 2023, 25(1): 2200829. doi: 10.1002/adem.202200829 [122] MELENKA G W, CHEUNG B K O, SCHOFIELD J S, et al. Evaluation and prediction of the tensile properties of continuous fiber-reinforced 3D printed structures[J]. Composite Structures, 2016, 153: 866-875. doi: 10.1016/j.compstruct.2016.07.018 [123] AL ABADI H, THAI H T, PATON-COLE V, et al. Elastic properties of 3D printed fibre-reinforced structures[J]. Composite Structures, 2018, 193: 8-18. doi: 10.1016/j.compstruct.2018.03.051 [124] LUPONE F, PADOVANO E, VENEZIA C, et al. Experimental Characterization and Modeling of 3D Printed Continuous Carbon Fibers Composites with Different Fiber Orientation Produced by FFF Process[J]. Polymers, 2022, 14(3): 426. doi: 10.3390/polym14030426 [125] HOU Z, TIAN X, ZHENG Z, et al. A constitutive model for 3D printed continuous fiber reinforced composite structures with variable fiber content[J]. Composites Part B:Engineering, 2020, 189: 107893. doi: 10.1016/j.compositesb.2020.107893 [126] WANG S, YAN X, CHANG B, et al. Atomistic Modeling of the Effect of Temperature on Interfacial Properties of 3D-Printed Continuous Carbon Fiber-Reinforced Polyamide 6 Composite: From Processing to Loading[J]. ACS Applied Materials & Interfaces, 2023. [127] FU Y, YAO X. Multi-scale analysis for 3D printed continuous fiber reinforced thermoplastic composites[J]. Composites Science and Technology, 2021, 216: 109065. doi: 10.1016/j.compscitech.2021.109065 [128] ZHANG J, YANG W, LI Y. Process-dependent multiscale modeling for 3D printing of continuous fiber-reinforced composites[J]. Additive Manufacturing, 2023, 73: 103680. doi: 10.1016/j.addma.2023.103680 [129] WANG F, ZHANG Z, NING F, et al. A mechanistic model for tensile property of continuous carbon fiber reinforced plastic composites built by fused filament fabrication[J]. Additive Manufacturing, 2020, 32: 101102. doi: 10.1016/j.addma.2020.101102 [130] WANG X, ZHENG T, LI Z, et al. Influence of realistic microscopic fiber misalignments on compressive damage mechanisms of 3D angle-interlock woven composites: In-situ measurements and numerical simulations[J]. Composites Science and Technology, 2024, 245: 110317. doi: 10.1016/j.compscitech.2023.110317 [131] WU T, LI G, XUE Y, et al. Electromechanical behavior and damage index system of 3D carbon fiber angle-interlock woven composites with FEA and data processing tools[J]. Composites Science and Technology, 2023, 244: 110318. doi: 10.1016/j.compscitech.2023.110318 -

点击查看大图

点击查看大图

计量

- 文章访问数: 413

- HTML全文浏览量: 173

- 被引次数: 0

下载:

下载: