Compressive behavior of concrete-filled multi-cavity composite rectangular columns

-

摘要: 为改善矩形拉挤型材受力性能,提高混凝土约束效率,提出一种多腔矩形纤维增强复合材料约束混凝土组合短柱。对多腔矩形纤维增强复合材料管及其约束混凝土构件进行了轴压试验,研究了多腔结构及增设格构腹板对拉挤型材约束混凝土结构破坏模式、峰值承载力及其延性特征的影响。试验结果表明,多腔结构有效改善拉挤型材脆性破坏特征,构件破坏前有明显征兆;多腔结构有效改善拉挤型材受力性能及其混凝土约束效率,其中拉挤型材承载力平均提高53.08%,约束混凝土强度平均提高约27.45%。增设格构腹板有效改善材料界面粘结性能,延缓约束面层局部屈曲,提高结构整体变形能力,其中格构增强多腔混凝土组合构件延性系数平均为2.23,远高于无格构构件的1.88;增设格构腹板进一步提高多腔结构混凝土约束效率,结构具有更高的峰值承载力,其中多腔约束混凝土构件承载力最大提高21.17%,远高于无格构构件的7.44%。此外,提出一种简易计算模型,分别对多腔矩形纤维增强复合材料管及其约束混凝土构件的峰值承载力进行了理论计算,计算结果与试验较一致。

-

关键词:

- 纤维增强复合材料约束混凝土柱 /

- 多腔结构 /

- 格构腹板 /

- 轴压性能 /

- 峰值荷载

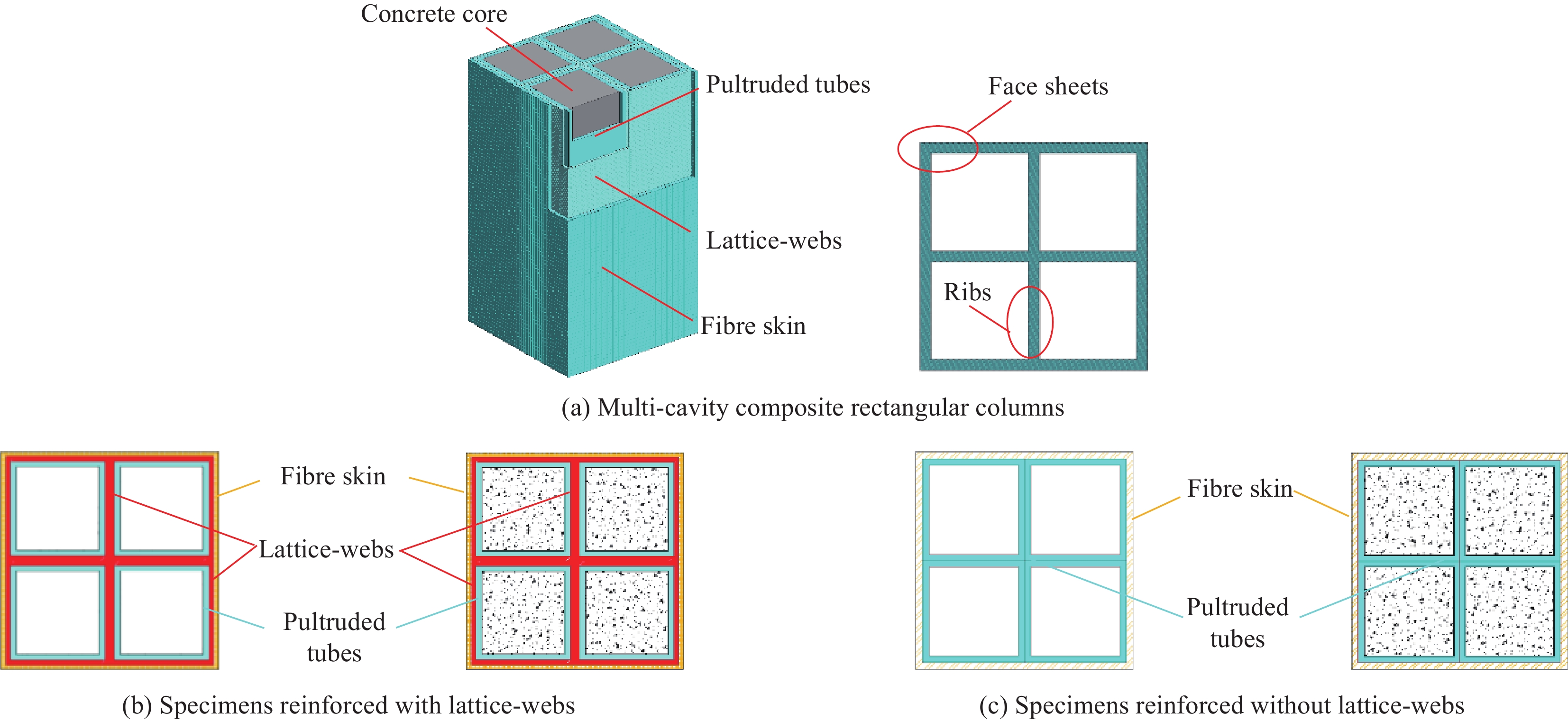

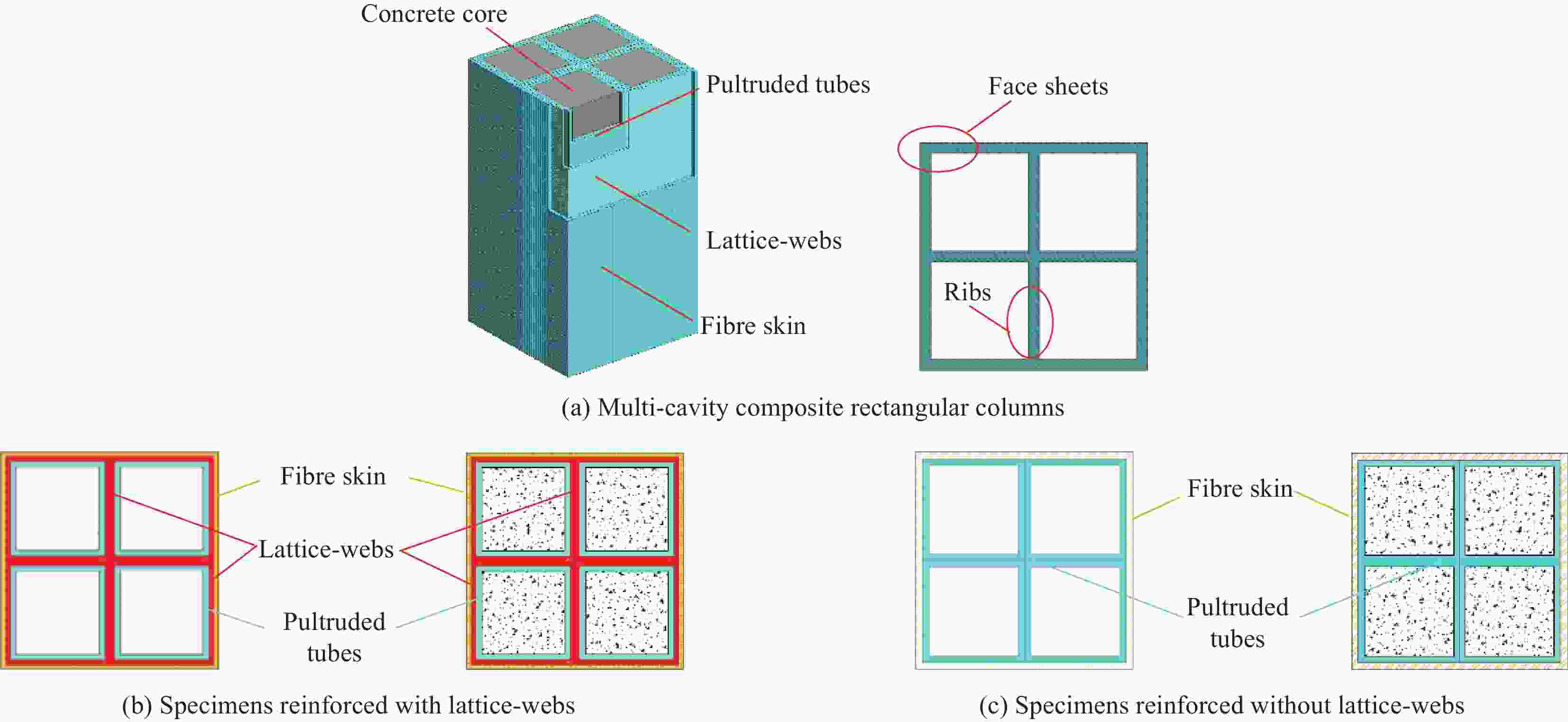

Abstract: Concrete-filled multi-cavity pultruded composite rectangular column are proposed to improve the mechanical performance of rectangular pultruded profiles and their confinement effectiveness on the concrete core. The axial compression tests were carried out on the concrete-filled multi-cavity composite rectangular columns and related multi-cavity pultruded tubes. The effects of applications of the multi-cavity structure and lattice-webs on the failure modes, bearing capacity and ductility of specimens were investigated. The results reveal that the multi-cavity structure effectively improves the brittle manner of pultruded tubes, and thus improves the mechanical performance and the confinement efficiency of pultruded profiles, with an average 53.08% increase in the peak load and an average 27.45% increase in the axial stress of confining concrete. Moreover, applications of lattice-webs have positive effects on improving the interface bonding performance and thus better deformation capacity of the structure is observed. The average ductility coefficient of concrete-filled specimens reinforced with lattice-webs is 2.23, higher than that of specimens without lattice-webs (1.88). Applications of lattice-webs further improve the confinement effectiveness of the multi-cavity structure on the concrete, thus increasing the peak load of specimens. The maximum increase in the peak load of the concrete-filled multi-cavity structure is 21.17%, which is much higher than 7.44% of specimens without lattice-webs. A simple design-oriented model was proposed to predict the peak load of concrete-filled multi-cavity specimens and related multi-cavity pultruded tubes. The results are consistent with the test data. -

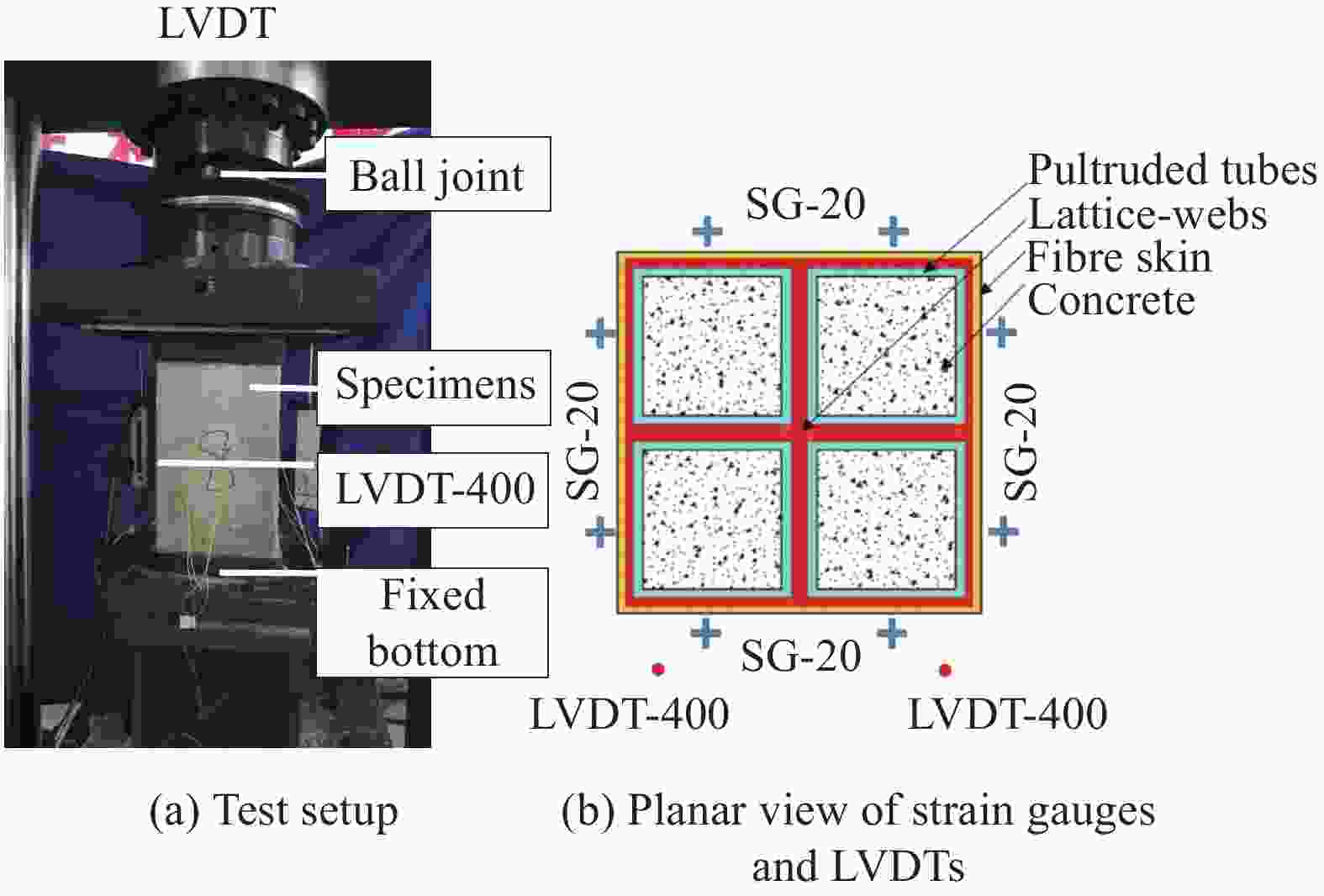

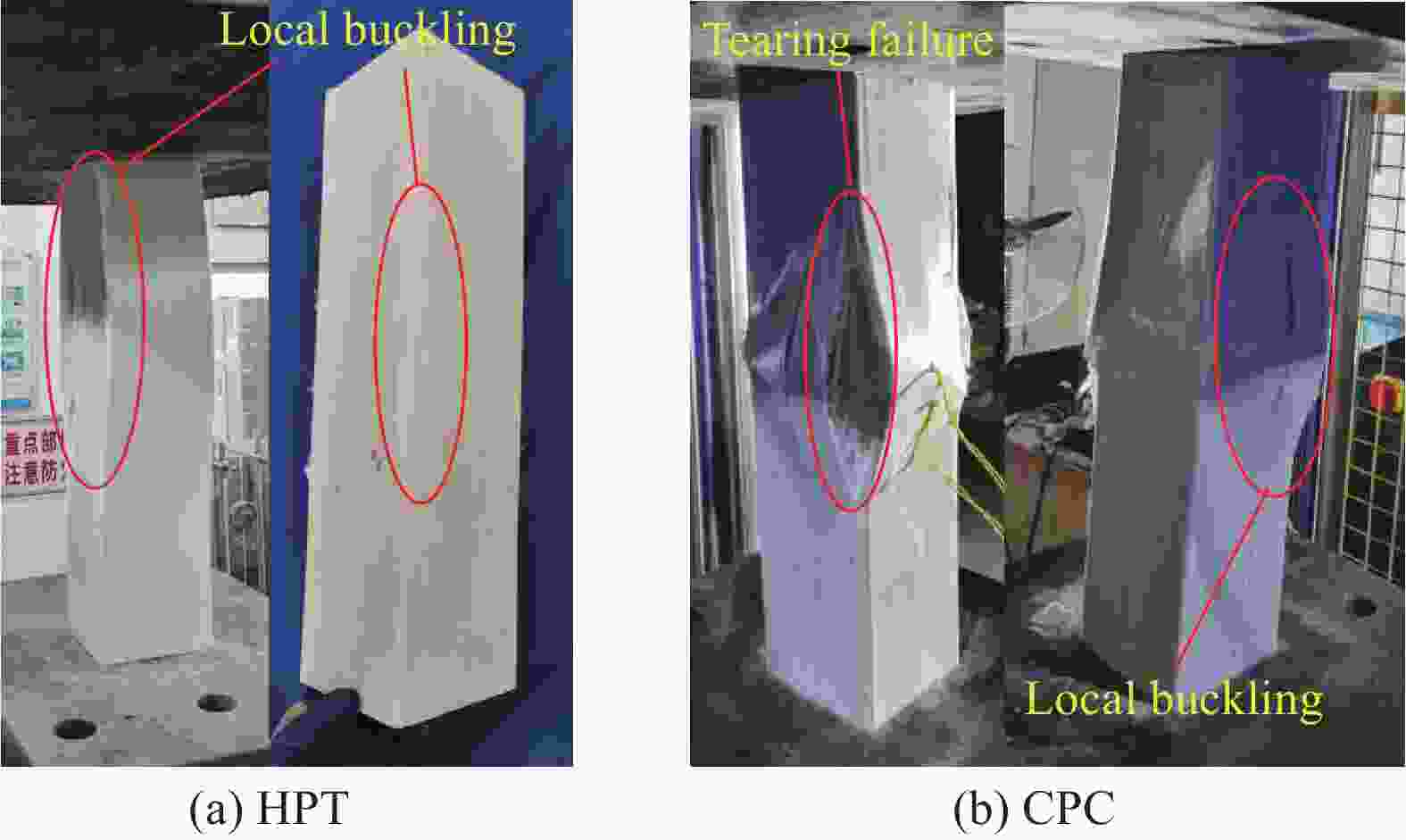

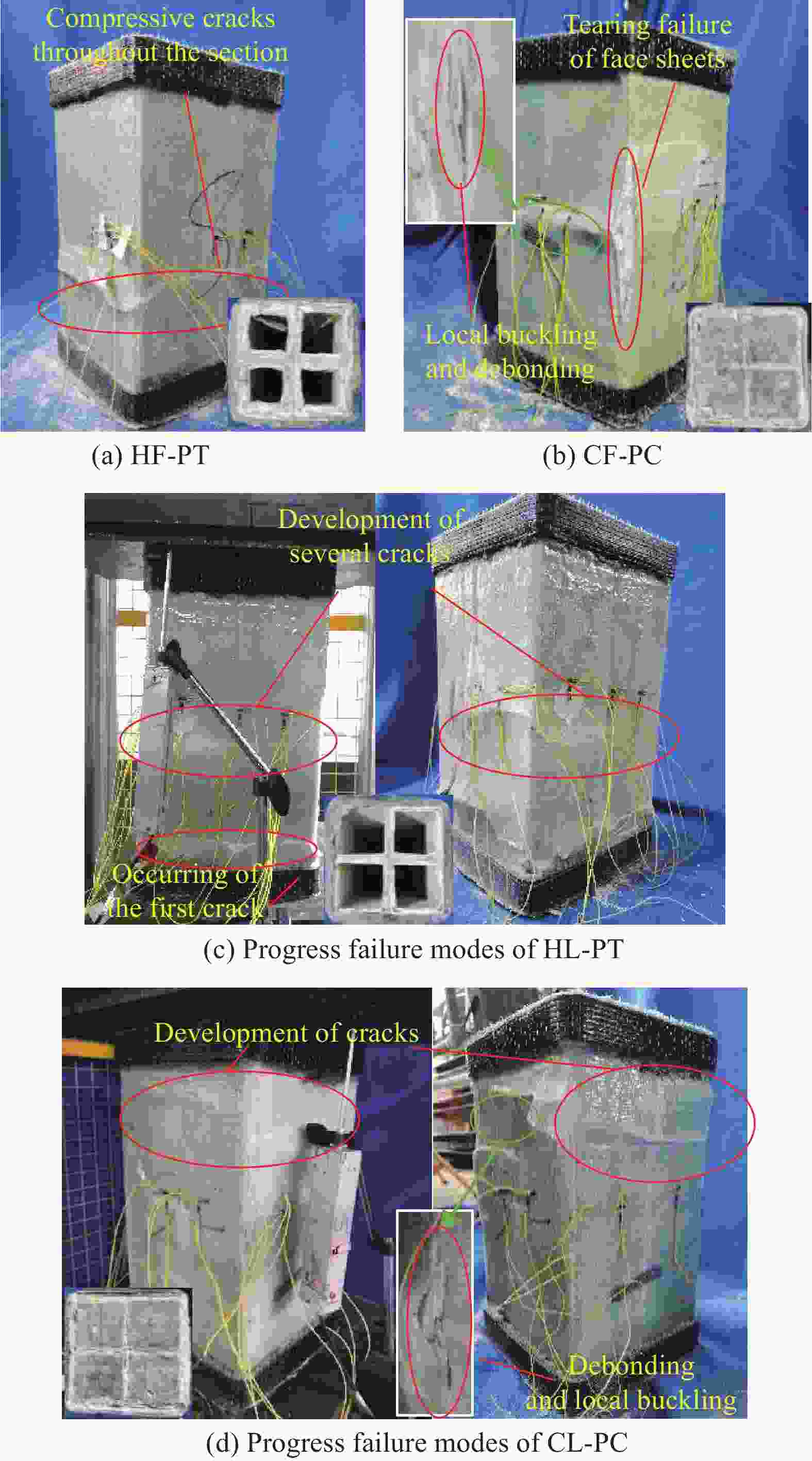

表 1 构件信息

Table 1. Details of specimens

Labels Size

(H×W×r)

/mmLayup of lattice-webs Layup of fibre skin Concrete HF-PT-1 400×208×3 — [(±45°)2/(0, 90°)2]2 — HF-PT-2 — HL-PT-1 (±45°)2 [(0, 90°)2/ (±45°)2] — HL-PT-2 — CF-PC-1 — [(±45°)2/(0, 90°)2]2 C60 CF-PC-2 C60 CL-PC-1 (±45°)2 [(0, 90°)2/ (±45°)2] C60 CL-PC-2 C60 HPT-1 400×100×3 — — HPT-2 CPC-1 C60 CPC-2 Notes: H—Height of specimens; W—Width of specimens; r is the corner radius of specimens. The thickness of GFRP wove fabrics of (±45°) and (0, 90°) was 0.5 mm. Labels of the specimens are as follows, “H”—hollow specimens; “C”—Concrete-filled specimens; “L”—Specimens reinforced with lattice-webs; “F”—Specimens without lattice-webs; “HPT” and “CPC”—Normal pultruded tubes and related concrete-filled specimens; the number “1” and “2” followed the labels represent two nominally identical specimens in each pair. 表 2 基本材料属性

Table 2. Material properties

Property (±45°) (0, 90°) Pultruded tubes Concrete Mean Standard deviation Mean Standard deviation Mean Standard deviation Mean Standard deviation Axial compression fxc/MPa 137.53 3.54 181.26 8.26 140.23 6.89 59.53 1.13 Exc/GPa 22.92 1.86 26.16 4.63 18.03 2.14 36.53 2.01 Transverse compression fyc/MPa 137.53 3.54 181.26 8.26 1.56 — — — Eyc/GPa 22.92 1.86 26.16 4.63 6.78 — — — Axial tension strength fxt/MPa 185.23 18.65 330.52 11.63 — — — Transverse tension strength fyt/MPa 185.23 18.65 330.52 11.63 18.05 1.63 — — Poisson’s ratio ν12 0.30 0.031 0.30 0.031 0.28 0.028 0.2 — ν21 0.30 0.026 0.30 0.026 0.09 0.011 — Notes: f—Stress of each kind of material; E—Elastic modulus. 表 3 单管轴压试验结果

Table 3. Test results of single tubes

Specimen H×W/mm Npp /kN εpp/10−6 NppA/kN εppA/10−6 HPT-1 400×100 214.86 5308 211.65 5367 HPT-2 400×100 208.44 5426 CPC-1 400×100 625.00 3829 609.74 4088 CPC-2 400×100 618.62 4043 Notes: Npp—Peak load; εpp—Corresponding strain; NppA—Average peak load; εppA—Average strain at the peak point. 表 4 拉挤型材组合柱试验结果

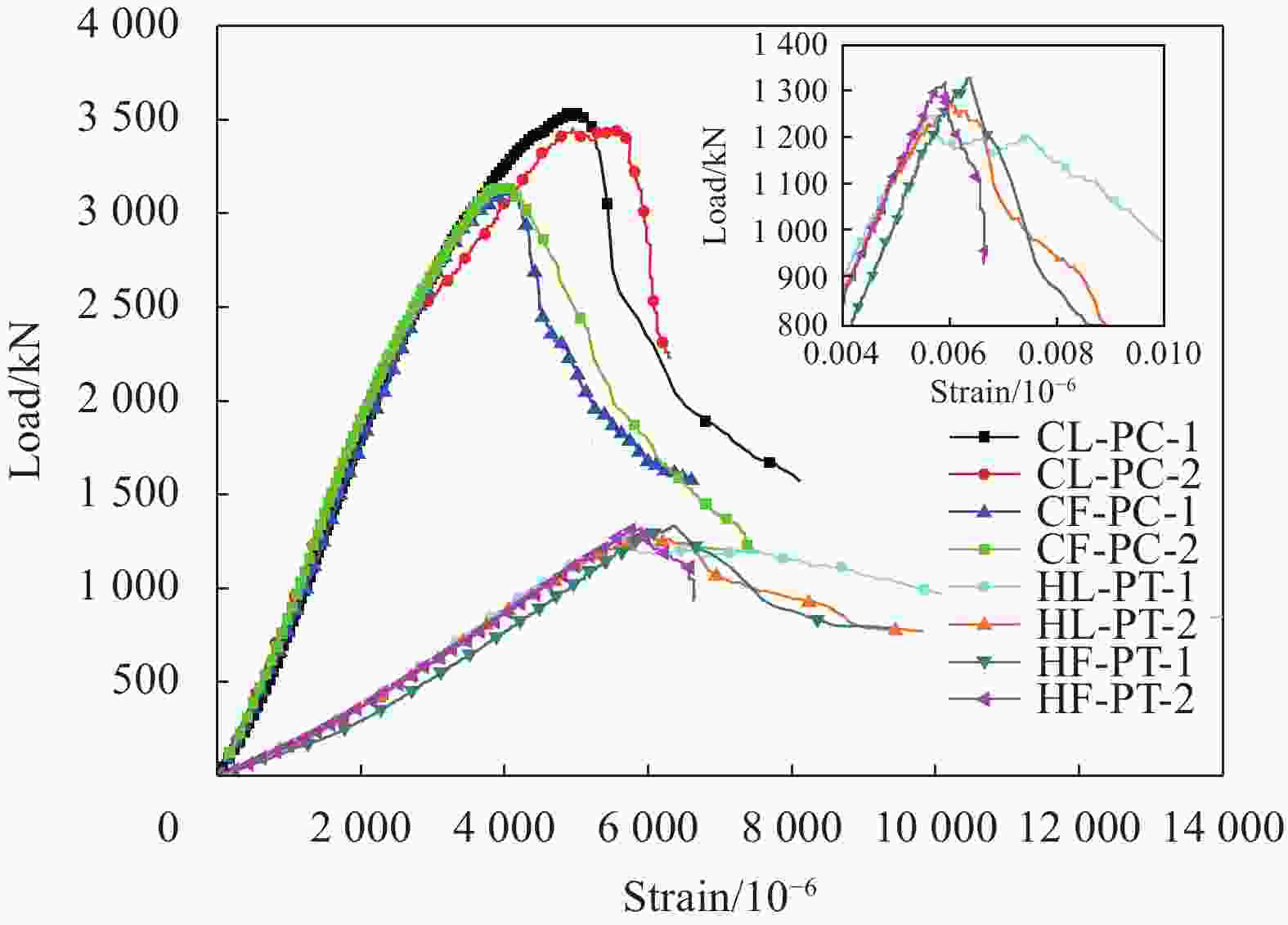

Table 4. Test results of composite pultruded columns

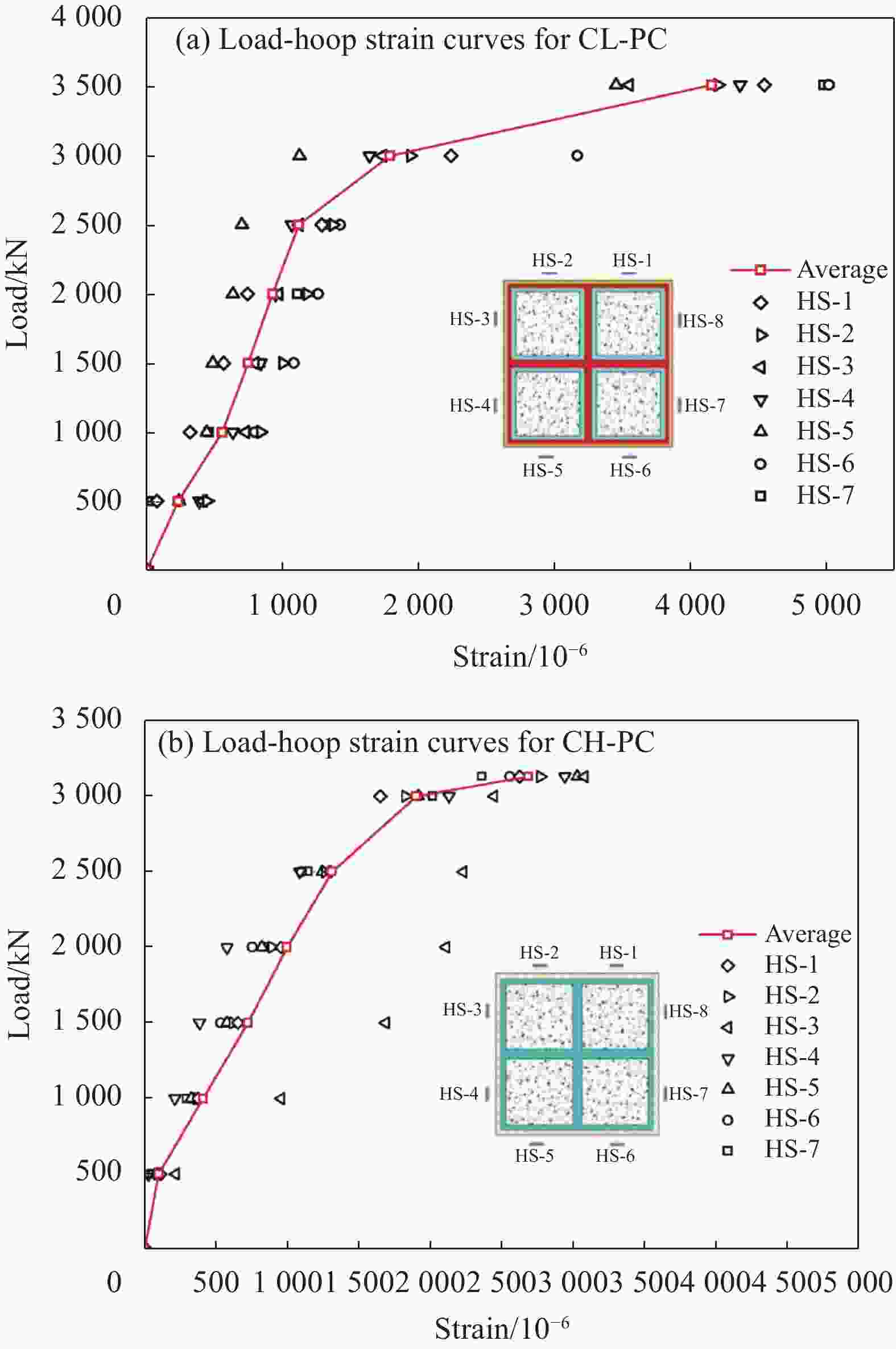

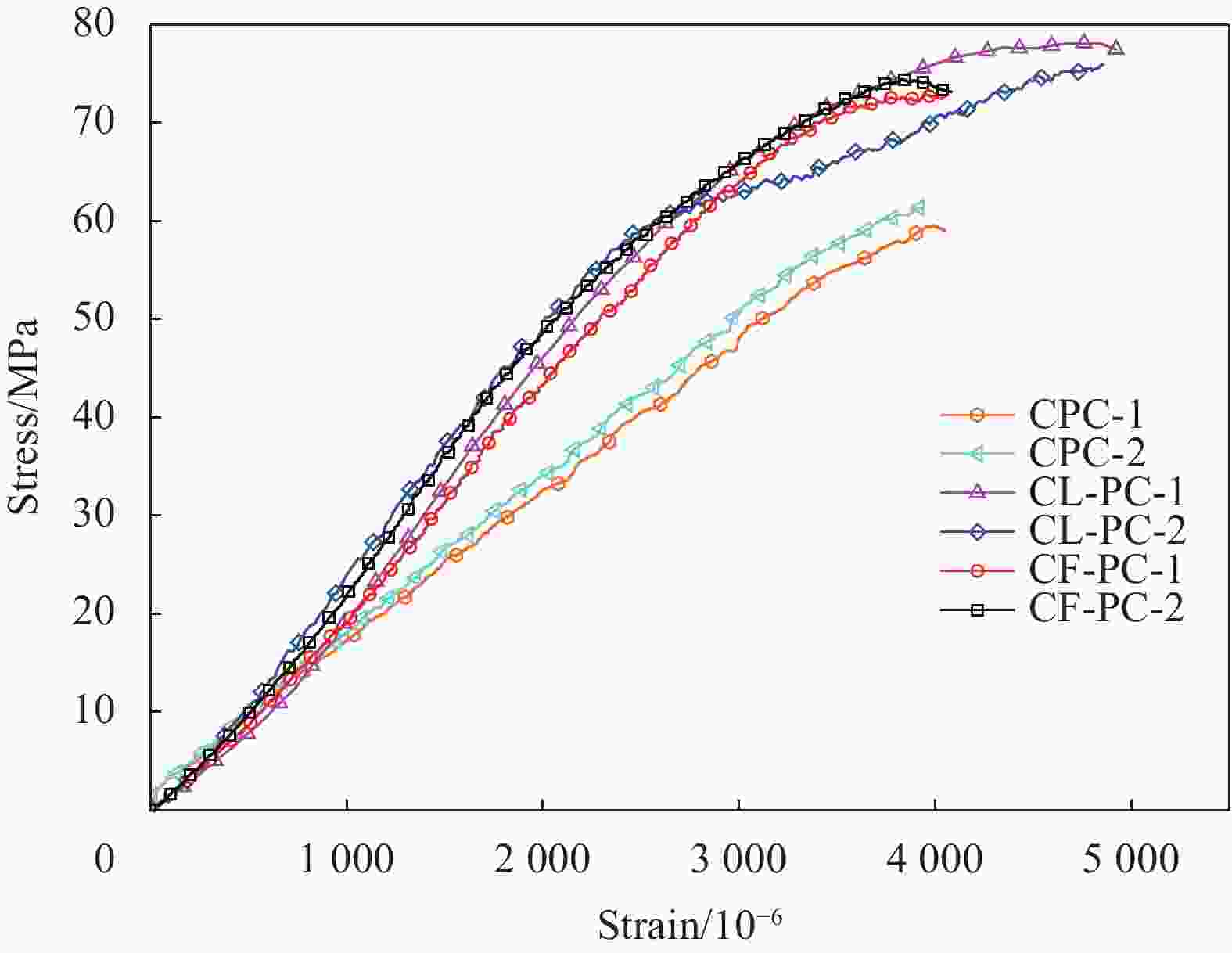

Specimen σc

/MPaNy

/kNεy

/10−6Np

/kNεp

/10−6Nu

/kNεu

/10−6ψ

/%η HF-PT-1 — 1293 5594 1323 5872 1125 6512 56.27 1.16 HF-PT-2 — 1283 5987 1319 6345 1121 7115 55.80 1.19 HL-PT-1 — 727 3344 1259 5606 1070 9054 48.71 2.71 HL-PT-2 — 1032 4648 1283 5998 1091 6825 51.55 1.47 CF-PC-1 74.28 2612 2951 3136 4036 2666 4750 7.44 1.61 CF-PC-2 72.35 1973 2072 3030 3872 2576 4472 7.23 2.16 CL-PC-1 79.29 2715 3047 3537 5011 3006 5475 21.17 1.80 CL-PC-2 80.03 2126 2251 3457 5518 2938 5978 18.43 2.66 Notes: σc—Compressive stress of confined concrete; Ny and εy—Yield load and corresponding strain of multi-cavity composite columns; Np and εp—Peak load and corresponding strain of multi-cavity composite columns; Nu and εu—Ultimate load and corresponding strain of multi-cavity composite columns; ψ and η—Load enhancement ratio and ductility coefficient of multi-cavity composite columns. 表 5 等效圆形及矩形截面约束混凝土计算值

Table 5. Theoretical results of confined concrete in equivalent circle and rectangular sections

Specimen L(D)

/mmt

/mmσc0

/MPaεc0

/10−6εhrup

/10−6σcc

/MPaεcu

/10−6CCL-PC 214 9 59.53 2600 4508 75.23 7745 CCF-PC 212 10 5151 81.85 9372 SCL-PC 190 9 1667 61.98 4869 SCF-PC 188 10 1905 63.02 5030 Notes: L—Inner length; D—Inner diameter; C—Circular section specimens; "S"—Square section specimens; t—Thcikness of face sheets ; σc0—Unconfined concrete strength ; εhrup—Rupture hoop strain; σcc—Confined concrete strength ; εcu—Ultimate axial starin.of confined concrete. 表 6 多腔组合柱试验及理论结果对比

Table 6. Comparison of theoretical and experimental results of multi-cavity composite rectangular columns

Specimen Experimental Theoretical (Fp−Fp c)/Fp Peak load Fp/kN Axial strain at peak load/10−6 Peak load Fp c/kN Axial strain at peak load/10−6 HF-PT-1 1323 5872 1302 5334 1.587% HF-PT-2 1319 6345 1.288% HL-PT-1 1259 5606 1257 5355 0.1589% HL-PT-2 1283 5998 2.026% CF-PC-1 3136 4036 3254 5334 3.763% CF-PC-2 3030 3872 7.393% CL-PC-1 3537 5011 3587 5355 1.414% CL-PC-2 3457 5518 3.760% -

[1] 刘伟庆, 方海, 方园. 纤维增强复合材料及其结构研究进展[J]. 建筑结构学报, 2019, 40(4): 1-16.LIU Weiqing, FANG Hai, FANG Yuan. Research progress of fiber-reinforced composites and structures[J]. Journal of Building Structures, 2019, 40(4): 1-16(in Chinese). [2] NUNES F, CORREIA J R, SILVESTRE N. Structural behaviour of hybrid FRP pultruded columns. Part 1: Experimental study[J]. Composite Structures, 2016, 139: 291-303. [3] 沈高奎, 齐玉军, 陆建成, 等. 内置复材约束的T形截面钢管混凝土组合柱轴压力学性能试验研究[J]. 复合材料学报, 2022, 39(7): 3388-403.SHEN Gaokui, QI Yujun, LU Jiancheng, et al. Experimental study on axial compression performance of T-section concrete filled steel and FRP tubular composite columns[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3388-3403(in Chinese). [4] 黄龙男, 张东兴, 李地红, 等. 轴向受压CFRP管混凝土柱的膨胀模型及应力-应变关系[J]. 复合材料学报, 2006, 23(1): 112-116.HUANG Longnan, ZHANG Dongxing, LI Dihong, et al. Dilation model and stress-strain relationships of CFRP tubes confining concrete columns under axial compression[J]. Acta Materiae Compositae Sinica, 2006, 23(1): 112-116(in Chinese)). [5] 缪坤廷, 魏洋, 朱超, 等. 钢管混凝土-FRP管海水海砂混凝土组合柱轴压模型[J]. 复合材料学报, 2022, 39(11): 5403-5414.MIAO Kunting, WEI Yang, ZHU Chao, et al. Model for stress-strain curves of concrete filled steel tube-seawater and sea sand concrete filled FRP tube composite columns under axial load[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5403-5414(in Chinese). [6] 王高飞, 魏洋, 缪坤廷, 等. 圆形CFRP-钢复合管海水海砂珊瑚混凝土柱轴压性能试验研究[J]. 复合材料学报, 2022, 39(8): 3982-3993.WANG Gaofei, WEI Yang, MIAO Kunting, et al. Experimental study on axial compression performance of CFRP-steel composite tube filled circular seawater sea-sand coral concrete columns[J]. Acta Materiae Compositae Sinica, 2022, 39(8): 3982-3993(in Chinese). [7] 柏佳文, 魏洋, 张依睿, 等. 新型碳纤维增强复合材料-钢复合管海水海砂混凝土圆柱轴压试验[J]. 复合材料学报 2021, 38(9): 3076-3085.BAI Jiawen, WEI Yang, ZHANG Yirui, et al. Axial compression behavior of new seawater and sea sand concrete filled circular carbon fiber reinforced polymer-steel composite tube columns[J]. Acta Materiae Compositae Sinica, 2021, 38(9): 3076-3085(in Chinese). [8] GUO Z, XIA L J, LIN Q, et al. Test on mechanical behavior of pultruded concrete-filled GFRP tubular short columns after elevated temperature [J]. Composite Structures, 2021, 257: 113163. [9] TABATABAEIAN M, KHALOO A, AZIZMOHAMMADI M. The effects of elevated temperatures on the performance of concrete-filled pultruded GFRP tubular columns[J]. Thin-Walled Structures, 2021, 169: 108404. [10] ALHAWAMDEH M, ALAJARMEH O, ARAVINTHAN T, et al. Modelling hollow pultruded FRP profiles under axial compression: Local buckling and progressive failure[J]. Composite Structures, 2021, 262: 113650. [11] TENG J G, CHEN J F, SMITH S T, et al. FRP strengthened RC structures[M]. New Jersey: John Wiley& Sons Ltd, 2002:57-71. [12] WANG L M, WU Y F. Effect of corner radius on the performance of CFRP-confined square concrete columns: Test[J]. Engineering Structures, 2008, 30(2): 493-505. [13] QIU N, GAO Y K, FANG J G, et al. Crashworthiness analysis and design of multi-cell hexagonal columns under multiple loading cases[J]. Finite Elementsin Analysis and Design, 2015, 104: 89-101. [14] HUANG L, YU T, ZHANG S S, et al. FRP-confined concrete-encased cross-shaped steel columns: Concept and behaviour[J]. Engineering Structures, 2017, 152: 348-358. [15] HUANG L, YU T, ZHANG S S. FRP-Confined concrete-encased cross-shaped steel columns: Effects of key parameters[J]. Composite Structures, 2021, 272: 114252. [16] OZBAKKALOGLU T. Compressive behavior of concrete-filled FRP tube columns: Assessment of critical column parameters[J]. Engineering Structures, 2013, 51: 188-199. [17] VINCENT T, OZBAKKALOGLU T. Influence of fiber orientation and specimen end condition on axial compressive behavior of FRP-confined concrete[J]. Constructionand Building Materials, 2013, 47: 814-826. [18] AL-SAADI A U, ARAVINTHAN T, LOKUGE W. Effects of fibre orientation and layup on the mechanical properties of the pultruded glass fibre reinforced polymer tubes[J]. Engineering Structures, 2019, 198: 109448. [19] GUO Z, XUE X L, YE M Y, et al. Experimental research on pultruded concrete-filled GFRP tubular short columns externally strengthened with CFRP[J]. Composite Structures, 2021, 255: 112943. [20] ZHANG X Y, CHEN Y, YE M Y. Research on square concrete filled GFRP tube columns strengthened with CFRP sheet[J]. Composite Structures, 2021, 275: 114407. [21] WU Z M, LIU W Q, WANG L, et al. Theoretical and experimental study of foam-filled lattice composite panels under quasi-static compression loading[J]. Composites Part B: Engineering, 2014, 60: 329-340. [22] SHI H Y, LIU W Q, FANG H, et al. Flexural responses and pseudo-ductile performance of lattice-web reinforced GFRP-wood sandwich beams[J]. Composites Part B: Engi-neering, 2017, 108: 364-376. [23] WANG L, LIU W Q, WAN L, et al. Mechanical performance of foam-filled lattice composite panels in four-point bending: Experimental investigation and analytical modeling[J]. Composites Part B: Engineering, 2014, 67: 270-279. [24] YANG L Y, LI X L, FANG H, et al. Compressive behaviour of wood-filled GFRP square columns with lattice-web reinforcements[J]. Constructionand Building Materials, 2021, 310: 125129. [25] ASTM. Standard test method for compressive properties of polymer matrix composite materials with unsupported gage section by shear loading: ASTM D3410/D3410 M-16[S]. West Conshohocken: ASTM, 2016. [26] ASTM. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039/D 3039 M–14[S]. West Conshohocken: ASTM, 2014. [27] ASTM. Standard test method for compressive strength of cylindrical concrete specimens: ASTM C39/C39 M[S]. West Conshohocken: ASTM, 2018. [28] LAM L, TENG J G. Ultimate condition of fiber reinforced polymer-confined concrete[J]. Journal of Composites for Construction, 2004, 8(6):539-548. [29] TAO Z, HAN L H, WANG D Y. Strength and ductility of stiffened thin-walled hollow steel structural stub columns filled with concrete[J]. Thin-Walled Structures, 2008, 46(10):1113-1128. [30] 冯鹏, 强翰霖, 叶列平. 材料、构件、结构的“屈服点”定义与讨论[J]. 工程力学 2017, 34(3): 36-46.FENG Peng, QIANG Hanlin, YE Lieping. Discussion and definition on yield points of materials, members and structures[J]. Engineering Mechanics, 2017, 34(3): 36-46(in Chinese). [31] LAM L, TENG J G. Design-oriented stress-strain model for FRP-confined concrete in rectangular columns[J]. Journal of Reinforced Plastics and Composites, 2003, 22(13): 1149-1186. [32] LAM L, TENG J G. Design-oriented stress-strain model for FRP-confined concrete[J]. Constructionand Building Materials, 2003, 17(6-7): 471-489. [33] QIAO P Z, SHAN L Y. Explicit local buckling analysis and design of fiber-reinforced plastic composite structural shapes[J]. Composite Structures, 2005, 70(4): 468-483. -

下载:

下载: