Experimental study on mechanical properties and recoverability of FRP/shape memory alloy composites

-

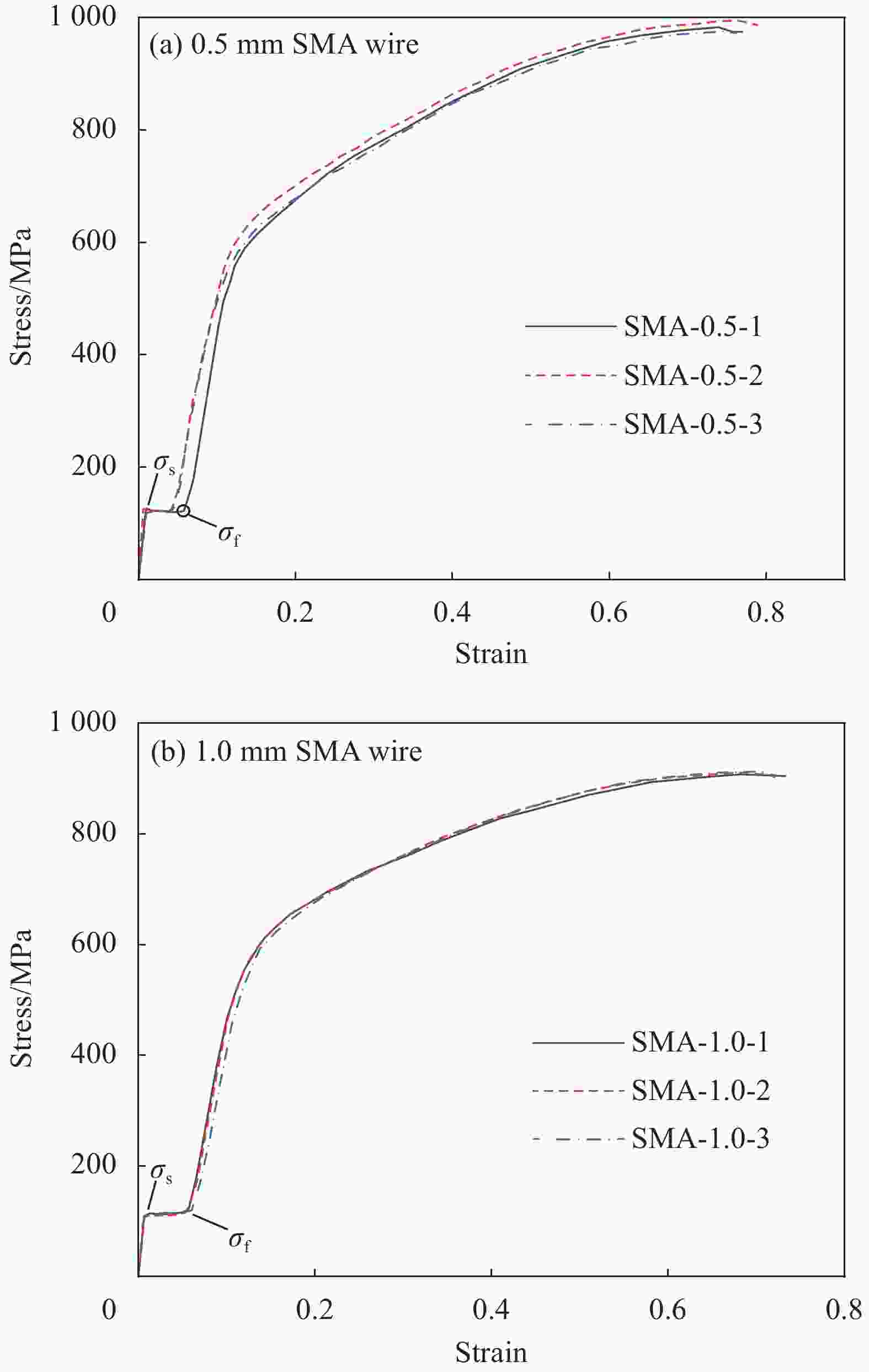

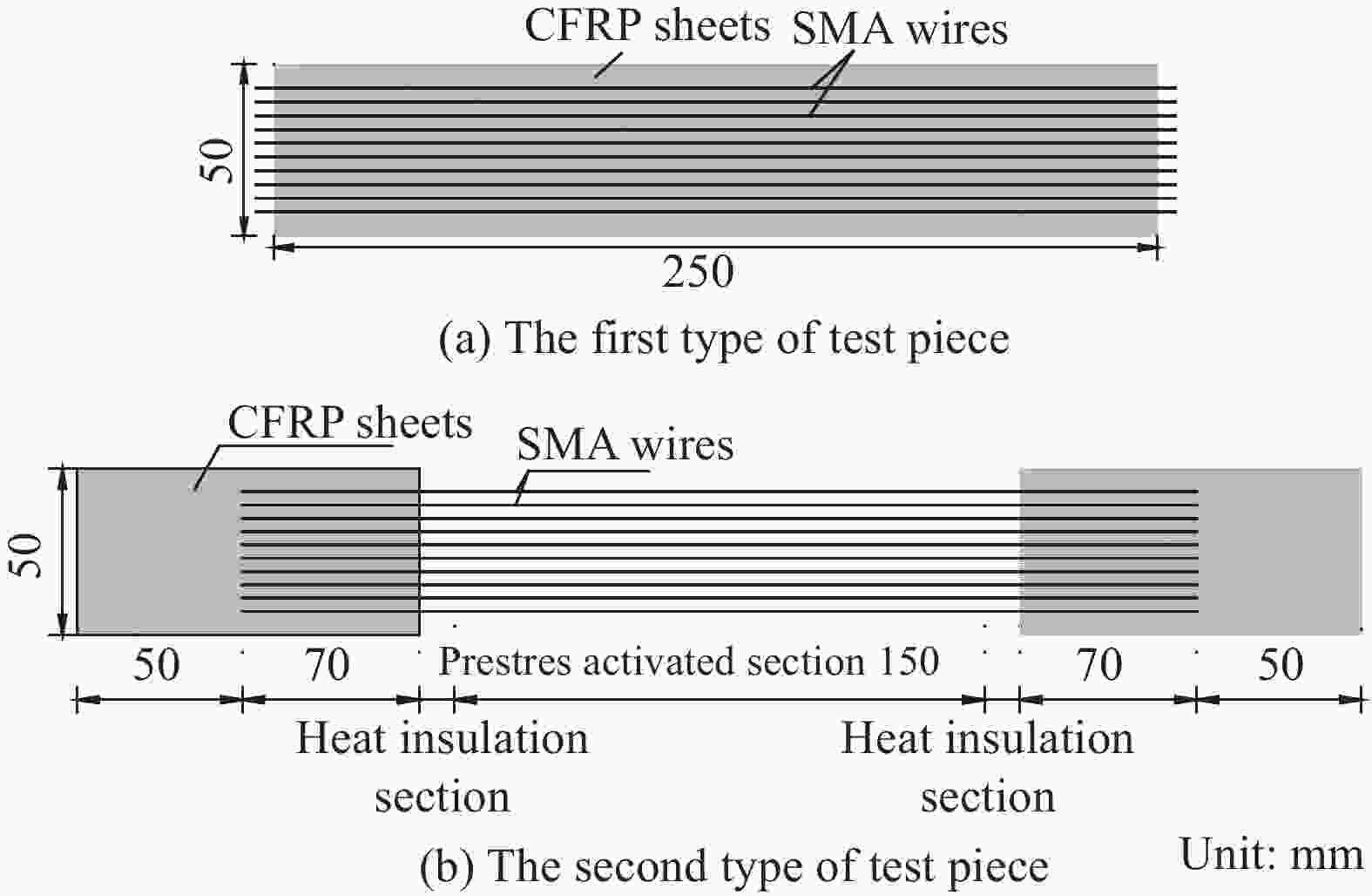

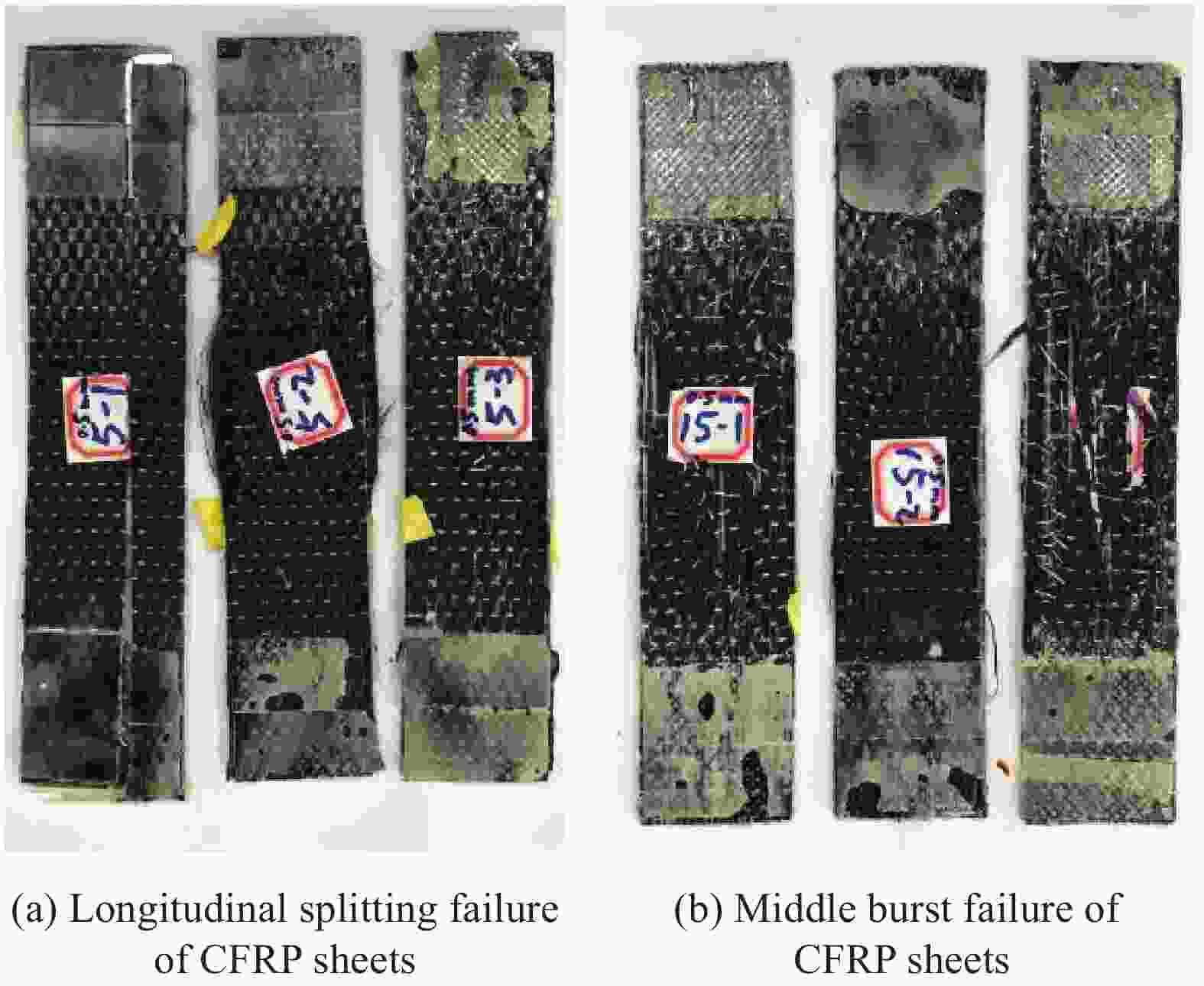

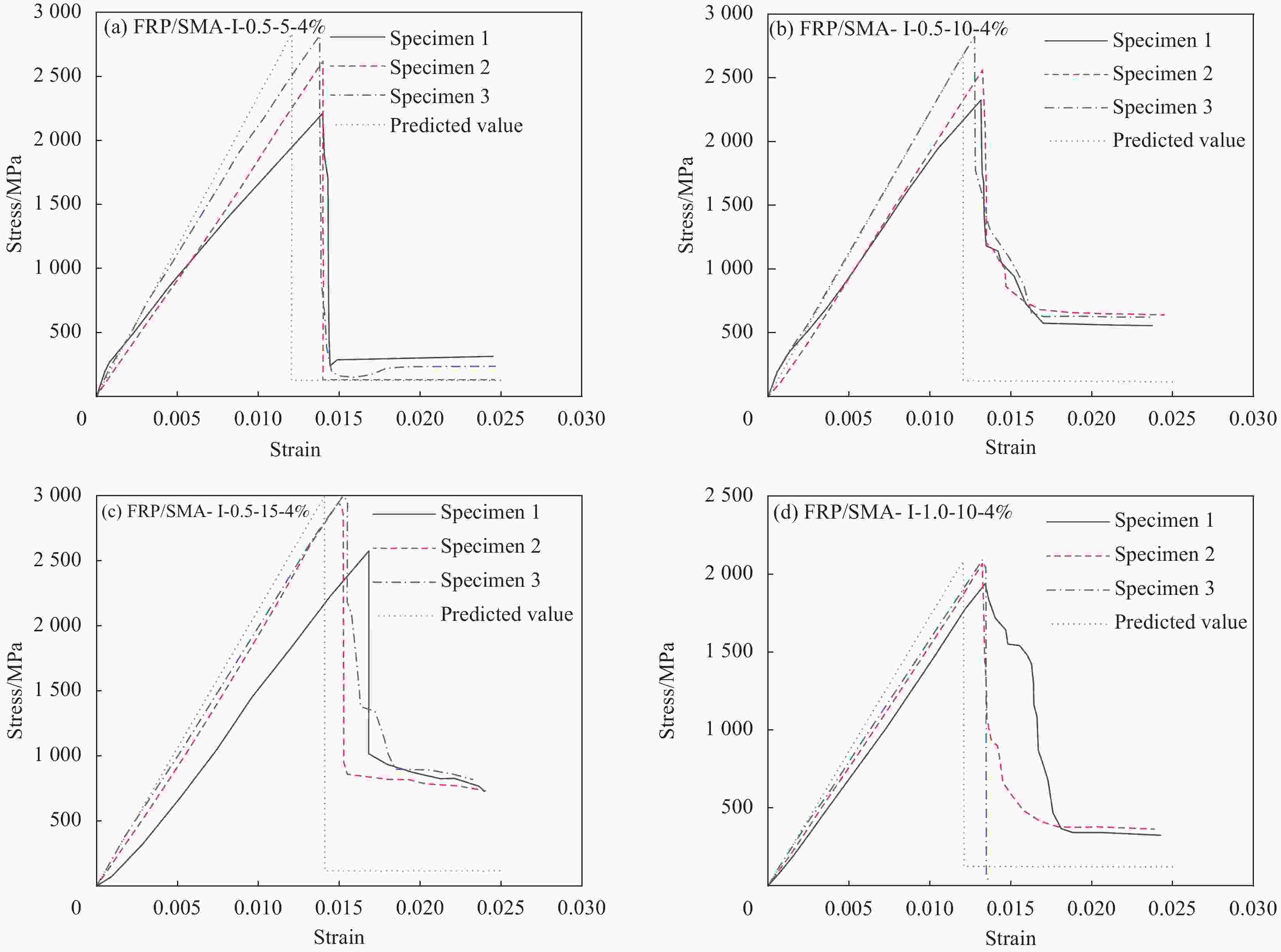

摘要: 利用形状记忆合金(SMA)的回复效应将预应力引入到纤维增强复合材料(FRP)中是一种新理念。本文将FRP与SMA复合,形成一种新的复合材料用于结构加固修复中,开展了FRP/SMA复合材料的力学性能和受限回复性能试验。在力学性能试验中,将SMA丝的数量和直径作为试验变量,分析它们对FRP/SMA复合材料拉伸性能的影响;在受限回复试验中,将SMA丝直径和预应变水平作为试验变量,分析其对SMA丝及FRP/SMA复合材料可回复性能的影响。在试验研究的基础上,给出了第一类FRP/SMA复合材料的材料强度、极限应变和弹性模量的预测模型和FRP/SMA复合材料回复应力-温度模型。试验结果表明,在一定掺量内,提高掺入SMA丝的数量能够提高复合材料的最大断裂应变和抗拉强度,掺入的丝数量越多,断后残余强度越大。SMA丝的直径显著影响复合材料试件的拉伸弹性模量。在受限回复性能试验中,FRP/SMA复合材料的回复应力在相变区间内随温度的升高呈明显的上升趋势,复合材料的最大回复应力将会随预应变水平的提高而增大。提出的基于Brinson模型的修正模型,预测值与试验值吻合较好,可以有效地预测SMA丝和FRP/SMA复合材料的回复应力与温度的关系。Abstract: Using the recovery effect of shape memory alloy (SMA) to introduce prestress into fiber reinforced polymer (FRP) is a new idea. In this paper, FRP and SMA are compounded to form a new composite material for structural strengthening and repair. The mechanical properties and limited recovery properties of FRP/SMA composites are tested. In the mechanical property test, the number and diameter of SMA wires are taken as test variables, and their effects on the tensile properties of FRP/SMA composites are analyzed. In the limited recovery test, the SMA wire diameter and pre-strain level were taken as test variables to analyze their effects on the recoverable properties of SMA wire and FRP/SMA composites. On the basis of experimental research, the regression equations of recovery stress temperature of SMA wire and FRP/SMA composites are given. The test results show that increasing the number of SMA wires can improve the maximum fracture strain and tensile strength of the composite. The more wires are added, the greater the residual strength after fracture. The diameter of SMA wire significantly affects the tensile elastic modulus of composite specimens. In the limited recovery performance test, the recovery stress of FRP/SMA composites shows an obvious upward trend with the increase of temperature in the phase transition range, and the maximum recovery stress of composites will increase with the increase of pre-strain level. The modified model based on Brinson’s model is proposed, and the predicted values are in good agreement with the experimental values, which can effectively predict the relationship between the recovery stress and temperature of SMA wire and FRP/SMA composites.

-

表 1 材料的物理力学性能

Table 1. Physical and mechanical properties of materials

Material Diameter φ/mm Austenite transition temperature/℃ Martensite transition temperature/℃ Phase transition stress/MPa Strength/

MPaElastic modulus/

GPaElongation/

%Start

AsFinish Af Start Ms Finish Mf SMA wire 0.5 106.12 121.40 55.34 27.34 122 982 12.2 78.0 1.0 79.13 105.46 59.00 35.81 117 906 10.4 75.0 CFRP – – – – – 3000 247.7 1.2 Epoxy resin – – – – – 35 2.2 1.6 Notes: CFRP—Carbon fiber reinfored plastic; Af—Austenite finish temperature; As—Austenite start temperature; Ms—Martensite start temperature; Mf—Martensite finish temperature. 表 2 两种类型的FRP/SMA复合材料试件

Table 2. Two types of FRP/SMA composite specimens

Specimen type Specimen Number of

SMA wiresDiameter of

SMA/

mmPrestrain/

%Length of composite

section/

mmFRP/SMA-I FRP/SMA-I-0.5-5-4% 5 0.5 4 250 FRP/SMA-I-0.5-10-4% 10 0.5 4 250 FRP/SMA-I-0.5-15-4% 15 0.5 4 250 FRP/SMA-I-1-10-4% 10 1.0 4 250 FRP/SMA-II FRP/SMA-II-1.0-10-4% 10 1.0 4 2×70 FRP/SMA-II-1.0-10-6% 10 1.0 6 2×70 FRP/SMA-II-1.0-10-8% 10 1.0 8 2×70 表 3 FRP/SMA复合材料试验与分析结果

Table 3. Test and analysis results of FRP/SMA composites

Specimen No. Strength/MPa Elastic modulus/GPa Fracture strain/% Failure mode Test value Calculated value Test value/

calculated valueTest value Calculated value Test value/

calculated

valueTest value Calculated value Test value/

calculated

valueFRP/SMA-I-0.5-

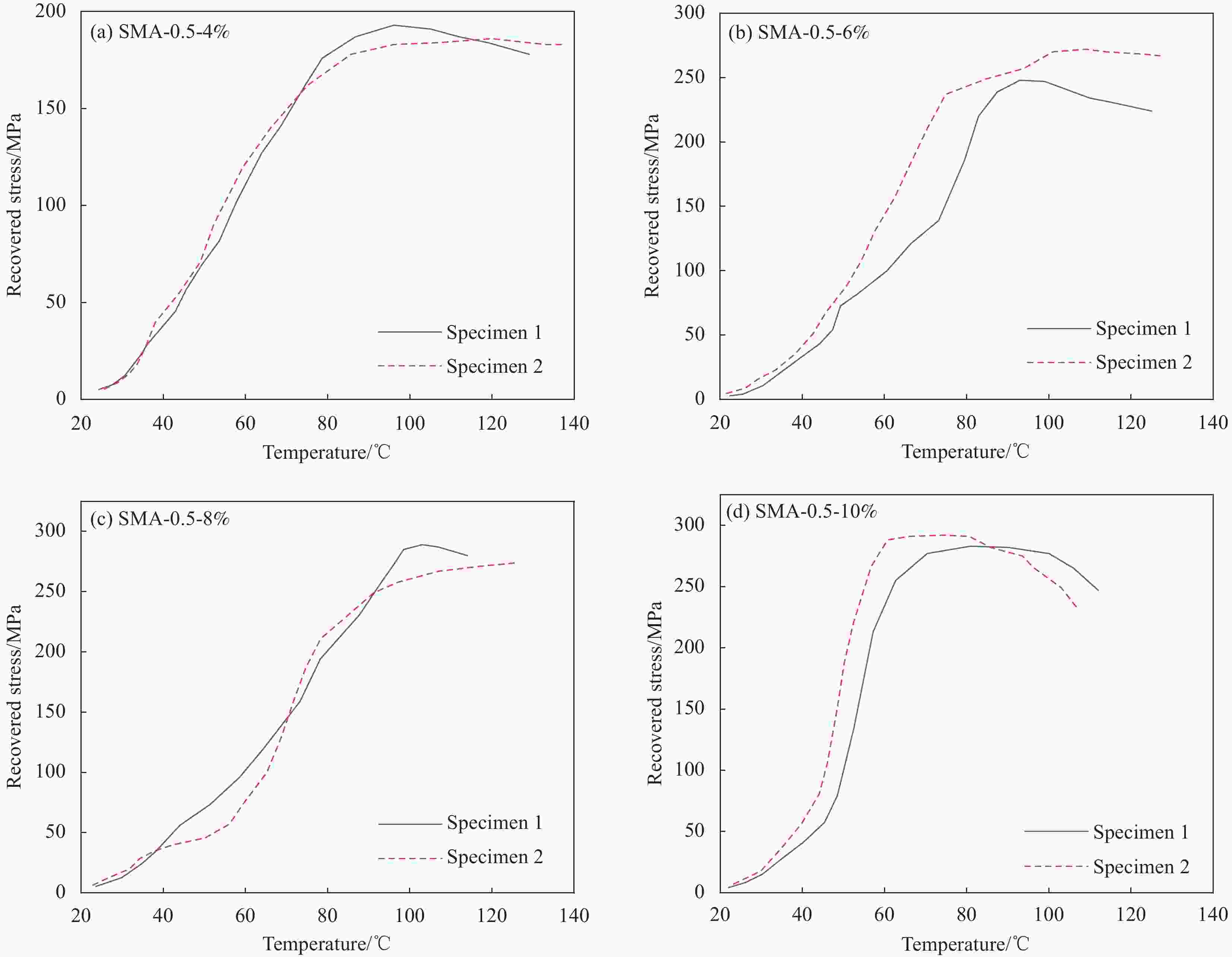

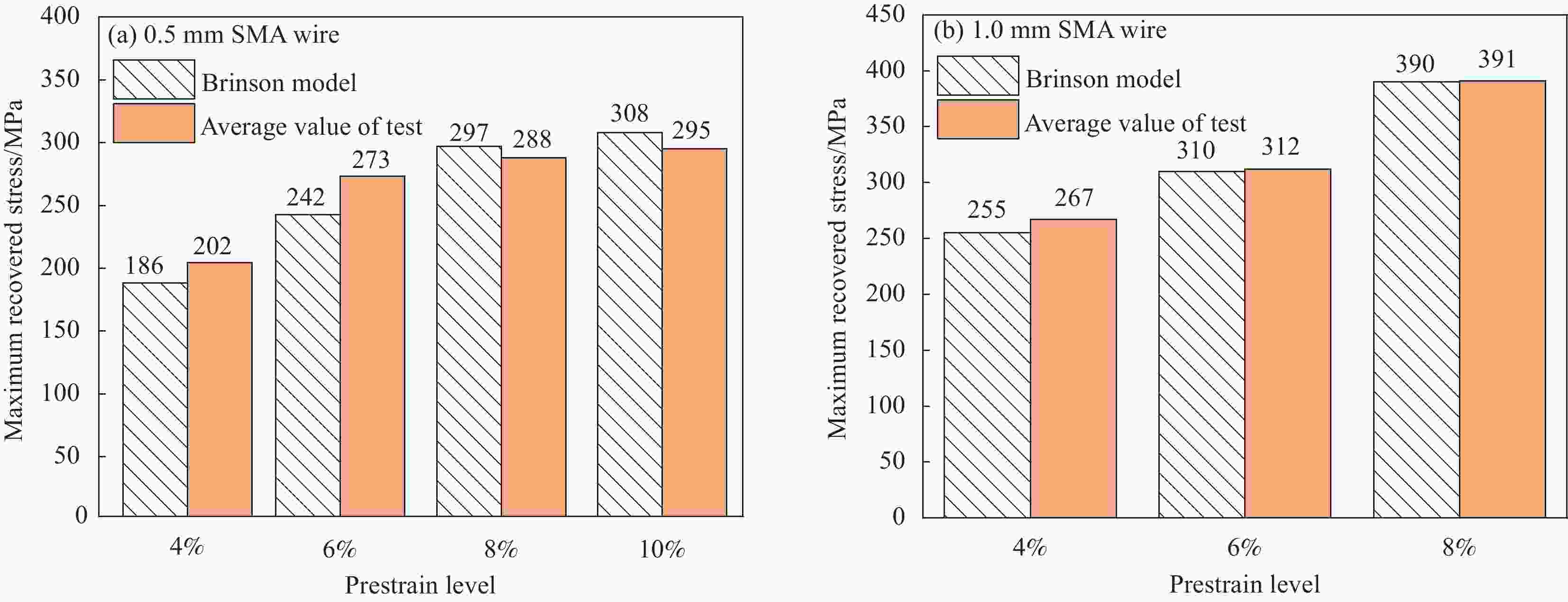

5-4%1 2206 2840 0.78 158.7 234.7 0.68 1.39 1.2 1.16 Longitudinal splitting 2 2617 0.92 186.9 0.80 1.40 1.17 3 2809 0.98 205.0 0.87 1.37 1.14 FRP/SMA-I-0.5-10-4% 1 2326 2697 0.86 169.7 222.9 0.76 1.32 1.2 1.10 Longitudinal splitting 2 2566 0.95 192.9 0.87 1.33 1.11 3 2828 1.05 212.6 0.95 1.28 1.07 FRP/SMA-I-0.5-15-4% 1 2602 3000 0.87 154.9 212.4 0.73 1.68 1.41 1.19 Burst failure 2 2992 1.04 188.4 0.89 1.65 1.17 3 2999 1.00 196.0 0.92 1.65 1.17 FRP/SMA-I-1.0-10-4% 1 1968 2078 0.95 145.8 171.8 0.85 1.35 1.2 1.13 Longitudinal splitting 2 2085 1.00 156.8 0.91 1.33 1.11 3 2039 0.98 156.8 0.91 1.30 1.08 Average value 0.95 0.85 1.13 Standard deviation 0.08 0.08 0.04 Coefficient of variation 0.08 0.09 0.04 表 4 SMA回复性能试验试件设计与试验结果

Table 4. Design and test results of SMA recovery test specimen

Specimen Length

of SMA/

mmDiameter of SMA/

mmPrestrain/

%Average value of

maximum recovery

stress/

MPaSMA-0.5-4% 200 0.5 4 202 SMA-0.5-6% 200 0.5 6 273 SMA-0.5-8% 200 0.5 8 288 SMA-0.5-10% 200 0.5 10 295 SMA-1.0-4% 200 1.0 4 267 SMA-1.0-6% 200 1.0 6 312 SMA-1.0-8% 200 1.0 8 391 表 5 FRP/SMA回复性能试验试件设计与试验结果

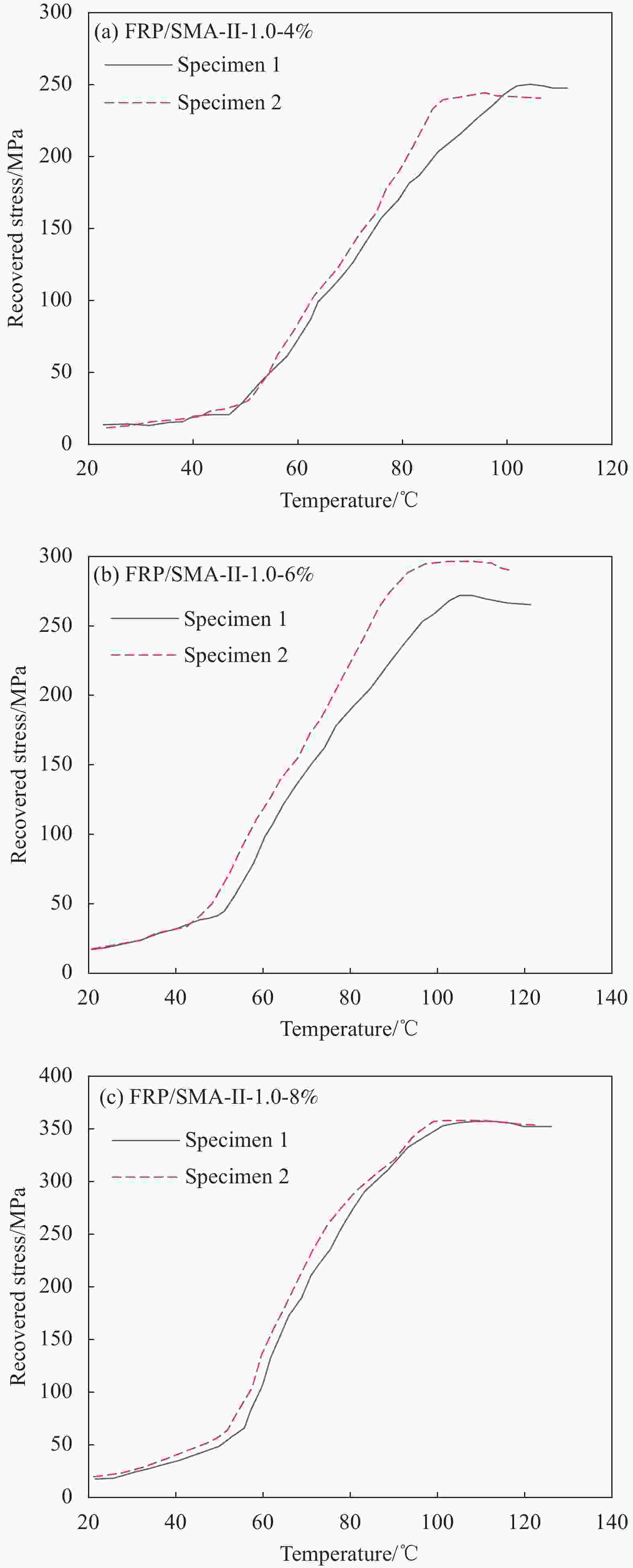

Table 5. FRP/SMA recovery test specimen design and test results

Specimen Length of activated section/

mmDiameter of SMA/

mmPrestrain/

%Average value of

maximum

recovery stress/MPaFRP/SMA-

II-1.0-4%150 1.0 4 247 FRP/SMA-

II-1.0-6%150 1.0 6 284 FRP/SMA-

II-1.0-8%150 1.0 8 358 -

[1] 吴智深, 汪昕, 吴刚, 等. FRP增强工程结构体系[M]. 北京: 科学出版社, 2017: 10-18.WU Zhishen, WANG Xin, WU Gang, et al. FRP reinforced engineering structural systems[M]. Beijing: Science Press, 2017: 10-18(in Chinese). [2] ZHENG Y Z, WANG W W, MOSALAM K M, et al. Experimental investigation and numerical analysis of RC beams shear strengthened with FRP/ECC composite layer[J]. Composite Structures,2020,246:112436. doi: 10.1016/j.compstruct.2020.112436 [3] ZHOU Y W, GAO H, HU Z H, et al. Ductile, durable, and reliable alternative to FRP bars for reinforcing seawater sea-sand recycled concrete beams: Steel/FRP composite bars[J]. Construction and Building Materials,2021,269:121264. doi: 10.1016/j.conbuildmat.2020.121264 [4] BASARAN B, KALKAN I. Investigation on variables affecting bond strength between FRP reinforcing bar and concrete by modified hinged beam tests[J]. Composite Structures,2020,242:112185. doi: 10.1016/j.compstruct.2020.112185 [5] KUERES S, WILL N, HEGGER J. Shear strength of prestressed FRP reinforced concrete beams with shear reinforcement[J]. Engineering Structures,2020,206:110088. doi: 10.1016/j.engstruct.2019.110088 [6] HUANG H, WANG W W, DAI J G, et al. Fatigue behavior of reinforced concrete beams strengthened with externally bonded prestressed CFRP sheets[J]. Journal of Compo-sites for Construction,2017,21(3):04016108. doi: 10.1061/(ASCE)CC.1943-5614.0000766 [7] RIUS J M, CLADERA A, RIBAS C, et al. Shear strengthening of reinforced concrete beams using shape memory alloys[J]. Construction and Building Materials,2019,200:420-435. doi: 10.1016/j.conbuildmat.2018.12.104 [8] ZHENG B T, EL-TAHAN M, DAWOOD M. Shape memory alloy-carbon fiber reinforced polymer system for strengthening fatigue-sensitive metallic structures[J]. Engineering Structures,2018,171:190-201. doi: 10.1016/j.engstruct.2018.05.046 [9] EL-TAHAN M, DAWOOD M. Fatigue behavior of a thermally-activated NiTiNb SMA-FRP patch[J]. Smart Materials and Structures,2015,25(1):015030. [10] CONCILIO A, ANTONUCCI V, AURICCHIO F, et al. Shape memory alloy engineering: For aerospace, structural and biomedical applications[M]. Amsterdam: Elsevier Ltd., 2015: 369-403. [11] XUE Y J, WANG W W, TAN X, et al. Mechanical behavior and recoverable properties of CFRP shape memory alloy composite under different prestrains[J]. Construction and Building Materials,2022,333:127186. doi: 10.1016/j.conbuildmat.2022.127186 [12] SHAHVERDI M, CZADERSKI C, MOTAVALLI M. Iron-based shape memory alloys for prestressed near-surface mounted strengthening of reinforced concrete beams[J]. Construction and Building Materials,2016,112(1):28-38. [13] TRAN H, BALANDRAUD X, DESTREBECQ J F. Recovery stresses in SMA wires for civil engineering applications: Experimental analysis and thermomechanical modelling[J]. Materials Science & Engineering Techology,2011,42(5):435-443. [14] ISSA A, ALAM M S. Comparative seismic fragility assessment of buckling restrained and self-centering (friction spring and SMA) braced frames[J]. Smart Materials and Structures,2020,29(5):055029. doi: 10.1088/1361-665X/ab7858 [15] CHEN Q W, ANDRAWES B. Cyclic stress–strain behavior of concrete confined with NiTiNb-shape memory alloy spirals[J]. Journal of Structural Engineering,2017,143(5):04017008. doi: 10.1061/(ASCE)ST.1943-541X.0001728 [16] SCHRANZ B, MICHELS J, CZADERSKI C, et al. Strengthening and prestressing of bridge decks with ribbed iron-based shape memory alloy bars[J]. Engineering Structures,2021,241:112467. doi: 10.1016/j.engstruct.2021.112467 [17] XUE Y J, WANG W W, WU Z H, et al. Experimental study on flexural behavior of RC beams strengthened with FRP/SMA composites[J]. Engineering Structures, 2023, 289: 116288. [18] ZAFAR A, ANDRAWES B. Seismic behavior of SMA-FRP reinforced concrete frames under sequential seismic hazard[J]. Engineering Structures,2015,98:163-173. doi: 10.1016/j.engstruct.2015.03.045 [19] ZHENG B T, DAWOOD M. Fatigue crack growth analysis of steel elements reinforced with shape memory alloy (SMA)/fiber reinforced polymer (FRP) composite patches[J]. Composite Structures,2017,164:158-169. doi: 10.1016/j.compstruct.2016.12.077 [20] ZHENG B, DAWOOD M. Fatigue strengthening of metallic structures with a thermally activated shape memory alloy fiber-reinforced polymer patch[J]. Journal of Composites for Construction,2017,21(4):04016113. doi: 10.1061/(ASCE)CC.1943-5614.0000776 [21] EL-TAHAN M, DAWOOD M, SONG G. Development of a self-stressing NiTiNb shape memory alloy (SMA)/fiber reinforced polymer (FRP) patch[J]. Smart Materials and Structures,2015,24(6):065035. doi: 10.1088/0964-1726/24/6/065035 [22] QIU Z X, YAO X T, YUAN J A, et al. Experimental research on strain monitoring in composite plates using embedded SMA wires[J]. Smart Materials and Structures, 2006, 15(4): 1047-1053. [23] WANG Y Q, ZHANG T, GUO S G, et al. Improvement and experimental research on the recovery stress-temperature model of NiTi shape memory alloys[J]. Rare Metal Materials and Engineering,2017,46(1):117-121. [24] DAWOOD M, EL-TAHAN M W, ZHENG B. Bond behavior of superelastic shape memory alloys to carbon fiber reinforced polymer composites[J]. Composites Part B: Engi-neering,2015,77:238-247. [25] HOLLAWAY L C. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties[J]. Construction and Building Materials, 2010, 24(12): 2419-2445. [26] EL-HACHA R, ALY M Y E. Anchorage system to prestress FRP laminates for flexural strengthening of steel-concrete composite girders[J]. Journal of Composites for Construction,2013,17(3):324-335. doi: 10.1061/(ASCE)CC.1943-5614.0000323 [27] ŞAKAR G, TANARSLAN H M. Prestressed CFRP fabrics for flexural strengthening of concrete beams with an easy prestressing technique[J]. Mechanics of Composite Materials, 2014, 50(4): 537-542. [28] 中华人民共和国住房与城乡建设部. 纤维增强复合材料建设工程应用技术规范: GB/T 50608—2020[S]. 北京: 中国计划出版社, 2010.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Technical specification for construction engineering application of fiber reinforced composite materials: GB/T 50608—2020[S]. Beijing: China Planning Press, 2010(in Chinese). [29] 中华人民共和国住房与城乡建设部. 树脂浇铸体拉伸性能试验方法: GB/T 2567—2008[S]. 北京: 中国计划出版社, 2008.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Test method for tensile properties of resin castings: GB/T 2567—2008[S]. Beijing: China Planning Press, 2008(in Chinese). [30] PATOOR E, LAGOUDAS D C, ENTCHEV P B, et al. Shape memory alloys, Part I: General properties and modeling of single crystals[J]. Mechanics of Materials,2006,38(5-6):391-429. doi: 10.1016/j.mechmat.2005.05.027 [31] BRINSON L C. One-dimensional constitutive behavior of shape memory alloys: Thermomechanical derivation with non-constant material functions and redefined martensite internal variable[J]. Journal of Intelligent Material Systems and Structures,1993,4(2):229-242. doi: 10.1177/1045389X9300400213 [32] BRINSON L C, HUANG M S. Simplifications and comparisons of shape memory alloy constitutive models[J]. Journal of Intelligent Material Systems and Structures, 1996, 7(1): 108-114. -

下载:

下载: