Self-healing and frost resistance of ultra-high performance concrete

-

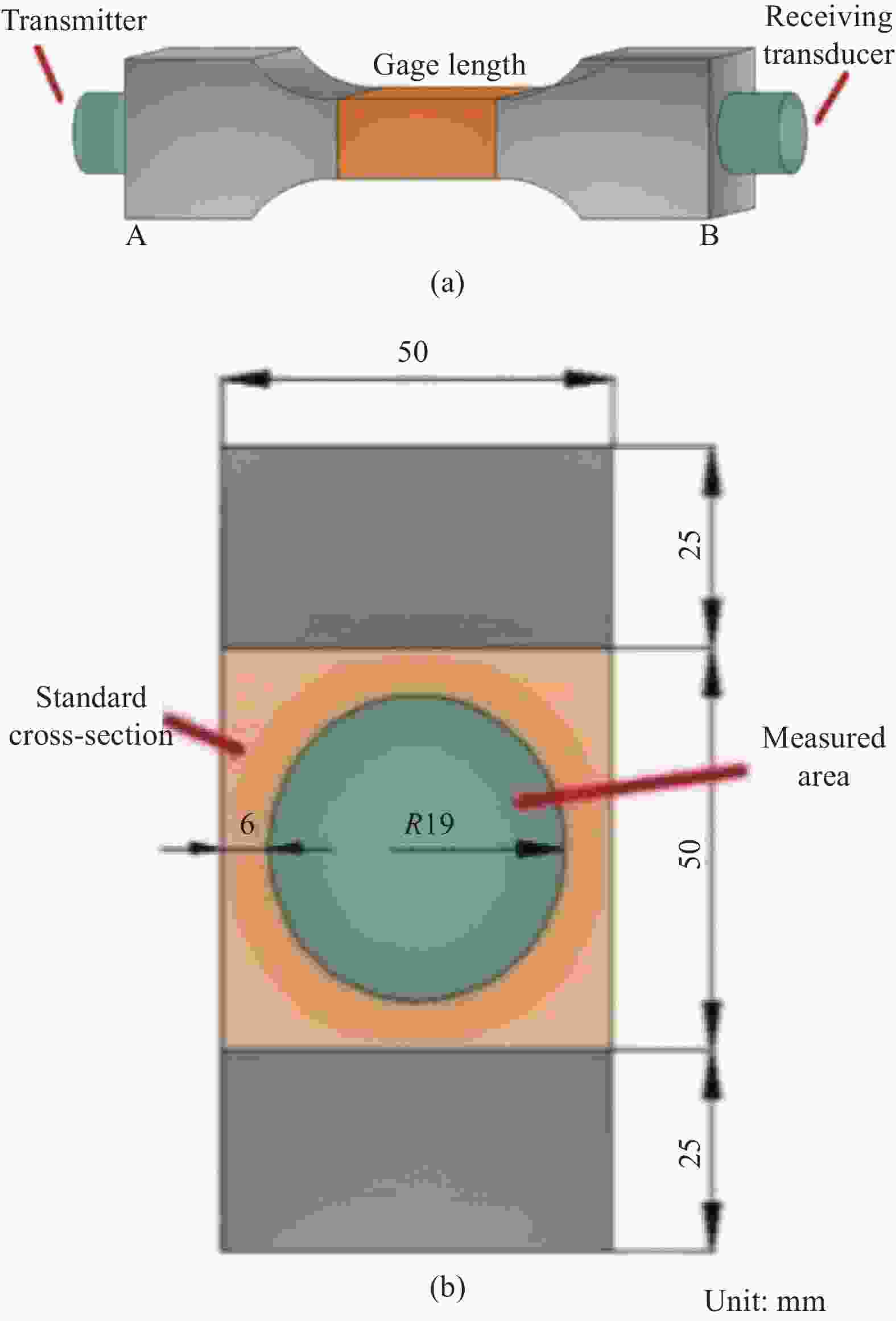

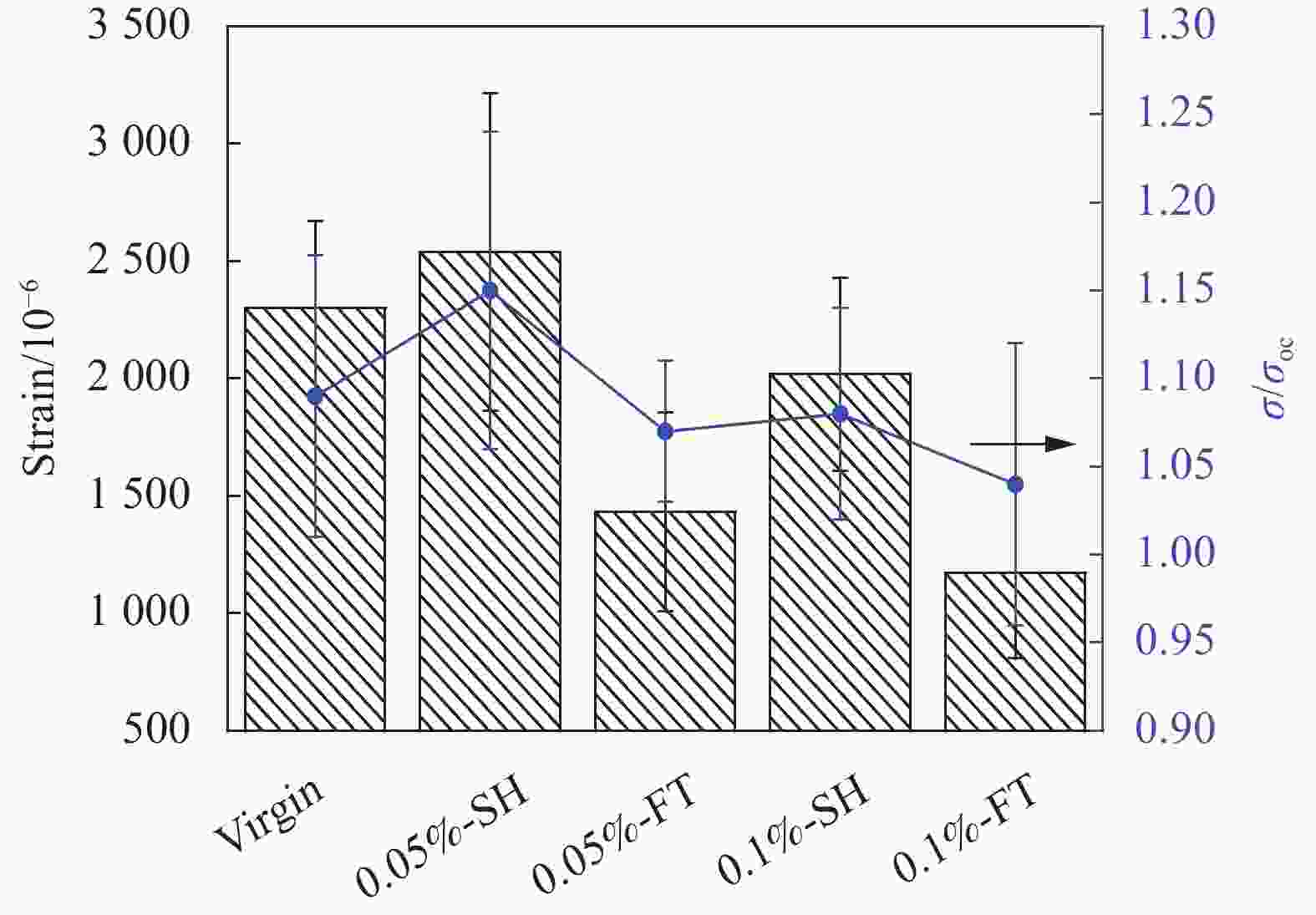

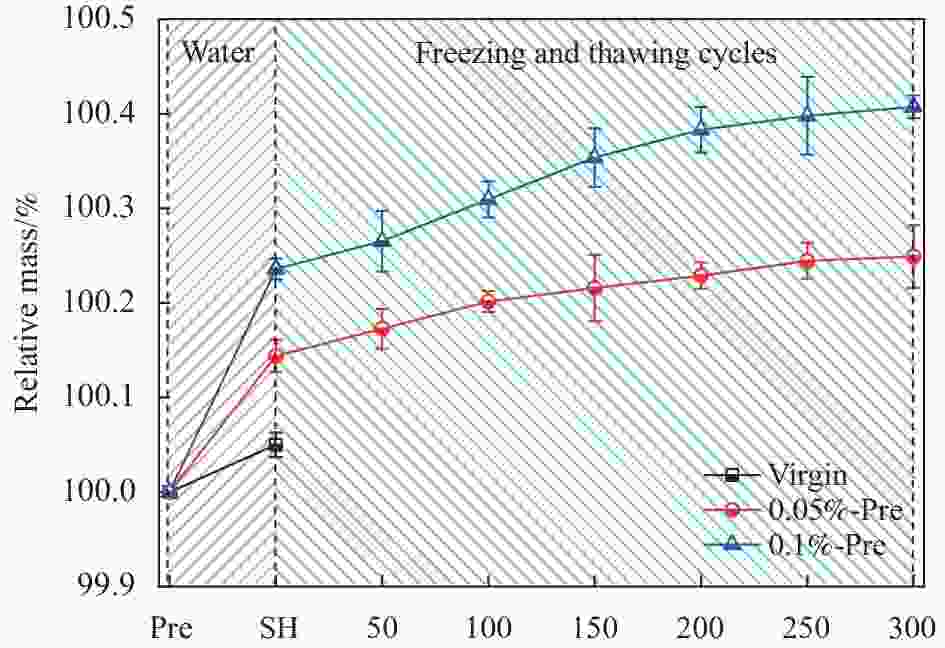

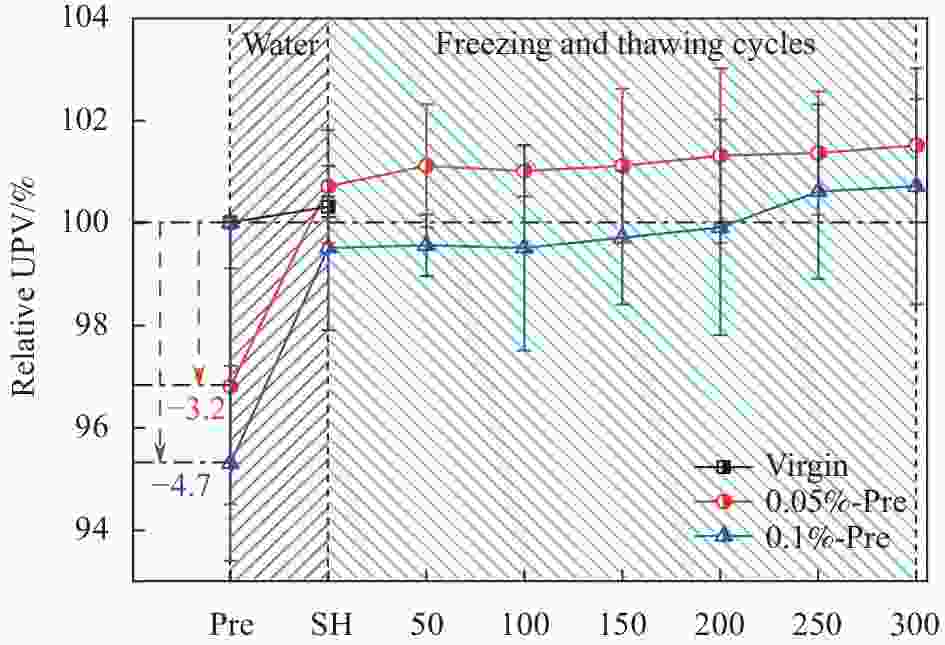

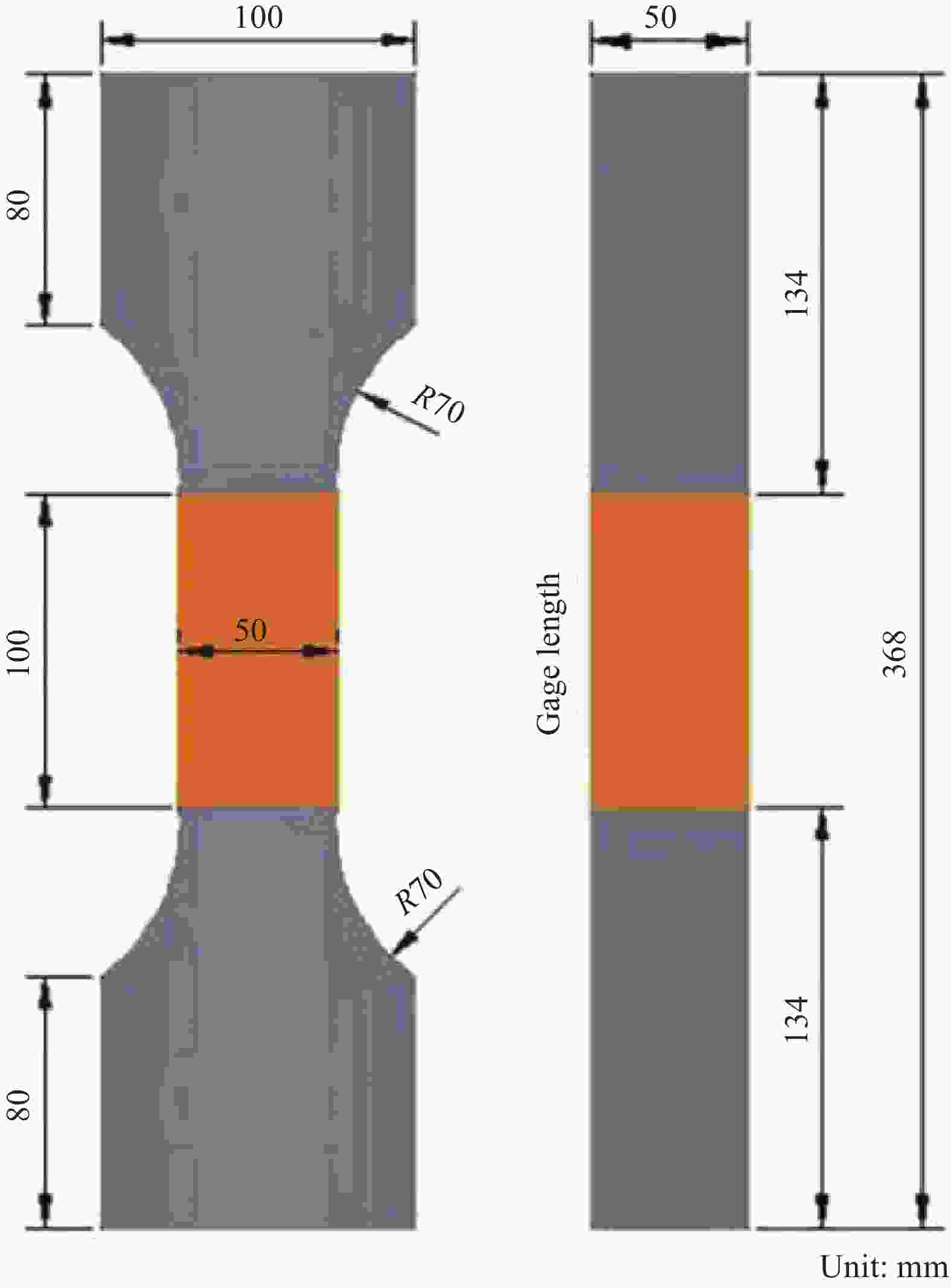

摘要: 为研究带裂服役超高性能混凝土(UHPC)的自愈合及抗冻性能,对混杂钢纤维UHPC试件预加0.05%和0.1%两种应变损伤,置于水中养护28天自愈合后进行300次冻融循环试验。通过单轴拉伸性能、裂缝特征、质量损失及超声波脉冲速率(UPV)指标综合评价UHPC的自愈合及抗冻性能,并利用扫描电子显微镜和能谱仪(SEM-EDS)分析微观结构和愈合产物。结果表明:28天水养后,预损伤0.05%试件表现出较好的自愈合性能,抗拉强度、拉伸应变和应变能均高于参照试件,表面所有裂缝全部愈合;预损伤0.1%试件的拉伸性能低于参照试件,表面最大裂缝(宽度为69 μm)并未完全愈合。300次冻融循环后,两种预损伤试件的初裂强度和抗拉强度均进一步增加,而拉伸应变和应变能均有所减小。相对质量与UPV的变化趋势能够很好地反映两种预损伤试件的再水化效应。SEM-EDS结果显示:距裂缝较近部位的纤维-基体粘结更牢固;裂缝表面的愈合产物主要为Ca(OH)2和CaCO3,内侧主要为水化硅酸钙(C-S-H)凝胶。Abstract: In order to study the self-healing and frost resistance performance of cracked ultra-high performance concrete (UHPC) in service, UHPC specimens with hybrid steel fibers were pre-loaded to the tensile strain level of 0.05% and 0.1%, respectively, cured in water for 28 days and then used for performing 300 freezing and thawing cycles experiment. The indexes including uniaxial tensile property, characteristics of crack, mass and ultrasonic pulse velocity (UPV) were utilized to comprehensively evaluate the self-healing and frost resistance performance. Meanwhile scanning electronic microscope and energy disperse spectroscopy (SEM-EDS) were adopted to analyze microstructure and self-healing products. The results show that: after 28 days water-curing, the specimen with pre-loaded strain of 0.05% exhibits better self-healing, in which the tensile strength, tensile strain and strain energy are higher than those of the reference specimen, and all surface cracks close; The parameters of tensile properties of the specimens with pre-loaded strain of 0.1% are lower compared to the reference specimen, with a partially healed maximum crack (the width of 69 μm). After 300 freezing and thawing cycles, the initial cracking strength and tensile strength of two types of pre-damaged specimens further increase, while both the tensile strain and strain energy show the decrease trend. The variation of relative mass and UPV can well reflect the secondary-hydration effect of two specimens. The results of SEM-EDS demonstrate that, the fiber-matrix bonding near crack is stronger; The healing products are mainly Ca(OH)2 and CaCO3 on the surface of crack, and calcium silicate hydrated (C-S-H) gel in the inner side of crack.

-

表 1 水泥和硅灰的化学组成

Table 1. Chemical composition of cement and silica fume

Material Mass fraction/wt% SiO2 Al2O3 Fe2O3 CaO MgO SO3 Na2O K2O LOI Cement 19.3 3.8 3.4 63.5 2.8 3.5 0.10 0.8 1.44 Silica fume 93.0 0.3 0.8 0.3 0.3 0.8 0.36 — 1.50 Note: LOI—Loss on ignition. 表 2 混杂钢纤维超高性能混凝土(UHPC)配合比

Table 2. Mixture proportion of ultra-high performance concrete (UHPC) with hybrid fibers

wt% Cement Silica fume Sand Water Superplasticizer Steel fibers Long Short 36.88 6.15 40.98 8.18 0.29 4.58 3.06 表 3 试件类型

Table 3. Specimen of type

Specimen types Mechanism Strain 0.05%-Pre Pre-damage 0.05% 0.05%-SH Self-healing in water after pre-damage 0.05% 0.05%-FT Freezing and thawing cycles after

self-healing0.05% 0.1%-Pre Pre-damage 0.1% 0.1%-SH Self-healing in water after pre-damage 0.1% 0.1%-FT Freezing and thawing cycles after

self-healing0.1% 表 4 两种预损伤UHPC试件愈合前后的表面裂缝信息

Table 4. Surface crack information of two kinds of pre-damaged UHPC specimens before and after self-healing

Specimen Number of cracks Maximum crack width/μm Total crack number ≤10 μm 10-50 μm >50 μm 0.05%-Pre 4±2 1±1 0±0 35±13 5±1 0.05%-SH 0±0 0±0 0±0 0±0 0±0 0.1%-Pre 2±1 1±1 1±1 67±21 4±1 0.1%-SH 0±0 1±1 0±0 29±17 1±1 表 5 EDS元素分析结果

Table 5. Analyzed results of elements by EDS

Element Content O C Si Ca Total Area-1 Mass percent/wt% 13.77 13.72 4.30 68.21 100 Atom percent/at% 22.31 29.60 3.97 44.12 100 Area-2 Mass percent/wt% 10.96 8.30 20.73 60.01 100 Atom percent/at% 18.97 19.13 20.43 41.46 100 -

[1] WILLE K, NAAMAN A E, PARRA-MONTESINOS G J. Ultra-high performance concrete with compressive strength exceeding 150 MPa (22 ksi): A simpler way[J]. ACI Materials Journal,2011,108(1):46-54. [2] 杲晓龙, 王俊颜, 郭君渊, 等. 循环荷载作用下超高性能混凝土的轴拉力学本构模型[J]. 复合材料学报, 2021, 38(11):3925-3938.GAO Xiaolong, WANG Junyan, GUO Junyuan, et al. Axial tensile mechanical properties and constitutive relation model of ultra-high performance concrete under cyclic loading[J]. Acta Materiae Compositiae Sinica,2021,38(11):3925-3938(in Chinese). [3] JIANG J Y, ZHENG X J, WU S P, et al. Nondestructive experimental characterization and numerical simulation on self-healing and chloride ion transport in cracked ultra-high performance concrete[J]. Construction and Building Materials,2019,198:696-709. doi: 10.1016/j.conbuildmat.2018.11.054 [4] 龚升, 张武满, 张劲松. 橡胶颗粒-钢纤维混掺对碾压混凝土抗冻性及抗冲击性能的影响[J]. 复合材料学报, 2018, 35(8):2199-2207.GONG Sheng, ZHANG Wuman, ZHANG Jinsong. Forst resistance and impact properties of roller compacted concrete mixed with rubber particles and steel fibers[J]. Acta Materiae Compositae Sinica,2018,35(8):2199-2207(in Chinese). [5] FERRARA L, KRELANI V, MORETTI F, et al. Effects of autogenous healing on the recovery of mechanical performance of high performance fiber reinforced cementitious composites (HPFRCCs): Part 1[J]. Cement and Concrete Composites,2017,83:76-100. doi: 10.1016/j.cemconcomp.2017.07.010 [6] HILLOULIN A B, GRONDINA F, MATALLAHA M, et al. Modelling of autogenous healing in ultra high performance concrete[J]. Cement and Concrete Research,2014,61-62:64-70. doi: 10.1016/j.cemconres.2014.04.003 [7] GRANGER S, LOUKILI A, PIJAUDIER-CABOT G, et al. Experimental characterization of the self-healing of cracks in an ultra high performance cementitious material: Mechanical tests and acoustic emission analysis[J]. Cement and Concrete Research,2007,37(4):519-527. doi: 10.1016/j.cemconres.2006.12.005 [8] GUO J Y, WANG J Y, WU K. Effects of self-healing on tensile behavior and air permeability of high strain hardening UHPC[J]. Construction and Building Materials,2019,204:342-356. doi: 10.1016/j.conbuildmat.2019.01.193 [9] KIM S, KIM M J, YOON H J, et al. Effect of cryogenic temperature on the flexural and cracking behaviors of ultra-high-performance fiber-reinforced concrete[J]. Cryogenics,2018,93:75-85. doi: 10.1016/j.cryogenics.2018.06.002 [10] KIM S, YOO D Y, KIM M J, et al. Self-healing capability of ultra-high-performance fiber-reinforced concrete after exposure to cryogenic temperature[J]. Cement and Concrete Composites,2019,104:103335. doi: 10.1016/j.cemconcomp.2019.103335 [11] WU Z M, SHI C J, KHAYAT K H. Investigation of mechanical properties and shrinkage of ultra-high performance concrete: Influence of stell fiber concent and shape[J]. Composities Part B: Engineering,2019,174:107021. doi: 10.1016/j.compositesb.2019.107021 [12] ZHANG Z G, QIAN S Z, MA H. Investigating mechanical properties and self-healing behavior of micro-cracked ECC with different volume of fly ash[J]. Construction and Building Materials,2014,52:17-23. doi: 10.1016/j.conbuildmat.2013.11.001 [13] YANG Y Z, LEPECH M D, YANG E H, et al. Autogenous healing of engineered cementitious composites under wet-dry cycles[J]. Cement and Concrete Research,2009,39(5):382-390. doi: 10.1016/j.cemconres.2009.01.013 [14] YOO D Y, SHIN W, CHUN B, et al. Assessment of steel fiber corrosion in self-healed ultra-high-performance fiber-reinforced concrete and its effect on tensile performance[J]. Cement and Concrete Research,2020,133:106091. doi: 10.1016/j.cemconres.2020.106091 [15] YOO D Y, SHIN W. Improvement of fiber corrosion resistance of ultra-high-performance concrete by means of crack width control and repair[J]. Cement and Concrete Composites,2021,121:104073. doi: 10.1016/j.cemconcomp.2021.104073 [16] HUANG W, KAZEMI-KAMYAB H, SUN W, et al. Effect of cement substitution by limestone on the hydration and microstructural development of ultra-high performance concrete (UHPC)[J]. Cement and Concrete Composites,2017,77:86-101. doi: 10.1016/j.cemconcomp.2016.12.009 [17] NIU Y F, WEI J X, JIAO C J. Crack propagation behavior of ultra-high-performance concrete (UHPC) reinforced with hybrid steel fibers under flexural loading[J]. Construction and Building Materials,2021,294:123510. doi: 10.1016/j.conbuildmat.2021.123510 [18] AN M Z, WANG Y, YU Z R. Damage mechanisms of ultra-high-performance concrete under freeze–thaw cycling in salt solution considering the effect of rehydration[J]. Construction and Building Materials,2019,198:546-552. doi: 10.1016/j.conbuildmat.2018.11.175 [19] KAN L L, WANG F, ZHANG Z, et al. Mechanical properties of high ductile alkali-activated fiber reinforced composites with different curing ages[J]. Construction and Building Materials,2021,306:124833. doi: 10.1016/j.conbuildmat.2021.124833 [20] ZHAO Y J, SHI T, CAO L Y, et al. Influence of steel slag on the properties of alkali-activated fly ash and blast-furnace slag based fiber reinforced composites[J]. Cement and Concrete Composites,2021,116:103875. doi: 10.1016/j.cemconcomp.2020.103875 [21] 刘建忠, 韩方玉, 周华新, 等. 超高性能混凝土拉伸力学行为的研究进展[J]. 材料导报, 2017, 31(23):24-32. doi: 10.11896/j.issn.1005-023X.2017.023.003LIU Jianzhong, HAN Fangyu, ZHOU Huaxin, et al. An overview on tensile behavior of ultra-high performance concrete[J]. Materials Reports,2017,31(23):24-32(in Chinese). doi: 10.11896/j.issn.1005-023X.2017.023.003 [22] RANADE R, STULTS M D, LI V C, et al. Development of high strength high ductility concrete[C]//2nd International RILEM Conference on Strain Hardening Cementitious Composites. Rio de Janeiro, Brazil, 2011: 1-8. [23] LEE Y, CHOI J, KIM H K, et al. Effects of a defoamer on the compressive strength and tensile behavior of alkali-activated slag-based cementless composite reinforced by polyethylene fiber[J]. Composite Structures,2017,172:166-172. doi: 10.1016/j.compstruct.2017.03.095 [24] 类泽灏. 基于纤维表面改性的超高性能混凝土应变硬化行为研究[D]. 北京: 北京交通大学, 2020.LEI Zehao. Research on strain hardening behavior of ultra-high performance concrete based on fiber surface modification[D]. Beijing: Beijing Jiaotong University, 2020(in Chinese). [25] KAN L L, SHI H S, SAKULICH A R, et al. Self-healing characterization of engineered cementitious composite materials[J]. ACI Materials Journal,2010,107(6):617-624. -

下载:

下载: