Durability study of polypropylene fibers on enzyme-induced carbonate precipitation cured sandy soil under dry-wet cycling

-

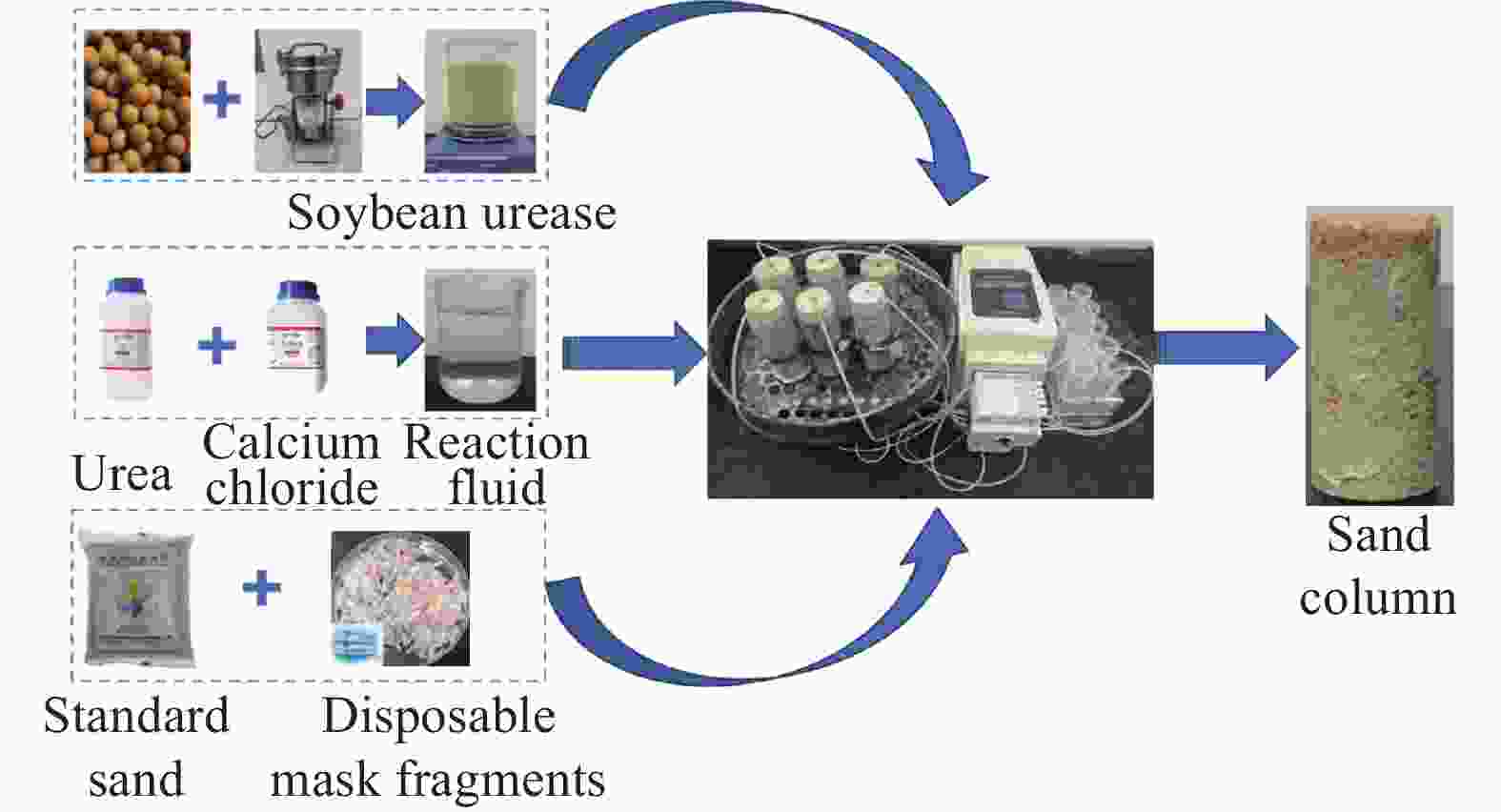

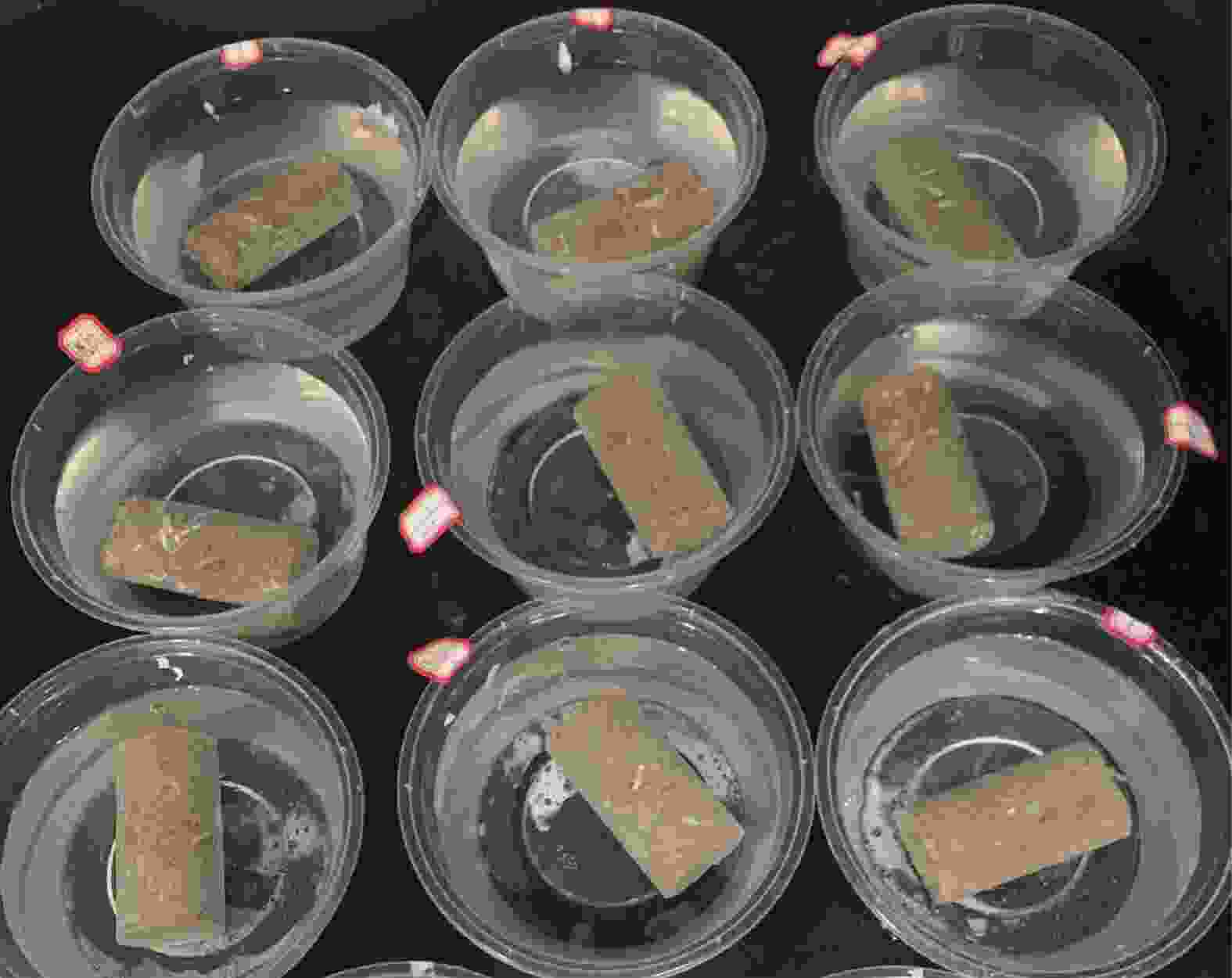

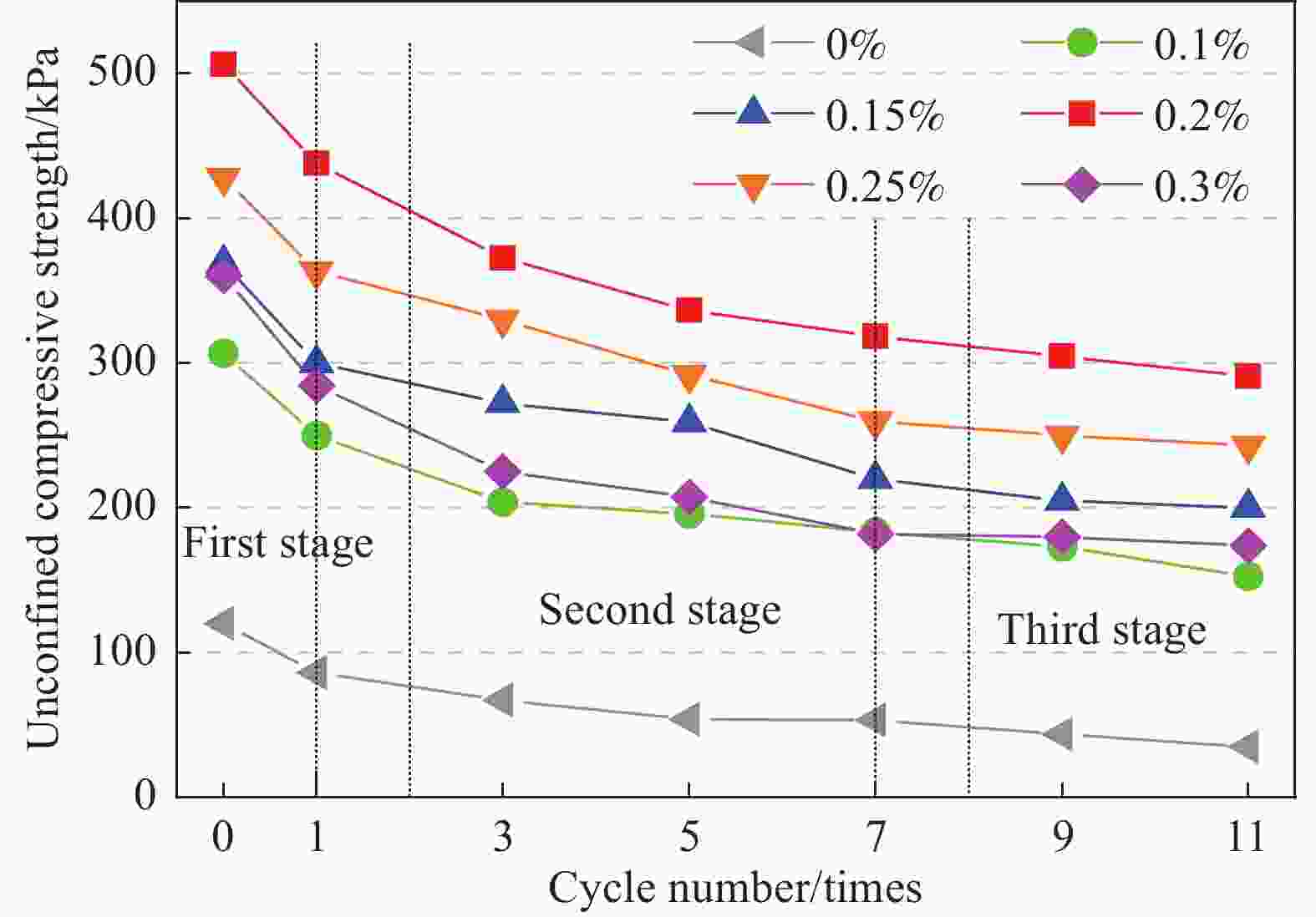

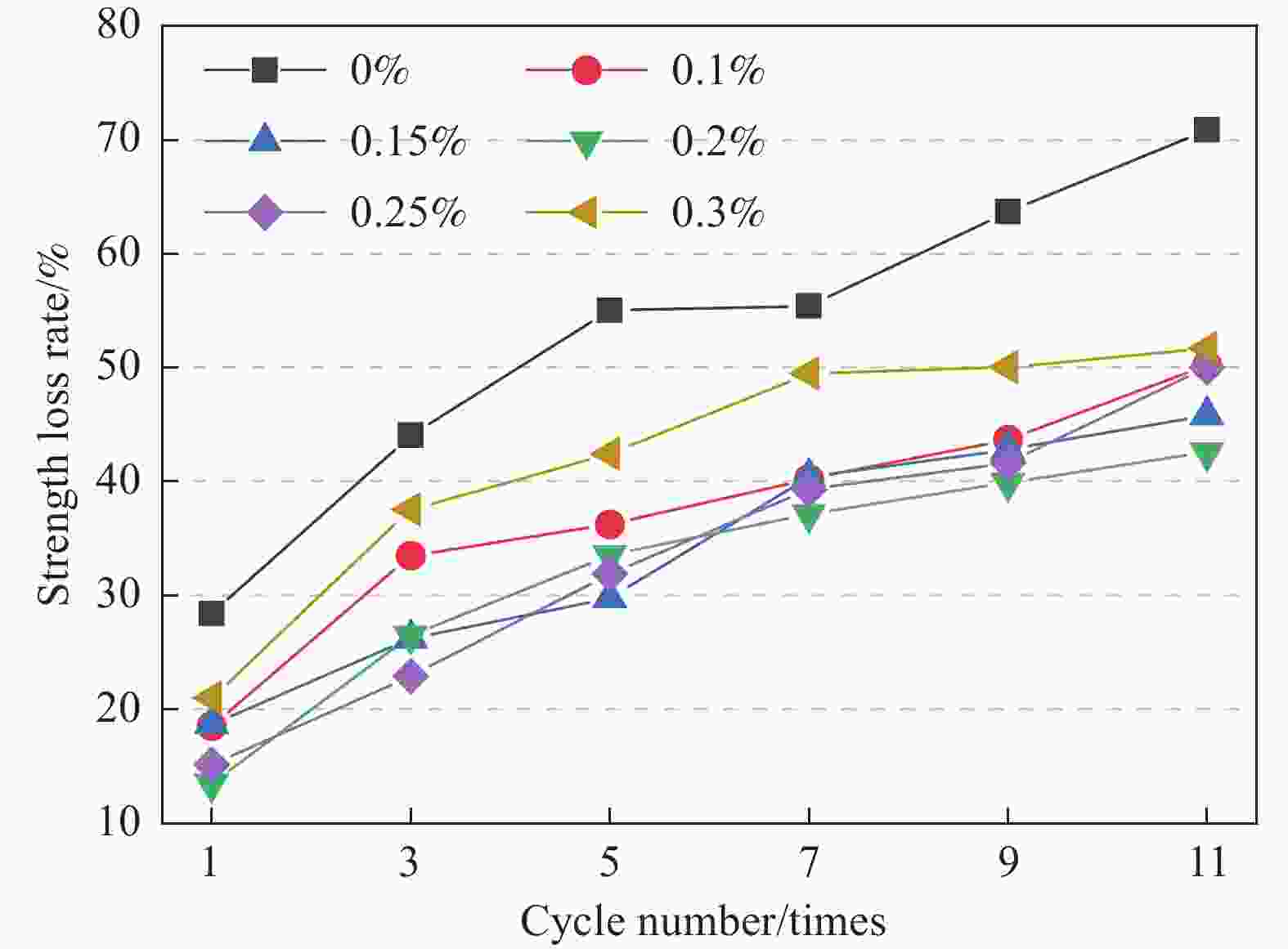

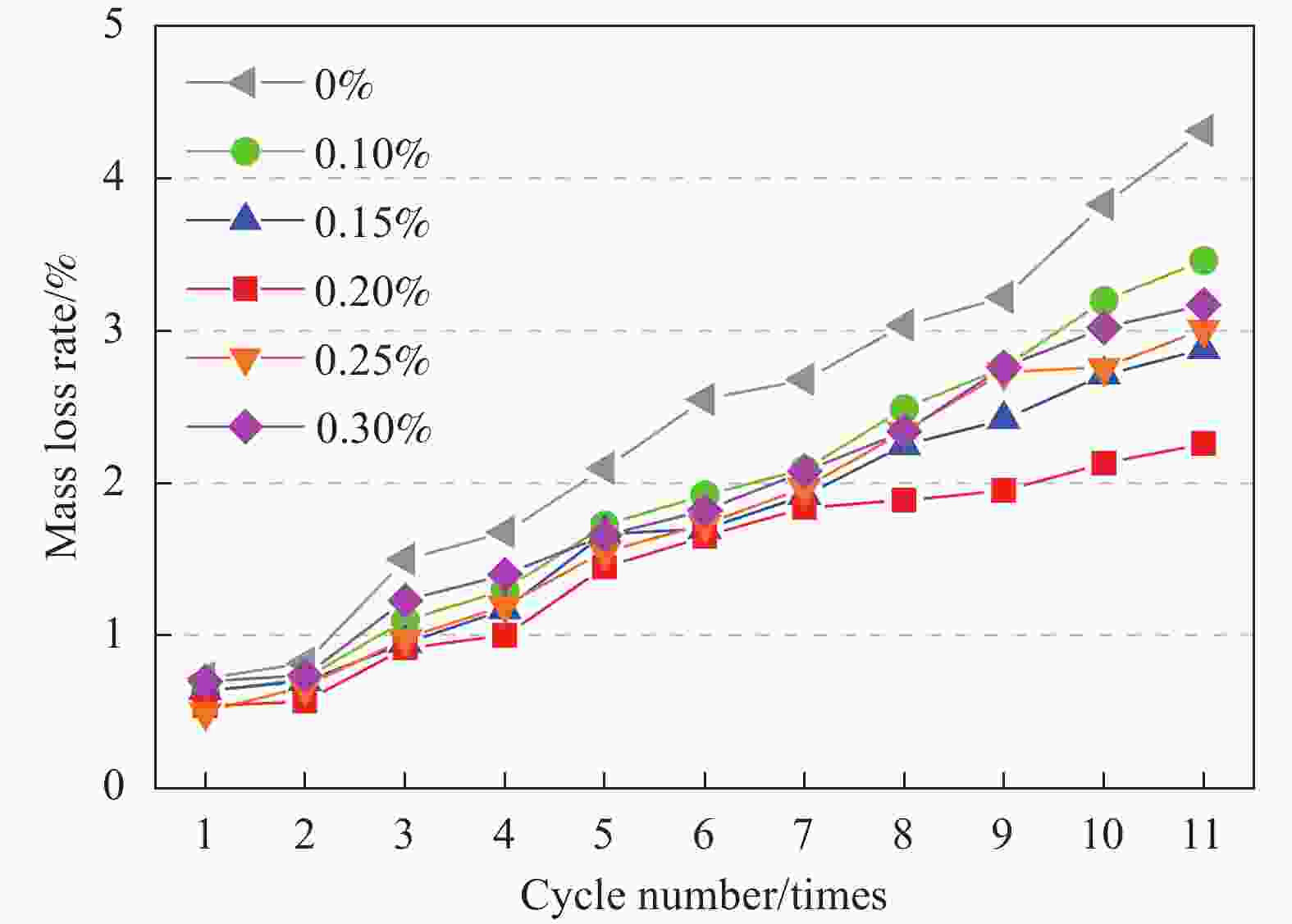

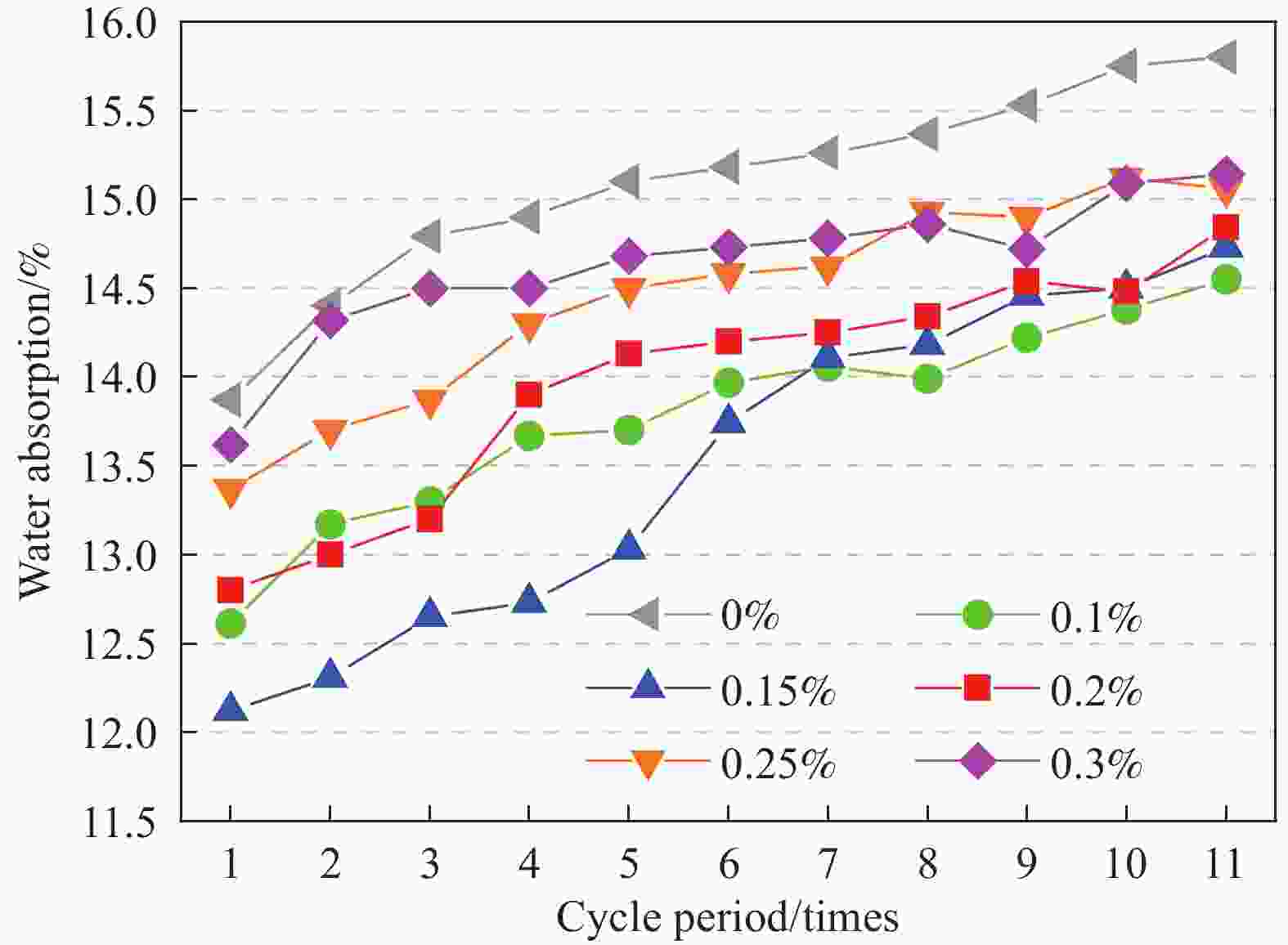

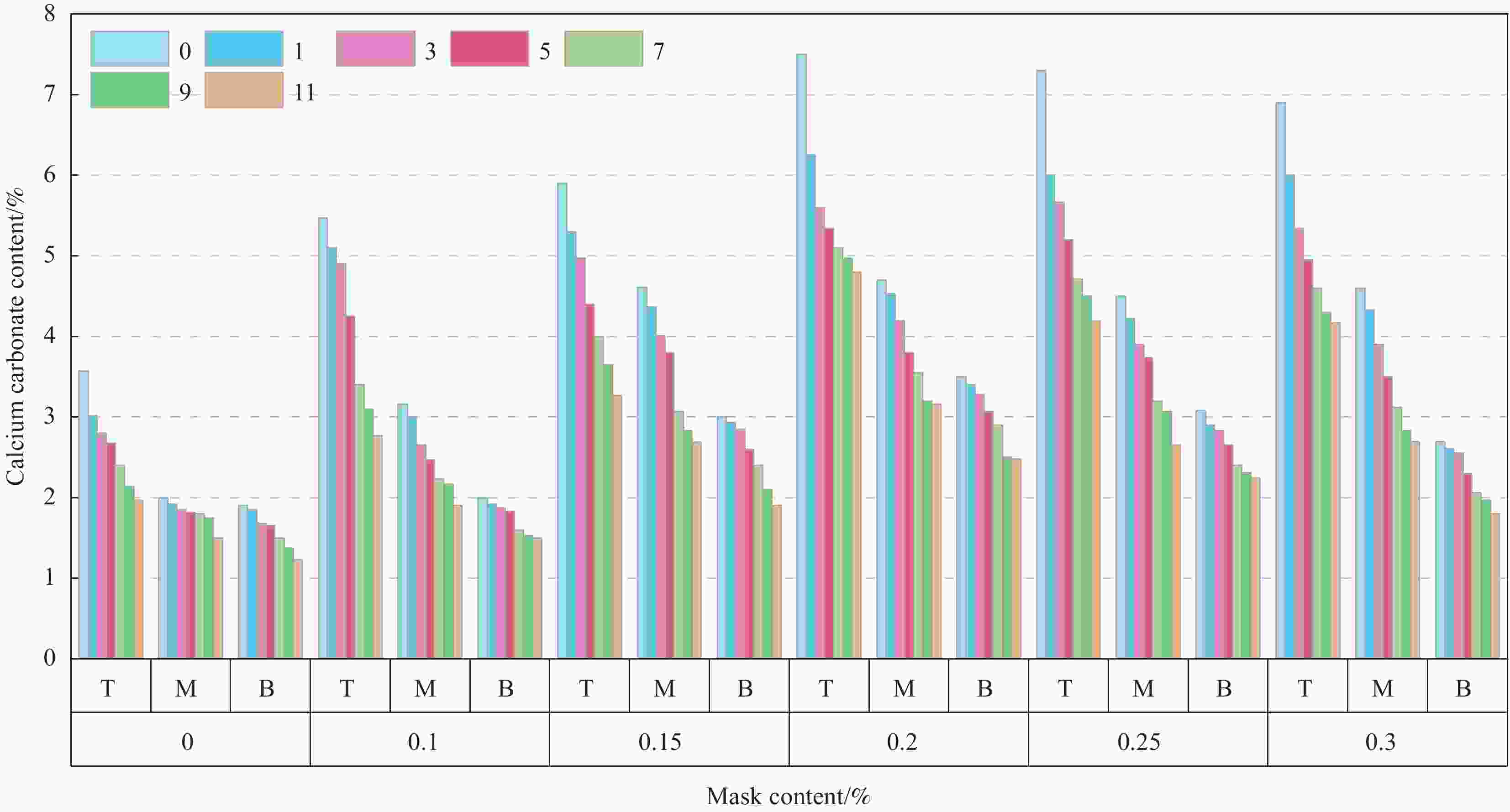

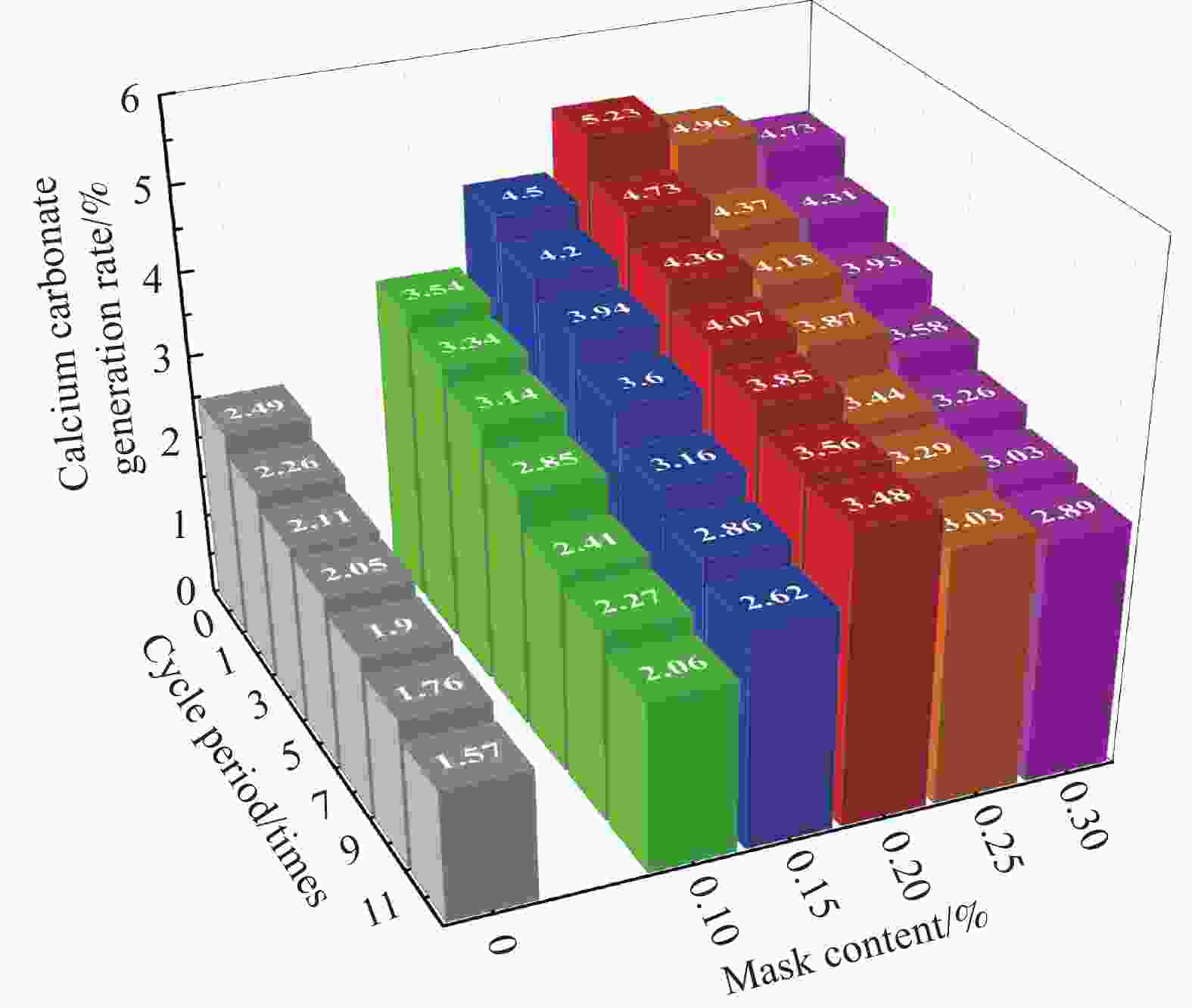

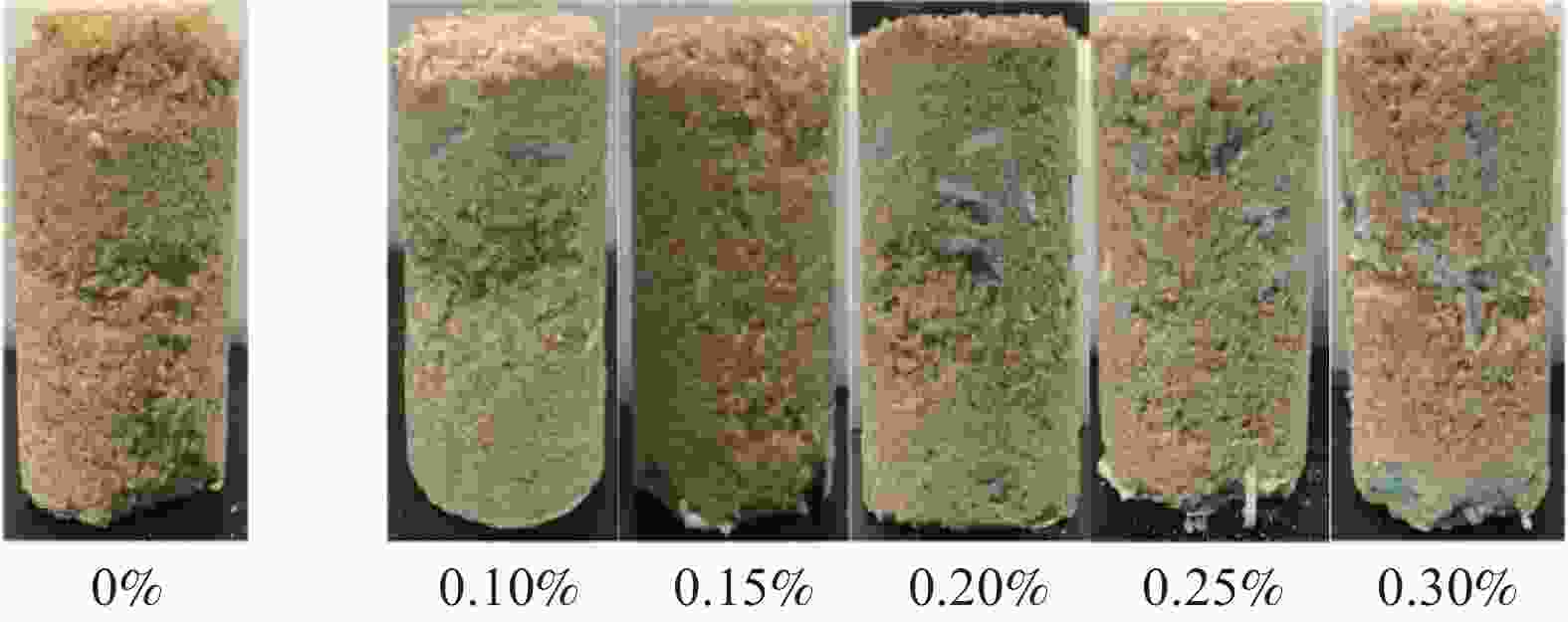

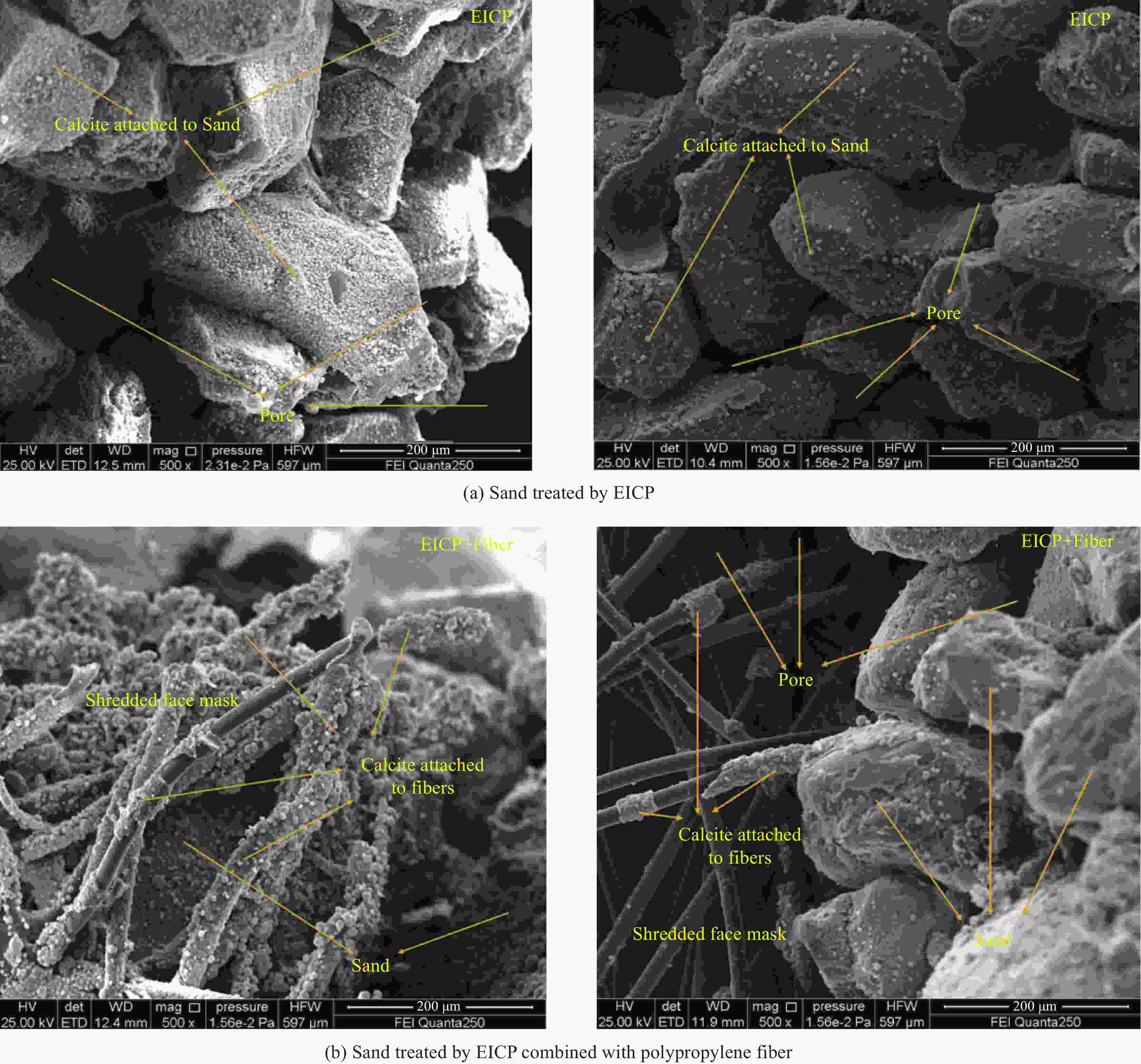

摘要: 为了研究砂土在干湿循环作用下的耐久性,进行纤维加筋法改良EICP的研究。将废弃口罩粉碎后作为纤维加筋,研究了不同纤维掺量和不同循环次数下砂土的无侧限抗压强度、质量损失率、浸泡吸水率、碳酸钙含量的变化,并结合扫描电子显微镜从微观层面分析聚丙烯纤维联合EICP固化砂土的机理。研究结果表明:随着干湿循环次数的增加,改良砂土的无侧限抗压强度逐渐减小,并且在纤维掺量为0.2%组时试样强度损失率最小,纤维过少无法形成“桥梁作用”,过多容易出现团聚体;并且纤维加筋能显著提高EICP固化砂土的碳酸钙生成率,还可以起到固定碳酸钙晶体的作用;质量损失率随干湿循环次数先减小后增大,纤维掺量为0.2%时最小;聚丙烯纤维加入后,可以生成更多碳酸钙填充空隙,减少干湿循环中水流的侵蚀作用。Abstract: To study the durability of sand under the action of dry and wet cycling, the fiber reinforcement method to improve EICP was studied. Utilizing the waste mask as fiber reinforcement after crushing, the unconfined compressive strength, mass loss rate, soaking water absorption rate, and calcium carbonate content of sand under different fibers content and different dry-wet cycles were studied. Additionally, the method of EICP combined with polypropylene fiber solidification of sand soil was integrated with scanning electronic microscopy under the microscope. The results demonstrate that the improved sand soil's unconfined compressive strength gradually decreases as the number of dry-wet cycles increases. At the minimum sample strength loss rate at the fibers content of 0.2% set, too few fibers are unable to form the "bridge effect" and too many fibers are too prone to clustering. Additionally, the fibers reinforcement can significantly increase the production of calcium carbonate in EICP-solidified sand soil and can also play a role in fixing calcium carbide crystals. The number of wet-dry cycles causes the quality loss rate to first decline before increasing and the rate is lowest when the fibers content is 0.2%; following the addition of polypropylene fibers, more calcium carbide is generated to fill in gaps and lessen the erosion effect of water flow in the dry-wet circulation.

-

Key words:

- EICP /

- polypropylene fiber /

- soybean urease /

- wet-dry cycle /

- microscopic analysis

-

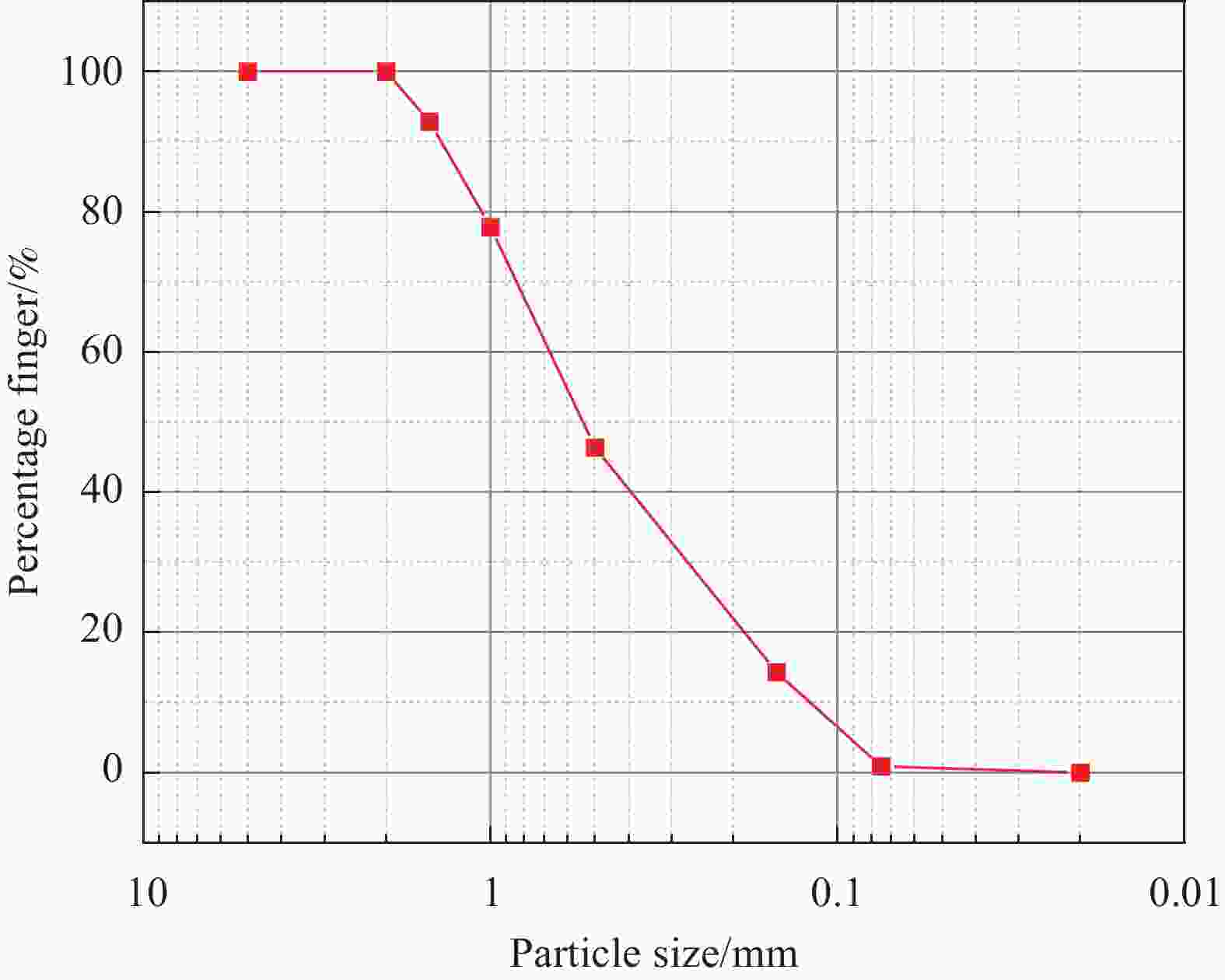

表 1 标准砂的物理力学性质

Table 1. Physical and Mechanical Properties of standard sand

Effective particle size/mm Relative density Curvature coefficient Nonuniformity

coefficientMaximum dry

density /(g·cm−3)Minimum dry

density/(g·cm−3)D10 D30 D60 0.13 0.3 0.66 2.65 1.05 5.07 1.9 1.54 表 2 聚丙烯纤维的物理力学性质

Table 2. Physical and Mechanical properties of polypropylene fiber

Specific gravity Melting point/℃ Water absorption/% Tensile strength/MPa Elongation at break/% Tensile strength at break/MPa 0.91 160 9.5 4.25 118.9 4.18 表 3 工况设置

Table 3. Operating condition settings

Test conditions Fiber content /% Dry wet cycle number/times W-D 0, 0.1, 0.15,

0.2, 0.25, 0.31, 3, 5,

7, 9, 11Notes: W—Wet; D—Dry. -

[1] Shuang S, Boyang Y, Hao M, et al. Comparative study of EICP treatment methods on the mechanical properties of sandy soil[J]. Soils and Foundations, 2022, 62(6): 101246. doi: 10.1016/j.sandf.2022.101246 [2] 张建伟, 李贝贝, 边汉亮, 等. 钙源对酶诱导碳酸钙沉淀影响的试验研究[J]. 应用基础与工程科学学报, 2022, 30 (05): 1245-1255.Zhang Jianwei, Li Beibei, Bian Hanliang, et al. Experimental study on the effect of calcium sources on enzyme-induced calcium carbonate precipitation [J] Journal of Applied Fundamentals and Engineering Science, 2022, 30 (05): 1245-1255(in Chinese) [3] 曹光辉, 刘士雨, 俞缙, 等. 酶诱导碳酸钙沉淀(EICP)技术及其在岩土工程中的应用[J]. 高校地质学报, 2021, 27 (06): 754-768.Cao Guanghui, Liu Shiyu, Yu Jin, et al. Enzyme-induced calcium carbonate precipitation (EICP) technology and its application in geotechnical engineering [J] Journal of Geology of Higher Education Institutions, 2021, 27 (06): 754-768(in Chinese) [4] 刘汉龙, 肖鹏, 肖杨, 等. 微生物岩土技术及其应用研究新进展[J]. 土木与环境工程学报(中英文), 2019, 41 (01): 1-14.Liu Hanlong, Xiao Peng, Xiao Yang, et al. New progress in microbial geotechnical technology and its application research [J] Journal of Civil and Environmental Engineering (Chinese English), 2019, 41(01): 1-14(in Chinese) [5] 吴林玉, 缪林昌, 孙潇昊, 等. 植物源脲酶诱导碳酸钙固化砂土试验研究[J]. 岩土工程学报, 2020, 42(04): 714-720Wu Linyu, Miao Linchang, Sun Xiaohao, et al. Experimental study on plant-derived urease-induced calcium carbonate solidification of sandy soil [J] Journal of Geotechnical Engineering, 2020, 42(04): 714-720(in Chinese) [6] 张茜, 叶为民, 刘樟荣, 等. 基于生物诱导碳酸钙沉淀的土体固化研究进展[J]. 岩土力学, 2022, 43(02): 345-357Zhang Qian, Ye Weimin, Liu Zhangrong, et al. Research progress on soil solidification based on biologically induced calcium carbonate precipitation [J] Geotechnical Mechanics, 2022, 43(02): 345-357(in Chinese) [7] 董博文, 刘士雨, 俞缙, 等. 基于微生物诱导碳酸钙沉淀的天然海水加固钙质砂效果评价[J]. 岩土力学, 2021, 42 (04): 1104-1114.Dong Bowen, Liu Shiyu, Yu Jin, et al. Evaluation of the effect of natural seawater reinforcement on calcareous sand based on microbial-induced calcium carbonate precipitation [J] Geotechnical Mechanics, 2021, 42 (04): 1104-1114 (in Chinese) [8] 何稼, 吴敏, 孟浩, 等. 生物固土用于防风固沙的研究进展[J]. 高校地质学报, 2021, 27 (06): 687-696.He Jia, Wu Min, Meng Hao, et al. Research progress on biological soil fixation for wind and sand prevention [J] Journal of Geology of Higher Education Institutions, 2021, 27 (06): 687-696 (in Chinese) [9] 范广才, 缪林昌, 孙潇昊, 等. 脲酶抑制剂对EICP防风固沙效果的影响研究[J]. 防灾减灾工程学报, 2022, 42(05): 1019-1027.Fan Guangcai, Miao Linchang, Sun Xiaohao, et al. A study on the effect of urease inhibitors on the windbreak and sand fixation of EICP [J] Journal of Disaster Prevention and Reduction Engineering, 2022, 42 (05): 1019-1027(in Chinese) [10] 边汉亮, 吉培瑞, 王俊岭, 等. EICP修复重金属污染土的环境耐久性研究[J]. 岩土力学, 2023, 44(10): 2779-2788Bian Hanliang, Ji Peirui, Wang Junling, et al. Research on Environmental Durability of EICP Remediation of Heavy Metal Polluted Soil [J] Geotechnical Mechanics, 2023, 44 (10): 2779-2788(in Chinese) [11] 邓红卫, 罗益林, 邓畯仁, 等. 微生物诱导碳酸盐沉积改善裂隙岩石防渗性能和强度的试验研究[J]. 岩土力学, 2019, 40(09): 3542-3548+3558.Deng Hongwei, Luo Yilin, Deng Jieren, et al. Experimental study on microbially induced carbonate deposition to improve the anti-seepage performance and strength of fractured rocks [J] Geotechnical Mechanics, 2019, 40 (09): 3542-3548+3558(in Chinese) [12] Xiangwei F, Yang Y, Zhe C, et al. Influence of Fiber Content and Length on Engineering Properties of MICP-Treated Coral Sand[J]. Geomicrobiology Journal, 2020, 37(6): 582-594. doi: 10.1080/01490451.2020.1743392 [13] DeJong T J, Fritzges B M, Nüsslein K. Microbially Induced Cementation to Control Sand Response to Undrained Shear[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2006, 132(11): 1381-1392. doi: 10.1061/(ASCE)1090-0241(2006)132:11(1381) [14] Xiao Y, He X, Evans M T, et al. “Unconfined Compressive and Splitting Tensile Strength of Basalt Fiber–Reinforced Biocemented Sand”[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2019, 145(9): 04019048 doi: 10.1061/(ASCE)GT.1943-5606.0002108 [15] Jianwei Z, Yue Y, Lei S, et al. Experimental investigation on mechanical behavior of sands treated by enzyme-induced calcium carbonate precipitation with assistance of sisal-fiber nucleation[J]. Frontiers in Earth Science, 2022, 10: 992474. doi: 10.3389/feart.2022.992474 [16] Sun X H, Miao L C, Wang H X, et al. Research on freeze-thaw and dry-wet durability of enzymatic calcification for surface protection.[J]. Environmental Science and Pollution Research International, 2022, 29(11): 16762-16771. doi: 10.1007/s11356-022-18621-4 [17] Wu L Y, Miao L C, Sun X H, et al. Enzyme-induced carbonate precipitation combined with polyvinyl alcohol to solidify aeolian sand[J]. Journal of Materials in Civil Engineering, 2021, 33(12): 04021373. doi: 10.1061/(ASCE)MT.1943-5533.0004009 [18] Huang W, Mou Y Q, Li Y, et al. Study on durability of MICP treated cohesive soils under dry–wet cycle and freeze-thaw cycle[J]. Arabian Journal of Geosciences, 2022, 15(5): 422. doi: 10.1007/s12517-022-09702-2 [19] Cheng L, Shahin M A, Mujah D. Influence of key environmental conditions on microbially induced cementation for soil stabilization[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2016, 143(1): 4016083. [20] 李艺隆, 国振, 徐强, 等. 海水环境下MICP胶结钙质砂干湿循环试验研究[J]. 浙江大学学报(工学版), 2022, 56(09): 1740-1749.Li Yilong, Guo Zhen, Xu Qiang, et al. Experimental study on dry wet cycles of MICP cemented calcareous sand in seawater environment [J] Journal of Zhejiang University (Engineering Edition), 2022, 56 (09): 1740-1749 (in Chinese) [21] Whiffin V S. Microbial CaCO3 precipitation for the production of biocement[D]. Perth, Australia: Murdoch University, 2004. [22] 闭东民, 孔纲强, 陈庚, 等. 废弃口罩加筋固化土的强度特性与破坏模式[J]. 防灾减灾工程学报, 2022, 42 (05): 993-998+1009.BI Dongmin, Kong Gangqiang, Chen Geng, et al. Strength characteristics and failure modes of reinforced solidified soil for discarded masks [J] Journal of Disaster Prevention and Reduction Engineering, 2022, 42 (05): 993-998+1009(in Chinese) [23] Abdullah G M S, Aal A A E. Assessment of the reuse of COVID-19 healthy personal protective materials in enhancing geotechnical properties of Najran's soil for road construction: Numerical and experimental study[J]. Journal of Cleaner Production, 2021, 320: 128772. doi: 10.1016/j.jclepro.2021.128772 [24] Xiang Y, Song Q, Gu W. Decontamination of surgical face masks and N95 respirators by dry heat pasteurization for one hour at 70 degrees C[J]. American Journal of Infection Control, 2020, 48(8): 880-882. doi: 10.1016/j.ajic.2020.05.026 [25] Mohammad S, Jie L, Shannon K, et al. Repurposing of COVID-19 single-use face masks for pavements base/subbase[J]. Science of the Total Environment, 2021, 769 145527-145527. [26] GB/T 50476-2008, 混凝土结构耐久性设计规范[S]. 2008GB/T 50476-2008, Standard for durability design of concrete structures. [S]. 2008(in Chinese) [27] Ciantia O M, Castellanza R, Prisco D C. Experimental Study on the Water-Induced Weakening of Calcarenites[J]. Rock Mechanics and Rock Engineering, 2015, 48(2): 441-461. doi: 10.1007/s00603-014-0603-z -

点击查看大图

点击查看大图

计量

- 文章访问数: 85

- HTML全文浏览量: 38

- 被引次数: 0

下载:

下载: