Coal tar pitch modification of the SiO interface enhances the cycling stability of lithium-ion batteries

-

摘要:

煤焦油沥青具有高碳含量、可调控性和经济性等优点,在制备碳材料和碳复合材料中具有广泛的应用前景。采用沥青对SiO界面改性是抑制SiO自身膨胀、提升首次库伦效率和循环稳定性的有效策略。为改善沥青与基体材料间的结合性能,本文采用添加黏结剂的方式制备负极材料。首先,通过空气交联低温条件下制备高软化点、高结焦值的改性沥青。以聚乙烯吡咯烷酮(PVP)为黏结剂,浸润结合SiO和改性沥青,制备得到前驱体(SiO@PVP@pitch)。通过原位聚合,将改性沥青转化为中间相沥青,然后高温炭化得到SiO/C复合材料,使碳涂层有一定的机械强度又具备导电性。偏光显微镜结果表明碳涂层良好的流线型结构,纤维更加细腻。高分辨透射电子显微镜(HRTEM)结果表明,SiO表面存在厚度约为90~100 nm的含有石墨晶格的碳包覆层。SiO和改性沥青按照5∶3质量比在400℃和900℃的温度条件下聚合和炭化,复合材料表现出优异的电化学性能,在0.5 A/g电流密度下具有550 mA·h/g的高比容量,可逆比容量660 mA·h/g,200次循环后比容量保持率为83.33%,在1.5 A/g电流密度下的比容量为472.8 mA·h/g。电化学阻抗谱(EIS)结果也证明了碳包覆层可以有效提高复合材料的导电性,从而增强SiO电极的循环稳定性。

Abstract:Coal tar pitch has the advantages of high carbon content, controllability and economy, and broad application prospects in preparing carbon materials and carbon composites. Using pitch to modify the interface of silicon monoxide is an effective strategy to inhibit the expansion of silicon monoxide itself and improve the first coulomb efficiency and cycle stability. To improve the bonding performance between pitch and matrix materials, this study prepared anode materials by adding binders. Firstly, we prepared a modified pitch with a high softening point, high coking value, and good rheology by air crosslinking at low temperatures. The precursor (SiO@PVP@pitch) was prepared, using polyvinylpyrrolidone (PVP) as a binder and infiltrating combined with silicon monoxide and modified pitch. Through in-situ polymerization, the modified pitch is converted into mesophase pitch and then carbonized at high temperature to obtain SiO/C composites, so that the carbon coating has certain mechanical strength and electrical conductivity. The results of the polarizing microscope show that the carbon coating has a good streamlined structure and the fiber is more delicate. High-resolution transmission electron microscopy (HRTEM) results show that there is a carbon coating layer containing graphite lattice with a thickness of about 90-100 nm on the surface of SiO. The synthesized SiO/C-5∶3-4 h composites showed excellent performance. It has a high specific capacity of 550 mA·h/g at 0.5 A/g, a reversible capacity of 660 mA·h/g, and a capacity retention rate of 83.33% after 200 cycles. The capacity is 472.8 mA·h/g at 1.5 A/g. Electrochemical impedance spectroscopy (EIS) results also prove that the carbon coating layer can effectively improve the conductivity of the composite material, thereby enhancing the cycle stability of the SiO electrode.

-

Keywords:

- anode /

- core-shell structure /

- mesophase pitch /

- carbon coating /

- lithium-ion battery

-

1991年,索尼开发并商业化了第一款采用LiCoO2作为正极材料和石墨炭作为负极的锂离子电池(LIBs)[1-2]。如今,作为电动和混合动力汽车(EVs和HEVs)的动力而言,商业石墨炭由于其较低的理论比容量(372 mA·h/g),确实限制了锂离子电池的能量密度[3-4]。因此研究和开发具有更高能量密度和更高循环稳定性的LIBs成为当前重要课题。

一氧化硅(SiO)具有显著高的理论比容量(

2400 mA·h/g)和低的充放电电位,因此被认为是下一代LIBs最有潜力的负极候选材料之一。但是,SiO颗粒在电化学循环过程中存在巨大的体积变化(接近初始体积的200%),并且其本身电导率低,限制了活性物质在快速充电和放电过程中的高倍率的电化学性能,导致倍率性能差,从而阻碍了SiO基材料在LIBs中的商业化使用[5]。对于改进SiO,提出了许多策略,例如缩小尺寸、构建多孔结构和核壳结构。通过将硅与不同的碳基体结合构建新的复合结构是解决硅基材料自身缺陷的有效方式之一。核壳结构可以吸收机械应力并保持结构的完整性,材料中的孔隙结构提供了容纳SiO机械应变的空间[6-9]。许多研究表明,碳材料不仅可以提高复合材料的导电性,还可以适应硅在Li+插入/脱嵌过程中的体积变化。此外,碳涂层还可以避免SiO的团聚和固液电解质界面(SEI)膜的持续生长。煤焦油沥青具有高碳含量、可调控性和经济性等优点,使得它在制备碳基材料和其他碳基复合材料中具有广泛的应用前景。目前有许多类型的聚合物被用作硅碳复合材料的碳源,例如聚丙烯腈(PAN)[10-11]、聚苯乙烯(PS)[12]、柠檬酸和金属有机框架材料(MOFs)[13-17]。然而,某些聚合物的性质并不理想,例如热稳定性差、氧化稳定性差、机械强度低和电导率差,限制了它们在某些领域的应用[18]。由煤焦油沥青调控的中间相沥青具有来源广泛、价格低廉、碳氢比高等优点[19-20],已成为制备高性能Si/C复合材料的良好碳源。此外,中间相沥青炭化之后碳的内部石墨化程度高,具有高结晶度和高残碳率,具备良好的导电性,并且,高残碳率的沥青在SiO表面能够形成稳定的SEI膜,减少副反应的发生[20]。然而,中间相沥青软化点普遍高、流变性能差、次生喹啉不溶物(QI)含量高,不能与基质很好地结合,容易出现剥离和脱落等问题,影响了涂层的稳定性。聚乙烯吡咯烷酮(PVP)室温下颗粒表现出的一定黏性[21-22],可以来解决中间相沥青与基质结合能力差、容易造成碳涂层与基质分离的问题。

本文采用原位聚合方法,首先,使用空气交联法低温条件下制备了高软化点、高结焦值、良好的流变性改性沥青。PVP作为黏结剂,渗透和结合硅基材料和碳材料制备前驱体(SiO@PVP@pitch)。然后通过原位聚合,将部分改性沥青转化为中间相沥青,再通过高温炭化得到SiO/C复合材料。沥青炭化后可以提供足够的机械强度,来克服SiO所带来的体积变化,既保证了碳涂层有一定的机械强度又具备导电性。本文中使用煤焦油沥青作为碳源,制备SiO/C复合材料,工艺简单,易于操作,以此改进负极材料的循环稳定性和倍率性能。

1. 实验材料及方法

1.1 原材料

原料煤焦油沥青来自山西某企业。聚乙烯吡咯烷酮(PVP,分子量为

18000 ,热分解温度约为600℃)购自MREDA公司。SiO纳米颗粒(约500 nm)购自中国南宫伯乐金属材料有限公司。1.2 SiO/C复合材料制备

1.2.1 改性沥青的制备、元素分析和特性分析

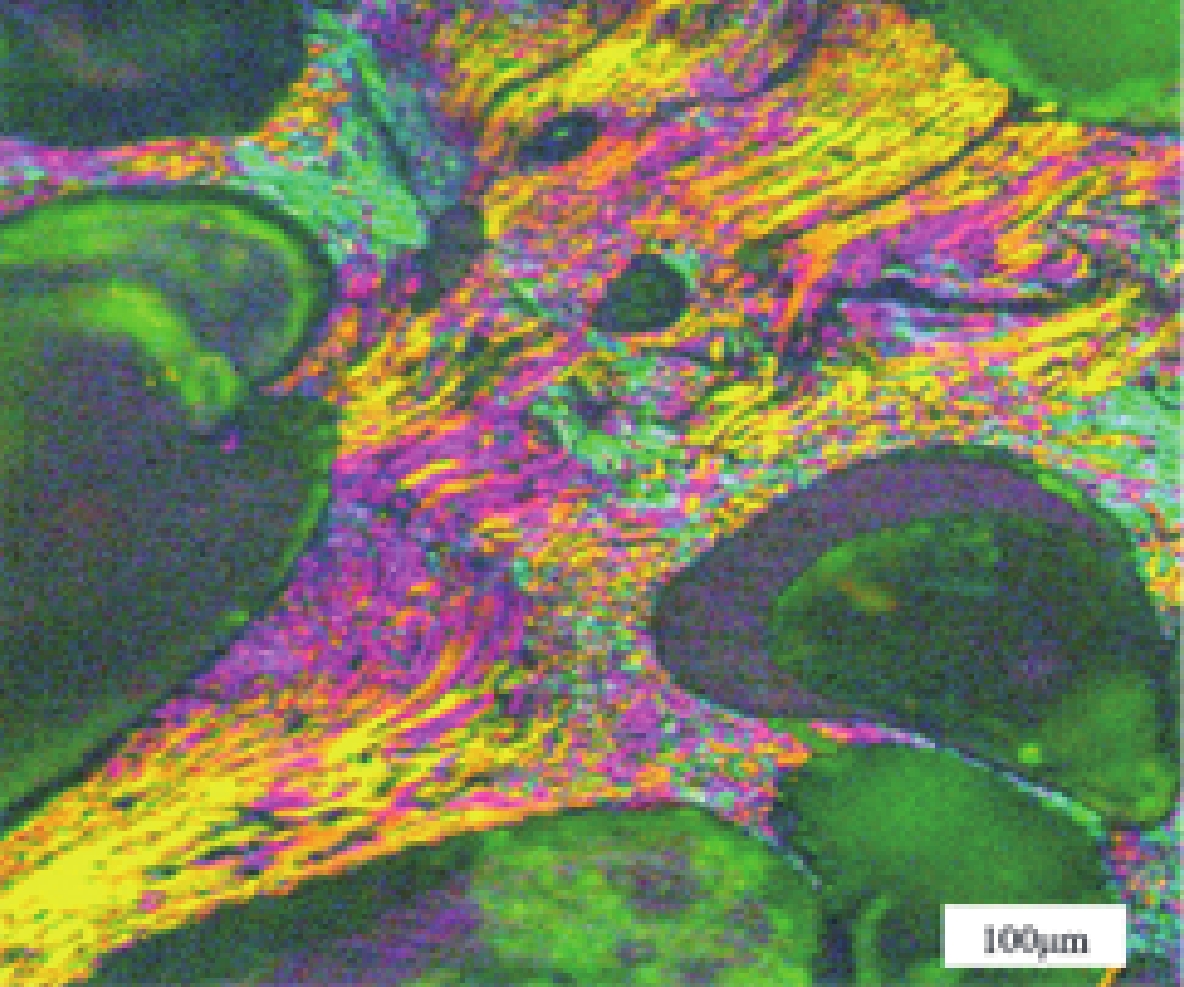

取50 g煤焦油沥青,放入不锈钢高压反应釜(上海申釜,耐腐蚀型)中。阶段升温,分为25~100℃、100~290℃和290~320℃ 3个阶段,并在320℃保温10 h。空气气氛下1 L/min进行吹扫。得到了软化点(Softening point) 230~240℃、结焦值(Coking value) 80%、QI不溶物含量为13%的高软化点、高结焦值、好的流变性的改性沥青,具体制备条件如表1所示,改性沥青的偏光显微镜图像如图1所示。改性沥青的元素分析和特性分析列于表2,组成分析由自制索式抽提器测得,元素分析由有机元素分析仪(EA,美国 Leeman,EA3000)测得。

表 1 改性沥青的制备条件Table 1. Preparation conditions of modified pitchAir purge air volume/(L·min−1) Soaking time/h Heating rate of different temperature stages/(℃·min−1) 25-100℃ 100-290℃ 290-320℃ 1 10 5 3 1 表 2 原料沥青与改性煤沥青的特性和元素分析对比Table 2. Characteristics and elemental analysis comparison table of raw pitch and modified coal tar pitchSP/℃ CV/% Pitch analysis/% Elementary analysis/at% HS HI-TS TI-QS QI N C H S O Pitch 31 32 30.98 53.03 18.55 0.031 1.145 92.474 4.979 0.356 1.046 Modified pitch 240 80 10.77 12.37 63.85 13.000 1.210 92.671 4.303 0.145 2.040 Notes: (1) Organic element analysis was based on air drying, and O content was calculated by subtraction method; (2) Softening point (SP) was measured by thermal mechanical analyzer; (3) Coking value (CV) was determined by GB/T 8727—2008[23] determination method of the coking value of coal tar pitch products; (4) HS and HI-TS were measured by soxhlet extraction, where HS is n-hexane soluble, HI-TS is n-hexane insoluble-toluene soluble; (5) TI-QS is toluene insoluble-quinoline soluble, its content is the percentage minus HS, HI-TS, QI content; (6) QI content is determined by the national standard GB/T 2293—2019[24] quinoline insoluble (QI) test method for coking pitch products. 1.2.2 SiO/C复合材料的合成

第一步,制备SiO@PVP@pitch前驱体,将SiO (500 nm)和PVP按照2∶1质量比加入到20 mL四氢呋喃中,剧烈搅拌3 h,然后SiO∶Pitch按照5∶3 (质量比)加入改性沥青。在25℃下搅拌1 h,超声(100 W) 3 h,迅速转移到水浴锅中,80℃下搅拌挥发有机溶剂,真空干燥箱60℃恒温12 h,得到前驱体SiO@PVP@pitch。第二步,在N2气氛下400℃聚合4 h快速升温到900℃下煅烧3 h,使改性沥青转变为中间相沥青,PVP分解生成含氮化合物,最后得到了SiO/C复合材料,得到的复合材料命名为SiO/C-x-y,其中x代表炭化前SiO∶Pitch的配比,y代表400℃下聚合的时间。具体SiO和C的百分比及炭化条件如表3所示,总的制备流程图如图2所示。

表 3 SiO/C复合材料中SiO和Pitch的质量比及炭化条件Table 3. Mass ration of SiO and pitch in SiO/C composites and carbonization conditionsComposites material Pitch:SiO mass ration SiO content/wt% Pitch content/wt% Polymerization temperature/℃ SiO/C-5∶3-4 h 5∶3 37.5 62.5 400℃-4 h/900℃-3 h SiO/C-5∶2-4 h 5∶2 28.5 71.5 400℃-4 h/900℃-3 h SiO/C-5∶4-4 h 5∶4 44.4 55.56 400℃-4 h/900℃-3 h SiO/C-5∶3-0 h 5∶3 37.5 62.5 400℃-900℃-3 h 1.3 材料表征

采用偏光显微镜(德国LEICA公司,DM2700型号)观察了复合材料碳涂层的偏光显微图像。通过透射电子显微镜(TEM,日本JEOL公司,JEM-F200型号)对复合材料的微观结构进行了表征分析。通过扫描电子显微镜(SEM,德国ZEISS公司,GeminiSEM 300型号)对复合材料的微观结构进行了表征。分析采用2θ为10°~80°的X射线衍射仪(日本Rigaku公司,SmartlabSE型号)测试产物的晶体结构和物相。采用473 nm激光拉曼光谱仪(日本Horiba公司,LabRAM HR Evolution型号)在

1000 ~2000 cm−1波数范围内研究了不同复合材料的石墨化程度。在空气气氛中,以10℃/min的升温速率,通过热重分析仪(TGA,美国TA公司)从35℃到800℃监测了不同复合材料中的C的含量和SiO的含量。通过XPS (Thermo Scientific K-Alpha)确定了样品中元素的化学价态。1.4 电化学测试

将复合材料组装在CR2032扣式半电池中进行电化学测试。首先,将活性物质与海藻酸钠(SA)和乙炔炭黑按质量比8∶1∶1混合。然后将混合物在氮气氛围下搅拌12 h,形成均匀的浆料。将浆料浇铸在铜箔集流体上,并进一步在真空条件下以100℃干燥12 h。将干燥后的电极裁剪为直径为12 mm的圆片,然后将极片组装成纽扣半电池,在氩气的手套箱(TONGRUN(2GBS),蓝电)中,对称电极是锂片,Celgard 2500作为隔膜。电解液为LiPF6 (1 mol/L)和碳酸乙烯酯、碳酸二甲酯和氟代碳酸乙烯酯(体积比为1∶1∶1)的混合液。采用LAND-Mon电池测试系统(武汉蓝电),在0.01~2.00 V电压窗口,以0.5 A/g的恒定电流密度进行充放电测试。在不同电流密度0.1、0.2、0.5、1、1.5、0.1 A/g下进行倍率性能测试。采用CHI660F电化学工作站(上海辰华)记录循环伏安曲线(CV)和电化学阻抗谱(EIS)。在0.005~1.8 V的电压范围内,以0.1 mV·s−1的扫描速率进行CV测试。在100 kHz~0.01 Hz的频率范围内,以10 mV·s−1的幅度进行EIS测试。

2. 结果与讨论

2.1 硅基碳复合材料的微观结构分析

2.1.1 复合材料晶相谱图分析和石墨化度分析

图3展示了复合材料的XRD图谱和拉曼光谱图。SiO/C复合材料的XRD图谱如图3(a)所示,在2θ=20°~30°的宽峰,对应于碳的无定形结构。SiO/C-5∶3-4 h、SiO/C-5∶2-4 h、SiO/C-5∶4-4 h和SiO/C-5∶3-0 h在约28.4°、47.3°和56.1°处的弱峰分别与(111)、(220)、(311)晶面相关,与Si的晶相衍射峰互相关联[25-30]。XRD图谱中Si的晶体衍射峰是由于SiO在900℃以上热解时发生歧化反应,SiO与均匀镶嵌在非晶SiOx基体中的Si纳米颗粒形成了独特的内部结构,SiO的这种结构重排主要是由于SiO在高温下的热稳定性差。图3(b)是聚合炭化得到的SiO/C-5∶3-4 h、SiO/C-5∶2-4 h、SiO/C-5∶4-4 h和SiO/C-5∶3-0 h复合材料的拉曼光谱图。

1364 cm−1、1592 cm−1处的特征峰对应于无序型碳带(D)和石墨烯带(G),强度比(ID/IG)可用于描述碳的石墨化程度[31-33]。SiO/C-5∶3-4 h、SiO/C-5∶2-4 h、SiO/C-5∶4-4 h和SiO/C-5∶3-0 h的ID/IG比值分别为0.74、0.77、0.78和0.94,可以看出,SiO/C-5∶3-4 h、SiO/C-5∶2-4 h、SiO/C-5∶4-4 h复合材料拉曼值相似,这可能表明相同工艺下得到的复合材料,它们具有相似的化学成分或分子结构。与SiO/C-5∶3-0 h相比,相同配比条件下聚合时间的增加,聚合度增加,部分改性沥青转为中间相沥青,因此SiO/C-5∶3-4 h、SiO/C-5∶2-4 h和SiO/C-5∶4-4 h复合材料石墨结构的相对比例更高,导致碳的石墨化程度高于SiO/C-5∶3-0 h。2.1.2 复合材料光学结构分析

SiO/C-5∶3-4 h、SiO/C-5∶2-4 h、SiO/C-5∶4-4 h复合材料聚合工艺及碳化条件相同,拉曼结果证明其有相似的分子结构,图4中主要展示了SiO/C-5∶3-0 h和SiO/C-5∶3-4 h复合材料偏光显微镜图像,可以看出聚合条件的不同,沥青在经过相同温度炭化形成的沥青碳相差较大。在图4(a)中,可以观察到SiO/C-5∶3-0 h复合材料的碳涂层在同色区域比较复杂,同时具有细流线性和马赛克型织构。图4(b)中SiO/C-5∶3-4 h呈现出明显的流线型结构,流线更加清晰,定向排列规则,各向异性显著。两种复合材料存在部分马赛克型结构,是由于沥青聚合分为3个基本阶段,小球的产生、小球生长为大球、大球体相互碰撞形成体相中间相,SiO/C-5∶3-0 h复合材料在生成中间相后没有聚合时间的停留然后快速炭化,使沥青快速固化生成半焦,存在大量的马赛克结构,SiO/C-5∶3-4 h复合材料由于聚合时间的增加,体相中间相在氮气气氛下吹扫形成流线型结构,纤维变细腻,长度增加,取向性增强。通过控制聚合反应,沥青炭化可以形成各向异性的流线型结构的沥青碳,与上述测试结果一致。SiO/C-5∶3-4 h复合材料中的碳具有更多的取向结构和良好的结晶度,使得材料拥有更低的电阻 [33-34]。

2.1.3 SiO/C-5∶3-4 h复合材料的微观形貌和结构分析

图5是采用高分辨透射电镜(HRTEM)拍摄的SiO/C-5∶3-4 h复合材料的微观结构,从图5(a)和图5(b)中可以看出,SiO粒径大约为500 nm,SiO为无定形颗粒,表面存在致密的碳涂层,说明沥青成功包覆SiO,炭化后表现出紧密的碳涂层,在图5(c)中出现了排列一致的石墨晶格结构,石墨晶格的出现表明炭层存在一定的类石墨结构,类石墨层状结构可以提供更多的储锂位点,其导电性、热稳定性好。从图5(d)和图5(e)中可以看出,碳涂层厚度在90~100 nm之间,碳涂层厚度可以良好地吸收SiO材料自身的体积膨胀,防止电极材料在循环过程中粉碎,从而提升电极材料的电化学性能。图5(f)观察到双碳层,一部分来自PVP热分解生成的含氮的碳氧化物,另一部分来自沥青热解的碳,图5(g)的TEM-mapping结果验证了复合材料存在Si、O、C和N元素,C元素分布在外层对应图5(a)和图5(b),表明碳涂层的成功引入,N元素主要分布在SiO与碳涂层连接处,表明PVP作为黏结剂成功将沥青包覆SiO,少量的N元素分布在碳层中,主要是来自改性沥青自身存在的N,以上结果说明,沥青对SiO颗粒进行了有效的包覆。

![]() 图 5 SiO/C-5∶3-4 h的高分辨透射电镜(HRTEM)图像:((a)~(c))不同放大倍数下的HRTEM图像;((d)~(f)) 碳涂层的厚度;(g) TEM-mapping图像Figure 5. High-resolution transmission electron microscopy (HRTEM) images of SiO/C-5∶3-4 h: ((a)-(c)) HRTEM images at different magnifications; ((d)-(f)) Thickness of the carbon coating; (g) TEM-mapping images

图 5 SiO/C-5∶3-4 h的高分辨透射电镜(HRTEM)图像:((a)~(c))不同放大倍数下的HRTEM图像;((d)~(f)) 碳涂层的厚度;(g) TEM-mapping图像Figure 5. High-resolution transmission electron microscopy (HRTEM) images of SiO/C-5∶3-4 h: ((a)-(c)) HRTEM images at different magnifications; ((d)-(f)) Thickness of the carbon coating; (g) TEM-mapping images图6显示了SiO/C-5∶3-4 h复合材料的元素化学价态,XPS谱图提供了有关复合材料中元素的组成和含量信息。图6(a)观察到的峰对应于元素Si、O、C和N。图6(b)的O1s谱图在532.9 eV处有一个主峰,对应于Si—O键。说明复合材料检测的O大部分存在于SiO中。图6(c)展示了高分辨N1s谱,可以分为3个独立的峰,分别属于吡啶N (398.08 eV) (标记为N1)、吡咯N (400.47 eV) (标记为N2)和吡啶N-氧化物(403.98 eV) (标记为N3),SiO/C-5∶3-4 h复合材料中N含量为1.9at%,沥青中N 的含量为1.21at%,可能是黏结剂PVP的加入在高温分解过程中分解为含氮化物,导致整体的N含量增高,其中吡啶氮占34.23%、吡咯氮占49.53%,吡啶N-氧化物占16.24%[35-37]。吡啶N-氧化物可能主要来自于PVP的热分解生成。图6(d)为复合材料的高分辨C1s谱。C1s的光谱中心分别为284.18、285.78、286.88、 288.28、289.98 eV。在C1s光谱中,284.18 eV处的主峰与石墨碳(sp2碳)相关,这表明复合材料中的大部分C原子排列在共轭的蜂窝状晶格中。在285.78和286.88 eV处的小峰代表了C—N键的不同键合结构,分别对应于N—sp2C和N—sp3C键,测试结果与N1s谱图相对应。碳材料中氮官能团的存在可以提供电化学活性位点,有助于增加电子转移和离子扩散,进一步提高倍率充放电性能。C1s峰位于288.28 eV,属于O—C=O键。该峰归因于物理吸附氧[38-39],C1s峰位于298.98 eV,属于主峰电子跃迁形成的Π-Π*卫星峰。图6(e)展示了Si2p的高分辨XPS谱,出现4个不同的峰,分别对应于Si的不同氧化态,分别为Si0、Si2+、Si3+和Si4+。其中,Si4+和Si3+是Si2p的XPS结果中观察到的主要两个峰。Si3+作为主峰说明部分SiO中发生了Si和SiOx的歧化反应,处于中间价态,但歧化反应未反应完全,因此Si0的峰较弱。

2.2 复合材料的热稳定性分析

图7展示了SiO/C复合材料和SiO的TGA结果。在高温下,SiO会发生歧化反应,分解成SiO2和Si,由于在空气气氛下燃烧,可能氧气与Si发生反应生成SiOx,或者在炭化条件下由于SiO反应不完全,在测试过程中与氧气反应,导致SiOx质量分数增加4.684wt%。另一方面,SiO/C-5∶3-4 h、SiO/C-5∶2-4 h、SiO/C-5∶4-4 h和SiO/C-5∶3-0 h复合材料的质量分数分别下降了56.58wt%、75.12wt%、53.68wt%和52.156wt%。相比于初始碳含量来说,含碳量减少,主要原因为在炭化过程中沥青中的轻组分逸出,导致整体碳含量呈现下降趋势,与SiO/C-5∶3-4 h和SiO/C-5∶3-0 h相比,随着聚合时间的增加,沥青轻组分逐渐减少,开始生成大分子化合物,QI和甲苯不溶-喹啉可溶物(TI-QS)的含量增加,导致沥青残碳率变高,残碳率越高,可以减少SEI膜副反应的发生。

2.3 复合材料的电化学性能分析

2.3.1 复合材料循环伏安图分析和容量电压图分析

图8展示了样品组装到CR2032纽扣电池中,研究其作为LIBs的电化学性能。图8(a)显示了扫描速率0.1 mV·s−1 (0.005~1.8 V)时SiO的循环伏安曲线。在第一个周期中,0.2~0.6 V和0.05~0.2 V左右的宽峰,可以归因于Si锂化和Li2SiO3不可逆锂化过程。在阳极扫描过程中,在0.5 V左右的峰值对应于非晶态LixSi的脱离。在接下来的循环中,锂化和脱锂峰值达到较低的电位,这表明在第一次循环中SiO转化为Si和Li2SiO3时,Si的锂化和脱锂行为是主导过程。可以看到,在第二周期的阳极峰最强,表明激活过程,在第三周期,其振幅减弱,表明达到稳定状态或可能发生退化,原因是原始SiO在循环中是不稳定的。图8(b)显示SiO/C-5∶3-4 h复合材料的CV变化曲线,在第一圈放电过程中,可以观察到在0.5~1.5 V之间出现了一个宽峰,表明有SEI膜形成,在0.2 V左右出现一个阴极峰,主要是晶相硅颗粒的锂化而形成LixSi。从CV曲线也可以看出,在充电过程中出现了两个阳极峰位于0.3 V和0.5 V左右,这两个阳极峰与非晶态LixSi相变中非晶态Si的特征峰有关,在接下来的循环中,由于不可逆反应的发生,阴极峰移至0.2 V。此外,循环过程中峰值强度的增加可以归因于SiO/C-5∶3-4 h电极的逐渐活化过程。SiO/C-5∶3-4 h、SiO/C-5∶2-4 h、SiO/C-5∶4-4 h、SiO/C-5∶3-0 h和SiO的首次库伦效率分别为71.84%、71.81%、72.13%、71.25%和44%。这些数值表明充电/放电的首次效率明显高于SiO。SiO/C-5∶3-4 h复合材料和SiO的循环放电电压曲线如图8(c)和图8(d)所示。SiO/C-5∶3-4 h复合材料的库伦效率从第3次循环到200次循环效率保持在99%以上,与SiO复合材料的首次循环相比具有良好的可逆性。

![]() 图 8 复合材料电化学性能图:((a), (b)) SiO和SiO/C-5∶3-4 h复合材料的CV曲线(电压范围为0.005~1.8 V,扫描速率为0.1 mV·s−1);((c), (d)) SiO/C-5∶3-4 h复合材料和SiO在第1个、第2个、第3个、第100个和第200个循环的充放电电压曲线Figure 8. Electrochemical performance of composite material: ((a), (b)) CV curves of SiO and SiO/C-5∶3-4 h composite material (Voltage range is 0.005-1.8 V, and the scanning rate is 0.1 mV·s−1); ((c), (d)) Charge and discharge voltage curves of SiO/C-5∶3-4 h composites and SiO at the 1st, 2nd, 3rd, 100th and 200th cycles

图 8 复合材料电化学性能图:((a), (b)) SiO和SiO/C-5∶3-4 h复合材料的CV曲线(电压范围为0.005~1.8 V,扫描速率为0.1 mV·s−1);((c), (d)) SiO/C-5∶3-4 h复合材料和SiO在第1个、第2个、第3个、第100个和第200个循环的充放电电压曲线Figure 8. Electrochemical performance of composite material: ((a), (b)) CV curves of SiO and SiO/C-5∶3-4 h composite material (Voltage range is 0.005-1.8 V, and the scanning rate is 0.1 mV·s−1); ((c), (d)) Charge and discharge voltage curves of SiO/C-5∶3-4 h composites and SiO at the 1st, 2nd, 3rd, 100th and 200th cycles2.3.2 复合材料循环性能分析

图9(a)展示了SiO/C复合材料的循环性能及相应的库伦效率。放电比容量来自于碳层和SiO,在0.5 A/g的电流密度下,SiO/C-5∶3-4 h、SiO/C-5∶2-4 h、SiO/C-5∶4-4 h、SiO/C-5∶3-0 h复合材料、SiO和碳层的首次放电比容量分别为

1156.3 、1035 、1310 、1159 、2164 和415.2 mA·h/g。在循环性能方面,SiO/C-5∶3-4 h、SiO/C-5∶2-4 h、SiO/C-5∶4-4 h、SiO/C-5∶3-0 h复合材料和SiO在100次循环后的放电比容量分别626.8、550.7、648.3、598.8和5 mA·h/g,比容量保有率分别为94.96%、91.2%、92%、88.98%和0%。即使在100次循环后,SiO/C复合材料仍然表现出相当大的比容量保持率,这主要归因于碳涂层的存在,碳包覆显著增强了SiO电极的导电性,并作为体积膨胀应力的缓冲层,从而在锂化和脱锂的过程中碳涂层保护电极的完整性。从图中可以观察到SiO/C复合材料前几圈出现容量骤降,主要是由于在最初的循环过程中,复合材料可能会与电解质发生反应,形成固态电解质界面层。这种界面层可能会限制锂离子的扩散和嵌入,可能导致电池比容量的急剧下降。另外,SiO/C-5∶3-4 h复合材料随着聚合时间的增加,氮气吹扫对沥青轻质组分进行了脱除。这一过程沥青的相对分子质量增加,进而增强了沥青基碳的机械强度。因此,与纯SiO相比,SiO/C-5∶3-4 h表现出更好的循环性能和比容量保有率。图10展示了SiO/C-5∶3-4 h复合材料的长循环稳定性能,在第200次循环中的比容量为550 mA·h/g,对应于第4个循环的可逆容量的容量保有率为83.33%,其透射电镜碳涂层表现出的石墨微晶结构可以增强复合材料的循环稳定性,使得SiO/C-5∶3-4 h表现出更好的循环性能和比容量保有率。SiO/C-5∶2-4 h复合材料与SiO/C-5∶3-4 h复合材料相比,碳涂层的厚度会阻碍离子的迁移,从而可能影响复合材料的电化学性能。这可能导致比容量低,比容量保有率较低。SiO/C-5∶4-4 h复合材料中较高的SiO含量可能会导致碳涂层无法提供足够的机械强度,从而导致结构塌陷和更快的容量衰减。同样,对于SiO/C-5∶3-0 h,聚合时间的差异可能导致碳涂层在炭化后的机械强度和结构不同,这也可能会随着循环次数的增加,循环稳定性存在差异。2.3.3 复合材料倍率性能分析

在不同电流密度下测试的SiO/C复合材料的倍率性能,如图9(b)所示,电流密度为1.5 A/g。SiO/C-5∶3-4 h、SiO/C-5∶2-4 h、SiO/C-5∶4-4 h、SiO/C-5∶3-0 h复合材料和SiO的比容量分别为472.8、403、551.4、384.2和5 mA·h/g。在0.1 A/g的电流密度下,复合材料比容量分别恢复到769.8、662、790和827 mA·h/g。而SiO由于自身的体积变化使得在循环过程中结构被破坏,比容量衰减严重,这表明SiO/C-5∶3-4 h复合材料在高倍率下具有良好的电化学可逆性和结构完整性,具有较高的储能容量,表现出更好的电化学性能。这可能是由于SiO/C-5∶3-4 h复合材料成功引入碳包覆层,可以吸收来自于SiO自身的体积变化,碳包覆层的取向性和定向排列电阻率降低,聚合时间的增加,使得整体复合材料残碳率提高,可以减少SEI膜副反应的发生,其透射电镜碳涂层表现出的石墨微晶结构可以增强循环稳定性,使其能够在高倍率下高效存储和释放电荷,并保持较好的结构完整性[40-41]。

2.3.4 复合材料阻抗图分析

如图11(a)所示,电化学阻抗谱和等效电路进一步验证了碳包覆对复合材料导电性能的影响。奈奎斯特图表现出明显的特征,包括高频处的小截距、中频处的半圆和低频处的斜率。这些特征对应于阻抗的不同位置。高频下的小截距代表欧姆电阻(Rs),它与电解液的电阻和电极与电解液之间的接触电阻有关。中频下的半圆对应于电极-电解液界面的电荷转移电阻(Rct)。这种电阻受到电极材料的导电性和界面处发生的电化学反应动力学等因素的影响。低频下的斜率表示Warburg阻抗(W),与离子在电极材料内部的扩散有关。对角线的斜率提供了有关离子扩散性质的信息。通过分析阻抗谱和等效电路,可以深入了解复合材料的导电性和电化学行为[42]。复合材料的电极-电解液界面电阻Rct分别为99.31、119.4、106.4、157.3和326 Ω,SiO/C-5∶3-4 h与SiO/C-5∶2-4 h、SiO/C-5∶4-4 h和SiO/C-5∶3-0 h复合材料相比具有最小的Rct。这说明合适的SiO∶C比和炭化条件有助于界面的电荷转移,使得电极材料表现出良好的循环稳定性。SiO/C-5∶3-4 h和SiO/C-5∶3-0 h复合材料相比,SiO/C-5∶3-4 h复合材料碳涂层具有更多的取向结构和良好的结晶度,使得材料拥有更低的电阻率。从图11(b)和图11(c)可以看出,在循环后,碳层和碳层的取向结构使得复合电极的电导率得到了提高,并实现了快速的离子和电子转移。电阻明显降低。这是由于活性物质与电解质之间有足够的界面接触,使Li+在复合材料中能够快速地嵌入和脱嵌。EIS拟合结果与循环稳定性能结果一致。

![]() 图 11 奈奎斯特图和相应的等效电路模型EIS图谱:(a) SiO/C复合材料阻抗;(b) SiO循环前后阻抗;(c) SiO/C-5∶3-4 h循环前后阻抗Figure 11. Nyquist diagram and EIS diagram of the corresponding equivalent circuit model: (a) Impedance of SiO/C composites; (b) Impedance before and after SiO cycling; (c) Impedance before and after SiO/C-5∶3-4 h cyclingZ''—Imaginary part of impedance; Z'—Real part of impedance; Rs—Ohmic resistance; Rct—Charge transfer resistance; W—Warburg; CPE1—Parallel connection

图 11 奈奎斯特图和相应的等效电路模型EIS图谱:(a) SiO/C复合材料阻抗;(b) SiO循环前后阻抗;(c) SiO/C-5∶3-4 h循环前后阻抗Figure 11. Nyquist diagram and EIS diagram of the corresponding equivalent circuit model: (a) Impedance of SiO/C composites; (b) Impedance before and after SiO cycling; (c) Impedance before and after SiO/C-5∶3-4 h cyclingZ''—Imaginary part of impedance; Z'—Real part of impedance; Rs—Ohmic resistance; Rct—Charge transfer resistance; W—Warburg; CPE1—Parallel connection图12展示了SiO和SiO/C-5∶3-4 h复合材料循环前和200个循环后的电极的体积变化,从图12(a)和图12(b)中可以看出原始SiO电极的巨大体积变化(约184%从26 μm增加到74 μm),从图12(c)和图12(d)中可以看出SiO/C-5∶3-4 h复合材料电极的体积变化,从16 μm增加到23 μm左右,体积膨胀约44%,在SiO/C-5∶3-4 h复合材料当中,碳层很好地抑制了SiO的体积膨胀,吸收了体积变化带来的机械应力,形成稳定的SEI膜,使得在循环过程中表现出良好的电化学性能。

![]() 图 12 SiO和SiO/C-5∶3-4 h复合材料循环前和200个循环后电极的体积变化的SEM图像:(a) SiO循环前;(b) SiO循环后;(c) SiO/C-5∶3-4 h循环前;(d) SiO/C-5∶3-4 h循环后Figure 12. SEM images of volume change of SiO and SiO/C-5∶3-4 h composite electrode before and after 200 cycles: (a) Before SiO cycle; (b) After SiO cycle; (c) Before SiO/C-5∶3-4 h cycle; (d) After SiO/C-5∶3-4 h cycle

图 12 SiO和SiO/C-5∶3-4 h复合材料循环前和200个循环后电极的体积变化的SEM图像:(a) SiO循环前;(b) SiO循环后;(c) SiO/C-5∶3-4 h循环前;(d) SiO/C-5∶3-4 h循环后Figure 12. SEM images of volume change of SiO and SiO/C-5∶3-4 h composite electrode before and after 200 cycles: (a) Before SiO cycle; (b) After SiO cycle; (c) Before SiO/C-5∶3-4 h cycle; (d) After SiO/C-5∶3-4 h cycle这些结果表明,中间相沥青对SiO的界面改性可以有效地稳定电极与电解液之间的固-液界面,低的电阻极大地改善了SiO/C复合材料的电化学性能。

3. 结 论

综上,采用了一种简单高效的方法,以聚乙烯吡咯烷酮(PVP)为黏结剂,将一氧化硅和碳材料浸润结合,然后通过原位聚合和高温炭化成功合成了SiO/C复合材料。

(1)当SiO∶Pitch质量比为5∶3时,从透射电镜可以观察到,SiO颗粒表面包覆了一层厚度约为90~100 nm的碳涂层,可以容纳吸收电极材料的体积膨胀,并提高电极材料的导电性。与SiO/C-5∶3-0 h相比,400℃下的聚合时间增加,可以有效地提高沥青的残碳率,形成致密的碳涂层和稳定的固液电解质界面(SEI)膜,减少副反应发生。

(2)聚合条件为4 h,碳层具有更均匀的流线型结构,纤维变细腻,长度增加,取向性增强,从而电阻率降低。以PVP作为黏结剂,可以更好地使得沥青在SiO表面均匀包覆,在SiO∶Pitch质量比为5∶3、400℃ 聚合时间为4 h和900℃炭化3 h条件下制备的SiO/C-5∶3-4 h复合材料表现出优异的电化学性能,在0.5 A/g的电流密度下循环200次后比容量达到550 mA·h/g。电化学阻抗谱(EIS)结果也证实了碳涂层和碳涂层的取向结构有效降低了SiO的电阻,从而提高电极材料的电化学性能。

-

图 5 SiO/C-5∶3-4 h的高分辨透射电镜(HRTEM)图像:((a)~(c))不同放大倍数下的HRTEM图像;((d)~(f)) 碳涂层的厚度;(g) TEM-mapping图像

Figure 5. High-resolution transmission electron microscopy (HRTEM) images of SiO/C-5∶3-4 h: ((a)-(c)) HRTEM images at different magnifications; ((d)-(f)) Thickness of the carbon coating; (g) TEM-mapping images

图 8 复合材料电化学性能图:((a), (b)) SiO和SiO/C-5∶3-4 h复合材料的CV曲线(电压范围为0.005~1.8 V,扫描速率为0.1 mV·s−1);((c), (d)) SiO/C-5∶3-4 h复合材料和SiO在第1个、第2个、第3个、第100个和第200个循环的充放电电压曲线

Figure 8. Electrochemical performance of composite material: ((a), (b)) CV curves of SiO and SiO/C-5∶3-4 h composite material (Voltage range is 0.005-1.8 V, and the scanning rate is 0.1 mV·s−1); ((c), (d)) Charge and discharge voltage curves of SiO/C-5∶3-4 h composites and SiO at the 1st, 2nd, 3rd, 100th and 200th cycles

图 11 奈奎斯特图和相应的等效电路模型EIS图谱:(a) SiO/C复合材料阻抗;(b) SiO循环前后阻抗;(c) SiO/C-5∶3-4 h循环前后阻抗

Figure 11. Nyquist diagram and EIS diagram of the corresponding equivalent circuit model: (a) Impedance of SiO/C composites; (b) Impedance before and after SiO cycling; (c) Impedance before and after SiO/C-5∶3-4 h cycling

Z''—Imaginary part of impedance; Z'—Real part of impedance; Rs—Ohmic resistance; Rct—Charge transfer resistance; W—Warburg; CPE1—Parallel connection

图 12 SiO和SiO/C-5∶3-4 h复合材料循环前和200个循环后电极的体积变化的SEM图像:(a) SiO循环前;(b) SiO循环后;(c) SiO/C-5∶3-4 h循环前;(d) SiO/C-5∶3-4 h循环后

Figure 12. SEM images of volume change of SiO and SiO/C-5∶3-4 h composite electrode before and after 200 cycles: (a) Before SiO cycle; (b) After SiO cycle; (c) Before SiO/C-5∶3-4 h cycle; (d) After SiO/C-5∶3-4 h cycle

表 1 改性沥青的制备条件

Table 1 Preparation conditions of modified pitch

Air purge air volume/(L·min−1) Soaking time/h Heating rate of different temperature stages/(℃·min−1) 25-100℃ 100-290℃ 290-320℃ 1 10 5 3 1 表 2 原料沥青与改性煤沥青的特性和元素分析对比

Table 2 Characteristics and elemental analysis comparison table of raw pitch and modified coal tar pitch

SP/℃ CV/% Pitch analysis/% Elementary analysis/at% HS HI-TS TI-QS QI N C H S O Pitch 31 32 30.98 53.03 18.55 0.031 1.145 92.474 4.979 0.356 1.046 Modified pitch 240 80 10.77 12.37 63.85 13.000 1.210 92.671 4.303 0.145 2.040 Notes: (1) Organic element analysis was based on air drying, and O content was calculated by subtraction method; (2) Softening point (SP) was measured by thermal mechanical analyzer; (3) Coking value (CV) was determined by GB/T 8727—2008[23] determination method of the coking value of coal tar pitch products; (4) HS and HI-TS were measured by soxhlet extraction, where HS is n-hexane soluble, HI-TS is n-hexane insoluble-toluene soluble; (5) TI-QS is toluene insoluble-quinoline soluble, its content is the percentage minus HS, HI-TS, QI content; (6) QI content is determined by the national standard GB/T 2293—2019[24] quinoline insoluble (QI) test method for coking pitch products. 表 3 SiO/C复合材料中SiO和Pitch的质量比及炭化条件

Table 3 Mass ration of SiO and pitch in SiO/C composites and carbonization conditions

Composites material Pitch:SiO mass ration SiO content/wt% Pitch content/wt% Polymerization temperature/℃ SiO/C-5∶3-4 h 5∶3 37.5 62.5 400℃-4 h/900℃-3 h SiO/C-5∶2-4 h 5∶2 28.5 71.5 400℃-4 h/900℃-3 h SiO/C-5∶4-4 h 5∶4 44.4 55.56 400℃-4 h/900℃-3 h SiO/C-5∶3-0 h 5∶3 37.5 62.5 400℃-900℃-3 h -

[1] ESCAMILLA-PÉREZ A M, AUDE R, SOPHIE G, et al. Pitch-based carbon/nano-silicon composite, an efficient anode for Li-ion batteries[J]. RSC Advances, 2019, 9(19): 10546-10553. DOI: 10.1039/C9RA00437H

[2] HUANG B, CHU B B, HUANG T, et al. Nitrogen-doped carbon-coating disproportionated SiO materials as long cycling stable anode for lithium-ion batteries[J]. Molecules, 2021, 26(6): 1536. DOI: 10.3390/molecules26061536

[3] SUN W H, SUN X G, PENG Q F, et al. Nano-MgO/AB decorated separator to suppress shuttle effect of lithium-sulfur battery[J]. Nanoscale Advances, 2019, 1(4): 1589-1597. DOI: 10.1039/C8NA00420J

[4] GUO C F, MAN J X, WANG D L. Nitrogen-doped carbon-coated SiO nanoparticles Co-modified with nitrogen-doped graphene as a superior anode material for lithium-ion batteries[J]. RSC Advances, 2014, 4(67): 35717-35725. DOI: 10.1039/C4RA06678B

[5] YU B C, YOON H, KIM J H, et al. A new approach to synthesis of porous SiO x anode for Li-ion batteries via chemical etching of Si crystallites[J]. Electrochimica Acta, 2014, 117: 426-430. DOI: 10.1016/j.electacta.2013.11.158

[6] YU B C, YOON H, PARK C M, et al. Reaction mechanism and enhancement of cyclability of SiO anodes by surface etching with NaOH for Li-ion batteries[J]. Journal of Materials Chemistry A, 2013, 1(15): 4820-4825.

[7] HWA Y, PARK C M, SOHN H J. Modified SiO as a high-performance anode for Li-ion batteries[J]. Journal of Power Sources, 2013, 222: 129-134.

[8] DOH C H, PARK C W, SHIN H M, et al. A new SiO/C anode composition for lithium-ion battery[J]. Journal of Power Sources, 2008, 179(1): 367-370. DOI: 10.1016/j.jpowsour.2007.12.074

[9] ZHANG X W, JI L W, TOPRAKCI O, et al. Electrospun nanofiber-based anodes, cathodes, and separators for advanced lithium-ion batteries[J]. Polymer Reviews, 2011, 51(3): 239-264.

[10] GUO J C, YANG Z C, ARCHER L A. Mesoporous silicon@carbon composites via nanoparticle-seeded dispersion polymerization and their application as lithium-ion battery anode materials[J]. Journal of Materials Chemistry A, 2013, 1(18): 5709-5714.

[11] JEONG J H, KIM K H, JUNG D W, et al. High-performance characteristics of silicon inverse opal synthesized by the simple magnesium reduction as anodes for lithium-ion batteries[J]. Journal of Power Sources, 2015, 300: 182-189. DOI: 10.1016/j.jpowsour.2015.09.064

[12] CHEN B J, CHEN L, ZU L H, et al. Zero-strain high-capacity silicon/carbon anode enabled by a MOF-derived space-confined single-atom catalytic strategy for lithium-ion batteries[J]. Advanced Materials, 2022, 34(21): 2200894. DOI: 10.1002/adma.202200894

[13] RU Z W, ZHANG X, ZHANG M, et al. Bimetallic-MOF-derived Zn xCo3− xO4/carbon nanofiber composited sorbents for high-temperature coal gas desulfurization[J]. Environmental Science & Technology, 2022, 56(23): 17288-17297.

[14] MAJEED M K, MA G Y, CAO Y X, et al. Metal-organic frameworks-derived mesoporous Si/SiO x@NC nanospheres as a long-lifespan anode material for lithium-ion batteries[J]. Chemistry-A European Journal, 2019, 25(51): 11991-11997. DOI: 10.1002/chem.201903043

[15] YANG H X, XIE Y, ZHU M M, et al. Hierarchical porous MnCo2O4 yolk-shell micro-spheres from MOFs as secondary nanomaterials for high-power lithium-ion batteries[J]. Dalton Transactions, 2019, 48(25): 9205-9213. DOI: 10.1039/C9DT00613C

[16] MASTROPIETRO T F. Metal-organic frameworks and plastic: An emerging synergic partnership[J]. Science and Technology of Advanced Materials, 2023, 24(1): 2189890. DOI: 10.1080/14686996.2023.2189890

[17] LIN Y F, CHEN Y F, ZHANG Y G, et al. Wet-chemical synthesized MCMB@Si@C microspheres for high-performance lithium-ion battery anodes[J]. Chemical Communications (Cambridge, England), 2018, 54(68): 9466-9469. DOI: 10.1039/C8CC04797A

[18] CHENG X L, ZHA Q F, LI X J, et al. Modified characteristics of mesophase pitch prepared from coal tar pitch by adding waste polystyrene[J]. Fuel Processing Technology, 2008, 89(12): 1436-1441. DOI: 10.1016/j.fuproc.2008.07.003

[19] LIN J H, KO T H, KUO W S, et al. Mesophase pitch carbon coated with phenolic resin for the anode of lithium-ion batteries[J]. Energy & Fuels, 2010, 24(7): 4090-4094.

[20] HUANG Z H, DANG G J, JIANG W P, et al. A low-cost and scalable carbon coated SiO-based anode material for lithium-ion batteries[J]. ChemistryOpen, 2021, 10(3): 380-386. DOI: 10.1002/open.202000341

[21] SIRIWACHIRACHAL C, PONGJANYAKUL T. Particle agglomeration of acid-modified tapioca starches: Characterization and use as direct compression fillers in tablets[J]. Pharmaceutics, 2022, 14(6): 1245. DOI: 10.3390/pharmaceutics14061245

[22] MAMIYA M, KIKUCHI M, TAKEI H. Crystallization of fine silicon particles from silicon monoxide[J]. Journal of Crystal Growth, 2002, 237-239: 1909-1914. DOI: 10.1016/S0022-0248(01)02244-8

[23] 中国国家标准化管理委员会. 煤沥青类产品结焦值的测定方法: GB/T 8727—2008[S]. 北京: 中国标准出版社, 2008. Standardization Administration of the People's Republic of China. Method for determination of coking value of coal pitch products: GB/T 8727—2008[S]. Beijing: Standard Press of China, 2008(in Chinese).

[24] 中国国家标准化管理委员会. 焦化沥青类产品喹啉不溶物试验方法: GB/T 2293—2019[S]. 北京: 中国标准出版社, 2019. Standardization Administration of the People's Republic of China. The method of quinoline-insolube for pitch products of coal carbonization: GB/T 2293—2019[S]. Beijing: Standard Press of China, 2019(in Chinese).

[25] LI D C, XU W F, CHENG H Y, et al. One-step thermochemical conversion of biomass waste into superhydrophobic carbon material by catalytic pyrolysis[J]. Global Challenges, 2020, 4(4): 1900085. DOI: 10.1002/gch2.201900085

[26] MORISSET A, FAMPROKIS T, HAUG F J, et al. In situ reflectometry and diffraction investigation of the multiscale structure of p-type polysilicon passivating contacts for c-Si solar cells[J]. ACS Applied Materials & Interfaces, 2022, 14(14): 16413-16423.

[27] QIAN G H, RAHMAN S A, GOH B T. Controlled growth of Si-based heterostructure nanowires and their structural and electrical properties[J]. Nanoscale Research Letters, 2015, 10(1): 267.

[28] NETOR D E T, DAVID H L, FRANCISCO J F J, et al. Evaluation of optical and electronic properties of silicon nano-agglomerates embedded in SRO: Applying density functional theory[J]. Nanoscale Research Letters, 2014, 9(1): 507. DOI: 10.1186/1556-276X-9-507

[29] LEE G, SCHWEIZER S L, WEHRSPOHN R B. CMOS-compatible metal-stabilized nanostructured Si as anodes for lithium-ion micro batteries[J]. Nanoscale Research Letters, 2014, 9(1): 613. DOI: 10.1186/1556-276X-9-613

[30] SHANG H S, PAN K C, ZHANG L, et al. , Enhanced activity of supported Ni catalysts promoted by Pt for rapid reduction of aromatic nitro compounds[J]. Nanomaterials, 2016, 6(6): 103. DOI: 10.3390/nano6060103

[31] JEONG S Y, CHO J S. Porous hybrid nanofibers comprising ZnSe/CoSe2/carbon with uniformly distributed pores as anodes for high-performance sodium-ion batteries[J]. Nanomaterials, 2019, 9(10): 1362. DOI: 10.3390/nano9101362

[32] HINSTSHO N, SHAIKJEE A, MASENDA H, et al. Direct synthesis of carbon nanofibers from South African coal fly ash[J]. Nanoscale Research Letters, 2014, 9(1): 387. DOI: 10.1186/1556-276X-9-387

[33] LEE S E, KIM J H, LEE Y S, et al. Effect of coke orientation on the electrochemical properties of lithium-ion battery anode[J]. Journal of Applied Electrochemistry, 2021, 51(10): 1407-1418. DOI: 10.1007/s10800-021-01581-x

[34] MOCHIDA S, FEI Y Q, OYAMA T, et al. Carbonization of coal-tar pitch into lump needle coke in a tube bomb[J]. Journal of Materials Science, 1987, 22(11): 3989-3994. DOI: 10.1007/BF01133349

[35] GUO J Y, ZHANG W L, CHEN D T, et al. Control over electrochemical CO2 reduction selectivity by coordination engineering of tin single-atom catalysts[J]. Advanced Science, 2021, 8(23): 2102884. DOI: 10.1002/advs.202102884

[36] WANG B, HE Q G, LI G L, et al. Sensitive determination of trace 4-nitrophenol in ambient environment using a glassy carbon electrode modified with formamide-converted nitrogen-doped carbon materials[J]. International Journal of Molecular Sciences, 2022, 23(20): 12182. DOI: 10.3390/ijms232012182

[37] JEONG M G, ISLAM M, DU H L, et al. Nitrogen-doped carbon coated porous silicon as high-performance anode material for lithium-ion batteries[J]. Electrochimica Acta, 2016, 209: 299-307. DOI: 10.1016/j.electacta.2016.05.080

[38] YARALI M, HAO J, KHODADADI M, et al. Physisorbed versus chemisorbed oxygen effect on thermoelectric properties of highly organized single walled carbon nanotube nanofilms[J]. RSC Advance, 2017, 7(23): 14078-14087. DOI: 10.1039/c6ra27846a

[39] PENG G M, ELLIS J E, XU X Q, et al. In situ grown TiO2 nano-spindles facilitate the formation of holey reduced graphene oxide by photodegradation[J]. ACS Applied Materials & Interfaces, 2016, 8(11): 7403-7410.

[40] ZHENG Z M, ZAO Y, ZHANG Q B, et al. Robust erythrocyte-like Fe2O3@carbon with yolk-shell structures as high-performance anode for lithium-ion batteries[J]. Chemical Engineering Journal, 2018, 347: 563-573. DOI: 10.1016/j.cej.2018.04.119

[41] LI Q G, WANG Y H, LU B, et al. Hollow core-shell structured Si@NiAl-LDH composite as high-performance anode material in lithium-ion batteries[J]. Electrochimica Acta, 2020, 331: 135331. DOI: 10.1016/j.electacta.2019.135331

[42] 石永刚, 张志勇, 陈彬, 等. 硅化镁还原CO2一步原位合成Si/C复合负极[J]. 复合材料学报, 2021, 38(10): 3512-3518. SHI Yonggang, ZHANG Zhiyong, CHEN Bin, et al. In-situ synthesis of Si/C composites anode by one-step reduction of CO2 with magnesium silicide[J]. Acta Materiae Compositae Sinica, 2021, 38(10): 3512-3518(in Chinese).

-

其他相关附件

-

目的

石墨作为负极材料的比容量(372 mAh g)较低,不能满足高能量密度和功率密度的要求。在锂离子电池的负极材料中,一氧化硅(SiO)由于具有2400 mA h/g的理论比容量和较低的充放电电位,具有良好的发展前景。然而,SiO颗粒的巨大体积变化和固有的低电导率显著限制了活性材料的快速充电和放电的高速率能力,导致较差的倍率性能,从而阻碍了SiO基材料在LIBs中的商业化使用。核壳结构可以吸收机械应力并保持结构的完整性,材料中的孔隙结构提供了容纳SiO机械应变的空间。许多研究表明,碳材料不仅可以提高复合材料的导电性,还可以适应硅在Li插入/脱嵌过程中的体积变化。此外,碳层还可以避免SiO的团聚和固液电解质界面(SEI)膜的持续生长。然而低软化点和结焦值的原料沥青适应SiO自身的体积膨胀,需要进行处理。

方法通过空气交联法控制氧化聚合温度和聚合时间,制备了高软化点和结焦值的改性沥青。这是由于氧能使沥青大分子发生断键所需的能量减少,促进了沥青大分子的氧化聚合,进而使烷烃、芳香侧链基团发生断裂,使其发生氧化交联,从而更容易生成大分子,提高其分子量,进而提高软化点和结焦值。为了更好的提升电化学性能,以聚乙烯吡咯烷酮(PVP)为粘结剂,SiO和改性沥青按照5:3比例浸润结合一氧化硅和改性沥青,制备得到前驱体(SiO@PVP@pitch)。然后通过原位聚合,在400 ℃聚合4 h和900 ℃的温度条件下炭化3 h,将部分改性沥青转化为中间相沥青然后得到SiO/C复合材料具备良好的电化学性能。本研究中使用煤焦油沥青作为碳源,制备SiO/C复合材料,工艺简单,易于操作的特点,以此改进负极材料的循环稳定性和倍率性能。

结论当SiO:C为5:3时从透射电镜可以观察到,SiO颗粒表面包覆了一层厚度约为90 - 100 nm的碳涂层,可以容纳吸收电极材料的体积膨胀,并提高电极材料的导电性。从偏光显微镜中可以看出聚合条件为4 h,碳层具有更均匀的流线型结构,纤维变细腻,长度增加,取向性增强,从而电阻率降低。

结果改性沥青修饰SiO表现出良好的电化学性能,SiO/C - 5:3 - 4 h,的首次库伦效率为71.84 %,在0.5 A/g的电流密度下SiO/C - 5:3 - 4 h循环200次后比容量达到550 mA h/g,表现出良好的电化学性能。电化学阻抗谱(EIS)结果也证实了碳包覆有效降低了SiO的电阻率,碳涂层的取向结构获得了低的电阻。原始SiO电极的巨大体积变化(约184 % 从26 μm增加到74 μm), SiO/C - 5:3 - 4 h复合材料电极的体积变化,从16 μm增加到23 μm左右,体积膨胀约44 %,很好的抑制了SiO的体积膨胀,使得在循环过程中表现出良好的电化学性能。

结论以煤焦油沥青作为碳源在锂离子电池领域和钠离子电池领域得到了广泛的关注,煤焦油沥青价格低廉、高的C含量、易获取,且有利于环保的优势,本文通过煤焦油沥青为原料,制备高软化点、结焦值的改性沥青,并以改性沥青作为碳源,制备SiO/C复合材料,有效地提升SiO复合材料的初始库伦效率,循环性能也有了明显的提升,但相比于现在主流的负极材料,仍然具有较大的差距。需要继续改进包覆方法和制备工艺,实现高负载SiO的锂离子电池负极材料,另外,沥青作为碳前驱体,其产业化应用潜力巨大,仍然是以后具有前景的热点之一。

-

煤焦油沥青具有高碳含量、可调控性和经济性等优点,在制备碳材料和碳复合材料中具有广泛的应用前景。采用沥青对一氧化硅界面改性是抑制一氧化硅自身的膨胀、提升首次库伦效率和循环稳定性的有效策略。为改善沥青与基体材料间的结合性能,本研究采用添加粘结剂的方式制备负极材料。首先,我们通过空气交联低温条件下制备高软化点、高结焦值、具有良好流变性的改性沥青。以聚乙烯吡咯烷酮(pvp)为粘结剂,浸润结合一氧化硅和改性沥青,制备得到前驱体(SiO@pvp@pitch)。通过原位聚合,将改性沥青转化为中间相沥青,然后高温炭化得到SiO/C复合材料。

偏光显微镜结果表明碳涂层良好的流线型结构,纤维更加细腻。高分辨透射电子显微镜( HRTEM )结果表明,SiO表面存在厚度约为90 - 100 nm的含有石墨晶格的碳包覆层。合成的SiO/C - 5:3 - 4 h复合材料表现出优异的电化学性能,在0.5 A/g下具有550 mA h/g的高比容量,可逆容量660 mA h/g,200次循环后容量保持率为83.33 %。在1.5 A/g下的容量为472.8 mA h/g。电化学阻抗谱( EIS )结果也证明了碳包覆层可以有效提高复合材料的导电性,从而增强SiO电极的循环稳定性。

复合材料的偏光显微图像 图2复合材料的长循环性能图。

下载:

下载: