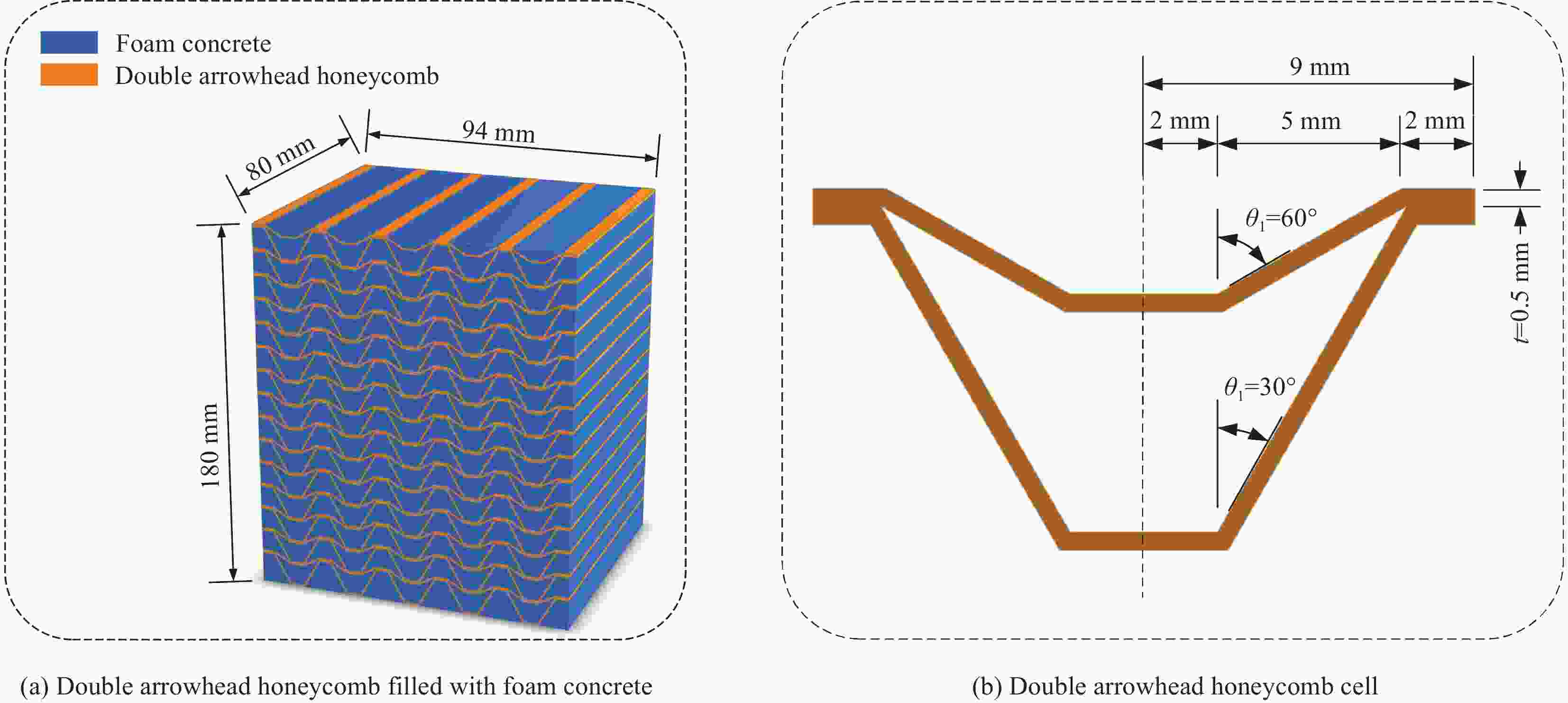

Quasi-static compression performance of double arrowhead honeycomb filled with foam concrete

-

摘要: 为提高三明治结构的力学和能量吸收性能,提出一种泡沫混凝土填充双箭头结构。制作双箭头结构并填充不同强度的低密度泡沫混凝土,通过试验得到准静态压缩下填充泡沫混凝土双箭头结构的变形模式、力学性能和能量吸收性能,并使用经试验验证的数值模型进一步分析了胞壁厚度与泡沫混凝土强度、胞元角度等重要因素对此填充结构压缩性能的影响。结果表明:双箭头结构可约束泡沫混凝土,双箭头结构和泡沫混凝土的合理匹配可有效利用两者间的相互作用,优化能量吸收性能。泡沫混凝土填充双箭头结构平均压缩强度的增量随填充泡沫混凝土强度的升高而升高,胞壁厚度为0.2 mm时,填充强度为0.46 MPa泡沫混凝土的结构比吸能最大;胞壁厚度为0.4 mm时,填充强度为1.02 MPa泡沫混凝土的结构比吸能最大。增加胞壁厚度可提高平均压缩强度的增量,提高比吸能。调整胞元角度,可实现对平均压缩强度增量和比吸能的调控。Abstract: To improve the mechanical and energy absorption performance of sandwich structures, a double arrowhead structure filled with foam concrete was proposed. The double arrowhead structure was prepared and filled with low density foam concrete of various strength. The deformation mode, mechanical properties, and energy absorption performance of the foam concrete-filled double arrowhead structure under quasi-static compression were experimentally obtained. Furthermore, a numerical model validated by test results was employed to investigate the influence of important factors such as cell wall thickness, strength of foam concrete and cell angle on the compression performance of the filled structure. The results suggest that if properly designed, the double arrowhead structure is able to effectively confine the foam concrete. The reasonable matching between the double arrowhead structure and foam concrete can benefit the interaction between the two to improve the energy absorption performance. The increment in mean crushing strength of double arrowhead structure filled with foam concrete increases with the strength of the foam concrete. The structure filled with foam concrete of strength 0.46 MPa exhibits the maximum specific energy absorption for cell wall thickness 0.2 mm, and the structure filled with foam concrete of strength 1.02 MPa exhibits the maximum specific energy absorption for cell wall thickness 0.4 mm. Increasing the cell wall thickness promotes the increment in mean crushing strength and specific energy absorption. Adjusting the cell angle enables the tuning of the increment in average crushing strength and specific energy absorption.

-

表 1 铝的力学性能

Table 1. Mechanical properties of aluminum

Aluminum Density/(kg·m-3) Young’s modulus/GPa Yield strength/MPa Ultimate strength/MPa 1060 2680 68.9 15 65 3A21 2730 69.2 100 134 表 2 试件的参数

Table 2. Parameters of the specimens

Sample Bottom

area/mm2Height/mm Mass/g Foam concrete

density/(kg·m−3)Compressive strength of

foam concrete/MPaDAH 7600 115 402 - - DAH-FC-0.10 7760 120 598 227 0.10 DAH-FC-0.46 7680 119 683 423 0.46 DAH-FC-1.02 7600 121 916 619 1.02 DAH-FC-1.70 7695 120 1038 838 1.70 Notes: DAH—Double arrowhead honeycomb; FC—Foam concrete. 表 3 试件的能量吸收性能

Table 3. Energy absorption performance of specimens

Specimen Densification strain Mean crushing strength/MPa SEA/(J·g−1) DAH 0.542 1.514 1.785 DAH-FC-0.10 0.433 1.973 1.330 DAH-FC-0.46 0.413 3.096 1.693 DAH-FC-1.02 0.401 4.843 1.950 DAH-FC-1.70 0.350 5.884 1.809 Notes: SEA—Specific energy absorption. 表 4 不同泡沫混凝土强度和胞壁厚度下泡沫混凝土填充双箭头结构的质量(g)

Table 4. Mass of double arrowhead honeycombs filled with foam concrete with different strength of foam concrete and cell wall thickness (g)

Foam concrete

density/(kg·m−3)Cell wall thickness/mm 0.2 0.4 0.6 0.8 227 311 472 633 795 423 442 601 761 922 619 613 770 929 1088 838 718 875 1032 1191 表 5 不同角度θ填充结构的能量吸收性能

Table 5. Energy absorption performance of filled structures at different angles

θ1 θ2 Densification

strainMean crushing

strength/MPaSEA/(J·g−1) 45° 30° 0.457 4.756 1.738 60° 30° 0.478 4.465 1.896 60° 45° 0.487 3.828 1.257 -

[1] 赵泽华, 张兆恒, 邢亚娟等. 新型夹层结构研究进展 [J/OL]. 复合材料科学与工程: 1-16[2024-02-04]. http://kns.cnki.net/kcms/detail/10.1683.tu.20230802.1606.008.html.ZHAO Zehua, ZHANG Zhaoheng, XING Yajuan, et al. Research progress of new sandwich structures [J/OL]. Composites Science and Engineering: 1-16[2024-02-04]. http://kns.cnki.net/kcms/detail/10.1683.tu.20230802.1606.008.html. (in Chinese). [2] SUN G Y, HUO X T, WANG H X, et al. On the structural parameters of honeycomb-core sandwich panels against low-velocity impact[J]. Composites Part B: Engineering, 2021, 216: 108881. doi: 10.1016/j.compositesb.2021.108881 [3] 周昊, 郭锐, 刘荣忠, 等. 碳纤维增强聚合物复合材料方形蜂窝夹层结构水下爆炸动态响应数值模拟[J]. 复合材料学报, 2019, 36(5): 1226-1234.ZHOU Hao, GUO Rui, LIU Rongzhong, et al. Simulations on dynamic responses of carbon fiber reinforced polymer composite sandwich plates with square honeycomb cores subjected to water blast[J]. Acta Materiae Compositae Sinica, 2019, 36(5): 1226-1234(in Chinese). [4] HUO X T, LIU H, LUO Q T, et al. On low-velocity impact response of foam-core sandwich panels[J]. International Journal of Mechanical Sciences, 2020, 181: 105681. doi: 10.1016/j.ijmecsci.2020.105681 [5] Wang H H, Xiao W, Zhao M K, et al. Dynamic response and energy absorption of aluminum foam sandwich under low-velocity impact[J]. Journal of Sandwich Structures & Materials, 2024, 26(4): 507-523. [6] CHEKKAL I, BIANCHI M, REMILLAT C D L, et al. Vibro-acoustic properties of auxetic open cell foam: Model and experimental results[J]. Acta Acustica United With Acustica, 2010, 96: 266-274. doi: 10.3813/AAA.918276 [7] Pang L S, Ma Y Q, Song X D, et al. Experimental and simulation study on effects of material and loading direction on the quasi-static compression behavior of re-entrant honeycomb structure[J]. Materials Today Communications, 2024, 39: 109005. doi: 10.1016/j.mtcomm.2024.109005 [8] ZHANG X Y, REN X, ZHANG Y, et al. A novel auxetic metamaterial with enhanced mechanical properties and tunable auxeticity[J]. Thin-Walled Structures, 2022, 174: 109162. doi: 10.1016/j.tws.2022.109162 [9] 于雅琳, 李健芳, 黄智彬, 等. 复合材料负泊松比格栅结构设计及力学性能评价[J]. 复合材料学报, 2021, 38(4): 1107-1114.YU Yalin, LI Jianfang, HUANG Zhibin, et al. Structural design and mechanical characterization of an auxetic advanced grid structure composite[J]. Acta Materiae Compositae Sinica, 2021, 38(4): 1107-1114(in Chinese). [10] 尤泽华, 肖俊华, 王美芬. 弧边内凹蜂窝负泊松比结构的力学性能[J]. 复合材料学报, 2022, 39(7): 3570-3580.YOU Zehua, XIAO Junhua, WANG Meifen. Mechanical properties of arc concave honeycomb structure with negative Poisson’s ratio[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3570-3580 (in Chinese). [11] QIAO J X, CHEN C Q. Impact resistance of uniform and functionally graded auxetic double arrowhead honeycombs[J]. International Journal of Impact Engineering, 2015, 83: 47-58. doi: 10.1016/j.ijimpeng.2015.04.005 [12] 刘彦佐, 李振羽, 杨金水. 碳纤维复合材料双箭头波纹拉胀结构的振动行为及减振性能[J]. 复合材料学报, 2022, 39(8): 4117-4128.LIU Yanzuo, LI Zhenyu, YANG Jinshui. Vibration behavior and damping performance of carbon fiber composite double-arrow corrugated auxetic structures[J]. Acta Materiae Compositae Sinica, 2022, 39(8): 4117-4128(in Chinese). [13] LAN X Q, YANG S Q, DONG Y A, et al. Phenomenological methods for defining elasticity and failure of double-arrowhead metamaterials[J]. International Journal of Mechanical Sciences, 2023, 252: 108361. doi: 10.1016/j.ijmecsci.2023.108361 [14] 卢子兴, 王欢, 杨振宇, 等. 星型-箭头蜂窝结构的面内动态压溃行为[J]. 复合材料学报, 2019, 36(8): 1893-1900.LU Zixing, WANG Huan, YANG Zhenyu, et al. In-plane dynamic crushing of star-arrowhead honeycomb structure[J]. Acta Materiae Compositae Sinica, 2019, 36(8): 1893-1900 (in Chinese). [15] 王雪松, 刘卫东, 刘典. 新型反四手性蜂窝结构的面内拉伸弹性[J]. 复合材料学报, 2023, 40(8): 4849-4861.WANG Xuesong, LIU Weidong, LIU Dian. In-plane tensile elasticity of a novel anti-tetrachiral cellular structure[J]. Acta Materiae Compositae Sinica, 2023, 40(8): 4849-4861 (in Chinese). [16] ZHANG X G, REN X, JIANG W, et al. A novel auxetic chiral lattice composite: Experimental and numerical study[J]. Composite Structures, 2022, 282: 115043. doi: 10.1016/j.compstruct.2021.115043 [17] 张政, 苏继龙. 六韧带手性蜂窝材料韧带的冲击动荷系数及稳定性分析[J]. 复合材料学报, 2019, 36(5): 1313-1318.ZHANG Zheng, SU Jilong. Impact dynamic load coefficient and stability analysis of ligament of chiral honeycomb[J]. Acta Materiae Compositae Sinica, 2019, 36(5): 1313-1318 (in Chinese). [18] CHEN M M, HUANG J X, JIANG W, et al. Elastic properties of lightweight rotating square structures[J]. Materials Today Communications, 2022, 33: 104256. doi: 10.1016/j.mtcomm.2022.104256 [19] JIN S G, KORKOLIS Y P, LI Y N. Shear resistance of an auxetic chiral mechanical metamaterial[J]. International Journal of Solids and Structures, 2019, 174-175: 28-37. doi: 10.1016/j.ijsolstr.2019.06.005 [20] GÜNAYDIN K, EREN Z, KAZANCI Z, et al. In-plane compression behavior of anti-tetrachiral and re-entrant lattices[J]. Smart Materials and Structures, 2019, 28(11): 115028. doi: 10.1088/1361-665X/ab47c9 [21] ZHANG J J, LU G X, YOU Z. Large deformation and energy absorption of additively manufactured auxetic materials and structures: A review[J]. Composites Part B: Engineering, 2020, 201: 108340. doi: 10.1016/j.compositesb.2020.108340 [22] 任鑫, 张相玉, 谢亿民. 负泊松比材料和结构的研究进展[J]. 力学学报, 2019, 51(3): 656-687. doi: 10.6052/0459-1879-18-381REN Xin, ZHANG Xiangyu, XIE Yimin. Research progress in auxetic materials and structures[J]. Chinese Journal of Theoretical and Applied Mechanics, 2019, 51(3): 656-687(in Chinese). doi: 10.6052/0459-1879-18-381 [23] GAO Q, ZHAO X, WANG C Z, et al. Multi-objective crashworthiness optimization for an auxetic cylindrical structure under axial impact loading[J]. Materials & Design, 2018, 143: 120-130. [24] ZHOU H Y, JIA K C, WANG X J, et al. Experimental and numerical investigation of low velocity impact response of foam concrete filled auxetic honeycombs[J]. Thin-Walled Structures, 2020, 154: 106898. doi: 10.1016/j.tws.2020.106898 [25] ZHAO C F, GOH K L, LEE H P, et al. Experimental study and finite element analysis on energy absorption of carbon fiber reinforced composite auxetic structures filled with aluminum foam[J]. Composite Structures, 2023, 303: 116319. doi: 10.1016/j.compstruct.2022.116319 [26] NOVAK N, Al-RIFAIE H, AIROLDI A, et al. Quasi-static and impact behaviour of foam-filled graded auxetic panel[J]. International Journal of Impact Engineering, 2023, 178: 104606. doi: 10.1016/j.ijimpeng.2023.104606 [27] 刘浩, 周宏元, 王小娟, 等. 泡沫混凝土填充旋转薄壁多胞方管负泊松比结构面内压缩性能[J]. 复合材料学报, 2024, 41(2): 838-856.LIU Hao, ZHOU Hong Yuan, WANG Xiao Juan, et al. In-plane compression properties of negative Poisson’s ratio structure of rotating thin walled multi-cell square tubes with foam concrete filler[J]. Acta Materiae Compositae Sinica, 2024, 41(2): 838-856(in Chinese). [28] AIROLD A, NOVAK N, SGOBBA F, et al. Foam-filled energy absorbers with auxetic behaviour for localized impacts[J]. Materials Science and Engineering: A, 2020, 788: 139500. doi: 10.1016/j.msea.2020.139500 [29] REN X, HAN D, SUN L, et al. Experimental and numerical investigations of aluminum foam-filled auxetic circular tubular metamaterials with elliptical cells[J]. Construction and Building Materials, 2023, 374: 130900. doi: 10.1016/j.conbuildmat.2023.130900 [30] REN X, ZHANG Y, HAN C Z, et al. Mechanical properties of foam-filled auxetic circular tubes: Experimental and numerical study[J]. Thin-Walled Structures, 2022, 170: 108584. doi: 10.1016/j.tws.2021.108584 [31] LUO C, REN X, HAN D, et al. A novel concrete-filled auxetic tube composite structure: Design and compressive characteristic study[J]. Engineering Structures, 2022, 268: 114759. doi: 10.1016/j.engstruct.2022.114759 [32] CHEN M, CHEN Z G, XUAN Y W, et al. Static and dynamic compressive behaviour of 3D printed auxetic lattice reinforced ultra-high performance concrete[J]. Cement and Concrete Composites, 2023, 139: 105046. doi: 10.1016/j.cemconcomp.2023.105046 [33] FAN G Z, REN X, WANG S L, et al. A novel cement-based auxetic foam composite: Experimental study[J]. Case Studies in Construction Materials, 2022, 17: e01159. doi: 10.1016/j.cscm.2022.e01159 [34] RAJ A, SATHYAN D, MINI K M. Physical and functional characteristics of foam concrete: A review[J]. Construction and Building Materials, 2019, 221: 787-799. doi: 10.1016/j.conbuildmat.2019.06.052 [35] 袁志颖, 陈波, 陈家林, 等. 泡沫混凝土孔结构表征及其对力学性能的影响[J]. 复合材料学报, 2023, 40(7): 4117-4127.YUAN Zhiying, CHEN Bo, CHEN Jialin, et al. Characterization of pore structure of foamed concrete and its influence on performance[J]. Acta Materiae Compositae Sinica, 2023, 40(7): 4117-4127(in Chinese). [36] WANG B, CHEN Y S, FAN H L, et al. Investigation of low-velocity impact behaviors of foamed concrete material[J]. Composites Part B: Engineering, 2019, 162: 491-499. doi: 10.1016/j.compositesb.2019.01.021 -

点击查看大图

点击查看大图

计量

- 文章访问数: 48

- HTML全文浏览量: 26

- 被引次数: 0

下载:

下载: