Preparation of corn stover-based lignin-cellulose acetate ultraviolet shielding film and its properties

-

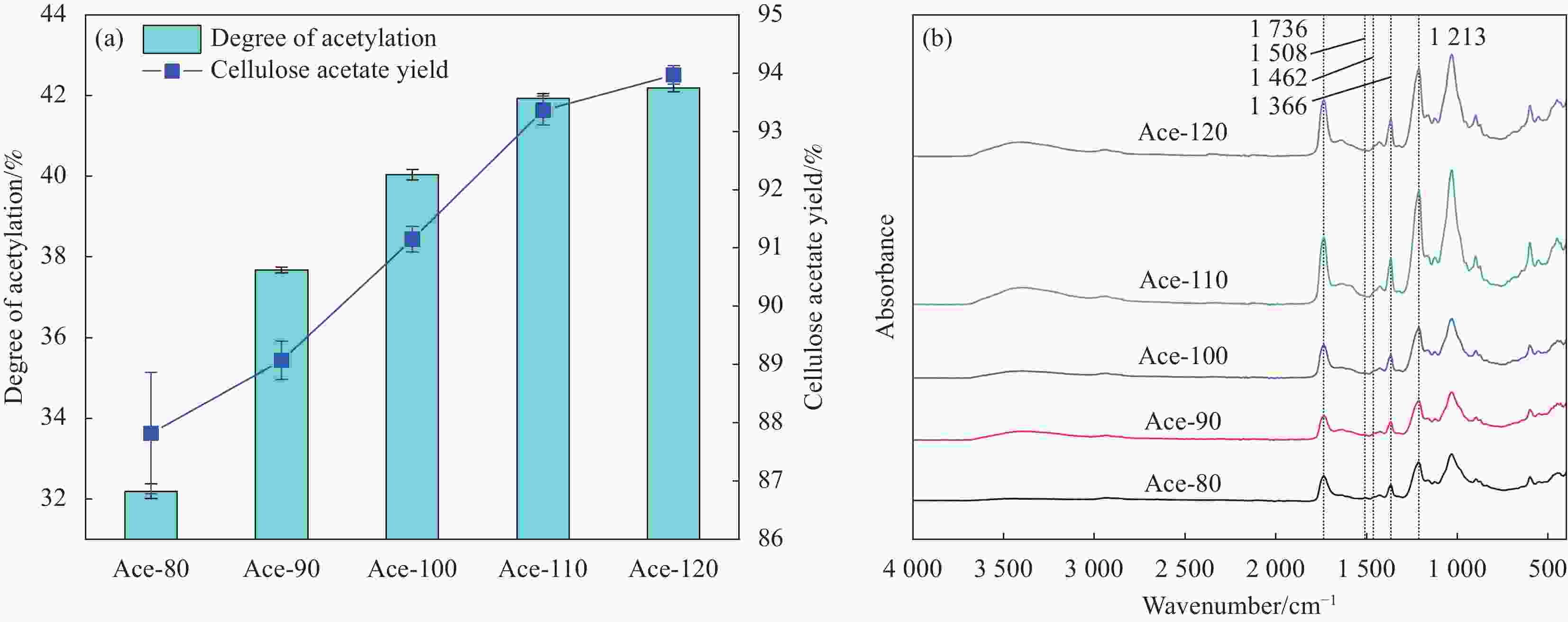

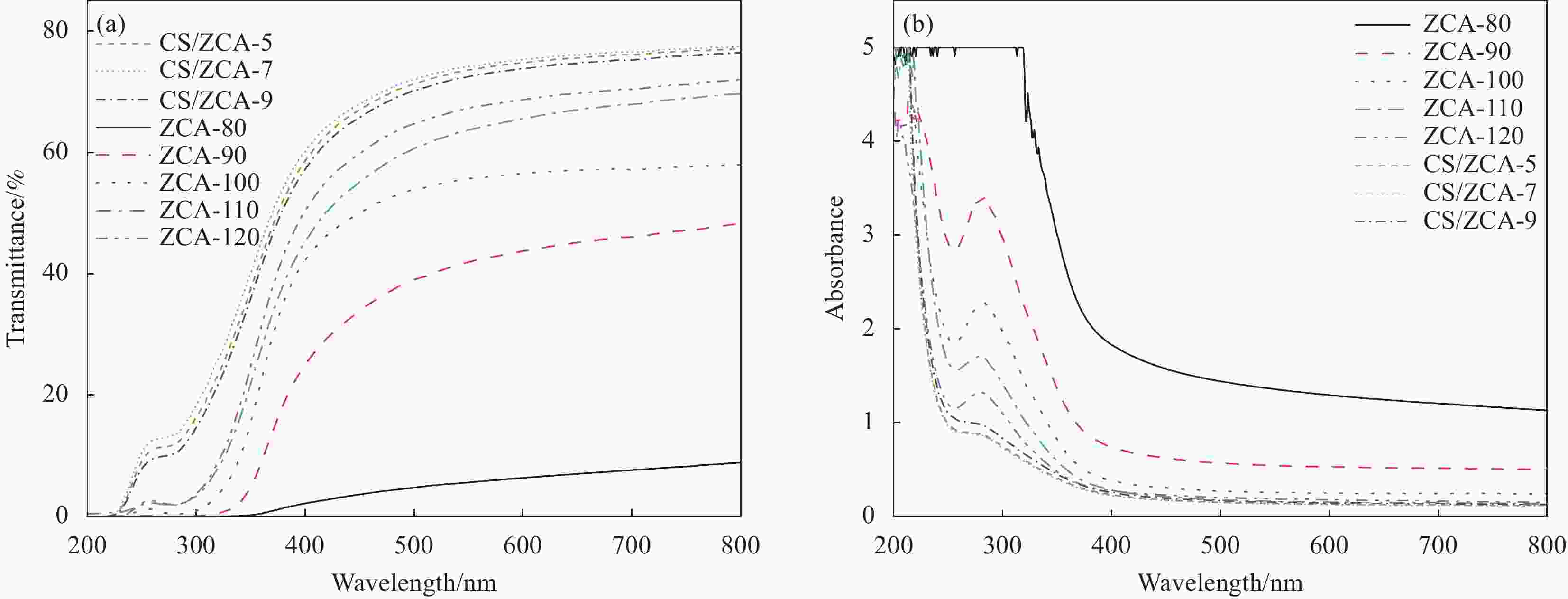

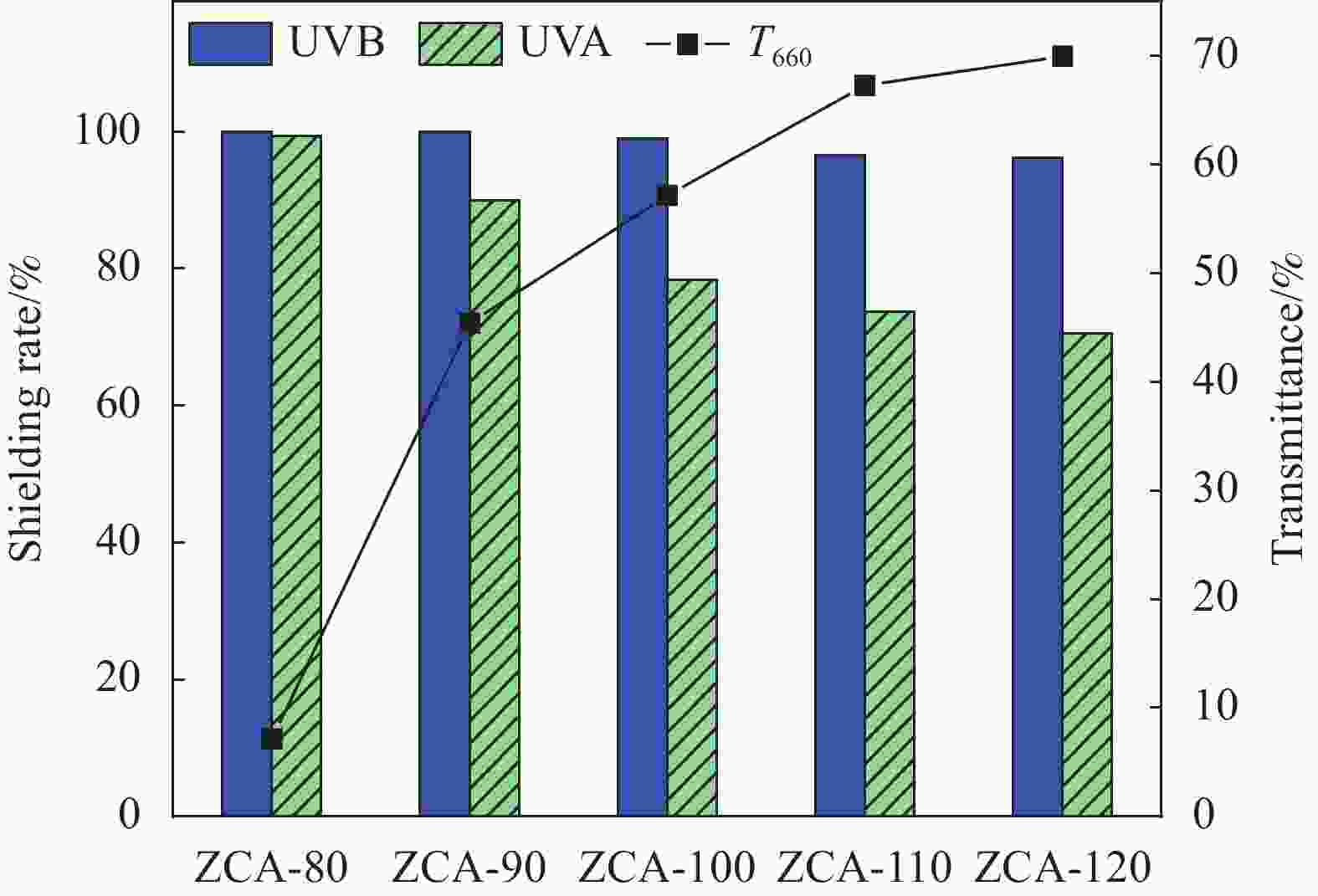

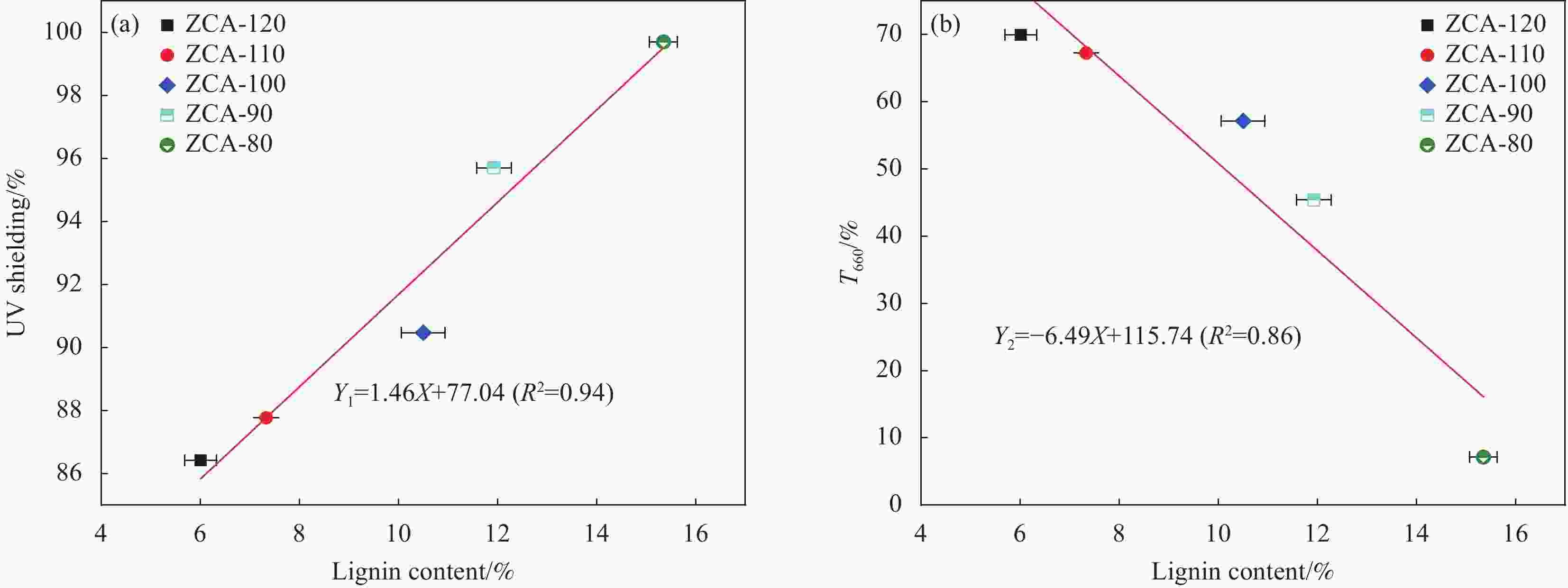

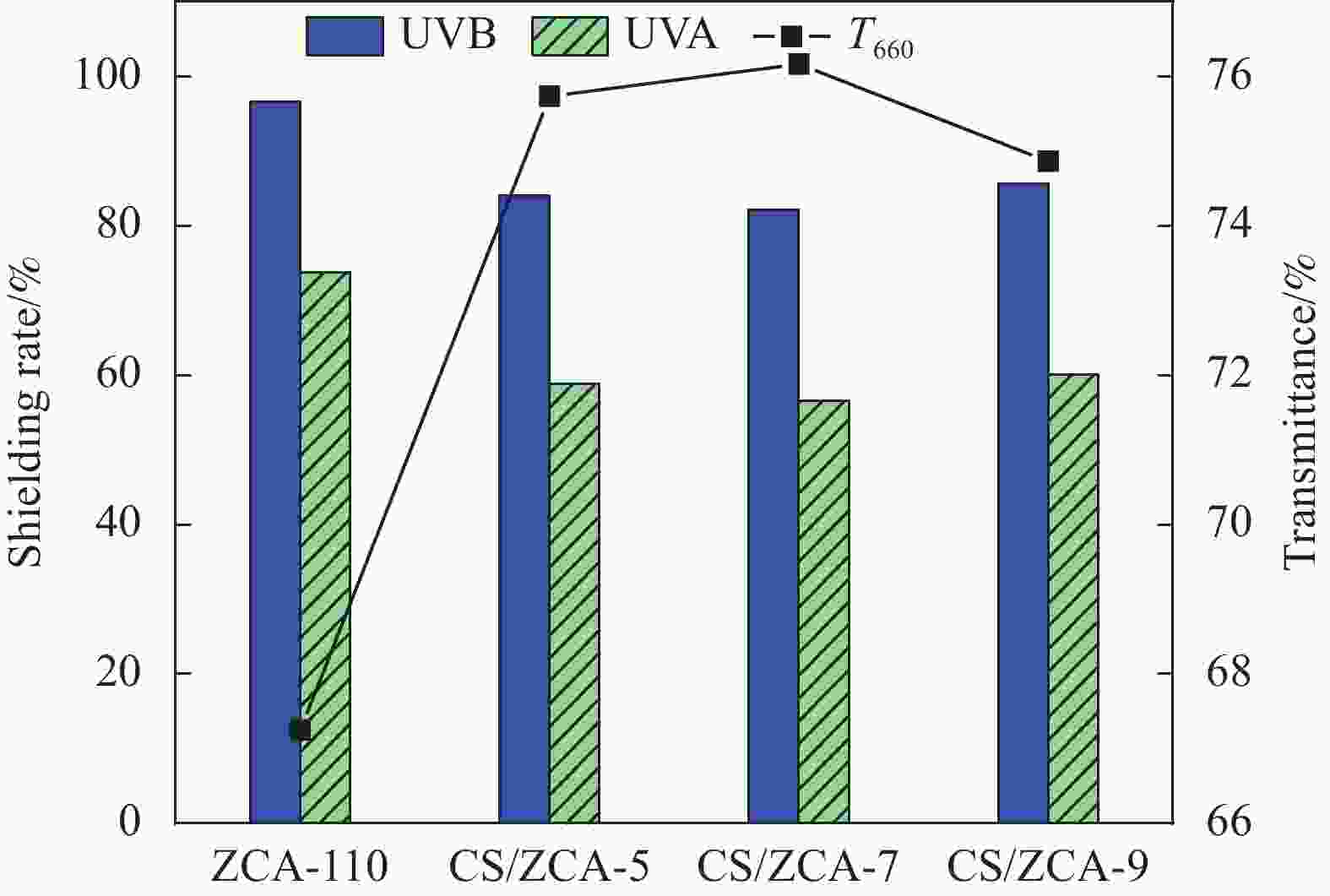

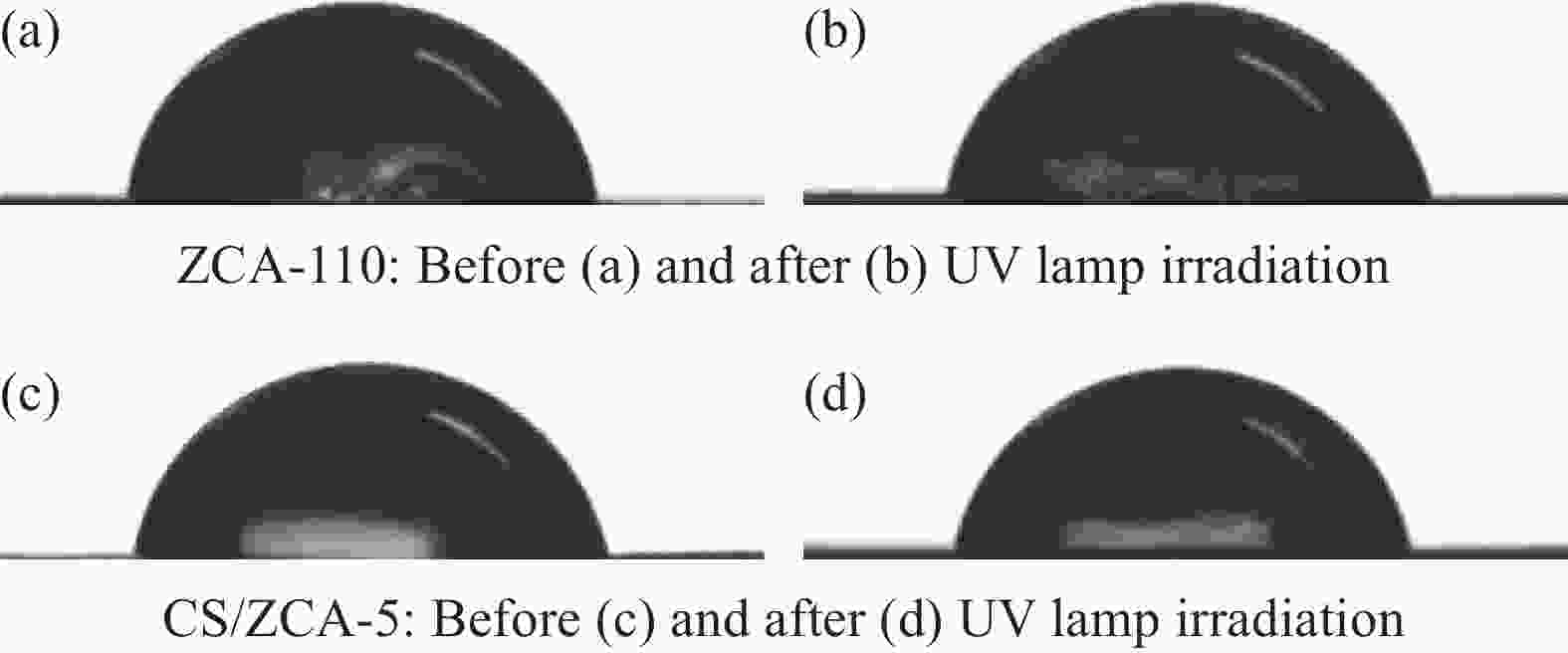

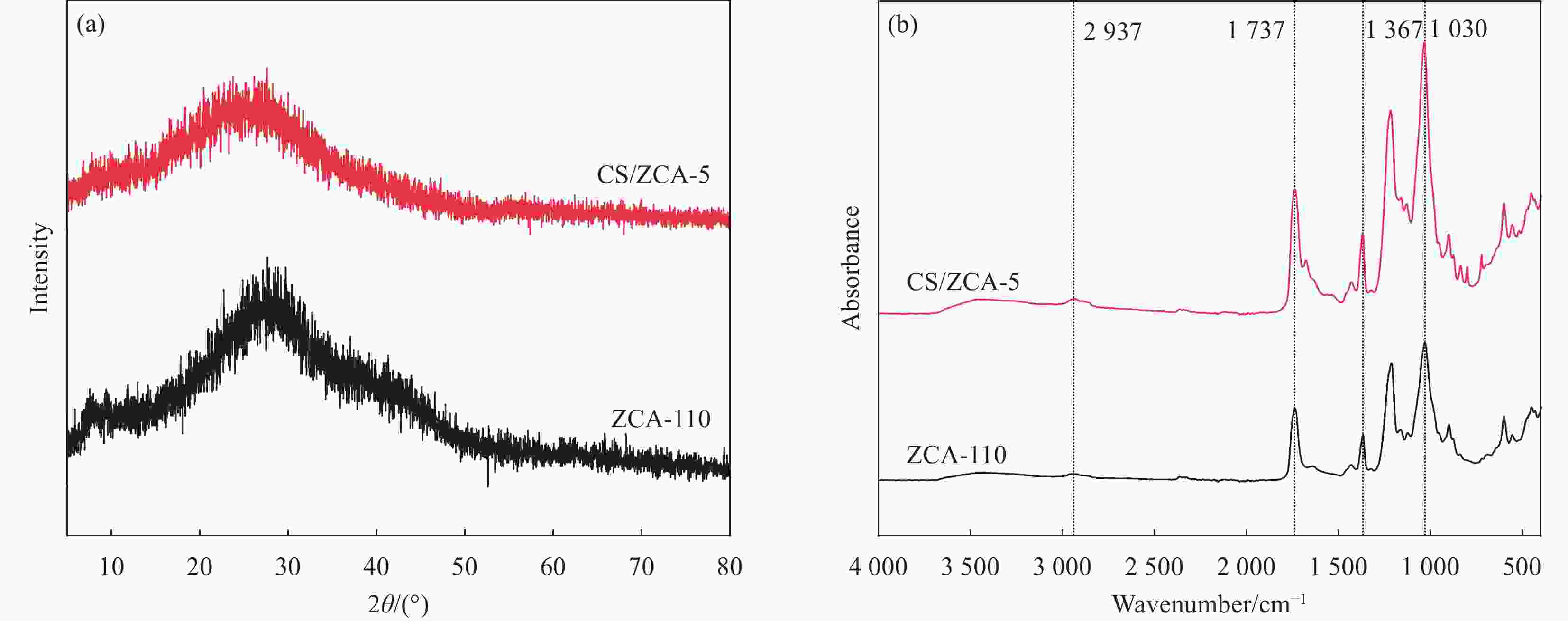

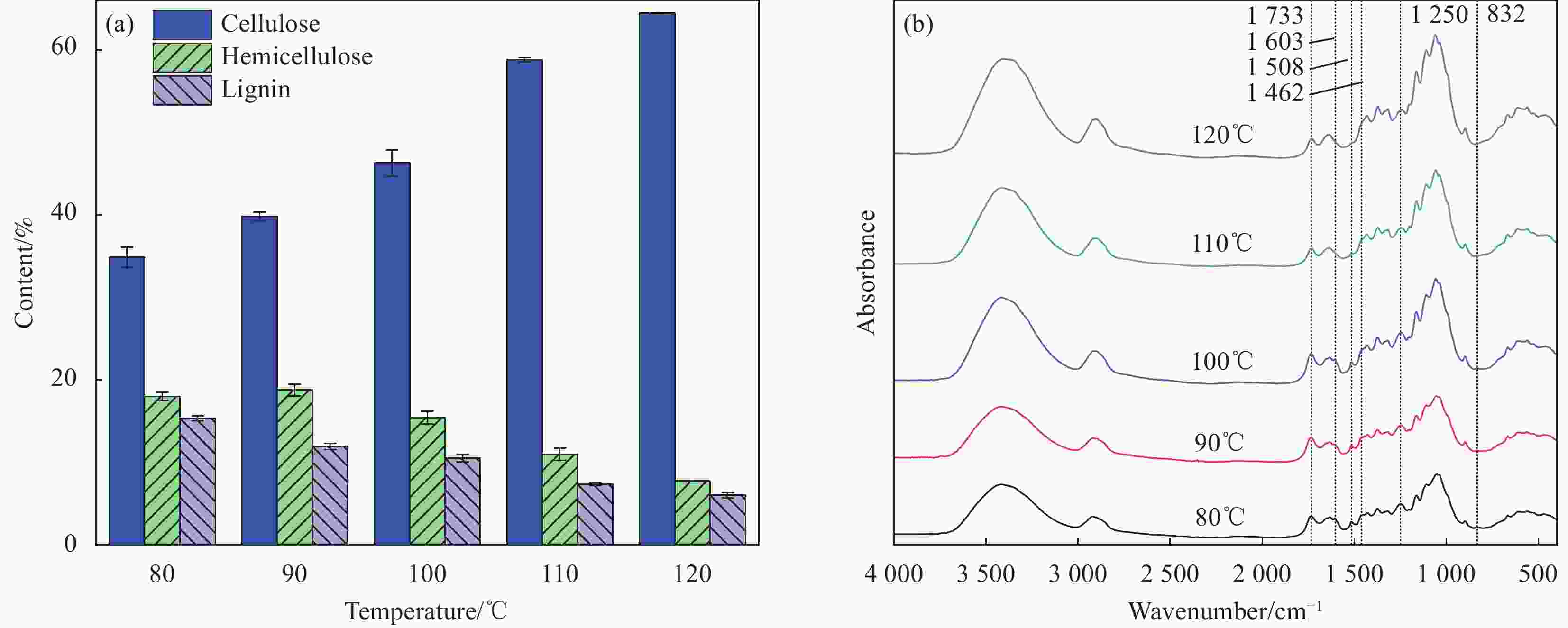

摘要: 为减少紫外线对人类造成的伤害和设施的破坏,本文以过氧乙酸复合马来酸预处理(PAM)玉米秸秆得到的纤维素产物为原料,以三氟乙酸作为催化剂和溶剂通过相转化法制备具有紫外屏蔽功能的玉米秸秆基醋酸纤维素膜。随着PAM预处理温度的提高,乙酰化程度和醋酸纤维素产率分别增加到42.19%和93.97%。制得的醋酸纤维素膜(ZCA-80~ZCA-120)的光学性能表征结果表明:该醋酸纤维素膜紫外线屏蔽性能良好,ZCA-110的中波紫外线(UVB)和长波紫外线(UVA)屏蔽率分别达到96.51%和73.72%。同时,揭示了ZCA-80~ZCA-120在紫外光区(200~400 nm)的屏蔽率及在660 nm处的透光率(T660)与木质素含量的相关关系,表明木质素含量是决定醋酸纤维素膜紫外屏蔽性能的关键因素。采用紫外分光光度计、接触角测试仪、XRD和FTIR对未添加壳聚糖(ZCA-110)和添加壳聚糖(CS/ZCA-5)的醋酸纤维素膜进行比较研究,发现添加壳聚糖的膜透光率得到改善、亲水性增强、结晶度降低。本文制备的木质纤维基醋酸纤维素膜将为生物可降解紫外屏蔽材料的研发提供新思路。Abstract: In order to reduce the harm caused by ultraviolet rays to human beings and the damage to facilities, the cellulose product obtained from peracetic acid and maleic acid pretreatment (PAM) corn stover was used as raw material, and the corn stover-based cellulose acetate film with UV shielding function was prepared by phase inversion method using trifluoroacetic acid as catalyst and solvent in this study. With the increase of PAM pretreatment temperature, the degree of acetylation and the yield of cellulose acetate increase to 42.19% and 93.97%, respectively. The optical properties of the prepared cellulose acetate films (ZCA-80-ZCA-120) show that the corn stover-based cellulose acetate films have good UV shielding performance, UVB and UVA shielding rates of ZCA-110 reach 96.51% and 73.72%, respectively. At the same time, the relationship between the UV (200-400 nm) shielding rate, the transmittance at 660 nm (T660) of ZCA-80-ZCA-120 and lignin content was revealed, indicating that the lignin content is the key factor determining the UV shielding performance of cellulose acetate film. A comparative study of corn stover-based cellulose acetate films without chitosan (ZCA-110) and with chitosan (CS/ZCA-5) was carried out by UV spectrophotometer, contact angle tester, XRD and FTIR, it is found that the light transmittance of the film added with chitosan is improved, the hydrophilicity is enhanced, the crystallinity is reduced. The lignocellulose-based cellulose acetate film prepared in this study will provide new ideas for the development of biodegradable UV shielding materials.

-

Key words:

- corn stover /

- lignin /

- cellulose acetate film /

- UV shielding /

- light transmittance /

- chitosan

-

表 1 醋酸纤维素(Ace)样品的命名

Table 1. Naming of cellulose acetate (Ace) sample

Sample name Pretreatment temperature/℃ Ace-80 80 Ace-90 90 Ace-100 100 Ace-110 110 Ace-120 120 表 2 醋酸纤维素膜(ZCA)样品的命名

Table 2. Naming of cellulose acetate film (ZCA) sample

Sample name Pretreatment temperature/°C Mass ratio of Ace-110

to chitosanZCA-80 80 — ZCA-90 90 — ZCA-100 100 — ZCA-110 110 — ZCA-120 120 — CS/ZCA-5 110 5:1 CS/ZCA-7 110 7:1 CS/ZCA-9 110 9:1 Note: CS—Chitosan. -

[1] ZHANG X F, SONG L, WANG Z G, et al. Highly transparent graphene oxide/cellulose composite film bearing ultraviolet shielding property[J]. International Journal of Biological Macromolecules,2020,145:663-667. doi: 10.1016/j.ijbiomac.2019.12.241 [2] 刘灵奕, 刘玉清, 王国钦, 等. 紫外线辐射对生态系统和人类健康的影响[J]. 国外医学 (卫生学分册), 2000, 27(5):269-273.LIU Lingyi, LIU Yuqing, WANG Guoqin, et al. Effects of ultraviolet radiation on ecosystems and human health[J]. Foreign Medicine (Hygiene Volume),2000,27(5):269-273(in Chinese). [3] 周念庭, 周豪, 卫茂平, 等. 不同紫外光对无机纳米材料改性聚丙烯老化行为的影响[J]. 中国塑料, 2016, 30(6):28-33.ZHOU Nianting, ZHOU Hao, WEI Maoping, et al. Effects of different UV on the aging behavior of PP modified with inorganic nanomaterials[J]. China Plastics,2016,30(6):28-33(in Chinese). [4] ZHANG Y, REMADEVI R, HINESTROZA J P, et al. Transparent ultraviolet (UV)-shielding films made from waste hemp hurd and polyvinyl alcohol (PVA)[J]. Polymers,2020,12(5):1190. doi: 10.3390/polym12051190 [5] WATABE Y, SUZUKI Y, KOIKE S, et al. Cellulose acetate, a new candidate feed supplement for ruminant animals: In vitro evaluations[J]. Journal of Dairy Science,2018,101(12):10929-10938. doi: 10.3168/jds.2018-14969 [6] CHEN J H, XU J K, WANG K, et al. Cellulose acetate fibers prepared from different raw materials with rapid synthesis method[J]. Carbohydrate Polymers,2016,137:685-692. doi: 10.1016/j.carbpol.2015.11.034 [7] LIU H Q, HU D C, CHEN X J, et al. Surface engineering of nanoparticles for highly efficient UV-shielding compo-sites[J]. Polymers for Advanced Technologies,2021,32(1):6-16. doi: 10.1002/pat.5081 [8] BOTLHOKO O J, LETWABA L, BANDYOPADHYAY J, et al. UV-protection, tribology, and mechanical properties of ZnO-containing polyamide composites[J]. Journal of Applied Polymer Science,2020,137(9):48418. [9] CHEN X, XU T, LEI H, et al. Multifunctional nano-ZnO/PMMA composites with high transparency prepared by one-step in situ polymerization[J]. Polymer Compo-sites,2019,40(2):657-663. doi: 10.1002/pc.24705 [10] ZHANG Y, NAEBE M. Lignin: A review on structure, properties, and applications as a light-colored UV absorber[J]. ACS Sustainable Chemistry & Engineering,2021,9(4):1427-1442. [11] 岳凤霞, 林敏生, 钱勇, 等. 木质素抗紫外辐射性能应用研究进展[J]. 林业工程学报, 2021, 6(2):12-20.YUE Fengxia, LIN Minsheng, QIAN Yong, et al. Recent advances of anti-UV radiation of lignin[J]. Chinese Journal of Forestry Engineering,2021,6(2):12-20(in Chinese). [12] MIAO Y N, TANG Z W, ZHANG Q W, et al. Biocompatible lignin-containing hydrogels with self-adhesion, conducti-vity, UV shielding, and antioxidant activity as wearable sensors[J]. ACS Applied Polymer Materials,2022,4(2):1448-1456. doi: 10.1021/acsapm.1c01817 [13] GUILHEN A, GADIOLI R, FERNANDES F C, et al. High-density green polyethylene biocomposite reinforced with cellulose fibers and using lignin as antioxidant[J]. Journal of Applied Polymer Science,2017,134(35):45219. doi: 10.1002/app.45219 [14] PIOTROWSKI J S, OKADA H, LU F C, et al. Plant-derived antifungal agent poacic acid targets β-1, 3-glucan[J]. Proceedings of the National Academy of Sciences of the United States of America, 2015, 112(12): E1490-E1497. [15] VINARDELL M P, UGARTONDO V, MITJANS M. Potential applications of antioxidant lignins from different sources[J]. Industrial Crops and Products,2008,27(2):220-223. doi: 10.1016/j.indcrop.2007.07.011 [16] 王欢, 杨东杰, 钱勇, 等. 木质素基功能材料的制备与应用研究进展[J]. 化工进展, 2019, 38(1):434-448.WANG Huan, YANG Dongjie, QIAN Yong, et al. Recent progress in the preparation and application of lignin-based functional materials[J]. Chemical Industry and Engineerging Progress(in Chinese),2019,38(1):434-448(in Chinese). [17] SADEGHIFAR H, VENDITTI R, JUR J, et al. Cellulose-lignin biodegradable and flexible UV protection film[J]. ACS Sustainable Chemistry & Engineering,2017,5(1):625-631. [18] BIAN H Y, CHEN L D, DONG M L, et al. Natural lignocellulosic nanofibril film with excellent ultraviolet blocking performance and robust environment resistance[J]. International Journal of Biological Macromolecules,2021,166:1578-1585. doi: 10.1016/j.ijbiomac.2020.11.037 [19] LYU Q, CHEN X L, ZHANG Y X, et al. One-pot fractionation of corn stover with peracetic acid and maleic acid[J]. Bioresource Technology,2021,320:124306. doi: 10.1016/j.biortech.2020.124306 [20] National Renewable Energy Laboratory. Determination of structural carbohydrates and lignin in biomass: NREL/TP-510-42618[S]. Colorado: Midwest Research Institute · Battelle, 2008. [21] 肖卫华, 刘润泽, 赵广路, 等. 三氟乙酸催化玉米秸秆纤维素制备三醋酸纤维素研究[J]. 农业机械学报, 2021, 52(9):331-337. doi: 10.6041/j.issn.1000-1298.2021.09.037XIAO Weihua, LIU Runze, ZHAO Guanglu, et al. Preparation of cellulose triacetate from corn stover cellulose by trifluoroacetic acid [J]. Transactions of the Chinese Society for Agricultural Machinery,2021,52(9):331-337(in Chinese). doi: 10.6041/j.issn.1000-1298.2021.09.037 [22] KHAM L, LE BIGOT Y, DELMAS M, et al. Delignification of wheat straw using a mixture of carboxylic acids and peroxoacids[J]. Industrial Crops and Products,2005,21(1):9-15. [23] LU Y L, MOSIER N S. Kinetic modeling analysis of maleic acid-catalyzed hemicellulose hydrolysis in corn stover[J]. Biotechnology and Bioengineering,2008,101(6):1170-1181. [24] KIM J S, LEE Y Y, KIM T H. A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass[J]. Bioresource Technology,2016,199:42-48. doi: 10.1016/j.biortech.2015.08.085 [25] KUMAR R, MAGO G, BALAN V, et al. Physical and chemi-cal characterizations of corn stover and poplar solids resulting from leading pretreatment technologies[J]. Bioresource Technology,2009,100(17):3948-3962. doi: 10.1016/j.biortech.2009.01.075 [26] TIAN C C, YAN M, HUANG X Y, et al. Highly acetylated lignocellulose prepared by alkaline extrusion pretreatment assisted acetylation reaction[J]. Cellulose,2022,29(3):1487-1500. doi: 10.1007/s10570-021-04397-2 [27] FISCHER S, THÜMMLER K, VOLKERT B, et al. Properties and applications of cellulose acetate[J]. Macromolecular Symposia,2008,262(1):89-96. doi: 10.1002/masy.200850210 [28] 赵广路. 玉米秸秆纤维素分离及醋酸纤维素制备的工艺优化研究[D]. 北京: 中国农业大学, 2019.ZHAO Guanglu. Research on process optimization of separation of corn stalk cellulose and preparation of cellulose acetate[D]. Beijing: China Agricultural University, 2019(in Chinese). [29] HOU G Y, LIU Y, ZHANG D J, et al. Approaching theoreti-cal haze of highly transparent all-cellulose composite films[J]. ACS Applied Materials & Interfaces,2020,12(28):31998-32005. [30] YOU T T and Xu F. Applications of molecular spectroscopic methods to the elucidation of lignin structure[M]. UK: IntechOpen, 2016. [31] LEE S C, TRAN T M T, CHOI J W, et al. Lignin for white natural sunscreens[J]. International Journal of Biological Macromolecules,2019,122:549-554. doi: 10.1016/j.ijbiomac.2018.10.184 [32] PATRULEA V, OSTAFE V, BORCHARD G, et al. Chitosan as a starting material for wound healing applications[J]. European Journal of Pharmaceutics and Biopharmaceutics,2015,97:417-426. doi: 10.1016/j.ejpb.2015.08.004 [33] VIJAYAKUMAR R, SIVARAMAN Y, PAVAGADA K M, et al. Synthesis of lignin nanoparticles employing acid precipitation method and its application to enhance the mechani-cal, UV-barrier and antioxidant properties of chitosan films[J]. International Journal of Polymer Analysis and Characterization,2022,27(2):99-110. doi: 10.1080/1023666X.2021.2016305 [34] VATANPOUR V, YAVUZTURK G B, ZEYTUNCU B, et al. Polysaccharides in fabrication of membranes: A review[J]. Carbohydrate Polymers,2022,281:119041. doi: 10.1016/j.carbpol.2021.119041 [35] 马豫峰, 蔡继业, 夏科. 硫酸软骨素/壳聚糖自组装复合膜的制备和表征[J]. 电子显微学报, 2004, 23(2):129-133. doi: 10.3969/j.issn.1000-6281.2004.02.008MA Yufeng, CAI Jiye, XIA Ke. Preparation and characterization of chondroitin sulfate/chitosan self-assembled composite films[J]. Journal of Electron Microscopy,2004, 23(2):129-133(in Chinese). doi: 10.3969/j.issn.1000-6281.2004.02.008 [36] 王丽鑫, 徐雅雯, 李志森, 等. 高强度醋酸纤维素/壳聚糖复合膜的制备及其性能研究[J]. 林产化学与工业, 2020, 40(4):107-113. doi: 10.3969/j.issn.0253-2417.2020.04.015WANG Lixin, XU Yawen, LI Zhisen, et al. Preparation and characterization of cellulose acetate/chitosan composites film with high mechanical strength[J]. Chemistry and Industry of Forest Products,2020,40(4):107-113(in Chinese). doi: 10.3969/j.issn.0253-2417.2020.04.015 [37] 刘莹, 孟凡浩, 刘井来, 等. 醋酸纤维素/壳糖复合膜制备与性能优化[J]. 塑料, 2020, 49(2):23-27, 31.LIU Ying, MENG Fanhao, LIU Jinglai, et al. Preparation and performance optimization of cellulose acetate/chitosan composite membrances[J]. Plastics,2020,49(2):23-27, 31(in Chinese). [38] ZHOU H M, TONG H, LU J, et al. Preparation of bio-based cellulose acetate/chitosan composite film with oxygen and water resistant properties[J]. Carbohydrate Polymers,2021,270:118381. doi: 10.1016/j.carbpol.2021.118381 [39] WAHEED S, AHMAD A, KHAN S M, et al. Synthesis, characterization, permeation and antibacterial properties of cellulose acetate/polyethylene glycol membranes modified with chitosan[J]. Desalination,2014,351:59-69. doi: 10.1016/j.desal.2014.07.019 -

下载:

下载: