Preparation and performance of CNT impregnating 3D Ethylene-Propylene Side By Side (ES)/PET nonwoven-based flexible pressure sensors

-

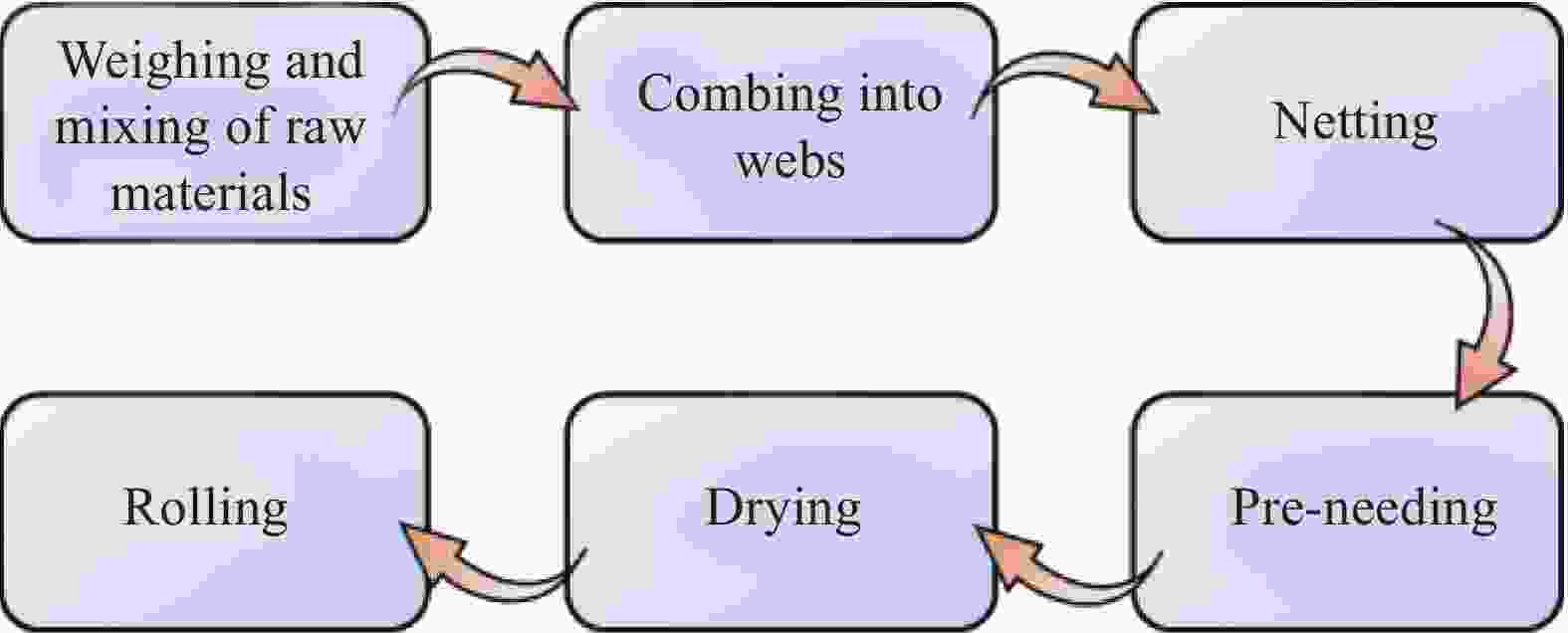

摘要: 为克服柔性传感器在灵敏度较低、生产流程复杂以及透气性不足等方面的挑战,本研究通过针刺-热熔技术制备了一种三维聚乙烯-聚丙烯(Ethylene-Propylene Side By Side,ES)/聚酯(PET)纤维非织造材料。随后,利用碳纳米管(CNT)对该材料进行浸渍处理,成功开发了一种性能优异的CNT包覆三维ES/PET非织造基压力传感器,并对比分析了不同CNT浸渍时间和浸渍次数对传感器性能的影响。研究结果显示,该CNT包覆三维ES/PET非织造基柔性压力传感器具有高达0.375 kPa−1的灵敏度和0-214.53 kPa的检测范围。经过2100次压缩循环,传感器展现了优异的稳定性和可重复性,响应时间为48 ms,恢复时间为122 ms。在实际应用中,该传感器能够精确识别如呼吸、吞咽、手指弯曲等人体细微生理活动,在运动、医疗、虚拟现实等多个领域具有潜在的广泛应用。Abstract: To address the challenges associated with low sensitivity, complex production processes, and insufficient breathability of flexible sensors, this study developed a three-dimensional nonwoven material made of polyethylene-polypropylene (Ethylene-Propylene Side By Side, ES)/polyester (PET) fibers through needle punching and thermal bonding techniques. The material was then impregnated with carbon nanotubes (CNTs), leading to the successful development of a high-performance CNT impregnating three-dimensional thermally bonded nonwoven-based pressure sensor. The impact of different CNT impregnation processes on sensor performance was comparatively analyzed. The findings indicate that the three-dimensional ES/PET nonwoven-based flexible pressure sensor exhibits a high sensitivity of up to 0.375 kPa−1 and a detection range of 0-214.53 kPa. After 2100 compression cycles, the sensor demonstrate excellent stability and repeatability, with a response time of 48 ms and a recovery time of 122 ms. In practical applications, this sensor can accurately identify subtle physiological activities such as breathing, swallowing, and finger bending, showing potential for widespread use in sports, medical, and virtual reality fields.

-

图 4 非织造材料在CNT溶液中浸渍不同时间的SEM图; ((a1)~(a3))未经过浸渍处理; ((b1)~(b3))浸渍5分钟; ((c1)~(c3))浸渍10分钟; ((d1)~(d3))浸渍15分钟

Figure 4. SEM images of nonwoven materials immersed in CNT solution for different durations; ((a1)~(a3)) untreated; ((b1)~(b3)) immersed for 5 minutes; ((c1)~(c3)) immersed for 10 minutes; ((d1)~(d3)) immersed for 15 minutes

图 5 非织造材料在CNT溶液中浸渍不同次数的SEM图; ((a1)~(a3))浸渍15分钟 1次; ((b1)~(b3))浸渍15分钟 2次; ((c1)~(c3))浸渍15分钟 3次; ((d1)~(d3))浸渍15分钟 4次

Figure 5. SEM images of nonwoven materials immersed in CNT solution for different numbers of cycles; ((a1)~(a3)) immersed for 15 minutes, one cycle; ((b1)~(b3)) immersed for 15 minutes, two cycle; ((c1)~(c3)) immersed for 15 minutes, three cycle; ((d1)~(d3)) immersed for 15 minutes, four cycle

图 14 三维ES/PET非织造基压力传感器在生活常见活动监测中的应用: (a)不同频率手指点击; (b)不同力度手指点击; (c)吞咽; (d)不同频率鼠标点击; (e)摩斯密码; (f)呼吸监测

Figure 14. Application of CNT impregnating 3 D ES/PET nonwoven-based pressure sensor in the monitoring of common activities of life: (a) Finger clicks of different frequencies; (b) Finger clicks of varying intensity; (c) Swallowing; (d) different frequency of mouse clicks; (e) Morse Code; (f) Respiratory monitoring

表 1 三维ES/PET非织造布性能测试

Table 1. Performance testing of 3 D ES/PET nonwovens

Performances Thicknesses/mm Surface density/

(g/100 cm2)Permeability/

(mm·s−1)Breaking

strength/NElongation

at break/%Breaking strength/

(cN·cm−2)1# 5.63 2.32 1990 53.50 103.20 1.07 2# 5.69 2.61 2380 63.30 116.50 1.27 3# 5.62 2.56 2210 70.00 113.90 1.40 Average value 5.65 2.50 2193.33 62.27 111.20 1.25 表 2 柔性压阻传感器性能对比表

Table 2. Performance comparison table of flexible piezoresistive sensors

Electrode Type Structure Sensitivity/kPa−1 Detect Range/kPa Response time/

msRef Silver nanowires Piezoresistive 3 D porous microstructured 0.014 0-100 64 [27] Expandable graphite Piezoresistive Planar structure 0.15 0.1-110 - [28] Reduced graphene oxide Piezoresistive Polyurethane foam 0.17 0-25 300 [29] Reduced graphene oxide Piezoresistive 3 D porous microstructured 0.009 0-180 13 [30] Reduced graphene oxide Piezoresistive Polyurethane sponge 0.13 0-30 - [31] CNT Piezoresistive 3 D nonwoven 5.57% 0-131.32 105 [32] CNT Piezoresistive 3 D ES/PET

network structure0.375 0-214.5 48 This work -

[1] 李港华, 王航, 史宝会等. 柔性电子织物的构筑及其压力传感性能[J]. 纺织学报, 2023, 44(2): 96-102.LI Ganghua, WANG Hang, SHI Baohui, et al. Construction of flexible electronic fabric and its Pressure Sensing Performance[J]. Journal of Textile Research, 2023, 44(2): 96-102(in Chinese). [2] 雷鹏, 鲍艳. 基于MXene柔性压阻传感器研究进展[J]. 材料导报, 2022, 36(14): 82-92. doi: 10.11896/cldb.20040214LEI Peng, BAO Yan. Research progress of flexible piezoresistive sensor based on MXene[J]. Materials Review, 2022, 36(14): 82-92(in Chinese). doi: 10.11896/cldb.20040214 [3] LIU Z, ALEXIS P M. Advancing Smart Biomedical Textiles with Humanoid Robots[J]. Advanced Fiber Materials, 2024, 6(1): 1-2. doi: 10.1007/s42765-023-00357-6 [4] 汤桂君, 殷柯柯, 原会雨. 纳米材料在柔性压阻式压力传感器中的研究进展[J]. 复合材料学报, 2023, 40(7): 3722-3737.TANG Guijun, YIN Keke, YUAN Huiyu. Research progress of nanomaterials in flexible piezoresistive pressure sensors[J]. Acta Materiae Compositae Sinica, 2023, 40(7): 3722-3737. [5] ZHANG S, SUN X, et al. A Wide-Range-Response Piezoresistive-Capacitive Dual-Sensing Breathable Sensor with Spherical-Shell Network of MWCNTs for Motion Detection andLanguage Assistance[J]. Nanomaterials, 2023, 13(5): 843-843. doi: 10.3390/nano13050843 [6] 王菲菲, 彭海益, 姚晓刚. 基于多向冷冻法制备的高灵敏度柔性电容式压力传感器[J]. 复合材料学报, 2023, 40(5): 2680-2687.WANG Feifei, PENG Haiyi, YAO Xiaogang. High-sensitive flexible capacitive pressure sensor based on multi-directional freezing method[J]. Acta Materiae Compositae Sinica, 2023, 40(5): 2680-2687. [7] LI L, ZHOU X, JIN B, et al. Highly compressible, breathable, and waterproof piezoresistive sensors based on commercial three-dimensional air-laid nonwovens[J]. Colloid and Polymer Science, 2023, 302(3): 449-461. [8] TIAN G, SHI Y, et al. Low-Cost, Scalable Fabrication of All-Fabric Piezoresistive Sensors via Binder-Free, In-Situ Welding of Carbon Nanotubes on Bicomponent Nonwovens[J]. Advanced Fiber Materials, 2023, 6(1): 120-132. [9] JIANG H, ZHANG J, Qin M, et al. A flexible piezoresistive strain sensor based on black phosphorus/gold nanocomposites interspersed sponge for motion sensing[J]. Sensors and Actuators A: Physical, 2023, 356: 114359. doi: 10.1016/j.sna.2023.114359 [10] CHEN K Y, XU Y T, et al. Recent progress in graphene-based wearable piezoresistive sensors: From 1D to 3D device geometries[J]. Nano Materials Science, 2023, 5(3): 247-264. doi: 10.1016/j.nanoms.2021.11.003 [11] DUCLOUÉ L, HAQUE M A, GORAL M, et al. Color-switching hydrogels as integrated microfluidic pressure sensors[J]. ScientificReports, 2024, 14(1): 6333. [12] ZHANG D, WANG Y, SUN S, et al. Ceramic hybrid nanofiber-based elastic scaffold pressure sensor with good sensitivity, breathability, and washability[J]. Ceramics International, 2024, 50(2): 3453-3460. doi: 10.1016/j.ceramint.2023.11.093 [13] 郭鑫雷, 刘鑫, 胡汉春等. 多孔聚二甲基硅氧烷/碳纳米管复合压阻式柔性压力传感器的制备[J]. 轻工机械, 2023, 41(2): 34-41. doi: 10.3969/j.issn.1005-2895.2023.02.006GUO Xinlei, LIU Xin, HU Hanchun, et al. Fabrication of piezoresistive flexible pressure sensor with porous polydimethylsiloxane/carbon nanotubes[J]. Light industry machinery, 2023, 41(2): 34-41(in Chinese). doi: 10.3969/j.issn.1005-2895.2023.02.006 [14] DING X H, CAO H L, ZHANG X H, et al. Large scale trib-electric nanogenerator and self-powered flexible sensor for human sleep monitoring[J]. Sensors, 2018, 18(6): 17. [15] JIAO H, YANG K, SANG S , et al. Graphene-based flexible temperature/pressure dual-mode sensor as a finger sleeve for robotic arms[J]. Diamond Related Materials, 2024, 142: 110799. [16] ARNALDO L J, VINICIUS C, et al. Low-cost and high-resolution pressure sensors using highly stretchable polymer optical fibers[J]. Materials Letters, 2020, 271: 127810. doi: 10.1016/j.matlet.2020.127810 [17] WANG P, MA X, LIN Z, et al. Well-defined in-textile photolithography towards permeable textile electronics.[J]. Nature communications, 2024, 15(1): 887-887. doi: 10.1038/s41467-024-45287-y [18] KAMONWAN C, ALBERT S. Dip-coated carbon nanotube surface deposits as stable, effectiveresponse enhancers in pencil lead electrode voltammetry.[J]. RSC advances, 2023, 13(46): 2672-32680. [19] FUJIKI H, TOBASE K, MUGURUMA H. Electrochemical determination of the procyanidins inpeanut skin using a carbon nanotube electrode.[J]. Analytical sciences : the international journal of the Japan Society for Analytical Chemistry, 2024, 40(3): 549-553. [20] JU B, FENG T, et al. Influence of ambient temperature and structural parameters on thermal conductivity of carbon nanotube arrays after secondary segmentation[J]. International Journal of Heat and Mass Transfer, 2023, 21: 124154. [21] ZHAO Y, SHEN T, ZHANG M , et al. Advancing the pressure sensing performance of conductive CNT/PDMS composite film by constructing a hierarchical-structured surface[J]. Nano Materials Science, 2023, 5(4): 343-350. [22] WU J Y, QIAN Y, et al. Strength prediction based on ultrasonic property of fractal gangue cemented rockfill reinforced by carbon nanotubes[J]. Construction and Building Materials, 2021, 303: 124444. doi: 10.1016/j.conbuildmat.2021.124444 [23] RAJRATAN B, GERMANO S, et al. Dielectric hysteresis, relaxation dynamics, and nonvolatile memory effect in carbon nanotube dispersed liquid crystal[J]. Journal of Applied Physics, 2009, 106(12): 124312. doi: 10.1063/1.3272080 [24] RASHID I A, IRFAN M S, Gill Y O, et al. Stretchable strain sensors based on polyaniline/thermoplastic polyurethane blends[J]. Polymer Bulletin, 2020, 77: 1081-1093. doi: 10.1007/s00289-019-02796-x [25] PROSUNG R, ARTHITTAYA C, et al. Rapid formation of carbon nanotubes-natural rubber films cured with glutaraldehyde for reducing percolation threshold concentration.[J]. Discover nano, 2024, 19(1): 30-30. doi: 10.1186/s11671-024-03970-5 [26] PATSAKORN L, SURANGSEE D. Effect of CNT on the Physical and Electrical Properties of CNT/UHMWPE Nanocomposite Sensor[J]. Materials Science Forum, 2023, 1103: 75-85. doi: 10.4028/p-Cnf88n [27] JING M Y, ZHOU J, ZHANG P C, et al. Porous AgNWs/Poly(vinylidene fluoride) Composite-Based Flexible Piezoresistive Sensor with High Sensitivity and Wide Pressure Ranges[J]. ACS Applied Materials & Interfaces, 2022, 14(49): 55119-55129. [28] 秦文峰, 王新远, 李亚云, 等. 基于膨胀石墨/聚二甲基硅氧烷复合材料的柔性压力传感器及加热除冰的应用[J]. 复合材料学报, 2021, 38(2): 461-469.QIN Wenfeng, WANG Xinyuan, LI Yayun, et al. Flexible piezoresistive sensor and heating de-icing performance based on expanded graphite/polydimethylsiloxane composite[J]. Acta Materiae Compositae Sinica, 2021, 38(2): 461-469(in Chinese). [29] ZHONG W, DING X, LI W, et al. Facile fabrication of conductive graphene/polyurethane foam composite and its application on flexible piezo-resistive sensors[J]. Polymers, 2019, 11(8): 1289. doi: 10.3390/polym11081289 [30] JIA, J M, YANG, Y. , CAI, B, et al. A 3D honeycomb graphene structure for wearable piezoresistive pressure sensor with high sensitivity[J]. Journal of Materials Science: Materials in Electronics, 2022, 33: 2003-2011. doi: 10.1007/s10854-021-07403-2 [31] GILANIZADEHDIZAJ G, AW K C, STRINGER J, et al. Facile fabrication of flexible piezo-resistive pressure sensor array using reduced graphene oxide foam and silicone elastomer[J]. Sensors and Actuators A: Physical, 2022, 340: 113549. doi: 10.1016/j.sna.2022.113549 [32] TIAN G, ZHAN L, DENG J, et al. Coating of multi-wall carbon nanotubes (MWCNTs) on three-dimensional, bicomponent nonwovens as wear-able and high-performance piezoresistive sen-sors[J]. Chemical Engineering Journal, 2021, 425: 130682. doi: 10.1016/j.cej.2021.130682 -

点击查看大图

点击查看大图

计量

- 文章访问数: 68

- HTML全文浏览量: 28

- 被引次数: 0

下载:

下载: