Effect of high wollastonite fiber incorporation on metakaolin base geopolymers' properties and microstructure

-

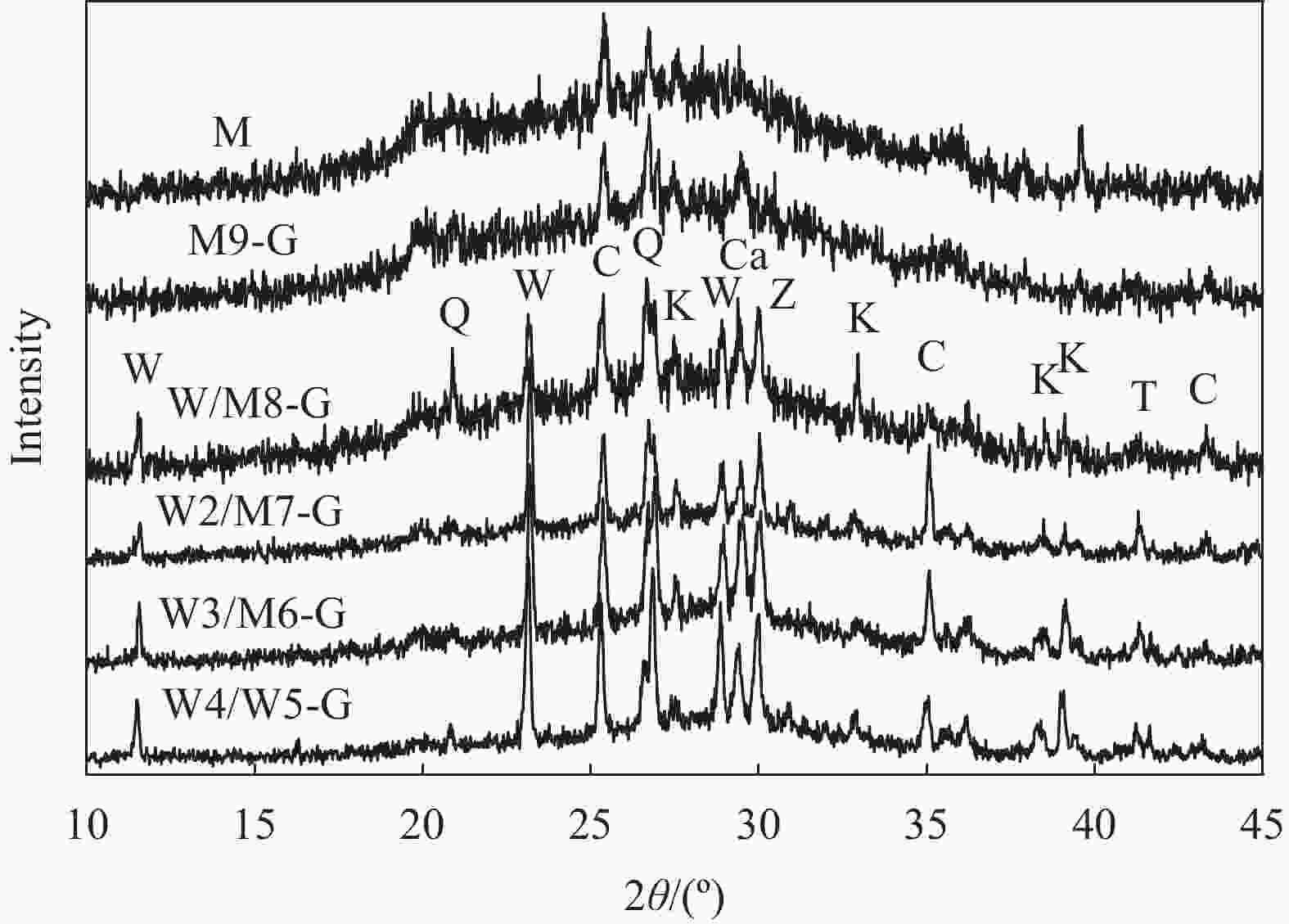

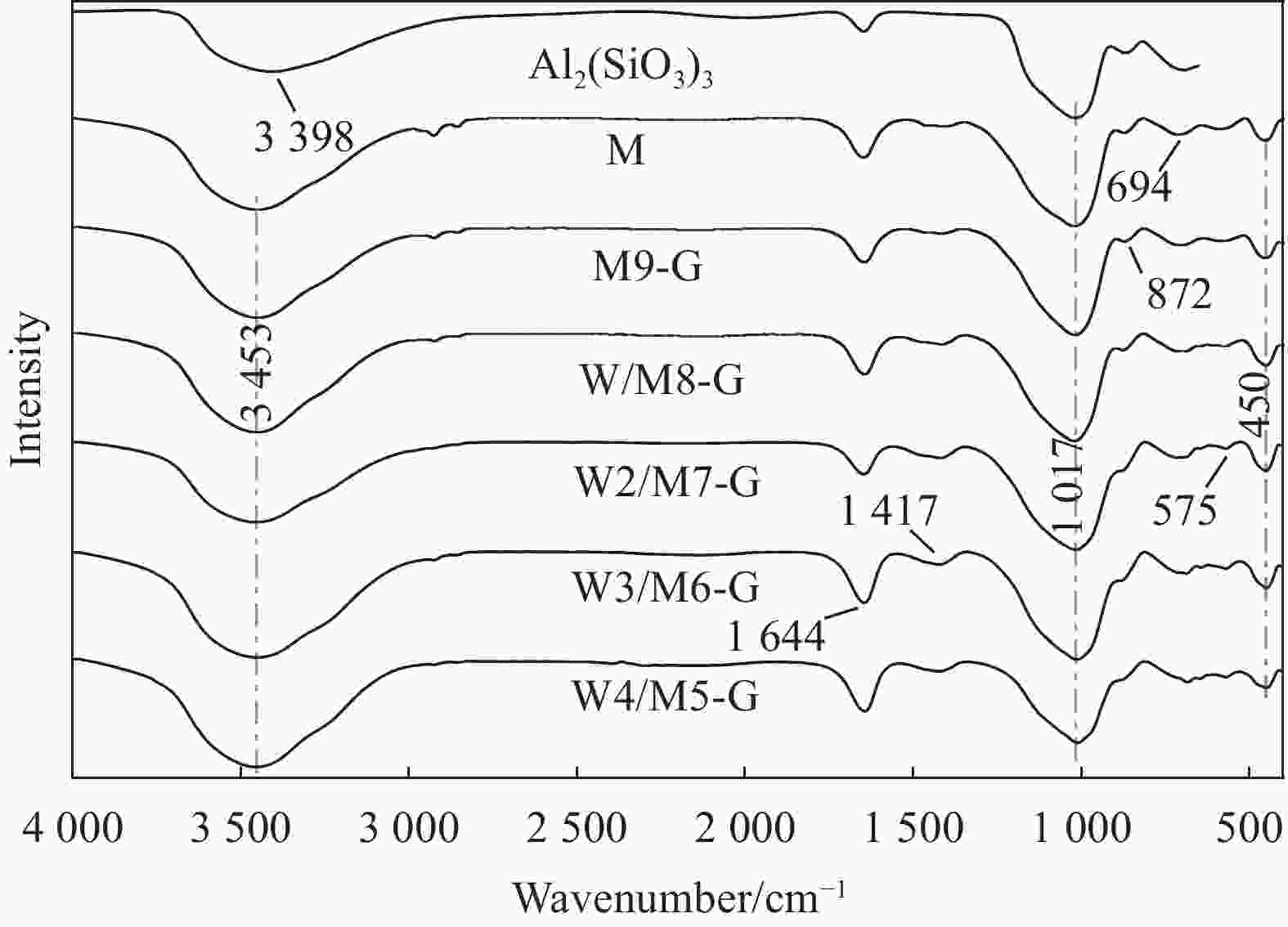

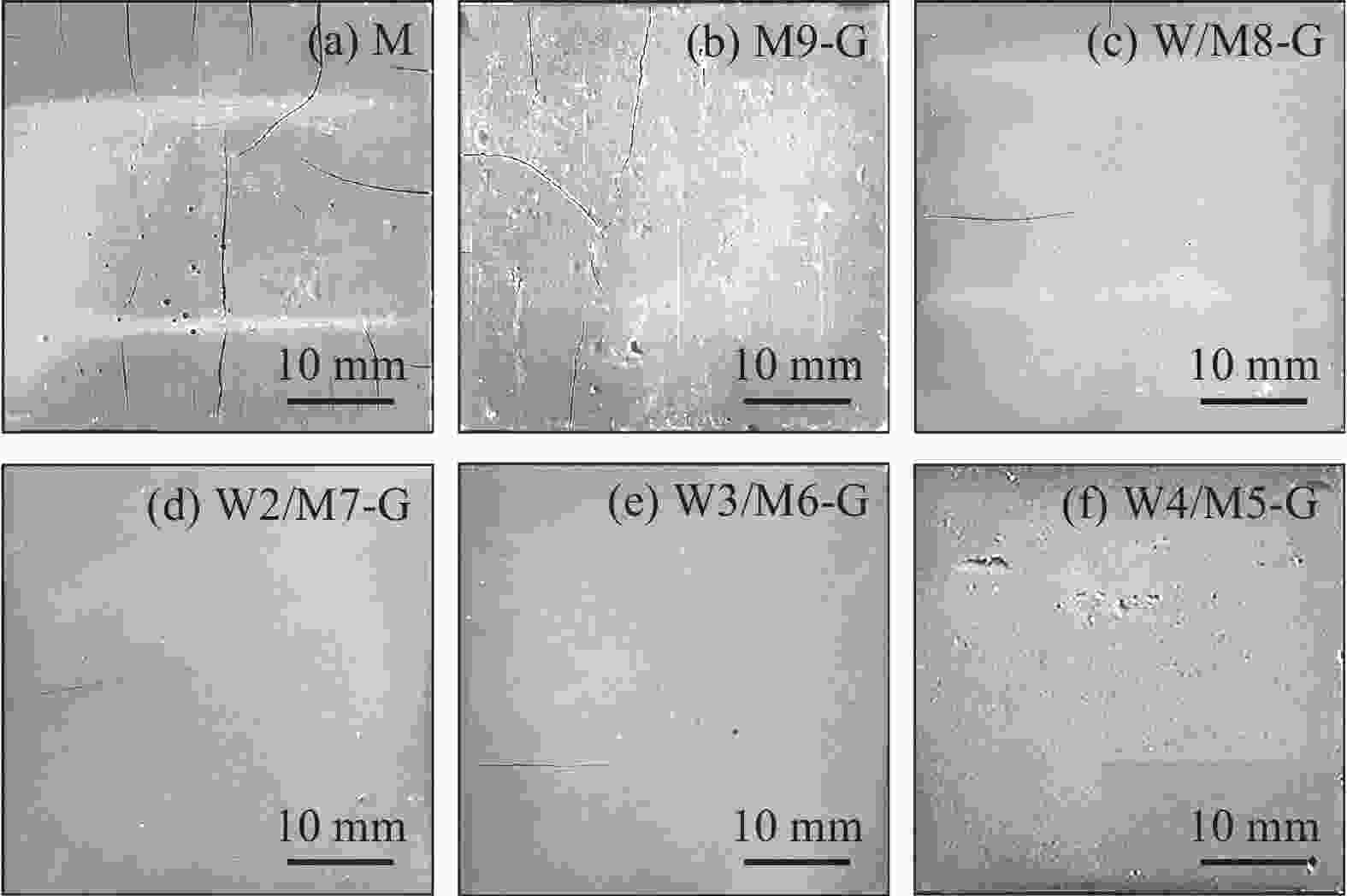

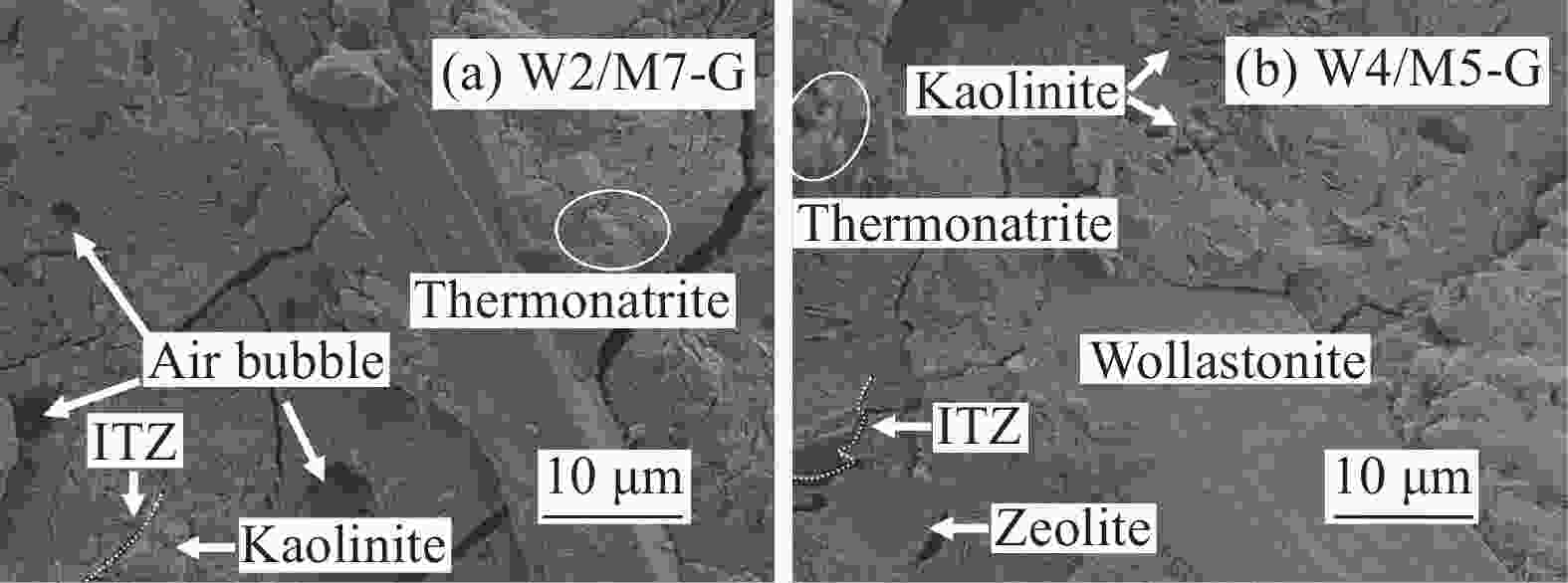

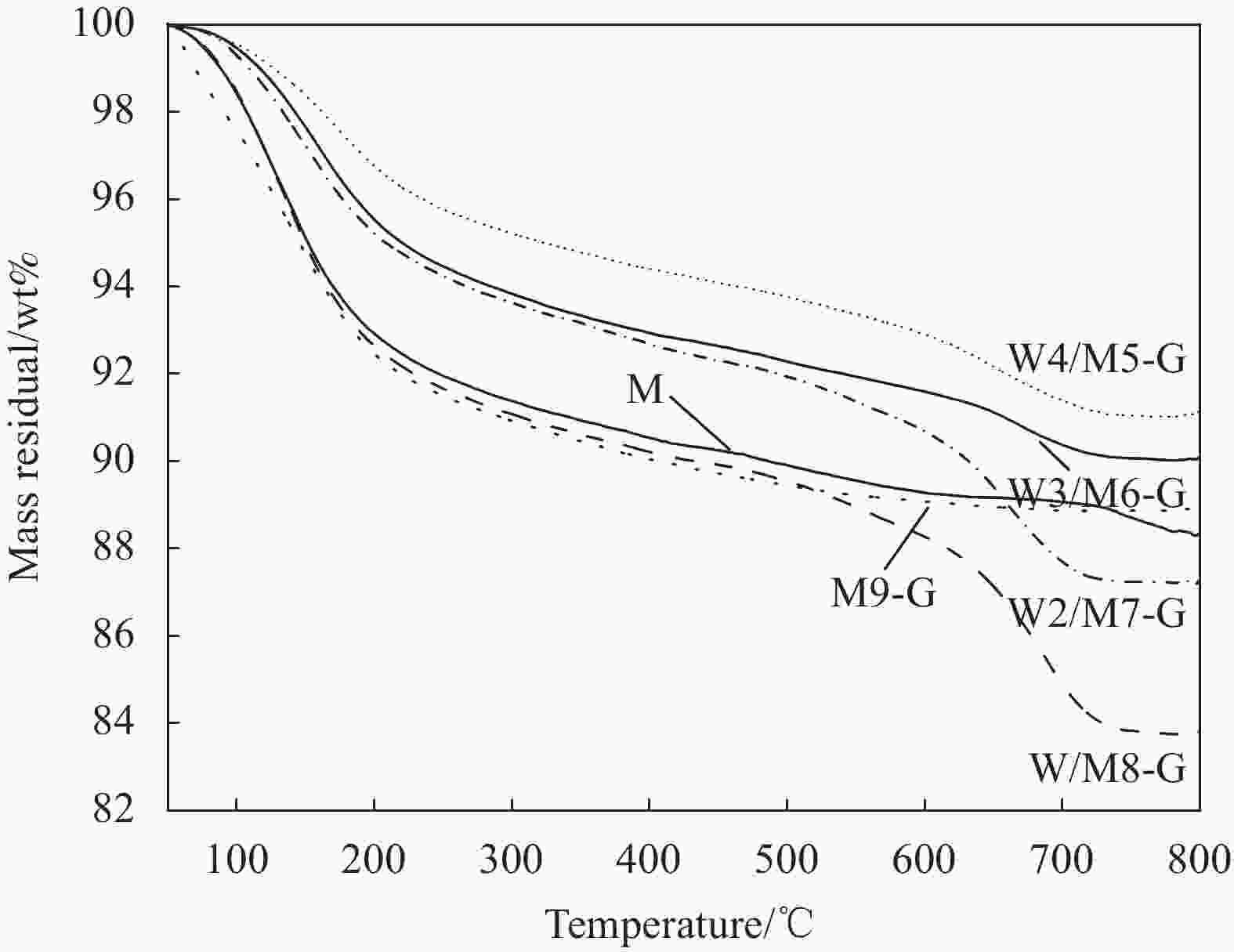

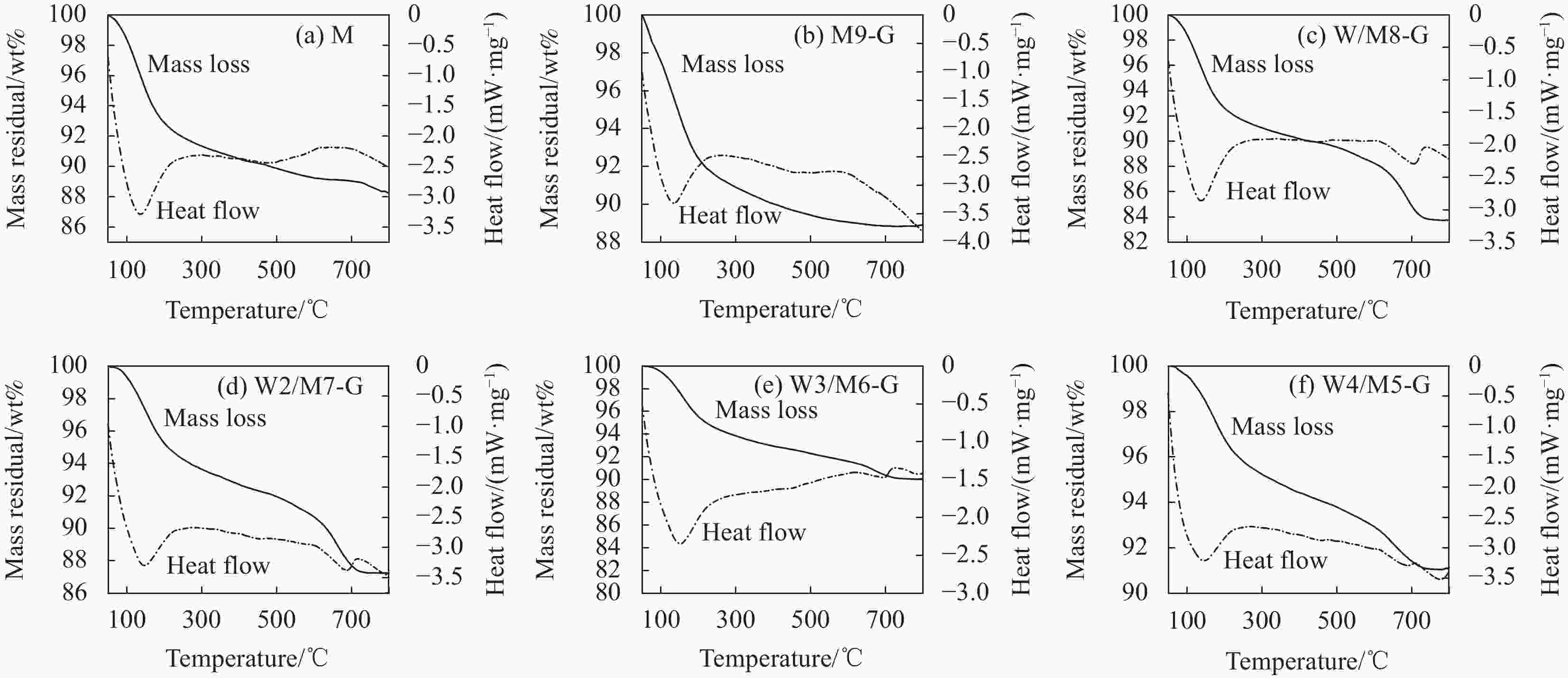

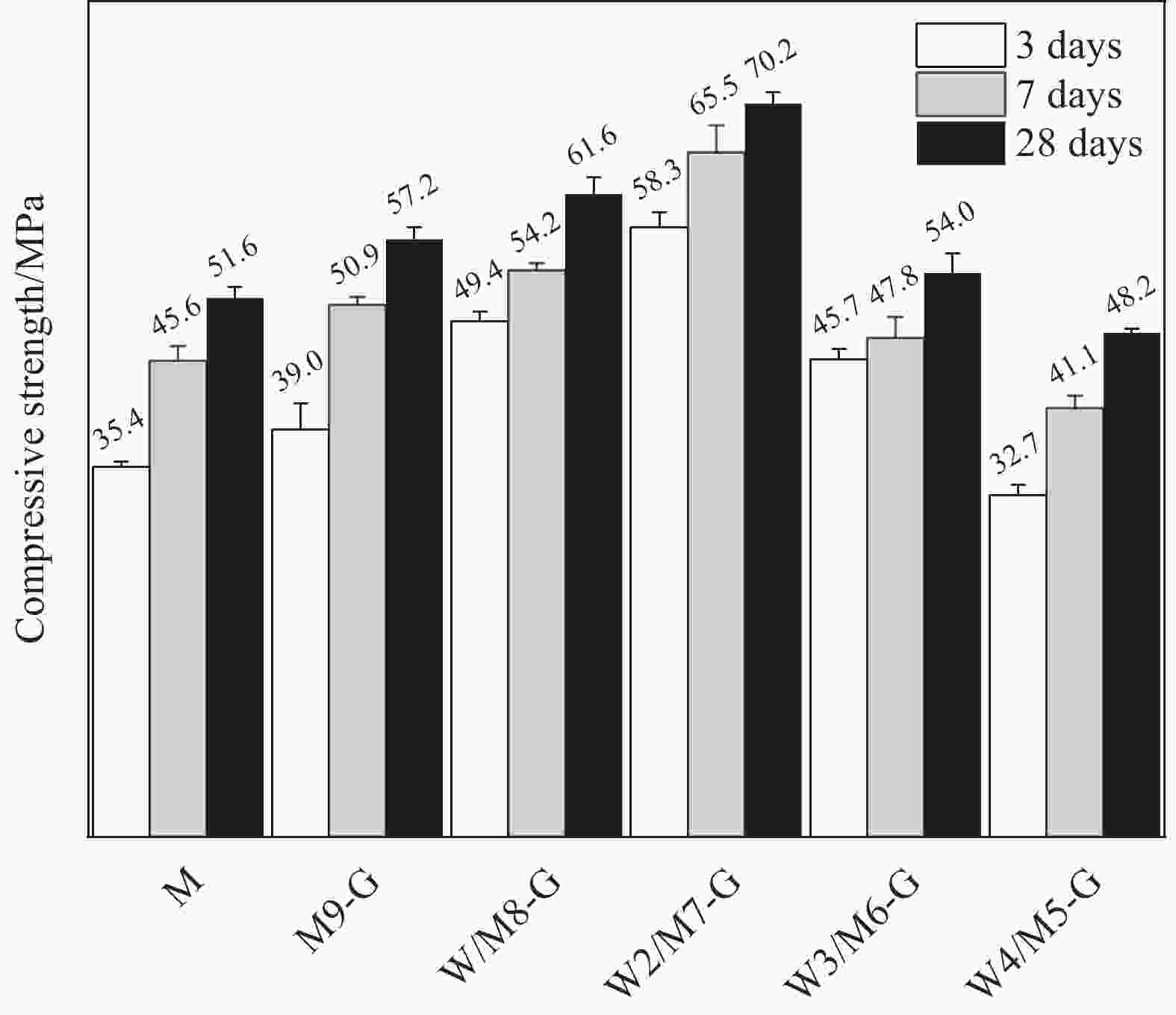

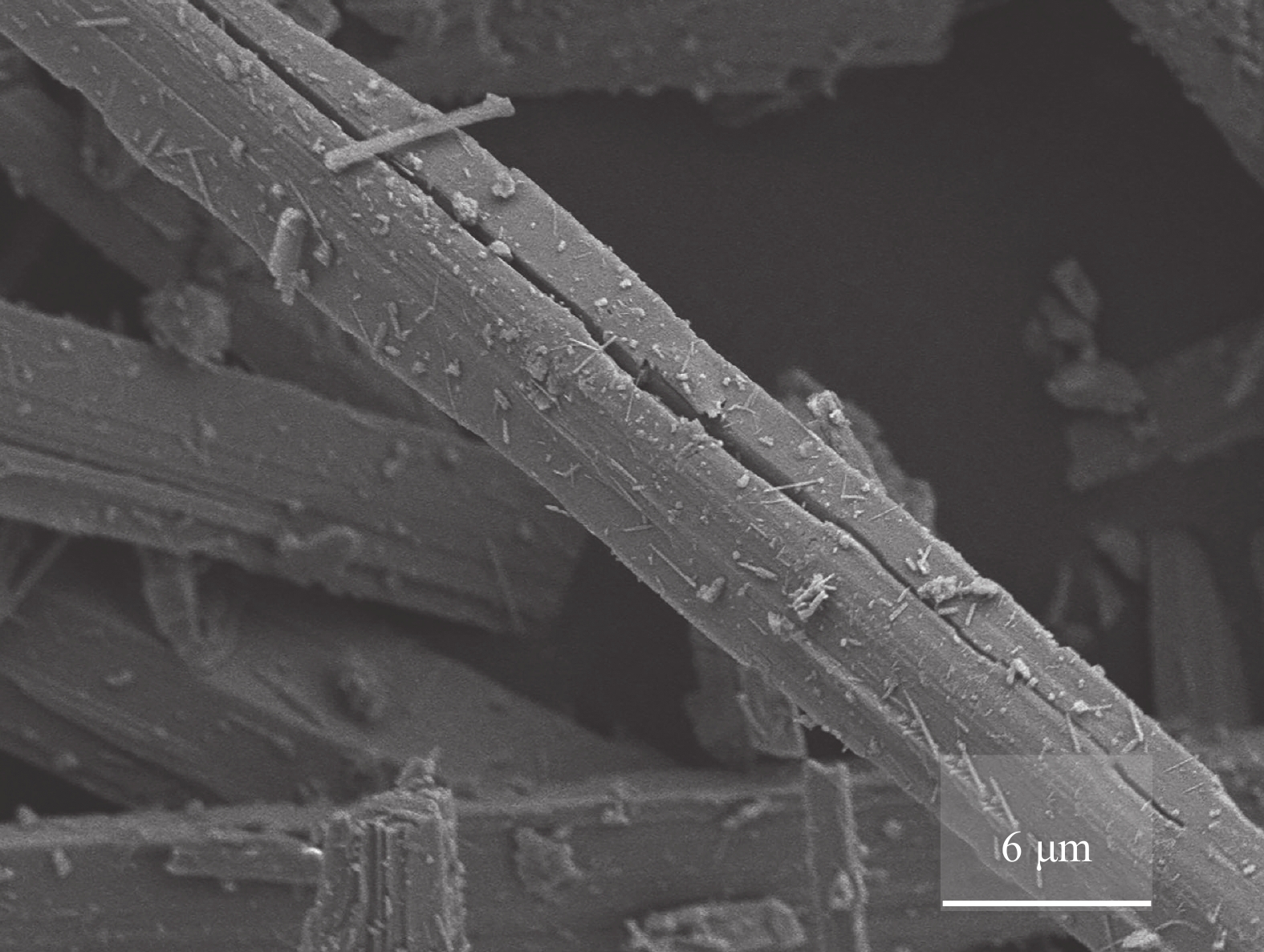

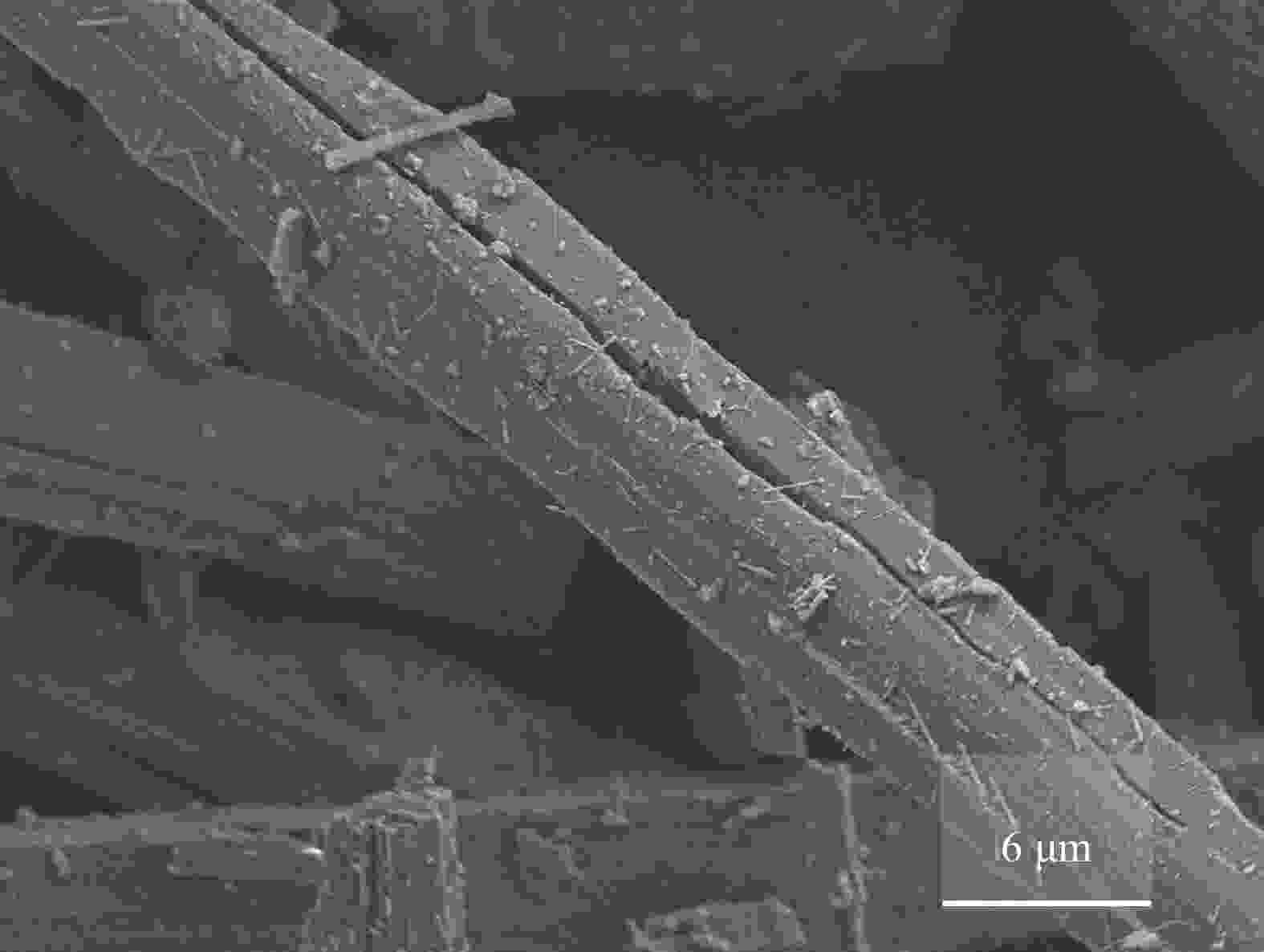

摘要: 为了研究高添加量的硅灰石纤维对偏高岭土-矿渣地聚物力学性能及开裂特性的影响,以硅灰石纤维替代质量分数(最高40wt%)为实验参数,制备了硅灰石/偏高岭土-矿渣地聚物,评估了与硅灰石含量有关的性能(力学强度、孔隙率和裂纹),并研究了硅灰石纤维对地聚物微结构的影响。结果表明:硅灰石纤维的加入对处于干燥环境下的地聚物抑制开裂行为有积极作用,且在替代量为40wt%以内是持续改善的;同时也观察到硅灰石纤维的加入对地聚物力学性能也有积极影响,其中硅灰石纤维替代量为20wt%的地聚物28天强度达到70.2 MPa,较偏高岭土基地聚物样品抗压强度增长了36%,但继续增加硅灰石纤维会导致地聚物抗压强度的降低;此外沸石相在复合物中被检测到,硅灰石的添加有利于沸石相的发展。Abstract: In order to study the effect of high addition of wollastonite fiber on the mechanical properties and cracking characteristics of metakaolin/slag geopolymer, wollastonite-metakaolin-slag geopolymer was prepared with the substitution mass fraction of wollastonite fiber (up to 40wt%) as the experimental parameter. The properties related to the content of wollastonite (mechanical strength, porosity and crack) were evaluated, and the effect of wollastonite fiber on the microstructure of geopolymer was studied. The results show that the addition of wollastonite fiber has a positive effect on inhibiting the cracking behavior of the geopolymer in dry environment, and it is continuously improved when the substitution amount is less than 40wt%. At the same time, it is also observed that the addition of wollastonite fiber has a positive effect on the mechanical properties of the geopolymer. The 28 days strength of the geopolymer with the substitution amount of wollastonite fiber of 20wt% reaches 70.2 MPa, which is 36% higher than the original compressive strength of metakaolin-based geopolymer. However, the continuous increase of wollastonite fiber will lead to the decrease of the compressive strength of the geopolymer. In addition, zeolite was detected in the composite, and the addition of wollastonite was beneficial to the development of zeolite phase.

-

Key words:

- geopolymer /

- wollastonite fibers /

- metakaolin /

- cracking behavior /

- LF-NMR

-

表 1 原料的主要成分及含量

Table 1. Main compositions and content of materials

(wt%) Material SiO2 Al2O3 Fe2O3 MgO CaO Metakaolin (MK) 47.83 43.54 3.55 0 0.68 Slag (GGBFS) 31.26 13.63 1.13 6.34 40.20 Wollastonite (WS) 41.84 0.32 0.31 1.77 54.89 表 2 原料的混合比例

Table 2. Geopolymer mixture proportion

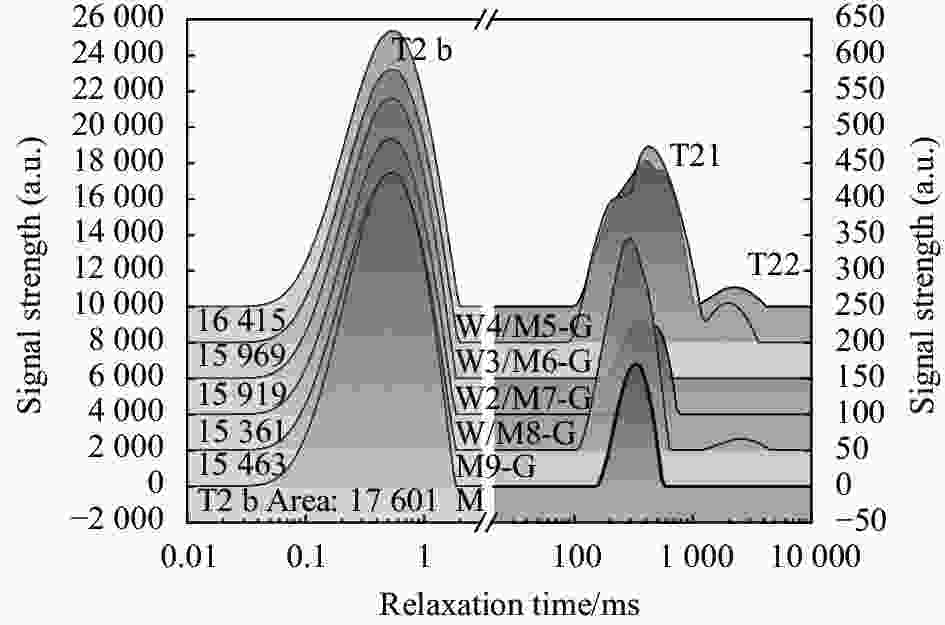

Number MK/g GGBFS/g WS/g AA/g M 100 0 0 100 M9-G 90 10 0 100 W/M8-G 80 10 10 100 W2/M7-G 70 10 20 100 W3/M6-G 60 10 30 100 W4/M5-G 50 10 40 100 Notes: MK and GGBFS were used as the matrix phase and WS as the reinforcing phase. They are denoted by M, G and W in the specimen numbering. As an example, 100 g AA (alkali activator), 50 g MK, 10 g GGBFS and 40 g WS are required to prepare W4/M5-G. 表 3 LF-NMR测得的地聚物孔隙度

Table 3. LF-NMR porosity of geopolymer samples

Number Porosity/% M 31.05 M9-G 27.91 W/M8-G 27.29 W2/M7-G 28.00 W3/M6-G 28.29 W4/M5-G 28.48 -

[1] 张超, 邓智聪, 马蕾, 等. 3D打印混凝土研究进展及其应用[J]. 硅酸盐通报, 2021, 40(6):1769-1795.ZHANG Chao, DENG Zhicong, MA Lei, et al. Research progress and application of 3D printing concrete[J]. Bulletin of the Chinese Ceramic Society,2021,40(6):1769-1795(in Chinese). [2] 孙杰, 陈国珍, 吕康琪, 等. 橡胶地聚物混凝土力学性能及阻尼特性试验研究[J]. 复合材料学报, 2022, 39(11):5321-5332. doi: 10.13801/j.cnki.fhclxb.20211201.002SUN Jie, CHEN Guozhen, LYU Kangqi, et al. Experimental study on mechanical properties and damping characteristics of rubber geopolymer concrete[J]. Acta Materiae Compositae Sinica,2022,39(11):5321-5332(in Chinese). doi: 10.13801/j.cnki.fhclxb.20211201.002 [3] 张佳康, 苏岳威, 姚耿, 等. 地聚物泡沫混凝土的研究与应用[J]. 硅酸盐通报, 2020, 39(5):1371-1376.ZHANG Jiakang, SU Yuewei, YAO Geng, et al. Research and application of geopolymer foamed concrete[J]. Bulletin of the Chinese Ceramic Society,2020,39(5):1371-1376(in Chinese). [4] 金宇, 冯伟鹏, 董志君, 等. 辅助胶凝材料玻璃体结构与胶凝活性的研究进展[J]. 材料导报, 2021, 35(3):3016-3020. doi: 10.11896/cldb.19100052JIN Yu, FENG Weipeng, DONG Zhijun, et al. Research progress on the glass structure of supplementary cementitious materials with relation to their hydraulic reactivity[J]. Materials Reports,2021,35(3):3016-3020(in Chinese). doi: 10.11896/cldb.19100052 [5] 乔宏霞, 路承功, 师莹莹, 等. 多因素下地铁混凝土耐久性试验[J]. 重庆大学学报, 2018, 41(3):32-41. doi: 10.11835/j.issn.1000-582X.2018.03.004QIAO Hongxia, LU Chenggong, SHI Yingying, et al. Experiments on the dura-bility of subway concrete under multi-factors[J]. Journal of Chongqing University,2018,41(3):32-41(in Chinese). doi: 10.11835/j.issn.1000-582X.2018.03.004 [6] 葛洁雅, 朱红光, 李宗徽, 等. 煤矸石粗骨料-地聚物混凝土的力学与耐久性能研究[J]. 材料导报, 2021, 35(z2):218-223.GE Jieya, ZHU Hongguang, LI Zonghui, et al. Study on mechanics and durability of coal gangue coarse aggregate-geopolymer concrete[J]. Materials Reports,2021,35(z2):218-223(in Chinese). [7] 郑昊, 梁咏宁, 詹建伟, 等. MgO和CaO对碱矿渣混凝土抗碳化性能的影响[J]. 硅酸盐通报, 2021, 40(8):2564-2573.ZHENG Hao, LIANG Yongning, ZHAN Jianwei, et al. Effects of MgO and CaO on the carbonization resistance of alkali-activated slag concrete[J]. Bulletin of the Chinese Ceramic Society,2021,40(8):2564-2573(in Chinese). [8] 杨世玉, 赵人达, 曾宪帅, 等. 用自然纤维增强地聚物材料: 综述[J]. 材料导报, 2021, 35(7):7107-7113. doi: 10.11896/cldb.19100048YANG Shiyu, ZHAO Renda, ZENG Xianshuai, et al. Reinforced geopolymer materials with natural fibers: A review[J]. Materials Reports,2021,35(7):7107-7113(in Chinese). doi: 10.11896/cldb.19100048 [9] RANJBAR N, MEHRALI M, MEHRALI M, et al. High tensile strength fly ash based geopolymer composite using copper coated micro steel fiber[J]. Construction and Building Materials,2016,112:629-638. doi: 10.1016/j.conbuildmat.2016.02.228 [10] ZHANG B, FENG Y, XIE J, et al. Effects of fibres on ultra-lightweight high strength concrete: Dynamic behaviour and microstructures[J]. Cement and Concrete Composites,2022,128:104417-104438. doi: 10.1016/j.cemconcomp.2022.104417 [11] WANG J, XIE J, HE J, et al. Combined use of silica fume and steel fibre to improve fracture properties of recycled aggregate concrete exposed to elevated temperature[J]. Journal of Material Cycles and Waste Management,2020,22(3):862-877. doi: 10.1007/s10163-020-00990-y [12] SU Z, GUO L, ZHANG Z, et al. Influence of different fibers on properties of thermal insulation composites based on geopolymer blended with glazed hollow bead[J]. Construction and Building Materials,2019,203:525-540. doi: 10.1016/j.conbuildmat.2019.01.121 [13] PUNURAI W, KROEHONG W, SAPTAMONGKOL A, et al. Mechanical properties, microstructure and drying shrinkage of hybrid fly ash-basalt fiber geopolymer paste[J]. Construction and Building Materials,2018,186:62-70. doi: 10.1016/j.conbuildmat.2018.07.115 [14] HE Z, SHEN A, LYU Z, et al. Effect of wollastonite microfibers as cement replacement on the properties of cementitious composites: A review[J]. Construction and Building Materials,2020,261:119920-119933. doi: 10.1016/j.conbuildmat.2020.119920 [15] LIU K, LONG Y, CHEN L, et al. Mechanisms of autogenous shrinkage for ultra-high performance concrete (UHPC) prepared with pre-wet porous fine aggregate (PFA)[J]. Journal of Building Engineering,2022,54:104622-104642. doi: 10.1016/j.jobe.2022.104622 [16] YÜCEL H E, ÖZ H Ö, GÜNEŞ M, et al. Rheological properties, strength characteristics and flexural performances of engineered cementitious composites incorporating synthetic wollastonite microfibers with two different high aspect ratios[J]. Construction and Building Materials,2021,306:124921. doi: 10.1016/j.conbuildmat.2021.124921 [17] ARCHEZ J, TEXIER-MANDOKI N, BOURBON X, et al. Influence of the wollastonite and glass fibers on geopolymer composites workability and mechanical properties[J]. Construction and Building Materials,2020,257:119511. doi: 10.1016/j.conbuildmat.2020.119511 [18] GUO L, WU Y, XU F, et al. Sulfate resistance of hybrid fiber reinforced metakaolin geopolymer composites[J]. Composites Part B: Engineering,2020,183:107689. doi: 10.1016/j.compositesb.2019.107689 [19] 张耀君, 张叶, 韩智超, 等. 地质聚合物原位转化沸石分子筛的研究进展[J]. 材料导报, 2020, 34(23):23033-23041. doi: 10.11896/cldb.19080095ZHANG Yaojun, ZHANG Ye, HAN Zhichao, et al. Research progresses on in-situ conversion of geopolymer into zeolite[J]. Materials Reports,2020,34(23):23033-23041(in Chinese). doi: 10.11896/cldb.19080095 [20] LIU J, LI X, LU Y, et al. Effects of Na/Al ratio on mechanical properties and microstructure of red mud-coal metakaolin geopolymer[J]. Construction and Building Materials,2020,263:120653. doi: 10.1016/j.conbuildmat.2020.120653 [21] PROVIS J L, LUKEY G C, VAN DEVENTER J S J. Do geopolymers actually contain nanocrystalline zeolites? A reexamination of existing results[J]. Chemistry of Materials,2005,17(12):3075-3085. doi: 10.1021/cm050230i [22] TCHAKOUTÉ H K, RÜSCHER C H, KONG S, et al. Geopolymer binders from metakaolin using sodium waterglass from waste glass and rice husk ash as alternative activators: A comparative study[J]. Construction and Building Materials,2016,114:276-289. doi: 10.1016/j.conbuildmat.2016.03.184 [23] ASSAEDI H, SHAIKH F U A, LOW I M. Characterizations of flax fabric reinforced nanoclay-geopolymer composites[J]. Composites Part B: Engineering,2016,95:412-422. doi: 10.1016/j.compositesb.2016.04.007 [24] ZHANG S, GONG K, LU J. Novel modification method for inorganic geopolymer by using water soluble organic polymers[J]. Materials Letters,2004,58(7):1292-1296. [25] KAZE R C, BELEUKÀMOUNGAM L M, FONKWE D M L, et al. The corrosion of kaolinite by iron minerals and the effects on geopolymerization[J]. Applied Clay Science,2017,138:48-62. doi: 10.1016/j.clay.2016.12.040 [26] ZHANG B, FENG Y, XIE J, et al. Rubberized geopolymer concrete: Dependence of mechanical properties and freeze-thaw resistance on replacement ratio of crumb rubber[J]. Construction and Building Materials,2021,310:125248. doi: 10.1016/j.conbuildmat.2021.125248 [27] GUO H, YUAN P, ZHANG B, et al. Realization of high-percentage addition of fly ash in the materials for the preparation of geopolymer derived from acid-activated metakaolin[J]. Journal of Cleaner Production,2021,285:125430. doi: 10.1016/j.jclepro.2020.125430 [28] LOUATI S, BAKLOUTI S, SAMET B. Geopolymers based on phosphoric acid and illito-kaolinitic clay[J]. Advances in Materials Science and Engineering,2016,2016:2359759. [29] OZER I, SOYER-UZUN S. Relations between the structural characteristics and compressive strength in metakaolin based geopolymers with different molar Si/Al ratios[J]. Ceramics International,2015,41(8):10192. doi: 10.1016/j.ceramint.2015.04.125 [30] LECOMTE I, LIÉGEOIS M, RULMONT A, et al. Synthesis and characterization of new inorganic polymeric compo-sites based on kaolin or white clay and on ground-granulated blast furnace slag[J]. Journal of Materials Research,2003,18(11):2571-2579. doi: 10.1557/JMR.2003.0360 [31] TCHAKOUTÉ H K, RÜSCHER C H, KAMSEU E, et al. The influence of gibbsite in kaolin and the formation of berlinite on the properties of metakaolin-phosphate-based geopolymer cements[J]. Materials Chemistry and Physics,2017,199:280-288. doi: 10.1016/j.matchemphys.2017.07.020 [32] ÁLVAREZ-AYUSO E, QUEROL X, PLANA F, et al. Environmental, physical and structural characterisation of geopolymer matrixes synthesised from coal (co-)combustion fly ashes[J]. Journal of Hazardous Materials,2008,154(1):175-183. [33] ZULKIFLY K, CHENG Y H, YUN M L, et al. Effect of phosphate addition on room-temperature-cured fly ash-metakaolin blend geopolymers[J]. Construction and Building Materials,2021,270:121486-121499. doi: 10.1016/j.conbuildmat.2020.121486 [34] 李浩, 王洪江. 复合外加剂对充填浆体固化前后性能的影响规律[J]. 复合材料学报, 2022, 39(8):3940-3949. doi: 10.13801/j.cnki.fhclxb.20210902.003LI Hao, WANG Hongjiang. Influence law of compound admixture on the mechanical properties of filling slurry before and after curing[J]. Acta Materiae Compositae Sinica,2022,39(8):3940-3949(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210902.003 [35] WANG A, LIU H, HAO X, et al. Geopolymer synthesis using garnet tailings from molybdenum mines[J]. Minerals,2019,9:48-60. [36] ARAVIND N, NAGAJOTHI S, ELAVENIL S. Machine learning model for predicting the crack detection and pattern recognition of geopolymer concrete beams[J]. Construction and Building Materials,2021,297:123785. doi: 10.1016/j.conbuildmat.2021.123785 [37] BONG S H, NEMATOLLAHI B, XIA M, et al. Properties of additively manufactured geopolymer incorporating mineral wollastonite microfibers[J]. Construction and Building Materials,2022,331:127282. doi: 10.1016/j.conbuildmat.2022.127282 [38] SASANO H, MARUYAMA I. Mechanism of drying-induced change in the physical properties of concrete: A mesoscale simulation study[J]. Cement and Concrete Research,2021,143:106401. doi: 10.1016/j.cemconres.2021.106401 [39] MARUYAMA I, SAKAMOTO N, MATSUI K, et al. Microstructural changes in white portland cement paste under the first drying process evaluated by WAXS, SAXS, and USAXS[J]. Cement and Concrete Research,2017,91:24-32. doi: 10.1016/j.cemconres.2016.10.002 [40] ZHU F L, CHEN M, FENG Q Q. Water distribution within wetted porous fabric exposed to a thermal radiation characterized by low-field nuclear magnetic resonance[J]. Heat and Mass Transfer,2019,55(4):1239-1253. doi: 10.1007/s00231-018-2463-7 [41] KAZE C R, TCHAKOUTE H K, MBAKOP T T, et al. Synthesis and properties of inorganic polymers (geopolymers) derived from cameroon-meta-halloysite[J]. Ceramics International,2018,44(15):18499-18508. doi: 10.1016/j.ceramint.2018.07.070 [42] RIBAS R G, CAMPOS T M B, SCHATKOSKI V M, et al. α-wollastonite crystallization at low temperature[J]. Ceramics International,2020,46(5):6575-6580. doi: 10.1016/j.ceramint.2019.11.143 [43] WANG J, JIN L, ZHOU Y, et al. Effect of Ca(NO3)2 addition in coal on properties of activated carbon for methane decomposition to hydrogen[J]. Fuel Processing Technology,2018,176:85-90. doi: 10.1016/j.fuproc.2018.03.012 [44] XIE J, WANG J, RAO R, et al. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate[J]. Composites Part B: Engineering,2019,164:179-190. doi: 10.1016/j.compositesb.2018.11.067 [45] 崔潮, 肖斌, 张建仁, 等. 偏高岭土-矿渣基地聚物与花岗岩骨料界面的分布特性及影响因素[J]. 复合材料学报, 2017, 34(11):2605-2613.CUI Chao, XIAO Bin, ZHANG Jianren, et al. Distribution and factors of interfacial transition zone between metakaolin-slag-based geopolymer and granite aggregate[J]. Acta Materiae Compositae Sinica,2017,34(11):2605-2613(in Chinese). -

下载:

下载: