Preparation and properties of supplementary cementing materials based on recycling of straw solid wastes

-

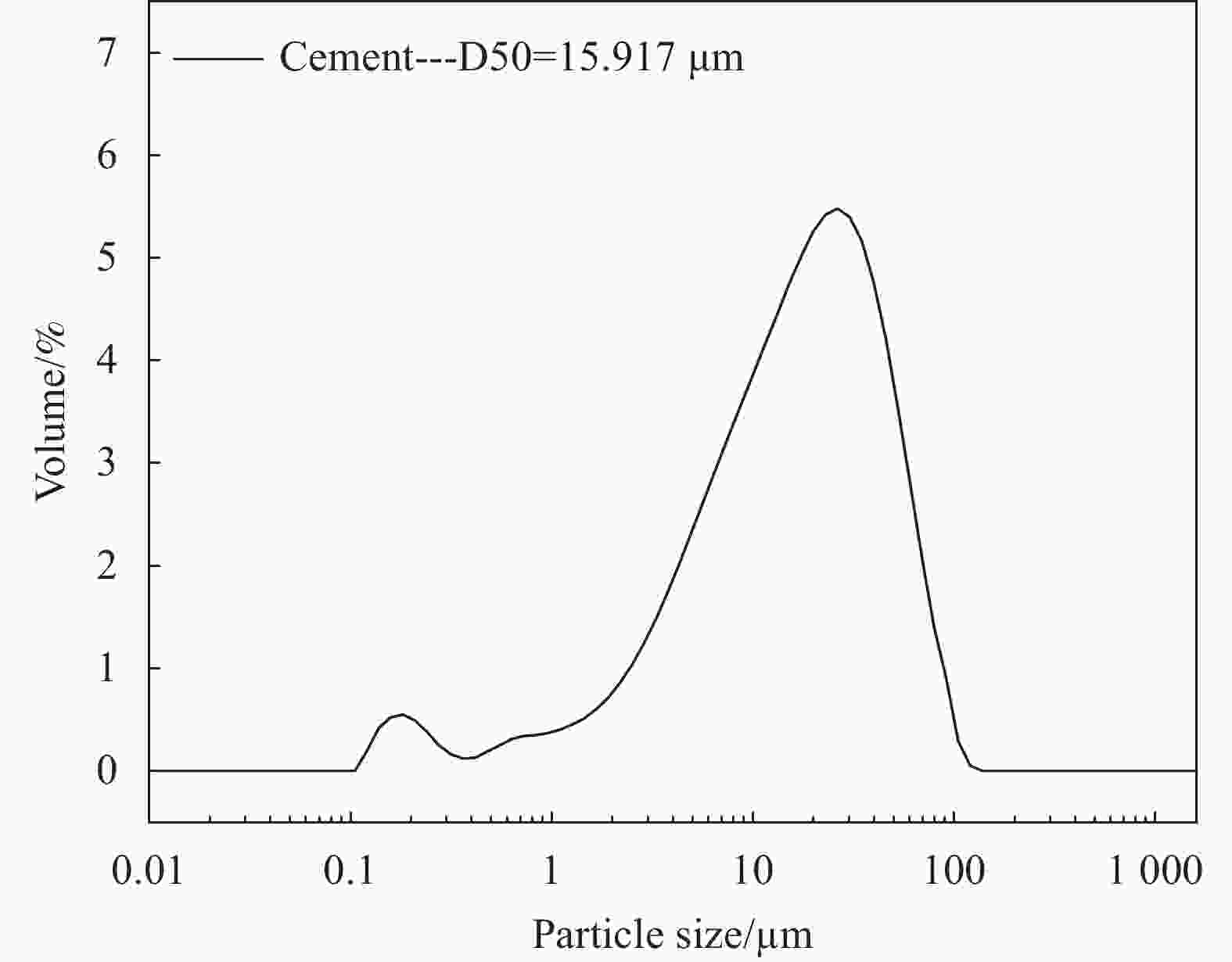

摘要: 针对双碳目标下水泥及其复材降低碳排放问题,本研究以玉米秸秆固废 (Corn straw waste, CSW) 为原料,发展预处理-热解-研磨三步工艺,制备一种可作为水泥辅助胶凝材料的可持续生物质灰材料。重点研究了预处理方式(未处理,蒸馏水洗涤,盐酸洗涤)、热解温度(500 ℃、600 ℃、700 ℃)和热解时间(1 h、2 h、3 h)对CSA性能的影响,以及不同预处理类型和玉米秸秆灰(Corn straw ash, CSA)掺量对水泥砂浆性能的影响。实验结果表明,随着热解温度的升高和热解时间的增长,CSA中SiO2含量逐渐增加,且热解温度对SiO2结晶的影响远大于热解时间的影响。掺入量为5 wt%的CSA可使砂浆抗压强度提高11.7%。当CSA掺入量超过5 wt%时,过多的多孔结构导致抗压强度降低。未处理、水洗和酸洗CSA的复掺,依次引发水泥基体内C-S-H形貌从蜂窝状、纤维状转变为致密的凝胶状,CSW经酸洗预处理、600 ℃下热解2 h制备的CSA具有优异的火山灰活性,可作为良好的水泥辅助胶凝材料。Abstract: This paper is aimed at the problem of reducing carbon emissions of cement and its composites under the Carbon Peaking and Carbon Neutrality Goals. This study used corn straw waste (CSW) as raw material to develop a three-step process of pretreatment-pyrolysis-grinding to prepare a sustainable corn straw ash (CSA) material that can be used as supplementary cementing materials. The study focused on studying the effects of pretreatment methods (untreated, distilled water washing, hydrochloric acid washing), pyrolysis temperature (500℃, 600℃, 700℃) and pyrolysis durations (1 h, 2 h, 3 h) on CSA activity, as well as the effects of different pretreatment types and blending amounts of CSA on the performance of prepared mortars. The experimental results showed that the content of SiO2 of CSA increased with the enhancement of pyrolysis temperature and duration. And the effect of pyrolysis temperature on SiO2 crystallization was much greater than that of pyrolysis durations. The incorporation of 5 wt% CSA increased the compressive strength of mortar by 11.7%. The incorporation of over 5 wt% CSA decreased the compressive strength due to the porous structure of CSA. The incorporation of untreated, distilled water washing and hydrochloric acid washing CSA demonstrated caused the C-S-H morphology in the cement matrix to change from honeycomb and fibrous to dense gel. The CSA treated by acid washing and pyrolysis at 600℃ for 2 h showed excellent pozzolanic activity and can be used as good supplementary cementing materials.

-

表 1 水泥的化学成分

Table 1. Chemical composition of cement

wt% SiO2 CaO Al2O3 Fe2O3 MgO SO3 TiO2 K2O Na2O LOI Cement 20.25 62.30 6.04 3.41 2.01 3.65 0.39 0.84 0.17 3.24 表 2 玉米秸秆灰(CSA)样品的制备条件

Table 2. The preparation conditions of corn straw ash (CSA) samples

Sample code Washing method Pyrolysis temperature Heating rate Pyrolysis duration Grinding time A1 500℃ 2 h A2 500℃ 3 h A3 600℃ 1 h A4 -U, -W, -A 600℃ 10℃/min 2 h 30 min A5 600℃ 3 h A6 700℃ 1 h A7 700℃ 2 h Notes: -U means unwashed. -W means pure water washed. -A means acid-washed. 表 3 砂浆的配合比

Table 3. Mix-proportion details of mortars

Series Cementing materials/wt. % water/binder ratio SP/wt. % Sand/binder ratio Cement CSA OPM 100 — — — 3 M3-A 97 3 0.5 0.15 3 M5-A 95 5 0.5 0.15 3 M10-A 90 10 0.5 0.15 3 M5-U 95 5 0.5 0.15 3 M5-W 95 5 0.5 0.15 3 Notes:OPM means Ordinary Portland mortar. SP means superplasticizer. 表 4 不同洗涤方式下CSA的化学组成及烧失量(LOI,Loss on ignition)

Table 4. Chemical composition and loss on ignition of CSA under different washing methods

wt% A5-U A5-W A5-A A6-U A6-W A6-A SiO2 24.386 66.748 75.653 23.109 68.675 76.749 Al2O3 0.980 0.919 0.909 0.981 0.985 0.927 Fe2O3 0.954 1.868 1.251 0.713 1.435 0.977 CaO 7.440 20.479 13.914 9.130 19.152 13.235 K2O 36.794 0.962 0.934 35.747 1.172 1.097 MgO 7.337 4.805 2.863 8.593 4.652 2.678 Na2O 2.767 0.011 0.032 2.391 0.085 0.013 P2O5 6.959 1.202 1.712 6.439 1.236 1.548 ZnO 0.057 0.199 0.080 0.075 0.135 0.048 SO3 0.951 2.386 2.011 1.162 1.936 2.291 Cl 10.977 0.273 0.480 11.234 0.360 0.187 Others 0.398 0.148 0.161 0.426 0.177 0.250 LOI 4.65 2.94 2.39 4.39 2.93 2.24 表 5 不同热解条件下CSA的氧化物组成及LOI

Table 5. Oxide composition and loss on ignition of CSA under different pyrolysis conditions

wt% A1-A A3-A A4-A A5-U A7-A SiO2 67.458 71.519 73.644 75.653 77.495 Al2O3 1.028 0.944 0.858 0.909 0.803 Fe2O3 0.889 1.713 1.674 1.251 1.272 CaO 15.380 15.676 14.302 13.914 12.385 K2O 2.805 1.756 1.178 0.934 1.091 MgO 6.708 3.516 3.967 2.863 2.699 Na2O 0.092 0.044 0.054 0.032 0.035 P2O5 1.781 1.222 1.409 1.712 1.532 ZnO 0.259 0.151 0.147 0.080 0.126 SO3 2.385 2.929 2.253 2.011 2.096 Cl 0.892 0.293 0.313 0.380 0.251 Others 0.323 0.237 0.201 0.261 0.215 LOI 2.82 2.79 2.66 2.39 2.21 -

[1] LAL R. World crop residues production and implications of its use as a biofuel[J]. Environment International, 2005, 31(4): 575-584. doi: 10.1016/j.envint.2004.09.005 [2] MEHMOOD K, CHANG S, YU S, et al. Spatial and temporal distributions of air pollutant emissions from open crop straw and biomass burnings in China from 2002 to 2016[J]. Environmental Chemistry Letters, 2018, 16(1): 301-309. doi: 10.1007/s10311-017-0675-6 [3] KIM OANH N T, PERMADI D A, HOPKE P K, et al. Annual emissions of air toxics emitted from crop residue open burning in Southeast Asia over the period of 2010–2015[J]. Atmospheric Environment, 2018, 187: 163-173. doi: 10.1016/j.atmosenv.2018.05.061 [4] TAO J, ZHANG L, CAO J, et al. A review of current knowledge concerning PM2.5 chemical composition, aerosol optical properties and their relationships across China[J]. Atmospheric Chemistry and Physics, 2017, 17(15): 9485-9518. doi: 10.5194/acp-17-9485-2017 [5] WANG Z, WANG Z, XU G, et al. Sustainability assessment of straw direct combustion power generation in China: From the environmental and economic perspectives of straw substitute to coal[J]. Journal of Cleaner Production, 2020, 273: 122890. doi: 10.1016/j.jclepro.2020.122890 [6] KHAN H A, NAQVI S R, MEHRAN M T, et al. A performance evaluation study of nano-biochar as a potential slow-release nano-fertilizer from wheat straw residue for sustainable agriculture[J]. Chemosphere, 2021, 285: 131382. doi: 10.1016/j.chemosphere.2021.131382 [7] TLAIJI G, PENNEC F, OULDBOUKHITINE S, et al. Hygrothermal performance of multilayer straw walls in different climates[J]. Construction and Building Materials, 2022, 326: 126873. doi: 10.1016/j.conbuildmat.2022.126873 [8] DE LIMA C P F, CORDEIRO G C. Evaluation of corn straw ash as supplementary cementitious material: Effect of acid leaching on its pozzolanic activity[J]. Cement, 2021, 4: 100007. doi: 10.1016/j.cement.2021.100007 [9] CORDEIRO G C, TOLEDO FILHO R D, TAVARES L M, et al. Ultrafine grinding of sugar cane bagasse ash for application as pozzolanic admixture in concrete[J]. Cement and Concrete Research, 2009, 39(2): 110-115. doi: 10.1016/j.cemconres.2008.11.005 [10] ADESANYA D A, RAHEEM A A. A study of the workability and compressive strength characteristics of corn cob ash blended cement concrete[J]. Construction and Building Materials, 2009, 23(1): 311-317. doi: 10.1016/j.conbuildmat.2007.12.004 [11] MILLER S A, CUNNINGHAM P R, HARVEY J T. Rice-based ash in concrete: A review of past work and potential environmental sustainability[J]. Resources, Conservation and Recycling, 2019, 146: 416-430. doi: 10.1016/j.resconrec.2019.03.041 [12] RERKPIBOON A, TANGCHIRAPAT W, JATURAPITAKKUL C. Strength, chloride resistance, and expansion of concretes containing ground bagasse ash[J]. Construction and Building Materials, 2015, 101: 983-989. doi: 10.1016/j.conbuildmat.2015.10.140 [13] GHOLIZADEH VAYGHAN A, KHALOO A R, RAJABIPOUR F. The effects of a hydrochloric acid pre-treatment on the physicochemical properties and pozzolanic performance of rice husk ash[J]. Cement and Concrete Composites, 2013, 39: 131-140. doi: 10.1016/j.cemconcomp.2013.03.022 [14] CORDEIRO G, NUNES LEMOS M, XAVIER K, et al. Production of agroindustrial ashes with pozzolanic activity via acid leaching, conjugated burning and ultrafine grinding[J]. Ambiente Construído, 2020, 20: 189-203. [15] SKIBSTED J, SNELLINGS R. Reactivity of supplementary cementitious materials (SCMs) in cement blends[J]. Cement and Concrete Research, 2019, 124: 105799. doi: 10.1016/j.cemconres.2019.105799 [16] MARTÍNEZ-LAGE I, VELAY-LIZANCOS M, VÁZQUEZ-BURGO P, et al. Concretes and mortars with waste paper industry: Biomass ash and dregs[J]. Journal of Environmental Management, 2016, 181: 863-873. doi: 10.1016/j.jenvman.2016.06.052 [17] ŠUPIĆ S, BULATOVIĆ V, MALEŠEV M, et al. Sustainable Masonry Mortars with Fly Ash, Blast Furnace Granulated Slag and Wheat Straw Ash[J]. Sustainability, 2021, 13(21): 12245. doi: 10.3390/su132112245 [18] 国家市场监督管理总局. 建筑用砂: GB/T 14684—2022[S]. 北京: 中国标准出版社, 2011.State Administration for Market Regulation. Sand for construction: GB/T 14684—2022[S]. Beijing: Standards Press of China, 2011(in Chinese). [19] 中国国家标准化管理委员会. 通用硅酸盐水泥 GB175-2023[S]. 北京: 中国标准出版社, 2023.Standardization Administration of the People’s Republic of China. Common portland cement GB175-2023[S]. Beijing: China Standards Press, 2023(in Chinese). [20] 中国建筑科学研究院. 混凝土外加剂应用技术规范: GB 50119—2013[S]. 北京: 中国建筑工业出版社, 2013.China Academy of Building Research. Technical specification for application of concrete admixtures : GB 50119-2013 [S]. Beijing: China Architecture & Building Press, 2013(in Chinese). [21] 中华人民共和国住房和城乡建设部. 混凝土用水标准: JGJ 63−2006[S]. 北京: 中国建筑工业出版社, 2006.Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Concrete water standard: JGJ 63−2006[S]. Beijing: China Architecture & Building Press, 2006(in Chinese). [22] ALEX J, DHANALAKSHMI J, AMBEDKAR B. Experimental investigation on rice husk ash as cement replacement on concrete production[J]. Construction and Building Materials, 2016, 127: 353-362. doi: 10.1016/j.conbuildmat.2016.09.150 [23] ASTM. Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete: ASTM C618[S]. West Conshohocken, 2019. [24] 王功勋. 陶瓷抛光砖粉作辅助胶凝材料的火山灰性[J]. 硅酸盐学报, 2010, (7): 1229-1234.WANG Gongxun. Pozzolanic activity of ceramic polishing powder as supplementary cementitious material[J]. Journal of the Chinese Ceramic Society, 2010, (7): 1229-1234(in Chinese). [25] MEMON S A, KHAN S, WAHID I, et al. Evaluating the Effect of Calcination and Grinding of Corn Stalk Ash on Pozzolanic Potential for Sustainable Cement-Based Materials[J]. Advances in Materials Science and Engineering, 2020, 2020. [26] SUWANMANEECHOT P, NOCHAIYA T, JULPHUNTHONG P. Improvement, characterization and use of waste corn cob ash in cement-based materials[J]. IOP Conference Series: Materials Science and Engineering, 2015, 103: 012023. doi: 10.1088/1757-899X/103/1/012023 [27] 中国国家标准化管理委员会. 水泥胶砂流动扩展度测定方法: GB/T 2419—2005[S]. 北京: 中国建材工业出版社, 2005.Standardization Administration of the People’s Republic of China. Test method for fluidity of cement mortar: GB/T 2419—2005[S]. Beijing: China Building Materials Press, 2005(in Chinese). [28] American Society for Testing and Materials. ASTM C348-21 Standard test method for flexural strength of hydraulic -cement mortars[S]. West Conshohocken: ASTM International, 2021. [29] American Society for Testing and Materials. ASTM C349-18 Standard test method for compressive strength of hydraulic-cement mortars (using portions of prisms broken in flexure) [S]. West Conshohocken: ASTM International, 2018. [30] LI Q, ZHAO Y, CHEN H, et al. Effect of waste corn stalk ash on the early-age strength development of fly ash/cement composite[J]. Construction and Building Materials, 2021, 303: 124463. doi: 10.1016/j.conbuildmat.2021.124463 [31] ATHIRA G, BAHURUDEEN A, APPARI S. Rice-Straw Ash as a Potential Supplementary Cementitious Material: Influence of Thermochemical Conversion on Its Properties[J]. Journal of Materials in Civil Engineering, 2021, 33(6): 04021123. doi: 10.1061/(ASCE)MT.1943-5533.0003727 [32] NAIR D G, FRAAIJ A, KLAASSEN A A K, et al. A structural investigation relating to the pozzolanic activity of rice husk ashes[J]. Cement and Concrete Research, 2008, 38(6): 861-869. doi: 10.1016/j.cemconres.2007.10.004 [33] 曹锋, 乔宏霞, 王鹏辉, 等. 新型活性混合材料青稞秸秆灰的制备及性能[J]. 工程科学与技术, 2022, 54(4): 155-163.CAO F, QIAO H, WANG P, et al. Preparation and Properties of Highland Barley Straw Ash as New Active Mixed Materials[J]. Advanced Engineering Sciences: 2022, 54(4): 155-163(in Chinese). [34] APRIANTI S E. A huge number of artificial waste material can be supplementary cementitious material (SCM) for concrete production – a review part II[J]. Journal of Cleaner Production, 2017, 142: 4178-4194. doi: 10.1016/j.jclepro.2015.12.115 [35] MEMON S A, KHAN M K. Ash blended cement composites: Eco-friendly and sustainable option for utilization of corncob ash[J]. Journal of Cleaner Production, 2018, 175: 442-455. doi: 10.1016/j.jclepro.2017.12.050 [36] XU W, LO Y T, OUYANG D, et al. Effect of rice husk ash fineness on porosity and hydration reaction of blended cement paste[J]. Construction and Building Materials, 2015, 89: 90-101. doi: 10.1016/j.conbuildmat.2015.04.030 [37] HUANG L, YAN P. Effect of alkali content in cement on its hydration kinetics and mechanical properties[J]. Construction and Building Materials, 2019, 228: 116833. doi: 10.1016/j.conbuildmat.2019.116833 [38] SHAKOURI M, EXSTROM C L, RAMANATHAN S, et al. Pretreatment of corn stover ash to improve its effectiveness as a supplementary cementitious material in concrete[J]. Cement and Concrete Composites, 2020, 112: 103658. doi: 10.1016/j.cemconcomp.2020.103658 [39] SALAS A, DELVASTO S, DE GUTIERREZ R M, et al. Comparison of two processes for treating rice husk ash for use in high performance concrete[J]. Cement and Concrete Research, 2009, 39(9): 773-778. doi: 10.1016/j.cemconres.2009.05.006 [40] P·库马尔·梅塔, 保罗·J·M·蒙蒂罗. 混凝土微观结构、性能和材料(原著第四版)[M]. 北京: 欧阳东, 译. 中国建筑工业出版社, 2016.MEHTA P K, MONTEIRO CONCRETE P J M: Microstructure, Properties, and Materials [M]. OUYANG Dong, translated. Beijing: China Architecture & Building Press, 2016(in Chinese). [41] ZHANG Q, ZHANG B, FENG Y, et al. Hydration development of blended cement paste with granulated copper slag modified with CaO and Al2O3[J]. Journal of Materials Research and Technology, 2022, 18: 909-920. doi: 10.1016/j.jmrt.2022.03.008 [42] BULLARD J W, JENNINGS H M, LIVINGSTON R A, et al. Mechanisms of cement hydration[J]. Cement and Concrete Research, 2011, 41(12): 1208-1223. doi: 10.1016/j.cemconres.2010.09.011 [43] LIU Q, LI B, XIAO J, et al. Utilization potential of aerated concrete block powder and clay brick powder from C&D waste[J]. Construction and Building Materials, 2020, 238: 117721. doi: 10.1016/j.conbuildmat.2019.117721 [44] 刘超, 胡天峰, 刘化威, 等. 再生复合微粉对混凝土力学性能及微观结构的影响[J]. 建筑材料学报, 2021, 24(4): 726-735.LIU Chao, HU Tianfeng, LIU Huawei, et al. Effect of Recycled Composite Micro-powder on Mechanical Properties and Microstructure of Concrete[J]. Journal of Building Materials, 2021, 24 (4) : 726-735(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 53

- HTML全文浏览量: 42

- 被引次数: 0

下载:

下载: