Preparation and properties of carbon nanotubes/ silicon microwave absorbing aerogel and its composite

-

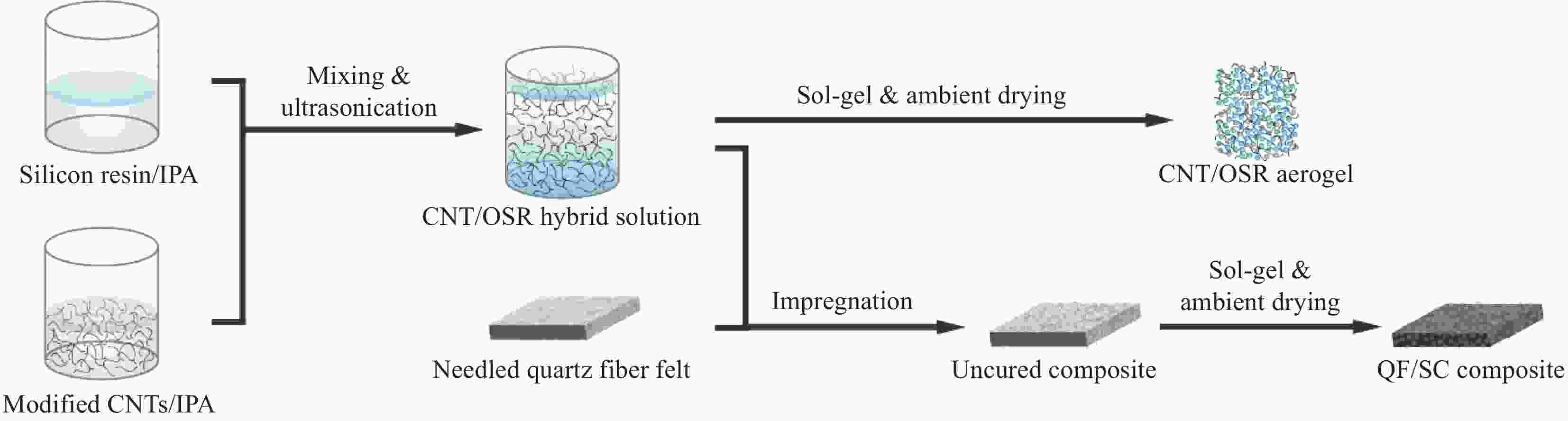

摘要: 基于溶胶-凝胶方法,制备不同比例多壁碳纳米管改性有机硅树脂(CNT/OSR)气凝胶和针刺石英纤维增强CNT/有机硅树脂气凝胶(QF/SC)复合材料,探究CNT含量对有机硅气凝胶及其复合材料的微观结构、防热性能和吸波性能的影响规律。研究结果表明:进行物理修饰后的CNT与有机硅树脂表现出良好的相容性,构建起了微导电、导热通道;改性后树脂的热稳定性有了明显提升,当CNT的质量分数为有机硅树脂的15wt%时,Td10提升111.1℃;QF/SC复合材料热导率在0.054~0.075 W/(m·K)之间,经600 s表面温度达1000℃的烧蚀后,最大背温为145.1℃;引入碳纳米管的QF/SC复合材料介电性能显著提高,实测8~18 GHz内反射率峰值和有效带宽分别达到−29 dB和3 GHz。该项工作有望在航空航天科学和工业领域实现新的应用。Abstract: Utilizing the sol-gel method, this study presents the fabrication of carbon nanotubes/organic silicon resin (CNT/OSR) aerogels and quartz fibre-reinforced CNT/silicon (QF/SC) composites incorporating varying proportions of multi-wall carbon nanotubes. The investigation focuses on discerning the influence of CNT content on the microstructural, thermal, and wave absorption properties of silicone aerogels and their composites. Results demonstrate the favorable compatibility of modified CNT with silicone resin, facilitating the establishment of micro-conductive and thermal conductive pathways. Remarkable enhancement in thermal stability of the modified resin is observed, notably with a 111.1℃ increase in Td10 when the CNT mass fraction constitutes 15wt% of the silicone resin. Moreover, the thermal conductivity of QF/SC composites spans from 0.054 to 0.075 W/(m·K), with a maximum rear temperature of 145.1℃ attained after 600 s exposure at 1000℃. Furthermore, the introduction of carbon nanotubes substantially augments the dielectric properties of QF/SC composites, leading to peak reflectance and effective bandwidth measurements within the range of 8-18 GHz, registering at -29 dB and 3 GHz, respectively. This research anticipates fostering novel applications in aerospace science and industry.

-

Key words:

- Silicone resin /

- carbon nanotubes /

- aerogel /

- microwave absorption /

- thermal protection

-

表 1 不同CNT含量的CNT/OSR气凝胶的性能参数

Table 1. Properties of CNT/OSR aerogels prepared at different content of CNT

Samples Density/

(g·cm−3)Average pore

diameter/nmSpecific pore

area/(m2·g−1)Td10 a/℃ Tmax b/℃ Residues/(900℃,%) S-0 0.3985 56.02 112.19 486.02 494.07 71.59 SC-2 0.3833 63.50 106.78 525.80 522.86 73.58 SC-5 0.3659 137.39 58.33 545.92 540.13 77.83 SC-10 0.3427 239.70 34.28 558.21 560.28 81.23 SC-15 0.3212 368.20 23.14 597.14 573.24 83.52 Notes:Td10 is the temperature corresponds to 10% weight loss of the materials; Tmax is the temperature corresponds to the maximum pyrolysis rate of the materials. 表 2 不同QF/SC复合材料的基本性能数据

Table 2. Density and thermal conductivity of QF/SC composites

Samples Density/

(g·cm−3)Thermal conductivity/

(W/(m·K)−1)QF/S-0 0.42663 0.054 QF/SC-2 0.42114 0.064 QF/SC-5 0.41384 0.069 QF/SC-10 0.39702 0.075 QF/SC-15 0.37182 0.064 -

[1] 冯志海, 师建军, 孔磊, 等. 航天飞行器热防护系统低密度烧蚀防热材料研究进展[J]. 材料工程, 2020, 48(8): 14-24. doi: 10.11868/j.issn.1001-4381.2020.000206FENG Zhihai, SHI Jianjun, KONG Lei, et al. Research progress in low-density ablative materials for thermal protection system of aerospace flight vehicles[J]. Journal of Materials Engineering, 2020, 48(8): 14-24(in Chinese). doi: 10.11868/j.issn.1001-4381.2020.000206 [2] 梁彩云, 王志江. 耐高温吸波材料的研究进展[J]. 航空材料学报, 2018, 38(3): 1-9. doi: 10.11868/j.issn.1005-5053.2018.001010LIANG Caiyun, WANG Zhijiang. Research Progress of High Temperature Microwave Absorption Materials[J]. Journal of Aeronautical Materials, 2018, 38(3): 1-9(in Chinese). doi: 10.11868/j.issn.1005-5053.2018.001010 [3] 黄文润. 硅烷偶联剂及硅树脂[M]. 四川科学技术出版社, 2010.HUANG Wenrun. Silane Coupling Agent and Silicone Resin [M]. Sichuan: Publishing House of Science & Technology, 2010(in Chinese). [4] 宋若康, 张梦珊, 戴珍, 等. 烧蚀型防热_吸波多功能一体化复合材料的制备及性能[J]. 2023.SONG Ruokang, ZHANG Mengshan, DAI Zhen, et al. Preparation and properties of multi-functional composite integrated with heat-shielding and radar-absorbing[J]. Acta Materiae Compositae Sinica, 2023(in Chinese). [5] 陈轲, 刘鸣飞, 赵彪, 等. 有机硅改性高分子材料阻燃及耐烧蚀性能研究进展[J]. 中国塑料, 2022, 36(6): 149-154.CHEN Ke, LIU Mingfei, ZHAO Biao, et al. Research progress in flame retardancy and ablation resistance of silicone-modified polymeric materials[J]. China Plastics, 2022, 36(6): 149-154(in Chinese). [6] 代广富, 裴勇兵, 褚俊涵, 等. 有机硅树脂耐高温改性方法及机制研究进展[J]. 高分子材料科学与工程, 2022, 38(3): 174-182.DAI Guanfu, PEI Yongbing, ZHU Junhan, et al. Progress in Modification Methods and Mechanisms of Silicone Resins for High Temperature Resistance[J]. Polymer Materials Science and Engineering, 2022, 38(3): 174-182(in Chinese). [7] HUADONG ZHANG, ZHONGYI YAN, ZHIZHOU YANG, et al. Study on the synthesis and thermal stability of silicone resins reinforced by si–o–ph cross-linking[J]. RSC Advances, 2021, 11(49): 30971-30979. doi: 10.1039/D1RA05524K [8] LIN TONG, YAKAI FENG, XUJUN SUN, et al. High refractive index adamantane-based silicone resins for the encapsulation of light-emitting diodes[J]. Polymers for Advanced Technologies, 2018, 29(8): 2245-2252. doi: 10.1002/pat.4335 [9] ZHIFENG HAO, JIN ZHANG, YAHONG WU, et al. Synthesis and thermal stability properties of boron-doped silicone resin[J]. Journal of Applied Polymer Science, 2014, 131(20): app. 40934. [10] 马嘉浩, 邓祚主, 展喜兵, 等. 高折射率钛杂化硅树脂制备及性能研究[J]. 中国胶粘剂, 2019, 28(2): 6-11+25.MA Jiahao, DENG Zuozhu, ZHAN Xibing, et al. Preparation and properties of titanium hybrid silicone resin with high refractive index[J]. China Adhesives, 2019, 28(2): 6-11+25(in Chinese). [11] 陆静娟, 杨辉, 郭兴忠, 等. 硅铝溶胶改性甲基硅树脂耐划伤薄膜[J]. 陶瓷学报, 2006, (1): 63-67. doi: 10.3969/j.issn.1000-2278.2006.01.014LU Jingjuan, YANG Hui, GUO Xingzhong, et al. The Abrasion-resistant Film of Methylsilicone Modified by Boehmite and Silica Sol[J]. Journal of Ceramics, 2006, (1): 63-67(in Chinese). doi: 10.3969/j.issn.1000-2278.2006.01.014 [12] QIAN WU, JING JIANG, FEI XIE, et al. Novel hybrid silicone resin composites with excellent low dielectric and high temperature mechanical properties[J]. Composites Communications, 2022, 35: 101288. doi: 10.1016/j.coco.2022.101288 [13] MENGQIU JIA, CHAOBO WU, WEI LI, et al. Synthesis and characterization of a silicone resin with silphenylene units in si-o-si backbones[J]. Journal of Applied Polymer Science, 2009, 114(2): 971-977. doi: 10.1002/app.30635 [14] PEI HUANG, HAN-QIAO SHI, HONG-MEI XIAO, et al. High performance surface-modified tio2/silicone nanocomposite[J]. Scientific Reports, 2017, 7(1): 5951. doi: 10.1038/s41598-017-05166-7 [15] YAOYUAN XU, JUN LONG, RUNZE ZHANG, et al. Greatly improving thermal stability of silicone resins by modification with poss[J]. Polymer Degradation and Stability, 2020, 174: 109082. doi: 10.1016/j.polymdegradstab.2020.109082 [16] CONSTANCE ROBEYNS, LOÏC PICARD, FRANÇOIS GANACHAUD. Synthesis, characterization and modification of silicone resins: an “augmented review”[J]. Progress in Organic Coatings, 2018, 125: 287-315. doi: 10.1016/j.porgcoat.2018.03.025 [17] ZHAOQUN PAN, KELIN ZENG, BINGSHENG HUANG, et al. A new dealcoholization method in the synthesis of vinyl methyl phenyl silicone resins for led encapsulation[J]. Silicon, 2020, 12(12): 3005-3013. doi: 10.1007/s12633-020-00396-3 [18] ZHIDONG HAN, ALBERTO FINA. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: a review[J]. Progress in Polymer Science, 2011, 36(7): 914-944. doi: 10.1016/j.progpolymsci.2010.11.004 [19] JUNWEI YUE, YIYU FENG, MENGMENG QIN, et al. Carbon-based materials with combined functions of thermal management and electromagnetic protection: preparation, mechanisms, properties, and applications[J/OL]. Nano Research, 2023[2024–01–07]. [20] 王一帆, 朱琳, 韩露, 等. 电磁吸波材料的研究现状与发展趋势[J]. 复合材料学报, 2023, 40(1): 1-12.WANG Yifan, ZHU Lin, HAN Lu, et al. Research status and development trend of electromagnetic absorbing materials[J]. Acta Materiae Compositae Sinica, 2023, 40(1): 1-12(in Chinese). [21] 董晓娜, 廖孝光, 游胜勇, 等. 多壁碳纳米管/硅树脂复合材料的导热性能研究[J]. 热固性树脂, 2017, 32(2): 8-11.DONG Xiaona, LIAO Xiaoguang, YOU Shengyong, et al. Study on the thermal conductivity of multiwall carbon nanotubes / silicone resin composites[J]. Thermosetting Resin, 2017, 32(2): 8-11(in Chinese). [22] 吴昊, 蔡炜, 王利民, 等. 超声分散法制备碳纳米管/有机硅树脂复合材料及其性能研究[J]. 化工新型材料, 2015, 43(5): 35-37.WU Hao, CAI Wei, WANG Limin, et al. Study on preparation and property of carbon nanotube/silicon resin composite by ultrasonic dispersion method[J]. New Chemical Materials, 2015, 43(5): 35-37(in Chinese). [23] ASGAR HUSEYNOV, AYDIN ISRAFILOV, SAMIRA MAMMADOVA, et al. Impact of mw-cnt/polymer composites matrix type on the electrical and gas-sensitive properties[J]. Journal of Composite Materials, 2023, 57: 002199832311705. [24] SADHANA AGRAWAL, K. S. OJHA, DILIP SAHU. Structural and dielectric studies of mwcnt reinforced microcellular silicone elastomer nanocomposite[J]. Materials Today: Proceedings, 2015, 2(9, Part A): 4516–4520. [25] 中国人民解放军总装备部. 雷达吸波材料反射率测试方法: GJB 2038A-2011 [S]. 北京: 中国标准出版社, 2011.The General Reserve Department. The measurement methods for reflectivity of radar absorbing material: GJB 2038A-2011 [S]. Beijing: China Standards Press, 2011(in Chinese). [26] 罗伟, 王林生, 陈裕欣, 等. 有机-无机复合气凝胶的制备及其阻燃性能研究进展[J]. 复合材料学报, 2021, 38(7): 2056-2069.LUO Wei, WANG Linsheng, CHEN Yuxin, et al. Research progress on preparation and flame retardant properties of organic-inorganic composite aerogel[J]. Acta Materiae Compositae Sinica, 2021, 38(7): 2056-2069(in Chinese). [27] 贾献峰, 陈伟, 马成, 等. 常压干燥制备酚醛树脂基炭气凝胶研究进展[J]. 化学通报, 2021, 84(3): 194-203.JIA Xianfeng, CHEN Wei, MA Cheng, et al. Research Progress in the Preparation of Phenolic Resin Based Carbon Aerogels via Ambient Pressure Drying[J]. Huaxue Tongbao, 2021, 84(3): 194-203(in Chinese). [28] BAHLOUL-HOURLIER D, LATOURNERIE J, DEMPSEY P. Reaction pathways during the thermal conversion of polysiloxane precursors into oxycarbide ceramics[J]. Journal of the European Ceramic Society, 2005, 25(7): 979-985. doi: 10.1016/j.jeurceramsoc.2004.05.012 [29] 师建军, 李弘瑜, 张凌东, 等. 烧蚀型防隔热/隐身多功能复合材料制备与性能[J]. 宇航材料工艺, 2021, 51(6): 59-64. doi: 10.12044/j.issn.1007-2330.2021.06.010SHI Jianjun, LI Hongyu, ZHANG Lingdong, et al. Preparation and Properties of Multi-Functional Composite Integrated With Heat-Shieling, Insulating and Radar-Absorbing[J]. Aerospace Materials & Technology, 2021, 51(6): 59-64(in Chinese). doi: 10.12044/j.issn.1007-2330.2021.06.010 [30] JINBO CHENG, HAIGANG SHI, MIN CAO, et al. Porous carbon materials for microwave absorption[J]. Materials Advances, 2020, 1(8): 2631-2645. doi: 10.1039/D0MA00662A [31] ZHANG Y, ZHOU W, CHEN H, et al. Facile preparation of cnts microspheres as improved carbon absorbers for high-efficiency electromagnetic wave absorption[J]. Ceramics International, 2021, 47(7, Part A): 10013–10018. [32] MAURIZIO NATALI, JOSE MARIA KENNY, LUIGI TORRE. Science and technology of polymeric ablative materials for thermal protection systems and propulsion devices: a review[J]. Progress in Materials Science, 2016, 84: 192-275. doi: 10.1016/j.pmatsci.2016.08.003 -

点击查看大图

点击查看大图

计量

- 文章访问数: 100

- HTML全文浏览量: 54

- 被引次数: 0

下载:

下载: