Interfacial and hygrothermal properties of high modulus carbon fiber composites modified with graphene nanoplates

-

摘要: 高模量碳纤维(HMCF)复合材料的界面性能一直是影响其应用的关键所在,对HMCF进行表面改性则是实现界面性能提高的重要途径之一。采用电泳沉积法将石墨烯纳米片(GNP)引入到HMCF表面,通过扫描电镜(SEM)、X射线光电子能谱(XPS)对改性前后的HMCF表面形貌、表面化学状态进行了表征,测试了改性前后HMCF增强环氧树脂复合材料的层间剪切强度(ILSS)和吸湿率。结果表明,HMCF表面电泳沉积GNP,不仅可以改善其增强环氧树脂复合材料的界面性能,同时也能降低复合材料的吸湿率。在GNP浓度为0.5 mg/mL,电泳沉积电压为10 V时,复合材料层间剪切性能提高了8.8%,达到75.6 MPa;90℃、80RH%环境下存放30天后,与未改性样品相比,其吸湿率降低了9.5%,存放60天后层间剪切性能仍保持在67.8 MPa。改性高模量碳纤维复合材料界面性能与耐湿热性能均得以提高。Abstract: The interfacial properties of high-modulus carbon fiber (HMCF) composites have always been the key to their applications, and surface modification of HMCF is one of the important ways to improve the interfacial properties. Graphene nanosheets (GNP) were introduced into the surface of HMCF by electrophoretic deposition, and the surface morphology and surface chemical state of HMCF before and after modification were characterized by scanning electron microscopy (SEM) and X-ray photoelectron spectroscopy (XPS), and the interlaminar shear strength (ILSS) and moisture absorption rate of HMCF reinforced epoxy resin composites before and after modification were tested. The results show that the surface electrophoretic deposition of GNP by HMCF can not only improve the interfacial properties of the reinforced epoxy resin composites, but also reduce the moisture absorption rate of the composites. When the GNP concentration was 0.5 mg/mL and the electrophoretic deposition voltage was 10 V, the interlaminar shear performance of the composites increased by 8.8% to 75.6 MPa, and the moisture absorption rate was reduced by 9.5% compared with the unmodified sample after 30 days of storage at 90°C and 80 RH%, and the interlayer shear performance remained at 67.8 MPa after 60 days of storage. Both interfacial and hygrothermal properties of the modified HMCF comosites have been improved.

-

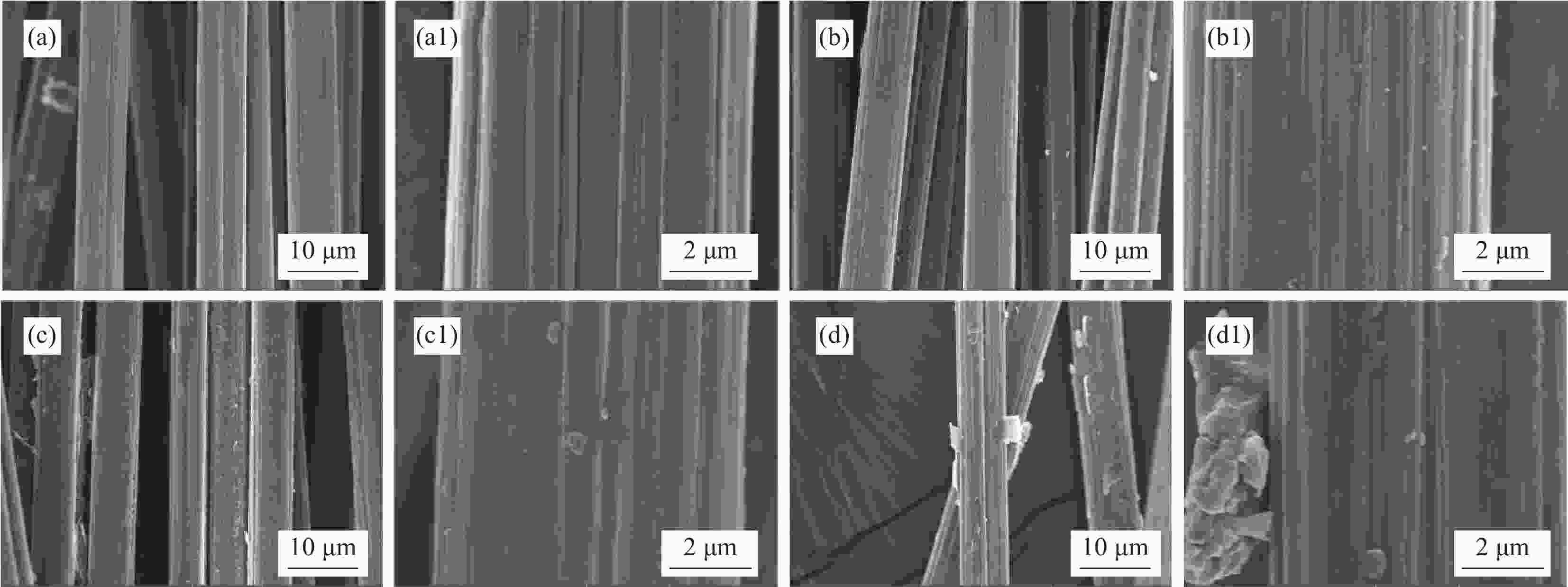

图 7 不同HMCF/EP复合材料轴向截面形态SEM图像(a) U-CF/EP; (a1) Aged U-CF/EP; (b) CF-10/EP; (b1) Aged CF-10/EP; (c) CF-20/EP; (c1) Aged CF-20/EP

Figure 7. SEM images of axial cross-section morphology of different HMCF/EP composites (a) U-CF/EP; (a1)Aged U-CF/EP; (b) CF-10/EP; (b1) Aged CF-10/EP; (c) CF-20/EP; (c1) Aged CF-20/EP

表 1 各样品缩写命名

Table 1. Abbreviations used for various samples prepared

Sample code Details U-CF Untreated commercial carbon fibers (CF) CF 0.5 mg/mL solution 5 V voltage electrophoresis deposited modified fibers CF-10 0.5 mg/mL graphene nanoplates solution 10 V voltage electrophoresis deposited modified fibers CF-20 0.5 mg/mL graphene nanoplates solution 20 V voltage electrophoresis deposited modified fibers U-CF/EP Untreated commercial carbon fiber reinforced epoxy (EP) composites CF-5/EP 0.5 mg/mL graphene nanoplates solution 5 V voltage electrophoresis deposited modified fibers reinforced epoxy composites CF-10/EP 0.5 mg/mL graphene nanoplates solution 10 V voltage electrophoresis deposited modified fibers reinforced epoxy composites CF-20/EP 0.5 mg/mL graphene nanoplates solution 20 V voltage electrophoresis deposited modified fibers reinforced epoxy composites Aged U-CF/EP After 30 days of hygrothermal test(90℃、80%RH) untreated commercial carbon fibers reinforced epoxy composites Aged CF-5/EP After 30 days of hygrothermal test(90℃、80%RH) 0.5 mg/mL graphene nanoplates solution 5 V voltage electrophoresis deposited modified fibers reinforced epoxy composites Aged CF-10/EP After 30 days of hygrothermal test(90℃、80%RH) 0.5 mg/mL graphene nanoplates solution 10 V voltage electrophoresis deposited modified fibers reinforced epoxy composites Aged CF-20/EP After 30 days of hygrothermal test(90℃、80%RH) 0.5 mg/mL graphene nanoplates solution 20 V voltage electrophoresis deposited modified fibers reinforced epoxy composites 表 2 不同HMCF C1 s特征峰结合能及相对含量

Table 2. C1 s characteristic peak binding energy and relative content of different HMCF

Functional group Binding energy/eV U-CF/% CF-5/% CF-10/% CF-20/% C—C 284.4 46.60 48.31 49.36 44.56 C—H 285.2 48.78 46.08 46.59 45.76 C—O 286.3 2.19 2.69 1.35 4.65 C=O 287.3 / / / / COOH 288.6 0.72 1.70 3.79 3.78 表 3 90℃、80 RH%湿热条件下HMCF/EP的吸湿率

Table 3. Moisture absorption of HMCF/EP at 90°C, 80 RH%

Sample M5 d/% M10 d/% M15 d/% M20 d/% M25 d/% M30 d/% U-CF 0.08 0.16 0.21 0.24 0.25 0.26 CF-10/EP 0.07 0.15 0.19 0.21 0.22 0.24 CF-20/EP 0.08 0.17 0.22 0.22 0.24 0.25 Note:Mxd—Moisture absorption of composite material after x days 表 4 80 RH%,90℃湿热老化HMCF/EP吸湿拟合参数

Table 4. Hygroscopic fitting parameters of HMCF/EP for hygrothermal at 90°C,80 RH%

CF-10/EP CF-20/EP U-CF/EP D/10−4mm/h 14.82 15.13 15.69 M1∞/% 0.12 0.14 0.12 M30 d/% 0.24 0.25 0.26 k/10−2 mm/h1/2 4.43 3.89 5.19 R2 0.96 0.95 0.97 Note:D—Diffusion coefficient of water molecules in composites

M1∞—Saturated moisture absorption rate of the first stage of the composite Fick M30 d—Moisture absorption of composite material after 30 days k—Constant related to the relaxation of resin structure表 5 80 RH%、90℃下HMCF/EP老化过程中层间剪切强度

Table 5. Interlaminar shear strength during HMCF/EP aging at 90℃、80 RH%

Sample ILSS0d/MPa ILSS10d/MPa ILSS20d/MPa ILSS30d/MPa ILSS60d/MPa U-CF/EP 69.5 68.6 65.4 64.4 61.3 CF-10/EP 75.6 73.2 69.3 69.5 67.8 CF-20/EP 72.2 68.9 68.1 66.7 65.5 Note:ILSSxd—Interlaminar shear strength of composite material after x days -

[1] 陶积柏, 黎昱, 张玉生等. 高模量碳纤维在中国宇航结构产品上的应用现状及实现自我保障的建议[J]. 材料科学与工艺, 2015, 23(6): 98-103. doi: 10.11951/j.issn.1005-0299.20150618TAO Jibai, LI Yu, ZHANG Yusheng, et al. Application status of high-modulus carbon fiber in domestic aerospace structural products and suggestions for self-supply[J]. Materials Science and Technology, 2015, 23(6): 98-103(in Chinese). doi: 10.11951/j.issn.1005-0299.20150618 [2] BARAL N, DAVIES P, BALEY C, et al. Delamination behaviour of very high modulus carbon/epoxy marine composites[J]. Composites Science and Technology, 2008, 68(3-4): 995-1007. doi: 10.1016/j.compscitech.2007.07.022 [3] HAO R, JIAO X, ZHANG X; et al. Fe3O4/graphene modified waterborne polyimide sizing agent for high modulus carbon fiber[J]. Applied Surface Science, 2019, 485: 304-313. doi: 10.1016/j.apsusc.2019.04.184 [4] LIN J, XU P, WANG L, et al. Multi-scale interphase construction of self-assembly naphthalenediimide/multi-wall carbon nanotube and enhanced interfacial properties of high-modulus carbon fiber composites[J]. Composites Science and Technology, 2019, 184(10): 107855. [5] GAO S-L, MADER E, ZHANDAROV S F, et al. Carbon fibers and composites with epoxy resins: Topography, fractography and interphases[J]. Carbon, 2004, 42(3): 515-529. doi: 10.1016/j.carbon.2003.12.085 [6] MCCRARY-D M C, OKOLI O I. A review of multiscale composite manufacturing and challenges[J]. Journal of Reinforced Plastics and Composites, 2012, 31(24): 1687-1711. doi: 10.1177/0731684412456612 [7] QI X, TIAN J, XIAN G. Hydrothermal ageing of carbon fiber reinforced polymer composites applied for construction: A review[J]. Journal of Materials Research and Technology, 2023, 27: 1017-1045. doi: 10.1016/j.jmrt.2023.09.198 [8] SUN P, ZHAO Y, LUO Y. Effect of temperature and cyclic hygrothermal aging on the interlaminar shear strength of carbon fiber/bismaleimide (BMI) composite[J]. Materials and Design, 2011, 32(8-9): 4341-4347. doi: 10.1016/j.matdes.2011.04.007 [9] DZUL-CERVANTES, PACHECO-SALAZAR O F, CAN-HERRERA L A, et al. Effect of moisture content and carbon fiber surface treatments on the interfacial shear strength of a thermoplastic-modified epoxy resin composites[J]. Journal of Materials Research and Technology 2020, 9(6): 15739-15749. [10] YU B, JIANG Z, YANG J. Long-term moisture effects on the interfacial shear strength between surface treated carbon fiber and epoxy matrix[J]. Composites Part A: Applied Science and Manufacturing 2015, 78: 311-317. [11] ZHANG S, LIU W B, HAO L F, et al. Preparation of carbon nanotube/carbon fiber hybrid fiber by combining electrophoretic deposition and sizing process for enhancing interfacial strength in carbon fiber composites[J]. Composites Science and Technology, 2013, 88: 120-125. doi: 10.1016/j.compscitech.2013.08.035 [12] WU G, MA L, LIU L, et al. Interface enhancement of carbon fiber reinforced methylphenylsilicone resin composites modified with silanized carbon nanotubes[J]. Materials and Design 2016, 89: 1343-1349. [13] ASADI A, MILLER M, MOON R. J, et al. Improving the interfacial and mechanical properties of short glass fiber/epoxy composites by coating the glass fibers with cellulose nanocrystals[J]. Abstracts of Papers of the American Chemical Society, 2016, 10(7): 587-597. [14] MOON R J, MARTINI A, NAIRN J, et al. Cellulose nanomaterials review: structure, properties and nanocomposites[J]. Chemical Society Reviews, 2011, 40(7): 3941-94. doi: 10.1039/c0cs00108b [15] 刘文军, 严建龙, 周川, 等. 氧化石墨烯改性碳纤维/环氧树脂复合材料的湿热性能及微观形貌[J]. 复合材料学报, 2021, 38(5): 1416-1425LIU Wenjun, YAN Jianlong, ZHOU Chuan, et al. Hygrothermal properties and micro morphology of graphene oxide modified carbon fiber/epoxy resin composites[J]. Acta Materiae Compositae Sinica, 2021, 38(5): 1416-1425(in Chinese). [16] ZHUANG X, MA J, DAN Y, et al. Hydrothermal aging of carbon fiber reinforced epoxy composites with different interface structures[J]. Polymer Degradation and Stability, 2023, 212: 110352. doi: 10.1016/j.polymdegradstab.2023.110352 [17] KONG N, KHALIL N Z. Water absorption mechanism and mechanical performance of adhesively joint aluminum alloy with GNP reinforced epoxy[J]. Materials Today, 2022, 51(2): 1392-1398. [18] KONG N U, KHALIL N Z, FRICKE H. Moisture Absorption Behavior and Adhesion Properties of GNP/Epoxy Nanocomposite Adhesives[J]. Polymers, 2021, 13(11): 1850. doi: 10.3390/polym13111850 [19] OZGE K, LISA M, ASADI A. Cellulose nanocrystal-enabled tailoring of the interface in carbon nanotube and graphene nanoplatelet-carbon fiber polymer composites: Implications for structural applications[J]. ACS Applied Nano Materials, 2022, 5(1): 1284-1295. doi: 10.1021/acsanm.1c03860 [20] 中国国家标准化管理委员会. 聚合物基复合材料短梁剪切强度试验方法: GB/T 30969-2014 [S]. 北京: 中国标准出版社, 2014.Standardization Administration of the People’s Republic of China. Test method for shear strength of short beams of polymer matrix composites: GB30969−2014[S]. Beijing: China Standards Press, 2014(in Chinese). [21] QIAN X, ZHANG Y G, WANG X F, et al. Effect of carbon fiber surface functionality on the moisture absorption behavior of carbon fiber/epoxy resin composites[J]. Surface and Interface Analysis, 2016, 48(12): 1271-1277. doi: 10.1002/sia.6031 [22] ZHONG Y, CHENG M, ZHANG X, et al. Hygrothermal durability of glass and carbon fiber reinforced composites – A comparative study[J]. Composite Structures, 2019, 211: 134-143. doi: 10.1016/j.compstruct.2018.12.034 [23] LI-RONG B, ALBERT F. Y. Mositure diffusion and hygrothermal aging bismaleimide matrix carbon fiber composites: part Ⅱ-woven and hybrid composites[J]. Composites Science and Technology, 2002, (62): 2111-2119. [24] TSOTSIS T K, WEITSMAN Y. A simple graphical method for determining diffusion parameters for two-stage sorption in composites[J]. Journal of Materials Science Letters, 1994, (13): 1635-1636. [25] VUKOVIC F, WALSH T R. Moisture Ingress at the Molecular Scale in Hygrothermal Aging of Fiber–Epoxy Interfaces[J]. ACS Applied Materials and Interfaces, 2020, 12(49): 55278-55289. doi: 10.1021/acsami.0c17027 -

点击查看大图

点击查看大图

计量

- 文章访问数: 49

- HTML全文浏览量: 26

- 被引次数: 0

下载:

下载: