Study and application of smart monitoring on compressed structures based on CFRP self-sensing

-

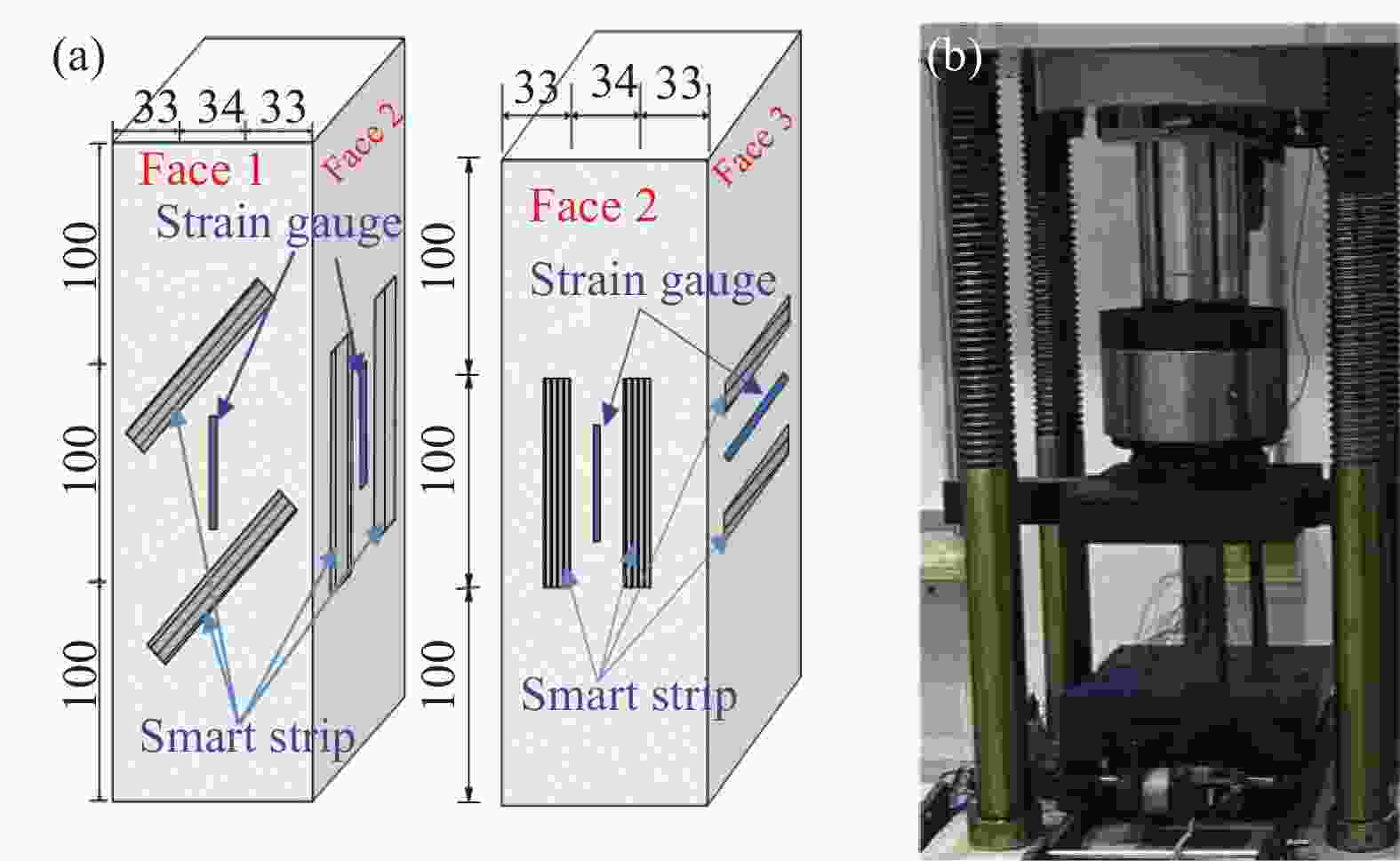

摘要: 本文探索了基于碳纤维增强聚合物基复合材料(CFRP)智能特性的受压构件健康监测新方法。将CFRP智能带以不同角度黏贴在轴向受压混凝土柱的侧面,研究准静态单调压缩和循环压缩作用下不同偏轴角的智能带的电阻响应特征。结果表明,CFRP智能带在单调加载全过程中的电阻与被监测结构的阶段化变化相关,经历了初期的缓慢变化、中期的快速变化和结构失效时的急剧变化,直至结构失效后电阻部分恢复;循环荷载作用下电阻呈周期性变化,且大部分电阻变化可以恢复,仅有少量不可恢复电阻产生于首次循环加载阶段。此外,偏轴角$ \mathrm{\;\beta } $对电阻响应具有重要影响:$ \mathrm{\;\beta } $=0°与90°时智能带分别呈现负压阻效应和正压阻效应,而45°偏轴角时智能带分阶段出现不同的压阻效应,且电阻变化幅度相对较小。工程应用实践结果验证了上述CFRP智能带在结构监测中的可行性和有效性。Abstract: A novel approach to structural health monitoring of compressed structures leveraging the intelligent properties of carbon fiber Reinforced Polymer (CFRP) was investigated. Smart CFRP strips were attached to the side surfaces of the axially compressed concrete column at various angles, and the electrical resistance of these strips under both monotonic and cyclic compression at different off-axial angles were analyzed. The findings reveal that the resistance of smart CFRP strips throughout the entire monotonic loading process correlates with the changes of the monitored structure, undergoing initial gradual changes, rapid changes at middle stage, and a sharp change upon the structural failure. The resistance changes partly reverse after failure. Under cyclic loading, the resistance shows periodic variations, with the resistance changes primarily being reversible, except for a small amount of irreversible resistance that occurs during the first loading cycle. Additionally, the off-axial angle, $ \mathrm{\;\beta } $, significantly influences the resistance response. At $ \mathrm{\;\beta } $=0° and $ \mathrm{\;\beta } $=90°, the smart strips exhibit negative and positive piezoresistive effects, respectively; while at $ \mathrm{\;\beta } $=45°, they display various piezoresistive effects in different phases, with a smaller change in resistance. The practical application results confirm the applicability and efficiency of the smart CFRP strips in structural monitoring.

-

图 9 嵌缝中CFRP带的电阻变化:(a) 监测点A1(横墙);(b) 监测点A2(横墙);(c) 监测点A3(纵墙);(d) 监测点A4(纵墙)

Figure 9. Fractional change in electrical resistance of CFRP strips in caulked joints: (a) Monitoring point A1 (transverse wall); (b) Monitoring point A2 (transverse wall); (c) Monitoring point A3 (longitudinal wall); (d) Monitoring point A4 (longitudinal wall)

图 10 延性混凝土表面CFRP带的电阻变化:(a) 监测点B1(横墙);(b) 监测点B2(横墙);(c) 监测点B3(纵墙);(d) 监测点B4(纵墙)

Figure 10. Fractional change in electrical resistance of CFRP strips on concrete substrate: (a) Monitoring point B1 (transverse wall); (b) Monitoring point B2 (transverse wall); (c) Monitoring point B3 (longitudinal wall); (d) Monitoring point B4 (longitudinal wall)

表 1 碳纤维增强聚合物基复合材料(CFRP)智能带分组详情

Table 1. Details of smart carbon fiber Reinforced Polymer (CFRP) strips

Group Number Dimension/mm3 Angle/(°) G1 G11 90×10×1 0 G12 90×10×1 0 G2 G21 90×10×1 45 G22 90×10×1 45 G3 G31 90×10×1 90 G32 90×10×1 90 -

[1] ZHOU W, ZHAO W, ZHANG Y, et al. Cluster analysis of acoustic emission signals and deformation measurement for delaminated glass fiber epoxy composites[J]. Composite Structures, 2018, 195: 349-358. doi: 10.1016/j.compstruct.2018.04.081 [2] SMITH R A, NELSON L J, MIENCZAKOWSKI M J, et al. Ultrasonic analytic-signal responses from polymer-matrix composite laminates[J]. IEEE transactions on ultrasonics, ferroelectrics, and frequency control, 2017, 65(2): 231-243. [3] BULL D J, HELFEN L, SINCLAIR I, et al. A comparison of multi-scale 3D X-ray tomographic inspection techniques for assessing carbon fibre composite impact damage[J]. Composites Science and Technology, 2013, 75: 55-61. doi: 10.1016/j.compscitech.2012.12.006 [4] FERNANDES H, ZHANG H, FIGUEIREDO A, et al. Carbon fiber composites inspection and defect characterization using active infrared thermography: numerical simulations and experimental results[J]. Applied optics, 2016, 55(34): D46-D53. doi: 10.1364/AO.55.000D46 [5] 周智, 何建平, 贾宏伟, 等. 平行钢丝束拉索的布里渊全尺度测试技术研究[J]. 光电子. 激光, 2009, 20(6): 766-770.ZHOU Zhi, HE Jianping, JIA Hongwei, et al. Full scale brillouin sensing technique based smart parallel wire stay cable[J]. Journal of Optoelectronics·Laser, 2009, 20(6): 766-770 (in Chinese). [6] TANG Y, YAO Y, CANG J. Structural and sensing performance of RC beams strengthened with prestressed near-surface mounted self-sensing basalt FRP bar[J]. Composite Structures, 2021, 259: 113474. doi: 10.1016/j.compstruct.2020.113474 [7] 邓朗妮, 谢宏, 刘阳, 等. CFRP-OFBG板嵌入式加固钢筋混凝土梁荷载效应计算分析[J]. 复合材料科学与工程, 2020, (3): 5-10. doi: 10.3969/j.issn.1003-0999.2020.03.001DENG Langni, XIE Hong, LIU Yang, et al. Load effect calculation and analysis of CFRP-OFBG plate embedded reinforced concrete beam[J]. Composites Science and Engineering, 2020, (3): 5-10(in Chinese). doi: 10.3969/j.issn.1003-0999.2020.03.001 [8] MING ZHAO M, DONG Y, ZHAO Y, et al. Monitoring of bond in FRP retrofitted concrete structures[J]. Journal of Intelligent material systems and structures, 2007, 18(8): 853-860. doi: 10.1177/1045389X06074571 [9] TANG Y, WANG Z, SONG M. Self-sensing and strengthening effects of reinforced concrete structures with near-surfaced mounted smart basalt fibre–reinforced polymer bars[J]. Advances in Mechanical Engineering, 2016, 8(10): 1687814016673499. [10] 张智梅, 杨旸. 外贴预应力CFRP布加固钢筋混凝土梁抗弯疲劳性能有限元分析[J]. 复合材料科学与工程, 2023, (2): 44-53.ZHANG Zhimei, YANG Hui. Finite element analysis of the flexural fatigue performance of reinforced conerete beams reinforced with externally bonded prestressed CFRP sheets[J]. Composites Science and Engineering, 2023, (2): 44-53(in Chinese). [11] 宋岩超, 蒋济同. 新型封闭式复丝缠绕CFRP箍筋抗拉强度正交试验研究[J/OL]. 复合材料科学与工程, 1-6[2024-04-06]. http://kns.cnki.net/kcms/detail/10.1683.tu.20240229.1612.003.html.SONG Yanchao, JIANG Jitong. Orthogonal test of a new type of closed compound filament wound CFRP stirrup [J/OL]. Composites Science and Engineering, 1-6[2024-04-06]. http://kns.cnki.net/kcms/detail/10.1683.tu.20240229.1612.003.html (in Chinese). [12] CHUNG D D L. A review to elucidate the multi-faceted science of the electrical- resistance-based strain/temperature/damage self-sensing in continuous carbon fiber polymer-matrix structural composites[J]. Journal of Materials Science, 2023, 58(2): 483-526. doi: 10.1007/s10853-022-08106-7 [13] SCHULTE K, BARON C. Load and failure analyses of CFRP laminates by means of electrical resistivity measurements[J]. Composites science and technology, 1989, 36(1): 63-76. doi: 10.1016/0266-3538(89)90016-X [14] 吴智深, 张建. 结构健康监测先进技术及理论[M]. 北京: 科学出版社, 2018: 119-122.WU Zhishen, ZHANG Jian. Advanced structural health monitoring technology and theory[M]. Beijing: Science press, 2018: 119-122(in Chinese). [15] LEE I Y, ROH H D, PARK Y B. Novel structural health monitoring method for CFRPs using electrical resistance based probabilistic sensing cloud[J]. Composites Science and Technology, 2021, 213: 108812. doi: 10.1016/j.compscitech.2021.108812 [16] 薛伟辰, 谭园. 土木工程自监测纤维复合材料[J]. 玻璃钢/复合材料, 2007, (5): 53-56.XUE Weichen, TAN Yuan. Fiber reinforced polymers with self-monitoring properties used in civil engineering[J]. Composites Science and Engineering, 2007, (5): 53-56(in Chinese). [17] 张小玉, 朱四荣, 李卓球. 碳纤维智能带电阻率层析成像实验[J]. 华中科技大学学报: 自然科学版, 2010, 38(5): 121-123.ZHANG Xiaoyu, ZHU Sirong, LI Zhuoqiu. Electrical resistance tomography experiment of carbon fiber smart layers[J]. Jouinal of Huazhong University of Science and Technology(Natural Science Edition), 2010, 38(5): 121-123(in Chinese). [18] HUANG H, YANG C, WU Z. Electrical sensing properties of carbon fiber reinforced plastic strips for detecting low-level strains[J]. Smart materials and structures, 2012, 21(3): 035013. doi: 10.1088/0964-1726/21/3/035013 [19] FOUAD N, SAIFELDEEN M A. Smart self-sensing fiber-reinforced polymer sheet with woven carbon fiber line sensor for structural health monitoring[J]. Advances in Structural Engineering, 2021, 24(1): 17-24. doi: 10.1177/1369433220944507 [20] FENG Q, OU J. Self-sensing CFRP fabric for structural strengthening and damage detection of reinforced concrete structures[J]. Sensors, 2018, 18(12): 4137. doi: 10.3390/s18124137 [21] ABRY J C, BOCHARD S, Chateauminois A, et al. In situ detection of damage in CFRP laminates by electrical resistance measurements[J]. Composites science and technology, 1999, 59(6): 925-935. doi: 10.1016/S0266-3538(98)00132-8 [22] WEBER I, SCHWARTZ P. Monitoring bending fatigue in carbon-fibre/epoxy composite strands: a comparison between mechanical and resistance techniques[J]. Composites Science and Technology, 2001, 61(6): 849-853. doi: 10.1016/S0266-3538(01)00028-8 [23] GOLDFELD Y, YOSEF L. Electrical–structural characterisation of smart carbon-based textile reinforced concrete beams by integrative gauge factors[J]. Strain, 2020, 56(4): e12344. doi: 10.1111/str.12344 [24] GOLDFELD Y, BEN-AAROSH S, RABINOVITCH O, et al. Integrated self-monitoring of carbon based textile reinforced concrete beams under repeated loading in the un-cracked region[J]. Carbon, 2016, 98: 238-249. doi: 10.1016/j.carbon.2015.10.056 [25] SALEH M N, YUDHANTO A, LUBINEAU G, et al. The effect of z-binding yarns on the electrical properties of 3D woven composites[J]. Composite Structures, 2017, 182: 606-616. doi: 10.1016/j.compstruct.2017.09.081 [26] HAN C, HUANG S, SUN B, et al. Electrical resistance changes of 3D carbon fiber/epoxy woven composites under short beam shear loading along different orientations[J]. Composite Structures, 2021, 276: 114549. doi: 10.1016/j.compstruct.2021.114549 [27] 石荣荣, 武宝林. 三维编织碳纤维复合材料电阻率的估算[J]. 复合材料学报, 2016, 33(12): 2775-2780.SHI Rongrong, WU Baolin. Resistivity estimation of 3D braided carbon fiber composites[J]. Acta Materiae Compositae Sinica, 2016, 33(12): 2775-2780(in Chinese). [28] 薛有松, 薛凌明, 孙宝忠, 等. 碳纤维三维角联锁机织复合材料弯曲作用下力阻响应[J]. 复合材料学报, 2023, 40(3): 1468-1476.XUE Yousong, XUE Lingming, SUN Baozhong, et al. Piezoresistive effect of carbon fiber 3D angle-interlock woven composites under bending[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1468-1476(in Chinese). [29] 中华人民共和国住房和城乡建设部. 混凝土物理力学性能方法试验标准: GB/T 50081—2019 [S]. 北京: 中国建筑工业出版社, 2019.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test methods of concrete physical and mechanical properties: GB/T 50081—2019 [S]. Beijing: China Architecture & Building Press, 2019(in Chinese). [30] TODOROKI A, TANAKA M, SHIMAMURA Y. Measurement of orthotropic electric conductance of CFRP laminates and analysis of the effect on delamination monitoring with an electric resistance change method[J]. Composites Science and Technology, 2002, 62(5): 619-628. doi: 10.1016/S0266-3538(02)00019-2 [31] 西安建筑科技大学. 高韧性混凝土加固砌体结构技术规程: T/CECS 997—2022 [S]. 北京: 中国建筑工业出版社, 2022.Xi’an University of Architecture and Technology. Technical specification for strengthening masonry structure with toughness-concrete: T/CECS 997—2022 [S]. Beijing: China Architecture & Building Press, 2022(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 44

- HTML全文浏览量: 14

- 被引次数: 0

下载:

下载: