Failure Mechanisms and Defect Analysis of 3D Printed CCF/PEEK Composites Based on Synchrotron Radiation

-

摘要: 针对丝材预浸渍处理的连续碳纤维增强聚醚醚酮复合材料(CCF/PEEK),采用同步辐射μCT表征手段,分析了拉伸/弯曲过程中碳纤维/树脂界面和层间的失效模式及机制,结合缺陷和拉伸力学性能分析,揭示了预浸渍处理对CCF/PEEK材料结构和力学性能的影响。研究结果表明:由于不良浸渍及层间温度梯度,预浸渍样品在纤维/树脂界面和层间均存在缺陷,并随拉伸/弯曲载荷作用演变为层间裂纹,原丝样品则发生纤维脱粘和拔出;预浸渍处理后试样平均拉伸强度提高17.21%,孔隙率降低56.6%,树脂充分渗入纤维丝束,明显改善了材料纤维/树脂界面结合和力学性能。

-

关键词:

- 连续碳纤维增强聚醚醚酮 /

- 同步辐射μCT /

- 失效模式 /

- 预浸渍 /

- 拉伸强度

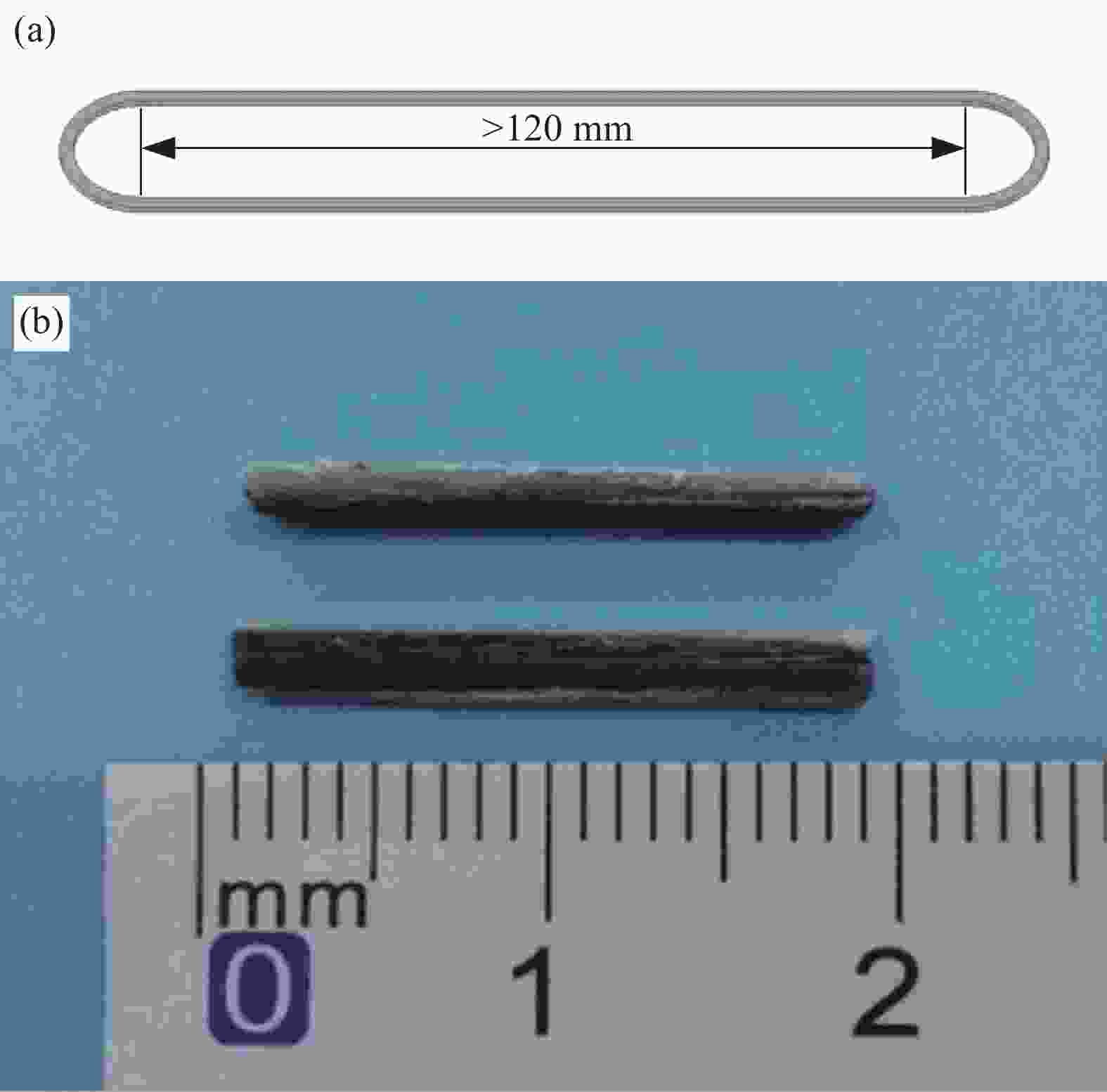

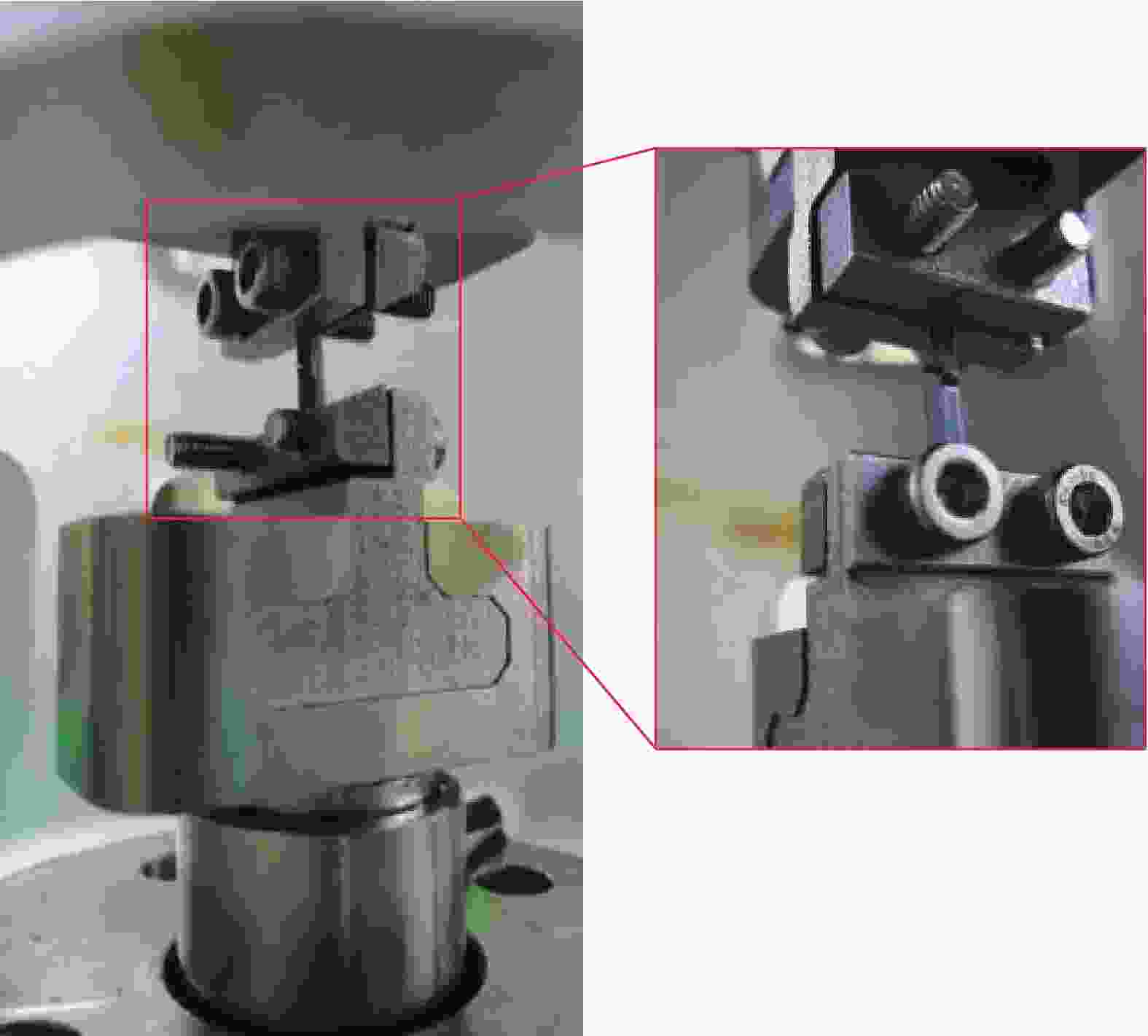

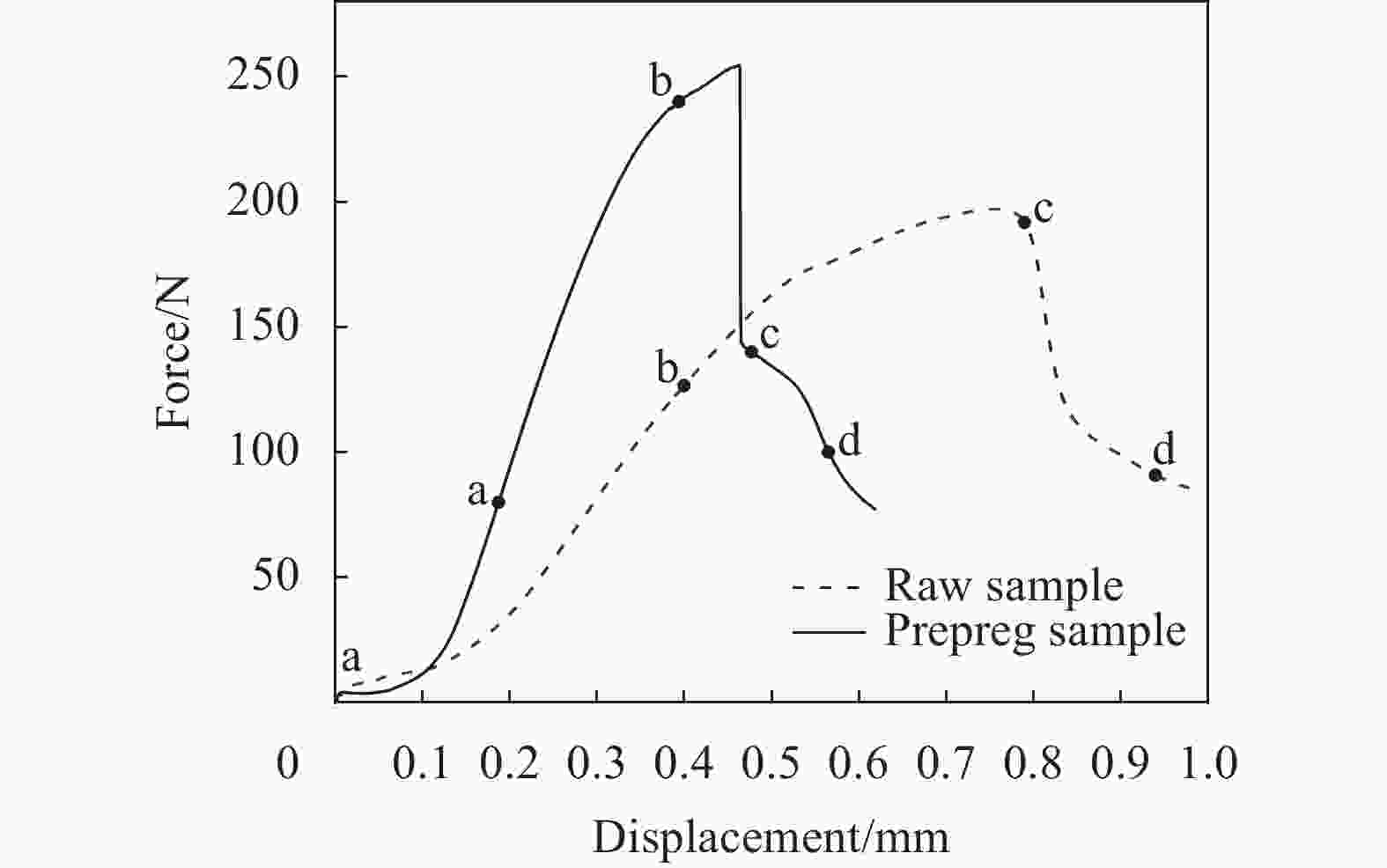

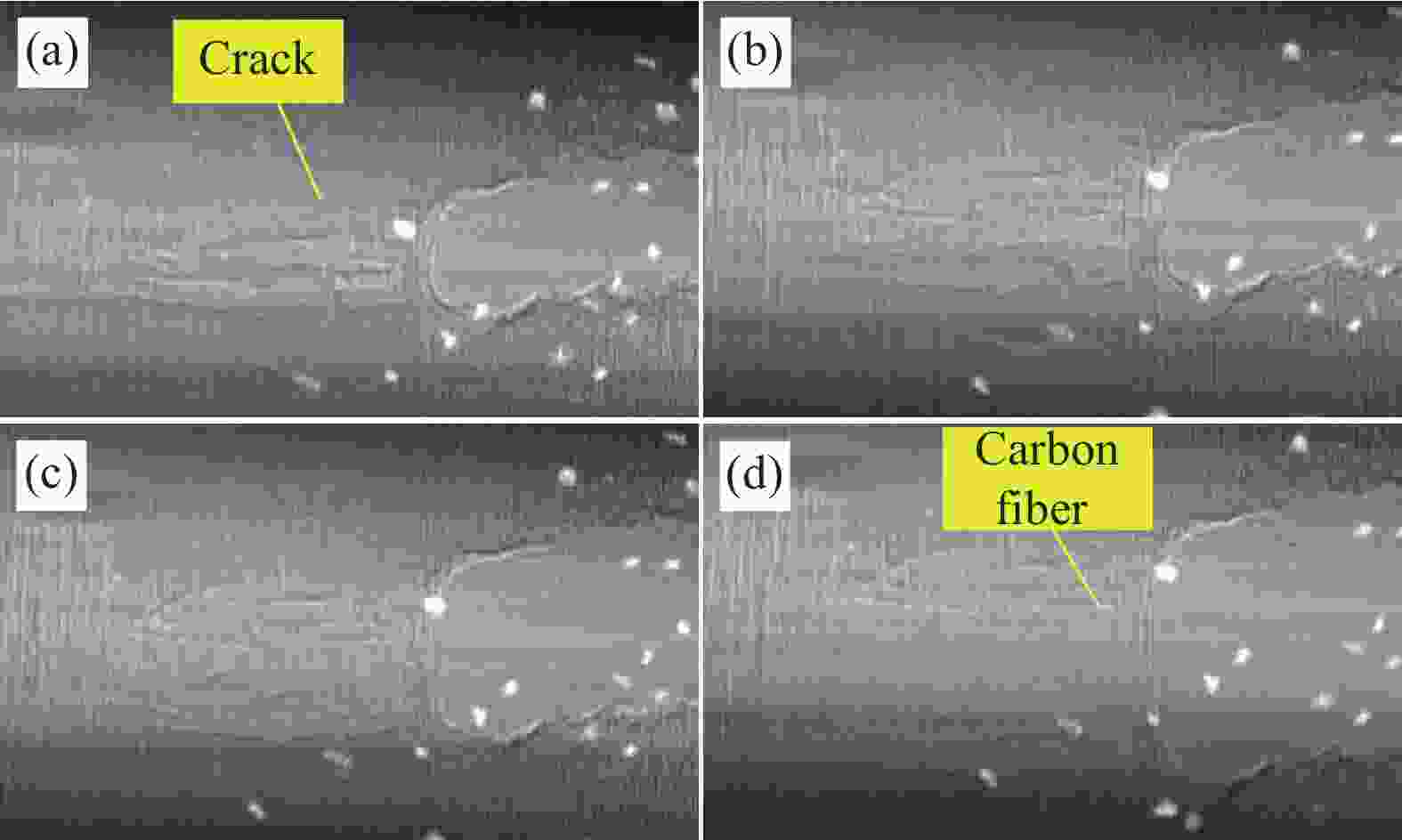

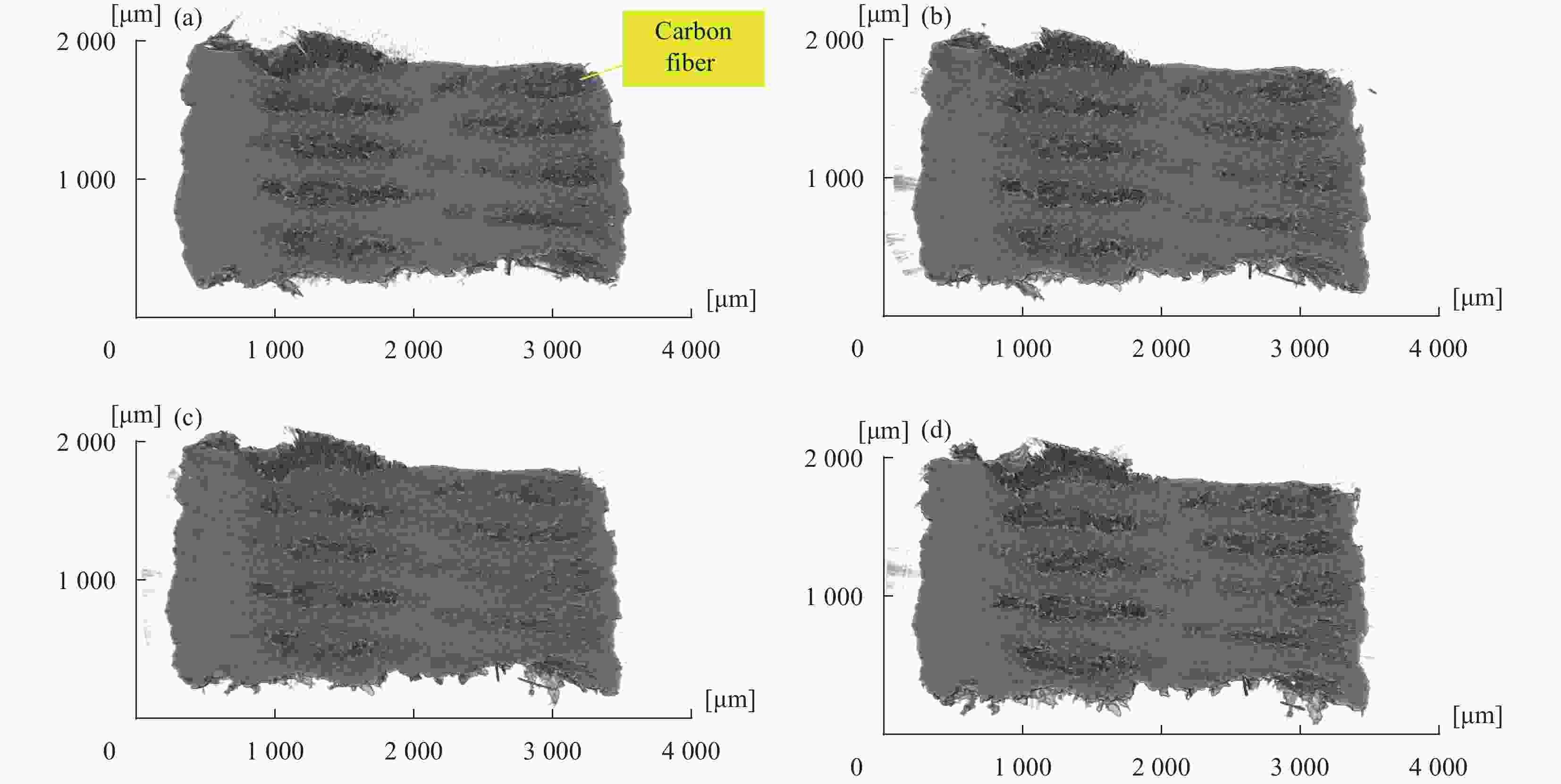

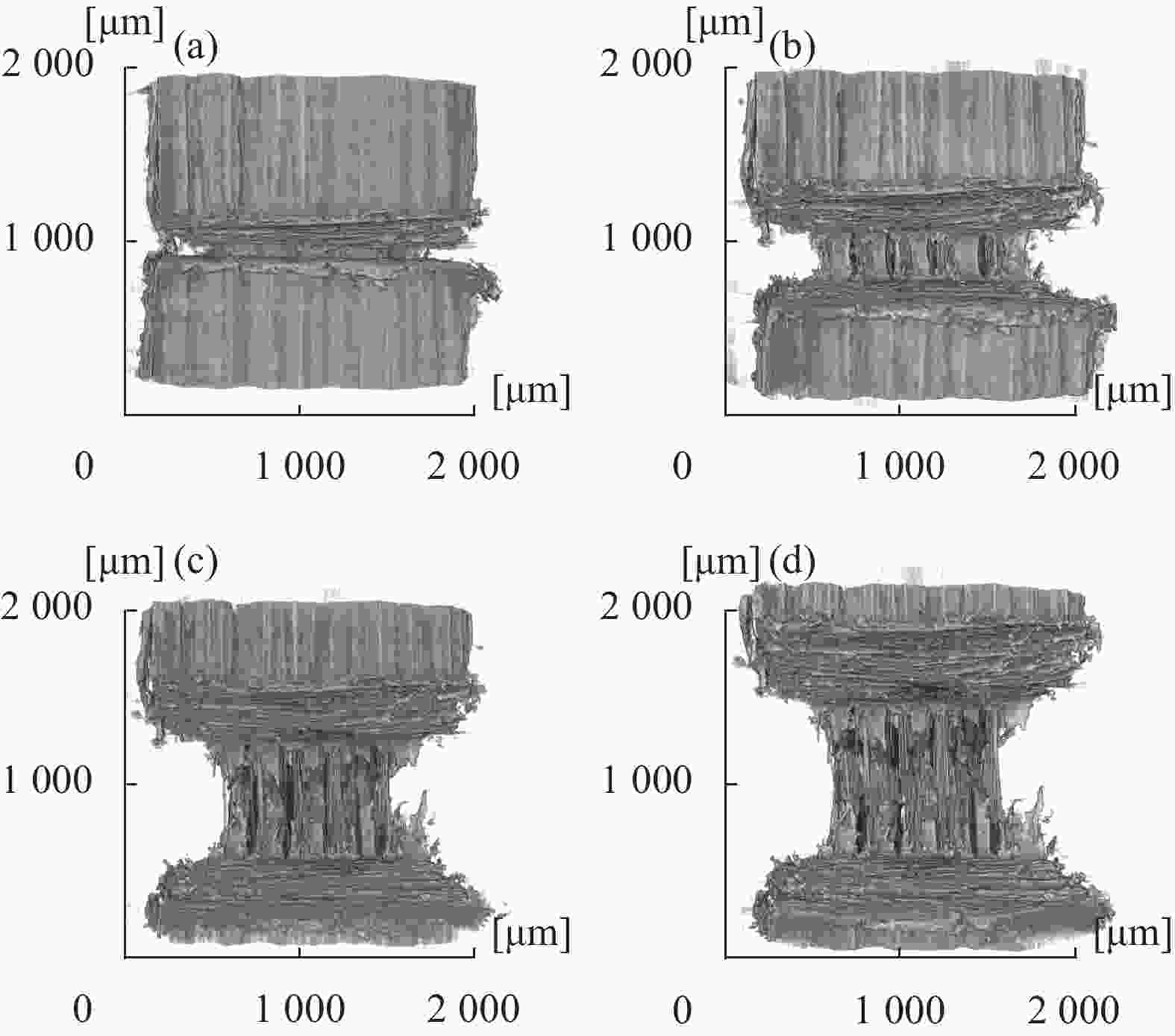

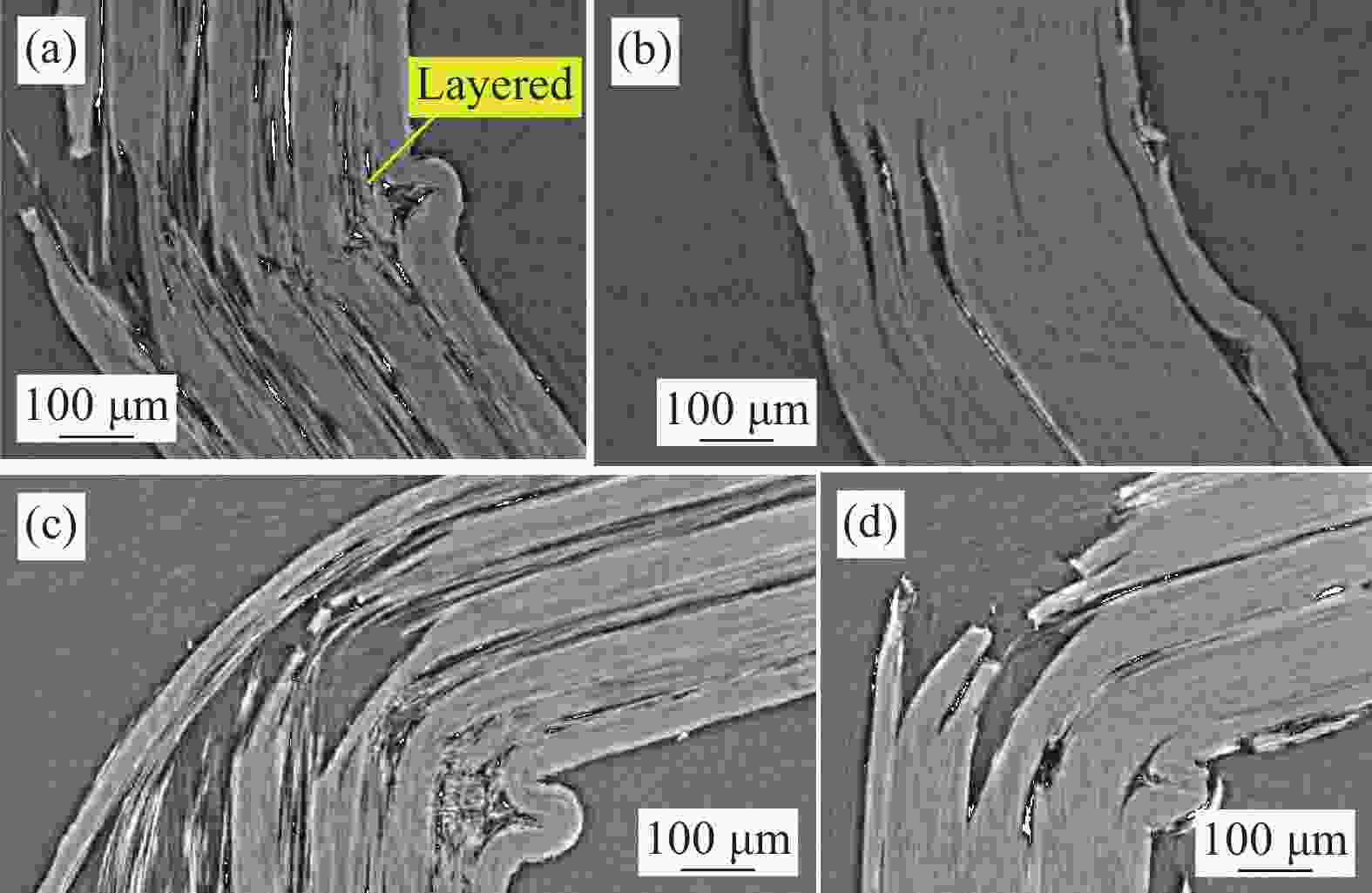

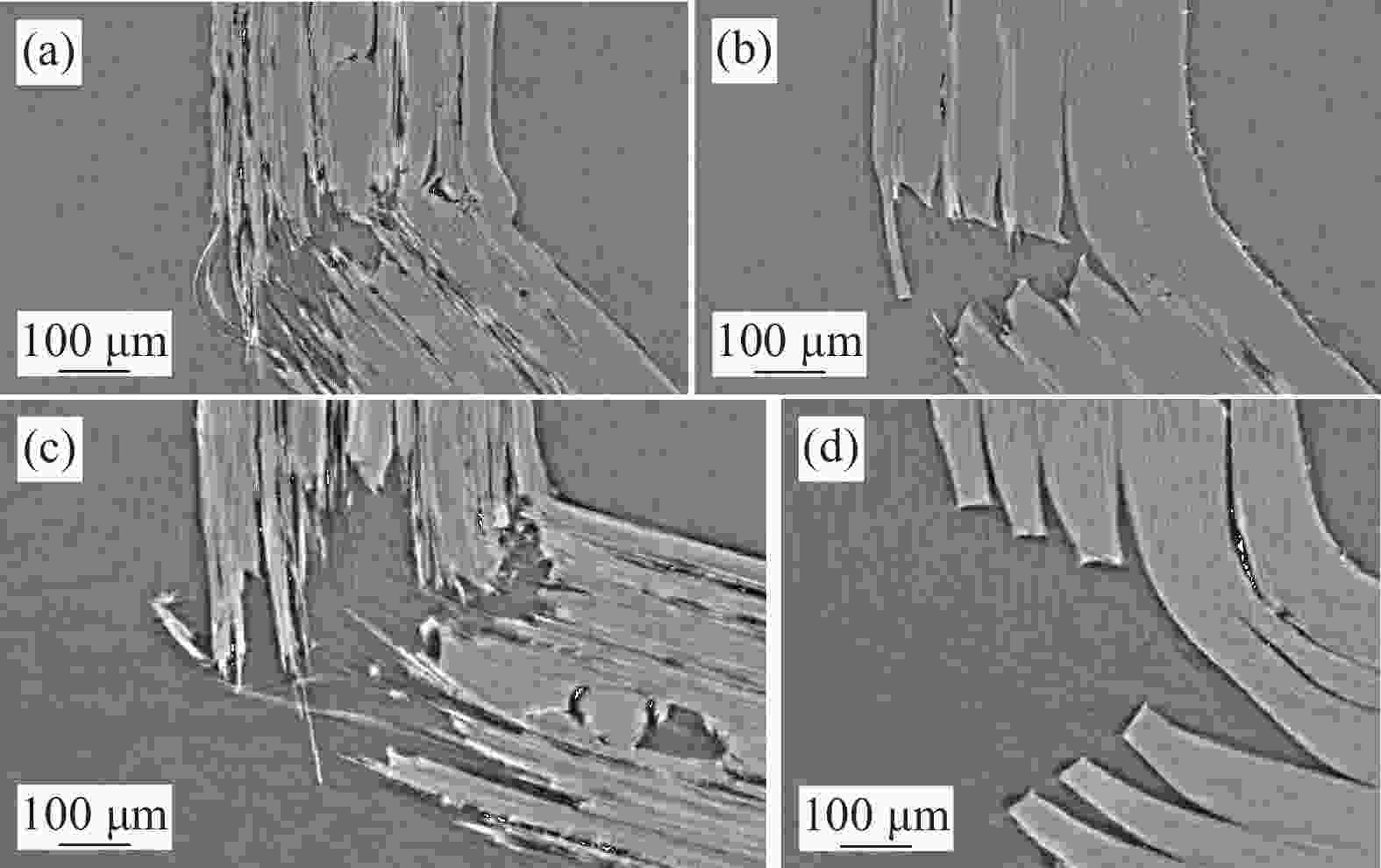

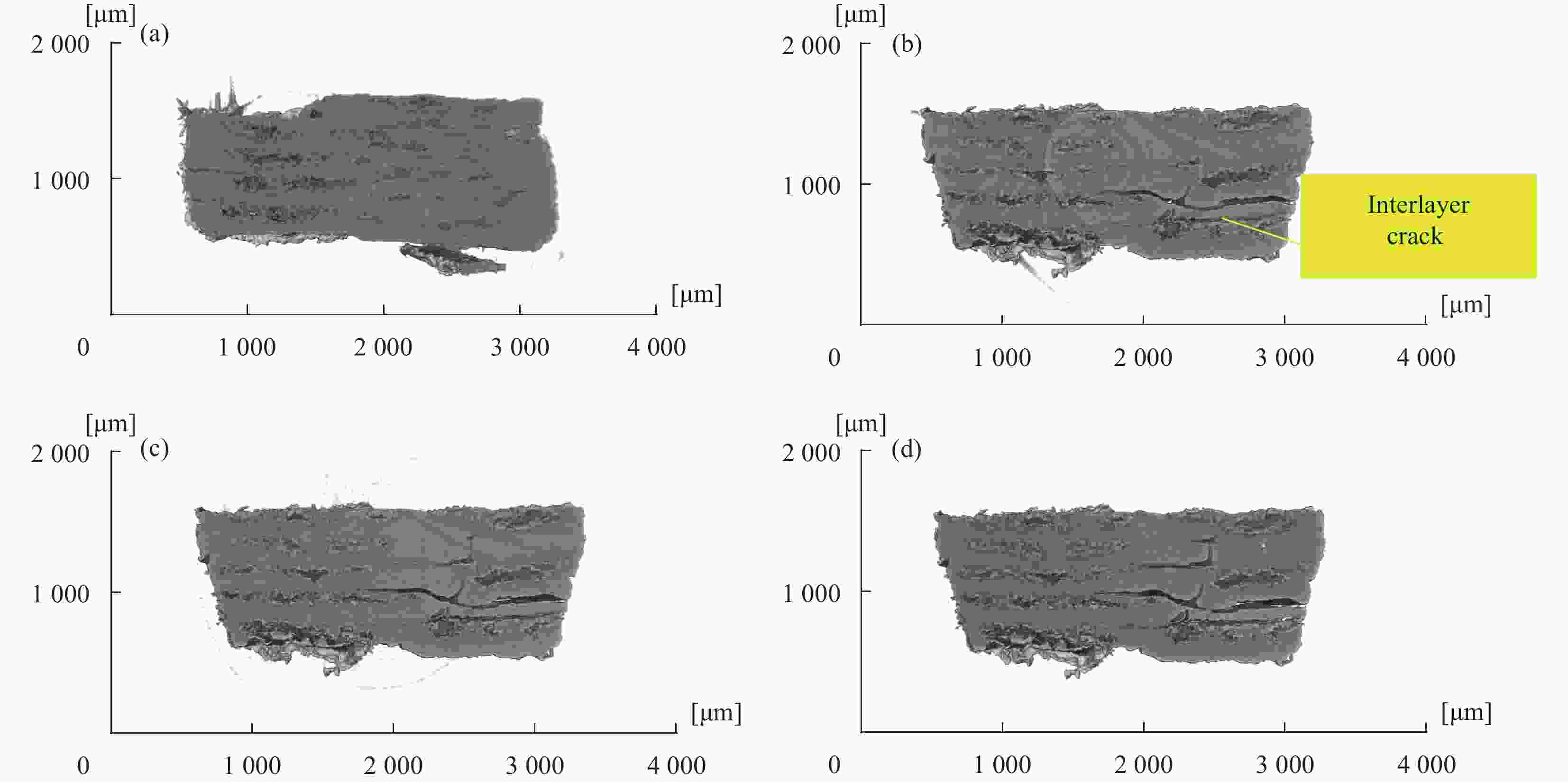

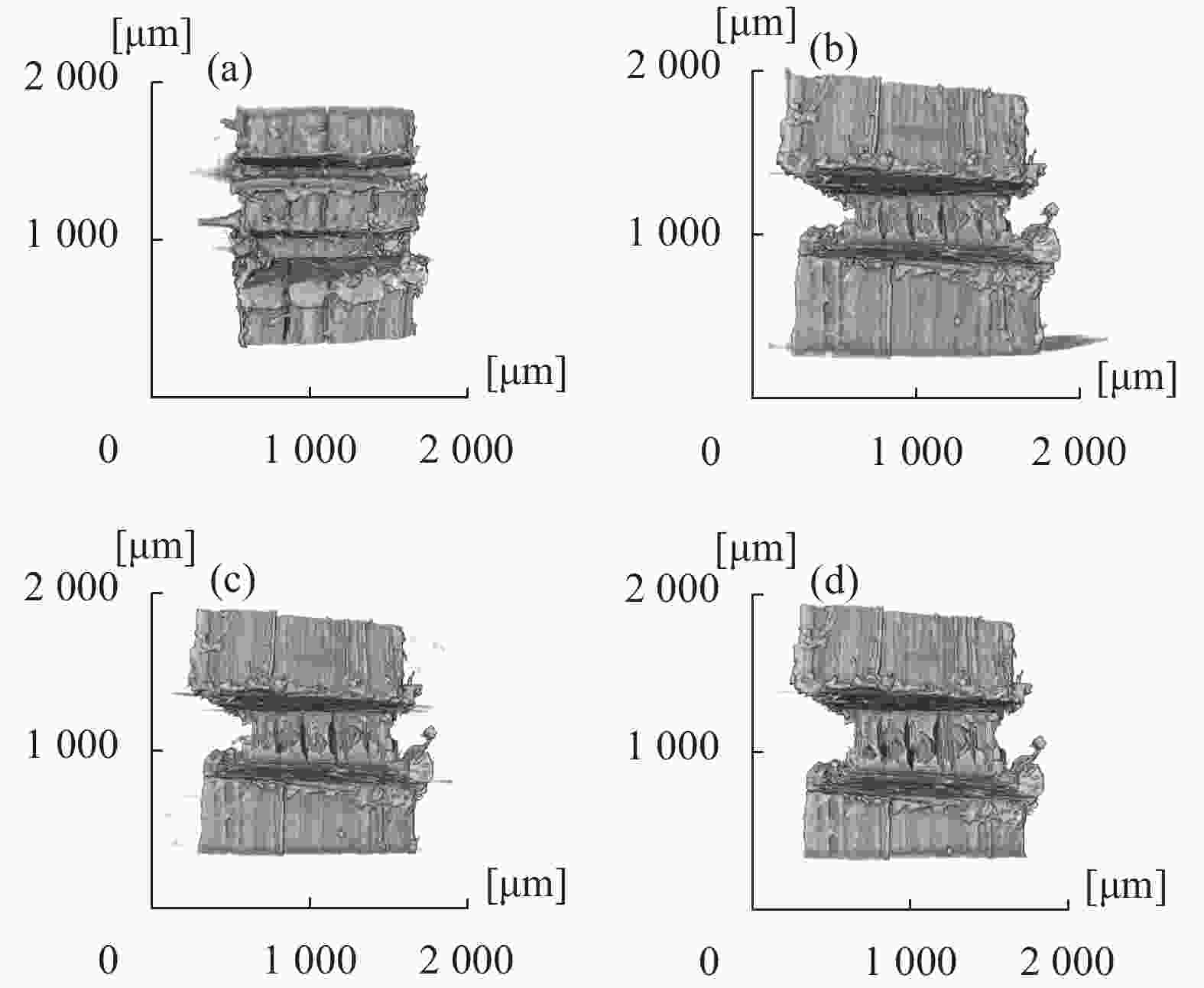

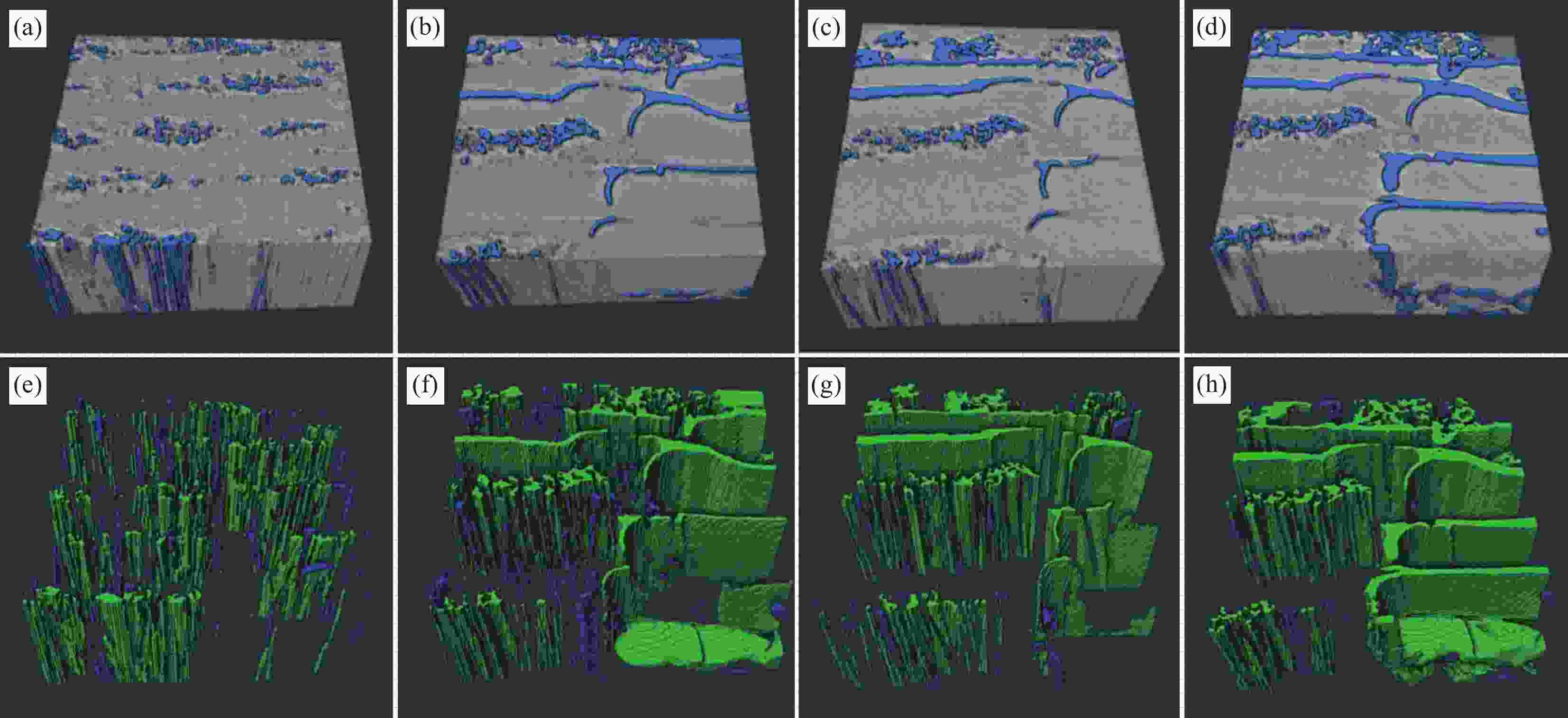

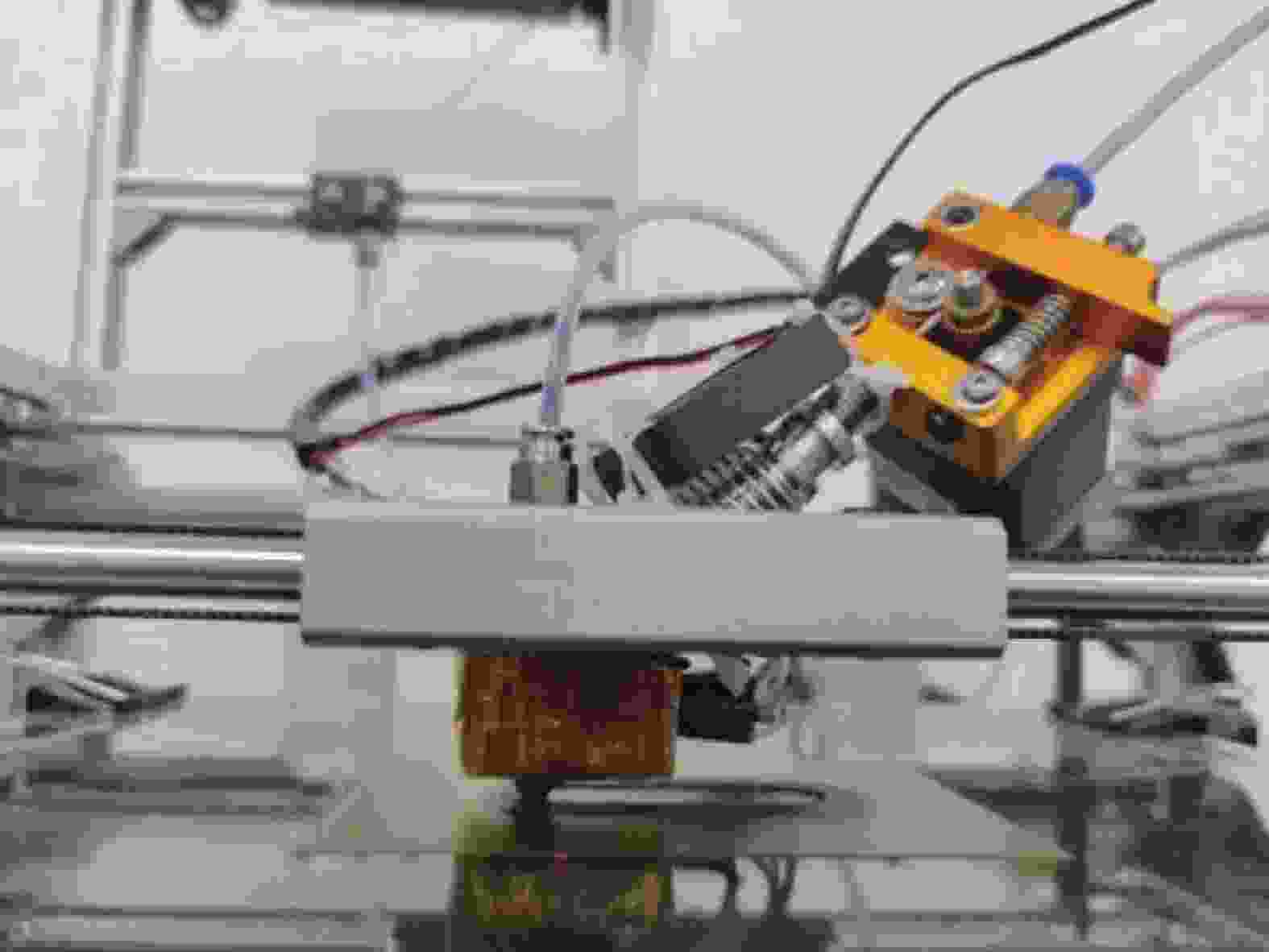

Abstract: In this study, continuous carbon fiber-reinforced poly-ether-ether-ketone composite (CCF/PEEK) with filament pre-impregnation(prepreg) treatment was investigated. Employing synchrotron radiation μCT characterization, the failure modes and mechanisms at the fiber/resin interface and interlayers during tensile/bending processes were analyzed. Combined with defect and tensile mechanical property analyses, the impact of prepreg on the structure and mechanical properties of CCF/PEEK materials was elucidated. The results revealed that due to inadequate impregnation and interlayer temperature gradients, defects existed at both the fiber/resin interface and interlayers in the prepreg sample, evolving into interlaminar cracks under tensile/bending loads, while fiber debonding and pull-out occurred in the original sample. After prepreg treatment, the average tensile strength of the samples increased by 17.21%, and the porosity decreased by 56.6%. The resin fully infiltrated the fiber bundles, significantly enhancing the fiber/resin interface bonding and mechanical properties of the material. -

表 1 碳纤维相关参数

Table 1. Properties of carbon fiber

Properties Typical value Density 1.76 g/cm³ Tensile strength 3880 MPa Tensile modulus 234 GPa 表 2 聚醚醚酮(PEEK)相关参数

Table 2. Properties of poly-ether-ether-ketone composite (PEEK)

Properties Typical value Density 1.30 g/cm³ Glass transition temperature 143℃ Melting Point 343℃ Tensile strength 99.9 MPa Young’s modulus 3738 MPa 表 3 预浸丝试样拉伸缺陷变化

Table 3. Porosity changes of prepreg sample during stretching process

Stretched state Tensile force Defect volume fraction 1 80 N 4.34% 2 240 N 10.60% 3 140 N 10.41% 4 100 N 14.80% 表 4 两类试样缺陷特征

Table 4. Defect characteristics of two types of samples

Void characteristics Raw sample Prepreg sample Volume/μm³ 109720.15±

1949990.0642468.19±

301969.30Surface area/μm2 (274.63,

60440843.13)(274.63,

9079102.5)Shape factor *1647.75 *1922.375 Defect volume fraction 4.61% 2.00% Note: Pore data larger than 200 voxels are expressed as: mean ± standard deviation (minimum, maximum) * median. 表 5 CCF/PEEK标准试样拉伸力学性能

Table 5. Tensile mechanical properties of CCF/PEEK standard specimens

Type σM/MPa Et/MPa εB/% Raw samples 270.054 31789.142 0.894 Prepreg samples 316.536 29465.054 0.990 Note: Physical significance of each parameter—σM represents tensile strength, Et represents tensile modulus of elasticity and εB represents tensile fracture strain. -

[1] ZHANG J, CHEVALI V S, WANG H, et al. Current status of carbon fibre and carbon fibre composites recycling[J]. Composites Part B: Engineering, 2020, 193: 108053. doi: 10.1016/j.compositesb.2020.108053 [2] 杨广林, 张启青, 史宾等. 碳纤维复合材料在汽车上的应用及成型工艺进展[J]. 塑料工业, 2023, 51(11): 27-33. doi: 10.3969/j.issn.1005-5770.2023.11.005YANG G L, ZHANG Q Q, SHI B, et al. Application and Molding Procedure Progress of Carbon Fiber Reinforced Polymer Materials in Automotive Parts[J]. China Plastics Industry, 2023, 51(11): 27-33(in Chinese). doi: 10.3969/j.issn.1005-5770.2023.11.005 [3] 曹丰, 曾志勇, 黄建等. 连续纤维增强复合材料的3D打印工艺及应用进展[J]. 中国科学. 技术科学, 2023, 53(11): 1815-1833. doi: 10.1360/SST-2023-0077CAO F, ZENG Z Y, HUANG J, et al. Printing process and application progress of 3D printing continuous fiber reinforced composites[J]. Scientia Sinica Technologica, 2023, 53(11): 1815-1833(in Chinese). doi: 10.1360/SST-2023-0077 [4] 陈思魁, 郭荣辉. 碳纤维增强树脂基复合材料的应用及展望[J]. 纺织科学与工程学报, 2023, 40(4): 102-107+122. doi: 10.3969/j.issn.2096-5184.2023.04.018CHEN S K, GUO R H. Applications and Prospects of Carbon Fiber Reinforced Resin Matrix Composites[J]. Journal of Textile Science and Engineering, 2023, 40(4): 102-107+122(in Chinese). doi: 10.3969/j.issn.2096-5184.2023.04.018 [5] 黄兴, 任天翔, 滕晓波等. 高性能聚醚醚酮纤维的制备及性能研究[J]. 塑料科技, 2023, 51(9): 45-49.HUANG X, REN T X, TENG X B, et al. Study on Preparation and Properties of High Performance PEEK Fiber[J]. Plastics Science and Technology, 2023, 51(9): 45-49(in Chinese). [6] 谢金梦, 逄显娟, 黄素玲等. 碳纤维改性PEEK复合材料摩擦学性能及其应用研究进展[J]. 化工新型材料, 2023, 51(10): 1-7.XIE J M, PANG X J, HUANG S L, et al. Research progress on tribological properties and application of carbon fiber modified PEEK composites[J]. New Chemical Materials, 2023, 51(10): 1-7(in Chinese). [7] BRENKEN B, , BAROCIO E, FAVALORO A, et al. Fused filament fabrication of fiber-reinforced polymers: A review[J]. Additive Manufacturing, 2018, 21: 1-16. [8] FALLON J J, MCKNIGHT S H, BORTNER M J. Highly loaded fiber filled polymers for material extrusion: A review of current understanding[J]. Additive Manufacturing, 2019, 30: 100810. doi: 10.1016/j.addma.2019.100810 [9] 陈书华, 韩建平, 王喜占等. 连续碳纤维增强聚醚醚酮预浸带成型工艺及性能[J]. 宇航材料工艺, 2016, 46(4): 48-51. doi: 10.3969/j.issn.1007-2330.2016.04.012CHEN S H, HAN J P, WANG X Z, et al. Preparation and Properties of Continuous Carbon Fiber Reinforced Polyetheretherketone Prepreg[J]. Aerospace Materials & Technology, 2016, 46(4): 48-51(in Chinese). doi: 10.3969/j.issn.1007-2330.2016.04.012 [10] LUO M, TIAN X Y, SHANG J F, et al. Impregnation and interlayer bonding behaviours of 3D-printed continuous carbon-fiber-reinforced poly-ether-ether-ketone composites[J]. Composites Part A: Applied Science and Manufacturing, 2019, 121: 130-138. doi: 10.1016/j.compositesa.2019.03.020 [11] CHEN R C, LIU P, XIAO T Q, et al. X-ray imaging for non-destructive microstructure analysis at SSRF[J]. Advanced Materials, 2014, 26(46): 7688-7691. doi: 10.1002/adma.201402956 [12] MEHDIKHANI M, GORBATIKH L, VERPOEST I, et al. Voids in fiber-reinforced polymer composites: a review on their formation, characteristics, and effects on mechanical performance[J]. Journal of Composite Materials, 2019, 53(12): 1579-1669. doi: 10.1177/0021998318772152 [13] TAO Y B, KONG F G, Li Z L, et al. A review on voids of 3D printed parts by fused filament fabrication[J]. Journal of Materials Science: Materials in Engineering, 2021, 15: 4860-4879. [14] WICKRAMASINGHE S, DO T, TRAN P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments[J]. Polymers, 2020, 12(7): 1529. doi: 10.3390/polym12071529 [15] NING F D, CONG W L, HU Y B, et al. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Effects of process parameters on tensile properties[J]. Journal of Materials Research, 2017, 51(4): 451-462. [16] NING F D, CONG W L, Qiu J J, et al. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling[J]. Composites Part B: Engineering, 2015, 80: 369-378. doi: 10.1016/j.compositesb.2015.06.013 [17] TEKINALP H L, KUNC V, VELEZ-GARCIA G M, et al. Highly oriented carbon fiber–polymer composites via additive manufacturing[J]. Composites Science and Technology, 2014, 105: 144-150. doi: 10.1016/j.compscitech.2014.10.009 [18] SÁNCHEZ D M, DE LA MATA M, DELGADO F J, et al. Development of carbon fiber acrylonitrile styrene acrylate composite for large format additive manufacturing[J]. Materials & Design, 2020, 191: 108577. [19] MEHDIKHANI M, PETROV N A, STRAUMIT I, et al. The effect of voids on matrix cracking in composite laminates as revealed by combined computations at the micro- and meso-scales[J]. Composites Part A: Applied Science and Manufacturing, 2019, 117: 180-192. doi: 10.1016/j.compositesa.2018.11.009 [20] LOVE L J, KUNC V, RIOS O, et al. The importance of carbon fiber to polymer additive manufacturing[J]. Journal of Materials Research, 2014, 29(17): 1893-1898. doi: 10.1557/jmr.2014.212 [21] LITTLE J E, YUAN X W, JONES M I. Characterisation of voids in fibre reinforced composite materials[J]. NDT & E International, 2012, 46: 122-127. [22] SO MMACAL S, MATSCHINSKI A, DRECHSLER K, et al. Characterisation of void and fiber distribution in 3D printed carbon-fiber/PEEK using X-ray computed tomography[J]. Composites Part A: Applied Science and Manufacturing, 2021, 149: 106487. doi: 10.1016/j.compositesa.2021.106487 [23] SO MMACAL S, MATSCHINSKI A, HOLMES J, et al. Detailed void characterisation by X-ray computed tomography of material extrusion 3D printed carbon fibre/PEEK[J]. Composite Structures, 2023, 308: 116635. doi: 10.1016/j.compstruct.2022.116635 [24] ZHANG H, CHEN J Y, YANG D M. Fibre misalignment and breakage in 3D printing of continuous carbon fibre reinforced thermoplastic composites[J]. Additive Manufacturing, 2021, 38: 101775. doi: 10.1016/j.addma.2020.101775 [25] HU Y W, LADANI R B, BRANDT M, et al. Carbon fibre damage during 3D printing of polymer matrix laminates using the FDM process[J]. Materials & Design, 2021, 205: 109679. [26] GALOS J, HU Y W, RAVINDRAN AR, et al. Electrical properties of 3D printed continuous carbon fibre composites made using the FDM process[J]. Composites Part A: Applied Science and Manufacturing, 2021, 151: 106661. doi: 10.1016/j.compositesa.2021.106661 -

点击查看大图

点击查看大图

计量

- 文章访问数: 83

- HTML全文浏览量: 69

- 被引次数: 0

下载:

下载: