Comparison of aging properties of starch/ PBAT degradable mulching film in different environments

-

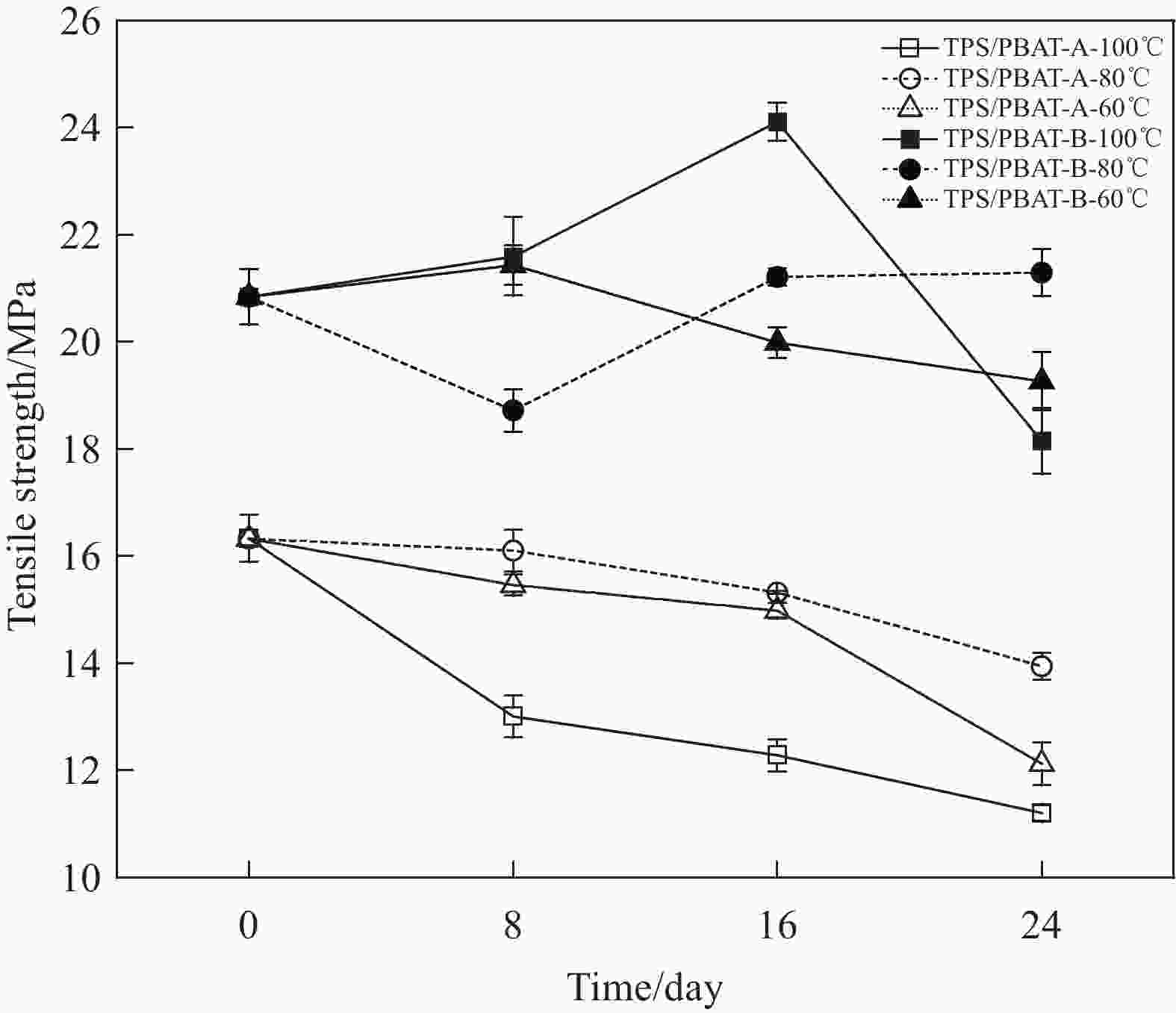

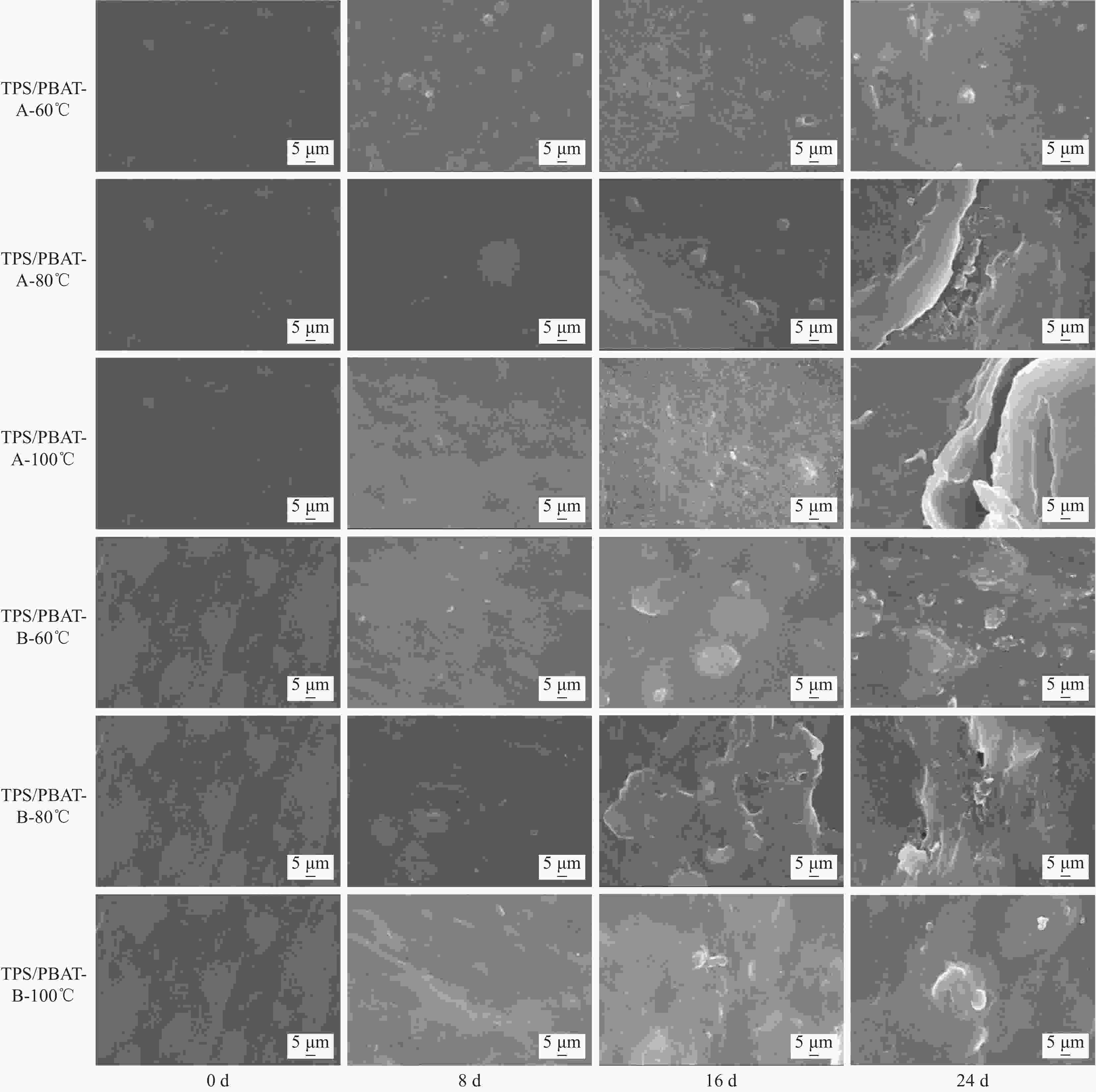

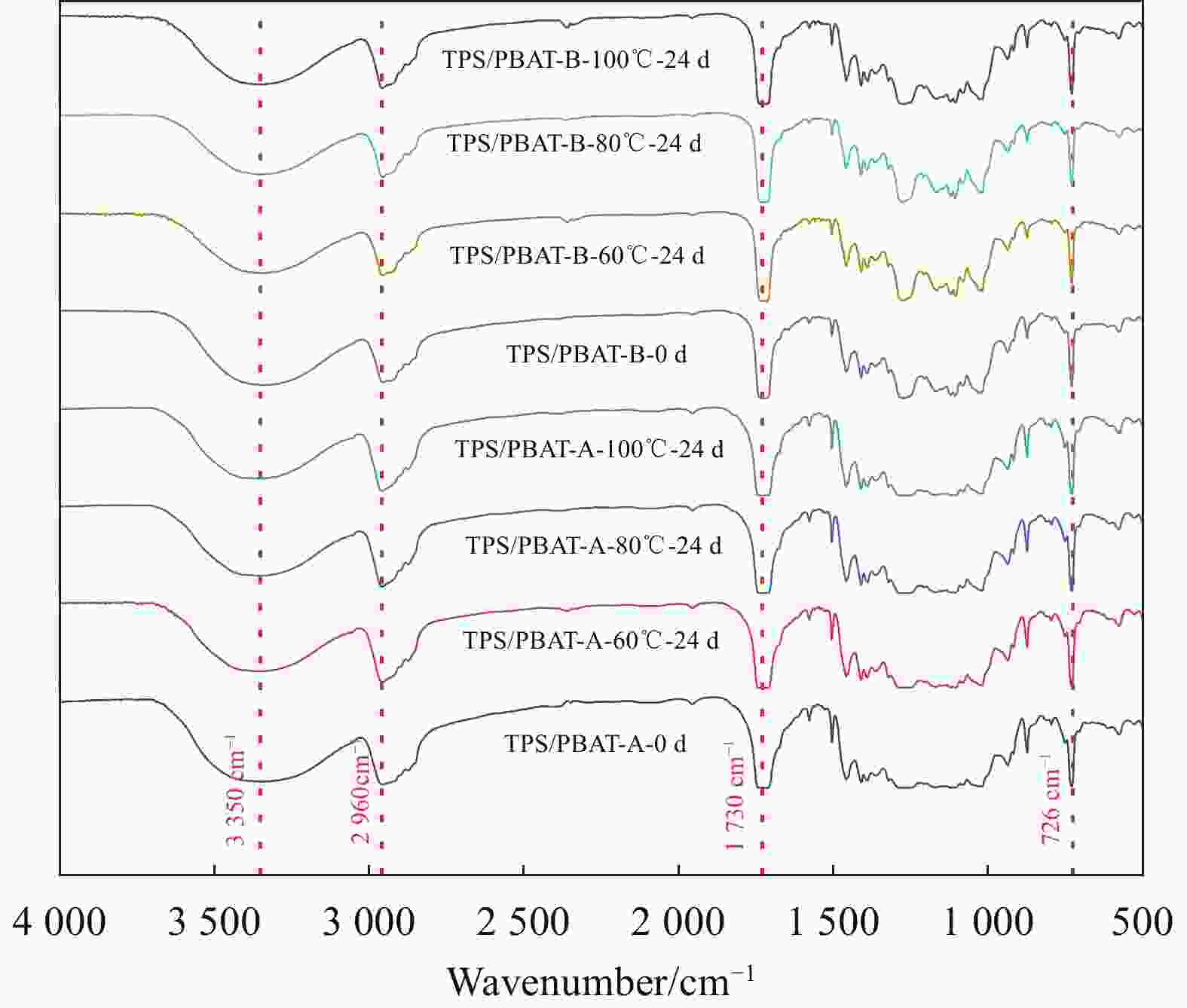

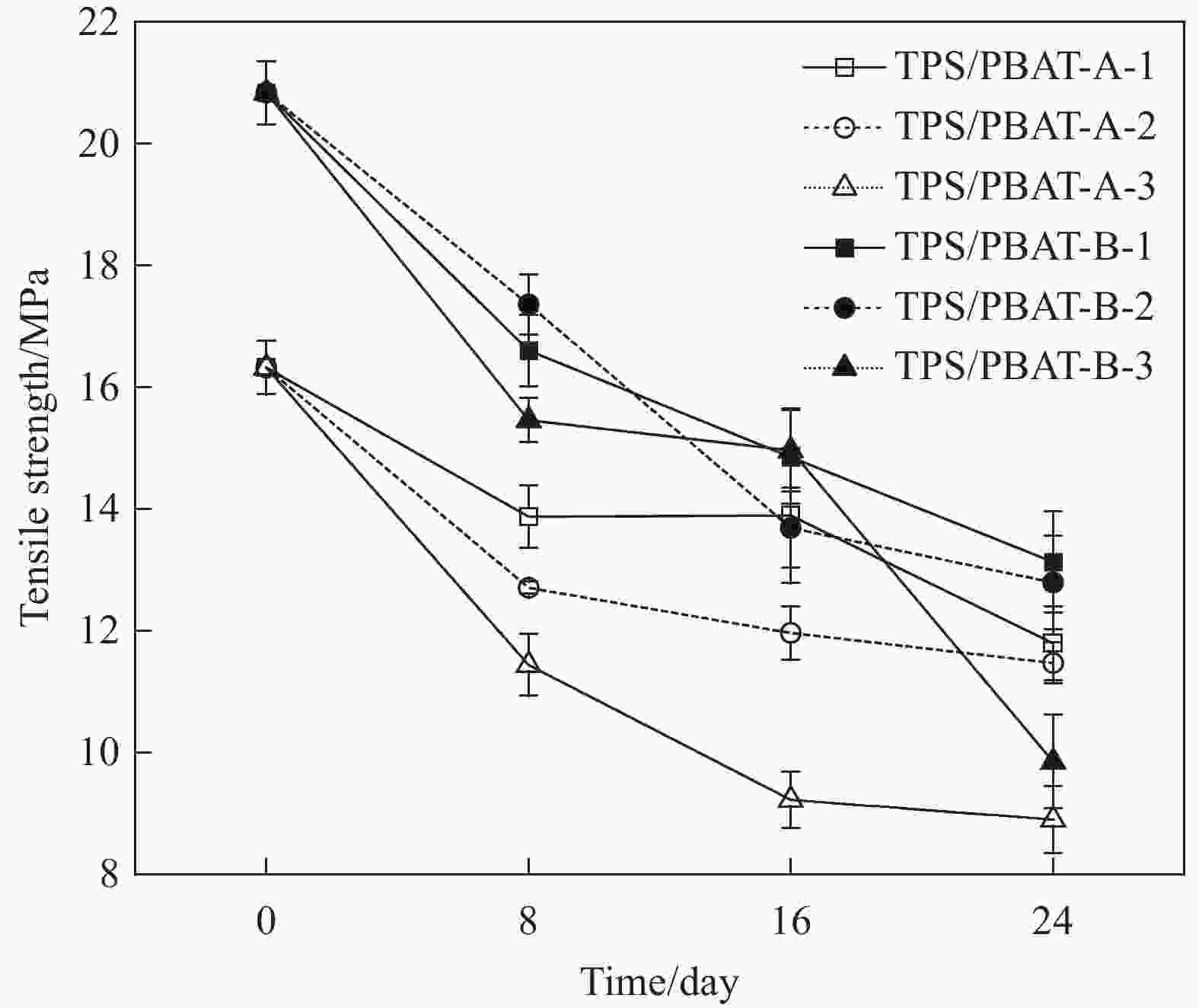

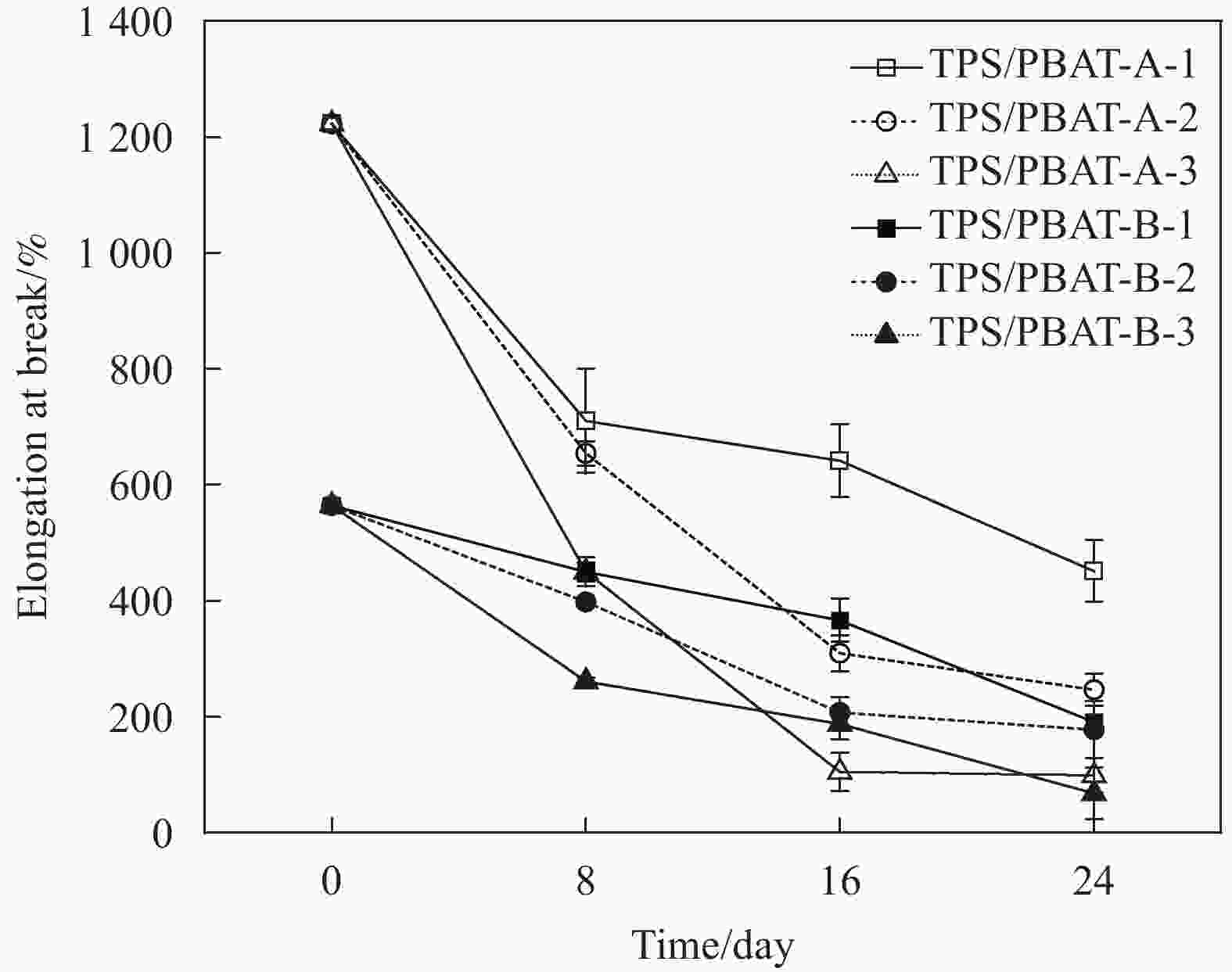

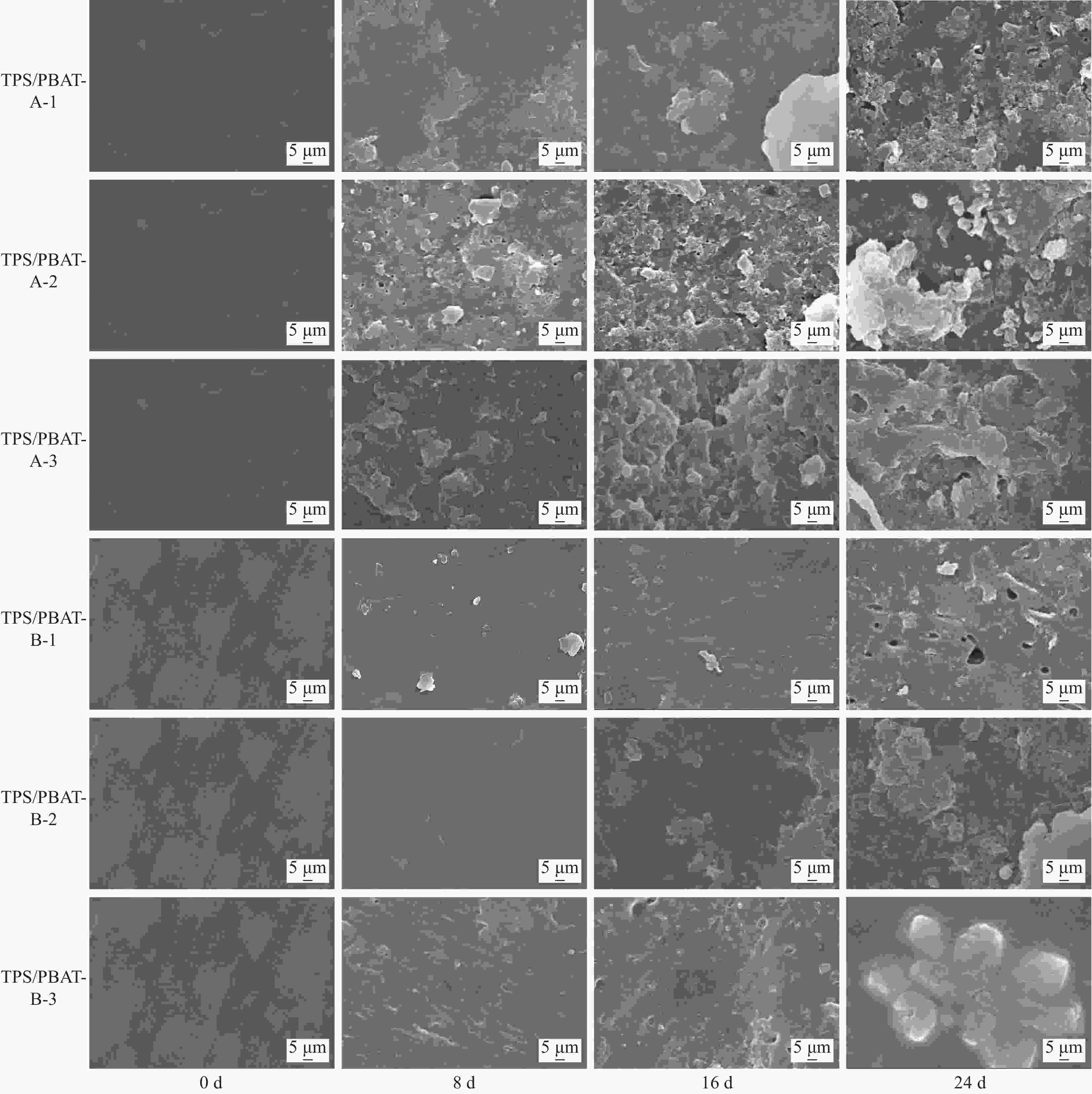

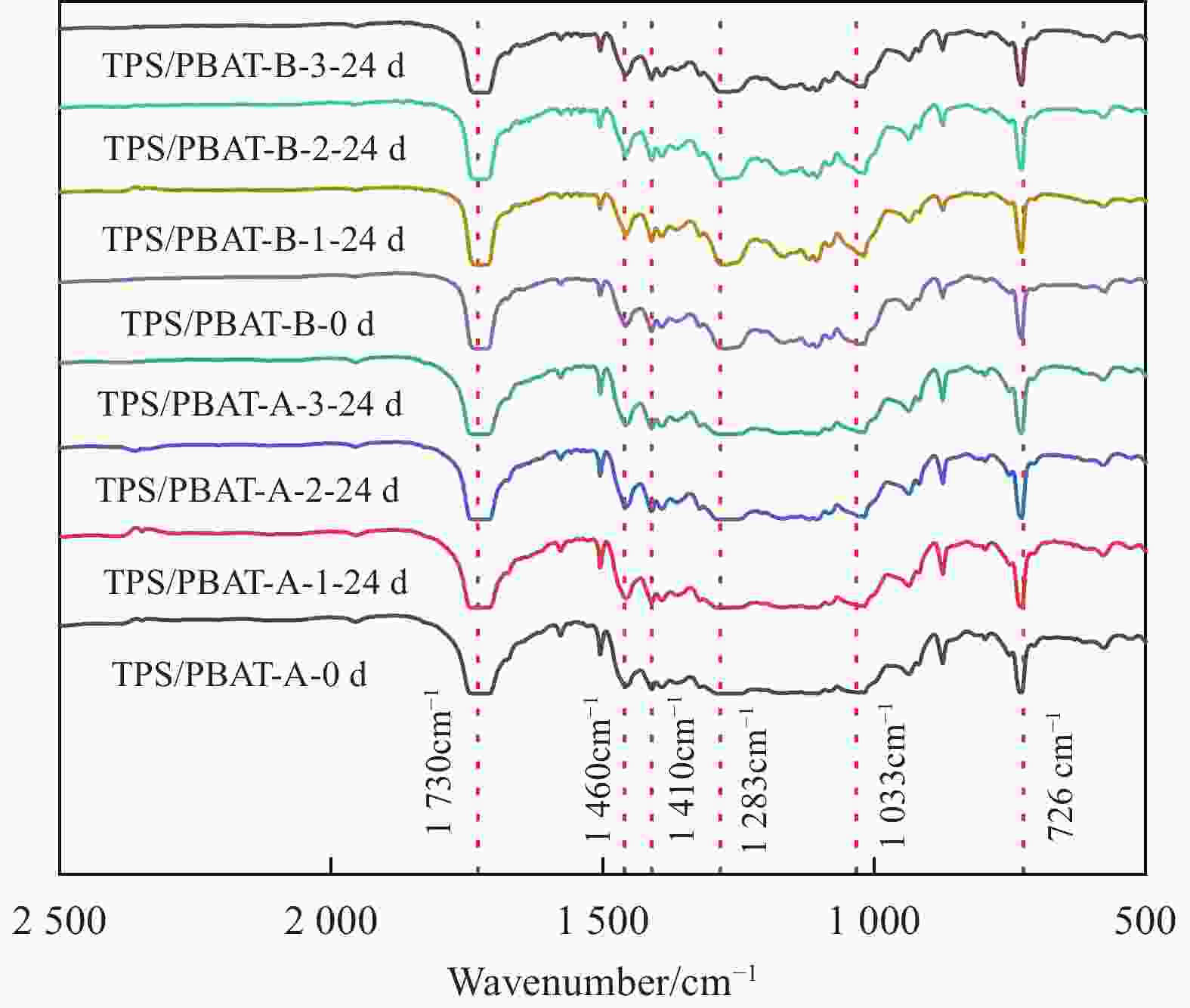

摘要: 为研制全生物降解地膜以减少传统塑料地膜的污染,以淀粉(TPS)和PBAT为原料,制备了2种原料配比的生物降解地膜TPS/PBAT-A和TPS/PBAT-B,研究其在热老化(60、80、100℃)和多因素老化(温度、湿度、光照强度分别为40℃-65%-310 W/m2、60℃-65%-310 W/m2和60℃-65%-648 W/m2)的综合性能。未老化前,2种地膜TPS/PBAT-A和TPS/PBAT-B的拉伸强度分别为16.3 MPa 和20.8 MPa,断裂伸长率分别为1222.7%和564.5%。高温热老化后2种地膜力学性能下降,经100℃热老化后,2种地膜TPS/PBAT-A和TPS/PBAT-B的拉伸强度分别降至11.2 MPa和18.2 MPa;TPS/PBAT-B地膜在热老化后表面缺陷相对较少,其性能保留较好。多因素老化下,光照强度对于2种地膜的力学性能的影响较大,在60℃-65%-310 W/m2和60℃-65%-648 W/ m2的对比环境中,2种地膜在24天后拉伸强度分别下降23.0%和22.4%;2种地膜在老化时主要表现为地膜的非结晶区先分解,分子链结构遭到破坏,分子断裂后内部空隙的存在使结合质量下降,表面出现多处孔洞和裂纹。Abstract: In order to develop a biodegradable mulching film to reduce the pollution of traditional mulching film, starch(TPS) and PBAT were used as raw materials to prepare two biodegradable mulching films TPS/PBAT-A and TPS/PBAT-B with a ratio of raw materials, and study their thermal aging (60, 80, 100 ℃) and multi-factor aging (temperature, humidity, and light intensity are 40℃-65%-310 W/m2、60℃-65%-310 W/m2 and 60℃-65%-648 W/m2). Before aging, the tensile strength of the two mulching films TPS/PBAT-A and TPS/PBAT-B are 16.3 MPa and 20.8 MPa, respectively, and the elongation at break is 1222.7% and 564.5%, respectively. After high temperature thermal aging, the mechanical properties of the two mulching films decreased. After thermal aging at 100 ℃, the tensile strength of the two mulching films TPS/PBAT-A and TPS/PBAT-B decreased to 11.2 MPa and 18.2 MPa, respectively; TPS/PBAT-B mulching films have relatively few surface defects after thermal aging, and their properties are well preserved. In the comparative environment of 60℃-65%-310 W/m2 and 60℃-65%-648 W/m2, the tensile strength of the two mulching films decreased by 23.0% and 22.4% after 24 days, respectively. When the two kinds of mulching films are aged, the amorphous area of the mulching films decomposes first, the molecular chain structure is destroyed, the existence of internal voids after molecular fracture reduces the bonding quality, and there are many holes and cracks on the surface.

-

表 1 TPS/PBAT地膜配方

Table 1. TPS / PBAT mulching films formulation

Sample Films PBAT/wt.% TPS/ wt.% Other/ wt.% TPS/PBAT-A 72.5 25 2.5 TPS/PBAT-B 62.5 35 2.5 Notes: PBAT—Polyadipate/butylene terephthalate; TPS—Thermoplastic starch 表 2 多因素老化试验条件

Table 2. Multi-factor aging test conditions

Sample Films Temperature/

℃Humidity/

%strength of

illumination/(W/ m2)TPS/PBAT-1 40 65 310 TPS/PBAT-2 60 65 310 TPS/PBAT-3 60 65 648 表 3 TPS/PBAT地膜力学性能数据

Table 3. Mechanical properties data of TPS / PBAT films

Sample Films Tensile strength/MPa elongation at break/% TPS/PBAT-A 16.3±0.4 1222.7±10.5 TPS/PBAT-B 20.8±0.5 564.5±10.6 -

[1] 刘婷婷, 侯丽君, 刘佳茜, 等. 基于文献计量的塑料地膜研究发展态势分析[J]. 中国农业大学学报, 2020, 25(9): 90-103.LIU Tingting, HOU Lijun, LIU Jiaxi, et al. Development trend analysis of plastic mulching film based on bibliometric analysis[J]. Journal of China Agricultural University, 2020, 25(9): 90-103(in Chinese). [2] 张芮, 李红霞, 高彦婷, 等. 基于熵权-TOPSIS模型的黄土高原半干旱区玉米覆膜类型综合评价[J]. 甘肃农业大学学报, 2023: 1-14.ZHANG Rui, LI Hongxia, GAO Yanting, et al. Comprehensive evaluation of film mulching types of maize in semi-arid area of loess plateau based on entropy weight — TOPSIS model[J]. Journal of Gansu Agricultural University, 2023: 1-14. (in Chinese) [3] 丁茜, 余佳, 蒋馨漫, 等. 生物降解地膜材料的研究进展[J]. 工程塑料应用, 2019, 47(12): 150-153. doi: 10.3969/j.issn.1001-3539.2019.12.028DING Qian, YU Jia, Jiang Xinman, et al. Research Progress on Biodegradable Mulching Film Materials[J]. Engineering Plastics Application, 2019, 47(12): 150-153(in Chinese). doi: 10.3969/j.issn.1001-3539.2019.12.028 [4] JIAN J, XIANGBIN Z, XIANBO H. An overview on synthesis, properties and applications of poly(butylene-adipate-co-terephthalate)–PBAT[J]. Advanced Industrial and Engineering Polymer Research, 2020, 3(1): 19-26. doi: 10.1016/j.aiepr.2020.01.001 [5] ZHANG S, LIN Z, LI J, et al. Elevated ductility, optical, and air barrier properties of poly (butyleneadipate-co-terephthalate) bio-based films via novel thermoplastic starch feature[J]. Polymers for Advanced Technologies, 2019, 30(4): 852-862. doi: 10.1002/pat.4518 [6] ZHAI X, ZHANG R, WANG W, et al. Relationship between phase morphologies and mechanical properties of thermoplastic starch/poly(butylene adipate-co-terephthalate) composite films prepared by extrusion blowing[J]. International Journal of Biological Macromolecules, 2023, 224: 1356-1360. doi: 10.1016/j.ijbiomac.2022.10.221 [7] GARALDE R A, THIPMANEE R, JARIYASAKOOLROJ P, et al. The effects of blend ratio and storage time on thermoplastic starch/poly(butylene adipate-co-terephthalate) films[J]. Heliyon, 2019, 5(3): e01251. doi: 10.1016/j.heliyon.2019.e01251 [8] NAYAK S K. Biodegradable PBAT/Starch Nanocomposites[J]. Polymer-Plastics Technology and Engineering, 2010, (13/15): 49. [9] OLIVATO J B, GROSSMANN M V E, YAMASHITA F, et al. Citric acid and maleic anhydride as compatibilizers in starch/poly(butylene adipate-co-terephthalate) blends by one-step reactive extrusion[J]. Carbohydrate Polymers, 2012, 87(4): 2614-2618. doi: 10.1016/j.carbpol.2011.11.035 [10] BAI J, PEI H, ZHOU X, et al. Reactive compatibilization and properties of low-cost and high-performance PBAT/thermoplastic starch blends[J]. European polymer journal, 2021, 143: 110198. doi: 10.1016/j.eurpolymj.2020.110198 [11] WEI D, WANG H, XIAO H, et al. Morphology and mechanical properties of poly ( butylene adipate-co-terephthalate )/ potato starch blends in the presence of synthesized reactive compatibilizer or modified poly ( butylene adipate-co-terephthalate )[J]. 2015. [12] TUNTIWORADET T, YOKSAN R. Property improvement of a thermoplastic starch/poly(butylene adipate-co-terephthalate) blown film by the addition of sodium nitrite[J]. International Journal of Biological Macromolecules, 2023, 242: 124991. doi: 10.1016/j.ijbiomac.2023.124991 [13] AKHIR M A M, ZUBIR S A, MARIATTI J. Effect of different starch contents on physical, morphological, mechanical, barrier, and biodegradation properties of tapioca starch and poly(butylene adipate-co-terephthalate) blend film[J]. Polymers for Advanced Technologies, 2023, 34(2): 717-730. doi: 10.1002/pat.5922 [14] 王明明, 关二旗, 李萌萌, 等. 淀粉含量和直链与支链比例对淀粉基可降解薄膜的性能影响及土壤降解研究[J]. 河南工业大学学报(自然科学版), 2022, 43(5): 68-76,101.WANG Mingming, GUAN Erqi, L. I. Mengmeng, et al. Effects of starch content and ratio of amylose to amylopectin on the performance of starch-based degradable film and its degradation in soil[J]. Journal of Henan University of Technology(Natural Science Edition), 2022, 43(5): 68-76,101(in Chinese). [15] XU M, LI F, YAN X, et al. Low-cost and high-performance poly(butylene adipate-co-terephthalate)/thermoplastic starch blends prepared by an eccentric rotor extruder: Morphology, rheological behavior, thermal and mechanical properties[J]. Journal of Applied Polymer Science, 2023, 140(48): 124716. [16] 全国生物基材料及降解制品标准化技术委员会. GB/T 35795—2017 全生物降解农用地面覆盖薄膜[S]. 北京: 中国标准出版社, 2017.Biobased Degradable Materials And Products. GB/T 35795—2017 Biodegradable mulching film for agriculturaluses[S]. Beijing: STANDARDS PRESS OF CHINA, 2017. (in Chinese) [17] GONZÁLEZ SELIGRA P, ELOY MOURA L, FAMÁ L, et al. Influence of incorporation of starch nanoparticles in PBAT/TPS composite films[J]. Polymer international, 2016, 65(8): 938-945. doi: 10.1002/pi.5127 [18] WADAUGSORN K, PANRONG T, WONGPHAN P, et al. Plasticized hydroxypropyl cassava starch blended PBAT for improved clarity blown films: Morphology and properties[J]. Industrial crops and products, 2022, 176: 114311. doi: 10.1016/j.indcrop.2021.114311 [19] 李慧, 田家瑶, 庞姗姗, 等. 淀粉/聚乙烯醇/氧化石墨烯生物降解地膜的降解性能研究[J]. 塑料科技, 2022, 50(08): 77-82.LI Hui, TIAN Jiayao, PANG Shanshan, et al. Degradation Performance of Starch/Polyvinyl Alcohol/GO Biodegradable Mulch Film[J]. Plastics Science and Technology, 2022, 50(08): 77-82(in Chinese). [20] 管彤晖, 付烨, 翁云宣. PBAT全生物降解地膜在土壤试验中的降解行为研究[J]. 中国塑料, 2022, 36(01): 67-72.GUAN Tonghui, FU Ye, WENG Yunxuan. Degradation behaviors of PBAT biodegradable mulch in soil[J]. China Plastics, 2022, 36(01): 67-72(in Chinese). [21] WONGPHAN P, PANRONG T, HARNKARNSUJARIT N. Effect of different modified starches on physical, morphological, thermomechanical, barrier and biodegradation properties of cassava starch and polybutylene adipate terephthalate blend film[J]. Food Packaging and Shelf Life, 2022, 32: 100844. doi: 10.1016/j.fpsl.2022.100844 [22] QIAO R, WANG X, QIN G, et al. Degradation Mode of PBAT Mulching Film and Control Methods Duringits Degradation Induction Period[J]. Mini-Reviews in Organic Chemistry, 2022, 19(5): 608-616. doi: 10.2174/1570193X18666210813142022 [23] WEI C, GUO P, LYU M, et al. High Barrier Poly(Glycolic Acid) Modified Poly(Butylene Adipate-co-terephthalate) Blown Films and Accelerated Ultraviolet Degradability Evaluation[J]. ACS applied polymer materials, 2023, 5(5): 3457-3467. doi: 10.1021/acsapm.3c00137 [24] QIAO R M, ZHAO C P, LIU J L, et al. Synthesis of Novel Ultraviolet Absorbers and Preparation and Field Application of Anti-Ultraviolet Aging PBAT/UVA Films[J]. Polymers (Basel), 2022, 14(7). [25] KIJCHAVENGKUL T, AURAS R, RUBINO M, et al. Biodegradation and hydrolysis rate of aliphatic aromatic polyester[J]. Polymer Degradation and Stability, 2010, 95(12): 2641-2647. doi: 10.1016/j.polymdegradstab.2010.07.018 [26] WANG Z, TIAN H, WANG X, et al. Study on thermal, rheological, mechanical, morphological, and barrier properties of poly(butylene adipate-co-terephthalate)/thermoplastic starch/poly(propylene carbonate) biodegradable blown films[J]. Journal of Thermal Analysis and Calorimetry, 2023, 148(5): 1853-1865. doi: 10.1007/s10973-022-11858-8 [27] GUO M, JIN Y, HAN X, et al. Biodegradable Poly (Butylene Adipate-Co-Terephthalate) and Thermoplastic Starch Sustainable Blends Modified by Epoxy-Terminated Hyperbranched Polyester with Excellent Mechanical Properties and High Transparency[J]. Starch - Stä rke, 2023, 75(3-4): 2200169. [28] 吴思, 高维常, 蔡凯, 等. PBAT生物降解地膜降解特征对不同土壤水分的响应[J]. 灌溉排水学报, 2020, 39(06): 43-50.WU Si, High-dimensional Constant, Cai Kai, et al. The Impact of Soil Moisture on Degradation of Biodegradable PBAT Mulching Films[J]. Journal of Irrigation and Drainage, 2020, 39(06): 43-50(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 138

- HTML全文浏览量: 77

- 被引次数: 0

下载:

下载: