Compression and bending properties of 3D braided tubular composites

-

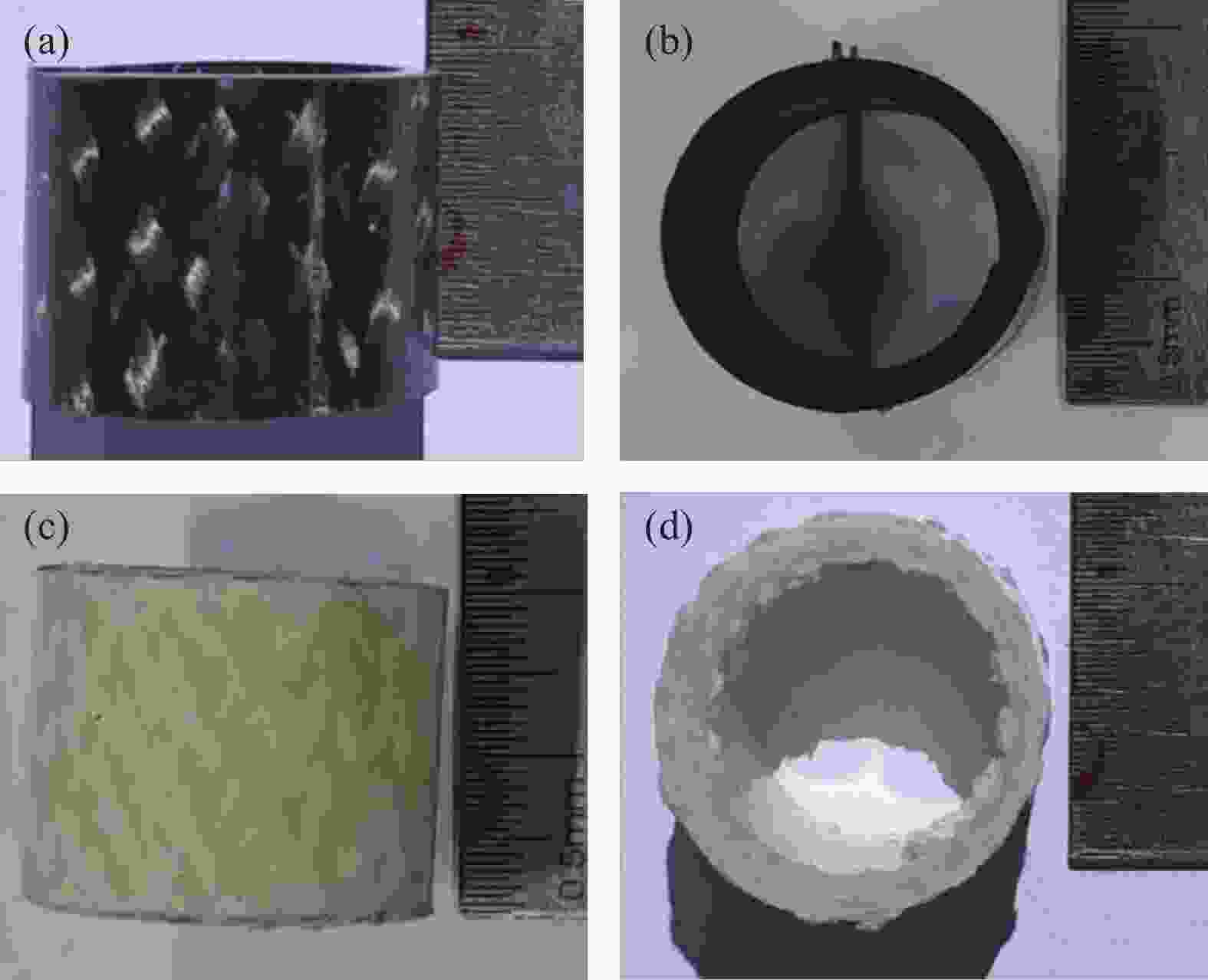

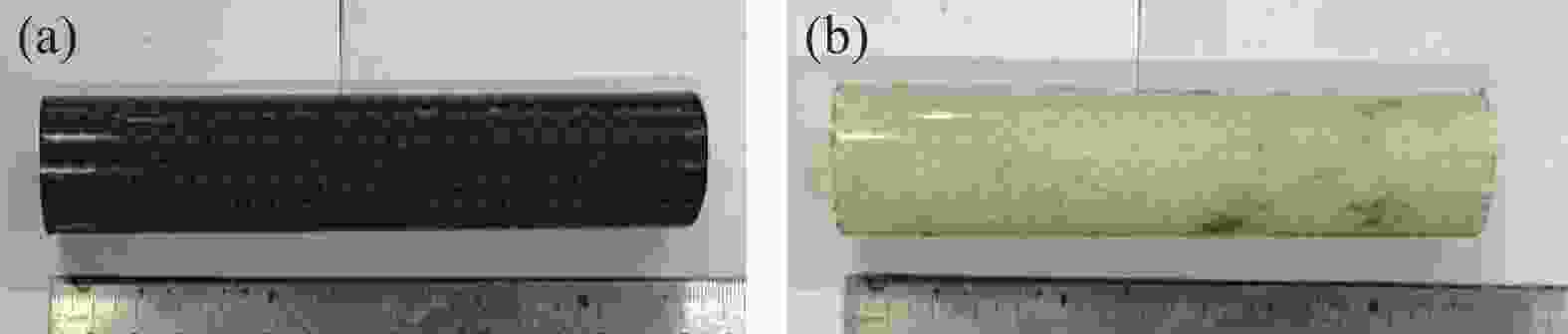

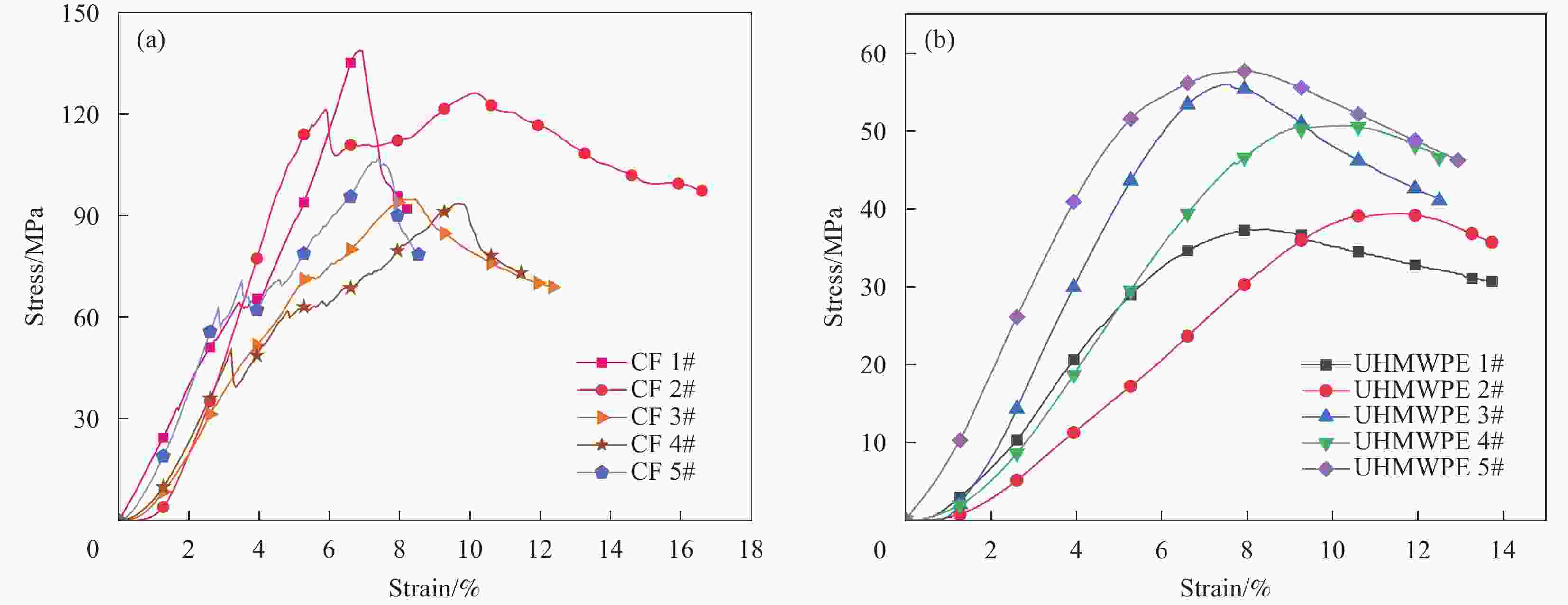

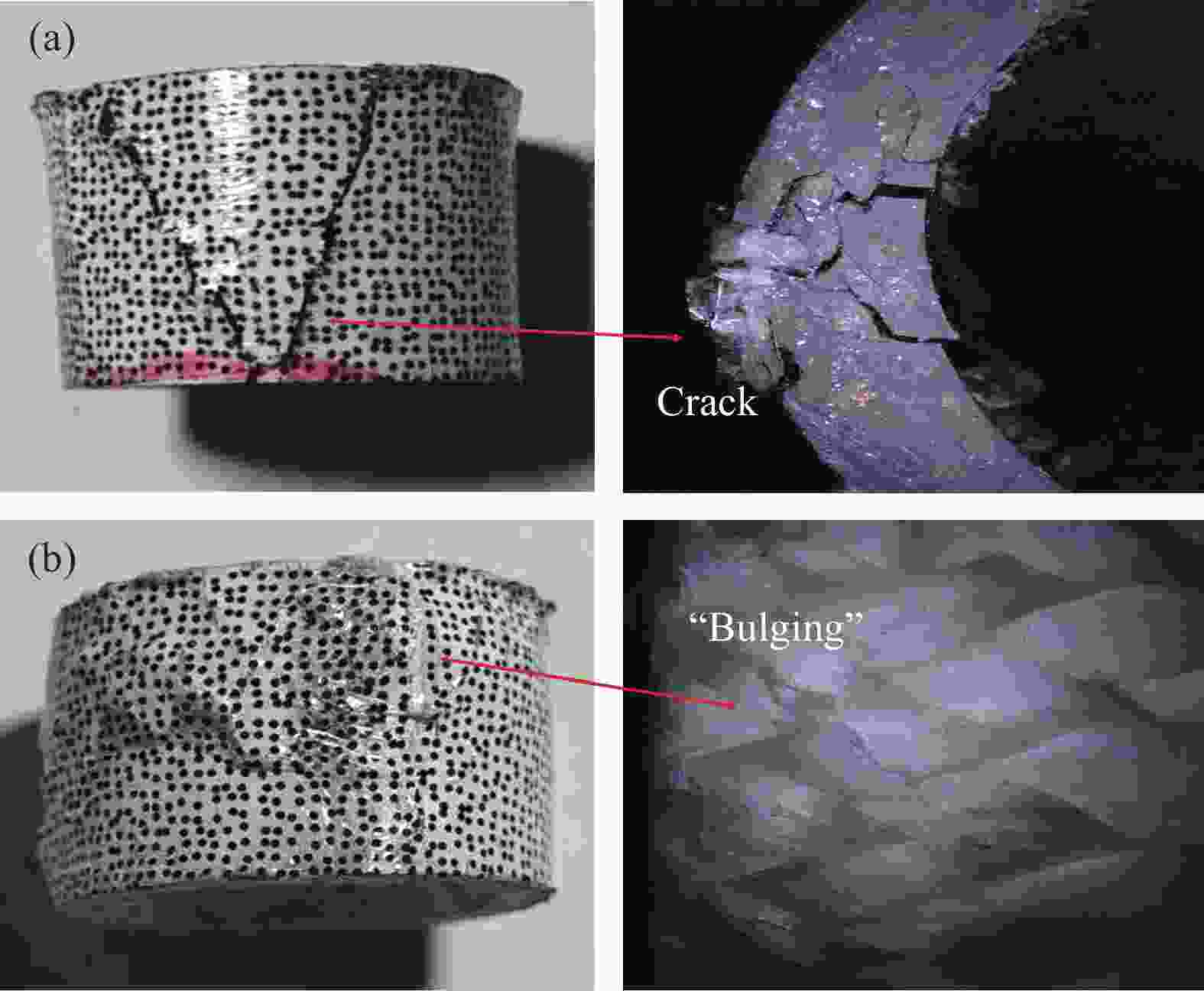

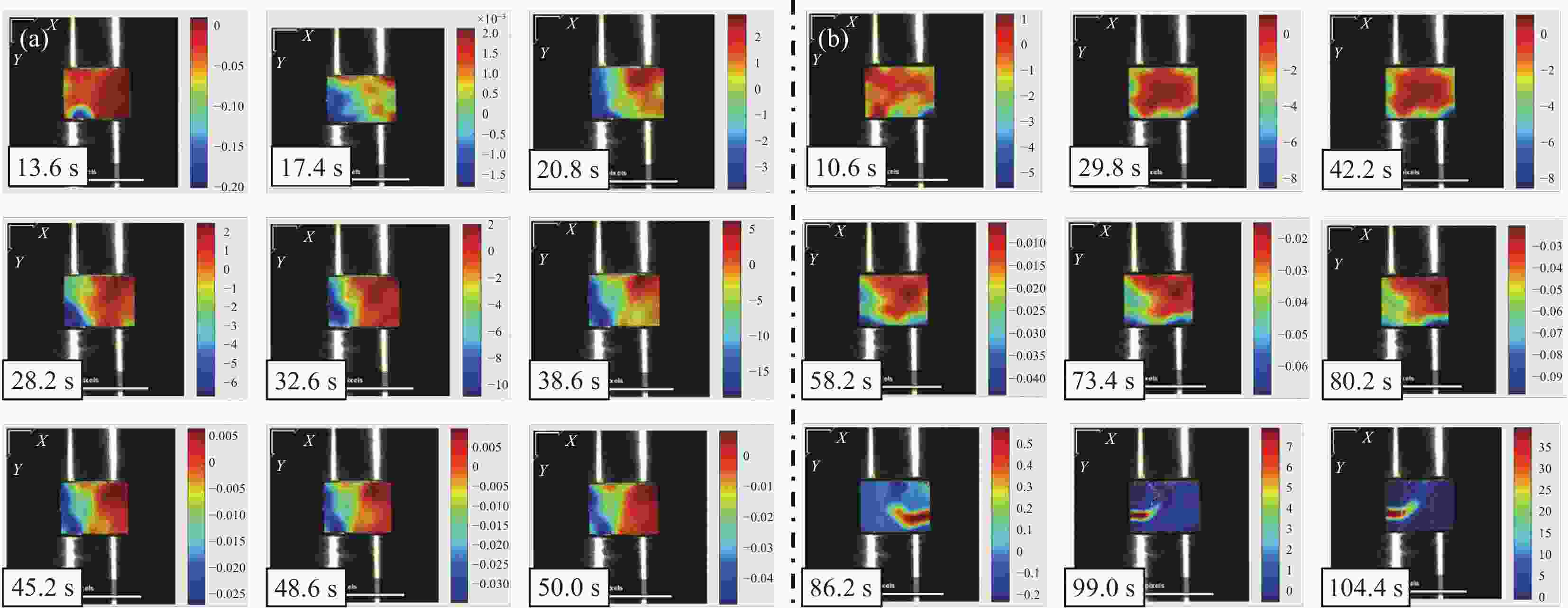

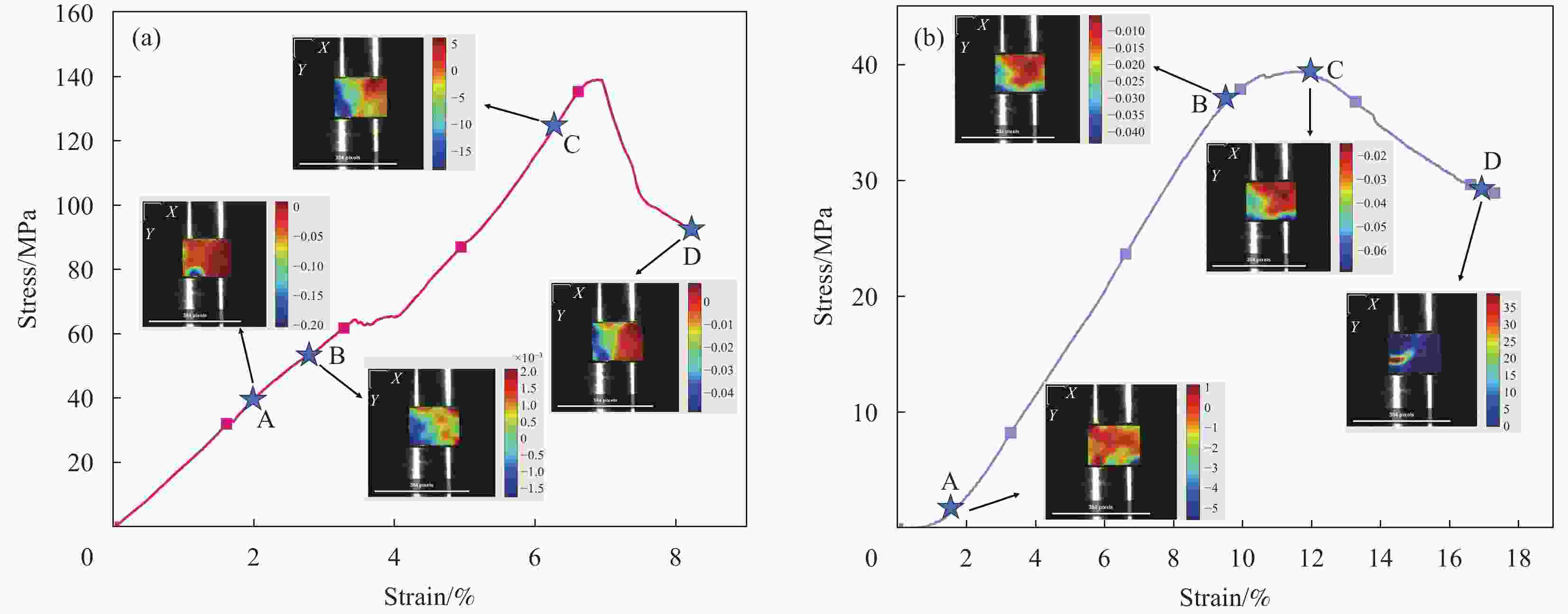

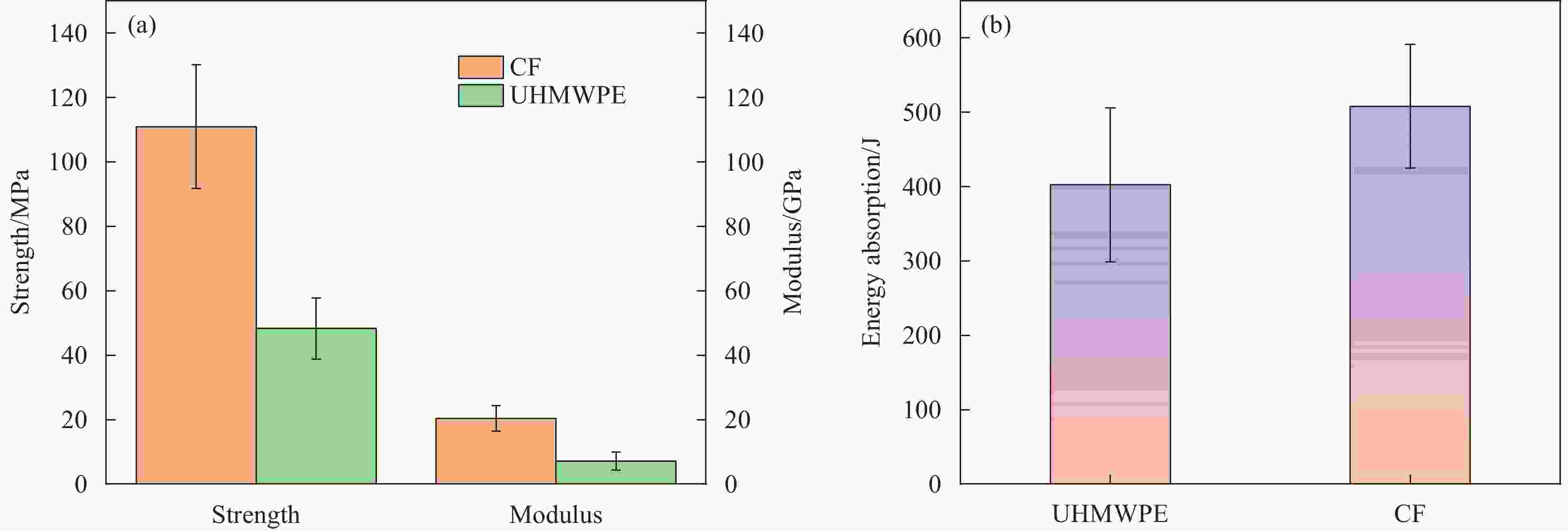

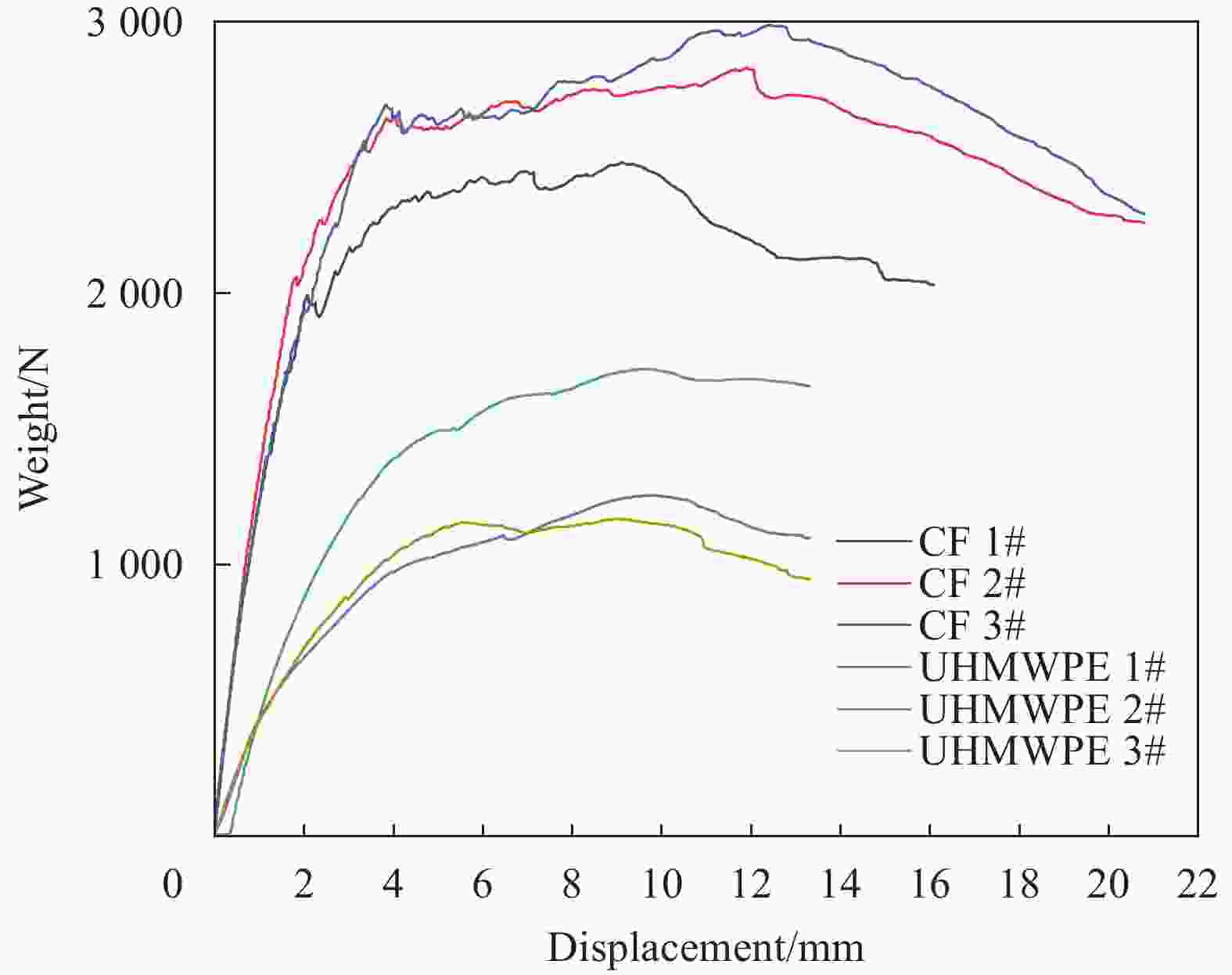

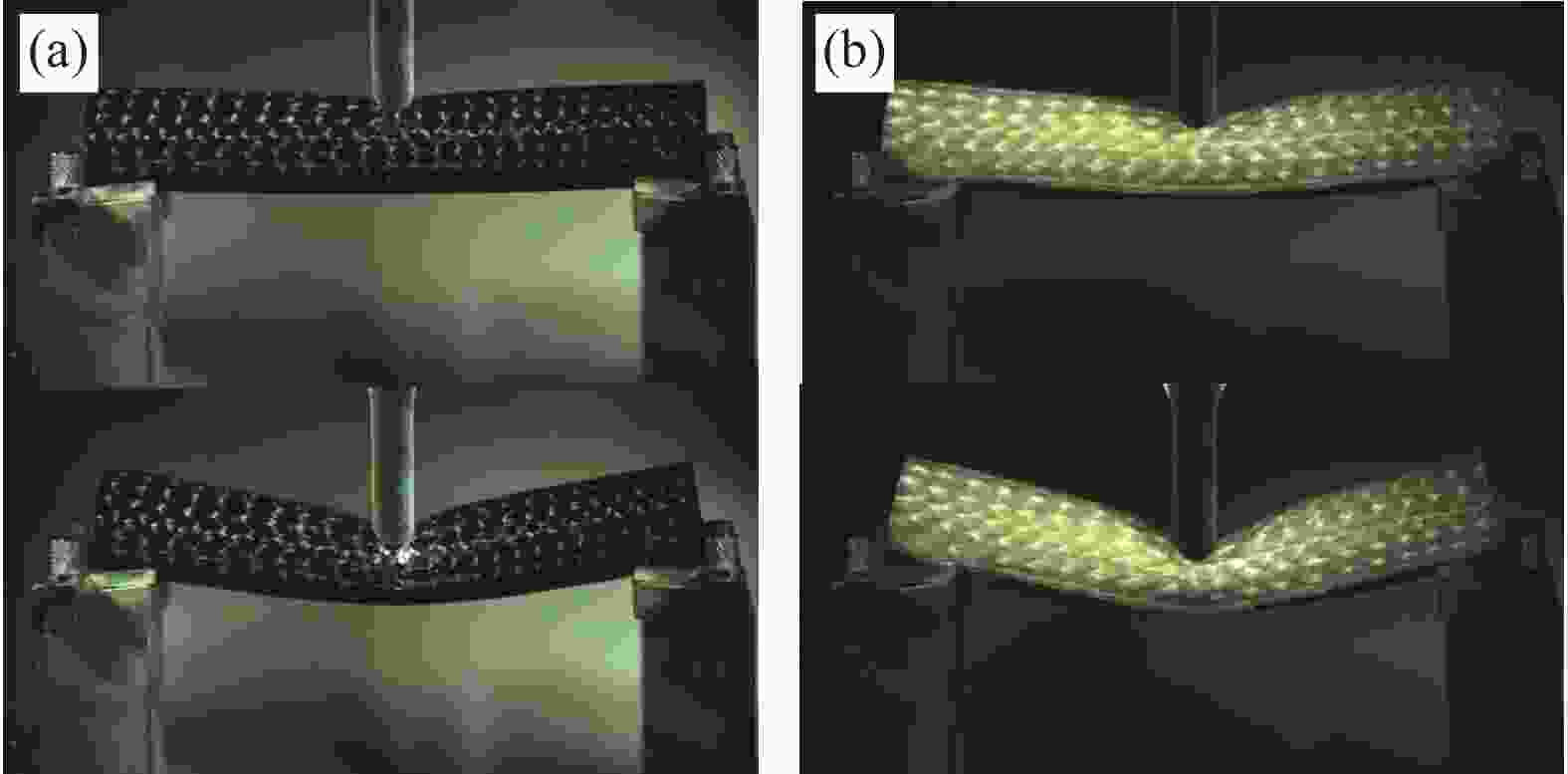

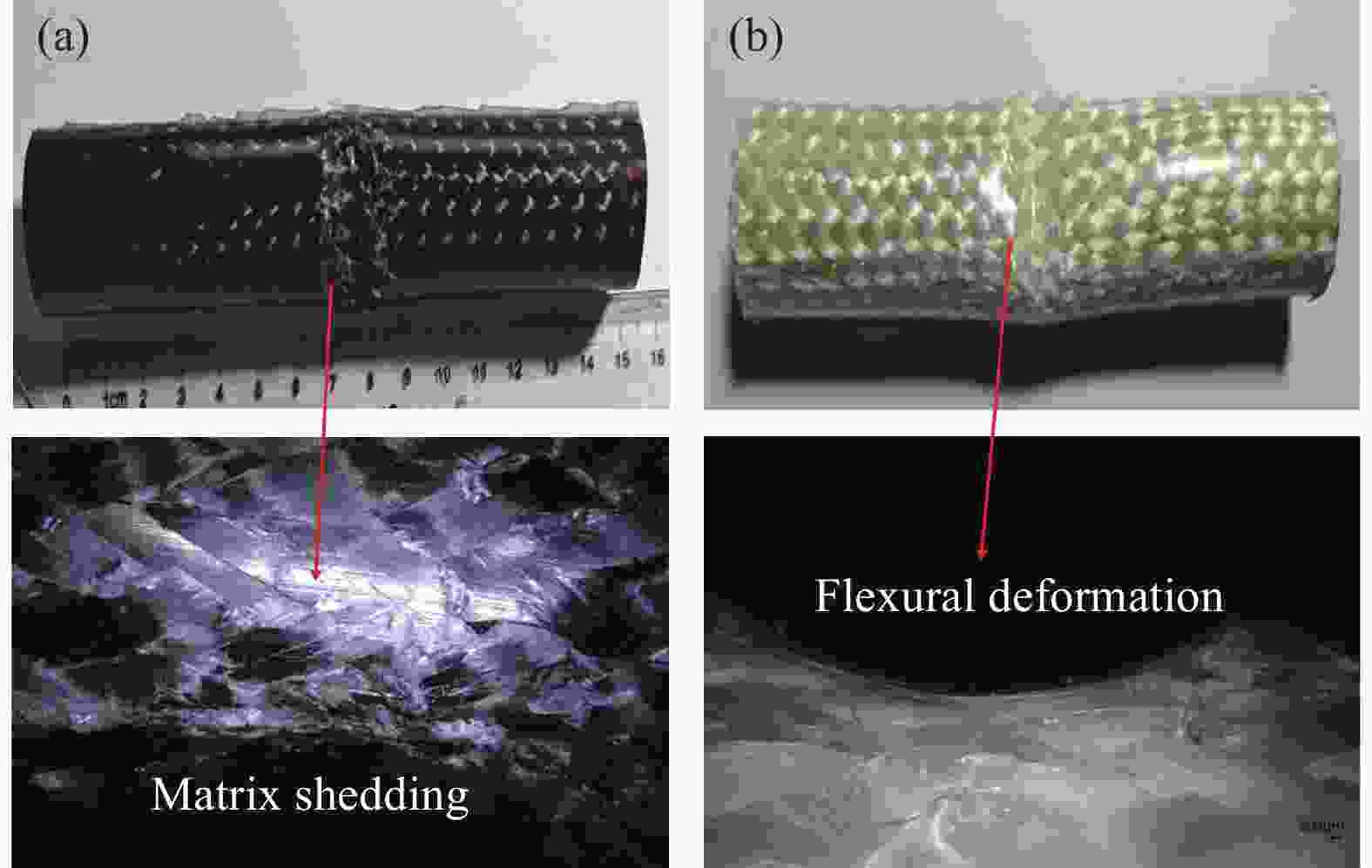

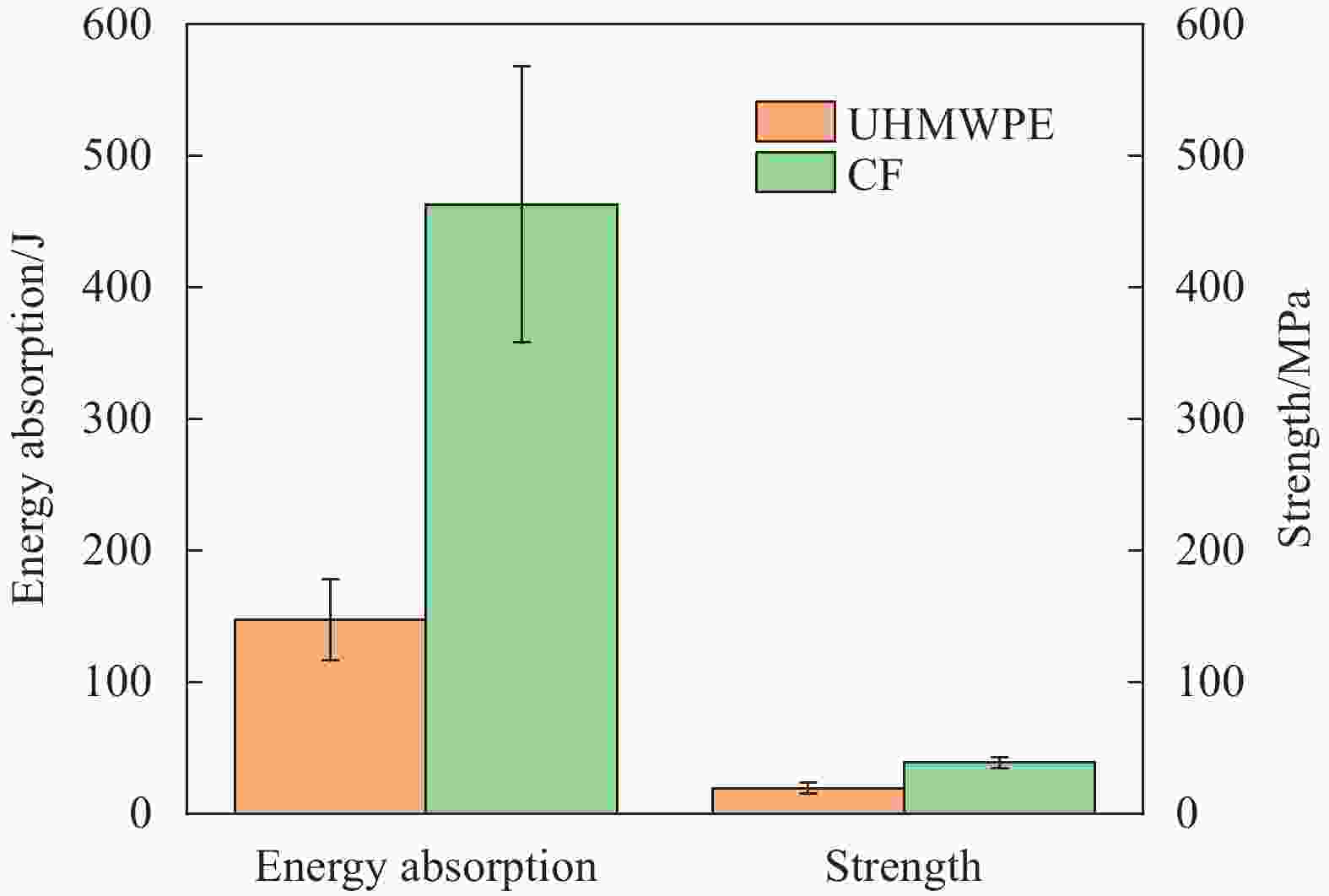

摘要: 三维编织复合材料管件在承力结构件中有广泛应用。纤维性能对其承载时变形和失效演化的影响机制是亟需解决的问题。本文探究了高模高强和高韧性两种纤维增强管件复合材料的失效行为,通过轴向压缩和三点弯曲试验,借助DIC技术,研究了不同纤维管件编织复合材料的力学性能。结果发现:高强高模管件更早发生变形分布变化,变形主要集中在发生剪切滑移的区域。高韧性管件较晚出现变形分布变化,变形逐渐集中到中间“鼓包”区域;高强高模管件的压缩和弯曲强度比高韧性管件分别高56%和50%;压缩和弯曲能量吸收比高韧性管件分别高20.9%和68%。这说明纤维的高强高模可以弥补其韧性差而导致吸能较少的弱点。本研究可为三维编织管件复合材料的设计提供理论指导。Abstract: 3D braided tubular composites have a wide range of applications in load-bearing structural components. The mechanism of the influence of fiber properties on their deformation and failure evolution during load bearing is a pressing issue. In this paper, the failure behavior of two kinds of fiber-reinforced tubular composites, high-modulus high-strength and high-toughness, was investigated. Through axial compression and three-point bending tests, with the help of DIC technology, the mechanical properties of different fiber braided tubular composites were studied. It is found that the deformation distribution of the high-strength high-modulus tubular composites changes earlier, and the deformation is mainly concentrated in the region where shear slip occurs. The deformation distribution change of high-toughness tubular composite occurs later, deformation gradually concentrates in the middle of the “bulging” region; high-strength high-modulus tubular’s compression and bending strength are 56% and 50% higher than that of high-toughness tubular composites; It’s compression and bending energy absorption are 20.9% and 68% higher than that of high-toughness tubular composites, respectively. This indicates that the high strength and high modulus of fibers can make up for the weakness of their poor toughness resulting in less energy absorption. This study can provide theoretical guidance for the design of 3D braided tubular composites.

-

表 1 碳纤维力学性能参数

Table 1. Mechanical property parameters of carbon fiber

Name Norm Density /(g·cm−3) 1.8 Tensile strength /GPa

Elongation at break /%5.31

2.18Tensile modulus of elasticity /GPa 240 表 2 UHMWPE纤维力学性能参数

Table 2. Mechanical property parameters of UHMWPE fiber

Name Norm Density /(g·cm-3) 0.97 Breaking strength /GPa

Elongation at break /%3.0

3.83Modulus of rupture /GPa 130 表 3 圆管复合材料试样参数

Table 3. Parameters of tubular composite specimen

Sample name Braiding angle /(°) Fiber volume fraction /% Carbon fiber 35.8 36.5 UHMWPE 35.7 34.8 -

[1] 熊信发, 王校培, 王坤, 等. 三维编织复合材料圆管轴向压缩性能及破坏机理[J]. 南京航空航天大学学报, 2023, 55(4): 702-10.XIONG Qifa, WANG Xiaopei, WANG Kun, et al. Axial compression properties and damage mechanism of three-dimensional braided composite circular tubes[J]. Journal of Nanjing University of Aeronautics and Astronautics, 2023, 55(4): 702-10(in Chinese). [2] XU K, QIAN X M. Analytical prediction of the elastic properties of 3D braided composites based on a new multiunit cell model with consideration of yarn distortion[J]. Mech Mater, 2016, 92: 139-54. doi: 10.1016/j.mechmat.2015.09.007 [3] ZHENG Y Y, SUN Y, LI J L, et al. Tensile response of carbon-aramid hybrid 3D braided composites[J]. Mater Des, 2017, 116: 246-52. doi: 10.1016/j.matdes.2016.11.082 [4] ZENG T, FANG D N, LU T J. Dynamic crashing and impact energy absorption of 3D braided composite tubes[J]. Mater Lett, 2005, 59(12): 1491-6. doi: 10.1016/j.matlet.2005.01.007 [5] ROY S S, POTLURI P, SOUTIS C. Tensile Response of Hoop Reinforced Multiaxially Braided Thin Wall Composite Tubes[J]. Appl Compos Mater, 2017, 24(2): 397-416. doi: 10.1007/s10443-016-9570-8 [6] MCGREGOR C, VAZIRI R, POURSARTIP A, et al. Axial crushing of triaxially braided composite tubes at quasi-static and dynamic rates[J]. Compos Struct, 2016, 157: 197-206. doi: 10.1016/j.compstruct.2016.08.035 [7] 遇家运, 刘佳. 复合材料圆管成型工艺及性能研究现状[J]. 纤维复合材料, 2022, 39(1): 82-6. doi: 10.3969/j.issn.1003-6423.2022.01.015YU Jiayun, LIU Jia. Current status of research on composite round tube molding process and properties[J]. Fiber Composite Materials, 2022, 39(1): 82-6(in Chinese). doi: 10.3969/j.issn.1003-6423.2022.01.015 [8] ZHANG W, GU B H, SUN B Z. Thermal-mechanical coupling modeling of 3D braided composite under impact compression loading and high temperature field[J]. Compos Sci Technol, 2017, 140: 73-88. doi: 10.1016/j.compscitech.2016.12.019 [9] 李金超, 陈利, 邢静忠. 三维五向编织复合材料强度的有限元分析[J]. 宇航材料工艺, 2010, 40(5): 37-9+46. doi: 10.3969/j.issn.1007-2330.2010.05.009LI Jinchao, CHEN Li, XING Jingzhong. Finite element analysis of the strength of three-dimensional five-way braided composites[J]. Aerospace Materials Processing, 2010, 40(5): 37-9+46(in Chinese). doi: 10.3969/j.issn.1007-2330.2010.05.009 [10] 同黎娜. 国产碳纤维大有可为 [N]. 中国纺织报2021-10-13.TONG Lina. Domestic carbon fiber has great promise [N]. China Textile Newspaper 2021-10-13. (in Chinese) [11] LAPENA M H, MARINUCCI G. Mechanical Characterization of Basalt and Glass Fiber Epoxy Composite Tube[J]. Mater Res-Ibero-am J Mater, 2018, 21(1): 7. [12] LEHTINIEMI P, DUFVA K, BERG T, et al. Natural fiber-based reinforcements in epoxy composites processed by filament winding[J]. J Reinf Plast Compos, 2011, 30(23): 1947-55. doi: 10.1177/0731684411431019 [13] THIRUMAVALAVAN K, SARUKASAN D. Experimental investigation on multi-layered filament wound basalt/E-glass hybrid fiber composite tubes[J]. Mater Res Express, 2022, 9(4): 29. [14] 杜刚, 曾竟成, 肖加余, 等. 复合材料圆管端部加强对其轴压性能影响的实验分析[J]. 材料科学与工程学报, 2007, (3): 457-9. doi: 10.3969/j.issn.1673-2812.2007.03.033DU Gang, ZENG Jingcheng, XIAO Jiayu, et al. Experimental analysis of the effect of end reinforcement on the axial compressive properties of composite circular tubes[J]. Journal of Materials Science and Engineering, 2007, (3): 457-9(in Chinese). doi: 10.3969/j.issn.1673-2812.2007.03.033 [15] 马其华, 查一斌, 周天俊. Al-CFRP复合管的径向压缩性能[J]. 工程塑料应用, 2019, 47(11): 99-104. doi: 10.3969/j.issn.1001-3539.2019.11.018MA Qihua, CHA Yibin, ZHOU Tianjun. Radial compression properties of Al-CFRP composite pipes[J]. Engineering Plastics Applications, 2019, 47(11): 99-104(in Chinese). doi: 10.3969/j.issn.1001-3539.2019.11.018 [16] 周伟旭. 碳纤维增强树脂基复合材料在轨道交通车辆车体中的应用与思考[J]. 城市轨道交通研究, 2018, 21(12): 10-3.ZHOU Weixu. Application and Reflection of Carbon Fiber Reinforced Resin Matrix Composites in Railway Vehicle Body[J]. Urban Rail Transportation Research, 2018, 21(12): 10-3(in Chinese). [17] 孙政, 付艳恕, 詹博文, 等. 复合材料吸能圆管轴向准静态压缩失效机理研究[J]. 塑料科技, 2017, 45(4): 36-40.SUN Zheng, FU Yashu, ZHAN Bowen, et al. Study on the failure mechanism of axial quasi-static compression of composite energy-absorbing circular pipe[J]. Plastics Technology, 2017, 45(4): 36-40(in Chinese). [18] CROUCH I G. Body armour - New materials, new systems[J]. Def Technol, 2019, 15(3): 241-53. doi: 10.1016/j.dt.2019.02.002 [19] QIN F Y, LEI Z K, MA Y, et al. Stress transfer of single yarn drawing in soft fabric studied by micro Raman spectroscopy[J]. Compos Pt A-Appl Sci Manuf, 2018, 112: 134-41. doi: 10.1016/j.compositesa.2018.06.002 [20] LIU Y, HAN Y, YUAN L, et al. Synergistic Enhancement of the Friction and Wear Performance for UHMWPE Composites under Different Aging Times[J]. Polymers, 2024, 16(14): 2059-. doi: 10.3390/polym16142059 [21] 陈利, 李学明. 三维四步法圆型编织结构分析[J]. 复合材料学报, 2003, (2): 76-80. doi: 10.3321/j.issn:1000-3851.2003.02.014CHEN Li, LI Xueming. Structural analysis of three-dimensional four-step circular braided structures[J]. Journal of Composite Materials, 2003, (2): 76-80(in Chinese). doi: 10.3321/j.issn:1000-3851.2003.02.014 [22] 张徐梁. 三维五向碳纤/玻纤混杂编织复合材料圆管的制备及能量吸收性能 [D], 2021.ZHANG Xuliang. Preparation and Energy Absorption Properties of Three-Dimensional Five-Way Carbon Fiber/Glass Fiber Hybrid Braided Composite Round Tubes [D], 2021. (in Chinese) [23] 户迎灿, 张联合, 崔健, 等. 基于VARTM的碳纤维单向与三维编织混杂织物树脂灌注工艺[J]. 工程塑料应用, 2024, 52(2): 57-65. doi: 10.3969/j.issn.1001-3539.2024.02.010HU Yingcan, ZHANG Lianhe, CUI Jian, et al. Resin infusion process for unidirectional and three-dimensional woven hybrid fabrics of carbon fibers based on VARTM[J]. Engineering Plastics Applications, 2024, 52(2): 57-65(in Chinese). doi: 10.3969/j.issn.1001-3539.2024.02.010 [24] 中华人民共和国国家质量监督检验检疫总局. 纤维增强塑料 压缩性能试验方法: GB/T 1446−2005[S]. 北京: 中国标准出 版社, 2005.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Fiberreinforced plastic composites-Determination of compress properties: GB/T 1446−2005[S]. Beijing: China Standards Press, 2005 (in Chinese). [25] 中华人民共和国国家质量监督检验检疫总局. 纤维增强塑料 弯曲性能试验方法: GB/T 1449−2005[S]. 北京: 中国标准出 版社, 2005.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Fiberreinforced plastic composites-Determination of flexural properties: GB/T 1449−2005[S]. Beijing: China Standards Press, 2005 (in Chinese). [26] 陈静, 莫莉花, 房怡, 等. 分层缺陷对CFRP层合板力学性能的影响[J]. 工程塑料应用, 2024, 52(4): 122-7. doi: 10.3969/j.issn.1001-3539.2024.04.019CHEN Jing, MO Lihua, FANG Yi, et al. Effect of delamination defects on mechanical properties of CFRP laminates[J]. Engineering Plastics Applications, 2024, 52(4): 122-7(in Chinese). doi: 10.3969/j.issn.1001-3539.2024.04.019 [27] 余海燕, 贺宏伟, 邢萍. 考虑不同刚度退化模式的碳纤维增强复合材料失效模型开发[J]. 机械工程学报, 2024, 60(2): 197-208.YU Haiyan, HE Hongwei, XING Ping. Development of failure models for carbon fiber reinforced composites considering different stiffness degradation modes[J]. Journal of Mechanical Engineering, 2024, 60(2): 197-208(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 47

- HTML全文浏览量: 25

- 被引次数: 0

下载:

下载: