| [1] |

HAN Z D, FINA A. Thermal conductivity of carbon nano-tubes and their polymer nanocomposites: A review[J]. Progress in Polymer Science,2011,36(7):914-944. doi: 10.1016/j.progpolymsci.2010.11.004

|

| [2] |

CHEN H Y, GINZBURG V V, YANG J, et al. Thermal conductivity of polymer-based composites: Fundamentals and applications[J]. Progress in Polymer Science,2016,59:41-85.

|

| [3] |

SHAHIL K M, BALANDIN A A. Graphene-multilayer graphene nanocomposites as highly efficient thermal interface materials[J]. Nano Letters,2012,12(2):861-867. doi: 10.1021/nl203906r

|

| [4] |

WU Y M, CAO Y, XIAO X S, et al. Enhanced thermal transport performance for poly(vinylidene fluoride) composites with superfullerene[J]. Fibers and Polymers,2017,18(6):1180-1186. doi: 10.1007/s12221-017-7001-6

|

| [5] |

ALAM F E, DAI W, YANG M H, et al. In situ formation of a cellular graphene framework in thermoplastic composites leading to superior thermal conductivity[J]. Journal of Materials Chemistry A,2017,5(13):6164-6169. doi: 10.1039/C7TA00750G

|

| [6] |

RUAN K P, ZHONG X, SHI X T, et al. Liquid crystal epoxy resins with high intrinsic thermal conductivities and their composites: A mini-review[J]. Materials Today Physics,2021,20:100456. doi: 10.1016/j.mtphys.2021.100456

|

| [7] |

吴宇明, 虞锦洪, 曹勇, 等. 高导热低填量聚合物基复合材料研究进展[J]. 复合材料学报, 2018, 35(04):760-766.WU Y M, YU J H, CAO Y, et al. Review of polymer-based composites with high thermal conductivity and low filler loading[J]. Acta Materiae Compositae Sinica,2018,35(04):760-766(in Chinese).

|

| [8] |

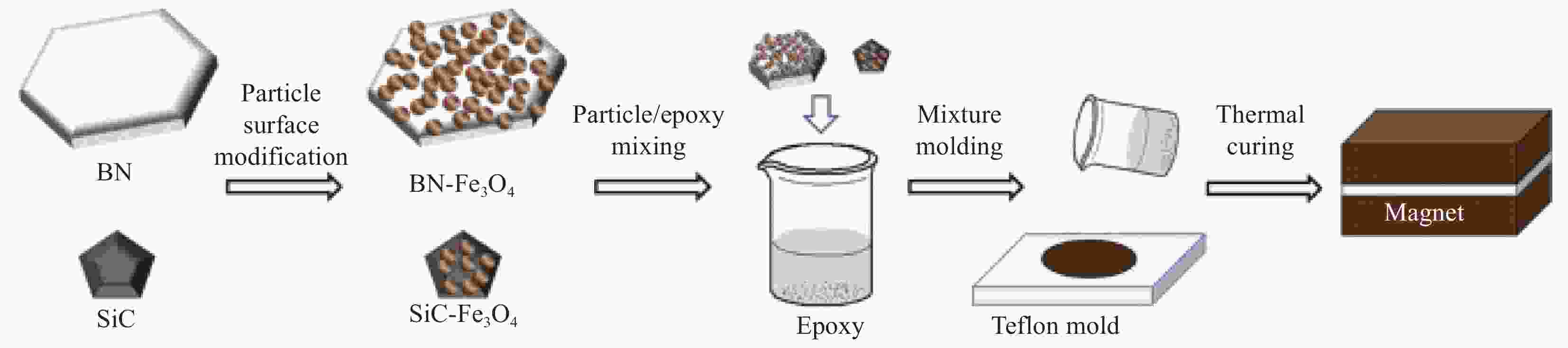

KIM K, KIM M, KIM J, et al. Magnetic filler alignment of paramagnetic Fe3O4 coated SiC/epoxy composite for thermal conductivity improvement[J]. Ceramics International,2015,41(9):12280-12287. doi: 10.1016/j.ceramint.2015.06.053

|

| [9] |

KIM K, JU H, KIM J. Vertical particle alignment of boron nitride and silicon carbide binary filler system for thermal conductivity enhancement[J]. Composites Science and Technology,2016,123:99-105. doi: 10.1016/j.compscitech.2015.12.004

|

| [10] |

YUAN C, DUAN B, LI L, et al. Thermal conductivity of polymer-based composites with magnetic aligned hexagonal boron nitride platelets[J]. ACS Applied Materials & Interfaces,2015,7(23):13000-13006.

|

| [11] |

YUAN J, QIAN X T, MENG Z C, et al. Highly thermally conducting polymer-based films with magnetic field-assisted vertically aligned hexagonal boron nitride for flexible electronic encapsulation[J]. ACS Applied Materials & Interfaces,2019,11(19):17915-17924.

|

| [12] |

YUAN F, JIAO W C, YANG F, et al. Surface modification and magnetic alignment of hexagonal boron nitride nanosheets for highly thermally conductive composites[J]. RSC Advances,2017,7(69):43380-43389. doi: 10.1039/C7RA08516H

|

| [13] |

RALPHS M, SCHEITLIN C, WANG R Y, et al. Buckling of magnetically formed filler fiber columns under compression increases thermal resistance of soft polymer compo-sites[J]. Journal of Heat Transfer,2019,141(1):012001.

|

| [14] |

GUO Y Q, RUAN K P, GU J W. Controllable thermal conductivity in composites by constructing thermal conduction networks[J]. Materials Today Physics,2021,20:100449. doi: 10.1016/j.mtphys.2021.100449

|

| [15] |

GUO Y Q, RUAN K P, SHI X T, et al. Factors affecting thermal conductivities of the polymers and polymer composites: A review[J]. Composites Science and Technology,2020,193:108134. doi: 10.1016/j.compscitech.2020.108134

|

| [16] |

GU J W, LV Z Y, WU Y L, et al. Dielectric thermally conductive boron nitride/polyimide composites with outstanding thermal stabilities via in-situ polymerization-electrospinning-hot press method[J]. Composites Part A:Applied Science and Manufacturing,2017,94:209-216. doi: 10.1016/j.compositesa.2016.12.014

|

| [17] |

FENG C P, WAN S S, WU W C, et al. Electrically insulating, layer structured SiR/GNPs/BN thermal management materials with enhanced thermal conductivity and breakdown voltage[J]. Composites Science and Technology,2018,167:456-462. doi: 10.1016/j.compscitech.2018.08.039

|

| [18] |

GUO Y Q, PAN L L, YANG X T, et al. Simultaneous improvement of thermal conductivities and electromagnetic interference shielding performances in polystyrene composites via constructing interconnection oriented networks based on electrospinning technology[J]. Composites Part A: Applied Science and Manufacturing,2019,124:105484. doi: 10.1016/j.compositesa.2019.105484

|

| [19] |

CHEN J, HUANG X Y, SUN B, et al. Vertically aligned and interconnected boron nitride nanosheets for advanced flexible nanocomposite thermal interface materials[J]. ACS Applied Materials & Interfaces,2017,9(36):30909-30917.

|

| [20] |

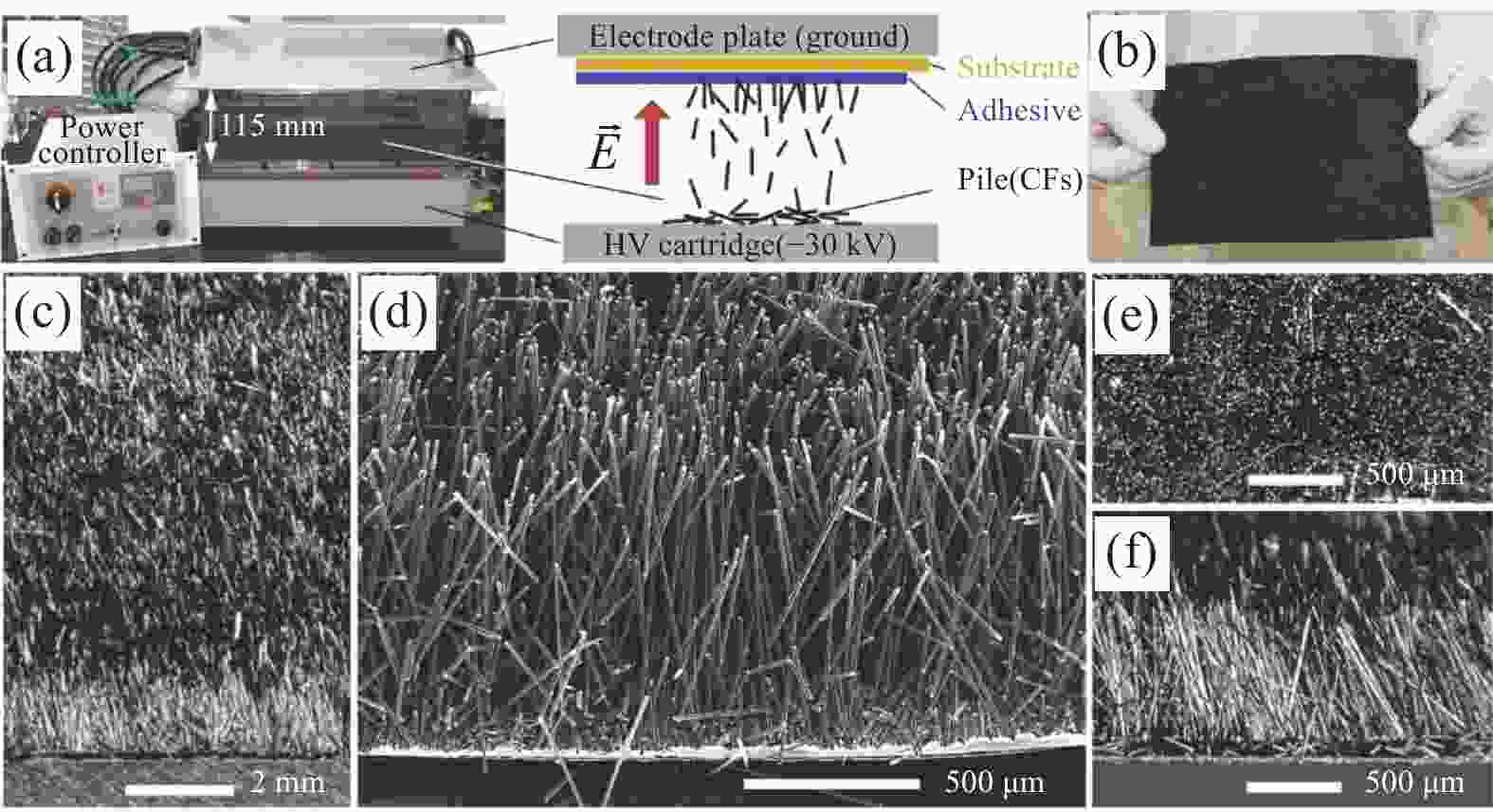

UETANI K, ATA S, TOMONOH S, et al. Elastomeric thermal interface materials with high through-plane thermal conductivity from carbon fiber fillers vertically aligned by electrostatic flocking[J]. Advanced Materials,2014,26(33):5857-5862. doi: 10.1002/adma.201401736

|

| [21] |

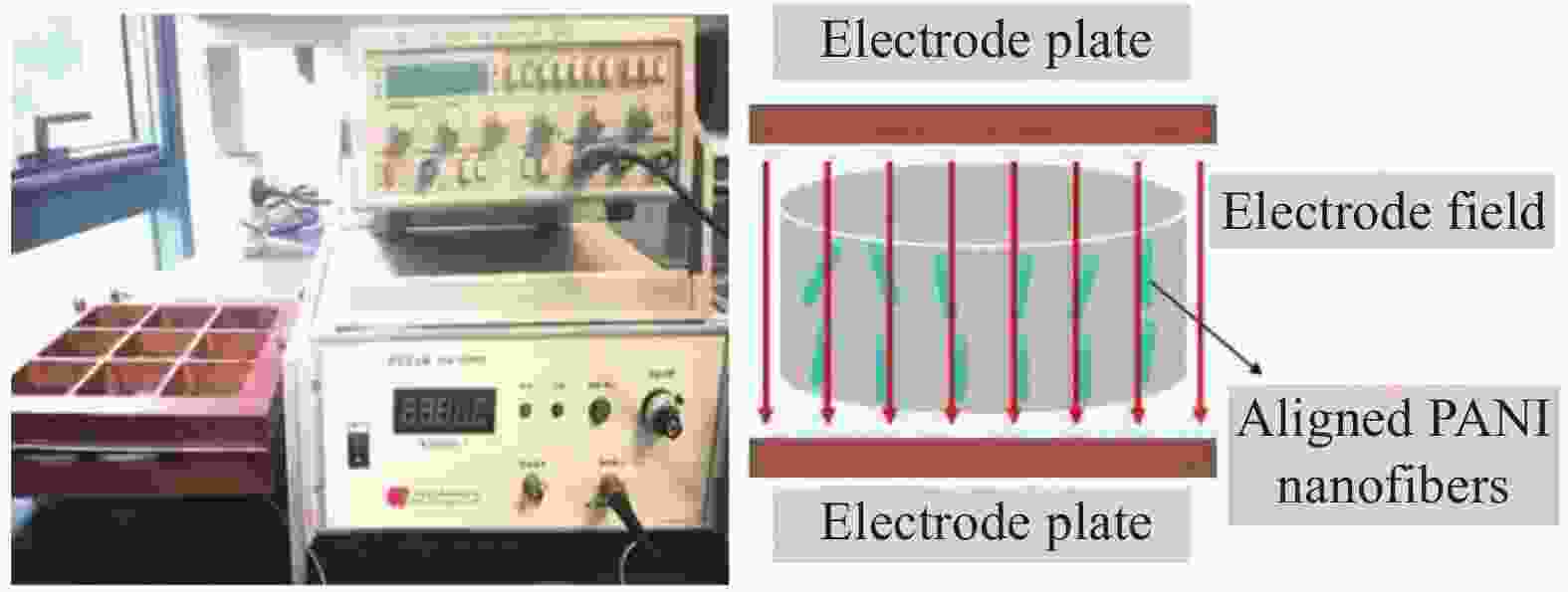

GUO H, LI X, WANG Z Y, et al. Thermal conductivity of PVDF/PANI-nanofiber composite membrane aligned in an electric field[J]. Chinese Journal of Chemical Engineering,2018,26(5):1213-1218. doi: 10.1016/j.cjche.2017.12.015

|

| [22] |

KIM K, JU H, KIM J. Filler orientation of boron nitride composite via external electric field for thermal conductivity enhancement[J]. Ceramics International,2016,42(7):8657-8663. doi: 10.1016/j.ceramint.2016.02.098

|

| [23] |

ZHI C Y, BANDO Y S, TAN C C, et al. Effective precursor for high yield synthesis of pure BN nanotubes[J]. Solid State Communications,2005,135(1-2):67-70. doi: 10.1016/j.ssc.2005.03.062

|

| [24] |

GU J W, RUAN K P. Breaking through bottlenecks for thermally conductive polymer composites: A perspective for intrinsic thermal conductivity, interfacial thermal resistance and theoretics[J]. Nano-Micro Letters,2021,13(1):118-126. doi: 10.1007/s40820-021-00640-4

|

| [25] |

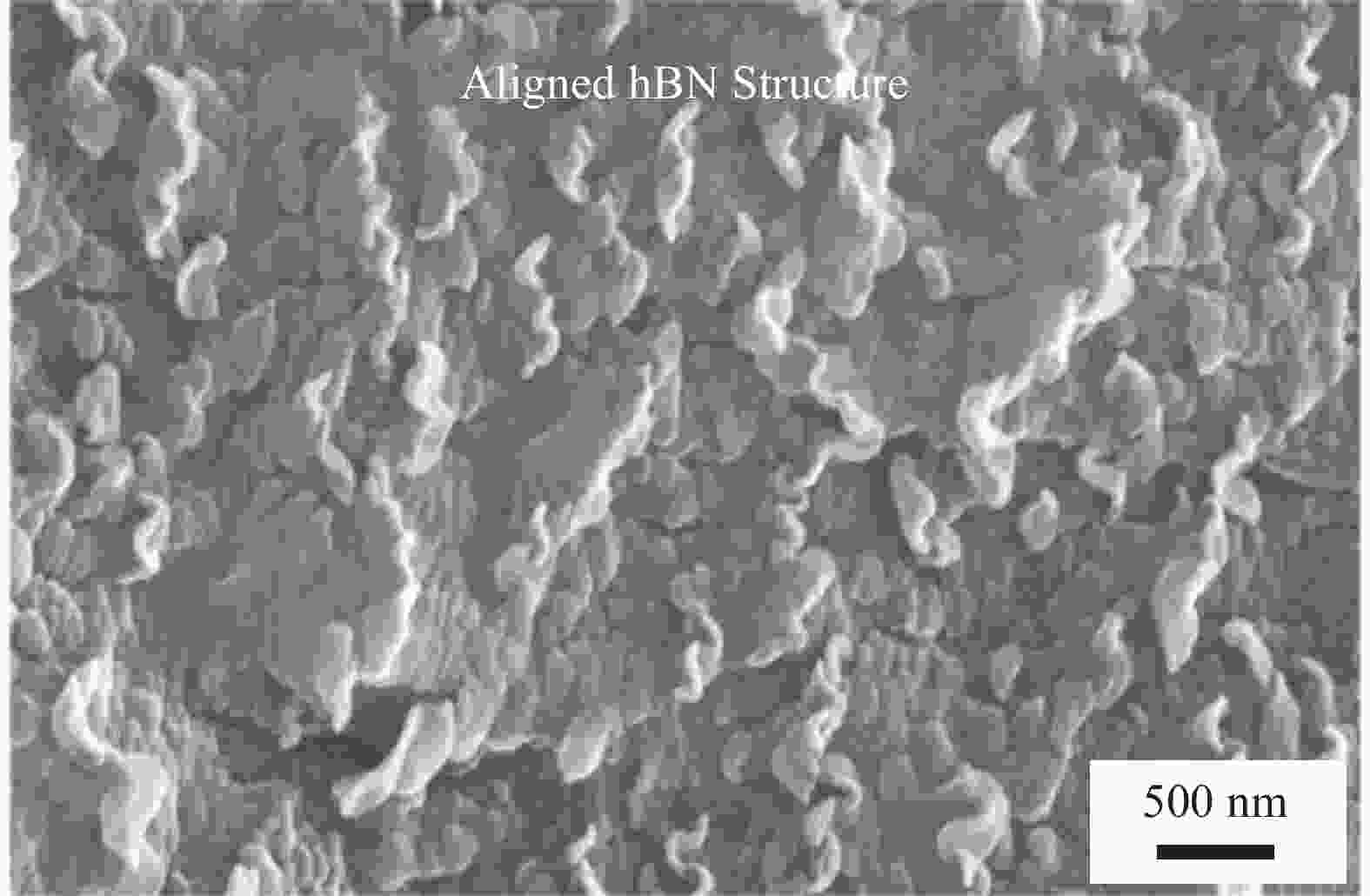

SHEN H, GUO J, WANG H, et al. Bioinspired modification of h-BN for high thermal conductive composite films with aligned structure[J]. ACS Applied Materials & Interfaces,2015,7(10):5701-5708.

|

| [26] |

WANG D Z, WEI H, LIN Y, et al. Achieving ultrahigh thermal conductivity in Ag/MXene/epoxy nanocompo-sites via filler-filler interface engineering[J]. Composites Science and Technology,2021,213:108953. doi: 10.1016/j.compscitech.2021.108953

|

| [27] |

WANG F F, ZENG X L, YAO Y M, et al. Silver nanoparticle-deposited boron nitride nanosheets as fillers for polymeric composites with high thermal conductivity[J]. Scientific Reports,2016,6(1):19394. doi: 10.1038/srep19394

|

| [28] |

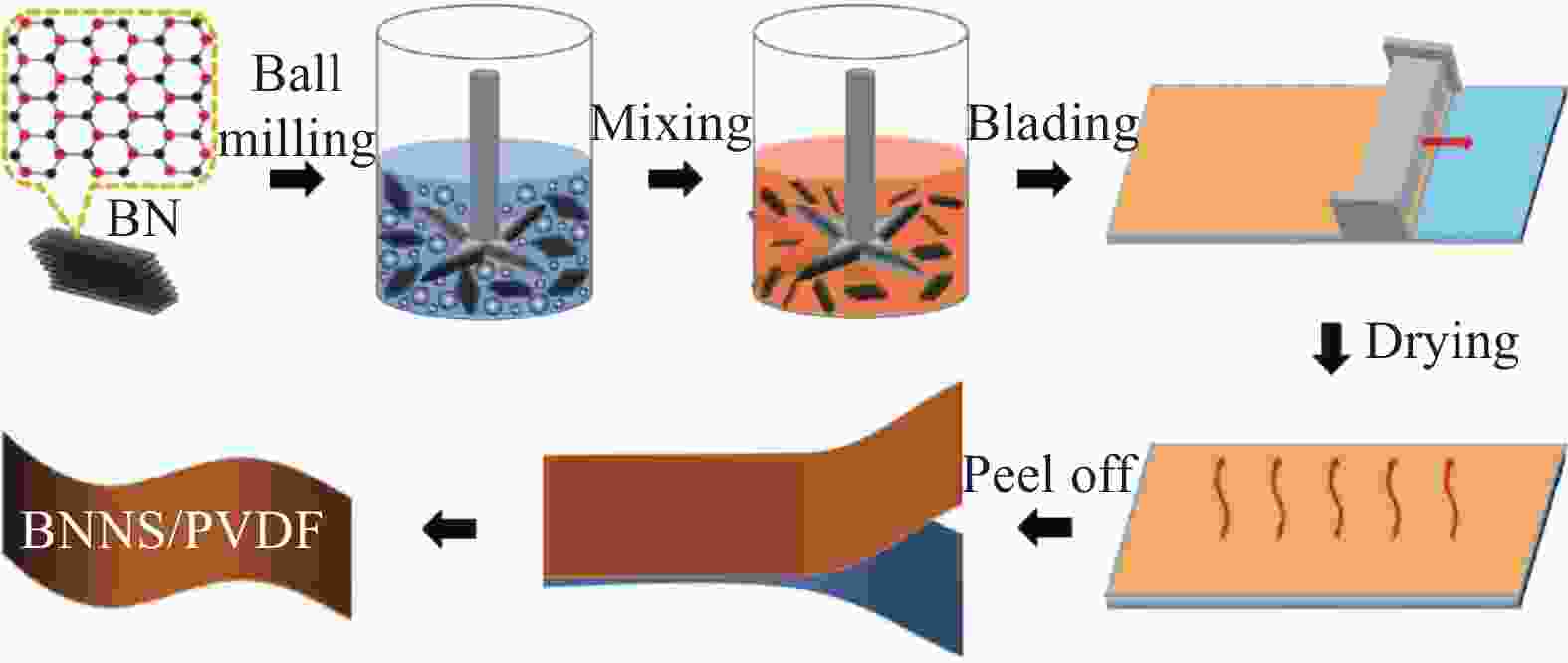

TENG C, SU L Y, CHEN J X, et al. Flexible, thermally conductive layered composite films from massively exfoliated boron nitride nanosheets[J]. Composites Part A: Applied Science and Manufacturing,2019,124:105498. doi: 10.1016/j.compositesa.2019.105498

|

| [29] |

HAN X, WU L J, ZHANG H B, et al. Inorganic-organic hybrid janus fillers for improving the thermal conductivity of polymer composites[J]. ACS Applied Materials & Interfaces,2019,11(13):12190-12194.

|

| [30] |

MORISHITA T, OKAMOTO H. Facile exfoliation and noncovalent superacid functionalization of boron nitride nanosheets and their use for highly thermally conductive and electrically insulating polymer nanocomposites[J]. ACS Applied Materials & Interfaces,2016,8(40):27064-27073.

|

| [31] |

HE X H, YU X, WANG Y C. Significantly enhanced thermal conductivity in polyimide composites with the matching of graphene flakes and aluminum nitride by in situ polymerization[J]. Polymer Composites,2019,41(2):740-747.

|

| [32] |

LIU Y C, LU M P, WU K, et al. Enhanced thermal conduction of functionalized graphene nanoflake/polydimethylsiloxane composites via thermoluminescence strategy[J]. Composites Science and Technology,2021,213:108940. doi: 10.1016/j.compscitech.2021.108940

|

| [33] |

LIN G L, XIE B H, HU J, et al. Aligned graphene oxide nanofillers: an approach to prepare highly thermally conductive and electrically insulative transparent polymer compo-sites[J]. Journal of Nanomaterials,2015,2015:957068.

|

| [34] |

GU J W, GUO Y Q, YANG X T, et al. Synergistic improvement of thermal conductivities of polyphenylene sulfide composites filled with boron nitride hybrid fillers[J]. Composites Part A: Applied Science and Manufacturing,2017,95:267-273. doi: 10.1016/j.compositesa.2017.01.019

|

| [35] |

YU C P, GONG W B, TIAN W, et al. Hot-pressing induced alignment of boron nitride in polyurethane for composite films with thermal conductivity over 50 W(m·K)−1[J]. Composites Science and Technology,2018,160:199-207. doi: 10.1016/j.compscitech.2018.03.028

|

| [36] |

YIN Z H, GUO J H, JIANG X H. Significantly improved thermal conductivity of silicone rubber and aligned boron nitride composites by a novel roll-cutting processing method[J]. Composites Science and Technology,2021,209:108794. doi: 10.1016/j.compscitech.2021.108794

|

| [37] |

JUNG H J, YU S G, BAE N S, et al. High through-plane thermal conduction of graphene nanoflake filled polymer composites melt-processed in an L-shape kinked tube[J]. ACS Applied Materials & Interfaces,2015,7(28):15256-15262.

|

| [38] |

YUAN H, WANG Y, LI T, et al. Fabrication of thermally conductive and electrically insulating polymer composites with isotropic thermal conductivity by constructing a three-dimensional interconnected network[J]. Nanoscale,2019,11(23):11360-11368. doi: 10.1039/C9NR02491C

|

| [39] |

QIN T F, WANG H, HE J, et al. Amino multi-walled carbon nanotubes further improve the thermal conductivity of boron nitride/liquid crystal epoxy resin composites[J]. Express Polymer Letters,2020,14(12):1169-1179. doi: 10.3144/expresspolymlett.2020.95

|

| [40] |

WANG Z G, GONG F, YU W C, et al. Synergetic enhancement of thermal conductivity by constructing hybrid conductive network in the segregated polymer composites[J]. Composites Science and Technology,2018,162:7-13. doi: 10.1016/j.compscitech.2018.03.016

|

| [41] |

ZHOU H J, DENG H, ZHANG L, et al. Significant enhancement of thermal conductivity in polymer composite via constructing macroscopic segregated filler networks[J]. ACS Applied Materials& Interfaces,2017,9(34):29071-29081.

|

| [42] |

LIAN G, TUAN C C, LI L Y, et al. Vertically aligned and interconnected graphene networks for high thermal conductivity of epoxy composites with ultralow loading[J]. Che-mistry of Materials,2016,28(17):6096-6104. doi: 10.1021/acs.chemmater.6b01595

|

| [43] |

YANG J, ZHANG E W, LI X F, et al. Cellulose/graphene aerogel supported phase change composites with high thermal conductivity and good shape stability for thermal energy storage[J]. Carbon,2016,98:50-57. doi: 10.1016/j.carbon.2015.10.082

|

| [44] |

HOU X, CHEN Y P, DAI W, et al. Highly thermal conductive polymer composites via constructing micro-phragmites communis structured carbon fibers[J]. Chemical Engineering Journal,2019,375:121921. doi: 10.1016/j.cej.2019.121921

|

| [45] |

ZENG X L, YAO Y M, GONG Z Y, et al. Ice-templated assembly strategy to construct 3D boron nitride nanosheet networks in polymer composites for thermal conductivity improvement[J]. Small,2015,11(46):6205-6213. doi: 10.1002/smll.201502173

|

| [46] |

GUO L C, ZHANG Z Y, LI M H, et al. Extremely high thermal conductivity of carbon fiber/epoxy with synergistic effect of MXenes by freeze-drying[J]. Composites Communications,2020,19:134-141. doi: 10.1016/j.coco.2020.03.009

|

| [47] |

YU C P, ZHANG J, LI Z, et al. Enhanced through-plane thermal conductivity of boron nitride/epoxy composites[J]. Composites Part A: Applied Science and Manufacturing,2017,98:25-31. doi: 10.1016/j.compositesa.2017.03.012

|

| [48] |

ZENG X L, YE L, YU S H, et al. Artificial nacre-like papers based on noncovalent functionalized boron nitride nanosheets with excellent mechanical and thermally conductive properties[J]. Nanoscale,2015,7(15):6774-6781. doi: 10.1039/C5NR00228A

|

| [49] |

LIANG C B, GU Z J, ZHANG Y L, et al. Structural design strategies of polymer matrix composites for electromagnetic interference shielding: A review[J]. Nano-Micro Letters,2021,13(11):322-350. doi: 10.1007/s40820-021-00707-2

|

下载:

下载: