Flexural properties and microstructure of recycled carbon fiber concrete with different morphologies

-

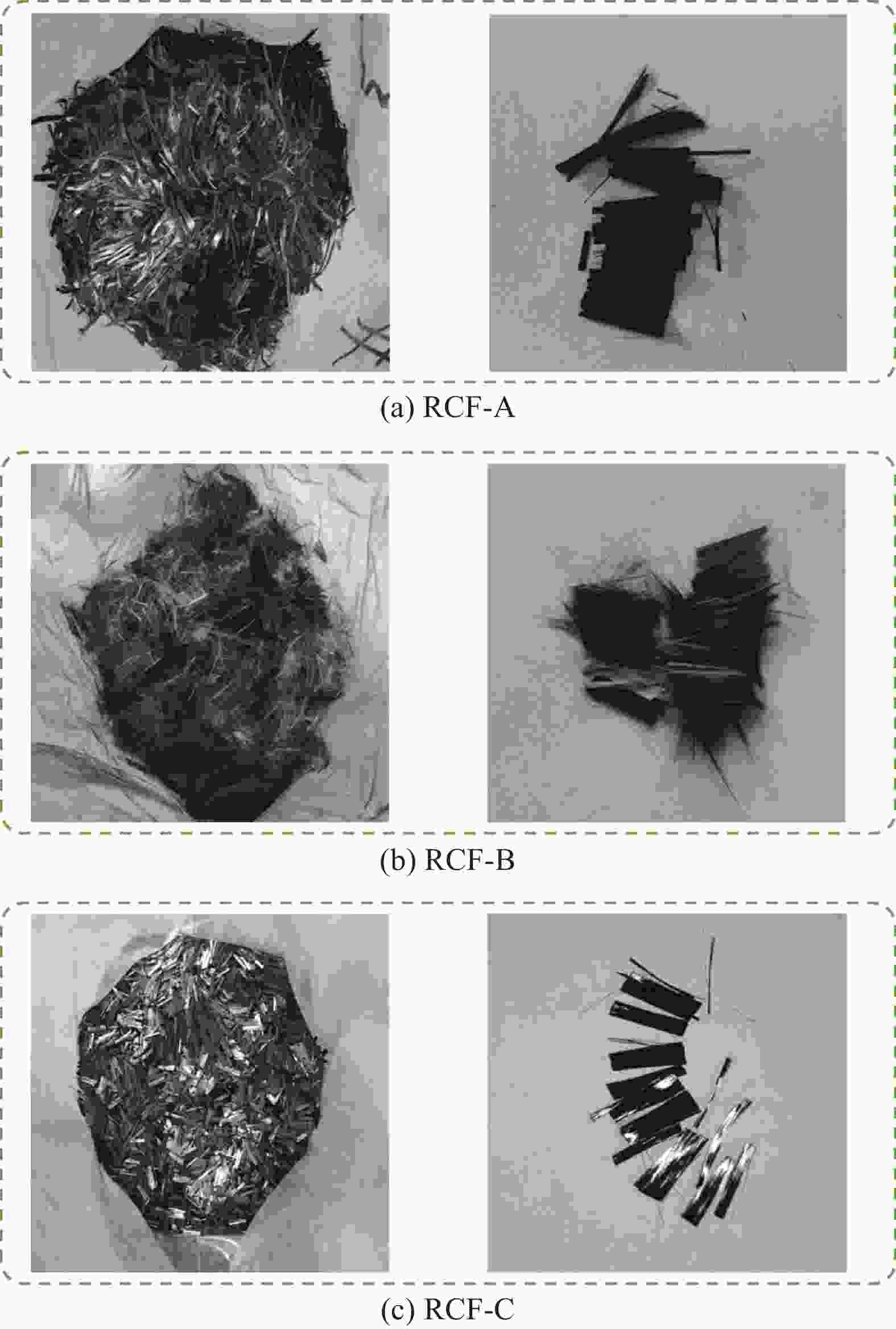

摘要: 将回收碳纤维(RCF)掺入混凝土制备绿色环保材料是实现碳纤维增强复合材料固废回收利用的有效方式。为探究RCF对混凝土材料弯曲性能的影响,将三种RCF按不同掺量与长度掺入混凝土中,通过四点弯曲试验,分析了回收碳纤维混凝土(RCFC)破坏形态、荷载-挠度曲线和弯曲强度的变化规律;提出了新的初裂点确定方法并进行了弯曲韧性评价,结合SEM从微观层面解释内在原因;基于MIP测得的孔隙率提出了新的弯曲强度预测公式。结果表明:RCF可改善试件破坏形式,提升RCFC弯曲强度和韧性,弯曲强度最高提升38.67%,弯曲韧性指标I20最高提升70.14%;不同形态的RCFC试件弯曲强度、弯曲韧性指数、等效弯曲强度及弯曲韧性比的影响规律并不相同,这主要和RCF表观形貌有关,从弯曲韧性角度来看掺入1.5%长度12mm的RCF-A时性能最佳。本文研究结论和提出的计算方法可为RCFC的性能提升及推广应用提供参考。Abstract: Green materials can be prepared by incorporating recycled carbon fibers (RCF) into concrete, which is an effective way to realize the recycling of carbon fiber reinforced composite solid waste. In order to investigate the effect of RCF on the flexural properties of concrete, RCF from three different manufacturers were incorporated into concrete at different contents and lengths. Four-point bending tests were carried out to analyze the failure modes, load-deflection curves and flexural strength of recycled carbon fiber reinforced concrete (RCFC). A new method for determining the initial cracking point was proposed, and the flexural toughness was evaluated. The intrinsic causes were explained at the microscopic level in combination with SEM. A new bending strength prediction formula was proposed based on the porosity measured by MIP. The results show that RCF can improve the failure mode and improve the flexural strength and toughness, with a maximum increase of 38.67% in flexural strength and 70.14% in flexural toughness index I20. The effects of different forms of RCFC specimens on the flexural strength, flexural toughness index, equivalent flexural strength and flexural toughness ratio are not the same, which is mainly related to the apparent morphology of RCF. From the perspective of flexural toughness, the best performance is achieved when 1.5 wt% RCF-A with a length of 12 mm is incorporated. The research conclusions and calculation methods can provide reference for the performance enhancement and application of RCFC.

-

Key words:

- recycled carbon fibers /

- flexural toughness /

- microstructure /

- porosity /

- flexural strength prediction

-

表 1 回收碳纤维性能参数

Table 1. Properties of RCFs

Fiber Length/

mmRecycling

methodAdhesive

Yes or NoDiameter/μm Density/

(g·cm−3)Tensile

strength/MPaTensile

modulus/GPaCarbon

content/%RCF-A 6/12/18 Direct cutting Yes 5.83 1.78 3536 230 95.0 RCF-B 6/12/18 Heat treatment No 7.28 1.80 3474 230 91.3 RCF-C 6/12/18 Direct cutting Yes 7.28 1.79 2866 230 92.8 表 2 试件编号及配合比

Table 2. Number and mix proportion of specimens

Sample No. RCF parameter Sample No. RCF parameter Type Content/wt% Length/mm Type Content/wt% Length/mm NC — — — RCF-B0.5%-L12 B 0.5 12 RCF-A0.5%-L6 A 0.5 6 RCF-B1.0%-L12 B 1 12 RCF-A0.5%-L12 A 0.5 12 RCF-B1.5%-L12 B 1.5 12 RCF-A0.5%-L18 A 0.5 18 RCF-B1.5%-L6 B 1.5 6 RCF-A1.0%-L6 A 1.0 6 RCF-B1.5%-L18 B 1.5 18 RCF-A1.0%-L12 A 1.0 12 RCF-D0.5%-L12 C 0.5 12 RCF-A1.0%-L18 A 1.0 18 RCF-C1.0%-L12 C 1 12 RCF-A1.5%-L6 A 1.5 6 RCF-C1.5%-L12 C 1.5 12 RCF-A1.5%-L12 A 1.5 12 RCF-C1.5%-L6 C 1.5 6 RCF-A1.5%-L18 A 1.5 18 RCF-C1.5%-L18 C 1.5 18 表 3 参数拟合结果及RCFC弯曲强度预测情况

Table 3. Parameter fitting results and flexural strength prediction of RCFC

Parameter fitting results $ k $ $ \alpha \tau $ $ \beta $ $ \gamma $ 1.3078 84.7983 0.5816 0.9273 Measured and predicted values of bending strength No. Porosity/% Measured value/MPa Predicted value /MPa RCF-A1.5%- L 6 12.67 6.30 6.27 RCF-A1.5%-L12 12.26 6.26 6.32 RCF-A0.5%-L18 10.85 6.92 6.92 RCF-A1.0%-L18 12.38 6.35 6.35 RCF-A1.5%-L18 13.09 6.40 6.37 -

[1] SUN Z, LUO Y, CHEN C, et al. Mechanical enhancement of carbon fiber-reinforced polymers: From interfacial regulating strategies to advanced processing technologies[J]. Progress in Materials Science, 2024, 142: 101221. doi: 10.1016/j.pmatsci.2023.101221 [2] 杨强, 刘洪新, 何端鹏, 等. 高导热沥青基碳纤维复合材料在航天器中的应用现状及展望[J]. 材料导报, 2024, 38(1): 216-223.YANG Qiang, LIU Hongxin, HE Duanpeng, et al. Application Status and Prospect of High Thermal Conductivity Pitch-based CarbonFiber Composites in Spacecraft[J]. Materials Reports, 2024, 38(1): 216-223(in Chinese). [3] 李成良, 杨超, 倪爱清, 等. 复合材料在大型风电叶片上的应用与发展[J]. 复合材料学报, 2023, 40(3): 1274-1284.LI Chengliang, YANG Chao, NI Aiqing, et al. Application and development of composite materials in large-scale wind turbine blade[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1274-1284(in Chinese). [4] 肖守讷, 江兰馨, 蒋维, 等. 复合材料在轨道交通车辆中的应用与展望[J]. 交通运输工程学报, 2021, 21(1): 154-176.XIAO Shouna, JIANG Lanxin, JIANG Wei, et al. Application and prospect of composite materials in rail transit vehicles[J]. Journal of Traffic and Transportation Engineering, 2021, 21(1): 154-176(in Chinese). [5] 吴杭姿, 许国文, 杨燕, 等. 碳纤维增强复合材料土木工程应用新进展[J]. 建筑结构, 2023, 53(S1): 1548-1555.WU Hangzi, XV Guowen, YANG Yan, et al. Review on CFRP applications in civil engineering[J]. Building Structure, 2023, 53(S1): 1548-1555(in Chinese). [6] MERLI R, PREZIOSI M, ACAMPORA A, et al. Recycled fibers in reinforced concrete: A systematic literature review[J]. Journal of Cleaner Production, 2020, 248: 119207. doi: 10.1016/j.jclepro.2019.119207 [7] RADEMACKER T. Challenges in CFRP recycling[J]. Breaking & sifting-Expert exchange on the end-of-life of wind turbines, 2018: 24-25. [8] 张少辉, 王艳, 牛荻涛. 废旧纤维在水泥基材料中的应用研究进展[J]. 材料导报, 2020, 34(23): 23042-23050. doi: 10.11896/cldb.19070105ZHANG Shaohui, WANG Yan, NIU Ditao T, et al. Research Progress of the Application of Waste Fiber in Cement-based Materials[J]. Materials Reports, 2020, 34(23): 23042-23050(in Chinese). doi: 10.11896/cldb.19070105 [9] LEFEUVRE A, GARNIER S, JACQUEMIN L, et al. Anticipating in-use stocks of carbon fiber reinforced polymers and related waste flows generated by the commercial aeronautical sector until 2050[J]. Resources, Conservation and Recycling, 2017, 125: 264-272. doi: 10.1016/j.resconrec.2017.06.023 [10] ZHAO C, WANG Z, ZHU Z, et al. Research on different types of fiber reinforced concrete in recent years: An overview[J]. Construction and Building Materials, 2023, 365: 130075. doi: 10.1016/j.conbuildmat.2022.130075 [11] GUO H, JIANG L, TAO J, et al. Influence of a hybrid combination of steel and polypropylene fibers on concrete toughness[J]. Construction and Building Materials, 2021, 275: 122132. doi: 10.1016/j.conbuildmat.2020.122132 [12] MUTHUKUMARANA T V, ARACHCHI M A V H M, SOMARATHNA H M C C, et al. A review on the variation of mechanical properties of carbon fibre-reinforced concrete[J]. Construction and Building Materials, 2023, 366: 130173. doi: 10.1016/j.conbuildmat.2022.130173 [13] 王春生, 张洋, 段兰. 共聚甲醛纤维超高性能水泥基复合材料抗弯性能试验[J]. 复合材料学报, 2024, 41(1): 373-382.WANG Chunsheng, ZHANG Yang, DUAN Lan. Flexural performance of ultra-high performance fiber reinforced cementitious composite material doped with copolymer formaldehyde fiber[J]. Acta Materiae Compositae Sinica, 2024, 41(1): 373-382(in Chinese). [14] CHEN L, CHEN Z, XIE Z, et al. Recent developments on natural fiber concrete: A review of properties, sustainability, applications, barriers, and opportunities[J]. Developments in the Built Environment, 2023, 16: 100255. doi: 10.1016/j.dibe.2023.100255 [15] 陈聪聪, 吴泽媚, 胡翔, 等. 钢纤维形状和养护制度对超高性能混凝土强度及韧性的影响[J]. 材料导报, 2024, 38(15): 23030088.CHEN Congcong, WU Zemei, HU Xiang, et al. Influence of steel fiber shape and curing system on strength and toughness of UHPC[J]. Materials Reports, 2024, 38(15): 23030088(in Chinese). [16] 苏骏, 钱维民. 超低温作用对超高韧性水泥基复合材料抗弯性能的影响[J]. 复合材料学报, 2022, 39(6): 2844-2854.SU Jun, QIAN Weimin. Effect of ultra-low temperature on flexural behavior of ultra-high toughness cementitious composites[J]. Acta Materiae Compositae Sinica, 2022, 39(6): 2844-2854(in Chinese). [17] 孟博旭, 许金余, 彭光. 纳米碳纤维增强混凝土抗冻性能试验[J]. 复合材料学报, 2019, 36(10): 2458-2468.MENG Boxu, XV Jinyu, PENG Guang. Anti-freeze performance test of nano carbon fiber reinforced concrete[J]. Acta Materiae Compositae Sinica, 2019, 36(10): 2458-2468(in Chinese). [18] 苏骏, 黄福, 王淞波, 等. 低温作用下改性骨料-钢纤维再生混凝土弯曲性能试验[J]. 复合材料学报, 2024, 41(2): 884-897.SU Jun, HUANG Fu, WANG Songbo, et al. Experimental study on bending properties of modified aggregate-steel fibre recycled concrete under low temperature[J]. Acta Materiae Compositae Sinica, 2024, 41(2): 884-897(in Chinese). [19] 曾伟, 丁一宁. 结构型纤维对混凝土弯曲韧性和裂缝表面形态的影响[J]. 复合材料学报, 2020, 37(9): 2303-2313.ZENG Wei, DING Yining. Effect of macro fibers on flexural toughness and crack surface topography of concrete[J]. Acta Materiae Compositae Sinica, 2020, 37(9): 2303-2313(in Chinese). [20] SAFIUDDIN Md, YAKHLAF M, SOUDKI K A. Key mechanical properties and microstructure of carbon fibre reinforced self-consolidating concrete[J]. Construction and Building Materials, 2018, 164: 477-488. doi: 10.1016/j.conbuildmat.2017.12.172 [21] FANECA G, SEGURA I, TORRENTS J M, et al. Development of conductive cementitious materials using recycled carbon fibres[J]. Cement and Concrete Composites, 2018, 92: 135-144. doi: 10.1016/j.cemconcomp.2018.06.009 [22] ZHOU Z, ZHAO B, LONE U A, et al. Experimental study on mechanical properties of shredded prepreg carbon cloth waste fiber reinforced concrete[J]. Journal of Cleaner Production, 2024, 436: 140456. doi: 10.1016/j.jclepro.2023.140456 [23] DE SOUZA ABREU F, RIBEIRO C C, DA SILVA PINTO J D, et al. Influence of adding discontinuous and dispersed carbon fiber waste on concrete performance[J]. Journal of Cleaner Production, 2020, 273: 122920. doi: 10.1016/j.jclepro.2020.122920 [24] AKBAR A, LIEW K M. Influence of elevated temperature on the microstructure and mechanical performance of cement composites reinforced with recycled carbon fibers[J]. Composites Part B: Engineering, 2020, 198: 108245. doi: 10.1016/j.compositesb.2020.108245 [25] WANG Y, ZHANG S, LUO D, et al. Effect of chemically modified recycled carbon fiber composite on the mechanical properties of cementitious mortar[J]. Composites Part B: Engineering, 2019, 173: 106853. doi: 10.1016/j.compositesb.2019.05.064 [26] 王艳, 全志平, 张少辉. 回收碳纤维对高强水泥基材料力学性能与导电性能的影响[J]. 硅酸盐学报, 2023, 51(5): 1332-1343.WANG Yan, QUAN Zhiping, ZHANG Shaohui. Effects of Recycled Carbon Fibers on Mechanical Property and Conductivity of High-Strength Cement-Based Material[J]. Journal of The Chinese Ceramic Society, 2023, 51(5): 1332-1343(in Chinese). [27] 国家市场监督管理总局. 水泥混凝土和砂浆用合成纤维: GB/T 21120-2018 [S]. 北京: 中国标准出版社, 2018.State Administration for Market Regulation. Synthetic fibres for cement concrete and mortar: GB/T 21120-2018 [S]. Beijing : Standards Press of China, 2018(in Chinese). [28] BHANDARI M, NAM I W. A Critical Review on the Application of Recycled Carbon Fiber to Concrete and Cement Composites[J]. Recycling, 2024, 9(1): 17. doi: 10.3390/recycling9010017 [29] 中国工程建设标准化协会. 纤维混凝土试验方法: CECS 13-2009[S]. 北京: 中国计划出版社, 2009.China Engineering Construction Standardization Association. Standard test methods for fiber reinforced concrete: CECS 13-2009 [S]. Beijing : China Planning Press, 2009(in Chinese). [30] 中华人民共和国住房和城乡建设部. 纤维混凝土应用技术规程: JGJ/T 221-2010[S]. 北京: 中国建筑工业出版社, 2010.Ministry of Housing and Urban-Rural Development of the People 's Republic of China. Technical specification for application of fiber reinforced concrete: JGJ/T 221-2010 [S]. Beijing : China Building Industry Press, 2010(in Chinese). [31] Standard test method for flexural toughness and first-crack strength of fiber reinforced concrete ( using beam with third-point loading): ASTM C 1018[S]. West Conshohocken: ASTM Internation, 1997. [32] Method of test for flexural strength and flexural toughness of steel fiber reinforced concrete: JSCE-SF4[S]. Tokyo: Japan Concrete Institute, 1984. [33] 陈维灯, 韩冬冬, 钟世云. 丁苯乳液和超高分子质量聚乙烯纤维对砂浆抗弯性能的影响[J]. 新型建筑材料, 2017, 44(2): 94-98. doi: 10.3969/j.issn.1001-702X.2017.02.022CHEN Weideng, HAN Dongdong, ZHONG Shiyun. Influences of SBR latex and UHMW-PE fiber on bending properties of mortar[J]. New Building Materials, 2017, 44(2): 94-98(in Chinese). doi: 10.3969/j.issn.1001-702X.2017.02.022 [34] 鲍聪, 赵晓钦, 樊伟, 等. 再生PET塑料骨料砂浆的弯曲韧性及阻尼特性[J]. 复合材料学报, 2023, 40(4): 2343-2354.BAO Cong, ZHAO Xiaoqin, PAN Wei, et al. Flexural toughness and damping property of recycled PET plastic aggregate mortar[J]. Acta Materiae Compositae Sinica, 2023, 40(4): 2343-2354(in Chinese). [35] 史占崇, 苏庆田, 邵长宇, 等. 粗骨料UHPC的基本力学性能及弯曲韧性评价方法[J]. 土木工程学报, 2020, 53(12): 86-97.SHI Zhanchong, SU Qingtian, SHAO Changning, et al. Basic mechanical behavior and flexural toughness evaluation method of coarse aggregate UHPC[J]. China Civil Engineering Journal, 2020, 53(12): 86-97(in Chinese). [36] 邓宗才, 薛会青. 混杂纤维增强超高性能混凝土弯曲韧性[J]. 哈尔滨工程大学学报, 2023, 44(8): 1288-1294. doi: 10.11990/jheu.202109043DENG Zongcai, XUE Huiqing. Flexural toughness of hybrid fiber-reinforced ultra-high performance concrete[J]. Journal of Harbin Engineering University, 2023, 44(8): 1288-1294(in Chinese). doi: 10.11990/jheu.202109043 [37] 王艳, 高腾翔, 张少辉, 等. 不同形态回收碳纤维水泥基材料力学与导电性能[J]. 材料导报, 2024, 38(9): 23010043. doi: 10.11896/cldb.23010043WANG, Yan, GAO Tengxiang, ZHANG Shaohui, et al. Mechanical and electrical properties of recycling carbon fiber cement-based materials with different forms[J]. Materials Reports, 2024, 38(9): 23010043(in Chinese). doi: 10.11896/cldb.23010043 [38] WAQAR A, KHAN M B, AFZAL M T, et al. Investigating the synergistic effects of carbon fiber and silica fume on concrete strength and eco-efficiency[J]. Case Studies in Construction Materials, 2024, 20: e02967. doi: 10.1016/j.cscm.2024.e02967 [39] LI H, ZHAO D, LIEBSCHER M, et al. An experimental and numerical study on the age depended bond-slip behavior between nano-silica modified carbon fibers and cementitious matrices[J]. Cement and Concrete Composites, 2022, 128: 104416. doi: 10.1016/j.cemconcomp.2022.104416 [40] 丁聪, 任金明, 王永明, 等. 高延性水泥基复合材料用短切PVA纤维的长度优选研究[J]. 材料导报, 2023, 37(13): 253-260.DING Cong, REN Jinming, WANG Yongming, et al. Study on PVA Fiber Length Optimization for High Ductility Cementitious Composites[J]. Materials Reports, 2023, 37(13): 253-260(in Chinese). [41] MIAH M J, PEI J, KIM H, et al. Role of fiber dosages and lengths on the mechanical strength, shrinkage, and pore structure of CO2-cured amorphous metallic-fiber-reinforced belite-rich cement composites[J]. Journal of Building Engineering, 2023, 79: 107752. doi: 10.1016/j.jobe.2023.107752 [42] WANG T, XU J, BAI E, et al. Research on a sustainable concrete synergistic reinforced with carbon fiber and carbon nanofiber: Mechanical properties, durability and environmental evaluation[J]. International Journal of Hydrogen Energy, 2023, 48(90): 35366-35386. doi: 10.1016/j.ijhydene.2023.05.234 [43] 刘美业, 龚思雨, 曹志远, 等. 钢-聚乙烯醇纤维混凝土力学性能与孔结构研究[J]. 工业建筑, 2023, 53(S1): 623-628.LIU Meiye, GONG Siyu, CAO Zhiyuan, et al. Study on mechanical properties and pore structure of steel-polyvinyl alcohol fiber reinforced concrete[J]. Industrial Construction, 2023, 53(S1): 623-628(in Chinese). [44] 李福海, 刘耕园, 刘梦辉, 等. 纤维协同效应下超高性能混凝土的弯曲性能[J]. 同济大学学报(自然科学版), 2023, 51(12): 1835-1844. doi: 10.11908/j.issn.0253-374x.23102LI Fuhai, LIU Ggengyuan, LIU Menghui, et al. Flexural Properties of Ultra-high Performance Concrete Under Fiber Synergistic Effect[J]. Journal of Tongji University (Natural Science), 2023, 51(12): 1835-1844(in Chinese). doi: 10.11908/j.issn.0253-374x.23102 [45] NAAMAN A E, REINHARDT H W. Proposed classification of HPFRC composites based on their tensile response[J]. Materials and Structures, 2006, 39(5): 547-555. -

点击查看大图

点击查看大图

计量

- 文章访问数: 54

- HTML全文浏览量: 48

- 被引次数: 0

下载:

下载: