Study on friction behaviors and wear mechanisms of carbon fiber reinforced composites under load and hygrothermal service conditions

-

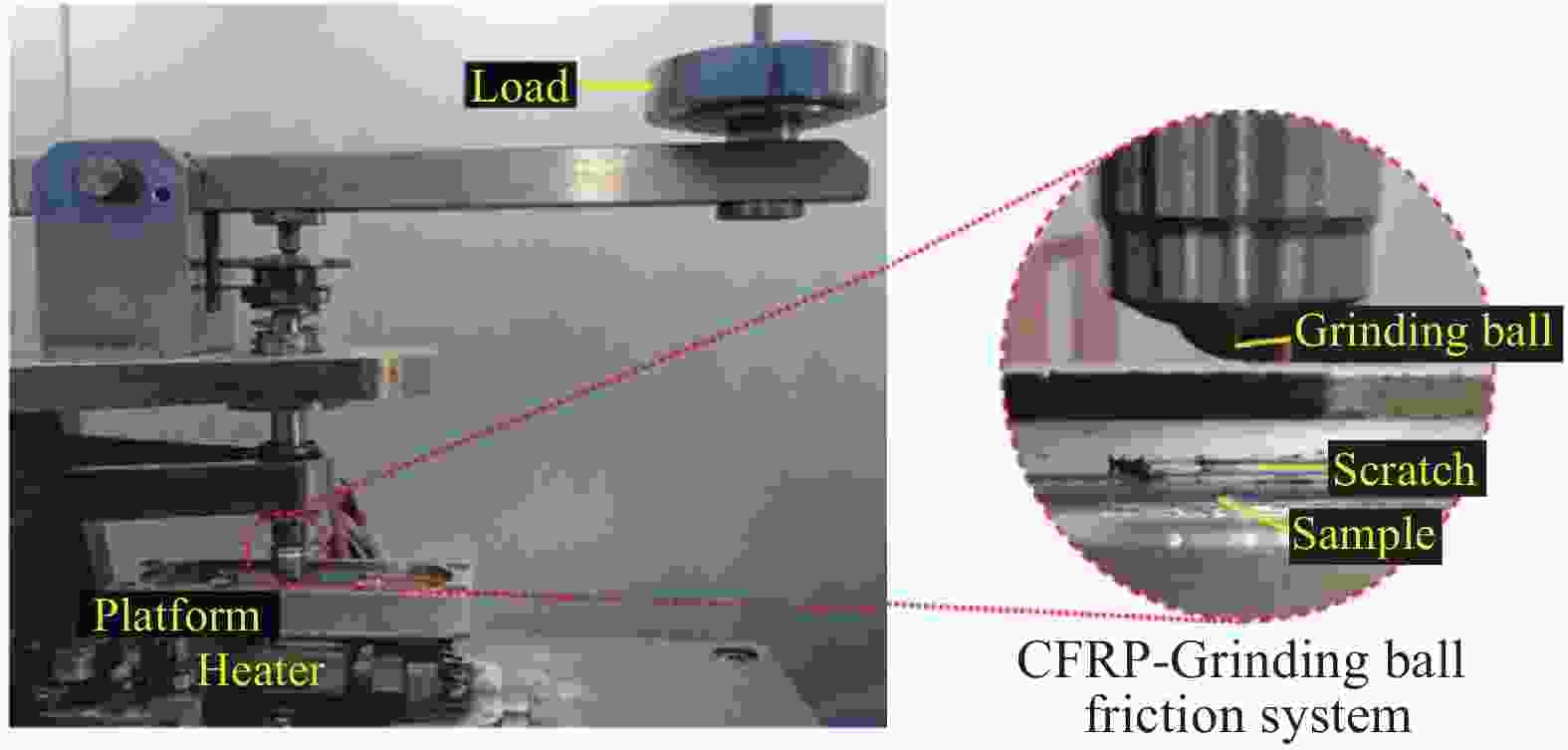

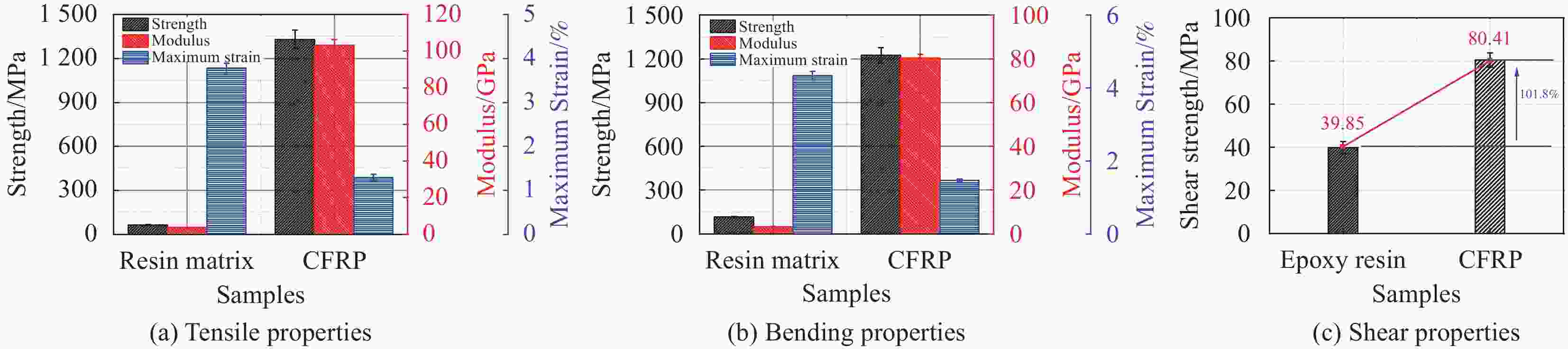

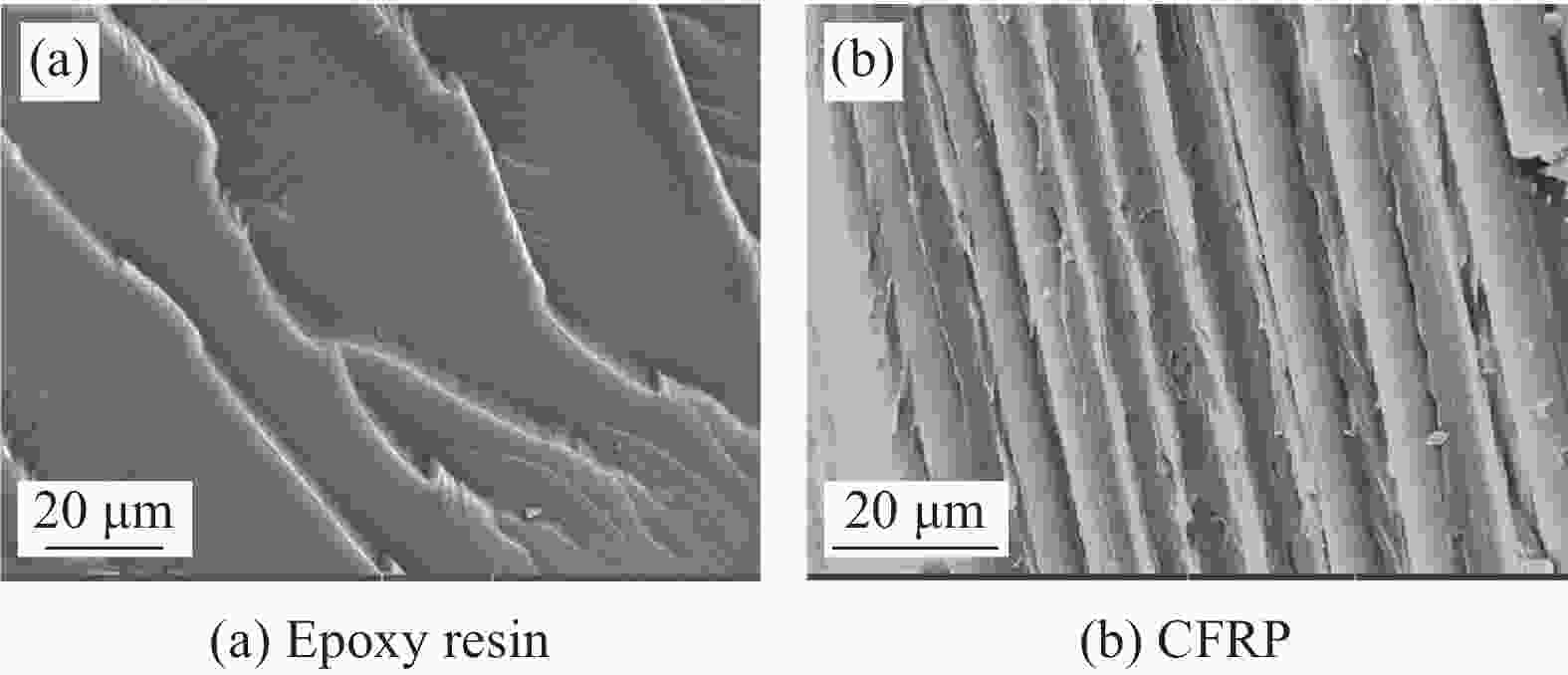

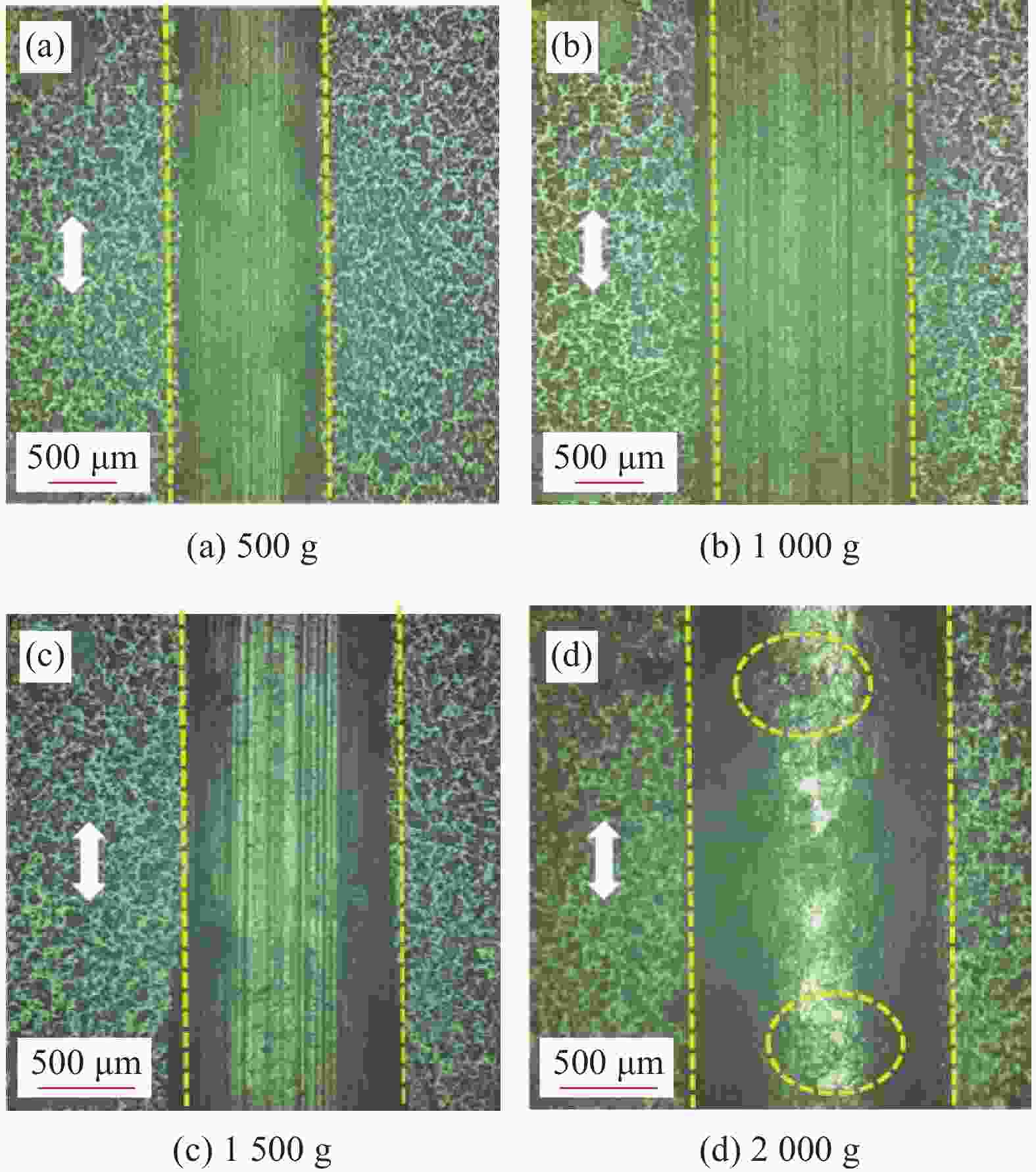

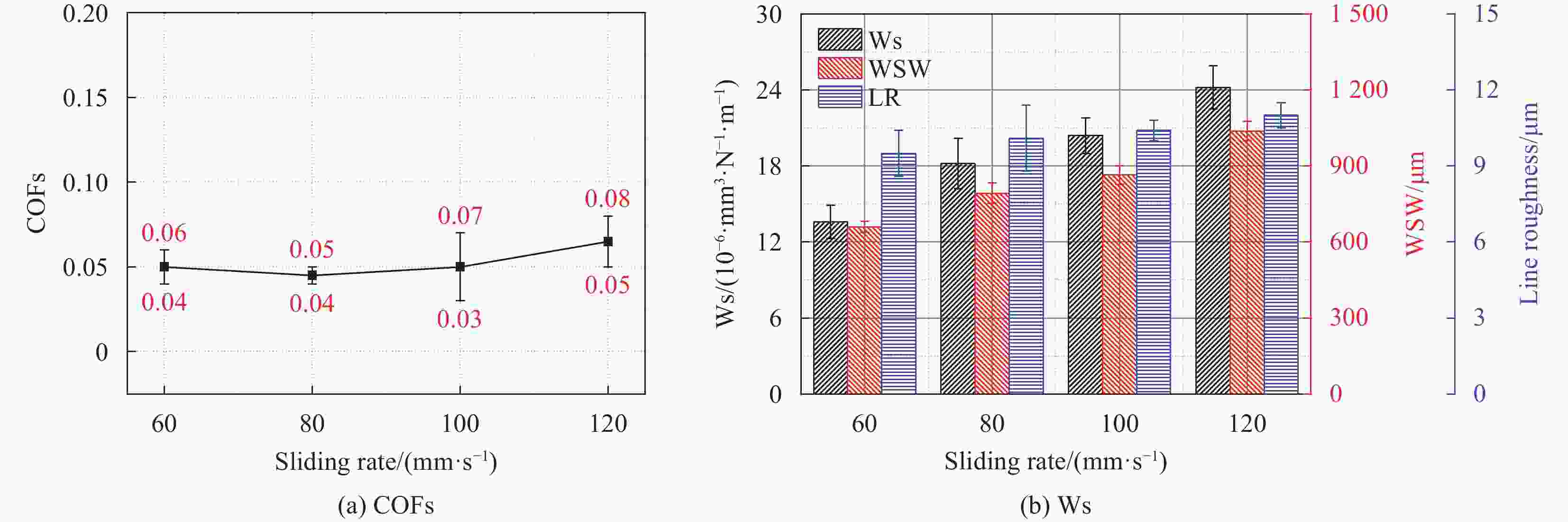

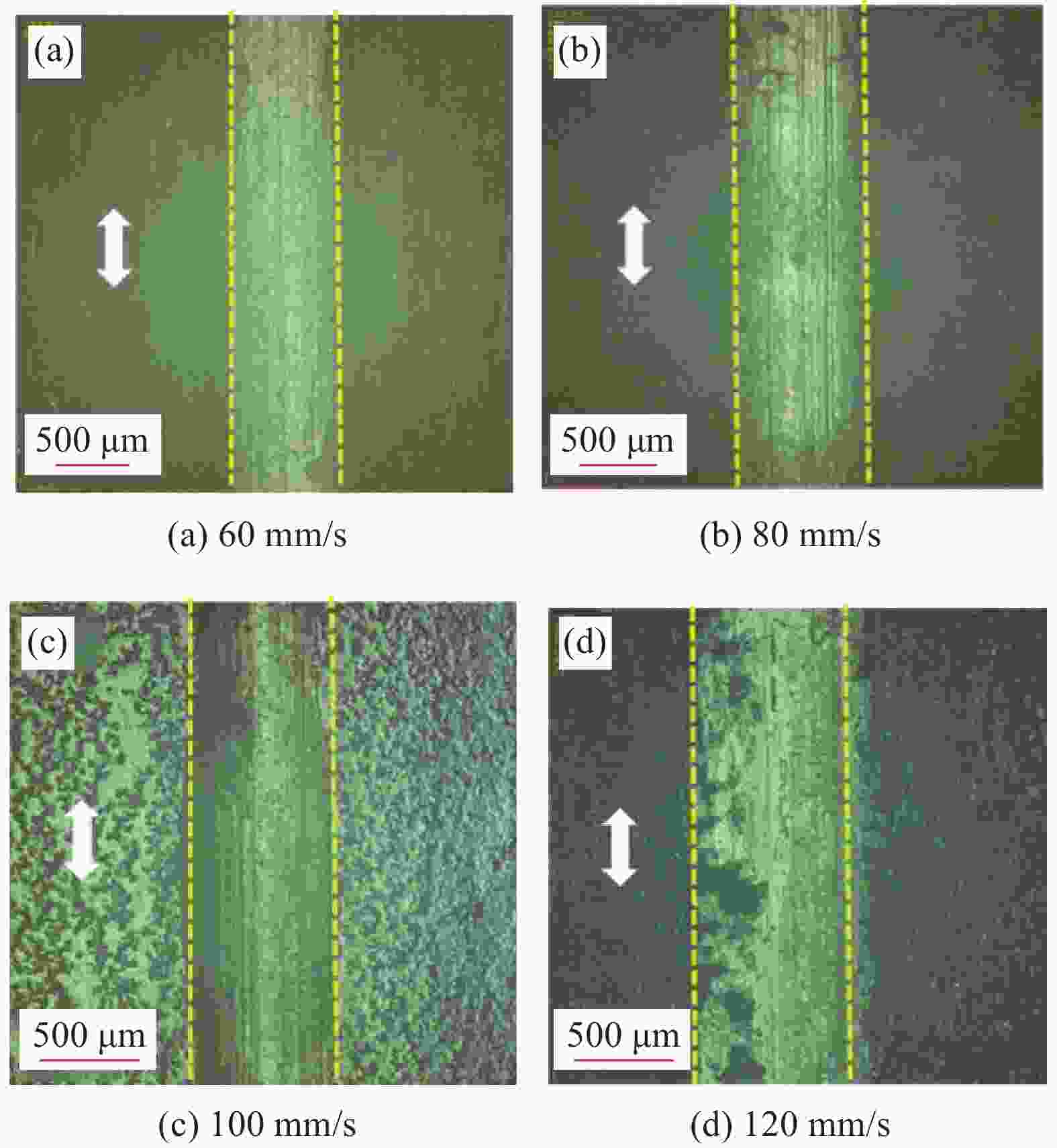

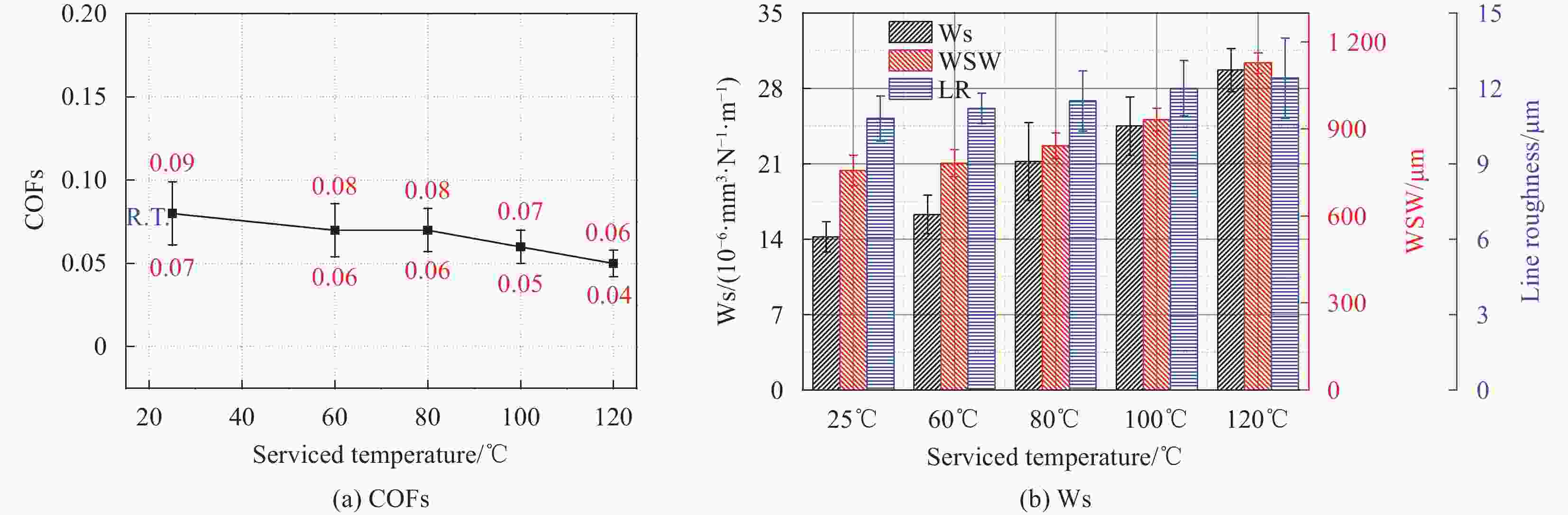

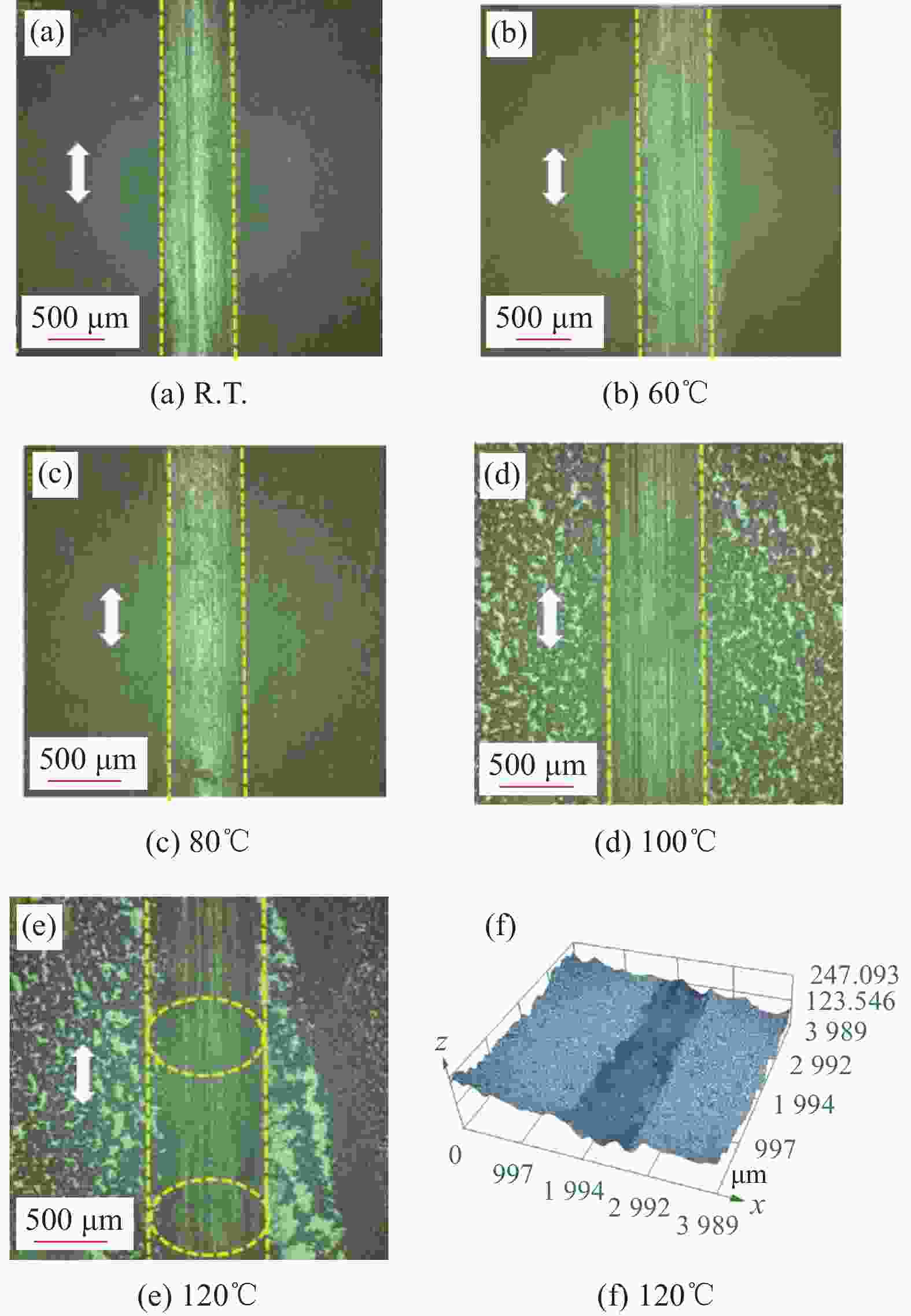

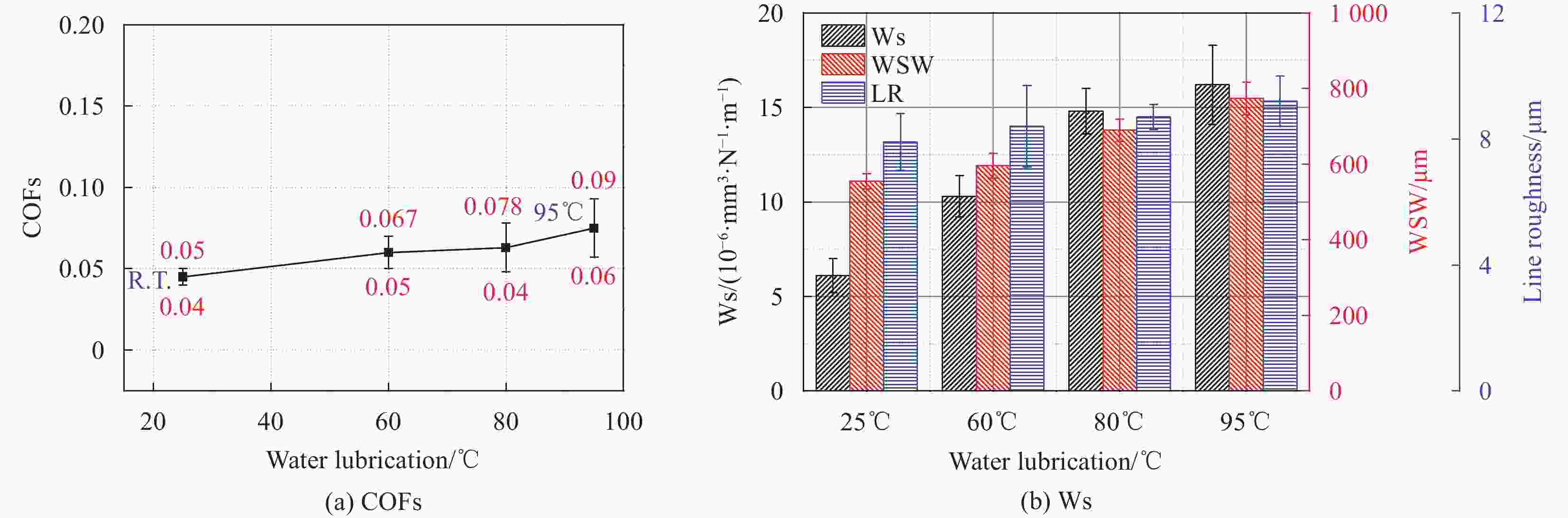

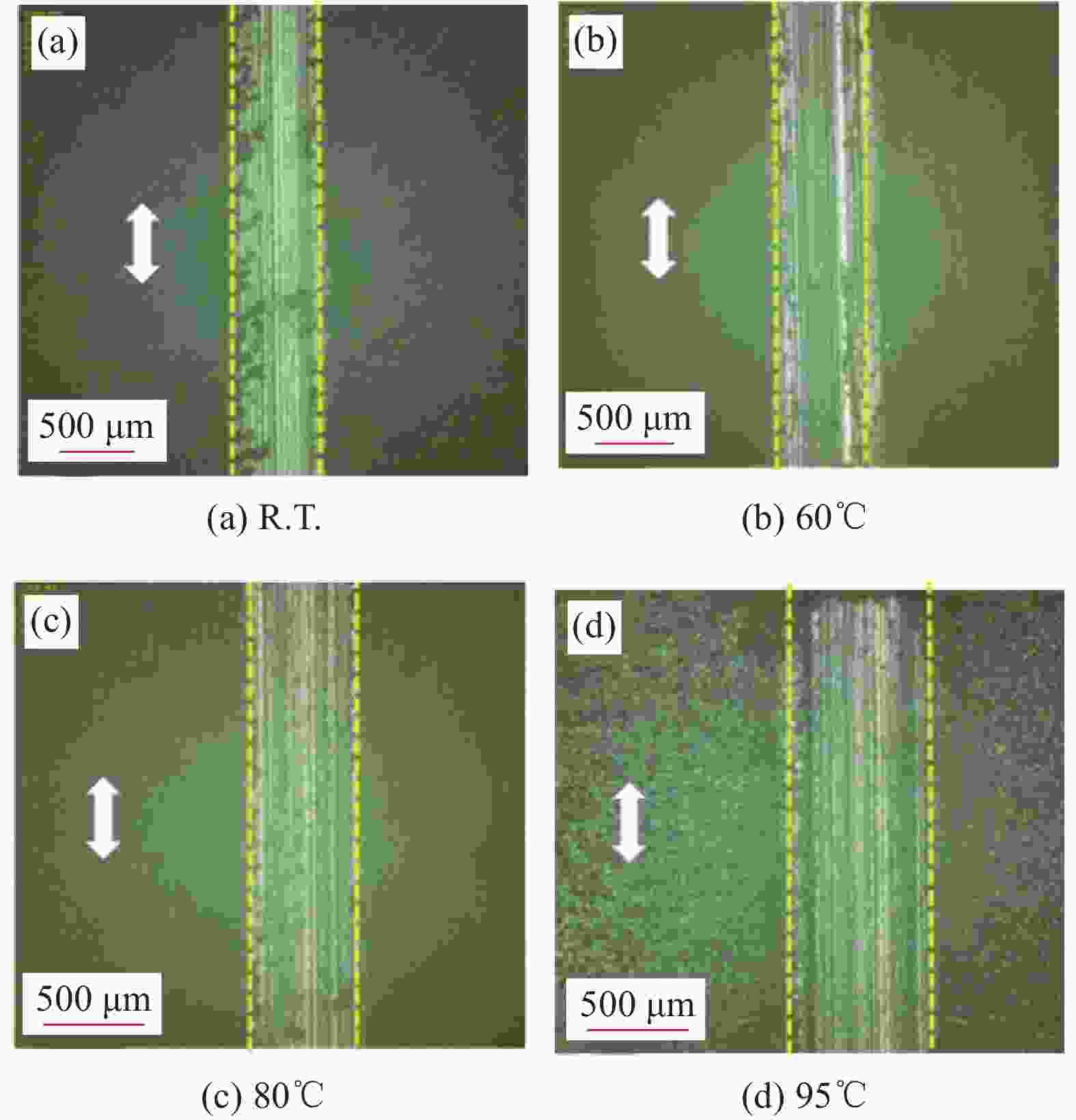

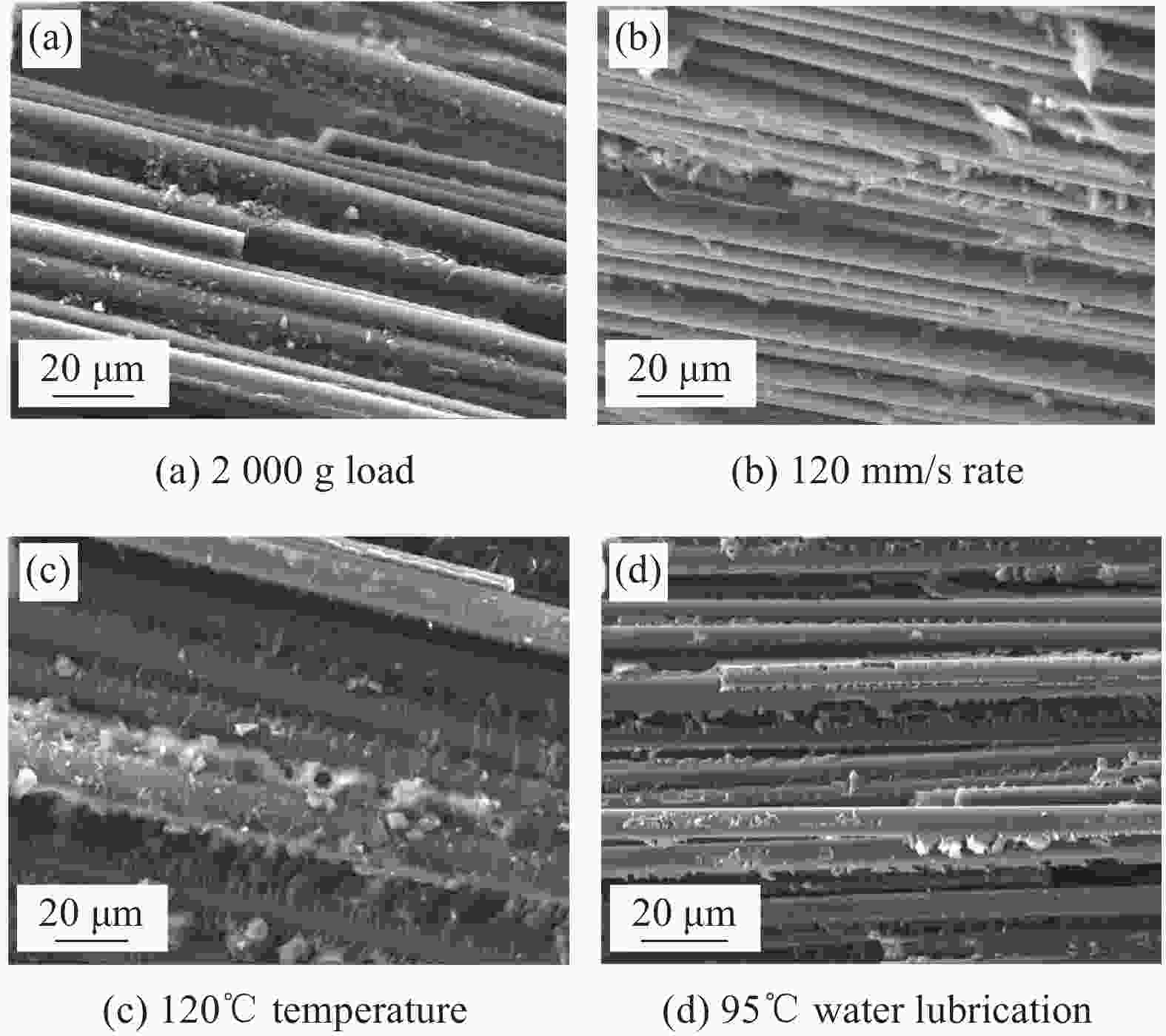

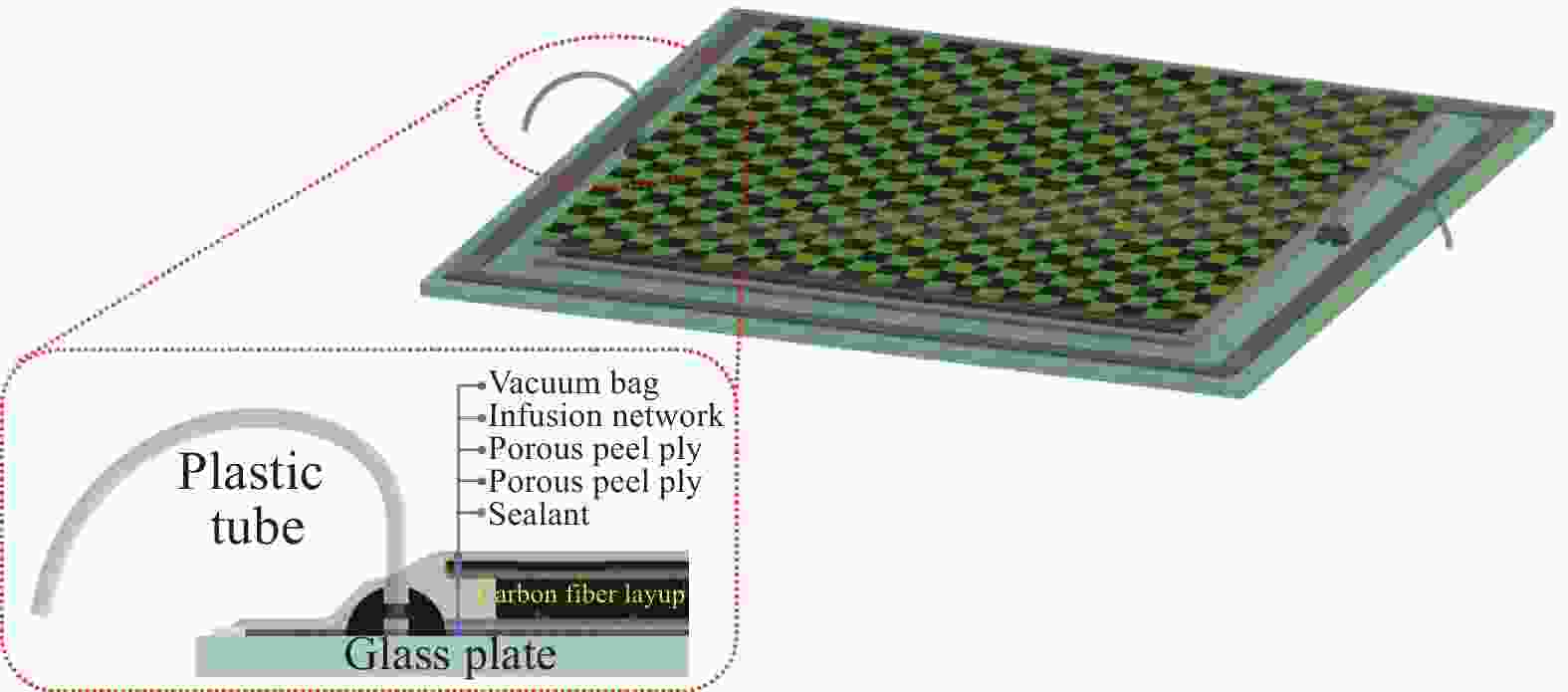

摘要: 海洋工程结构用金属材料易产生锈蚀、磨损与疲劳等不可逆损伤,严重降低结构的服役寿命与安全储备。碳纤维增强环氧树脂(CFRP)复合材料具有较高的比强度/模量,尤其在高载、冲刷、高温、高湿等湿热服役工况下具有优异耐摩擦与抗磨损性能,作为工程材料有望大幅度提高海洋工程结构服役寿命。本文中,研究了CFRP力学性能以及在不同施加荷载、滑动速率、服役温度以及水润滑等湿热服役工况下摩擦行为与磨损机制。研究发现,基于真空灌注工艺,CFRP板破坏断口显示纤维被树脂紧紧包裹,并没有出现纤维团聚及纤维布分层现象。CFRP摩擦磨损性能对荷载最敏感,因为切向位移使得摩擦副界面产生较大剪切应力;服役温度第二;滑动速率第三;水润滑影响最小,归因于水分子增加了对磨面距离,缓解了磨损程度。与500 g相比,负载2000 g试样磨损速率和划痕宽度分别增加了155.9%和111.0%,归因于高负载工况使得纤维/树脂界面发生脱粘损伤,并引发严重分层磨损;与室温相比,100 ℃和120 ℃服役温度下CFRP磨损速率分别增加了72.5%和109.2%,归因于高温服役工况使得环氧树脂从玻璃态变为高弹态,引发过度塑性变形,最终使得CFRP发生明显疲劳磨损。此外,滑动速率和水润滑工况对CFRP摩擦系数影响不明显(小于20%),尤其60 ℃水润滑下其摩擦系数仅波动了13.4%,这是因为水分子的润滑功能和散热作用减少了摩擦程度,仅发生轻微的磨粒磨损;120 mm/s速率下CFRP磨损速率较60 mm/s增加了77.9%,归因于较大速率差使得CFRP表面和亚表面变形不一致,导致粘着磨损发生。Abstract: Metal materials used in marine engineering structures are prone to irreversible damage such as corrosion, wear and fatigue, which seriously reduces the service life and safety reserve of structures. Carbon fiber reinforced epoxy resin (CFRP) composites have a high specific strength/modulus, especially in the high load, washing, high temperature, high humidity and other hygrothermal service conditions have excellent friction and wear resistance, as engineering materials is expected to greatly improve the service life of the marine engineering structure. In this paper, the basic mechanical properties of CFRP as well as the friction behavior and wear mechanism under different applied loads, sliding rates, service temperatures and water lubrication were studied. It was found that based on the vacuum perfusion process, the failure fracture of CFRP plates showed that the fibers were tightly wrapped by resin, and there was no fiber agglomeration and fiber lamination. The friction and wear properties of CFRP were most sensitive to the load, because the tangential displacement caused large shear stress at the interface between the specimen and the grinding ball; service temperature was second; sliding rate was third. The influence of water lubrication was minimal, which because the water molecules increased the distance and eased the wear degrees. Compared with 500 g, the wear rate and scratch width of samples loaded with 2000 g increased by 155.9% and 111.0%, respectively, which was attributed to the irreversible debonding damage at the fiber/resin interface under high load conditions, leading to severe delamination wear. Compared with room temperature, the wear rate of CFRP at 100 ℃ and 120 ℃ increased by 72.5% and 109.2% respectively, which was attributed to the fact that the elevated temperature condition caused the epoxy resin matrix to change from a glassy state to a high elastic state, resulting in excessive plastic deformation of the resin, and finally obvious fatigue wear of CFRP. In addition, the effects of sliding rate and water lubrication on the friction coefficient of CFRP were not obvious (less than 20%), especially under 60 ℃ water lubrication, the friction coefficient fluctuated only 13.4%. This was because the lubrication function and heat dissipation of water molecules reduced the friction degree, and only slight abrasive wear occurred. The wear rate of CFRP at 120 mm/s increased by 77.9% compared with 60 mm/s, which was attributed to the inconsistency of surface and subsurface deformation of CFRP due to the large speed difference, resulting in adhesive wear.

-

表 1 不同磨损服役工况下CFRP的热力学性能

Table 1. Thermodynamic properties of CFRP under different wear service conditions

Service conditions Tg/℃ Storage modulus/MPa Loss modulus/MPa Loss factor Pre-service 137.40(±1.68) 36358 11434 0.3145 2000 g load 131.93(±1.24) 32431 7135 0.2245 120 mm/s rate 134.51(±2.46) 34632 9129 0.2636 120℃ temperature 138.14(±2.45) 37542 10752 0.2864 95℃ water lubrication 136.85(±1.24) 35214 9665 0.2745 Note: Tg—Glass transition temperature. -

[1] TIAN J W, LI C G, XIAN G J. A layered superhydrophobic coating with excellent mechanical robustness and anti-corrosion performances[J]. J Mater Res Technol, 2022, 21: 4281-4298. doi: 10.1016/j.jmrt.2022.11.034 [2] TIAN Y, ZHANG G, YE H, et al. Corrosion of steel rebar in concrete induced by chloride ions under natural environments[J]. Construction and Building Materials, 2023, 369: 130504. doi: 10.1016/j.conbuildmat.2023.130504 [3] TIAN J, LI C, QI X, et al. Hygrothermal aging behavior and mechanism of multi-filler reinforced epoxy composites for steel structure coatings[J]. European Polymer Journal, 2023, 184: 111780. doi: 10.1016/j.eurpolymj.2022.111780 [4] 周竞洋, 汪昕, 梁训美, 等. 混杂纤维发热格栅增强砂浆/混凝土板力学性能[J]. 南京工业大学学报(自然科学版), 2023, 45(6): 682-694.ZHOU Jingyang, WANG Xin, LIANG Xunmei, et al. Mechamical properties of hybrid fiber healing texlile reinoreed mortar/conerete slab[J]. Journal of Nanjing Tech University (Natural Scienee Ediion), 2023, 45(6): 682-694 (in Chinese) [5] SUN Z, LUO Y, CHEN C, et al. Mechanical enhancement of carbon fiber-reinforced polymers: from interfacial regulating strategies to advanced processing technologies[J]. Progress in Materials Science, 2023: 101221-101246. [6] QI X, TIAN J, XIAN G. Hydrothermal ageing of carbon fiber reinforced polymer composites applied for construction: A review[J]. Journal of Materials Research and Technology, 2023. [7] QI X, TIAN J, GUO R, et al. Hydrothermal aging of carbon fiber reinforced polymer rods intended for cable applications in civil engineering[J]. Journal of Materials Research and Technology, 2023, 26: 5151-5166. doi: 10.1016/j.jmrt.2023.08.285 [8] XIA Z, JIANG T, YU T. Innovating arch structures with fiber-reinforced polymer composites: A review[J]. Advances in Structural Engineering, 2023, 26(13): 2341-58. doi: 10.1177/13694332231180373 [9] LOBANOV D, SLOVIKOV S, LUNEGOVA E. Influence of Internal Technological Defects on the Mechanical Properties of Structural CFRP[J]. Frattura ed Integrità Strutturale, 2023, 17(65): 74-87. [10] 李昊, 宋世聪, 张炫烽, 等. 树脂基防隔热一体化热防护复合材料高温性能演变分析[J]. 南京工业大学学报(自然科学版), 2024, 46(2): 180-187.Ll Hao, SONG Shicong, ZHANG Xuanfeng, et al. Analysis of the evolution of high temperature perormance of resin-based anti-insulation integrated thermal protection composites[J]. Joural of Naniing Tech University ( Natural Science Edition), 2024, 46(2): 180-187 (in Chinese). [11] 王安妮, 刘晓刚, 岳清瑞. 碳纤维复合材料拉索的锚固体系及服役性能研究进展[J]. 建筑结构学报, 2022, 43(9): 45-54.WANG Anni, LIU Xiaogang, YUE Qingrui. Research progress of carbon fiber reinforced polymer composite cable: anchorage system and service performance[J]. Journal of Building Structures, 2022, 43(9): 45-54 (in Chinese). [12] 刘文迪, 张芝芳, 王景东. 纤维增强复合材料结构的弯曲疲劳性能研究现状[J]. 南京工业大学学报(自然科学版), 2023, 45(05): 478-89.LIU Wendi, ZHANG Zhifang, WANG Jingdong. Review of bending fatigue behavior of fiber reinforced polymer composites[J]. Journal of Nanjing Tech University ( Natural Science Edition) , 2023, 45(5): 478-489 (in Chinese). [13] SAHU R, PONNUSAMI S A, WEIMER C, et al. Interface engineering of carbon fiber composites using CNT: A review[J]. Polymer Composites, 2024, 45(1): 9-42. doi: 10.1002/pc.27772 [14] TIAN J, TANG Q, LI C, et al. Mechanical, bonding and tribological performances of epoxy-based nanocomposite coatings with multiple fillers[J]. J Appl Polym Sci, 2022, 139(23): 52303. doi: 10.1002/app.52303 [15] ZHUANG X, MA J, DAN Y, et al. Hydrothermal aging of carbon fiber reinforced epoxy composites with different interface structures[J]. Polymer Degradation and Stability, 2023, 212-220: 110352. [16] YONG D, YU'E M, WENBO S, et al. Effect of hygrothermal aging on moisture diffusion and tensile behavior of CFRP composite laminates[J]. Chinese Journal of Aeronautics, 2023, 36(3): 382-392. doi: 10.1016/j.cja.2022.11.022 [17] TIAN J, QI X, LI C, et al. Friction behaviors and wear mechanisms of multi-filler reinforced epoxy composites under dry and wet conditions: Effects of loads, sliding speeds, temperatures, water lubrication[J]. Tribology International, 2023, 179: 108148. doi: 10.1016/j.triboint.2022.108148 [18] TIAN J, LI C, XIAN G. Reciprocating friction and wear performances of nanometer sized-TiO2 filled epoxy composites[J]. Polymer Composites, 2021, 42(4): 2061-2072. doi: 10.1002/pc.25959 [19] 李烁. 基于碳纳米管和石墨烯的环氧树脂复合材料的摩擦学性能研究 [D], 2020.LI Shuo. Study on Tribological Properties of Epoxy Resin Composites Based on Carbon Nanotubes and Graphene [D], 2020 (in Chinese). [20] YADAV R, SINGH M, SHEKHAWAT D, et al. The role of fillers to enhance the mechanical, thermal, and wear characteristics of polymer composite materials: A review[J]. Composites Part A: Applied Science and Manufacturing, 2023, 175: 107775-107787. doi: 10.1016/j.compositesa.2023.107775 [21] 于志强, 姜月. 颗粒填充环氧复合材料的摩擦学性能研究进展[J]. 材料工程, 2016, 44(3): 114-121. doi: 10.11868/j.issn.1001-4381.2016.03.018YU Zhi-qiang, JIANG Yue. Research Progress in Tribological Properties of Particles Filled Epoxy Resin Composites[J]. Journal of Materials Engineering, 2016, 44(3): 114-121 (in Chinese). doi: 10.11868/j.issn.1001-4381.2016.03.018 [22] 张哲轩, 杨忠仪, 夏荣华, 等. Cr-C类石墨复合涂层制备表征及其在硬质合金铣刀上的应用[J]. 南京工业大学学报(自然科学版), 2024, 46(1): 55-64.ZHANG Zhexuan, YANG Zhongyi, XlA Ronghua, et al. Preparation and characterization of Cr-C type graphite composite coating and its application in cemented carbide milling cuters[J]. Joural of Nanjing Tech Universily ( Natural Science Edition), 2024, 46(1): 55-64 (in Chinese). [23] TIAN J, QI X, XIAN G. Effect of hygrothermal aging on the friction behavior and wear mechanism of the multi-filler reinforced epoxy composites for coated steel[J]. Journal of Materials Research and Technology, 2024, 32: 140-151. doi: 10.1016/j.jmrt.2024.07.096 [24] Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials: [S]. D30.04, 2000. [25] ASTM D. 7264/D 7264M–07[J]. Standard test method for flexural properties of polymer matrix composite materials, 2007, 1. [26] Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates: [S]. D30.04, 2022. [27] GANGINENI P K, GUPTA K B G, PATNAIK S, et al. Recent advancements in interface engineering of carbon fiber reinforced polymer composites and their durability studies at different service temperatures[J]. Polymer Composites, 2022, 43(7): 4126-4164. doi: 10.1002/pc.26716 [28] 田经纬, 齐肖, 郭瑞, 等. 湿热老化对碳纤维增强复合材料力学和摩擦磨损性能的影响[J]. 复合材料学报: 1-13.TIAN Jingwei, QI Xiao, GUO Rui, et al. Effect of hygrothermal aging on the mechanical and frictional wear properties of carbon fiber reinforced composites[J]. Acta Materiae Compositae Sinica, 2025, 42 (in Chinese). [29] 杜岳峰. 石墨烯超润滑以及石墨烯复合材料摩擦学性能研究 [D], 2021.DU Yuefeng. Superlubricity of Graphene and Tribological Properties of Graphene Composites [D], 2021 (in Chinese). [30] ZAGHLOUL M M Y, STEEL K, VEIDT M, et al. Wear behaviour of polymeric materials reinforced with man-made fibres: A comprehensive review about fibre volume fraction influence on wear performance[J]. Journal of Reinforced Plastics and Composites, 2022, 41(5-6): 215-241. doi: 10.1177/07316844211051733 [31] ASMAEL M, SAFAEI B, KALAF O, et al. Recent developments in tensile properties of friction welding of carbon fiber-reinforced composite: A review[J]. Nanotechnology Reviews, 2022, 11(1): 1408-1436. doi: 10.1515/ntrev-2022-0083 [32] MAN Z, WANG H, HE Q, et al. Friction and wear behaviour of additively manufactured continuous carbon fibre reinforced PA6 composites[J]. Composites Part B: Engineering, 2021, 226: 109332. doi: 10.1016/j.compositesb.2021.109332 [33] SUDHAGAR S, KUMAR S S. Determination of wear, friction behavior and characterization of carbon fiber reinforced epoxy composites for transport applications[J]. Materials Research, 2020, 23(6): e20200268. doi: 10.1590/1980-5373-mr-2020-0268 [34] ZHANG X, ZHANG M, SHAO M, et al. Comparative Study on Tribological Behavior of Fe 3 Al Alloy Against Different Counterparts in Seawater[J]. Journal of Materials Engineering and Performance, 2021, 30: 8030-8039. doi: 10.1007/s11665-021-06031-5 [35] DASARI A, YU Z-Z, MAI Y-W. Fundamental aspects and recent progress on wear/scratch damage in polymer nanocomposites[J]. Materials Science and Engineering: R: Reports, 2009, 63(2): 31-80. doi: 10.1016/j.mser.2008.10.001 [36] 田经纬, 白艳博, 李承高, 等. 尼龙6填料对碳纤维-环氧树脂复合材料力学与摩擦磨损性能的提升机制[J]. 复合材料学报, 2023, 40(9): 5011-5025.TIAN Jingwei, BAl Yanbo, LI Chenggao, et al. Enhancement mechanism of nylon 6 filler on the mechanical and frictional wear properties of carbon fiber-epoxy resin composites[J]. Acta Materiae Compositae Sinica, 2023, 40(9): 5011-5025 (in Chinese). [37] ABDULLA F A, HAMID K L, OGAILI A A F, et alExperimental study of Wear Rate Behavior for Composite Materials under Hygrothermal Effect; proceedings of the IOP Conference Series: Materials Science and Engineering, F, 2020 [C]. IOP Publishing. [38] BANDARU A K, WEAVER P M, O’HIGGINS R M. Abrasive wear performance of hygrothermally aged glass/PTFE composites[J]. Polymer Testing, 2021, 103: 107369-107379. doi: 10.1016/j.polymertesting.2021.107369 [39] BACHCHAN A A, DAS P P, CHAUDHARY V. Effect of moisture absorption on the properties of natural fiber reinforced polymer composites: A review[J]. Materials Today: Proceedings, 2022, 49: 3403-3408. doi: 10.1016/j.matpr.2021.02.812 -

点击查看大图

点击查看大图

计量

- 文章访问数: 22

- HTML全文浏览量: 9

- 被引次数: 0

下载:

下载: