Lateral crushing performance of rib-reinforced foam partition-filled thin-walled tube

-

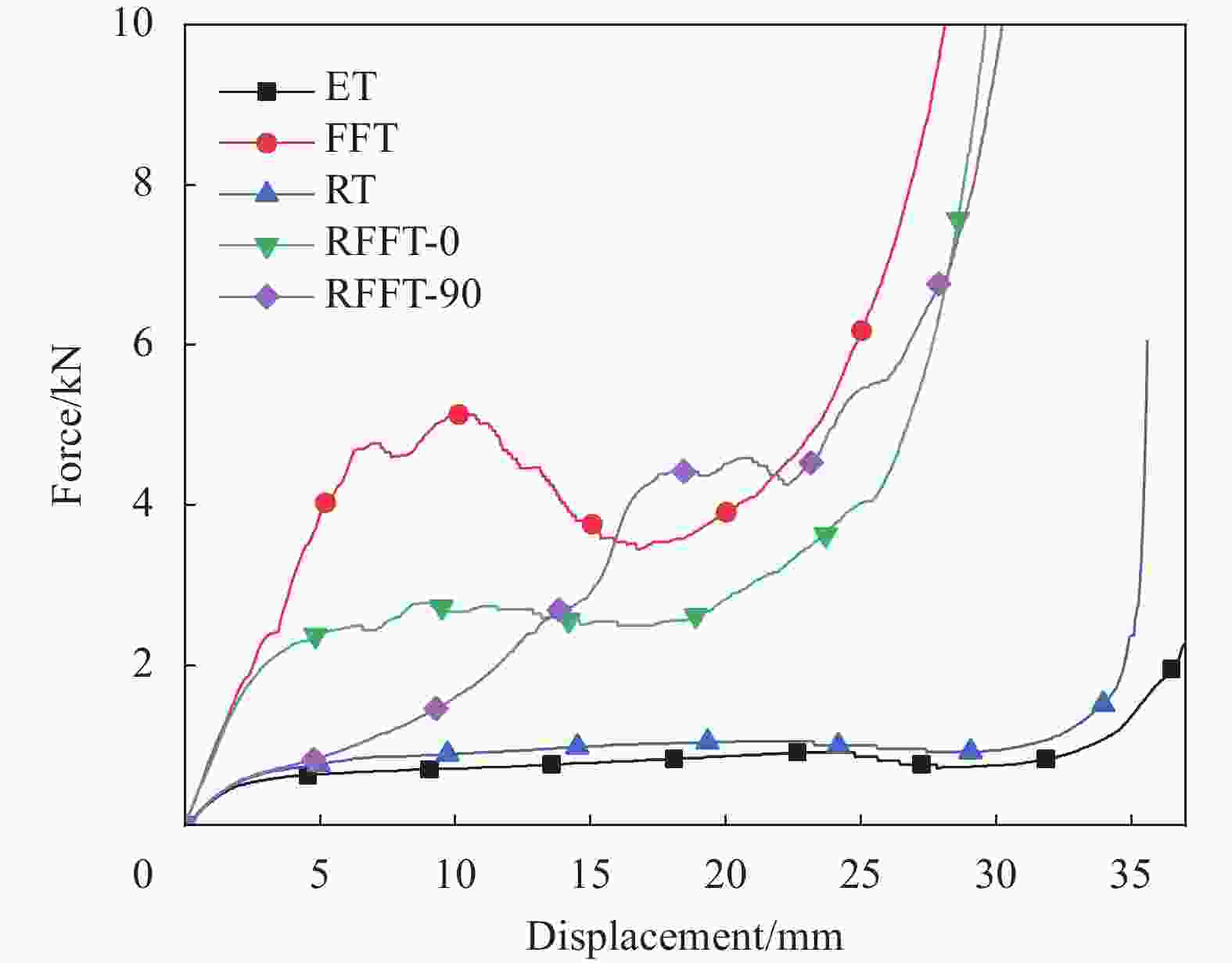

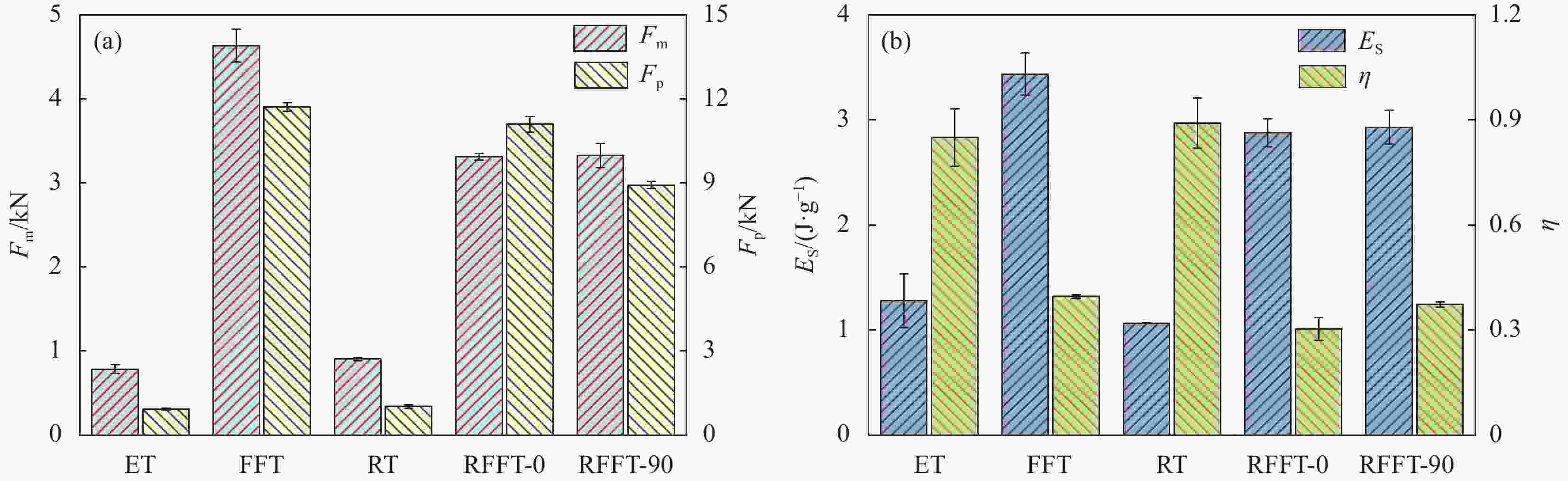

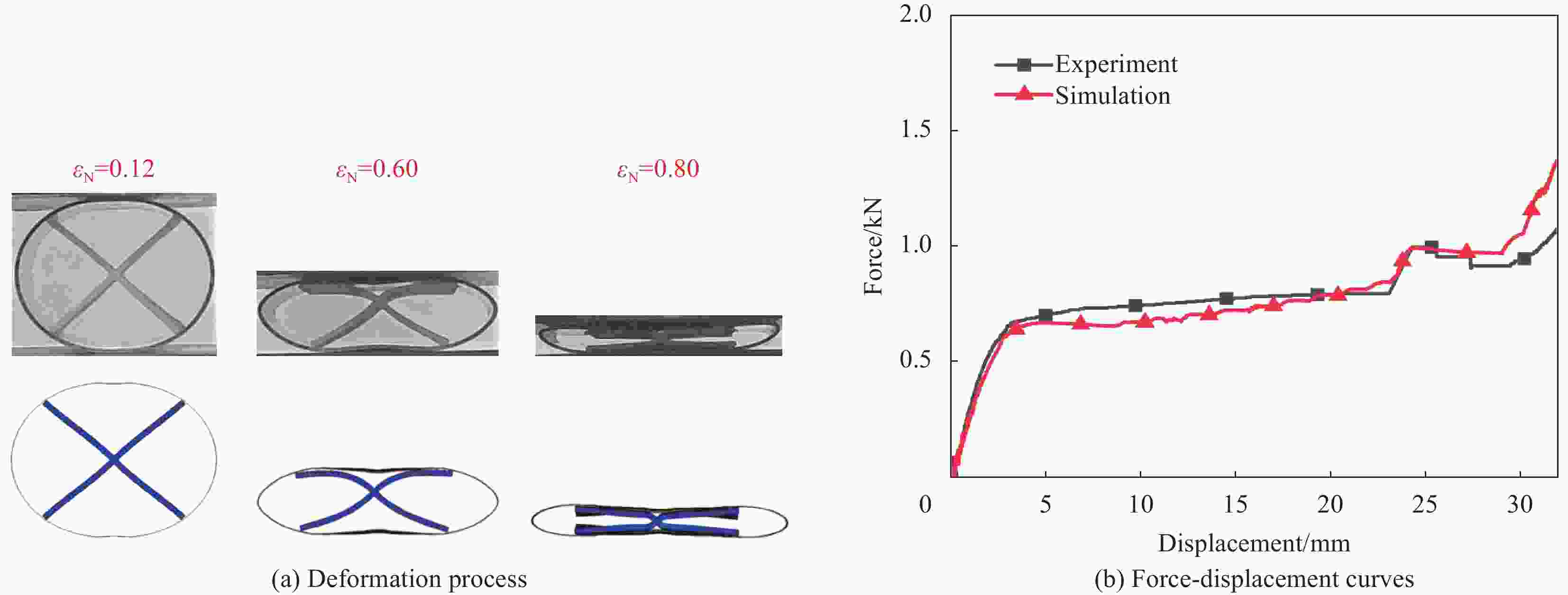

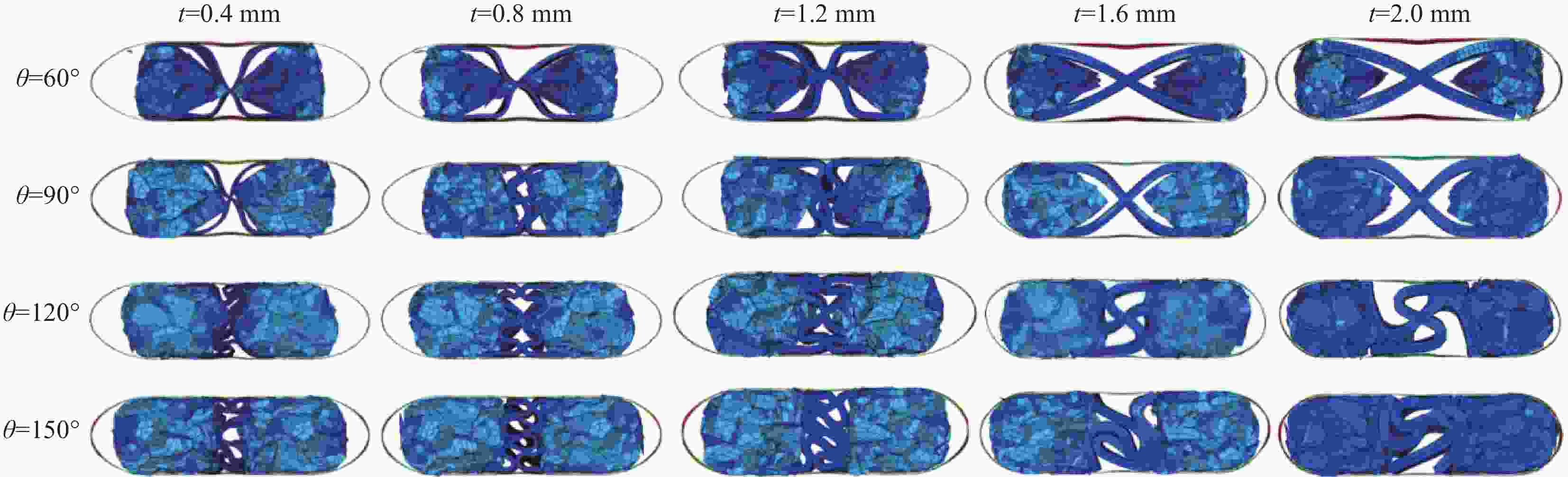

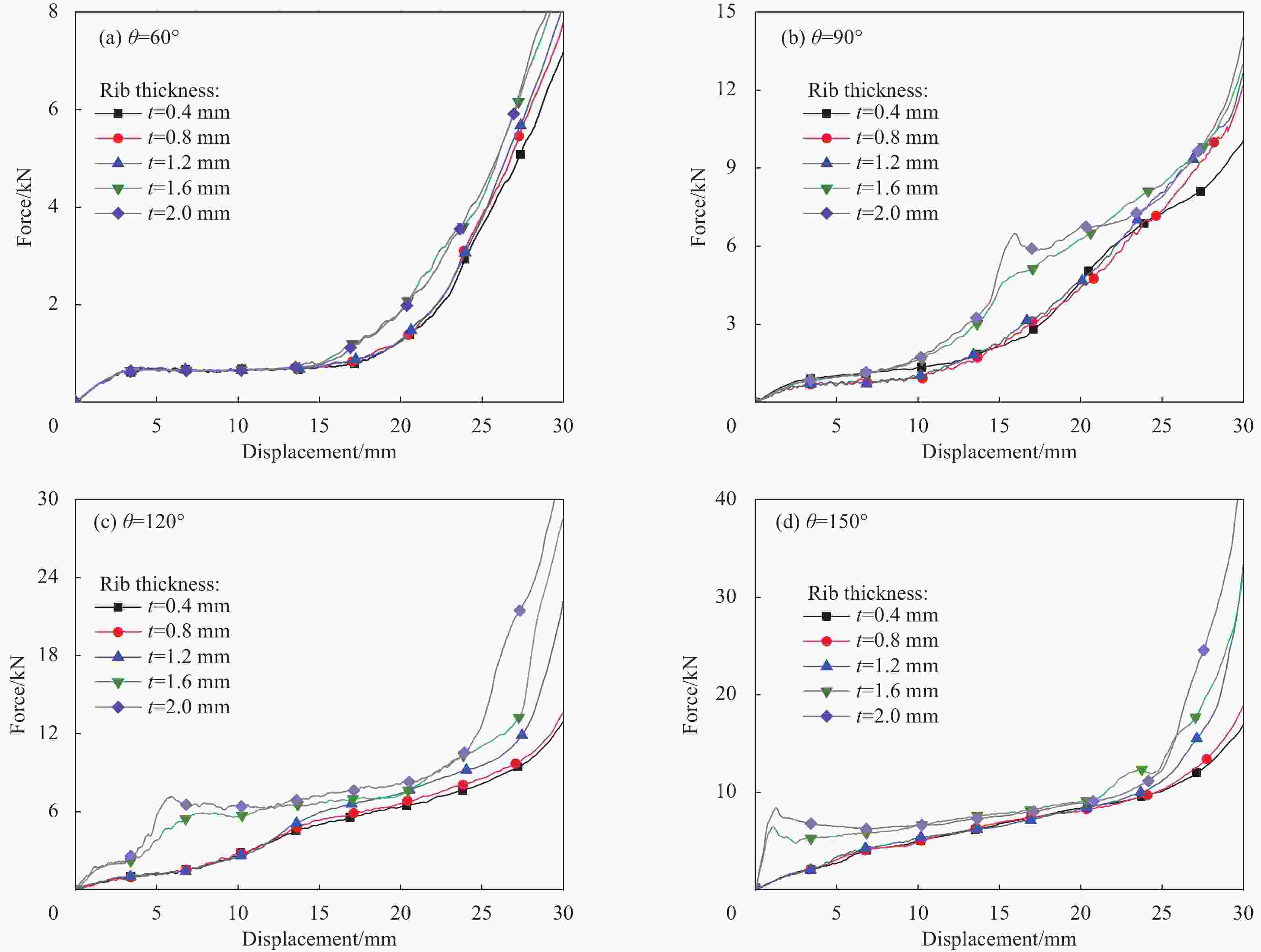

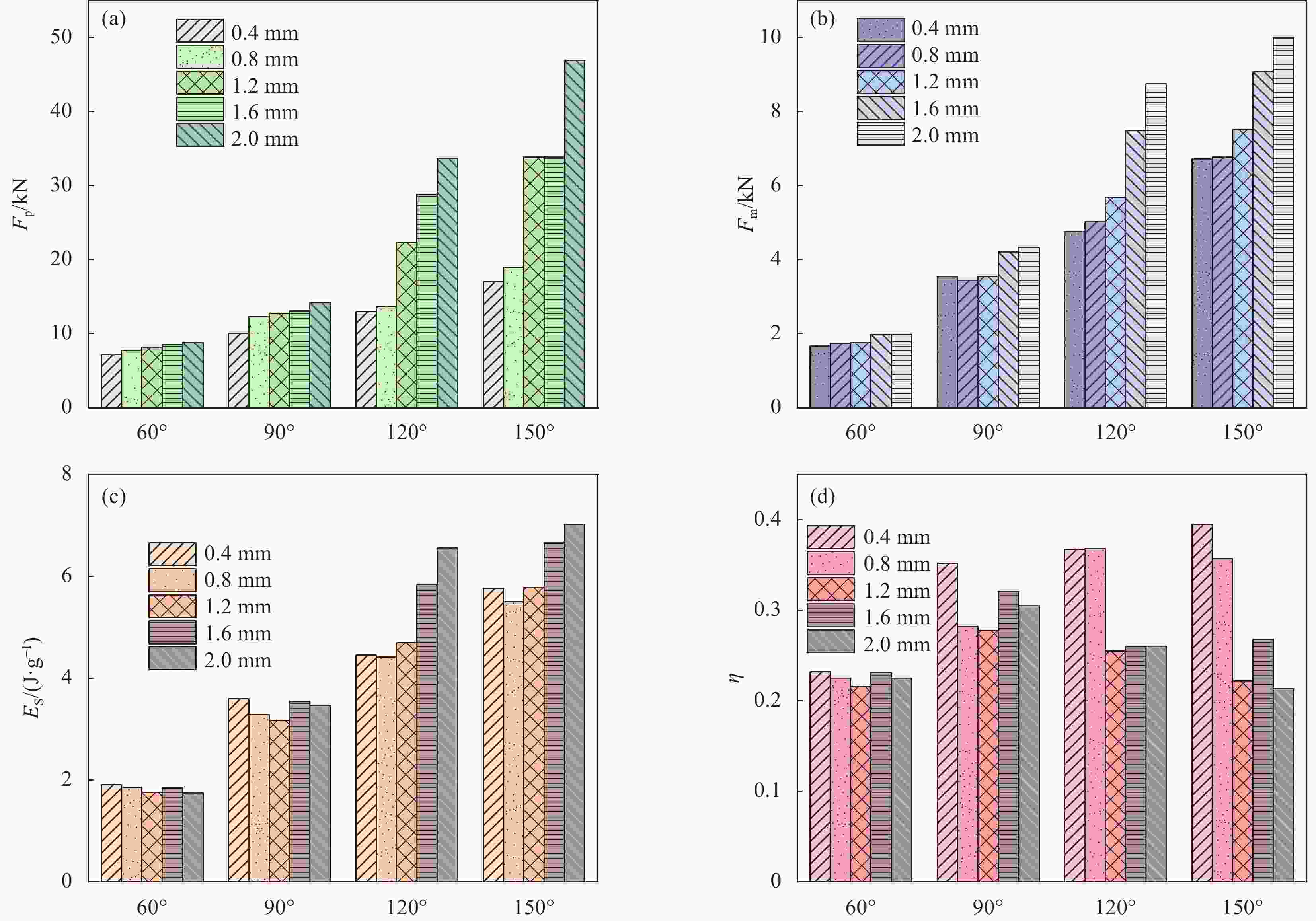

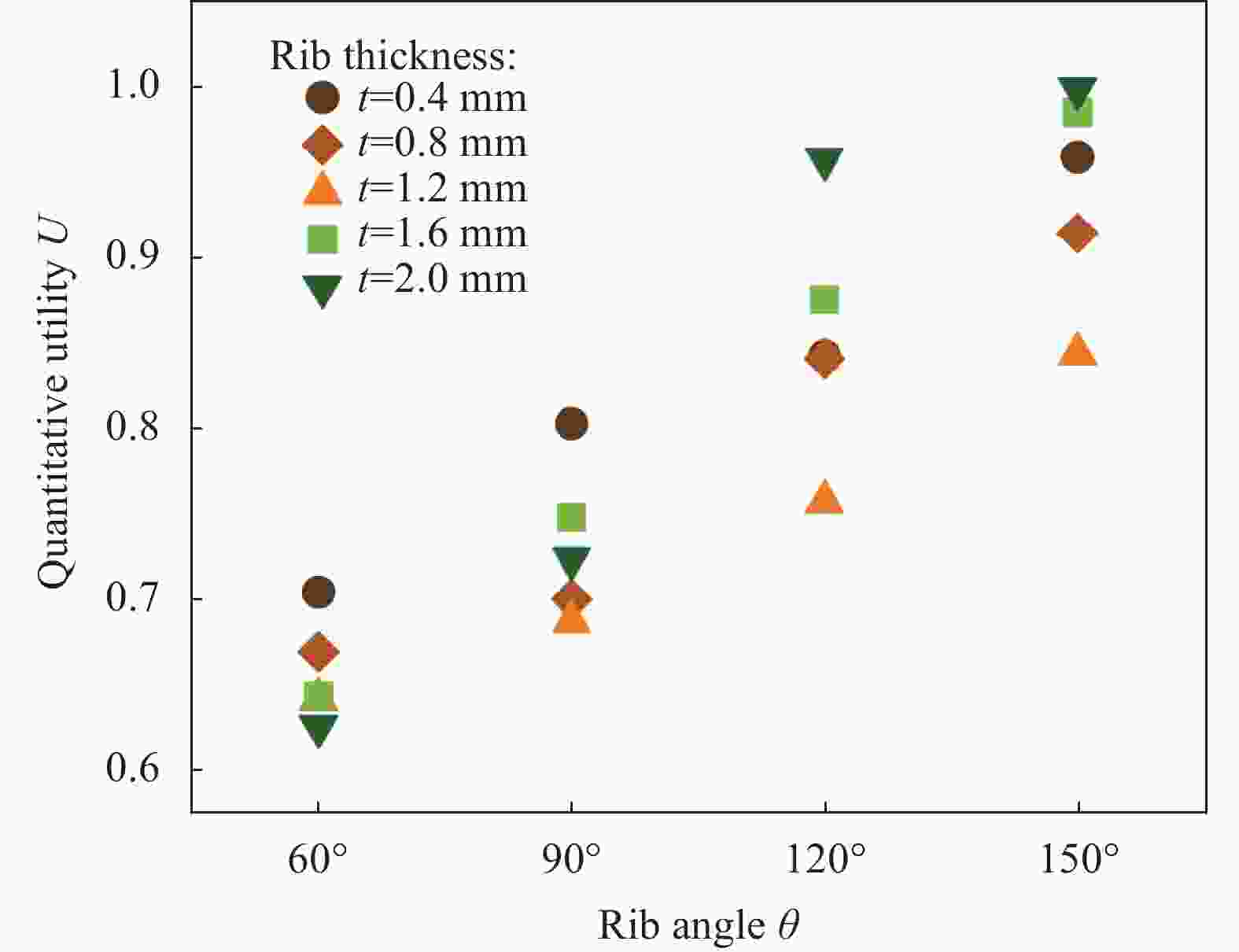

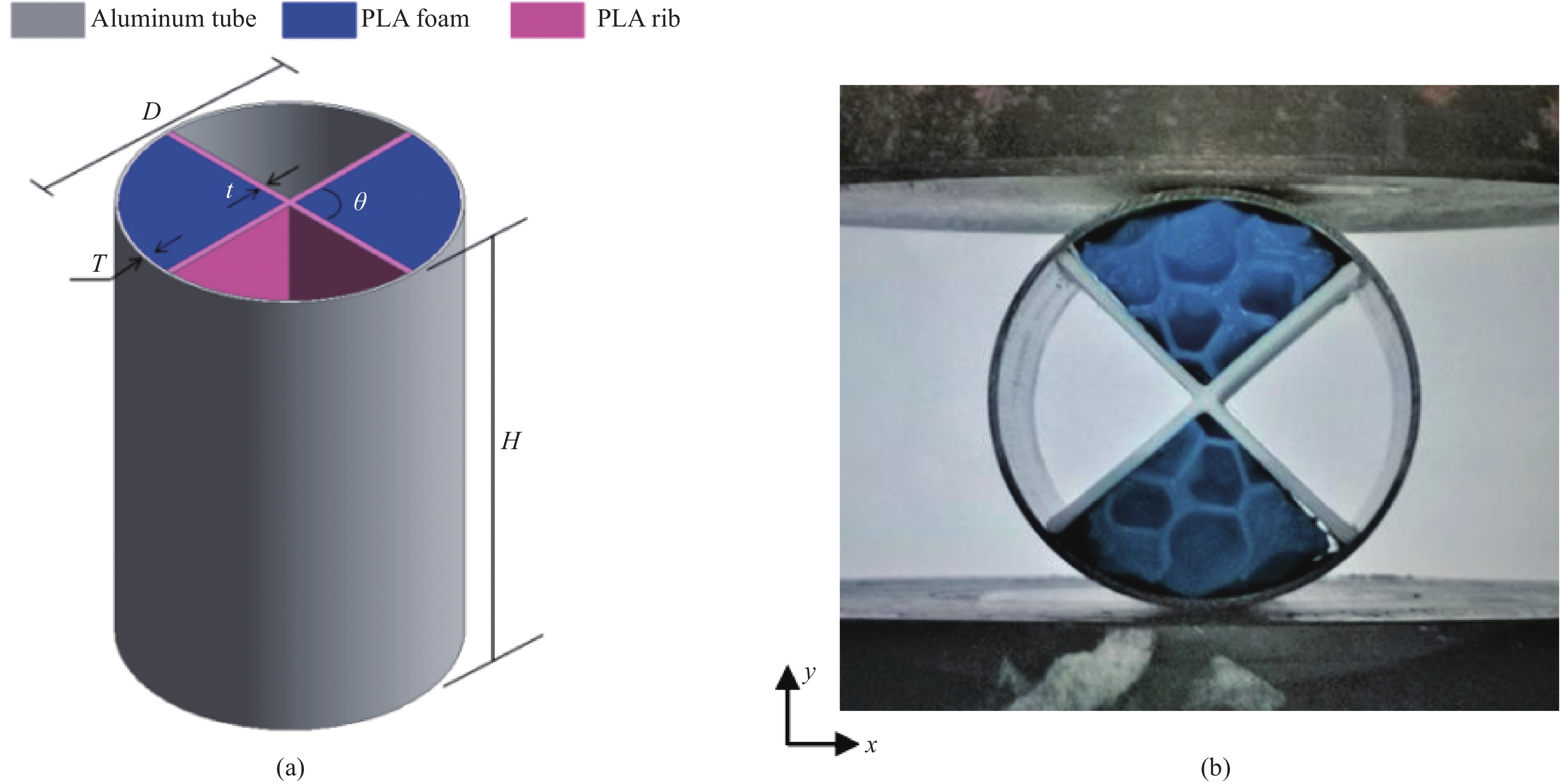

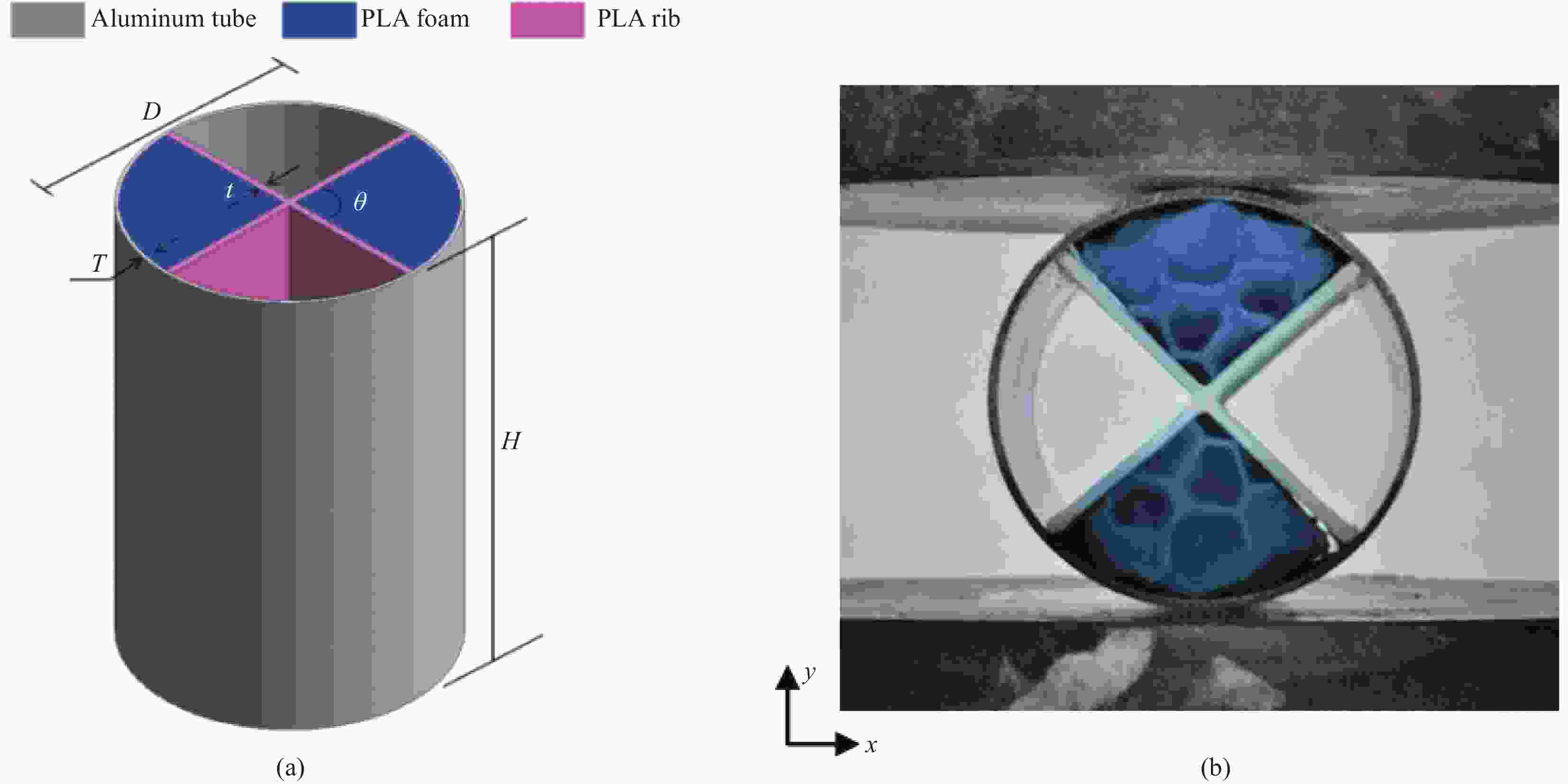

摘要: 利用3D打印技术制备了聚乳酸(PLA)十字形肋板和基于三维Voronoi的闭孔泡沫结构,提出了一种肋板增强泡沫分区填充薄壁管结构(RFFT),研究了该结构在准静态横向荷载作用下的压溃性能。结果表明:在横向压溃中,RFFT结构组成元件的失效次序和元件之间的相互作用随横向荷载的作用区域而改变,使结构的力-位移曲线的响应和结构的压溃性能(峰值荷载、平均压溃荷载、比吸能、荷载一致性)呈现典型的各向异性特征。针对两种典型受载情形(即横向荷载作用于结构填充区和非填充区),结构的比吸能相比于空管结构分别提高了125.16%和129.22%,而峰值荷载相比于完全填充结构降低了5.54%和31.28%。进一步运用细观有限元模型分析了设计参数的影响规律并揭示了分区泡沫填充结构的能量吸收机制。最后,引入复合比例评估法对RFFT结构的多个耐撞性指标进行综合评估。Abstract: Polylactide (PLA) cross-shaped ribbed plates and Voronoi-based closed-cell foam structures were prepared using 3D printing technology. A rib-reinforced foam partition-filled thin-walled tube structure (RFFT) was proposed and the crushing performance of RFFT under quasi-static lateral compression was investigated. The results show that the failure sequence of the constituent elements within RFFT structure as well as the interaction between the elements changes with the location of the lateral load. Typically, for RFFT structures, the force-displacement responses and the crushing performance (i.e., the peak force, the mean crush force, the specific energy absorption, and the crush force efficiency) exhibit anisotropic characteristics. For two typical loading scenarios (i.e., lateral loads acting on the foam-filled and -unfilled zones of RFFT structure), the specific energy absorption of RFFT structure is increased by 125.16% and 129.22%, respectively, compared to the empty tube structure, whereas the peak force is found to be reduced by 5.54% and 31.28% compared to the fully foam-filled structure. Moreover, the finite element model was adopted to analyze the influence of design parameters and reveal the energy absorption mechanism of the partition foam-filled structure. Finally, the complex proportional assessment method was introduced to comprehensively evaluate the crashworthiness of RFFT structure with multiple indicators.

-

表 1 肋板增强泡沫分区填充管各项相关指标对应的权重系数Wj

Table 1. Corresponding mass coefficients Wj for each relevant indicators of rib-reinforced foam partition-filled thin-walled tube

Performance indicator Total comparison sets,

N=4×(4−1)/2=6$ \displaystyle\sum\nolimits_{i = 1}^m {{N_{ij}}} $ $ {W_{j} } $ 1 2 3 4 5 6 E 2 2 3 − − − 7 7/24=0.291 Fp 2 − − 2 3 − 7 7/24=0.291 ES − 2 − 2 − 3 7 7/24=0.291 η − − 1 − 1 1 3 3/24=0.125 Total, $ \displaystyle\sum\nolimits_{j = 1}^n {\displaystyle\sum\nolimits_{i = 1}^m {{N_{ij}}} } $ 24 1 Notes: E—Energy absorption; ES—Specific mass energy absorption; Fp—Peak crushing load; η—Crushing load efficiency. 表 2 用复合比例评价法(COPRAS)得到的所有肋板增强泡沫分区填充管试样的加权归一化值

Table 2. Weighted normalized values for all specimens obtained by the complex proportional assessment (COPRAS) method

θ/(°) t/mm E Fp ES η $ {S}_{+i} $ $ {S}_{-i} $ Qi Ui Rank 60 0.4 0.00485 0.00572 0.00668 0.00514 0.01666 0.00572 0.04418 0.70516 14 0.8 0.00509 0.00620 0.00653 0.00499 0.01661 0.00620 0.04200 0.67036 17 1.2 0.00515 0.00652 0.00616 0.00479 0.01610 0.00652 0.04026 0.64251 19 1.6 0.00577 0.00685 0.00648 0.00511 0.01736 0.00685 0.04036 0.64418 18 2.0 0.00578 0.00704 0.00612 0.00499 0.01689 0.00704 0.03926 0.62663 20 90 0.4 0.01028 0.00801 0.01263 0.00779 0.03071 0.00801 0.05037 0.80386 10 0.8 0.01003 0.00976 0.01152 0.00624 0.02779 0.00976 0.04392 0.70099 15 1.2 0.01034 0.01018 0.01115 0.00616 0.02765 0.01018 0.04312 0.68822 16 1.6 0.01224 0.01044 0.01247 0.00712 0.03183 0.01044 0.04691 0.74865 12 2.0 0.01260 0.01133 0.01216 0.00675 0.03151 0.01133 0.04540 0.72459 13 120 0.4 0.01384 0.01034 0.01564 0.00813 0.03760 0.01034 0.05284 0.84326 8 0.8 0.01463 0.01090 0.01551 0.00815 0.03829 0.01090 0.05275 0.84186 9 1.2 0.01654 0.01780 0.01649 0.00564 0.03866 0.01780 0.04751 0.75826 11 1.6 0.02178 0.02296 0.02050 0.00576 0.04803 0.02296 0.05490 0.87613 6 2.0 0.02545 0.02683 0.02302 0.00576 0.05423 0.02683 0.06010 0.95916 4 150 0.4 0.01956 0.01357 0.02025 0.00875 0.04857 0.01357 0.06018 0.96042 3 0.8 0.01972 0.01514 0.01933 0.00791 0.04696 0.01514 0.05737 0.91552 5 1.2 0.02187 0.02701 0.02031 0.00492 0.04709 0.02701 0.05292 0.84455 7 1.6 0.02641 0.02700 0.02340 0.00619 0.05560 0.02701 0.06183 0.98676 2 2.0 0.02907 0.03741 0.02467 0.00472 0.05846 0.03741 0.06267 1.00026 1 Notes: S+i—Beneficial attributes; S−i—Non-beneficial attributes; Qi—Relative priorities; Ui—Quantitative utility. -

[1] BAROUTAJI A, SAJJIA M, OLABI A. On the crashworthiness performance of thin-walled energy absorbers: Recent advances and future developments[J]. Thin-Walled Structures,2017,118:137-163. doi: 10.1016/j.tws.2017.05.018 [2] BAROUTAJI A, GILCHRIST M, OLABI A. Quasi-static, impact and energy absorption of internally nested tubes subjected to lateral loading[J]. Thin-Walled Structures,2016,98:337-350. doi: 10.1016/j.tws.2015.10.001 [3] RAHI A. Controlling energy absorption capacity of combined bitubular tubes under axial loading[J]. Thin-Walled Structures,2018,123:222-231. doi: 10.1016/j.tws.2017.11.032 [4] 宋涛, 余许多, 江晟达, 等. 变刚度碳纤维/环氧树脂复合材料薄壁圆管轴向压溃响应与破坏机制[J]. 复合材料学报, 2021, 38(11):3586-3600. doi: 10.13801/j.cnki.fhclxb.20210126.002SONG Tao, YU Xuduo, JIANG Shengda, et al. Axial crush response and damage mechanism of thin-walled circular tubes of carbon fiber/epoxy composites with variable stiffness[J]. Acta Materiae Compositae Sinica,2021,38(11):3586-3600(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210126.002 [5] DING X, TONG Z, LIU Y, et al. Dynamic axial crush analysis and design optimization of a square multi-cell thin-walled tube with lateral variable thickness[J]. International Journal of Mechanical Sciences,2018,140:13-26. doi: 10.1016/j.ijmecsci.2018.02.034 [6] ZHANG X, LENG K, ZHANG H. Axial crushing of embedded multi-cell tubes[J]. International Journal of Mechani-cal Sciences,2017,131-132:459-470. doi: 10.1016/j.ijmecsci.2017.07.019 [7] 邓亚斌, 任毅如, 蒋宏勇. 复合材料吸能圆管在半圆凹槽触发机制下的斜向压溃失效行为[J]. 复合材料学报, 2022, 39(4):1790-1797.DENG Yabin, REN Yiru, JIANG Hongyong. Oblique crush failure behavior of composite energy-absorbing circular tubes under semicircular notch triggering mechanism[J]. Acta Materiae Compositae Sinica,2022,39(4):1790-1797(in Chinese). [8] YIN H, XIAO Y, WEN G, et al. Multiobjective optimization for foam-filled multi-cell thin-walled structures under lateral impact[J]. Thin-Walled Structures,2015,94:1-12. doi: 10.1016/j.tws.2015.03.031 [9] WANG Z, LI Z, ZHANG X. Bending resistance of thin-walled multi-cell square tubes[J]. Thin-Walled Structures,2016,107:287-299. doi: 10.1016/j.tws.2016.06.017 [10] ZHANG X, ZHANG H, LENG K. Experimental and numerical investigation on bending collapse of embedded multi-cell tubes[J]. Thin-Walled Structures,2018,127:728-740. doi: 10.1016/j.tws.2018.03.011 [11] ZHANG X, ZHANG H. Static and dynamic bending collapse of thin-walled square beams with tube filler[J]. International Journal of Impact Engineering,2018,112:165-179. doi: 10.1016/j.ijimpeng.2017.11.001 [12] ALGHAMDI A. Collapsible impact energy absorbers: An overview[J]. Thin-Walled Structures,2001,39(2):189-213. doi: 10.1016/S0263-8231(00)00048-3 [13] PANDARKAR A, GOEL M, HORA M. Axial crushing of hollow and foam filled tubes: An overview [J]. Sādhanā, 2016, 41: 909-921. [14] TRAN T, TON T. Lateral crushing behaviour and theoretical prediction of thin-walled rectangular and square tubes[J]. Composite Structures,2016,154:374-384. doi: 10.1016/j.compstruct.2016.07.068 [15] ROUZEGAR J, ASSAEE H, NIKNEJAD A, et al. Geometrical discontinuities effects on lateral crushing and energy absorption of tubular structures[J]. Materials and Design,2015,65:343-359. doi: 10.1016/j.matdes.2014.09.041 [16] FAN Z, SHEN J, LU G, et al. Dynamic lateral crushing of empty and sandwich tubes[J]. International Journal of Impact Engineering,2013,53:3-16. doi: 10.1016/j.ijimpeng.2012.09.006 [17] KUMAR P. Influence of plain end-cap on the energy absorption characteristics of cylindrical tubular structures for lateral impact vehicle collisions[J]. Thin-Walled Structures,2019,138:32-45. doi: 10.1016/j.tws.2019.01.036 [18] LIU J, LIU H, YANG J. Lateral crushing and energy absorption behavior of hexagonal tubes with non-uniform thickness distributions[J]. Composite Structures,2022,285:115196. doi: 10.1016/j.compstruct.2022.115196 [19] EYVAZIAN A, NAJAFIAN S, MOZAFARI H, et al. Crashworthiness analysis of a novel aluminum Bi-tubular corrugated tube-experimental study[C]. Advances in Manufacturing Processes, 2019: 599-607. [20] SUN G, LI S, LIU Q, et al. Experimental study on crashworthiness of empty/aluminum foam/honeycomb-filled CFRP tubes[J]. Composite Structures,2016,152:969-993. doi: 10.1016/j.compstruct.2016.06.019 [21] LIU Z, HUANG Z, QIN Q. Experimental and theoretical investigations on lateral crushing of aluminum foam-filled circular tubes[J]. Composite Structures,2017,175:19-27. doi: 10.1016/j.compstruct.2017.05.004 [22] ELAHI S, ROUZEGAR J, NIKNEJAD A, et al. Theoretical study of absorbed energy by empty and foam-filled composite tubes under lateral compression[J]. Thin-Walled Structures,2017,114:1-10. doi: 10.1016/j.tws.2017.01.029 [23] MA W, LI Z, XIE S. Crashworthiness analysis of thin-walled bio-inspired multi-cell corrugated tubes under quasi-static axial loading[J]. Engineering Structures,2019,204:110069. [24] JUSUF A, DIRGANTARA T, GUNAWAN L, et al. Crashworthiness analysis of multi-cell prismatic structures[J]. International Journal of Impact Engineering,2015,78:34-50. doi: 10.1016/j.ijimpeng.2014.11.011 [25] ZHANG X, ZHANG H. Some problems on the axial crushing of multi-cells[J]. International Journal of Mechanical Sciences,2015,103:30-39. doi: 10.1016/j.ijmecsci.2015.08.026 [26] ZHENG D, ZHANG J, LU B, et al. Energy absorption of fully clamped multi-cell square tubes under transverse loading[J]. Thin-Walled Structures,2021,169:108334. doi: 10.1016/j.tws.2021.108334 [27] ALBAK E. Optimization for multi-cell thin-walled tubes under quasi-static three-point bending[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering,2022,44:207. doi: 10.1007/s40430-022-03525-8 [28] ZHU G, WANG Z, HUO X, et al. Experimental and numerical investigation into axial compressive behaviour of thin-walled structures filled with foams and composite skeleton[J]. International Journal of Mechanical Sciences,2017,122:104-119. doi: 10.1016/j.ijmecsci.2016.12.019 [29] ZHU G, ZHAO Z, HU P, et al. On energy-absorbing mechanisms and structural crashworthiness of laterally crushed thin-walled structures filled with aluminum foam and CFRP skeleton[J]. Thin-Walled Structures,2021,160:107390. doi: 10.1016/j.tws.2020.107390 [30] STANDAU T, ZHAO C, MURILLO C S, et al. Chemical modification and foam processing of polylactide (PLA)[J]. Polymers, 2019, 11(2): 306. [31] ZHU H, HOBDELL J, WINDLE A. Effects of cell irregularity on the elastic properties of 2D Voronoi honeycombs[J]. Journal of the Mechanics and Physics of Solids,2001,49(4):857-870. doi: 10.1016/S0022-5096(00)00046-6 [32] ZHENG Z, YU J, LI J. Dynamic crushing of 2D cellular structures: A finite element study[J]. International Journal of Impact Engineering,2005,32:650-664. doi: 10.1016/j.ijimpeng.2005.05.007 [33] 中国国家标准化管理委员会. 金属材料拉伸试验: GB/T 228.1—2010[S]. 北京: 中国标准出版社, 2011.Standardization Administration of the People's Republic of China. Metallic materials tensile testing: GB/T 228.1—2010[S]. Beijing: China Standards Press, 2011(in Chinese). [34] ZHAO X, WEI L, WEN D, et al. Bending response and energy absorption of sandwich beams with novel auxetic honeycomb core[J]. Engineering Structures,2021,247:113204. doi: 10.1016/j.engstruct.2021.113204 [35] HA N, PHAM T, CHEN W, et al. Crashworthiness analysis of bio-inspired fractal tree-like multi-cell circular tubes under axial crushing[J]. Thin-Walled Structures,2021,169:108315. doi: 10.1016/j.tws.2021.108315 -

下载:

下载: