Preparation and research progress of bio-based high resistance oxygen composites

-

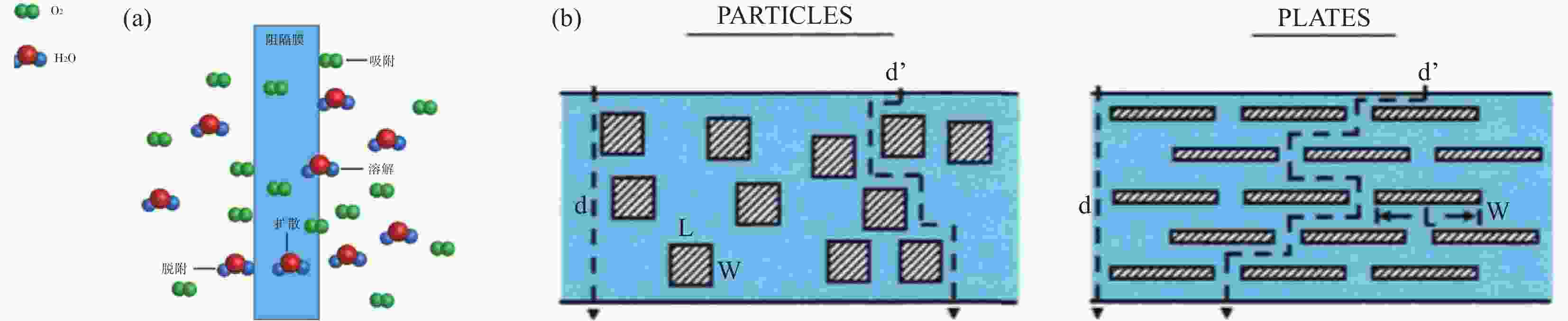

摘要: 随着环保意识的提升以及国家“以纸代塑”政策的提出,研究者一直致力于研发更环保的材料以代替石油基材料。生物质资源由于来源广泛是有望部分替代石油资源的主要可再生资源之一。本文综述了近几年一些具有高阻氧潜力生物基复合材料(纤维素、淀粉、半纤维素、壳聚糖、胶原)的研究进展。介绍了生物基材料改性的两种常用方法(薄膜基体改性和薄膜表面改性),简要总结了氧气分子渗透的理论与机制。最后,对目前的一些具有潜力的生物基复合材料在食品、医学、先进功能材料等领域的应用进行简要概述,对存在的问题进行简单总结,最后展望了未来生物质基材料的发展方向与趋势。Abstract: With the promotion of environmental awareness and the proposal of the national "paper instead of plastic" policy, researchers have been working to develop more environmentally friendly materials to replace petroleum-based materials. Biomass resources are one of the main renewable resources that are expected to partially replace petroleum resources because of their extensive sources. In this paper, the recent research progress of bio-based composites (cellulose, starch, hemicelluloses, chitosan, collagen) with high oxygen inhibition potential is reviewed. Two common methods of modification of biobased materials (film substrate modification and film surface modification) are introduced. The theory and mechanism of oxygen molecular infiltration are briefly summarized. Finally, the current applications of some potential bio-based composites in food, medicine, advanced functional materials and other fields are briefly summarized, and the existing problems are briefly summarized. Finally, the development direction and trend of bio-based materials in the future are prospected.

-

Key words:

- biomass-based materials /

- oxygen blocking /

- obstruct /

- cellulose /

- starch /

- hemicellulose /

- chitosan

-

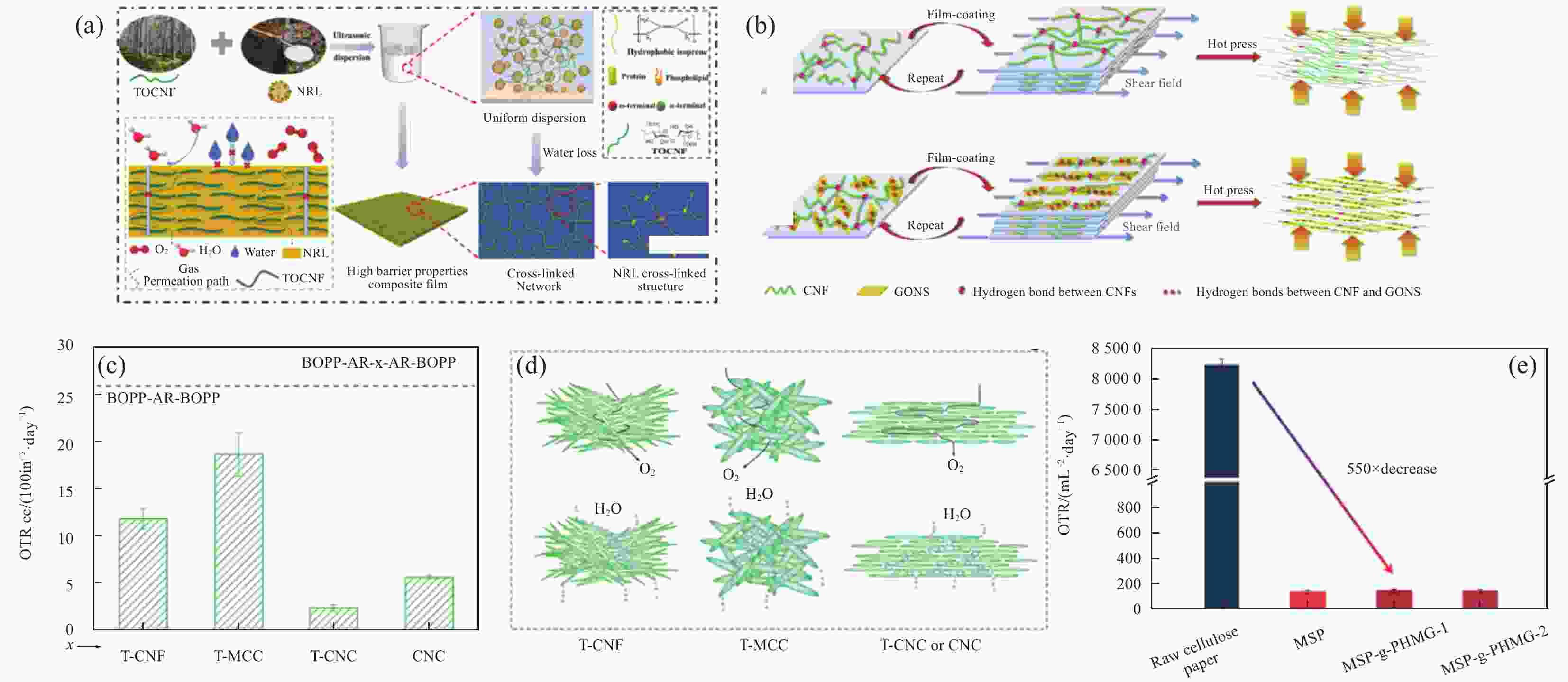

图 2 (a)TOCNF/NRL复合膜的制备过程及复合膜的阻隔机制[17];(b)CNF和CNF5纳米复合材料在成型过程中的取向机制示意图[18];(c)夹层膜的OTR值[15];(d)CNP层横截面上O2和H2O的移动途径[15];(e)原纤维素纸和MSP-g-PHMG样品的OTR[21];

Figure 2. (a)The preparation process of TOCNF/NRL composite film and the barrier mechanism of the composite film[17]; (b)The orientation mechanism diagram of CNF and CNF5 nanocomposites during the molding process[18]; (c)OTR value of sandwich film[15]; (d)The movement path of O2 and H2 O on the cross section of the CNP laye[15]r; (e)OTR of procellulose paper and MSP-g-PHMG samples[21];

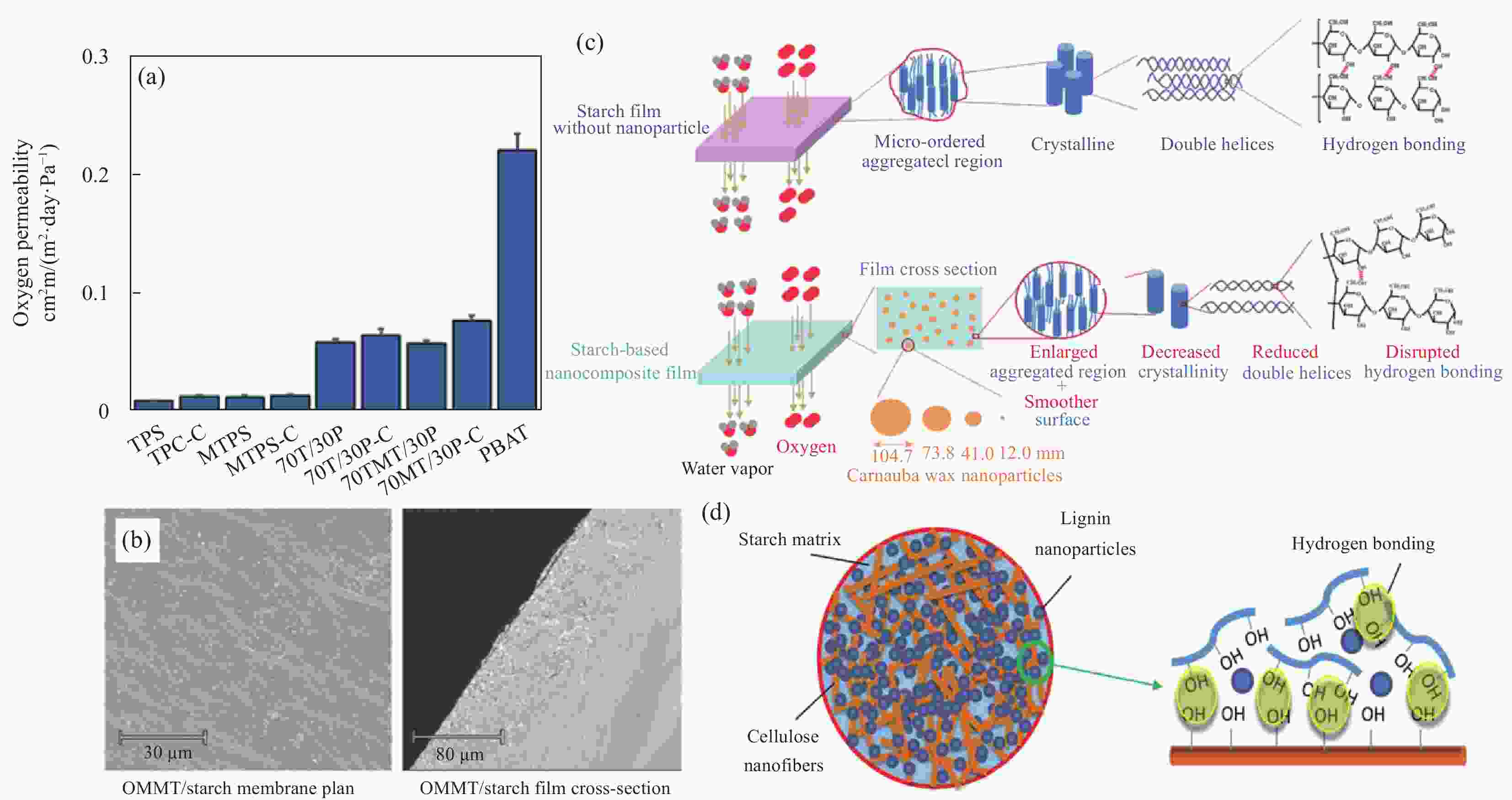

图 3 (a) MTPS/PBAT薄膜的透氧性[29];(b) OMMT/淀粉膜的平面图和OMMT/淀粉膜的横截面[25];(c) 纳米复合薄膜多尺度结构变化及其对水蒸气和氧气渗透的影响示意图[28];(d) CNF、淀粉和木质素在生物复合材料中的键合机制示意图[31]

Figure 3. (a) Oxygen permeability of MTPS/PBAT films[29];(b) OMMT/ starch film plan and cross section of OMMT/ starch film[25]; (c) Schematic diagram of multi-scale structural changes of nanocomposite films and their effects on water vapor and oxygen penetration[28]; (d) Schematic diagram of the bonding mechanism of CNF, starch and lignin in biocomposites[31]

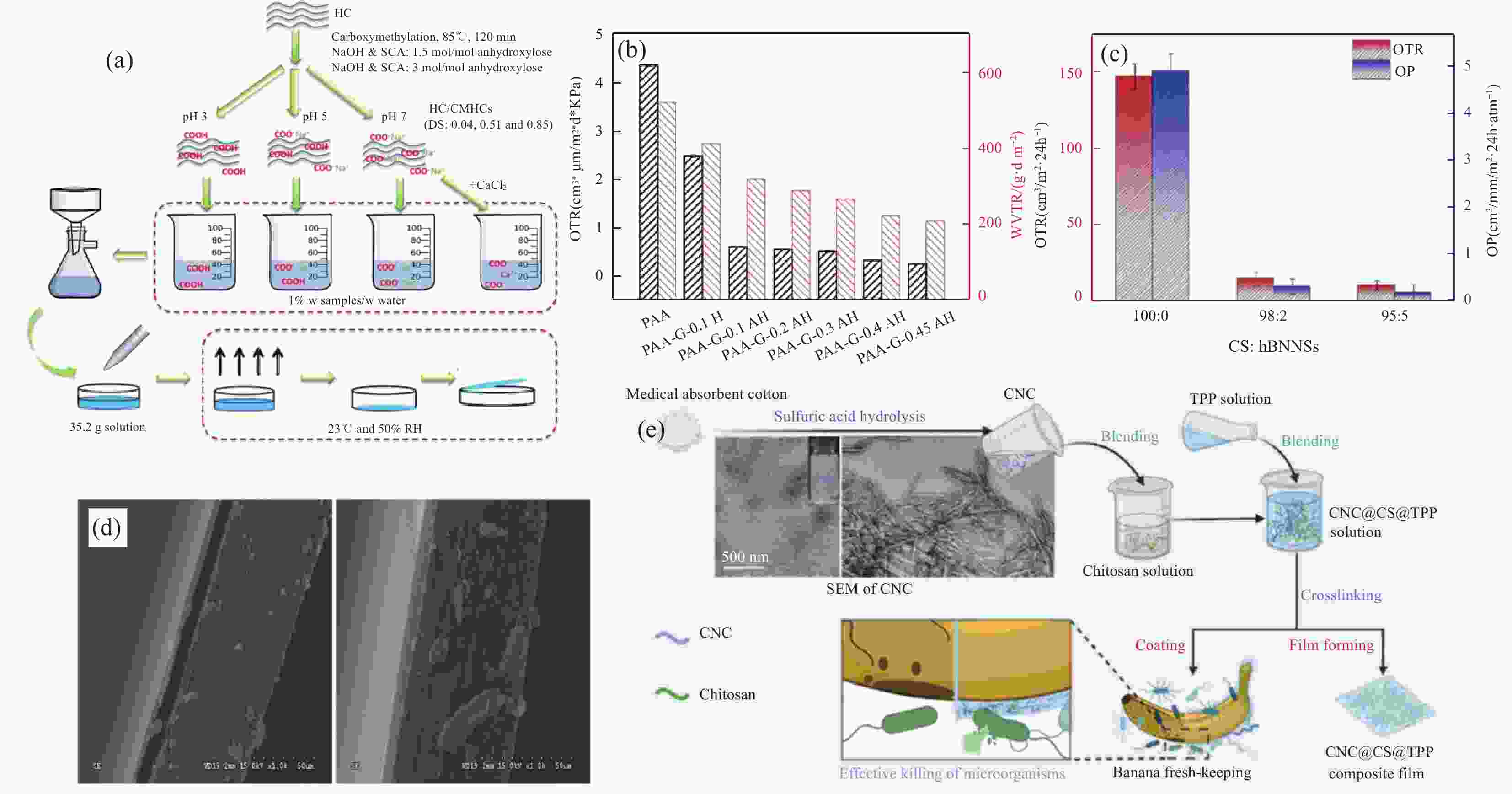

图 4 (a)使用浇注法制备HC/CMHC薄膜的工艺图、未改性的HC、CMHC-取代度(DS0.51)[33];(b)合成薄膜分别的氧气透过率和水蒸气透过率[34];(c) CS/hBNNS薄膜透氧率[41];(d) PLA/CS和 PLA/SiOx/CS横截面的SEM图像[43];(e)CS/CNC/TPP生物复合涂层的制备工艺及其在水果保鲜中的应用[39]

Figure 4. (a) Process diagram of HC/CMHC film prepared by casting method, unmodified HC, CMHC- degree of substitution (DS0.51)[33]; (b) Oxygen and water vapor transmissibility of the synthesized film respectively[34]; (c) Oxygen permeability of CS/hBNNS films[41]; (d) SEM images of PLA/CS and PLA/SiOx/CS cross sections[43]; (e) Preparation process of CS/CNC/TPP biocomposite coating and its application in fruit preservation[39]

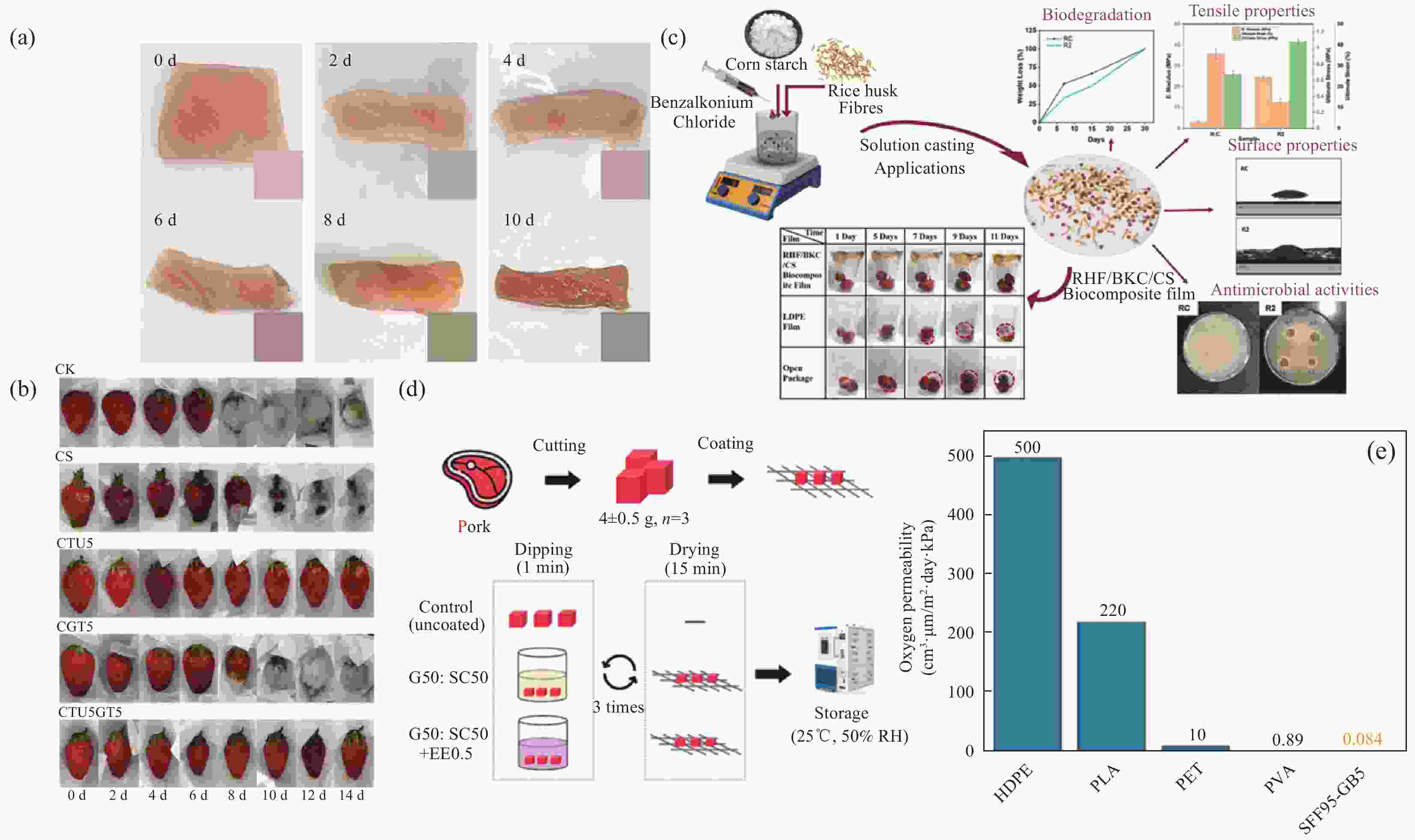

图 5 (a)用ECG4-P30-4 PL纳米膜包装的猪肉,在储存过程中其颜色[49];(b)草莓和灰芽孢杆菌引起的腐烂症状的图像,无包衣草莓(CK)、.用壳聚糖薄膜(CS)包衣、涂有含有 5% 姜黄提取物(CTU5)的壳聚糖薄膜、涂有含有 5% 绿茶提取物(CGT5)的壳聚糖薄膜和涂有含有 5% 姜黄提取物和 5% 绿茶提取物(CTU5 GT5)的壳聚糖薄膜[52];(c)稻壳纤维与玉米淀粉复合膜示意图[53];(d)接骨木果提取物的明胶-酪蛋白酸钠高氧阻隔膜对猪肉的抗氧化能力[55];(e) 高阻隔SFF95-GB5与传统包装塑料(HDPE:高密度聚乙烯、PLA:聚乳酸,PET:聚对苯二甲酸乙二醇酯,PVA:聚乙烯醇)在50%RH下的透氧性[56]

Figure 5. (a) Pork packaged with ECG4-P30-4 PL nanomembrane, its color during storage[49]; (b) Image of strawberry and rot symptoms caused by Bacillus griseus, uncoated strawberry (CK). Coated with a chitosan film (CS), coated with a chitosan film containing 5% turmeric extract (CTU5), coated with a chitosan film containing 5% green tea extract (CGT5) and coated with a chitosan film containing 5% turmeric extract and 5% green tea extract (CTU5 GT5)[52]; (c) Schematic diagram of rice husk fiber and corn starch composite membrane[53]; (d) Antioxidant capacity of elderberry extract's gelatin-sodium caseinate hyperoxic barrier film on pork[55]; (e) Oxygen permeability of high barrier SFF95-GB5 and traditional packaging plastics (HDPE: high-density polyethylene, PLA: polylactic acid, PET: polyethylene terephthalate, PVA: polyvinyl alcohol) at 50%RH[56]

-

[1] ZHONG Y, GODWIN P, JIN Y, et al. Biodegradable polymers and green-based antimicrobial packaging materials: A mini-review[J]. Advanced Industrial and Engineering Polymer Research, 2020, 3(1): 27-35. doi: 10.1016/j.aiepr.2019.11.002 [2] 肖彬. 有机无机复合高阻隔薄膜材料的制备及其性能研究 [D], 2023.XIAO B. Preparation and properties of organic and inorganic composite high barrier thin films [D], 2023(in Chinese). [3] FREDI G, DORIGATO A. Compatibilization of biopolymer blends: A review[J]. Advanced Industrial and Engineering Polymer Research, 2023, In Press. [4] PŁOSKA J, GARBOWSKA M, RYBAK K, et al. Study on application of biocellulose-based material for cheese packaging[J]. International Journal of Biological Macromolecules, 2024, 264(130433): 77-98 [5] UPADHYAY A, AGBESI P, ARAFAT K M Y, et al. Bio-based smart packaging: Fundamentals and functions in sustainable food systems[J]. Trends in Food Science & Technology, 2024, 245(104369): 17-28. [6] 李家旭. 生物可降解聚己二酸对苯二甲酸丁二酯薄膜气体阻隔性能研究及调控 [D], 2020.LI J X. Study on gas barrier properties and regulation of biodegradable polybutylene adipate terephthalate films [D], 2020(in Chinese). [7] NOIVOIL N, YOKSAN R. OLIGO (lactic acid)-grafted starch: A compatibilizer for poly (lactic acid)/thermoplastic starch blend[J]. International Journal of Biological Macromolecules, 2020, 160(89): 506-517. [8] XU H J, MEI H F, CHEN W X, et al. Renewable thermoplastic starch/sugar alcohol blends and their oxygen barrier application[J]. Polymer Engineering & Science, 2023, 64(1): 231-242 [9] MANABE K, KOYAMA E, NORIKANE Y. Cephalopods-inspired rapid self-healing nanoclay composite coatings with oxygen barrier and super-bubble-phobic properties[J]. ACS Applied Materials & Interfaces, 2021, 13(30): 36341-36349. [10] SHENG W, CHEN Y, MAO H, et al. Rational design of vapor-deposited self-crosslinking polymer for transparent flexible oxygen barrier coatings[J]. Journal of Applied Polymer Science, 2021, 138(21): 50505. doi: 10.1002/app.50505 [11] WIJMANS J G, BAKER R W. The solution-diffusion model: a review[J]. Journal of membrane science, 1995, 107(1-2): 1-21. doi: 10.1016/0376-7388(95)00102-I [12] VINH-THANG H, KALIAGUINE S. A comprehensive computational strategy for fitting experimental permeation data of mixed matrix membranes[J]. Journal of membrane science, 2014, 452(8): 271-276. [13] YAN L, ABDALKALIRM S Y H, CHEN X, et al. Nucleation and property enhancement mechanism of robust and high-barrier PLA/CNFene composites with multi-level reinforcement structure[J]. Composites Science and Technology, 2024, 110364. [14] SHI X, WANG Z, LIU S, et al. Scalable production of carboxylated cellulose nanofibres using a green and recyclable solvent[J]. Nature Sustainability, 2024, 7(21): 315-325. [15] DU L, YU H, ZHANG B, et al. Transparent oxygen barrier nanocellulose composite films with a sandwich structure[J]. Carbohydrate polymers, 2021, 268(118206): 40-55. [16] 王小英, 唐淑玮, 吴正国, 等. 生物质基高阻隔复合膜的研究现状[J]. 林业工程学报, 2021, 6(6): 13-22.WANG Xiaoying, TANG Shuwei, WU Zhengguo, et al. Research status of biomass-based high barrier composite membranes[J]. Journal of Forestry Engineering, 2021, 6(6): 13-22(in Chinese). [17] MENG L, XI J, BIAN H, et al. Nanocellulose/natural rubber latex composite film with high barrier and preservation properties[J]. Sustainable Chemistry and Pharmacy, 2024, 37(101399): 5908. [18] REN F, TAN W, DUAN Q, et al. Ultra-low gas permeable cellulose nanofiber nanocomposite films filled with highly oriented graphene oxide nanosheets induced by shear field[J]. Carbohydrate polymers, 2019, 209(77): 309-310. [19] NGUYEN H-L, HANIF Z, PARK S-A, et al. Sustainable boron nitride nanosheet-reinforced cellulose nanofiber composite film with oxygen barrier without the cost of color and cytotoxicity[J]. Polymers, 2018, 10(5): 501. doi: 10.3390/polym10050501 [20] JIANG J, ZHANG X, GAO S, et al. Effects of adding methods and modification types of cellulose on the physicochemical properties of starch/PBAT blown films[J]. International Journal of Biological Macromolecules, 2022, 223(100): 1335-1343. [21] HUANG H, MAO L, WANG W, et al. A facile strategy to fabricate antibacterial hydrophobic, high-barrier, cellulose papersheets for food packaging[J]. International Journal of Biological Macromolecules, 2023, 236(123630): 1578. [22] AHMED J, RAVICHANDRAN S, THAKUR R, et al. Starch-based edible packaging: Rheological, thermal, mechanical, microstructural, and barrier properties–A review[J]. Sustainable Food Technology, 2024, 2(99): 307-330. [23] DANG K M, YOKSAN R. Thermoplastic starch blown films with improved mechanical and barrier properties[J]. International Journal of Biological Macromolecules, 2021, 188(20): 290-299. [24] WU Y, TANG R, GUO A, et al. Enhancing Starch− Based Packaging Materials: Optimization of Plasticizers and Process Parameters[J]. Materials, 2023, 16(17): 5953. doi: 10.3390/ma16175953 [25] HUANG L, HAN X, CHEN H, et al. Preparation and barrier performance of layer-modified soil-stripping/cassava starch composite films[J]. Polymers, 2020, 12(7): 1611. doi: 10.3390/polym12071611 [26] GE C, LANSING B, LEWIS C L. Thermoplastic starch and poly (vinyl alcohol) blends centered barrier film for food packaging applications[J]. Food Packaging and Shelf Life, 2021, 27(100610): 88-100. [27] PATIL S, BHARIMALLA A K, MAHAPATRA A, et al. Effect of polymer blending on mechanical and barrier properties of starch-polyvinyl alcohol based biodegradable composite films[J]. Food Bioscience, 2021, 44(101352): 23-44. [28] LIU S, LI L, LI B, et al. Size effect of carnauba wax nanoparticles on water vapor and oxygen barrier properties of starch-based film[J]. Carbohydrate Polymers, 2022, 296(119935): 99-110. [29] CHANG C C, TRINH B M, MEKONNEN T H. Robust multiphase and multilayer starch/polymer (TPS/PBAT) film with simultaneous oxygen/moisture barrier properties[J]. Journal of Colloid and Interface Science, 2021, 593(23): 290-303. [30] ESLAMI H, MEKONNEN T H. Flexible and green multilayer paper coating for barrier enhancement of paper packaging[J]. Sustainable Materials and Technologies, 2023, 37(0694): 55-68. [31] ZHAO Y, TROEDSSON C, BOUQUET J-M, et al. Mechanically reinforced, flexible, hydrophobic and UV impermeable starch-cellulose nanofibers (CNF)-lignin composites with good barrier and thermal properties[J]. Polymers, 2021, 13(24): 4346. doi: 10.3390/polym13244346 [32] LIU R, LI Q, GAN L, et al. Robust, versatile, and hemicellulose-derived biocomposite Janus membrane for saline wastewater desalination[J]. Journal of Membrane Science, 2024, 345(122566): 355-369. [33] GENG W, VENDITTI R A, PAWLAK J J, et al. Carboxymethylation of hemicellulose isolated from poplar (Populus grandidentata) and its potential in water-soluble oxygen barrier films[J]. Cellulose, 2020, 27(9): 3359-3377. [34] LIU R, DU J, ZHANG Z, et al. Preparation of polyacrylic acid-grafted-acryloyl/hemicellulose (PAA-g-AH) hybrid films with high oxygen barrier performance[J]. Carbohydrate polymers, 2019, 205(88): 83-88. [35] LIU G, SHI K, SUN H, et al. Enhancing Hydrophobicity and Oxygen Barrier of Xylan/PVOH Composite Film by 1, 2, 3, 4-Butane Tetracarboxylic Acid Crosslinking[J]. Polymers, 2023, 15(13): 2811. doi: 10.3390/polym15132811 [36] ZHAO Y, SUN H, YANG B, et al. Enhancement of mechanical and barrier property of hemicellulose film via crosslinking with sodium trimetaphosphate[J]. Polymers, 2021, 13(6): 927. doi: 10.3390/polym13060927 [37] CAZóN P, VáZQUEZ M. Mechanical and barrier properties of chitosan combined with other components as food packaging film[J]. Environmental chemistry letters, 2020, 18(2): 257-267. doi: 10.1007/s10311-019-00936-3 [38] SIRVIO J A, KANTOLA A M, KOMULAINEN S, et al. Aqueous modification of chitosan with itaconic acid to produce strong oxygen barrier film[J]. Biomacromolecules, 2021, 22(5): 2119-2128. doi: 10.1021/acs.biomac.1c00216 [39] DU Y, SHI B, LUAN X, et al. Chitosan/cellulose nanocrystal biocomposite coating for fruit postharvest preservation[J]. Industrial Crops and Products, 2023, 205(117543): 2398-2412. [40] CHENG Z, LI J, SU M, et al. High-Barrier Oxidized Cellulose Nanofibril/Chitosan Coating for Functional Food Packaging Materials[J]. ACS Applied Polymer Materials, 2024, 6(5): 2877-2888. doi: 10.1021/acsapm.3c03115 [41] WANG K, LI F, SUN X, et al. Transparent chitosan/hexagonal boron nitride nanosheets composite films with enhanced UV shielding and gas barrier properties[J]. International Journal of Biological Macromolecules, 2023, 251(126308): 99-110. [42] 张钊滟, 马帅, 卢鑫, 等. 壳聚糖-氧化石墨烯/热塑性聚氨酯复合材料的原位溶液聚合及性能[J]. 复合材料学报, 2020, 37(11): 2726-2734.ZHANG Zhaoyan, MA Shuai, LU Xin, et al. In-situ Solution polymerization and properties of chitosan-graphene oxide/thermoplastic polyurethane composites[J]. Journal of Composite Materials, 2020, 37(11): 2726-2734(in Chinese). [43] LI Y, REN J, WANG B, et al. Development of biobased multilayer films with improved compatibility between polylactic acid-chitosan as a function of transition coating of SiOx[J]. International Journal of Biological Macromolecules, 2020, 165(9): 1258-1263. [44] LI C, GE J, GUO Q, et al. Polyvinyl alcohol/collagen composite scaffold reinforced with biodegradable polyesters/gelatin nanofibers for adipose tissue engineering[J]. International Journal of Biological Macromolecules, 2024, 123(130237): 44-60. [45] LIU S, QIAO S, ZHU J, et al. Enhanced barrier and antioxidant properties of gelatin films by structural-colored bioactive materials for food packaging[J]. Food Hydrocolloids, 2024, 150(109744): 567-580. [46] XU J, LIU F, GOFF H D, et al. Effect of pre-treatment temperatures on the film-forming properties of collagen fiber dispersions[J]. Food Hydrocolloids, 2020, 107(105326): 126-139. [47] SHAO X, SUN H, ZHOU R, et al. Effect of bovine bone collagen and nano-TiO2 on the properties of hydroxypropyl methylcellulose films[J]. International journal of biological macromolecules, 2020, 158(8): 937-944. [48] 张群利, 邬泽凯, 崔琳琳, 等. 蒲公英提取物-茶多酚-玉米秸秆纤维素抗菌复合膜制备与性能[J]. 复合材料学报, 2023, 40(9): 5341-5349.ZHANG Qunli, WU Zekai, CUI Linlin, et al. Preparation and properties of dandelion extract-tea polyphenol-corn straw cellulose antibacterial composite membrane[J]. Journal of Composite Materials, 2023, 40(9): 5341-5349(in Chinese). [49] WU J-H, LIAO J-H, HU T-G, et al. Fabrication of multifunctional ethyl cellulose/gelatin-based composite nanofilm for the pork preservation and freshness monitoring[J]. International Journal of Biological Macromolecules, 2024, 265(130813): 55-78. [50] ZHANG W, JIANG H, RHIM J-W, et al. Tea polyphenols (TP): a promising natural additive for the manufacture of multifunctional active food packaging films[J]. Critical Reviews in Food Science and Nutrition, 2022, 63(2): 288-301. [51] LIU Y, MA M, YUAN Y. The potential of curcumin-based co-delivery systems for applications in the food industry: food preservation, freshness monitoring, and functional food[J]. Food Research International, 2023, 171(113070): 35-47. [52] MA M, GU M, ZHANG S, et al. Effect of tea polyphenols on chitosan packaging for food preservation: Physicochemical properties, bioactivity, and nutrition[J]. International Journal of Biological Macromolecules, 2024, 33(129267): 12-23. [53] SRIVASTAVA V, SINGH S, DAS D. Rice husk fiber-reinforced starch antimicrobial biocomposite film for active food packaging[J]. Journal of Cleaner Production, 2023, 421(138525): 12-20. [54] YONG H, XU F, YUN D, et al. Antioxidant packaging films developed by in-situ cross-linking chitosan with dialdehyde starch-catechin conjugates[J]. International Journal of Biological Macromolecules, 2022, 222(3): 3203-3214. [55] CHOI J, LEE J-S, HAN J, et al. Development of gelatin–sodium caseinate high-oxygen-barrier film containing elderberry (Sambucus nigra L. ) extract and its antioxidant capacity on pork[J]. Food Bioscience, 2023, 53(102617): 723-733. [56] SHAIKH A A, DATTA P, DASTIDAR P, et al. Biopolymer-based nanocomposites for application in biomedicine: a review[J]. Journal of Polymer Engineering, 2024, 44(2): 83-116. doi: 10.1515/polyeng-2023-0166 [57] YUE S, WANG S, HAN D, et al. Perhydropolysilazane-derived-SiO x coated cellulose: a transparent biodegradable material with high gas barrier property[J]. Cellulose, 2022, 29(15): 8293-8303. doi: 10.1007/s10570-022-04746-9 [58] 周可可, 唐亚丽, 卢立新, 等. 氧化纳米纤维素增强再生纤维素全纤维素复合薄膜的制备及性能[J]. 复合材料学报, 2020, 37(7): 1657-1666.ZHOU Keke, TANG Yali, LU Lixin, et al. Preparation and Properties of oxidized nanocellulose reinforced regenerated cellulose whole cellulose composite films[J]. Journal of Composite Materials, 2020, 37(7): 1657-1666(in Chinese). [59] CHEN L, CHI Z, LIU G-L, et al. Improved pullulan production by a mutant of Aureobasidium melanogenum TN3-1 from a natural honey and capsule shell preparation[J]. International journal of biological macromolecules, 2019, 3(141): 268-277. [60] GORUR Y C, FRANCON H S, SETHI J, et al. Rapidly Prepared Nanocellulose Hybrids as Gas Barrier, Flame Retardant, and Energy Storage Materials[J]. ACS Applied Nano Materials, 2022, 5(7): 9188-9200. doi: 10.1021/acsanm.2c01530 [61] TU H, XIE K, LIN X, et al. Superior strength and highly thermoconductive cellulose/boron nitride film by stretch-induced alignment[J]. Journal of Materials Chemistry A, 2021, 9(16): 10304-10315. doi: 10.1039/D1TA00143D [62] BHARMORIA P, HISAMITSU S, SASAKI Y, et al. Photon upconverting bioplastics with high efficiency and in-air durability[J]. Journal of Materials Chemistry C, 2021, 9(35): 11655-11661. doi: 10.1039/D1TC00287B -

点击查看大图

点击查看大图

计量

- 文章访问数: 175

- HTML全文浏览量: 93

- 被引次数: 0

下载:

下载: