Effect of cold rolling deformation on microstructure and properties of Al2O3/Cu composites

-

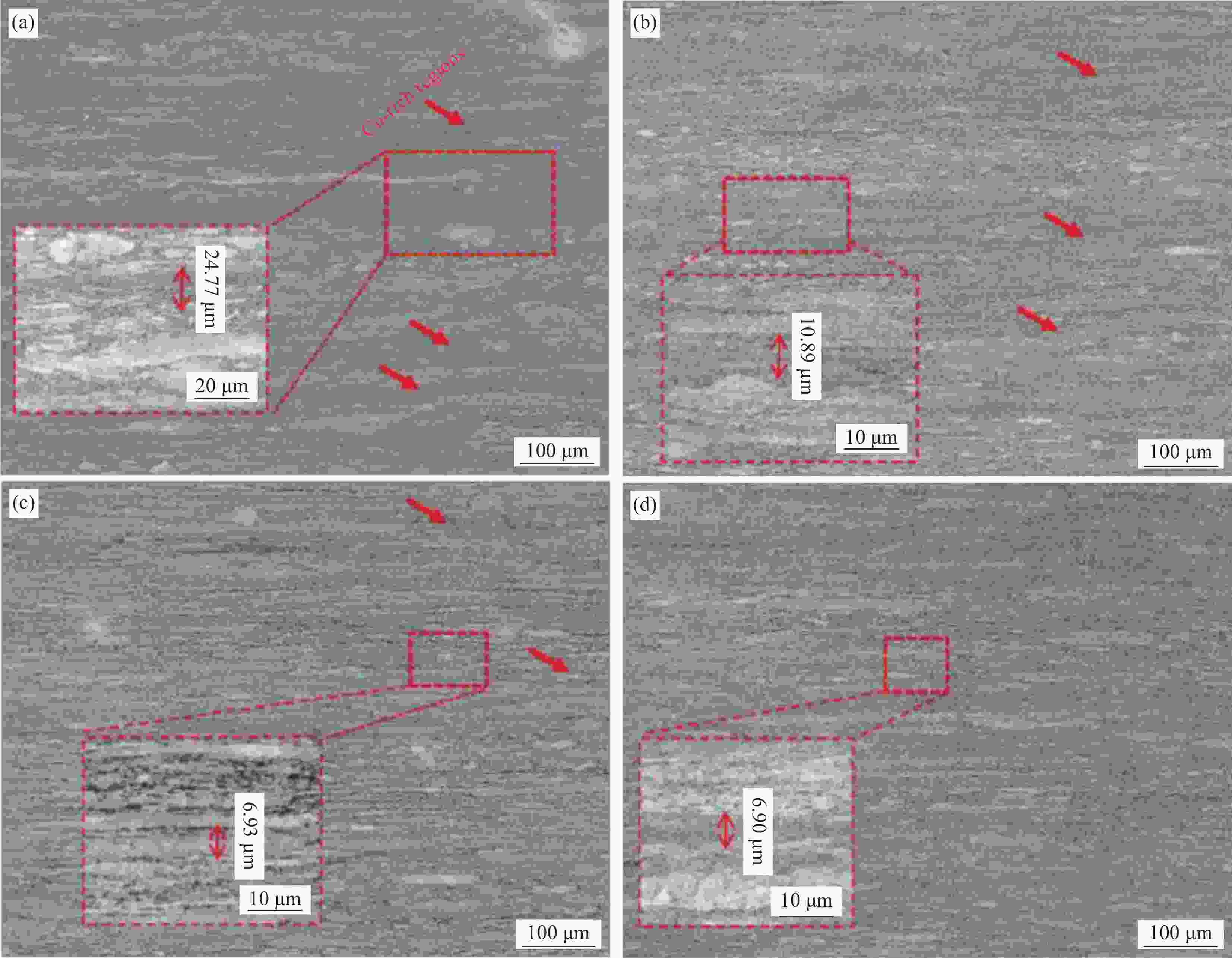

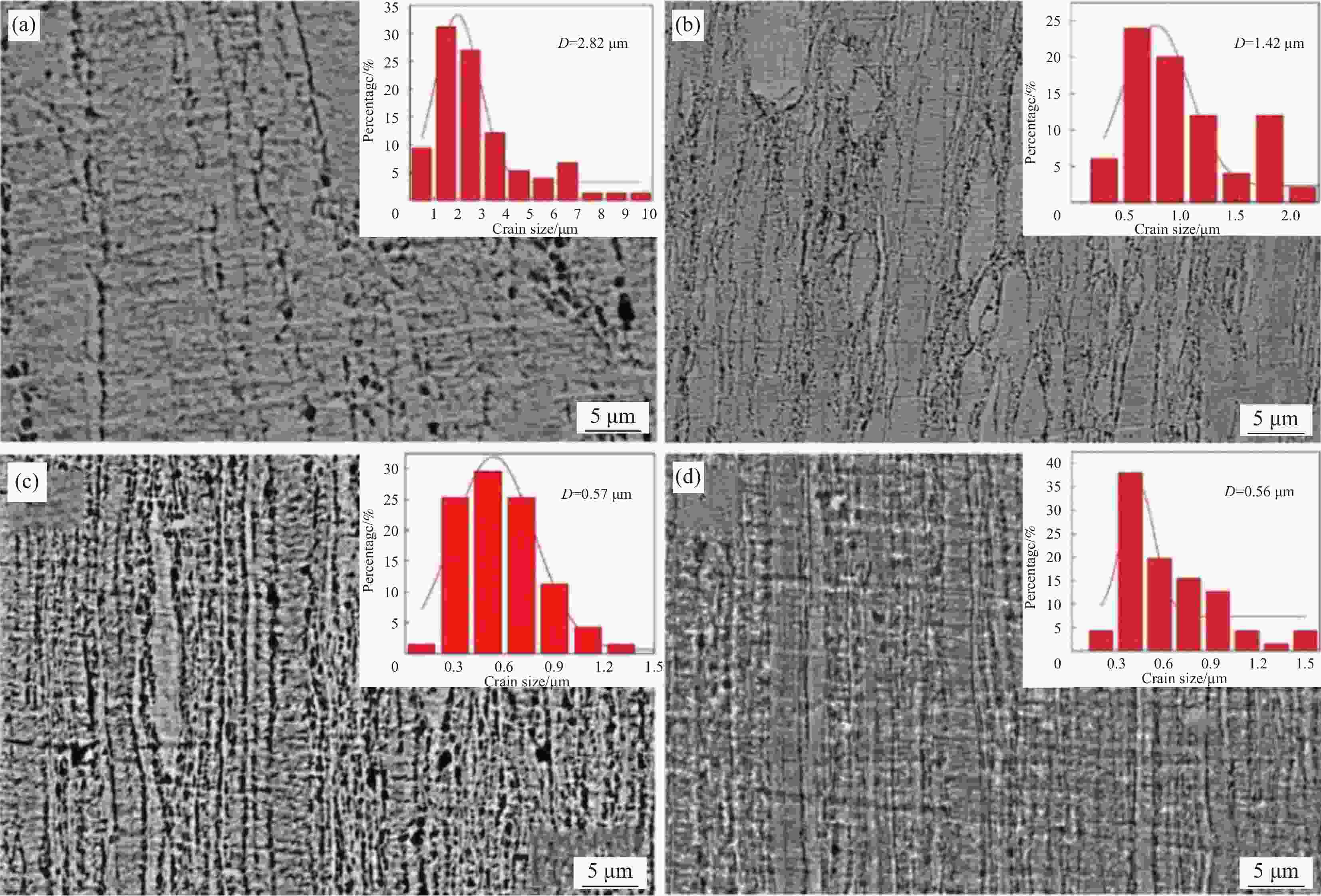

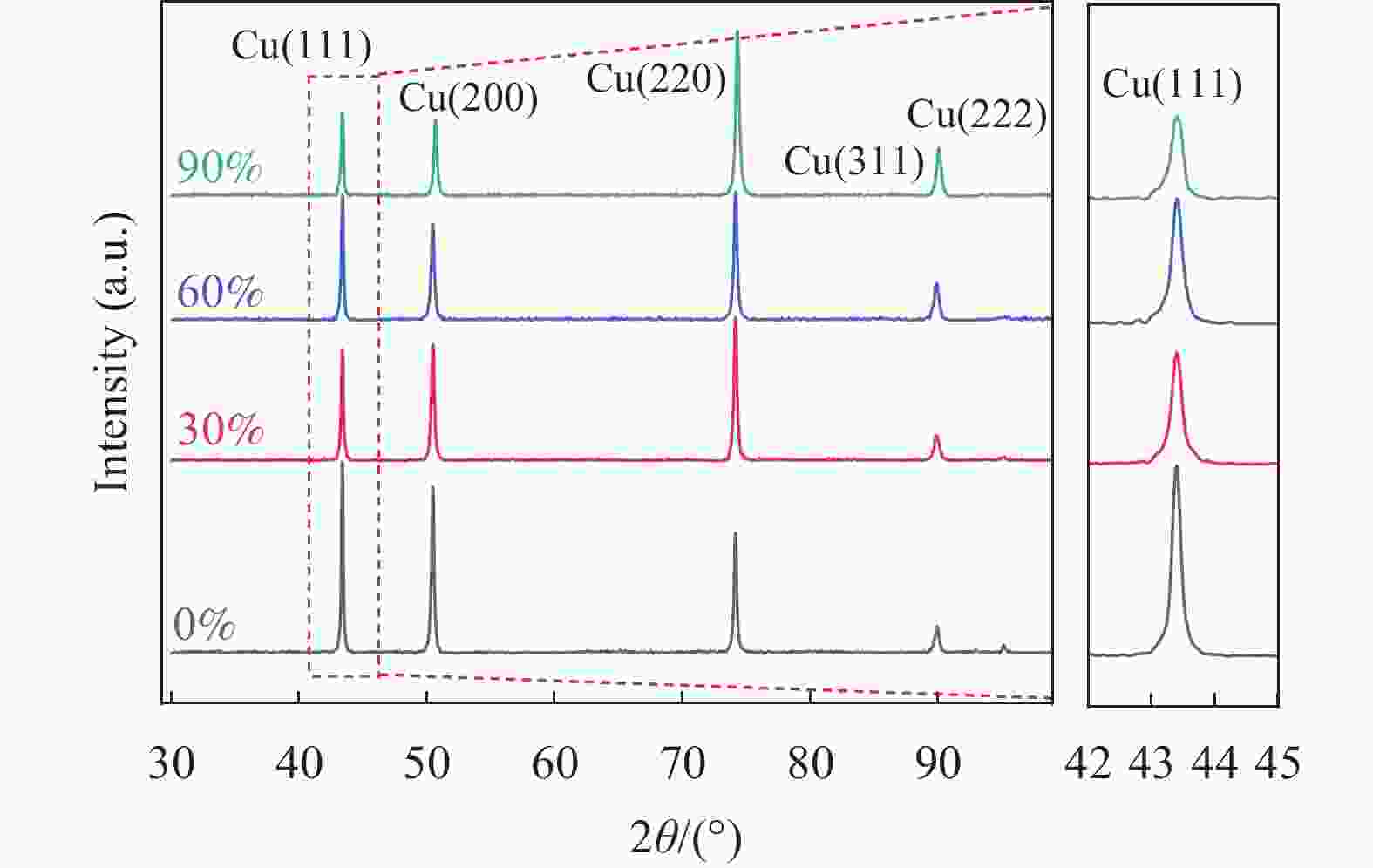

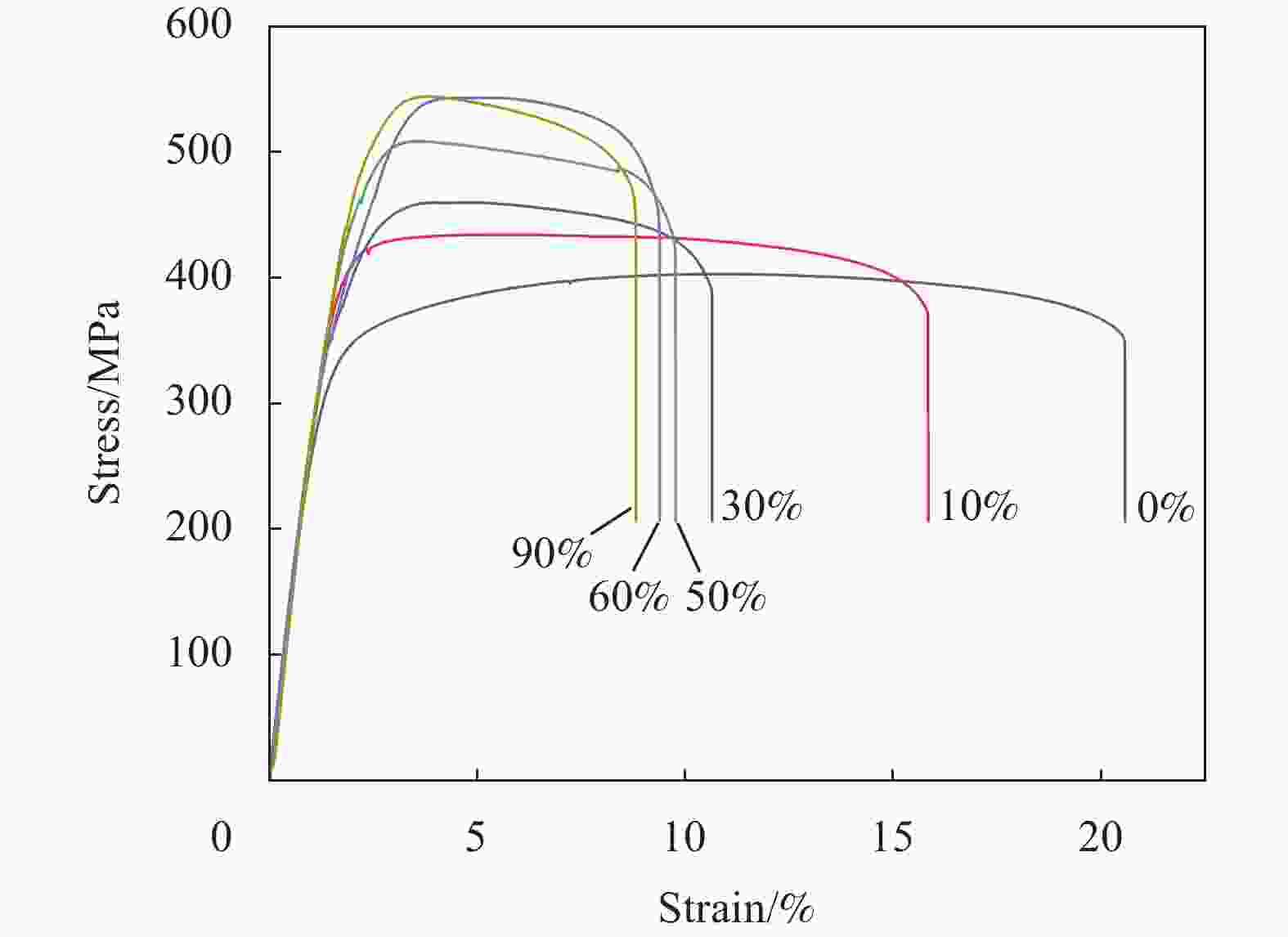

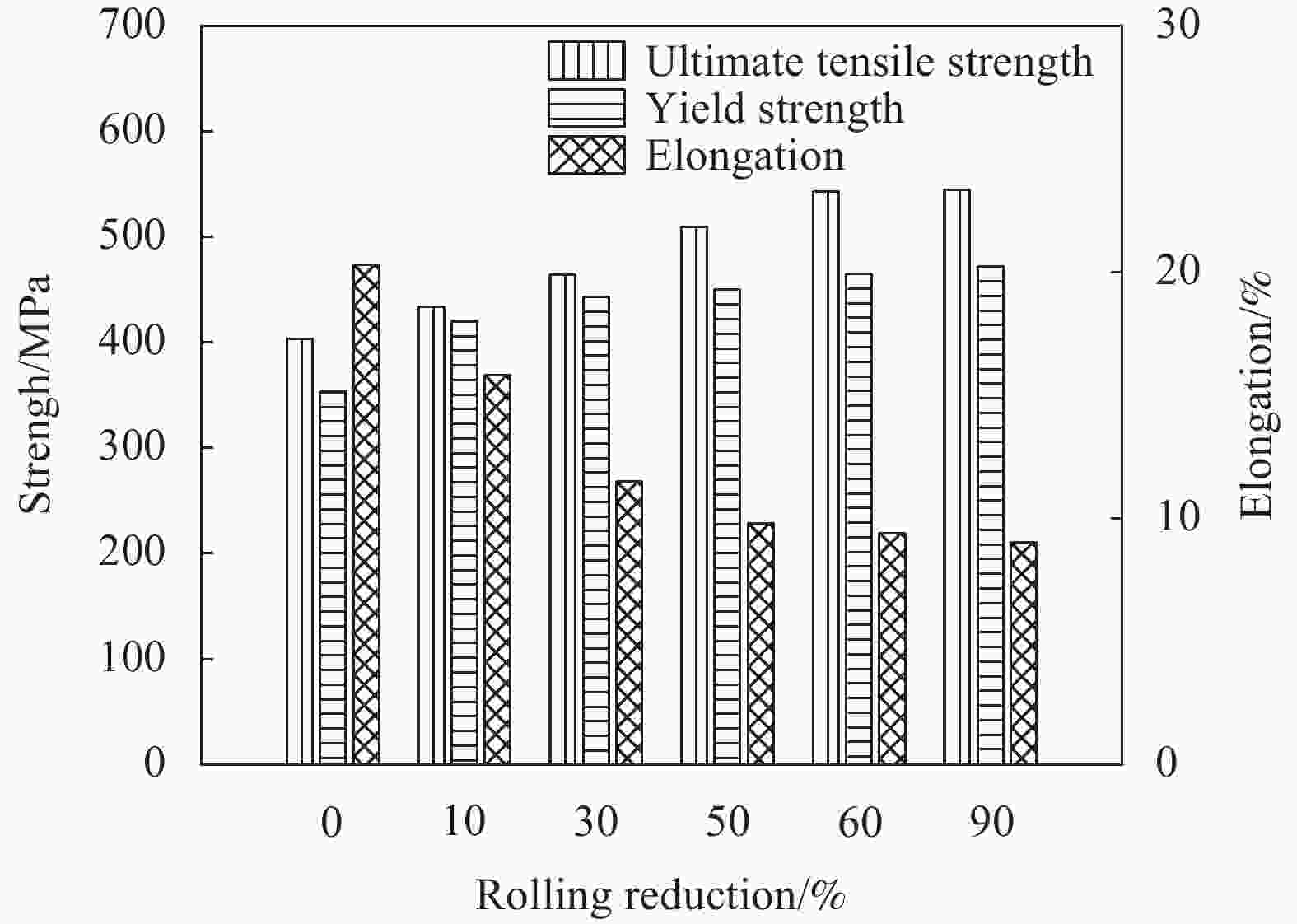

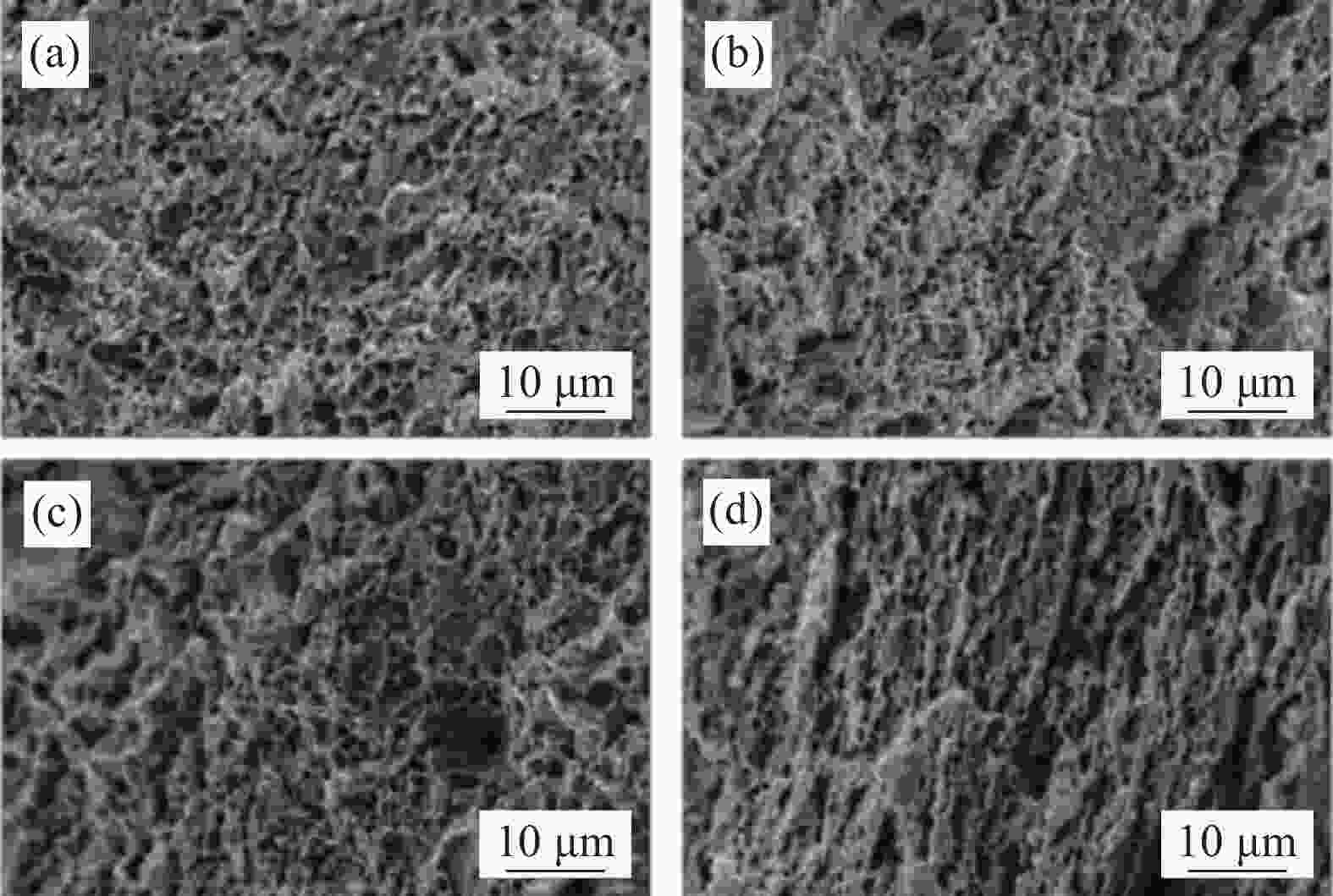

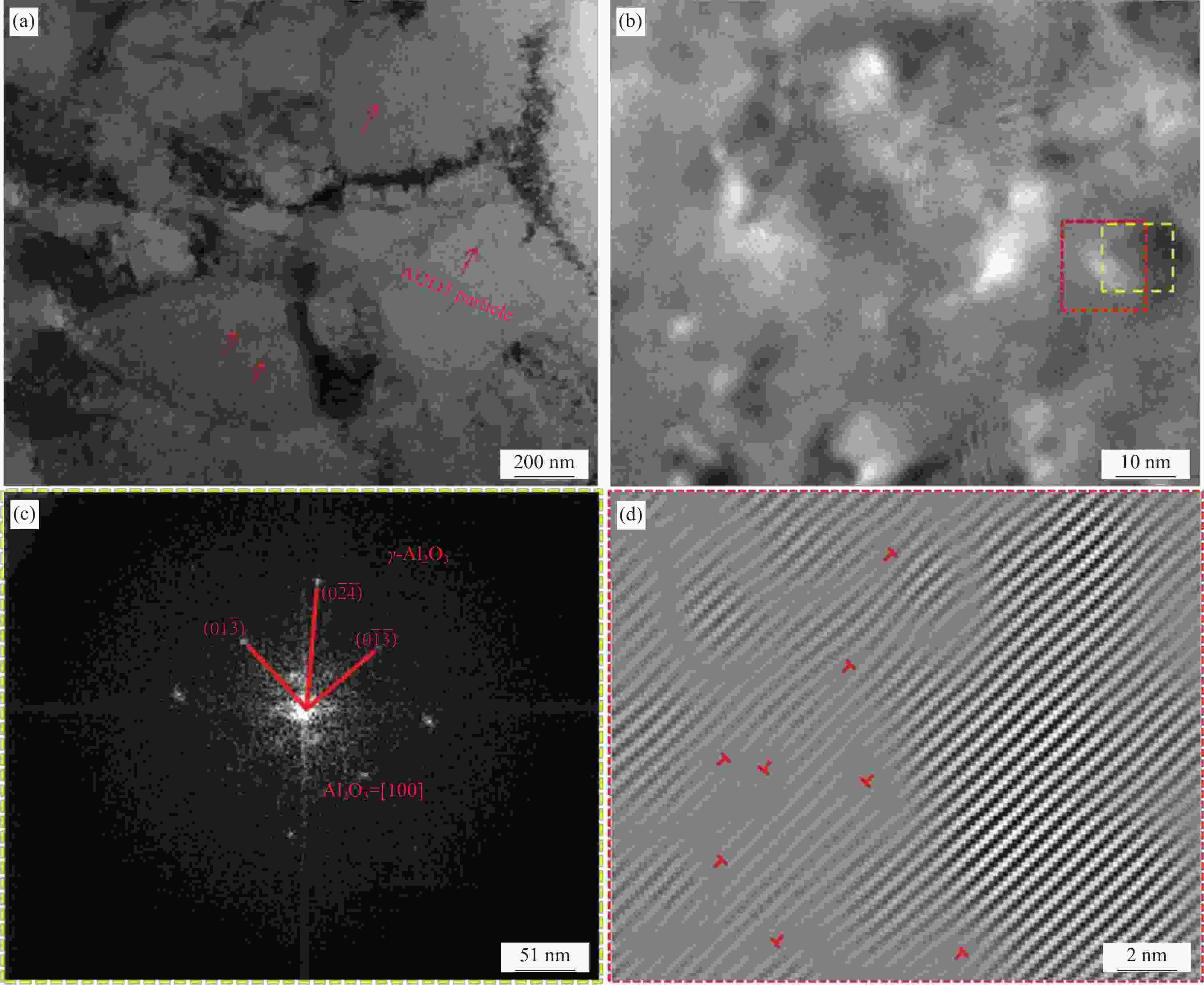

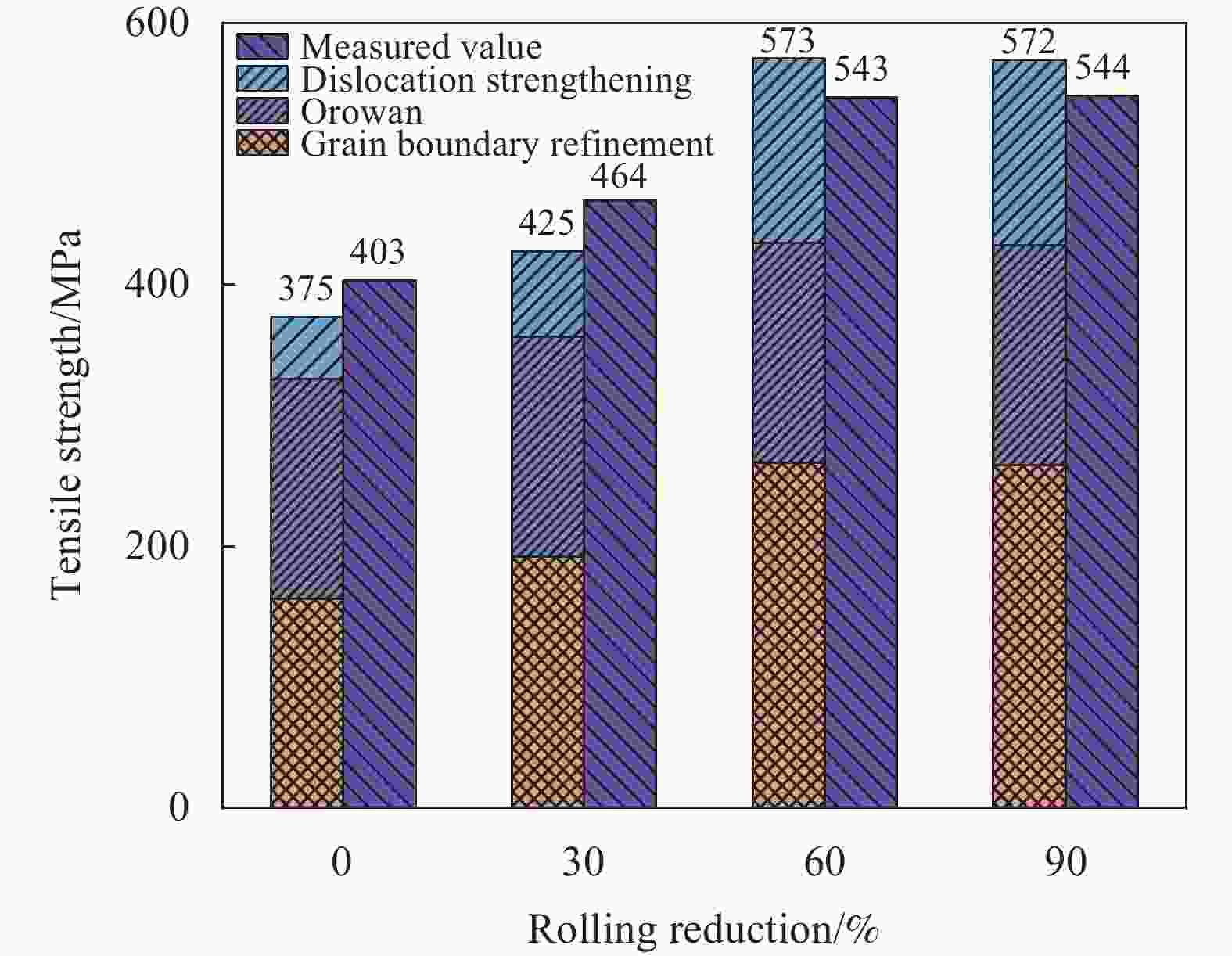

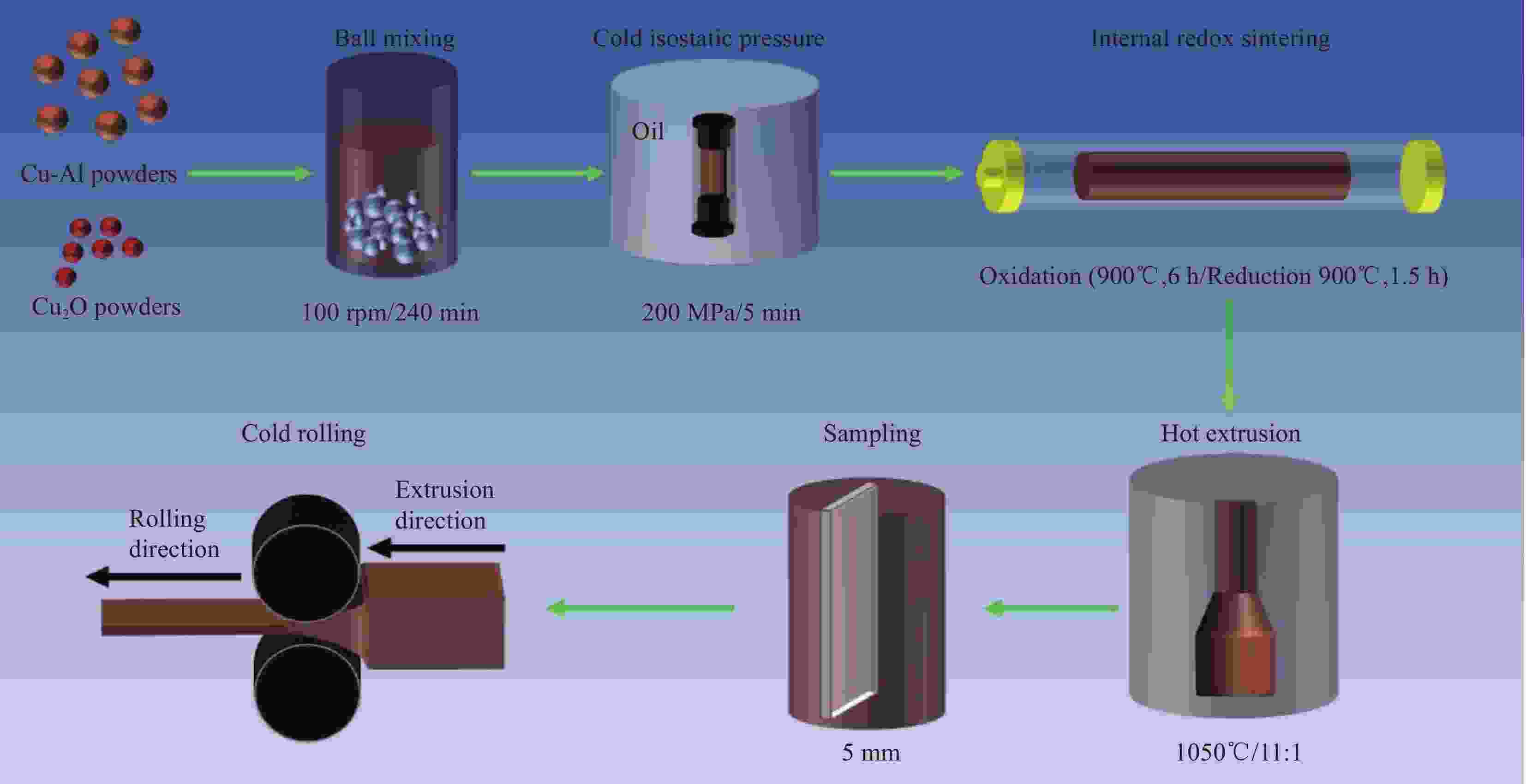

摘要: 为进一步提升Al2O3/Cu复合材料的力学性能,本文采用内氧化法制备了Cu-0.57wt%Al2O3 复合材料,研究了不同冷轧变形量对Al2O3/Cu复合材料的显微组织、导电率、力学性能的影响,重点探讨了不同变形量下复合材料强化机制的贡献。结果表明:随着冷轧变形量的增加,Al2O3/Cu复合材料的晶粒逐渐变为细长纤维状结构,平均晶粒尺寸由2.82 μm(原始态)减小到0.56 μm(90%变形量)。随着冷轧变形量的增加,Al2O3/Cu复合材料力学性能逐渐提升,60%变形量时达到峰值,强度和硬度分别为544 MPa和156 HV,分别提升了35% 和14%,而导电率仅从85%IACS减小到83%IACS。这是由于冷变形过程中,纳米级Al2O3颗粒与位错交互作用逐渐增强,晶界强化和位错强化对强度的贡献逐渐增大,分别由160 MPa增加到264 MPa和47 MPa增加到141 MPa。当变形量超过60%时,晶粒尺寸(0.56 μm)与位错密度(3.5×1014 m−2)趋于稳定,位错强化与晶界强化对强度的贡献达到顶峰,力学性能最佳。

-

关键词:

- Al2O3/Cu 复合材料 /

- 冷轧变形 /

- 力学性能 /

- 晶界强化 /

- 位错强化

Abstract: In order to further enhance the room temperature mechanical properties of Al2O3 composites, 0.57wt%Al2O3/Cu composites were prepared by internal oxidation method. The effects of different cold-rolling deformation on the microstructure, electrical conductivity, and mechanical properties of Al2O3/Cu composites were studied, focusing on the contribution of various strengthening mechanisms to the strength of composite under different amounts of deformation. The results show that the grains of Al2O3/Cu composites gradually change to elongated fiber-like structure with increasing cold rolling deformation, and the average grain size decreases from 2.82 μm (initial state) to 0.56 μm (90% deformation). The mechanical properties of the composites gradually improve with increasing cold rolling deformation, peaking at 60% deformation, with a strength of 544 MPa and a hardness of 156 HV, which are increased by 35% and 14%, respectively, while the electrical conductivity only decreases from 85 %IACS to 83 %IACS. This is due to the interaction between nanoscale Al2O3 particles and dislocations during cold deformation, grain boundary strengthening and dislocation strengthening gradually increase, and the calculated contributions values of grain boundary strengthening and dislocation strengthening increase from 160 MPa and 47 MPa to 264 MPa and 141 MPa, respectively. When the deformation exceeds 60%, the grain size (0.56μm) and dislocation density (3.5×1014m−2) tend to stabilize, the contribution of dislocation strengthening and grain boundary strengthening reaches its peak, and the mechanical properties are optimal. -

表 1 不同变形量下Al2O3/Cu复合材料的强化机制对抗拉强度的贡献

Table 1. Contribution of strengthening mechanism to tensile strength of Al2O3/Cu composites at different deformations

Rolling reduction/% ρ/1014m−2 σgb/MPa σor/MPa σdis/MPa Theoretical value /MPa Measured value/MPa Deviation/% 0 0.39 160 168 47 375 403 6.9 30 0.75 192 168 65 425 464 8.5 60 3.56 264 168 141 573 543 5.5 90 3.60 262 168 142 572 544 5.1 Notes: ρ is the dislocation density, σgb is the grain boundary strengthening, σor is the orowan strengthening, σdis is the dislocation strengthening. -

[1] CHANDRASEKHAR S B, RAMAKRISHNA M, WASEKAR N P, et al. Grain boundary and grain interior strengthening in nano-micron grain sized Cu-1wt. %Al2O3 composite[J]. Materials Science and Technology, 2023, 39(11): 1313-1321 doi: 10.1080/02670836.2023.2165653 [2] 高翔, 罗丰华, 谭永菊, 等. 内氧化-冷轧制备Al2O3弥散强化铜合金的组织与性能[J]. 中国有色金属学报, 2010, 20(10): 2019-2024.GAO Xiang, LUO Feng-hua, TAN Yong-ju, et al. Microstructure and properties of A12O3 dispersion strengthened copper alloys prepared by internal oxidation and cold rolling[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 2019-2024(in Chinese). [3] 杨豫博, 国秀花, 宋克兴, 等. CNTs 添加对 Cu-Al2O3 复合材料耐电弧侵蚀性能的影响[J]. 复合材料学报, 2023, 40(1): 280-289.YANG Yubo, GUO Xiuhua, SONG Kexing, et al. Arc erosion resistance of Cu-Al2O3 composite effected by CNTs[J]. Acta Materiae Compositae Sinica, 2023, 40(1): 280-289(in Chinese). [4] ZHANG X, YUAN Y, ZHAO S, et al. Microstructure stability, softening temperature and strengthening mechanism of pure copper, CuCrZr and Cu-Al2O3 up to 1000 ℃[J]. Nuclear Materials and Energy, 2022, 30: 101123. doi: 10.1016/j.nme.2022.101123 [5] WANG X, LI J, ZHANG Y, et al. Improvement of interfacial bonding and mechanical properties of Cu-Al2O3 composite by Cr-nanoparticle-induced interfacial modification[J]. Journal of Alloys and Compounds, 2017, 695: 2124-2130. doi: 10.1016/j.jallcom.2016.11.055 [6] 罗骥, 曹慧钦, 贾步超, 等. 新型铜基受电弓滑板材料的制备与性能[J]. 复合材料学报, 2012, (2): 103-108.LUO Ji, CAO Huiqin, JIA Buchao, et al. Preparation and properties of the new type copper matrix pantograph slider[J]. Acta Materiae Compositae Sinica, 2012, (2): 103-108(in Chinese). [7] 李周, 肖柱, 姜雁斌, 等. 高强导电铜合金的成分设计、相变与制备[J]. 中国有色金属学报, 2019, 29(9): 2009-2049.LI Zhou, XIAO Zhu, JIANG Yanbin, et al. Composition design, phase transformation and preparation of high strength conductive copper alloy[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(9): 2009-2049(in Chinese). [8] ZHOU D, WANG X, MURÁNSKY O, et al. Heterogeneous microstructure of an Al2O3 dispersion strengthened Cu by spark plasma sintering and extrusion and its effect on tensile properties and electrical conductivity[J]. Materials Science and Engineering: A, 2018, 730: 328-335. doi: 10.1016/j.msea.2018.06.010 [9] YE T N. A novel approach for strengthening Cu–Y2O3 composites by in situ reaction at liquidus temperature[J]. Materials Science and Engineering: A, 2013, 584: 1-6. doi: 10.1016/j.msea.2013.07.007 [10] 程建奕, 汪明朴, 李周. Cu-0.54Al2O3弥散强化铜合金的拉伸变形和断裂行为[J]. 复合材料学报, 2004, 21(3): 157-161. doi: 10.3321/j.issn:1000-3851.2004.03.030CHENG Jianyi, WANG Mingpu, LI Zhou. Tensile deformation and fracture behavior of Cu-0.54Al2O3 dispersion strengthened copper alloy[J]. Acta Materiae Compositae Sinica, 2004, 21(3): 157-161(in Chinese). doi: 10.3321/j.issn:1000-3851.2004.03.030 [11] 林焕然, 国秀花, 宋克兴, 等. (WC+SiCw)/Cu-Al2O3复合材料载流摩擦磨损行为[J]. 表面技术, 2022, 51(1): 33-42.LIN Huan-ran, GUO Xiu-hua, SONG Ke-xing, et al. Current carrying friction and wear behavior of (WC+SiCw)/Cu-Al2O3 composites[J]. Surface Technology, 2022, 51(1): 33-42(in Chinese). [12] REN F Z, LI Y J, ZHANG D W, et al. Preparation of Cu-Al2O3 composite bulk by internal oxidation of Cu-Al alloy sheets[J]. Cailiao Rechuli Xuebao/Transactions of Materials and Heat Treatment, 2015, 36(5): 45-48. [13] LEE J, KIM Y C, LEE S, et al. Correlation of the microstructure and mechanical properties of oxide-dispersion-strengthened coppers fabricated by internal oxidation[J]. Metallurgical & Materials Transactions A, 2004, 35(2): 493-502. [14] WANG CHANGSHENG F H, ZHANG HONGTAO, XIE JIANXIN. Effect of Cold-Rolling Deformation on Microstructure, Properties, and Precipitation Behavior of High-Performance Cu-Ni-Si Alloys[J]. Acta Metall Sin, 2023, 59(5): 585-598. [15] 张雪辉, 李晓闲, 刘位江, 等. 冷加工变形量对Al2O3-弥散强化铜合金组织与性能的影响[J]. 中国有色金属学报, 2018, 28(4): 705-711.ZHANG Xue-hui, LI Xiao-xian, LIU Wei-jiang, et al. Effect of cold deformation on microstructures and properties of Al2O3-dispersion strengthened copper[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(4): 705-711(in Chinese). [16] GUO M X, WANG M P, CAO L F, et al. Work softening characterization of alumina dispersion strengthened copper alloys[J]. Materials Characterization, 2007, 58(10): 928-935. doi: 10.1016/j.matchar.2006.09.005 [17] 李亚明, 李文生, 李文有等. 冷变形与时效对Cu-15Cr-Ce原位复合材料组织和性能的影响[J]. 中国稀土学报, 1-102023-12-20 LI Yaming, Li Wensheng, Li Wenyou et al. Effect of cold deformation and aging treatment on micro structure and properties for Cu-15Cr-Ce in-situ composites[J]. Journal of the Chinese Society of Rare Earths, 1-10[2023-12-20] (in Chinese). [18] 陆东梅, 杨瑞霞, 王清周. 掺杂纳米 SnO2-Al2O3/Cu新型电触头复合材料的制备及耐磨性能[J]. 复合材料学报, 2016, 33(12): 2815-2823.LU DM, YANG R X, WANG Q Z. Fabricationandwearresistancesofdopednano-SnO2-Al2O3/Cu novel electrical contact composites.[J]. Acta Materiae Compositae Sinica, 2016, 33(12): 2815-2823(in Chinese). [19] 张明晨, 郭瑞鹏, 张勇. 高熵硬质合金WC-AlCo0.4CrFeNi2.7的制备及表征[J]. 材料导报, 2024, 38(4): 168-173. doi: 10.11896/cldb.22060288ZHANG Mingchen, GUO Ruipeng, ZHANG Yong et al. Preparation and Characterization of High-entropy Cemented CarbideWC-AlCo0.4CrFeNi2.7.[J]. Materials Reports, 2024, 38(4): 168-173(in Chinese). doi: 10.11896/cldb.22060288 [20] DONG Y, WANG X, XIE Y, et al. Tunable microstructures and tensile mechanical properties of oxide-dispersion-strengthened Cu by extrusion and secondary processing[J]. Journal of Alloys and Compounds, 2020, 812: 152112 doi: 10.1016/j.jallcom.2019.152112 [21] 赵郅磊, 李周, 肖柱. Cu-3.6%Al2O3铜合金细丝加工过程中组织结构演变规律[J]. 中国有色金属学报, 2017, 27(03): 486-495.ZHAO Zhi-lei, LI Zhou, XIAO Zhu Structure evolution of Cu-3.6%Al2O3 alloy fine wire during cold drawing [J] The Chinese Journal of Nonferrous Metals, 2017, 27(03): 486-495. (in Chinese). [22] CHEN W, GAO G, MENG X, et al. Microstructure, properties and strengthening mechanism of Cu-TiB2-Al2O3 composite prepared by liquid phase in-situ reaction casting[J]. Journal of Alloys and Compounds, 2022, 912: 165170. doi: 10.1016/j.jallcom.2022.165170 [23] GUOBIN L, JIBING S, QUANMEI G, et al. Fabrication of the nanometer Al2O3/Cu composite by internal oxidation[J]. Journal of Materials Processing Technology, 2005, (1/2): 170,336-370. [24] 刘德宝, 崔春翔. TiN颗粒增强铜基复合材料的制备及性能研究[J]. 稀有金属, 2004, (5): 856-861. doi: 10.3969/j.issn.0258-7076.2004.05.011LIU Debao, Cui Chunxiang. Fabrication and Properties of TiN Particle-Reinforced Copper Matrix Composites[J]. CHINESE JOURNAL OF RARE METALS, 2004, (5): 856-861(in Chinese). doi: 10.3969/j.issn.0258-7076.2004.05.011 [25] 毛西秦. 热处理及形变对纯铜组织和性能的影响[D]. 贵州大学, 2021.MAO Xiqin. Effect of heat treatment and deformation on the organization and properties of pure copper[D]. Guizhou University, 2021. (in Chinese). [26] 郭明星. 不同浓度Cu-Al2O3弥散强化铜合金冷加工及退火行为的研究 [D]. 中南大学, 2005.GUO Mingxing. Study on cold working and annealing behavior of copper alloys strengthened by dispersion of Cu-Al2O3 at different concentrations [D]. Central South University, 2005 (in Chinese). [27] ZHUO H O and TANG J C and YE N. A novel approach for strengthening Cu–Y2O3 composites by in situ reaction at liquidus temperature[J]. Materials Science and Engineering: A, 2013, 584: 1-10. doi: 10.1016/j.msea.2013.07.007 [28] LI C, XIE Y, ZHOU D, et al. A novel way for fabricating ultrafine grained Cu-4.5 vol% Al2O3 composite with high strength and electrical conductivity[J]. Materials Characterization, 2019, 155: 109775. doi: 10.1016/j.matchar.2019.06.017 [29] ZHANG X-H, LI X-X, CHEN H, et al. Investigation on microstructure and properties of Cu–Al2O3 composites fabricated by a novel in-situ reactive synthesis[J]. Materials & Design, 2016, 92: 58-63. [30] 李忠华, 易健宏, 游昕, 等. 氮化硼纳米片增强铜基复合材料的界面调控与性能[J]. 复合材料学报, 2023, 41: 1-10.LI Zhonghua, YI Jianhong, YOU Xin, et al. Interface regulation and properties of boron nitride nanosheets reinforced copper matrix composites[J]. Acta Materiae Compositae Sinica, 2023, 41: 1-10(in Chinese). [31] HUANG K, ZHAO Q, LI Y, et al. Two-stage annealing of a cold-rolled Al–Mn–Fe–Si alloy with different microchemistry states[J]. Journal of Materials Processing Technology, 2015, 221: 87-99. doi: 10.1016/j.jmatprotec.2015.02.016 [32] WANG F, LI Y, YAMANAKA K, et al, Influence of Two-step Ball-Milling Condition on Electrical and Mechanical Properties of TiC-Dispersion-Strengthened Cu Alloys, Mater. Design, 2014, 64: 441–449. [33] SYLVAIN, QUEYREAU, et al. Orowan strengthening and forest hardening superposition examined by dislocation dynamics simulations[J]. Acta Materialia, 2010, 58(17): 5586-5595. doi: 10.1016/j.actamat.2010.06.028 [34] MA K, WEN H, HU T, et al. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy[J]. Acta Materialia, 2014, 62(5): 141-155. [35] HUANRAN L, XIUHUA G, KEXING S, et al. Synergistic strengthening effect of tungsten carbide (WC) particles and silicon carbide whiskers (SiCw[1]) on mechanical properties of Cu–Al2O3 composite[J]. Journal of Materials Research and Technology, 2021, 15: 2837-2847. doi: 10.1016/j.jmrt.2021.09.103 [36] FENG X, ZHANG D, FENG B, et al. Microstructure and Properties of Cu-0.4 wt. % Al2O3 Composites Fabricated by Hot Extrusion and Cold Drawing[J]. 2022, 31(2): 1241-1249. [37] 袁继慧, 陈辉明, 谢伟滨, 等. Cu-Cr-Ti-Si合金加工软化的机理[J]. 材料工程, 2020, 48(11): 140-146. doi: 10.11868/j.issn.1001-4381.2019.000173YUAN Jihui, Chen Huiming, XIE Weibin et al. Work-softening mechanism of Cu-Cr-Ti-Sialloy[J]. Journal of Materials Engineering, 2020, 48(11): 140-146(in Chinese). doi: 10.11868/j.issn.1001-4381.2019.000173 -

点击查看大图

点击查看大图

计量

- 文章访问数: 111

- HTML全文浏览量: 81

- 被引次数: 0

下载:

下载: