Strength characteristics and constitutive model of rubber-sand-polyurethane composites after freeze-thaw cycles

-

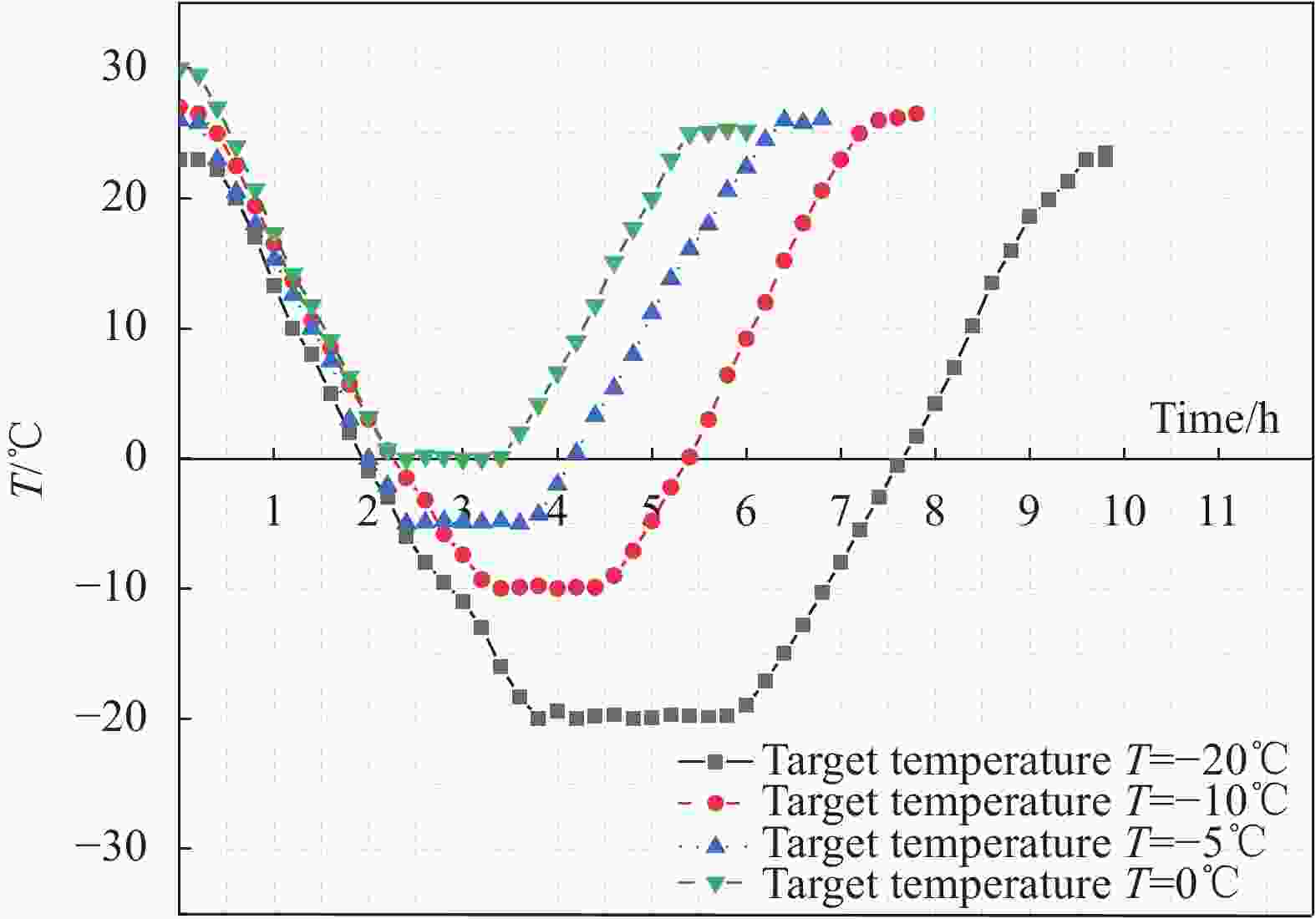

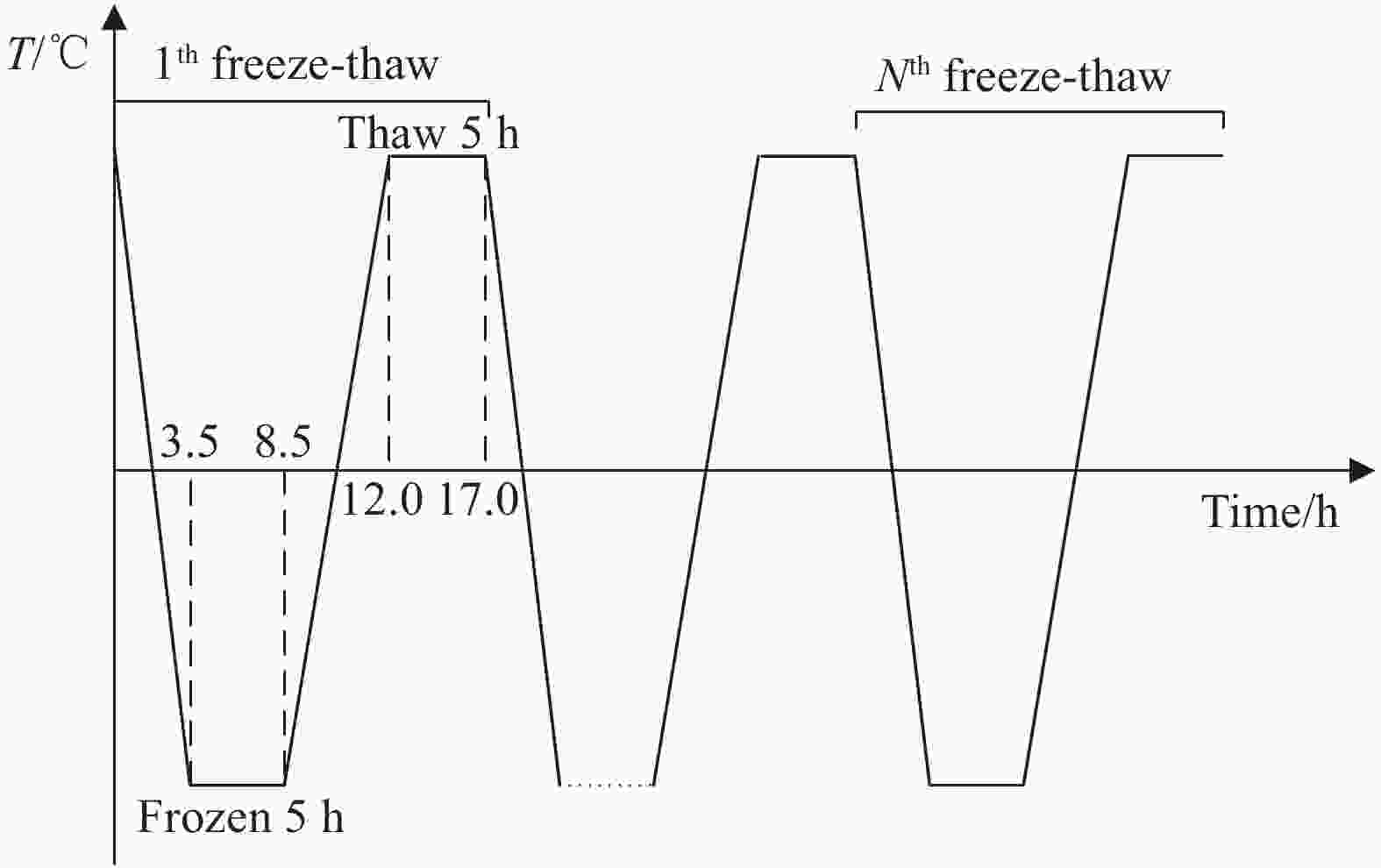

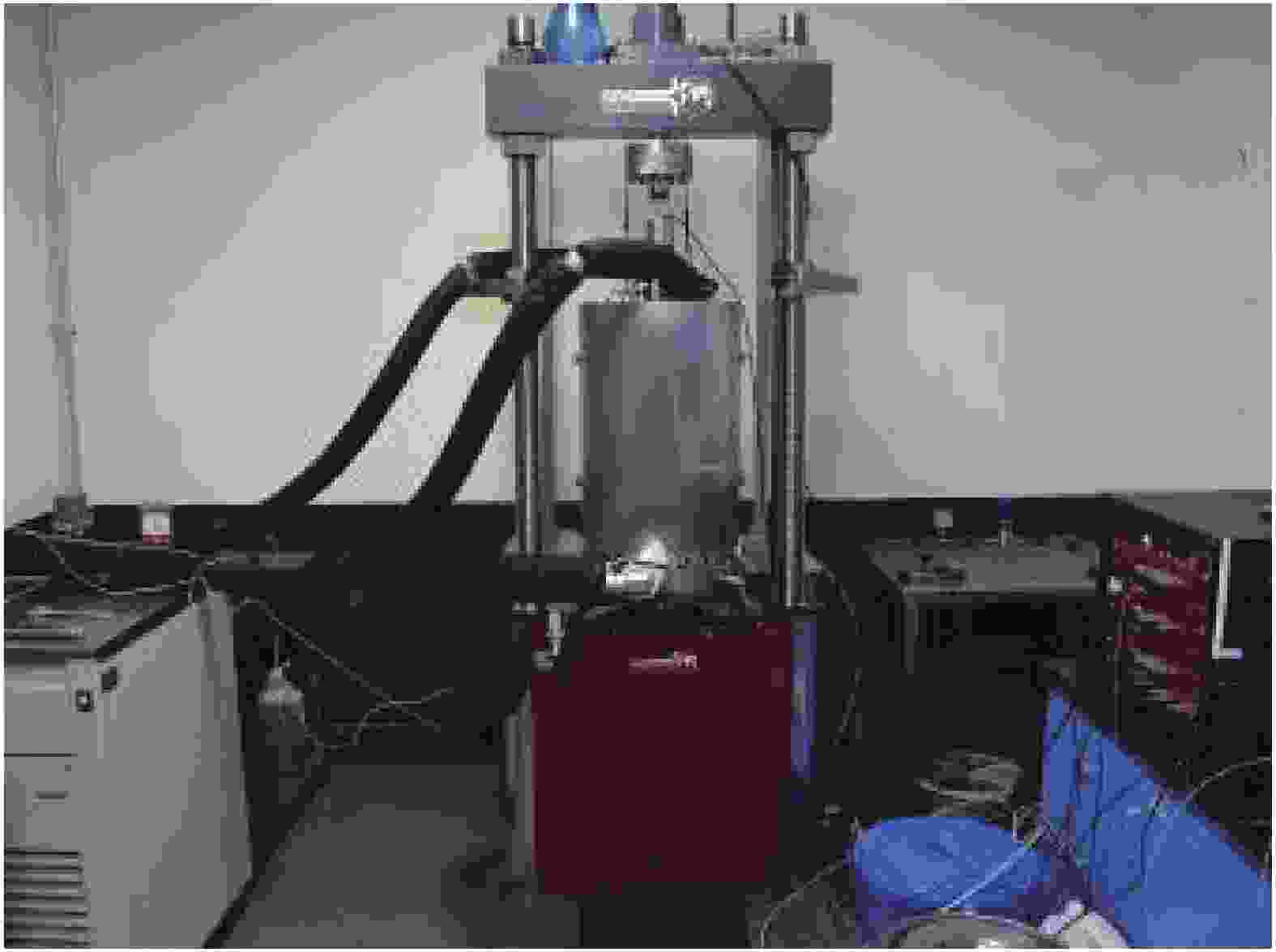

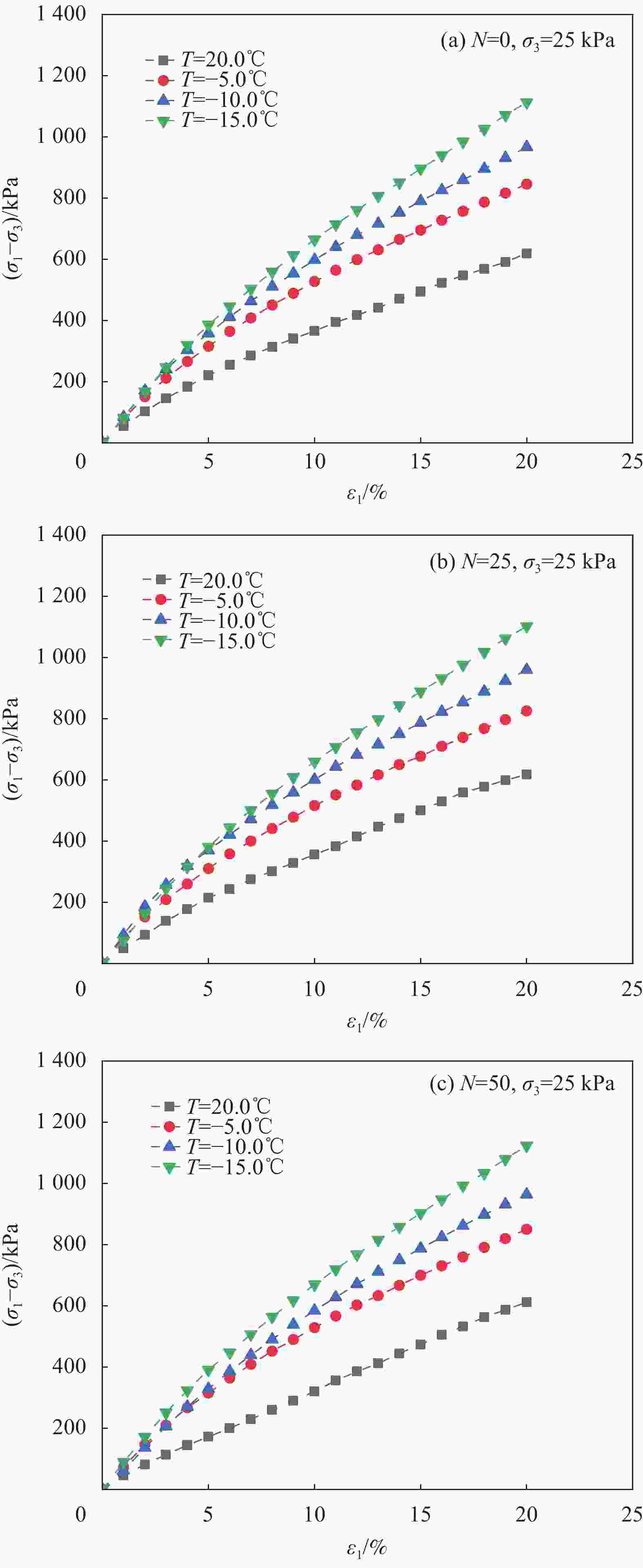

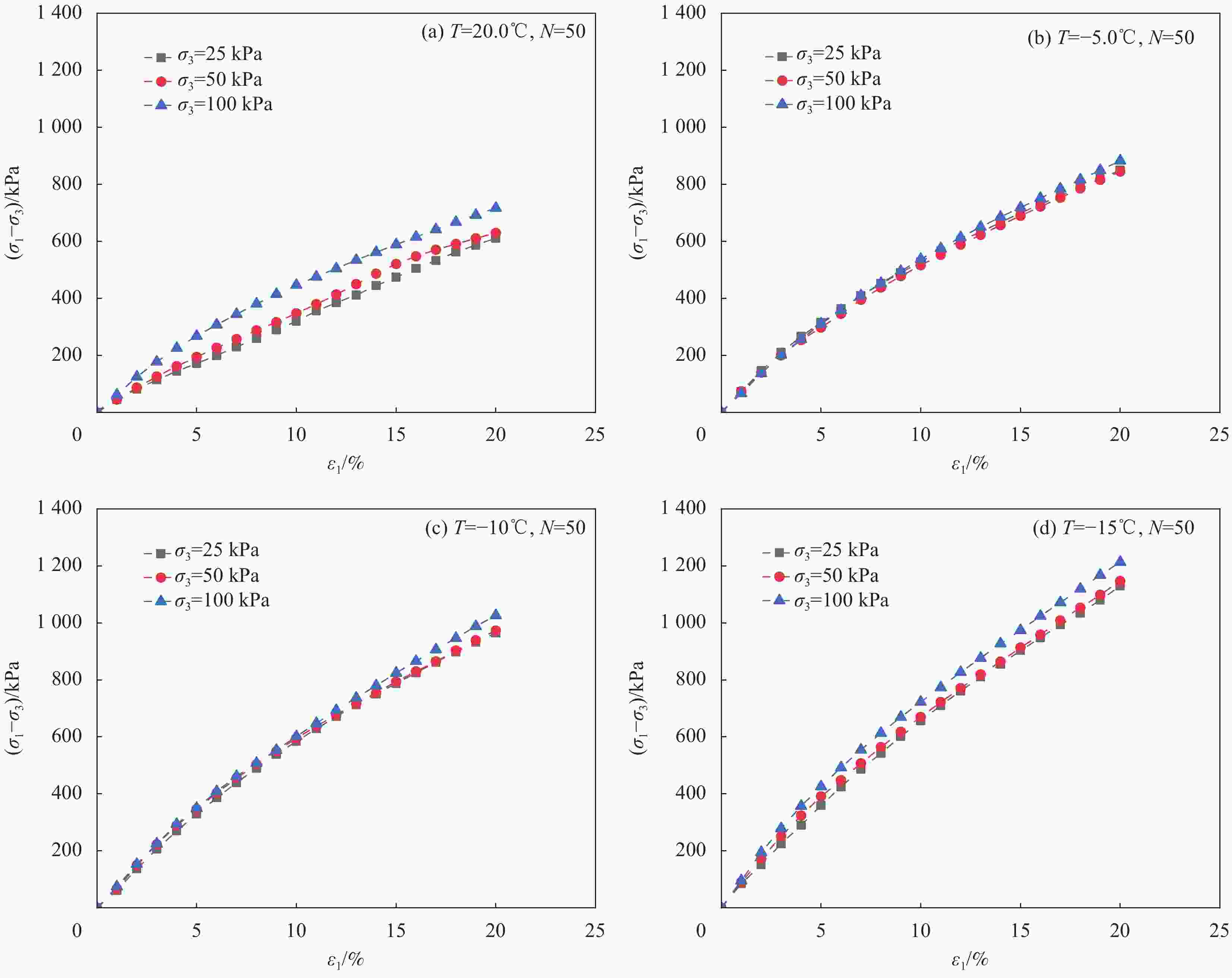

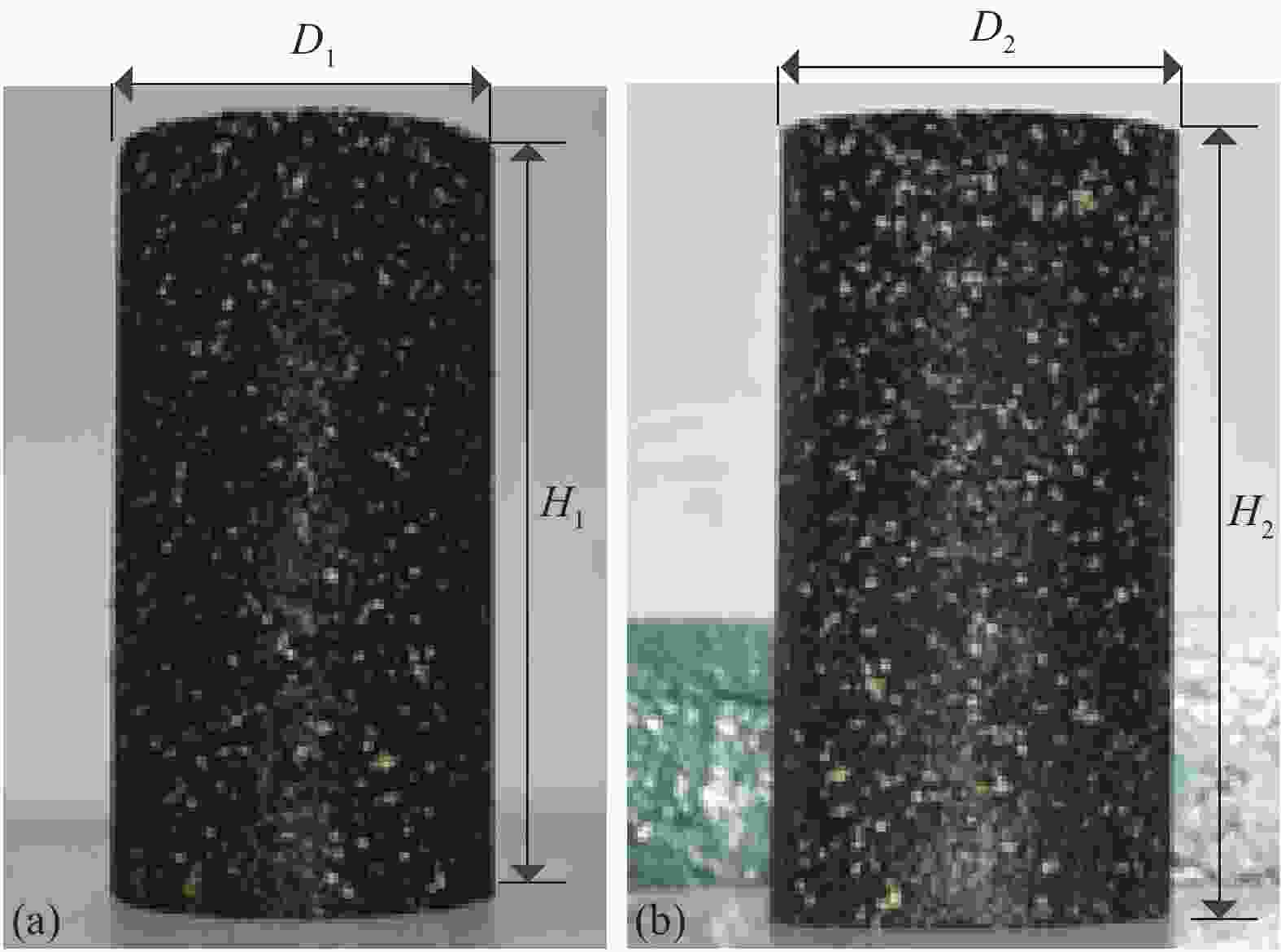

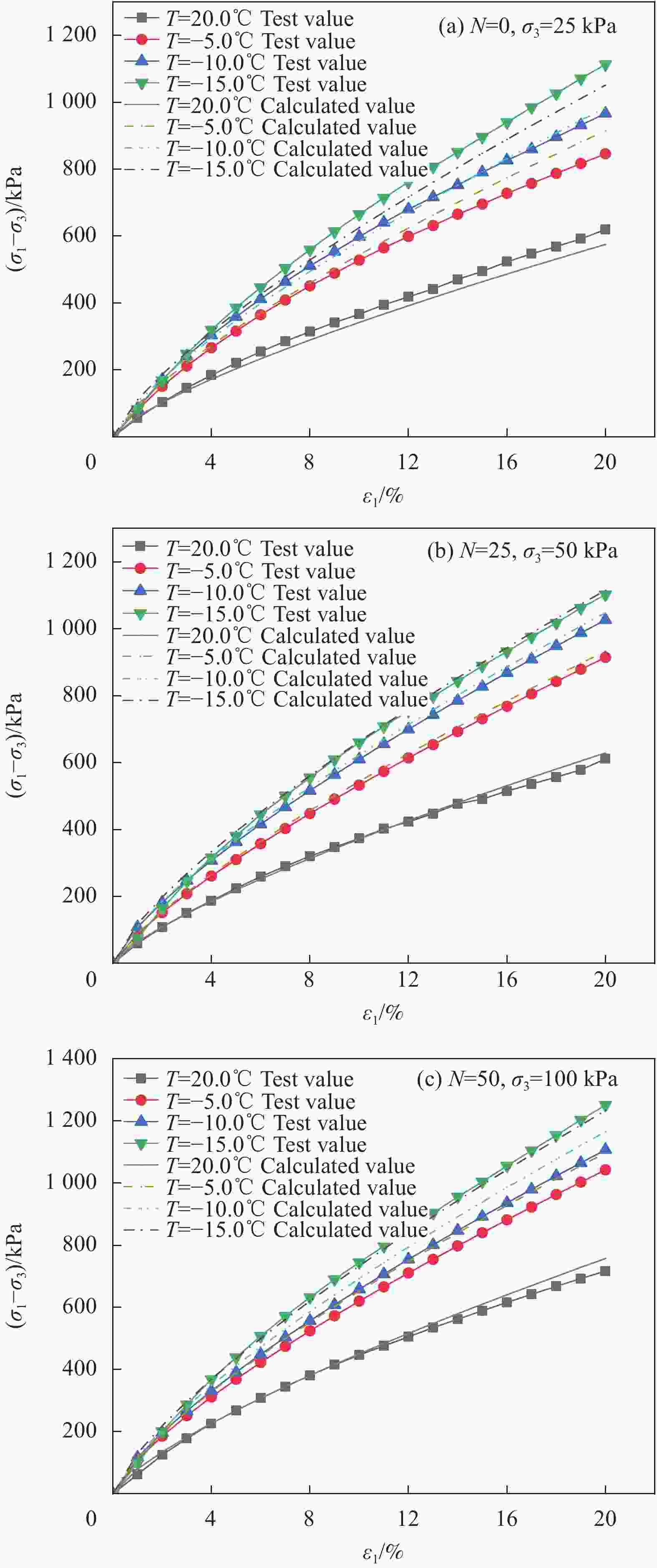

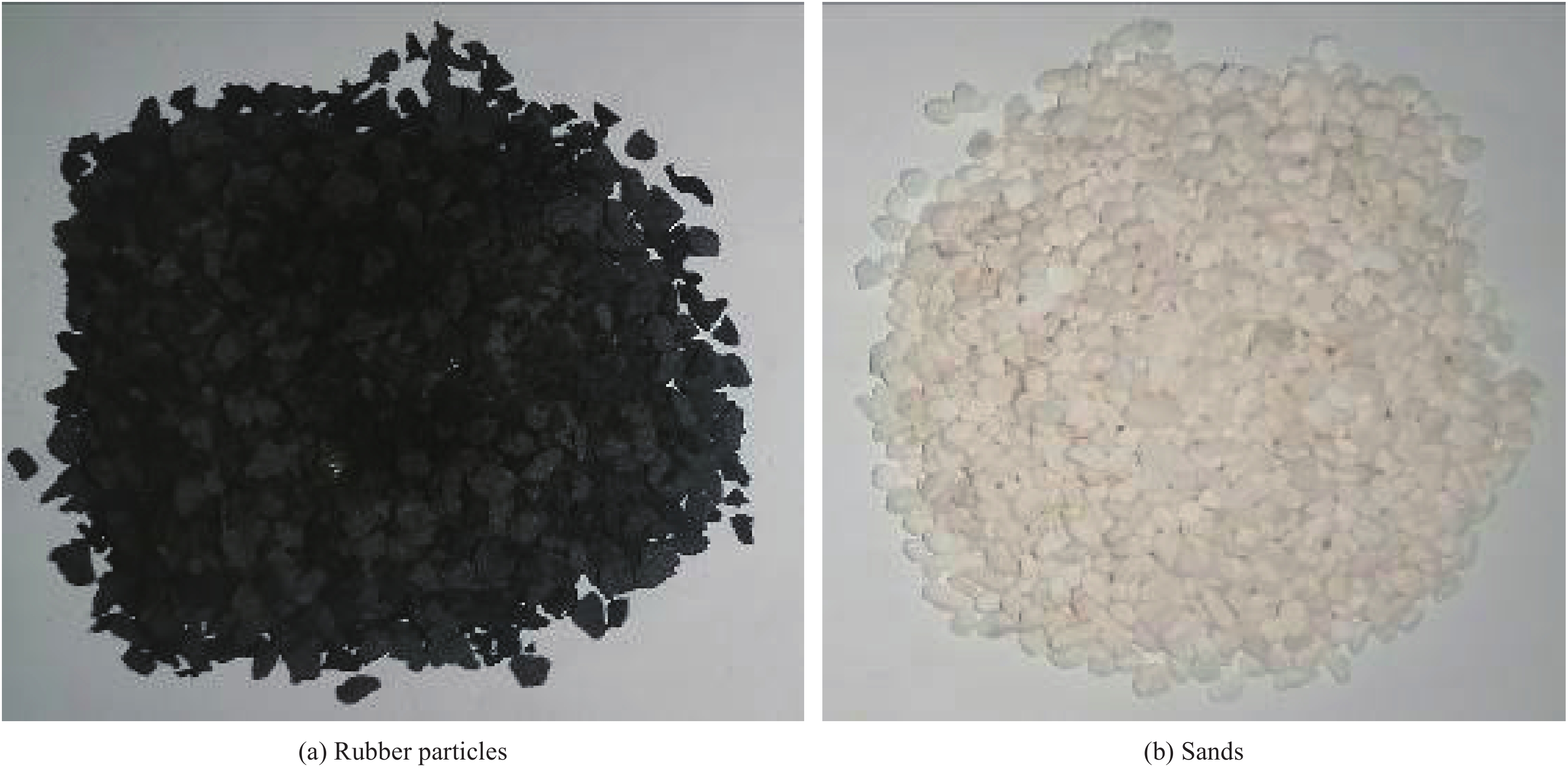

摘要: 研究废旧轮胎颗粒材料改良方法及强度特性是将其用于寒区桩基抗冻性能改善的基础。首先,按橡胶∶砂∶聚氨酯=3∶2∶1的质量比制作了若干复合材料试样;其次,通过静三轴试验,获得了不同温度、冻融循环次数及围压下试样的应力-应变曲线。试验结果表明:橡胶-砂-聚氨酯复合材料的应力-应变曲线无明显峰值点,具有显著的应变强硬化特征;试样破坏强度随温度降低而增加;冻结状态下,试验温度每降低5.0℃,其破坏强度约增加15.0%;试样破坏强度随冻融循环次数增加而降低,但平均降幅不足5.0%;围压对20.0℃常温试样破坏强度的影响幅度达15.0%,而对冻结试样破坏强度的影响幅度不足5.0%。敏感性分析显示:温度对试样破坏强度的影响最大,围压及冻融循环次数的影响相对较小,说明橡胶-砂-聚氨酯复合材料具有强度适中、结构稳定和抗冻融等特性。在此基础上,建立了考虑温度、围压和冻融循环的橡胶-砂-聚氨酯复合材料应力-应变本构模型,验证了模型参数拟合公式的合理性。Abstract: The improvement methods and strength properties of scrap tire granular materials are the research basis on the frost resistance performance improvement of piles in cold regions. Several composite samples were made according to the mass ratio of rubber∶sand∶polyurethane = 3∶2∶1. The stress-strain curves of samples under different temperatures, confining pressures and number of freeze-thaw cycles were obtained by triaxial tests. The test results show that the stress-strain curve of rubber-sand-polyurethane composite has no obvious peak point, and has obvious strain hardening characteristic. The failure strength of the sample increases with the decrease of temperature, and increases by 15.0% when the test temperature decreases by 5.0℃ for frozen samples. The failure strength values of samples decrease with the increase of freeze-thaw cycles, but the average decrease is less than 5.0%. The effect of confining pressures on the failure strength of the 20.0℃ sample is about 15.0%, while that of the frozen samples is less than 5.0%. The sensitivity analysis shows that the temperature has the greatest impact on the failure strength of rubber-sand-polyurethane composites, while the confining pressure and the number of freeze-thaw cycles have little effect. The rubber-sand-polyurethane composites have the characteristics of moderate strength, stable structure and freeze-thaw resistance. The stress-strain constitutive model of rubber-sand-polyurethane composite after consideration of the temperature, confining pressure and freeze-thaw cycle was established, and the rationality of the model parameters fitting formula was verified.

-

Key words:

- rubber /

- polyurethane /

- freeze-thaw cycle /

- strength property /

- constitutive model

-

表 1 试验材料的物理参数

Table 1. Physical parameters of testing materials

Material d50/mm Cu Cc Bulk density

/(g·cm−3)Apparent density

/(g·cm−3)Sands 2.79 1.40 0.89 1.87 2.68 Rubber

particles2.81 2.68 1.35 0.68 1.25 Notes: d50—Average size; Cu—Coefficient of uniformity; Cc—Coefficient of curvature. 表 2 试验方案

Table 2. Testing programs

Serial number T/℃ N/times σ3/kPa A 20.0 0、25、50 25、50、100 B −5.0 0、25、50 25、50、100 C −10.0 0、25、50 25、50、100 D −15.0 0、25、50 25、50、100 Notes: T—Temperature; N—Number of freeze-thaw cycles; σ3—Confining pressure. 表 3 冻融循环对不同类别土体强度的影响

Table 3. Influences of freeze-thaw cycles on strength of different types of soils

表 4 橡胶-砂-聚氨酯复合材料试样破坏强度(单位:kPa)

Table 4. Failure strength of rubber-sand-polyurethane composite samples (Unit: kPa)

N/times σ3/kPa T/℃ 20.0 −5.0 −10.0 −15.0 0 25 620 846 967 1113 50 630 853 1010 1190 100 755 897 1075 1280 25 25 618 825 960 1102 50 618 832 982 1157 100 748 892 1058 1228 50 25 612 845 964 1124 50 610 850 973 1147 100 705 883 1042 1251 表 5 影响因素(A, B)的频数列联表

Table 5. Frequency contingency of influencing factors (A, B)

B1 B2 ··· Bc Total A1 n11 n12 ··· n1c n1+ A2 n21 n22 ··· n2c n2+ ··· ··· ··· ··· ··· ··· Ar nr1 nr2 ··· nrc nr+ Total n+1 n+2 ··· n+c n 表 6 卡方检验统计量汇总表

Table 6. Summary table of chi-square statistics

Variable factor Fixed factor DOF $\chi _{0.05}^2 $(DOF) $\chi _{n}^2 $ A B T σ3 N=0 6 12.592 6.15 N=25 5.22 N=50 2.96 N T σ3=25 kPa 6 12.592 0.32 σ3=50 kPa 0.46 σ3=100 kPa 1.64 σ3 N T=20.0℃ 4 9.488 0.73 T=−5.0℃ 0.32 T=−10.0℃ 0.35 T=−15.0℃ 0.83 Note: DOF—Degree of freedom. 表 7 橡胶-砂-聚氨酯复合材料破坏强度极差分析(单位:kPa)

Table 7. Range analysis of failure strength of rubber-sand-polyurethane composites (Unit: kPa)

Impact factor T/℃ σ3/kPa N/times K1 5916 10596 11236 K2 7723 10852 11020 K3 9031 11814 11006 K4 10592 — — k1 657 883 936 k2 858 904 918 k3 1003 985 917 k4 1177 — — Rj 520 102 19 Notes: Ki is the sum of the corresponding calculation results when the influencing factor is i; ki=K/s, s is the number of occurrences of each level in any column; Rj=max{k1, k2, k3}-min{k1, k2, k3}. 表 8 橡胶-砂-聚氨酯复合材料本构模型的拟合参数α和β

Table 8. Fitting parameters α and β of the constitutive model of rubber-sand-polyurethane composites

N/times σ3/kPa T/℃ α β R2 0 50 20.0 2136.79 0.76 0.9992 −5.0 2798.09 0.73 0.9971 −10.0 3615.17 0.78 0.9979 −15.0 4214.97 0.78 0.9994 100 20.0 2427.85 0.72 0.9983 −5.0 3031.68 0.75 0.9983 −10.0 3959.97 0.80 0.9991 −15.0 4545.01 0.78 0.9953 25 25 20.0 1951.92 0.72 0.9991 −5.0 2617.91 0.71 0.9992 −10.0 2917.70 0.69 0.9990 −15.0 3788.79 0.77 0.9985 100 20.0 2699.34 0.79 0.9972 −5.0 3025.88 0.76 0.9988 −10.0 3919.82 0.81 0.9994 −15.0 4490.65 0.80 0.9966 50 25 20.0 2707.83 0.92 0.9994 −5.0 2879.89 0.75 0.9990 −10.0 3434.36 0.78 0.9973 −15.0 3885.88 0.77 0.9992 50 20.0 2136.79 0.76 0.9992 −5.0 2729.17 0.72 0.9983 −10.0 3255.56 0.75 0.9977 −15.0 4134.18 0.79 0.9994 表 9 橡胶-砂-聚氨酯复合材料试验与计算结果对比

Table 9. Comparison of test and calculation results of rubber-sand-polyurethane composites

N/times σ3/kPa T/℃ Failure strength/kPa Error/% Test value Calculated value 0 25 20.0 620 575 −7.3 −5.0 846 915 8.2 −10.0 967 983 1.7 −15.0 1113 1051 −5.6 25 50 20.0 618 629 1.8 −5.0 832 914 9.9 −10.0 982 1047 6.7 −15.0 1157 1116 −3.6 50 100 20.0 705 757 7.4 −5.0 883 962 8.9 −10.0 1042 1165 11.8 −15.0 1251 1234 −1.4 -

[1] ZHU Y, CARBEE D L. Uniaxial compressive strength of frozen silt under constant deformation rates[J]. Cold Regions Science and Technology,1984,9(1):3-15. doi: 10.1016/0165-232X(84)90043-0 [2] FEI W, YANG Z J. Modeling unconfined compression behaviour of frozen Fairbanks silt considering effects of temperature, strain rate and dry density[J]. Cold Regions Science and Technology,2019,158:252-263. doi: 10.1016/j.coldregions.2018.09.002 [3] 张正甫, 刘松玉, 蔡光华, 等. 废旧轮胎在道路工程中的研究进展[J]. 土木工程学报, 2018, 48(S2):361-368.ZHANG Zhengfu, LIU Songyu, CAI Guanghua, et al. Research progress of scrap tires used in road engineering[J]. China Civil Engineering Journal,2018,48(S2):361-368(in Chinese). [4] 方芳, 周勇敏, 张继. 废轮胎回收制胶粉及其应用进展[J]. 材料科学与工程学报, 2007, 25(1):164-168. doi: 10.3969/j.issn.1673-2812.2007.01.040FANG Fang, ZHOU Yongmin, ZHANG Ji. Advances in recycling of waste tire for preparation of powdered rubber and its applications[J]. Journal of Materials Science and Engineering,2007,25(1):164-168(in Chinese). doi: 10.3969/j.issn.1673-2812.2007.01.040 [5] GAO H M, BU C Y, WANG Z H, et al. Dynamic characteristics of expanded polystyrene composite soil under traffic loadings considering intial consolidation state[J]. Soil Dynamics and Earthquake Engineering,2017,102:86-98. doi: 10.1016/j.soildyn.2017.08.012 [6] LI J, SABERINA M, NGUYEN B T. Effect of crumb rubber on the mechanical properties of crushed recycled pavement materials[J]. Journal of Environmental Management,2018,218:291-299. [7] MOGHADAM M J, ZAD A, MEHRANNIA N, et al. Experimental evaluation of mechanically stabilized earth walls with recycled crumb rubbers[J]. Journal of Rock Mechanics and Geotechnical Engineering,2018,10(5):947-957. doi: 10.1016/j.jrmge.2018.04.012 [8] TSANG H H. Seismic isolation by rubber-soil mixtures for developing countries[J]. Earthquake Engineering and Structural Dynamics,2008,37(2):283-303. doi: 10.1002/eqe.756 [9] LI B, HUANG M S, ZENG X W. Dynamic behavior and liquefaction analysis of recycled-rubber sand mixtures[J]. Journal of Materials in Civil Engineering,2016,28(11):04016122. doi: 10.1061/(ASCE)MT.1943-5533.0001629 [10] SELLAF H, TROUZINE H, HAMHAMI M, et al. Geotechnical properties of rubber tires and sediments mixtures[J]. Engineering Technology and Applied Science Research,2014,4(2):618-624. doi: 10.48084/etasr.424 [11] BALUNAINI U, MOHAN V K D, PREZZI M, et al. Shear strength of tyre chip-sand and tyre shred-sand mixtures[C]. Proceedings of the ICE-Geotechnical Engineering, 2014: 585-595. [12] PEREZ J C L, KWOK C Y, SENETAKIS K. Effect of rubber size on the behaviour of sand-rubber mixtures: A numerical investigation[J]. Computers and Geotechnics,2016,80:199-214. doi: 10.1016/j.compgeo.2016.07.005 [13] SIGNES C H, FERNANDEZ P M, PERALLON E M, et al. Characterisation of an unbound granular mixture with waste tyre rubber for subballast layers[J]. Materials and Structures,2015,48(12):3847-3861. doi: 10.1617/s11527-014-0443-z [14] 亢景付, 任海波, 张平祖. 橡胶混凝土的抗裂性能和弯曲变形性能[J]. 复合材料学报, 2006, 23(6):158-162. doi: 10.3321/j.issn:1000-3851.2006.06.026KANG Jingfu, REN Haibo, ZHANG Pingzu. Cracking-resistance and flexural property of rubberized concrete[J]. Acta Materiae Compositae Sinica,2006,23(6):158-162(in Chinese). doi: 10.3321/j.issn:1000-3851.2006.06.026 [15] 姚韦靖, 刘雨姗, 王婷雅, 等. 橡胶/混凝土盐冻循环后性能劣化及微观结构[J]. 复合材料学报, 2021, 38(12):4294-4304.YAO Weijing, LIU Yushan, WANG Tingya, et al. Performance degradation and microscopic structure of rubber/concrete after salt freeze-thaw cycles[J]. Acta Materiae Compositae Sinica,2021,38(12):4294-4304(in Chinese). [16] 周恩全, 王琼, 陆建飞. 干燥及饱和橡胶砂压缩和剪切特性[J]. 土木与环境工程学报, 2019, 41(6):101-110.ZHOU Enquan, WANG Qiong, LU Jianfei. Compressibility and shear properties of dry/saturated rubber sand[J]. Journal of Civil and Environmental Engineering,2019,41(6):101-110(in Chinese). [17] 张涛, 刘松玉, 蔡国军. 橡胶-砂颗粒混合物压缩特性与胶结退化试验[J]. 中国公路学报, 2018, 31(11):21-30. doi: 10.3969/j.issn.1001-7372.2018.11.003ZHANG Tao, LIU Songyu, CAI Guojun. Experimental on compression characteristics and bonding degradation of rubber-sand mixtures[J]. Journal of Highway and Transport,2018,31(11):21-30(in Chinese). doi: 10.3969/j.issn.1001-7372.2018.11.003 [18] 刘方成, 郑玉凤, 刘娜, 等. 配比和相对密实度对橡胶砂静力参数的影响[J]. 湖南工业大学学报, 2017, 31(5):24-31. doi: 10.3969/j.issn.1673-9833.2017.05.005LIU Fangcheng, ZHENG Yufeng, LIU Na, et al. Influence of proportioning and relative density on static parameters of rubber-sand[J]. Journal of Hunan University of Technology,2017,31(5):24-31(in Chinese). doi: 10.3969/j.issn.1673-9833.2017.05.005 [19] 刘方成, 吴孟桃, 杨俊. 土工格栅加筋橡胶砂强度特性试验研究[J]. 岩土力学, 2019, 40(2):580-591.LIU Fangcheng, WU Mengtao, YANG Jun. Experimental study of strength characteristics of geogrid reinforced rubber sand mixtures[J]. Rock and Soil Mechanics,2019,40(2):580-591(in Chinese). [20] 董超, 李大勇, 李珊珊. 橡胶颗粒粒径对砂土抗剪强度的影响[J]. 广西大学学报(自然科学版), 2017, 42(4):1392-1398.DONG Chao, LI Dayong, LI Shanshan. Effects of scrap tire crumb size on shear strength of sand[J]. Journal of Guangxi University(Natural Science),2017,42(4):1392-1398(in Chinese). [21] ASTM. Standard practice for classification of soils for engineering purposes (Unified Soil Classification System)ASTM D2487—2011[S]. United States: American Society of Testing Materials, 2011. [22] 孙建, 段鹏飞, 韩海军. 低溶剂型单组份聚氨酯防水涂料的制备[J]. 新型建筑材料, 2018, 45(6):130-132, 136. doi: 10.3969/j.issn.1001-702X.2018.06.032SUN Jian, DUAN Pengfei, HAN Haijun. Preparation of the low solvent type one-component polyurethane waterproof coating[J]. New Building Materials,2018,45(6):130-132, 136(in Chinese). doi: 10.3969/j.issn.1001-702X.2018.06.032 [23] 陆冬贞. 我国聚氨酯胶粘剂发展概况与展望[J]. 聚氨酯, 2007(5):68-78.LU Dongzhen. General situation and prospect of development of polyurethane adhesive in China[J]. Polyurethane,2007(5):68-78(in Chinese). [24] 中华人民共和国交通运输部. 公路土工试验规程: JTGE40—2007[S]. 北京: 人民交通出版社, 2007.Ministry of Transport of the People’s Republic of China. Test methods of soils for highway engineering: JTGE40—2007[S]. Beijing: China Communications Press, 2007 (in Chinese). [25] 朱思哲, 刘虔, 包承纲, 等. 三轴试验原理与应用技术[M]. 北京: 中国电力出版社, 2003.ZHU Sizhe, LIU Qian, BAO Chenggang, et al. Principle and application technology of triaxial test[M]. Beijing: China Electric Power Press, 2003 (in Chinese). [26] 刘祖典, 李靖, 郭增玉, 等. 陕西关中黄土变形特性和变形参数的探讨[J]. 岩土工程学报, 1984, 6(3):24-34. doi: 10.3321/j.issn:1000-4548.1984.03.003LIU Zudian, LI Jing, GUO Zengyu, et al. Deformation behaviours and deformation parameter of loess in Shaanxi district[J]. Chinese Journal of Geotechnical Engineering,1984,6(3):24-34(in Chinese). doi: 10.3321/j.issn:1000-4548.1984.03.003 [27] 刘寒冰, 张互助, 王静. 冻融及含水率对压实黏质土力学性质的影响[J]. 岩土力学, 2018, 39(1):158-164.LIU Hanbing, ZHANG Huzhu, WANG Jing. Effect of freeze-thaw and water content on mechanical properties of compacted clayey soil[J]. Rock and Soil Mechanics,2018,39(1):158-164(in Chinese). [28] 胡田飞, 刘建坤, 王青志, 等. 冻融循环下粉质黏土不排水剪切性状的试验研究[J]. 中南大学学报(自然科学版), 2018, 49(6):1481-1490. doi: 10.11817/j.issn.1672-7207.2018.06.022HU Tianfei, LIU Jiankun, WANG Qingzhi, et al. Experimental study on undrained strength characteristics of silty clay after freeze-thaw cycling[J]. Journal of Central South University(Science and Technology),2018,49(6):1481-1490(in Chinese). doi: 10.11817/j.issn.1672-7207.2018.06.022 [29] 周泓, 张豫川, 张泽, 等. 冻融作用下冻结黄土黏聚力长期强度变化规律[J]. 岩土力学, 2014, 35(8):2241-2246.ZHOU Hong, ZHANG Yuchuan, ZHANG Ze, et al. Changing rule of long-term strength of frozen loess cohesion under impact of freeze-thaw cycle[J]. Rock and Soil Mechanics,2014,35(8):2241-2246(in Chinese). [30] 严晗, 刘建坤, 王天亮. 冻融对粉砂土力学性能影响的试验研究[J]. 北京交通大学学报, 2013, 37(4):73-77. doi: 10.3969/j.issn.1673-0291.2013.04.014YAN Han, LIU Jiankun, WANG Tianliang. Experimental research of influences of freeze-thaw on the mechanical properties of silty soil[J]. Journal of Beijing Jiaotong University,2013,37(4):73-77(in Chinese). doi: 10.3969/j.issn.1673-0291.2013.04.014 [31] 胡田飞, 刘建坤, 常丹, 等. 冻融循环对粉质黏土力学性质的影响及邓肯-张模型[J]. 中国公路学报, 2018, 31(2):298-307. doi: 10.3969/j.issn.1001-7372.2018.02.032HU Tianfei, LIU Jiankun, CHANG Dan, et al. Influence of freeze-thaw cycling on mechanical properties of silty clay and Duncan-Chang constitutive model[J]. China Journal of Highway and Transport,2018,31(2):298-307(in Chinese). doi: 10.3969/j.issn.1001-7372.2018.02.032 [32] 曹桃云, 陈敏琼. 基于距离协方差的二维列联表的独立性检验[J]. 系统科学与数学, 2020, 40(9):1687-1700. doi: 10.12341/jssms13973CAO Taoyun, CHEN Minqiong. A test of independence for two dimensional contingency tables based on distance covariance[J]. Journal of Systems Science and Mathematical Sciences,2020,40(9):1687-1700(in Chinese). doi: 10.12341/jssms13973 -

下载:

下载: