Bending properties of three-dimensional angle interlocking woven reinforced composites with different proportions of warp insertion

-

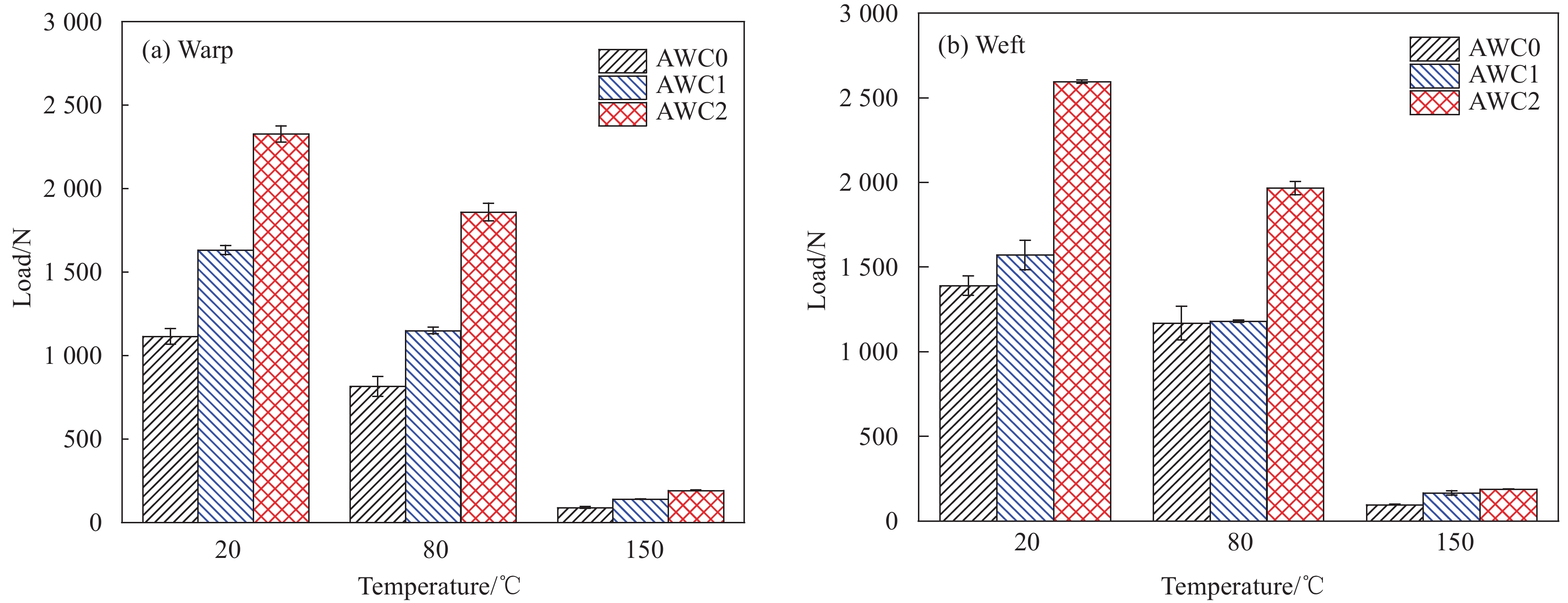

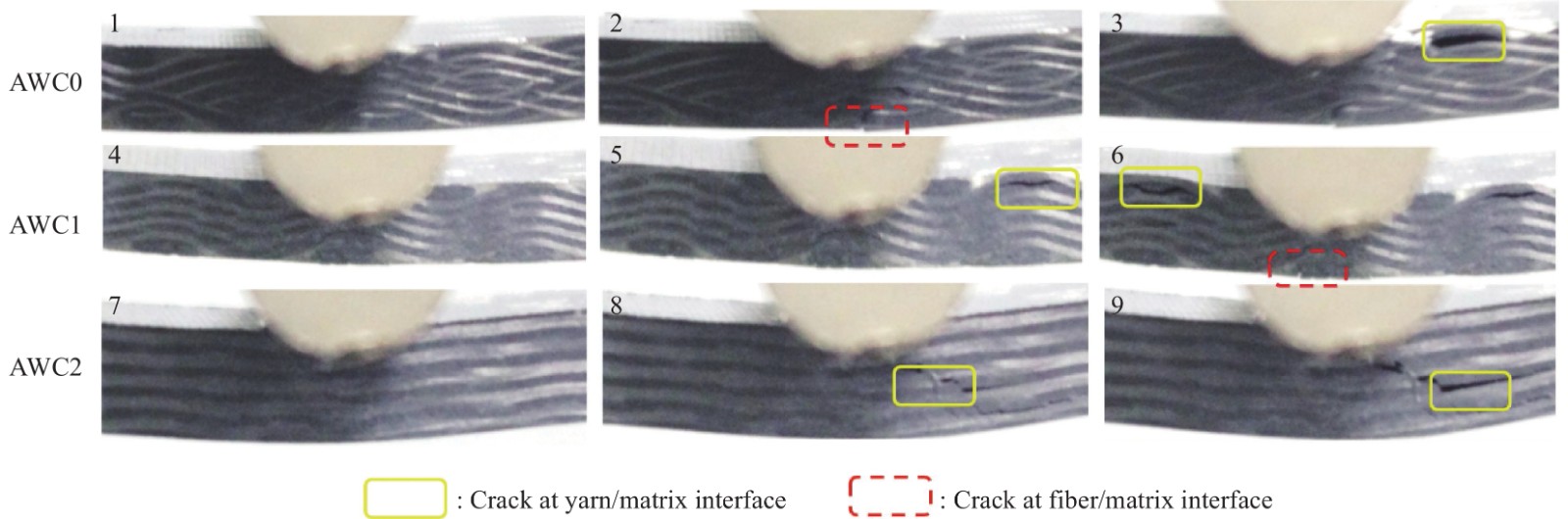

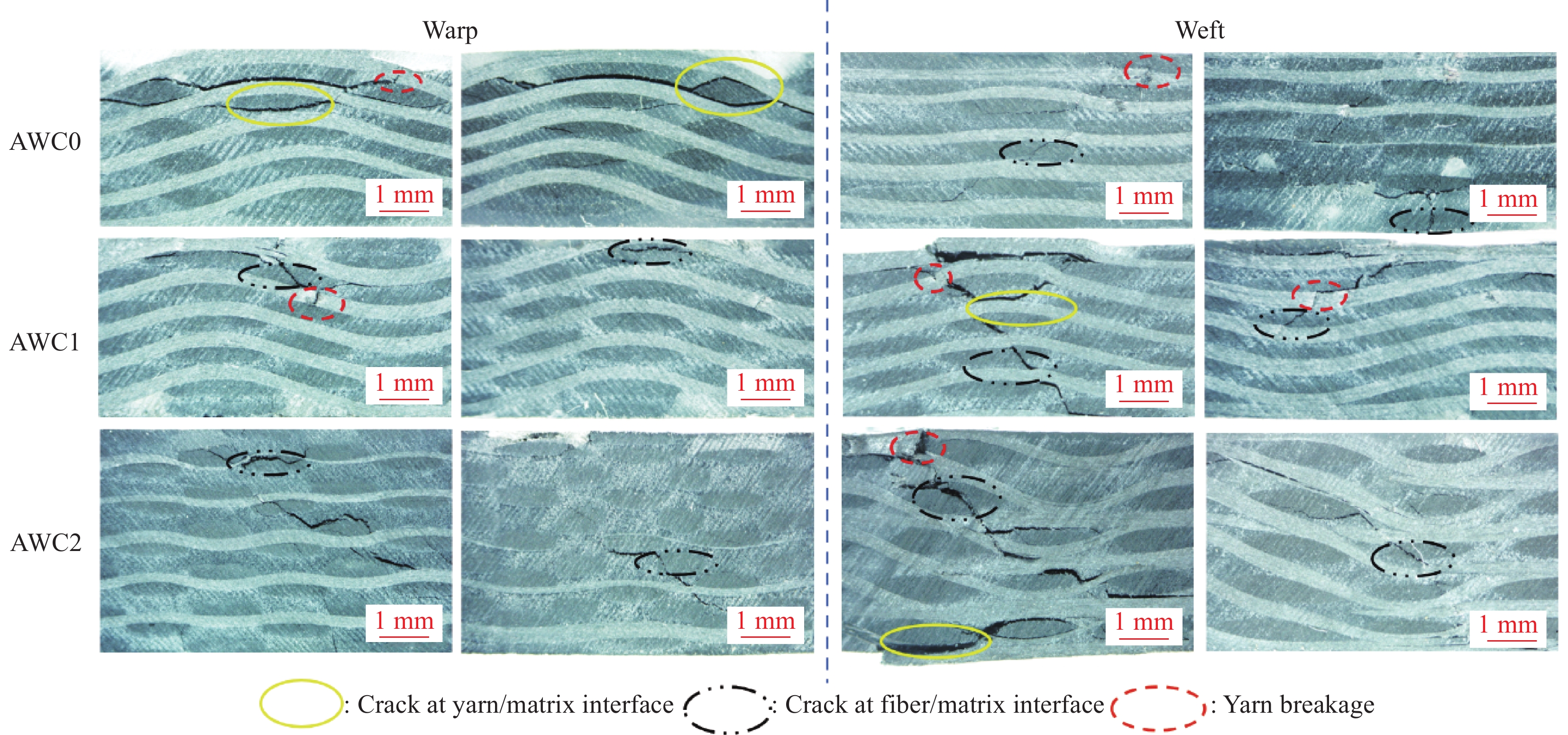

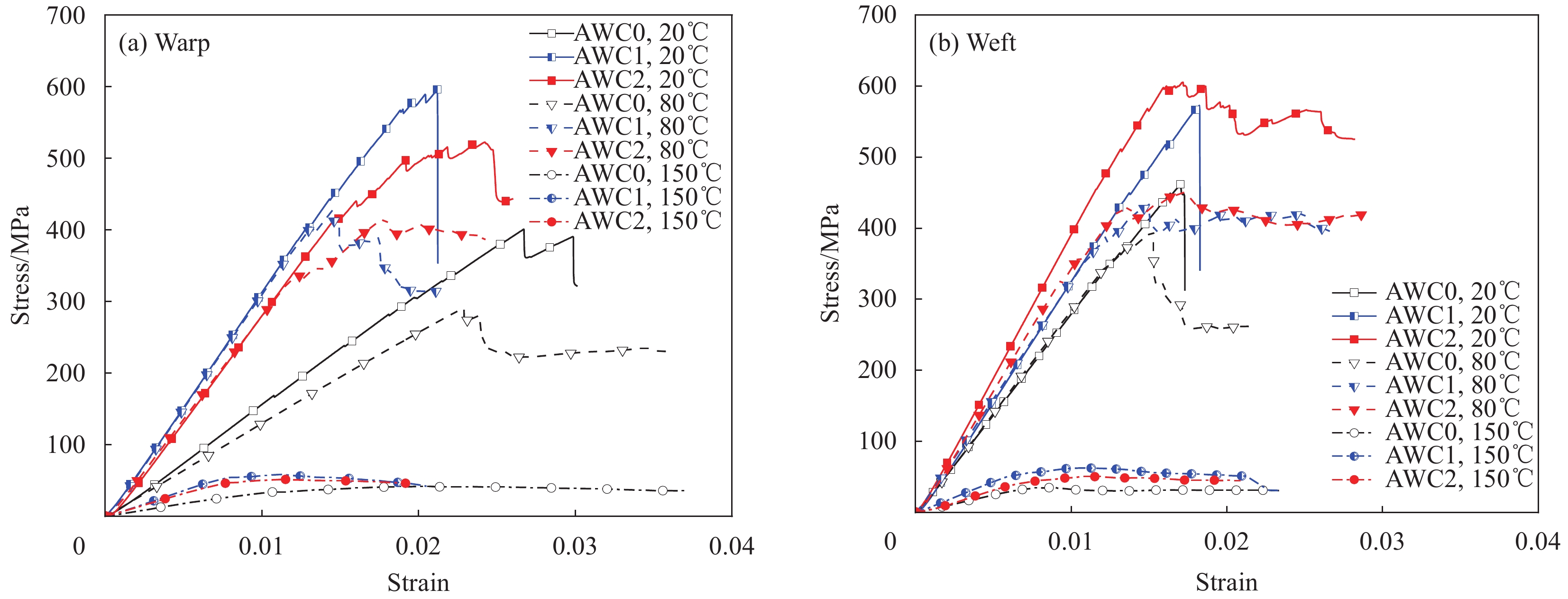

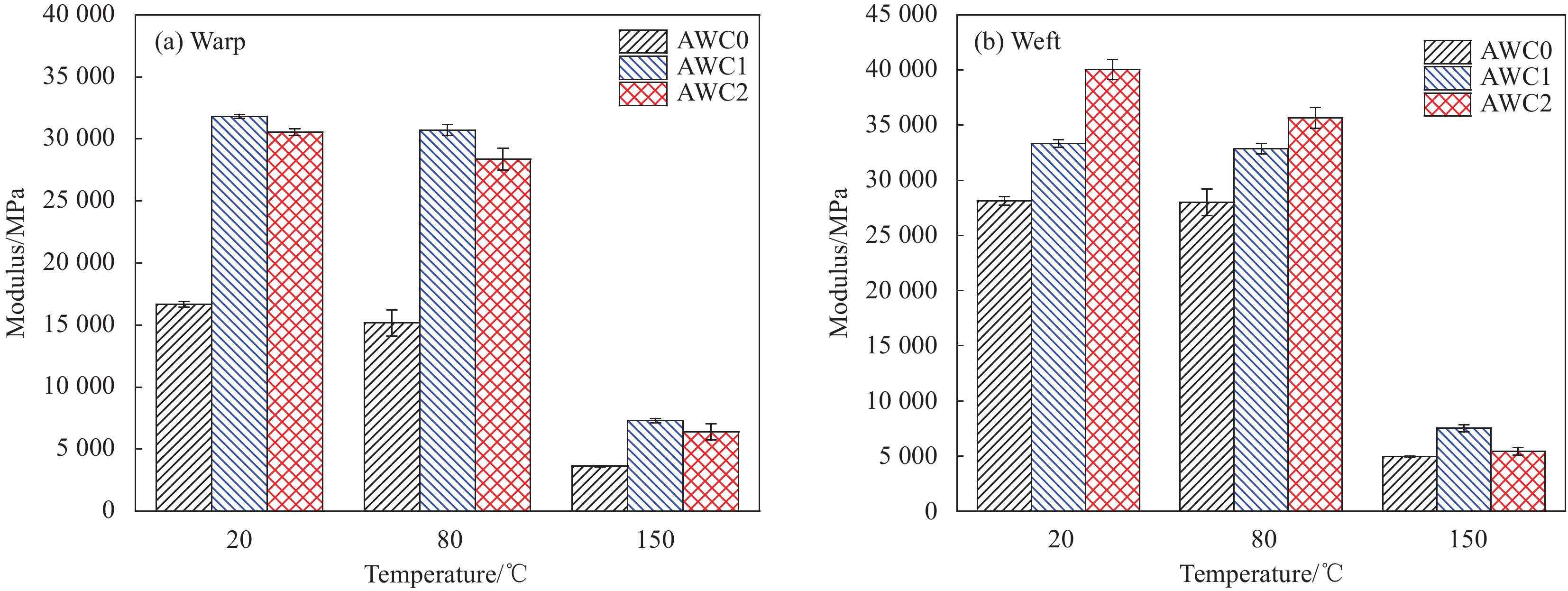

摘要: 三维角联锁机织增强复合材料(3DAWCs)具有优异的结构整体性和力学性能。为探究3DAWCs中衬经纱对力学性能的影响,本文设计并制备不同衬经纱占比的3DAWCs,研究不同温度场中不同衬经纱占比3DAWCs的弯曲性能。衬经纱与经纱比例包括:0∶1、1∶1和2∶1。温度场包括:20℃、80℃和150℃。研究结果表明:衬经纱对3DAWCs厚度、纱线形态、载荷-挠度曲线形态、弯曲强度、损伤分布均影响显著;随衬经纱占比增加,3DAWCs的厚度和最大弯曲载荷增加,但1∶1型和2∶1型试样的弯曲强度相差较小;随温度升高,试样弯曲性能下降,但在不同温度场中,不同衬经占比试样的经纬向弯曲性能对温度的敏感性不同。Abstract: 3D woven reinforced composites have good structural integrity and mechanical properties. In order to explore the influence of warp insertion on mechanical properties of three-dimensional angle interlocking woven reinforced composites (3DAWCs), 3DAWCs with different proportions of warp insertion were designed and prepared in this paper. The bending properties of 3DAWCs with different proportions of warp insertion were studied in different temperature fields. The ratios of warp insertion to warp are 0∶1, 1∶1 and 2∶1. The testing temperatures include 20°C, 80°C and 150°C. The results show that the warp insertion have a significant effect on 3DAWC’s thickness, shape of yarn, shape of load-deflection curve, bending strength and damage distribution. The thickness and maximum bending load of 3DAWCs increase with the increase of the proportion of warp insertion, but the difference of bending strength between 1∶1 and 2∶1 is minor. The bending properties of the specimen decrease with the increase of temperature. In different temperature fields, the warp and weft bending properties of samples with different warp insertion ratios have different sensitivities to temperature.

-

Keywords:

- 3D angle interlocking woven /

- warp insertion /

- composite /

- bending property /

- temperature

-

在航空航天、现代化军事、通信等领域,智能压电材料、电磁材料已得到广泛应用[1-2],其中智能压电材料因兼具驱动和传感性能,已成为近年来的研究热点之一。压电陶瓷由于机电响应速度快、驱动力大等特点[3],被广泛用作传感或驱动器。但陶瓷本身的脆性大、难以变形等缺点极大地限制了其在曲面结构件中的应用。压电纤维复合材料的概念由美国麻省理工学院智能材料和结构实验室首次提出[4],压电纤维复合材料是将压电陶瓷纤维与聚合物进行复合,克服了传统压电陶瓷的不足,具有高柔性、大应变等显著优势。压电纤维复合材料不仅具有高压电性能,同时也具有较好的柔性、较大的变形量及优异的驱动性能。因此,已在军事和民用领域广泛应用,如飞机机翼变形控制[5-6]、管道结构健康监测[7]、振动抑制[8-9]、能量采集[10-11]等。

压电纤维复合材料因其优异的性能和广泛的应用前景,引起了许多科研工作者的关注。LIN等[12]制备了方形陶瓷纤维和圆形陶瓷纤维,对比了不同纤维形状的压电纤维复合材料的应变及驱动性能的差异。陈子琪等[13]对纤维厚度和体积分数对压电纤维复合材料应变性能的影响进行了研究。陈海燕等[14]和WU等[15]研究了改性环氧树脂相对压电纤维复合材料驱动性能的影响。Bowen等[16]通过改变叉指状电极的结构参数,研究了叉指状电极对压电纤维复合材料性能的影响。

目前,对压电纤维复合材料的研究主要集中于复合材料本身的组成成分上,而对压电纤维复合材料在应用时所处极端环境温度条件下发生的性能变化研究较少且极少数在低温条件下进行。当压电纤维复合材料应用于航空航天结构与器件中时,面临着极端的环境温度条件,如航天器在太空中工作时所处环境温度范围约为−100~100℃。Pandey等[17]利用模拟分析和实验相结合,研究了不同温度下压电纤维复合材料的使用寿命情况,发现复合材料的使用寿命随着温度的升高而降低。Henslee等[18]研究了压电纤维复合材料在不同温度下的使用寿命,结果表明工作温度的降低或升高都会缩短压电纤维复合材料的使用寿命。Hobeck等[19]在不同温度下对压电纤维复合材料的性能稳定性进行测试,研究了循环过程中驱动性能的变化规律,结果表明温度的改变会增加复合材料达到性能稳定状态的时间。当压电纤维复合材料在极端环境温度下工作时,压电陶瓷相的压电活性也会受到影响而发生改变。Kungl等[20]通过向锆钛酸铅(PZT)陶瓷中掺杂不同含量的La、Sr,研究了应变特性与温度的关系,发现材料的剩余应变随着温度的升高而逐渐减小。Webber等[21]研究了PZT陶瓷的应变大小与温度的关系,发现随着温度的升高应变减小。Senousy等[22]通过实验和结果模拟分析相结合,测试了不同温度下PZT陶瓷的电滞回线,发现电滞回线的大小随着温度的升高而改变。

基于压电纤维复合材料在航空航天领域的应用,详细研究压电纤维复合材料在高低温下的性能演变规律十分必要。本文系统研究了环境温度对压电纤维复合材料电学、驱动和力学性能的影响,为压电纤维复合材料在极端环境温度下的应用提供了研究基础。

1. 实验材料及方法

制备压电纤维复合材料,采用PZT-5H陶瓷片(山东淄博宇海电子陶瓷有限公司),分子式为Pb(Zr0.52Ti0.48)O3,介电常数为3 200、压电常数d33为500×10−12 C/N;聚合物相为Araldite2020环氧树脂(美国Huntsman公司),A、B双组分混合质量比为10∶3,透明液体,黏度为0.15 Pa·s,拉伸剪切强度为23 MPa。利用切割-填充法制备PZT/树脂复合层,再利用环氧树脂对PZT/树脂复合层和叉指状电极进行封装。将封装后的压电纤维复合材料放于硅油中,施加电压进行极化,其中极化电场为4 kV/mm,极化时间为20 min,极化温度为80℃。

采用美国MTS万能力学拉伸试验机对压电纤维复合材料进行力学性能测试。采用美国Agilent 4294A阻抗分析仪进行阻抗性能测试。采用自行搭建的测试平台进行其他性能测试,如图1(a)为不同环境温度下压电纤维复合材料自由应变测试平台,自由应变测试平台的最小精度为0.1×10−6,响应时间为0.5 ms。测试压电纤维复合材料的自由应变时,在样品有效面积的中心位置分别粘贴垂直于纤维方向和平行于纤维方向的应变片,通过对样品施加一定大小和频率的交流驱动电压,测试出不同环境温度下压电纤维复合材料的横向自由应变和纵向自由应变。通过测试驱动1 mm厚的Al悬臂梁产生的顶端位移值,来表征压电纤维复合材料的驱动性能。将粘贴有压电纤维复合材料的Al板,一端固定在测试平台的基座上,另一端悬于空中。通过悬空端Al板上方的激光位移传感器采集振动,Al板的位移变化值通过NI-labview数据采集系统对位移信号与电信号进行匹配处理,驱动性能测试平台如图1(b)所示。驱动性能测试平台的最小精度为6 µm,响应时间为0.05 ms。

2. 结果与讨论

2.1 压电纤维复合材料的结构

图2(a)为压电纤维复合材料的结构示意图。可以看出,压电陶瓷纤维、环氧树脂和电极之间结合需紧密,叉指状电极的上下电极需对齐。压电纤维复合材料的结构完整性和各相之间的紧密结合性,保证了压电纤维复合材料良好的驱动性能。本实验测试采用的压电纤维复合材料的实物图如图2(b)所示,其有效尺寸为28 mm×7 mm。

2.2 环境温度对压电纤维复合材料阻抗性能的影响

图3是压电纤维复合材料的电学阻抗性能与环境温度的关系图。图3(a)~3(c)为环境温度−88℃、20℃、80℃时,压电纤维复合材料的阻抗、相位角与频率之间的关系。在低温和高温环境条件下,压电纤维复合材料的谐振频率基本保持不变,但是其相位角差值会发生变化,相位角差值大小表示压电纤维复合材料的极化程度[23]。当环境温度为−88℃、20℃、80℃时,压电纤维复合材料的相位角差值分别为24.5°、39.8°、20.5°,在20℃下相位角差值最大。由图3(d)可知,当环境温度从−88℃升高至80℃时,复合材料的相位角差值随着温度的升高先增加后减小。当环境温度为10℃时,相位角差值达到最大为40.4°。由于陶瓷相的活性在低温或高温下都会下降,引起压电常数d33变化[24]。同时环氧树脂的存在也会影响压电纤维复合材料的频率特性,并且放大温度的影响效应[25]。因此,环境温度的改变会影响压电纤维复合材料的极化程度,低温或高温环境下都会逐渐减弱,具体表现为压电纤维复合材料相位角差值的减小。

2.3 环境温度对压电纤维复合材料应变及驱动性能的影响

当环境温度为20℃,驱动电压大小为−400~1 200 V时,研究了不同驱动电压频率下对压电纤维复合材料的纵向自由应变和横向自由应变的影响,如图4所示。可知,随着驱动电压频率的增大,压电纤维复合材料的自由应变逐渐减小。当电压频率为0.1 Hz时,压电纤维复合材料的纵向应变为850.5×10−6,横向应变为496.0×10−6。当电压频率为1 Hz、10 Hz、20 Hz、50 Hz时,压电纤维复合材料的纵向应变分别为604.0×10−6、473.5×10−6、317.8×10−6、256.7×10−6,相比0.1 Hz时分别降低了29.0%、44.3%、62.6%、69.8%。当电压频率为1 Hz、10 Hz、20 Hz、50 Hz时,压电纤维复合材料的横向应变分别为345.5×10−6、295.4×10−6、227.5×10−6、178.1×10−6,相比0.1 Hz时分别降低了30.3%、40.4%、54.1%、64.1%。低频下压电纤维复合材料的自由应变值大于高频下的自由应变值,这种现象可以归因于压电陶瓷压电效应的频率依赖性[26]。压电陶瓷的压电效应主要源于原子能级晶格变形的内在影响和非180°电畴运动的外在影响[27-28],在较低的电压频率下,影响压电纤维复合材料应变的主要是非180°电畴的运动。随着频率的增大,非180°电畴进行重新排列的时间减少,导致电畴的宽度减小,陶瓷的压电性能降低[29],引起的压电响应变弱,表现为压电纤维复合材料的自由应变减小。

在驱动电压大小为−400~1 200 V、驱动电压频率为1 Hz时,不同环境温度下压电纤维复合材料纵向及横向自由应变如图5所示。随着环境温度的升高,压电纤维复合材料的自由应变先增大后减小。在相同的电压和频率下驱动,环境温度为20℃时压电纤维复合材料比其他温度下具有更高的纵向应变,环境温度为−10℃时复合材料具有更高的横向应变,主要是由于粘贴在压电纤维复合材料表面的应变片引起的差异。本研究中压电纤维复合材料的宽度明显小于其长度,测试用的横向应变片与复合材料的宽度相当,会影响复合材料的变形特性,导致横向应变与纵向应变的变化差异,但从图中可看出两者的数值随温度变化的整体趋势相同。环境温度为20℃时压电纤维复合材料的纵向应变和横向应变分别为604.0×10−6和345.5×10−6,而环境温度为−88℃时复合材料的纵向应变和横向应变仅为该值的46.9%和77.7%,环境温度为80℃时复合材料的纵向应变和横向应变仅为该值的51.3%和79.6%。在驱动电压和频率相同的条件下,压电纤维复合材料中各相的活性及整体的极化程度还与环境温度有关。在低温条件下,压电纤维复合材料的电畴偏转受到影响,压电陶瓷相的活性降低[30-31]。同时温度降低时,导致环氧树脂的刚度增加,压电纤维复合材料整体的柔性降低、变形能力减弱。因此,产生的自由应变大幅度下降。在高温条件下,压电纤维复合材料的极化程度同样也会受到影响。压电陶瓷相的热膨胀随温度的升高而增大[24],树脂相的黏弹性效应对压电纤维复合材料整体响应的影响会增加[32]。温度升高时,树脂相会发生软化、硬度降低,粘结性变差[33],同时部分压电转换能量会被软化的树脂相吸收,从而导致压电纤维复合材料产生的自由应变减小。

为了进一步研究环境温度对压电纤维复合材料自由应变的影响,将所得应变结果代入式(1)和式(2)[34]计算复合材料的等效横向压电系数d31和等效纵向压电系数d33:

(1) (2) 其中:V是驱动电压;s是叉指电极的相邻指间距;S1和S3是复合材料的横向应变和纵向应变。

实验所用电压V=1.6 kV,s=600 µm,将材料参数代入可计算得出不同温度下压电纤维复合材料的等效压电系数。计算选取的驱动电压−400~1 200 V和频率1 Hz为压电纤维复合材料一般工作时的条件。当环境温度为20℃时,压电纤维复合材料在准静态0.1 Hz工作条件下的等效纵向压电系数d33为319×10−12 C/N,等效横向压电系数d31为186×10−12 C/N。图6是压电纤维复合材料的等效横向压电系数d31和等效纵向压电系数d33与环境温度的关系。由于压电纤维复合材料在准静态0.1 Hz工作条件下的自由应变大于1 Hz时,因此1 Hz下计算出的压电纤维复合材料的等效压电系数小于0.1 Hz时。压电纤维复合材料的等效压电系数变化趋势与自由应变相同,由图6可知,随着环境温度从−88℃升高至80℃,压电纤维复合材料的等效横向压电系数d31和等效纵向压电系数d33均先增大后减小。当环境温度为20℃时,压电纤维复合材料的等效横向压电系数d31为130×10−12 C/N,等效纵向压电系数d33为227×10−12 C/N。而环境温度为−88℃和80℃时等效横向压电系数d31分别为101×10−12 C/N和103×10−12 C/N,等效纵向压电系数d33分别为106×10−12 C/N和116×10−12 C/N。Hooker[24]研究了纯PZT-5H陶瓷在−150~250℃温度范围内的横向压电系数d31和纵向压电系数d33值,变化趋势与本研究的相同。这说明环境温度的改变会影响压电纤维复合材料的等效压电系数。

通过自搭建的顶端位移测试平台,对压电纤维复合材料施加大小为−400~1 200 V、频率为1 Hz的交流电压,使其驱动1 mm厚的Al悬臂梁。压电纤维复合材料顶端位移与环境温度的关系如图7所示。可知,当环境温度从−88℃升高至20℃时,压电纤维复合材料的顶端位移随着温度的升高而增大;当环境温度从20℃升高至80℃时,压电纤维复合材料的顶端位移随着温度的升高而减小。20℃时驱动产生的顶端位移值为0.789 mm,而环境温度为−88℃时复合材料驱动Al板产生的顶端位移值仅为该值的79.6%,环境温度为80℃时复合材料驱动Al板产生的顶端位移值仅为该值的83.7%。由于压电材料在外加电场作用下会产生逆压电效应,因此压电纤维复合材料会发生形变,从而具有驱动性能。不同环境温度下,压电纤维复合材料驱动性能整体变化趋势的原因和自由应变变化的原因类似,但是在顶端位移测试中,低温下压电纤维复合材料是通过环氧树脂和Al悬臂梁之间黏接的,对压电纤维复合材料性能的影响因素更多,因此在低温时产生的顶端位移相对较小。在−88℃升高至20℃时,压电纤维复合材料驱动Al板产生的顶端位移变化差别较大,且在−50℃时位移值减小,是由于Al悬臂梁在低温使用时会发生收缩;同时压电纤维复合材料粘贴在Al悬臂梁上所用的环氧树脂在温度较低时,也会发生硬化,进一步减弱了复合材料的变形能力。

2.4 环境温度对压电纤维复合材料力学性能的影响

在不同环境温度下对压电纤维复合材料进行了抗拉强度测试,测试方法为沿其纤维长度方向进行拉伸,得到拉伸应力-位移曲线,如图8所示。压电纤维复合材料一般粘贴在结构表面使用,当结构发生较大弯曲变形时,结构表面承受的轴向应力会增加,进而复合材料也需承受较大应力,会导致复合材料断裂失效。可以看出,随着环境温度的升高,压电纤维复合材料的抗拉强度也增大。当环境温度为−88℃时,压电纤维复合材料的抗拉强度为41.2 MPa;当环境温度为20℃时,压电纤维复合材料的抗拉强度为68.8 MPa,该值是环境温度为−88℃时的1.67倍;当环境温度为80℃时,压电纤维复合材料的抗拉强度为71.3 MPa,该值是环境温度为−88℃时复合材料的1.73倍,同时也高于环境温度为20℃时复合材料的抗拉强度值。在低温条件下,树脂相会发生脆化,抗拉强度降低[35-36],从而压电纤维复合材料的力学性能降低。在高温条件下,树脂相会发生软化,聚合物分子链间的结合力减弱,分子链的运动性增强,与固化后未能反应的支链基团进行再交联,聚合物间的交联密度增加,复合材料柔性增大,韧性提高。随着温度的升高,复合材料中树脂相的软化程度也越高,当达到断裂极限后,由于树脂相的黏连,会导致断裂程度的不完全。在拉伸应力-位移图中表现为达到最大拉伸应力后,位移值还在继续增加。

3. 结 论

(1)当环境温度升高时,压电纤维复合材料的电学和应变及驱动性能先升高后降低,环境温度为20℃时,复合材料的相位角差值为39.8°,纵向和横向应变分别为604.0×10−6和345.5×10−6,产生的顶端位移为0.789 mm,均高于−88℃低温和80℃高温时压电纤维复合材料产生的应变及顶端位移。

(2)压电纤维复合材料的力学性能随着温度的升高而升高,抗拉强度值在环境温度为80℃时达到最大为71.3 MPa。

(3)压电纤维复合材料在高低温环境下未失效,仍然可以工作,但各项性能均有下降。未来将针对如何提高复合材料的温度稳定性方面开展工作,提高其在极端环境下的工作性能,促进其在航天、航空及民用领域的应用。

-

表 1 碳纤维性能参数

Table 1 Performance parameters of carbon fiber

Density/

(g·cm−3)Breakage elongation/% Tensile strength/MPa Tensile modulus/GPa 1.79 2.1 4900 230 表 2 环氧树脂性能参数

Table 2 Performance parameters of epoxy resin

Density/

(g·cm−3)Compressive strength/MPa Compressive modulus/MPa Glass transition temperature/℃ 1.12 117 2166 110-120 表 3 三维角联锁机织物(3DAWF)的结构参数

Table 3 Structural parameters of three-dimensional angle interlocking woven (3DAWF)

Symbol Warp insertion: Warp Weave density in weft direction/(ends·cm−1) Weave density in warp direction/(ends·cm−1) Warp yarn volume fraction/vol% Warp insertion yarn volume fraction/vol% AWF0 0∶1 20 20 20.6 0 AWF1 1∶1 20 20 12.9 12.9 AWF2 2∶1 20 20 7.8 13.2 表 4 不同衬经占比三维角联锁机织增强复合材料(3DAWC)厚度

Table 4 Thickness of three-dimensional angle interlocking woven reinforced composites (3DAWC) with different proportion of warp insertion

Sample Thickness/mm AWC0 4.05 AWC1 4.14 AWC2 5.15 -

[1] 薛有松, 薛凌明, 孙宝忠, 等. 碳纤维三维角联锁机织复合材料弯曲作用下的力阻响应[J]. 复合材料学报, 2023, 40(3):1468-1476. DOI: 10.13801/j.cnki.fhclxb.20220516.006 XUE Yousong, XUE Lingming, SUN Baozhong, et al. Piezoresistive effect of carbon fiber three-dimensional angle interlocking woven composites under bending[J]. Acta Materiae Compositae Sinica,2023,40(3):1468-1476(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20220516.006

[2] 郭玉路, 关留祥, 李嘉禄, 等. 航空发动机复合材料叶片用3D机织预制体研究进展[J]. 复合材料学报, 2018, 35(10):748-759. GUO Yulu, GUAN Liuxiang, LI Jialu, et al. Research progress on 3D woven preforms for aero-engine composite blades[J]. Acta Materiae Compositae Sinica,2018,35(10):748-759(in Chinese).

[3] 郭瑞卿, 张一帆, 吕庆涛, 等. 多层多向层联三维机织复合材料的拉伸性能[J]. 复合材料学报, 2020, 37(10):2409-2417. GUO Ruiqing, ZHANG Yifan, LU Qingtao, et al. Tensile properties of multilayer multidirectional laminated three-dimensional woven composites[J]. Acta Materiae Compositae Sinica,2020,37(10):2409-2417(in Chinese).

[4] WIELHORSKI Y, MENDOZA A, RUBINO M, et al. Numerical modeling of 3D woven composite reinforcements: A review[J]. Composites Part A: Applied Science and Manufacturing,2022,154:106729. DOI: 10.1016/j.compositesa.2021.106729

[5] BANDARU A K, AHMAD S, BHATNAGAR N. Ballistic performance of hybrid thermoplastic composite armors reinforced with Kevlar and basalt fabrics[J]. Composites Part A: Applied Science and Manufacturing, 2017, 97: 151-165.

[6] DONG K, LIU K, PAN L, et al. Experimental and numerical investigation on the thermal conduction properties of 2.5D angle-interlock woven composites[J]. Composite Structures, 2016, 154: 319-333.

[7] KUO W. The role of loops in 3D fabric composites[J]. Composites Science and Technology,2000,60(9):1835-1849. DOI: 10.1016/S0266-3538(00)00075-0

[8] LEE L, RUDOV-CLARK S, MOURITZ A P, et al. Effect of weaving damage on the tensile properties of three-dimensional woven composites[J]. Composite Structures,2002,57(1):405-413.

[9] 王忠远, 蔡长春, 王振军, 等. 三维角联锁机织铝基复合材料面内拉伸力学行为与失效机制[J]. 复合材料学报, 2021, 38(9):2989-2999. WANG Zhongyuan, CAI Changchun, WANG Zhenjun, et al. In-plane tensile mechanical behavior and failure mechanism of three-dimensional angle interlocking woven aluminum matrix composites[J]. Acta Materiae Compositae Sinica,2021,38(9):2989-2999(in Chinese).

[10] LAPEYRONNIE P, LE G P, BINETRUY C, et al. Homogenization of the elastic behavior of a layer-to-layer angle-interlock composite[J]. Composite Structures,2011,93(11):2795-2807. DOI: 10.1016/j.compstruct.2011.05.025

[11] JIN L, NIU Z, JIN B C, et al. Comparisons of static bending and fatigue damage between 3D angle-interlock and 3D orthogonal woven composites[J]. Journal of Reinforced Plastics and Composites,2012,31(14):935-945. DOI: 10.1177/0731684412450626

[12] 姚思远, 陈秀华. 三维机织复合材料在拉压循环载荷下的疲劳性能[J]. 复合材料学报, 2018, 35(10):2706-2714. YAO Siyuan, CHEN Xiuhua. Fatigue behaviors of 3D woven composites under tension-compression cyclic loading[J]. Acta Materiae Compositae Sinica,2018,35(10):2706-2714(in Chinese).

[13] 王琦, 蒋秋梅, 杨旭锋, 等. 三维机织复合材料残余应力/应变多尺度分析及工艺参数优化[J]. 复合材料学报, 2021, 38(4):1167-1176. WANG Qi, JIANG Qiumei, YANG Xufeng, et al. Multiscale analysis and process parameters optimization of residual stress/strain of 3D woven composite[J]. Acta Materiae Compositae Sinica,2021,38(4):1167-1176(in Chinese).

[14] 郭兴峰. 三维机织物[M]. 北京: 中国纺织出版社, 2015. GUO Xingfeng. 3D woven fabric[M]. Beijing: China Textile Press, 2015(in Chinese).

[15] 陆慧中, 孙颖, 焦亚男, 等. 典型多向2.5D机织预制体近净形编织结构设计[J]. 复合材料学报, 2021, 38(9):3101-3109. LU Huizhong, SUN Ying, JIAO Yanan, et al. Design of near-net-shape braided structure of typical multi-directional 2.5D woven preform[J]. Acta Materiae Compositae Sinica,2021,38(9):3101-3109(in Chinese).

[16] 冯古雨, 钱坤, 曹海建, 等. 衬经结构对角联锁机织复合材料拉伸力学性能的影响[J]. 玻璃钢/复合材料, 2017(7):45-48. FENG Guyu, QIAN Kun, CAO Haijian, et al. Effect of warp lining structure on tensile mechanical properties of angular interlocking woven composites[J]. Fiberglass/Composite Materials,2017(7):45-48(in Chinese).

[17] 杨梦琪, 陈晓钢, 高强. 三维角联锁织物的可模塑性能研究[J]. 产业用纺织品, 2020, 38(5):27-31. DOI: 10.3969/j.issn.1004-7093.2020.05.006 YANG Mengqi, CHEN Xiaogang, GAO Qiang. Study on moldability of 3D corner interlocking fabrics[J]. Technical Textiles,2020,38(5):27-31(in Chinese). DOI: 10.3969/j.issn.1004-7093.2020.05.006

[18] LI J, FAN W, LIU T, et al. The temperature effect on the inter-laminar shear properties and failure mechanism of 3D orthogonal woven composites[J]. Textile Research Journal,2020,90:2806-2817.

[19] DANG M, LI D, JIANG L. Temperature effects on mechanical response and failure mechanism of 3D angle-interlock woven carbon/epoxy composites[J]. Composites Communications,2020,18:37-42. DOI: 10.1016/j.coco.2020.01.001

[20] SONG L, WEN W, CUI H. Experimental and numerical investigation of mechanical behaviors of 2.5D woven composites at ambient and un-ambient temperatures[J]. Composite Structures, 2018.

[21] SORRENTINO L, DE VASCONCELLOS D S, D'AURIA M, et al. Effect of temperature on static and low velocity impact properties of thermoplastic composites[J]. Composites Part B: Engineering,2017,113:100-110. DOI: 10.1016/j.compositesb.2017.01.010

[22] WANG S, ZHANG J, ZHOU Z, et al. Compressive and flexural behavior of carbon fiber-reinforced PPS composites at elevated temperature[J]. Mechanics of Advanced Materials and Structures,2020,27(4):286-294. DOI: 10.1080/15376494.2018.1472334

[23] RICCIARDI M R, PAPA I, IMPERO F, et al. Low-temperature effect on the impact and flexural behaviour of basalt composite laminates[J]. Composite Structures,2020,249:112607. DOI: 10.1016/j.compstruct.2020.112607

[24] VIEILLE B, CHABCHOUB M, GAUTRELET C. Influence of matrix ductility and toughness on strain energy release rate and failure behavior of woven-ply reinforced thermoplastic structures at high temperature[J]. Composite Part B: Engineering,2017,132:125-140.

[25] WANG M, CAO M, WANG H, et al. Drop-weight impact behaviors of 3-D angle interlock woven composites after thermal oxidative aging[J]. Composite Structures,2017,82223(16):31556.

[26] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能实验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005. Standardization Administration of the People's Republic of China. Test method for flexural properties of fiber-reinforced plastics: GB/T 1449—2005[S]. Beijing: China Standard Press, 2005(in Chinese).

-

期刊类型引用(4)

1. 陈宇龙,汤林,袁晰,罗行,张斗. 基于场致应变的钛酸铋钠基压电纤维复合材料性能研究. 中南大学学报(自然科学版). 2024(08): 2857-2866 .  百度学术

百度学术

2. 鹿海军,张杜鹃,李亚锋. 温度对石英纤维增强中温固化环氧树脂复合材料性能的影响. 中国胶粘剂. 2023(06): 32-37 .  百度学术

百度学术

3. 渠娇,杜月敏,季宏丽,裘进浩. 柔性压电纤维复合材料驱动器的驱动特性研究. 振动工程学报. 2023(06): 1695-1705 .  百度学术

百度学术

4. 王兵,丁亮,林秀娟,刘欢,李佳楠,黄世峰. 不同聚合物基压电纤维复合材料应变性能的温度稳定性. 复合材料学报. 2021(06): 1817-1824 .  本站查看

本站查看

其他类型引用(4)

-

下载:

下载: