Sensitivity performance prediction and optimisation of flexible pressure sensing unit based on RSM and SVR-IDBO

-

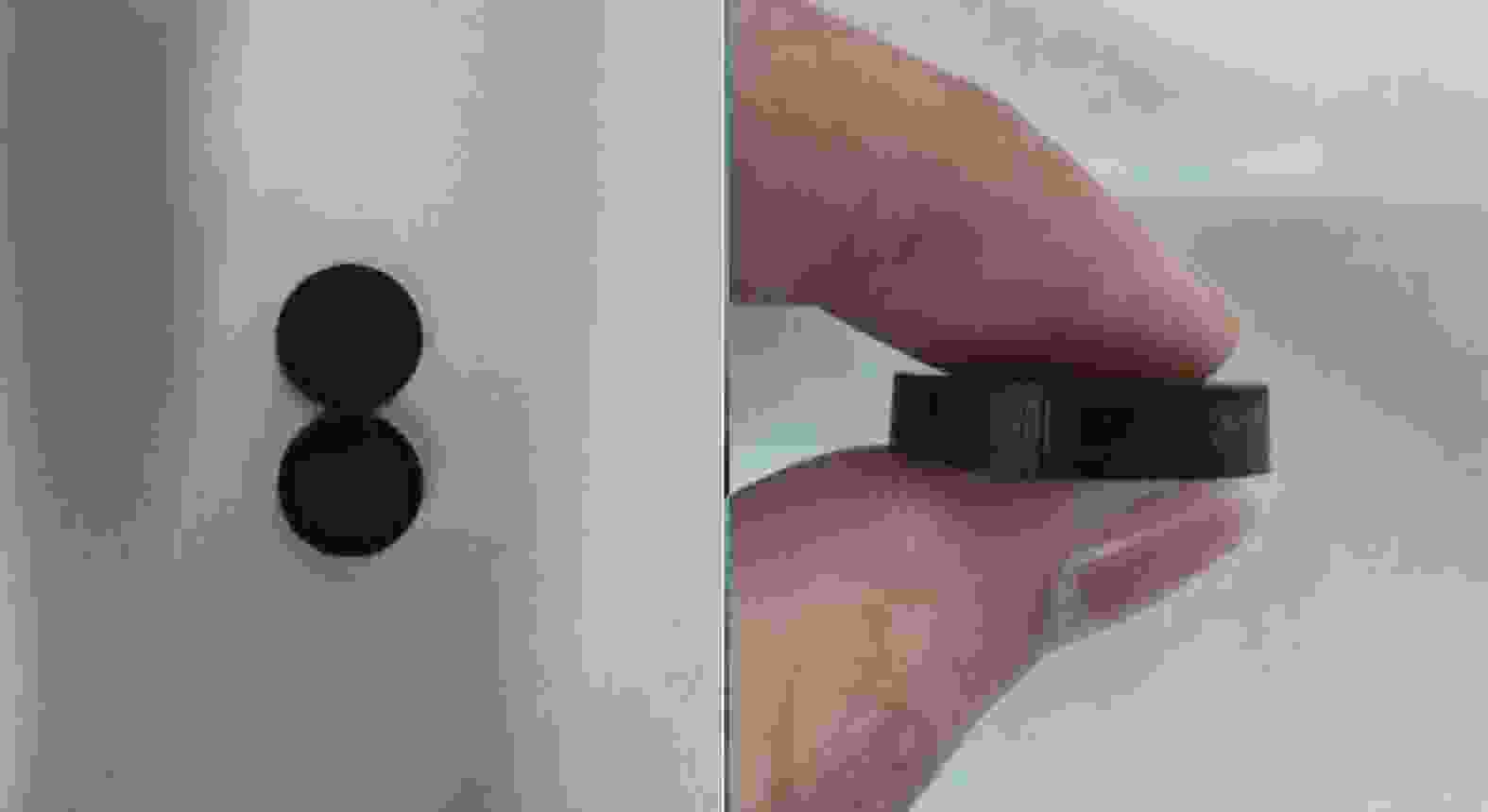

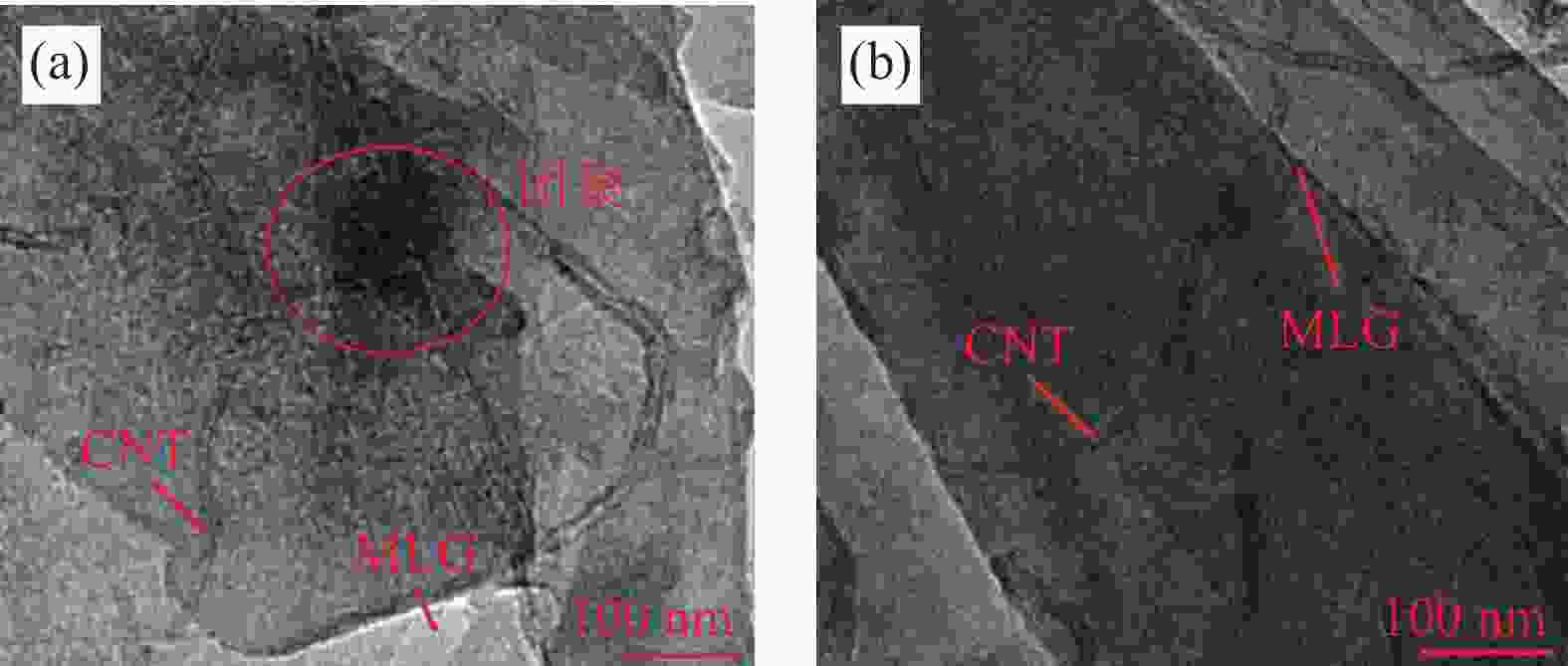

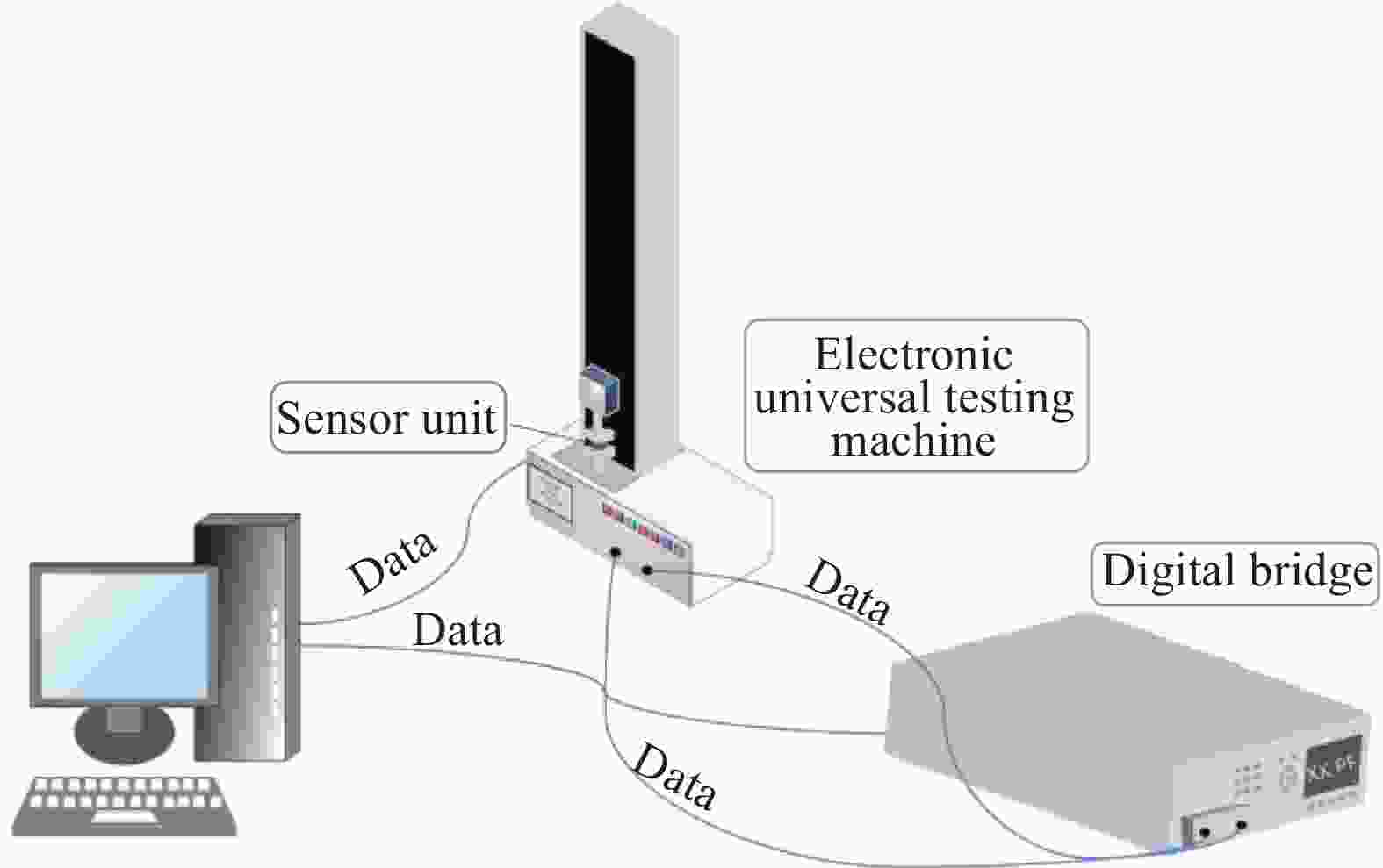

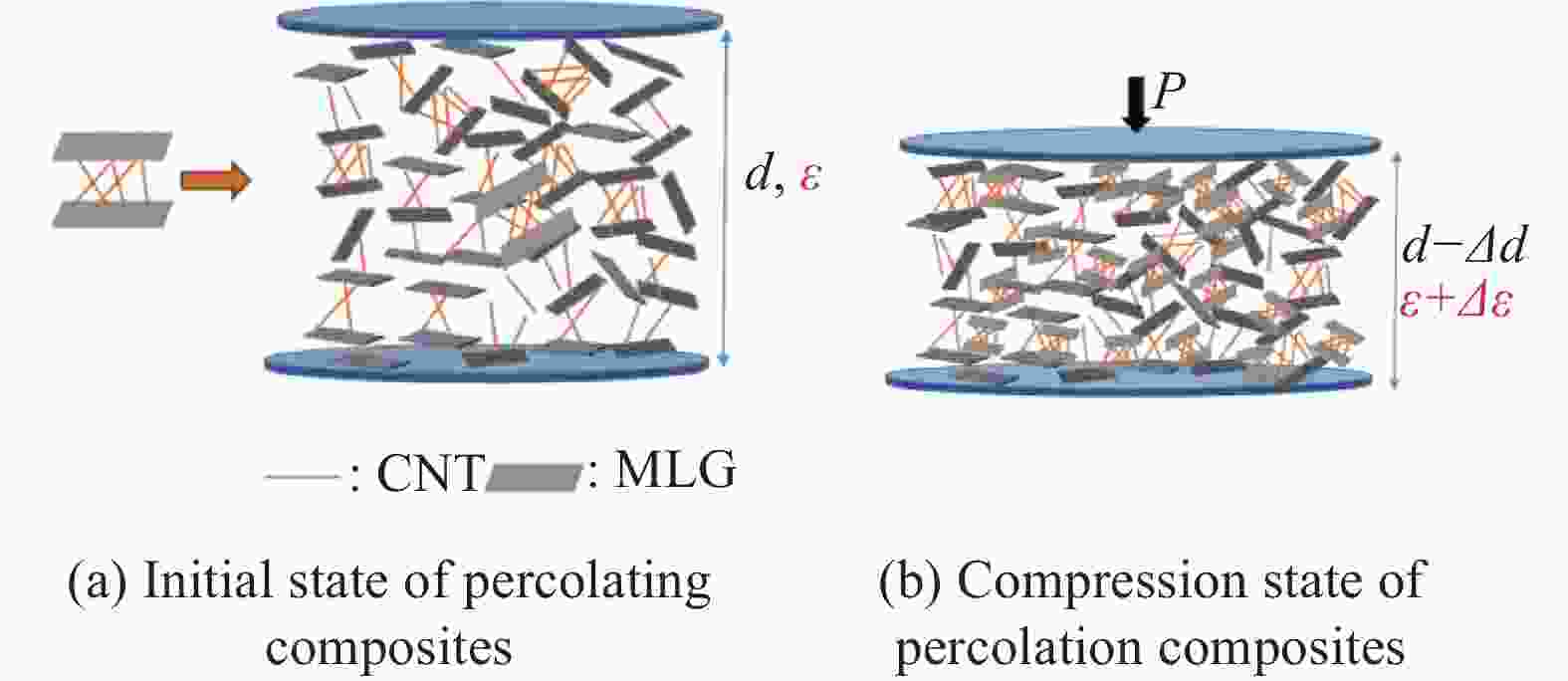

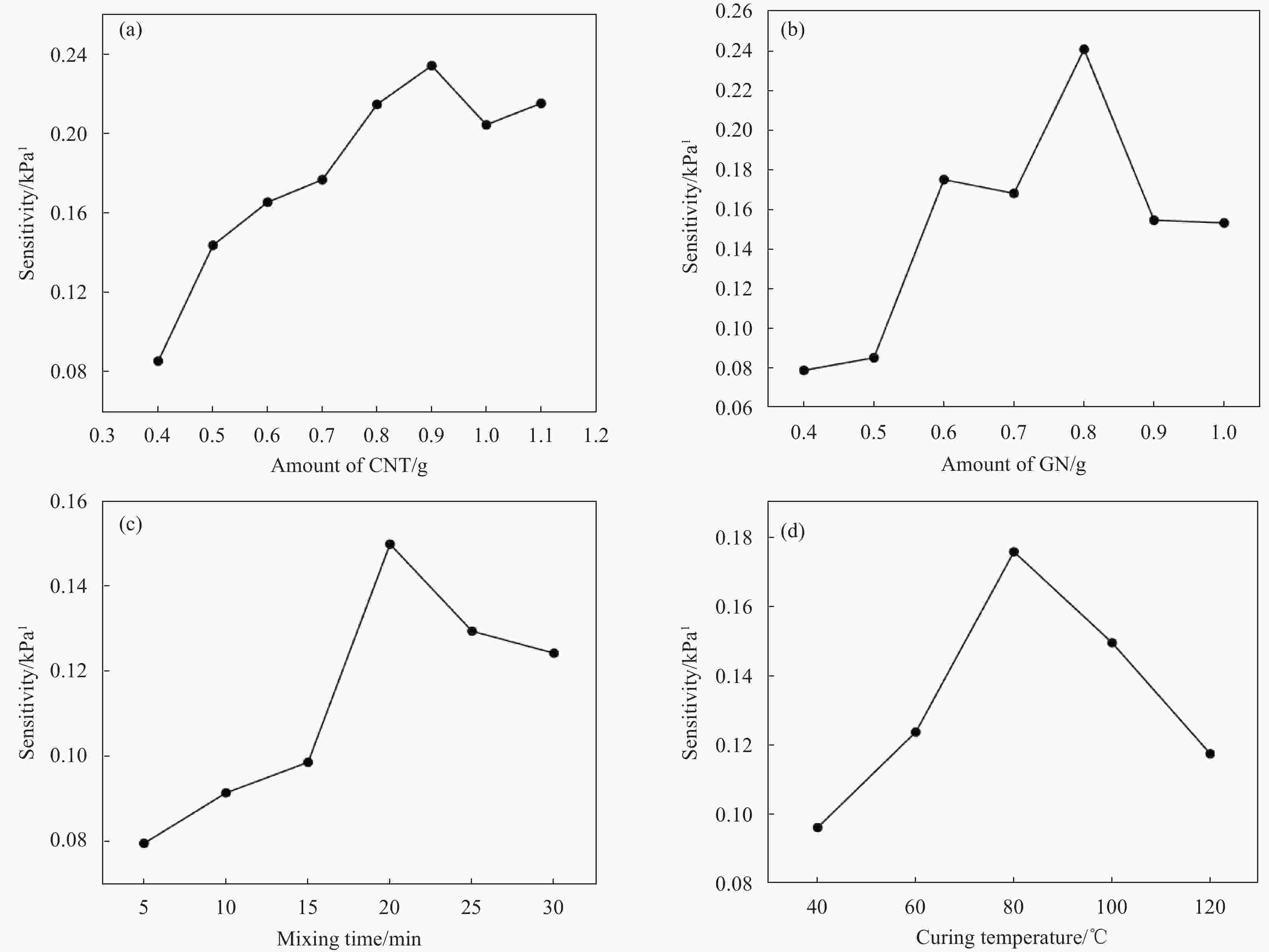

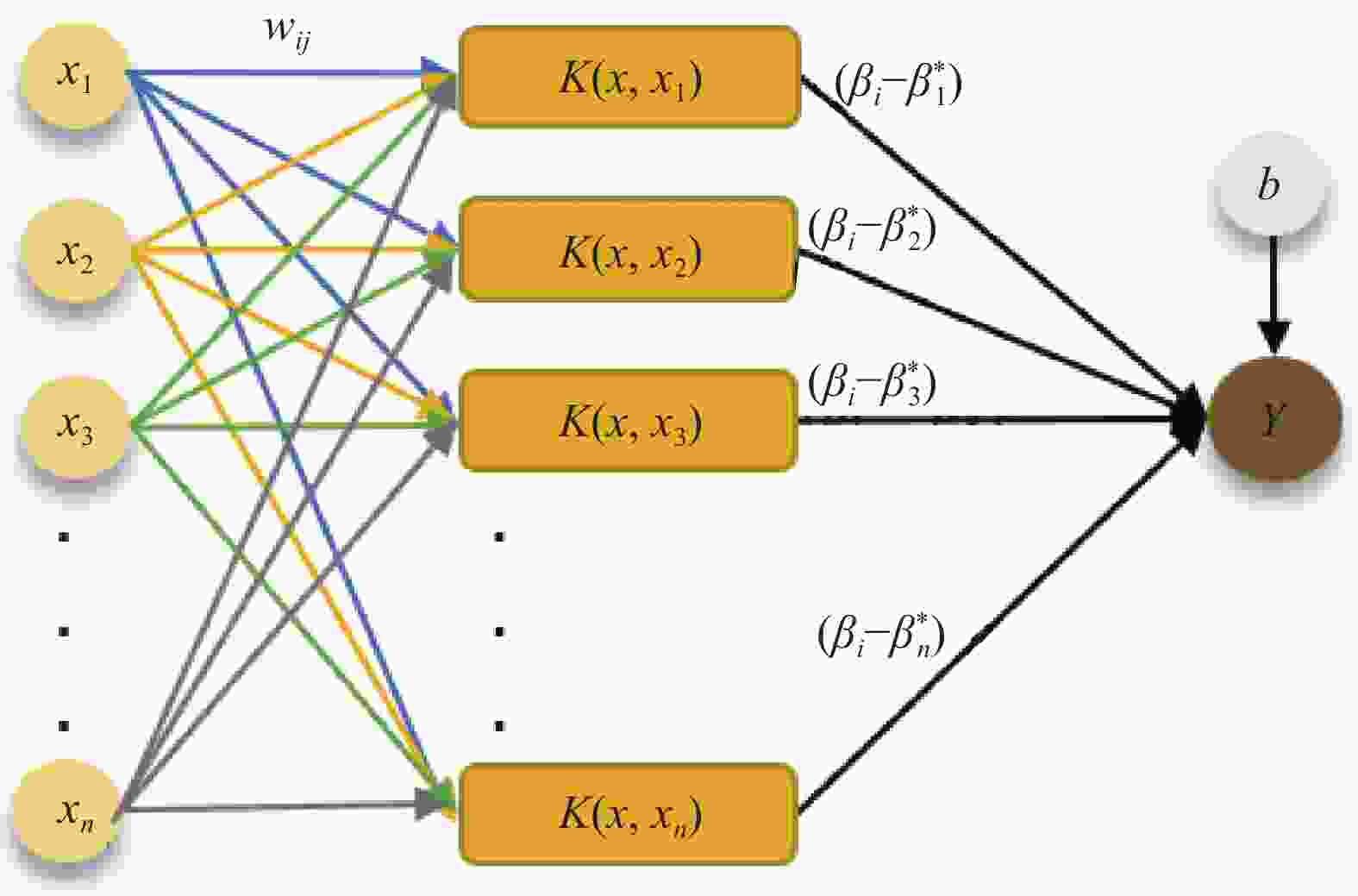

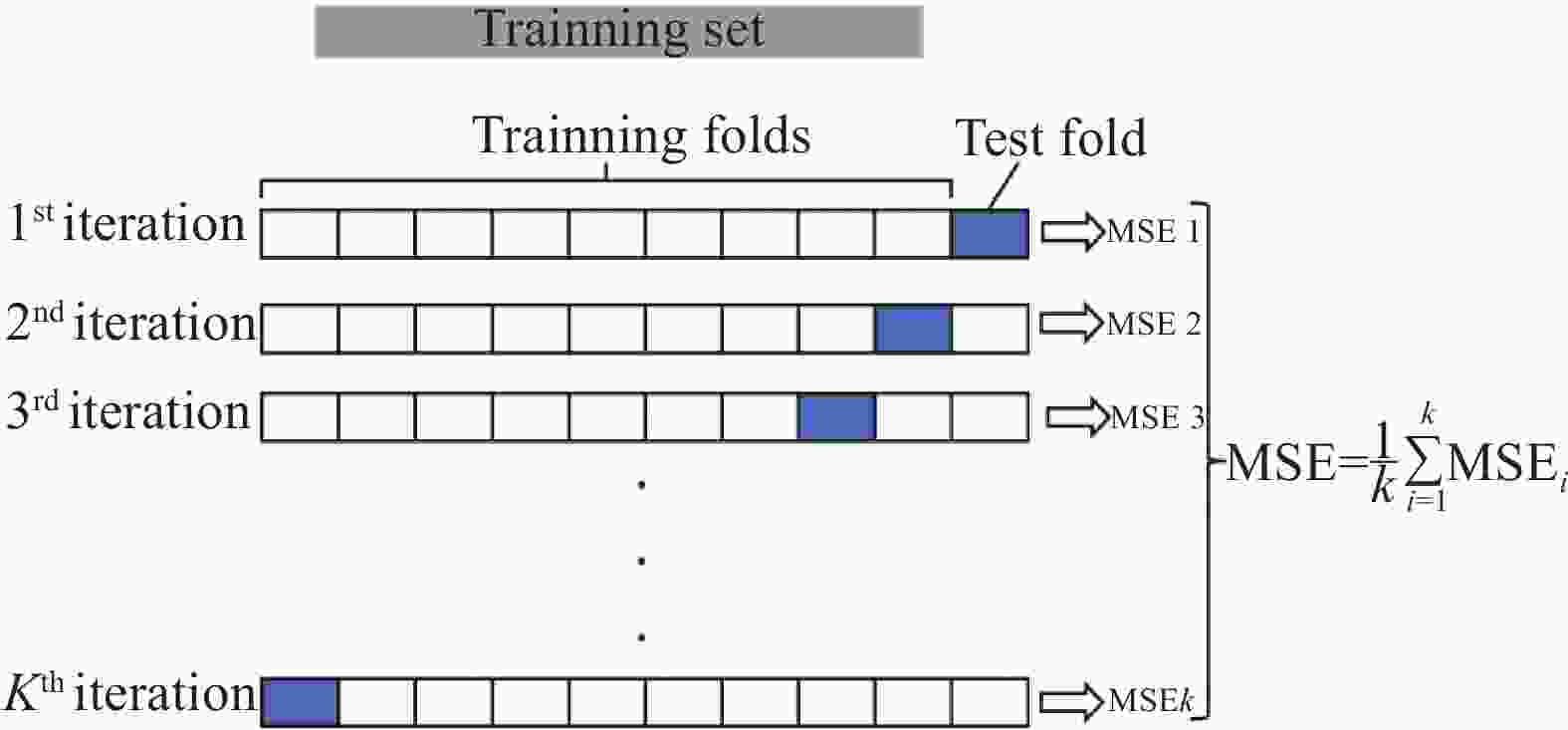

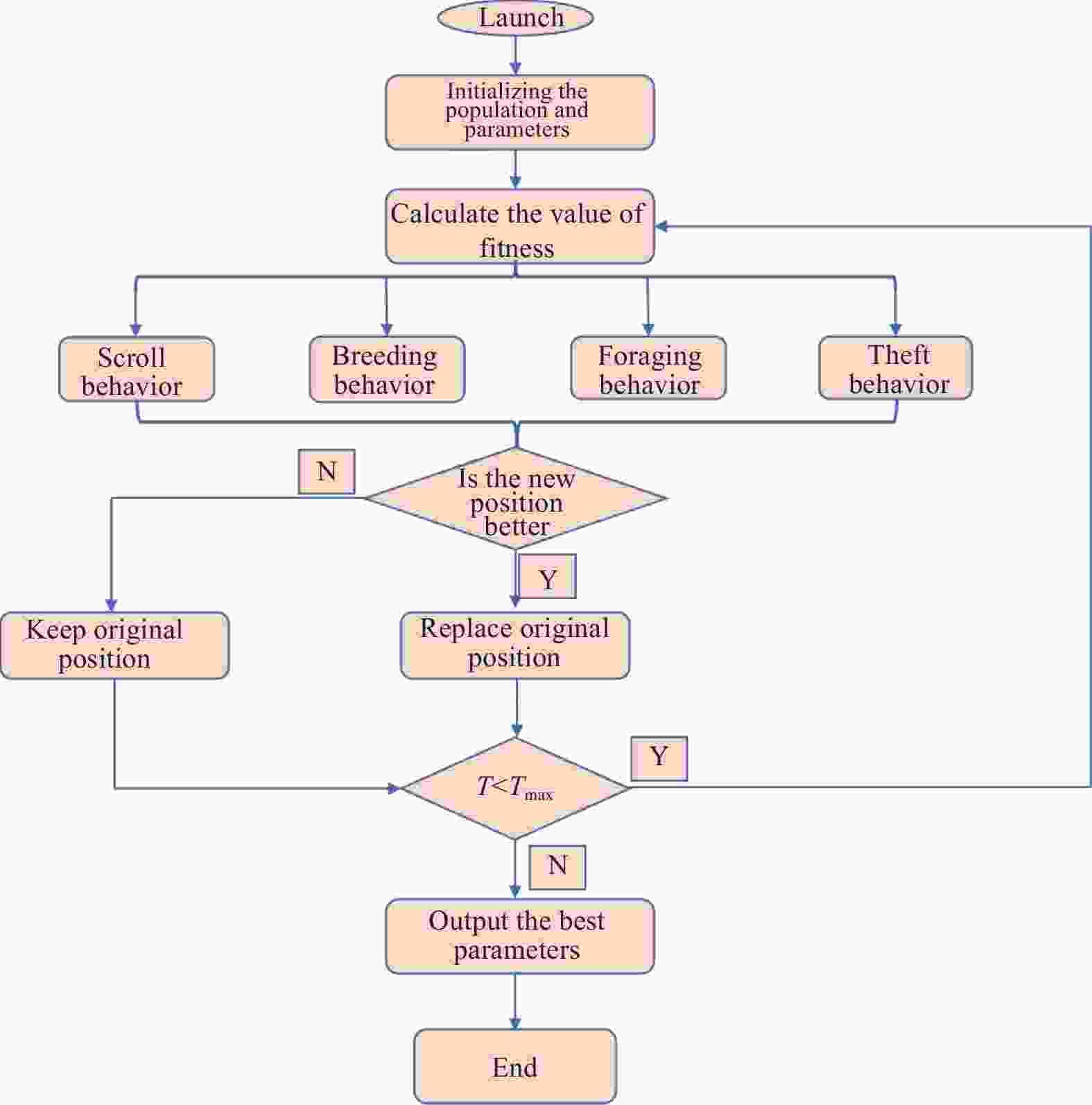

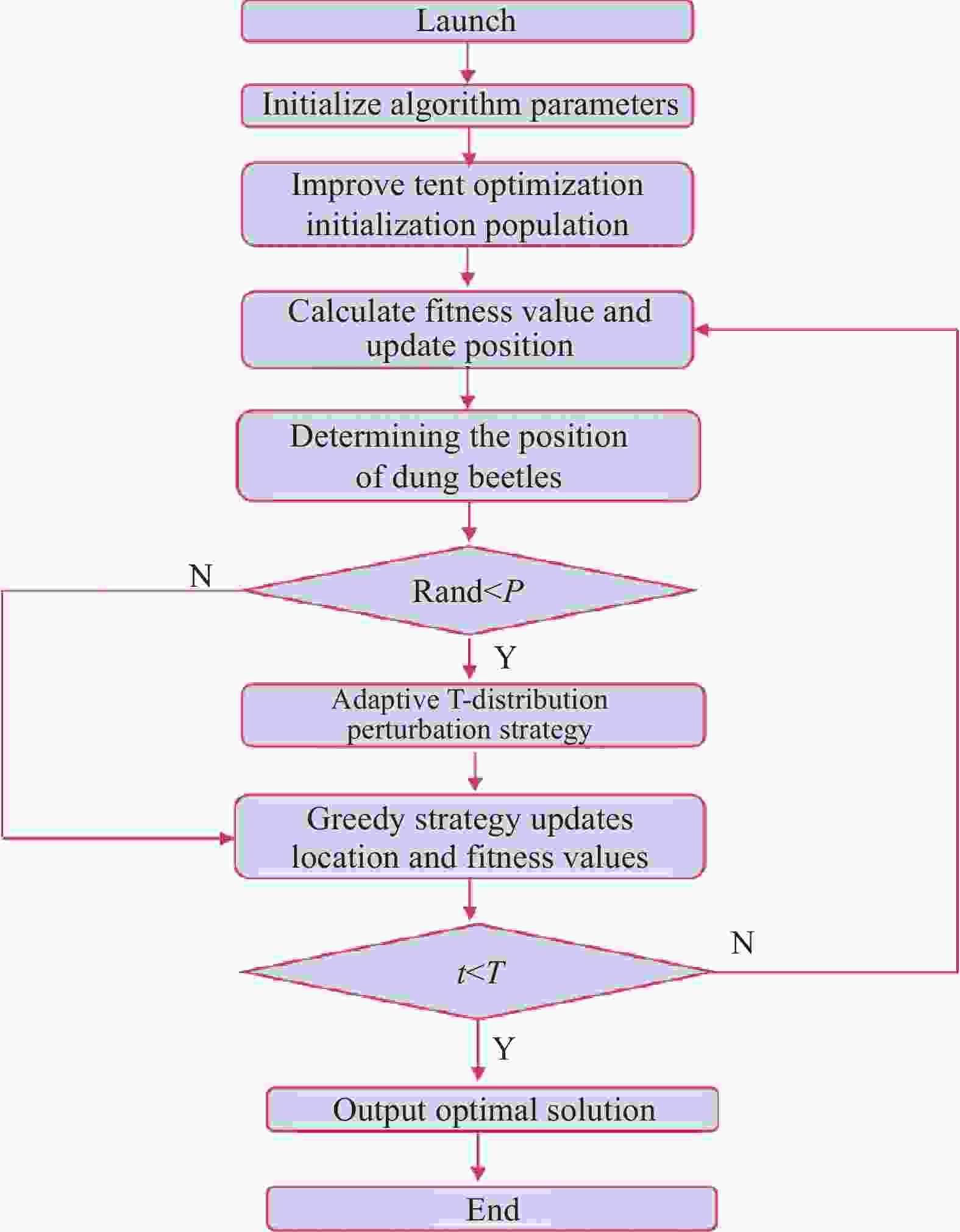

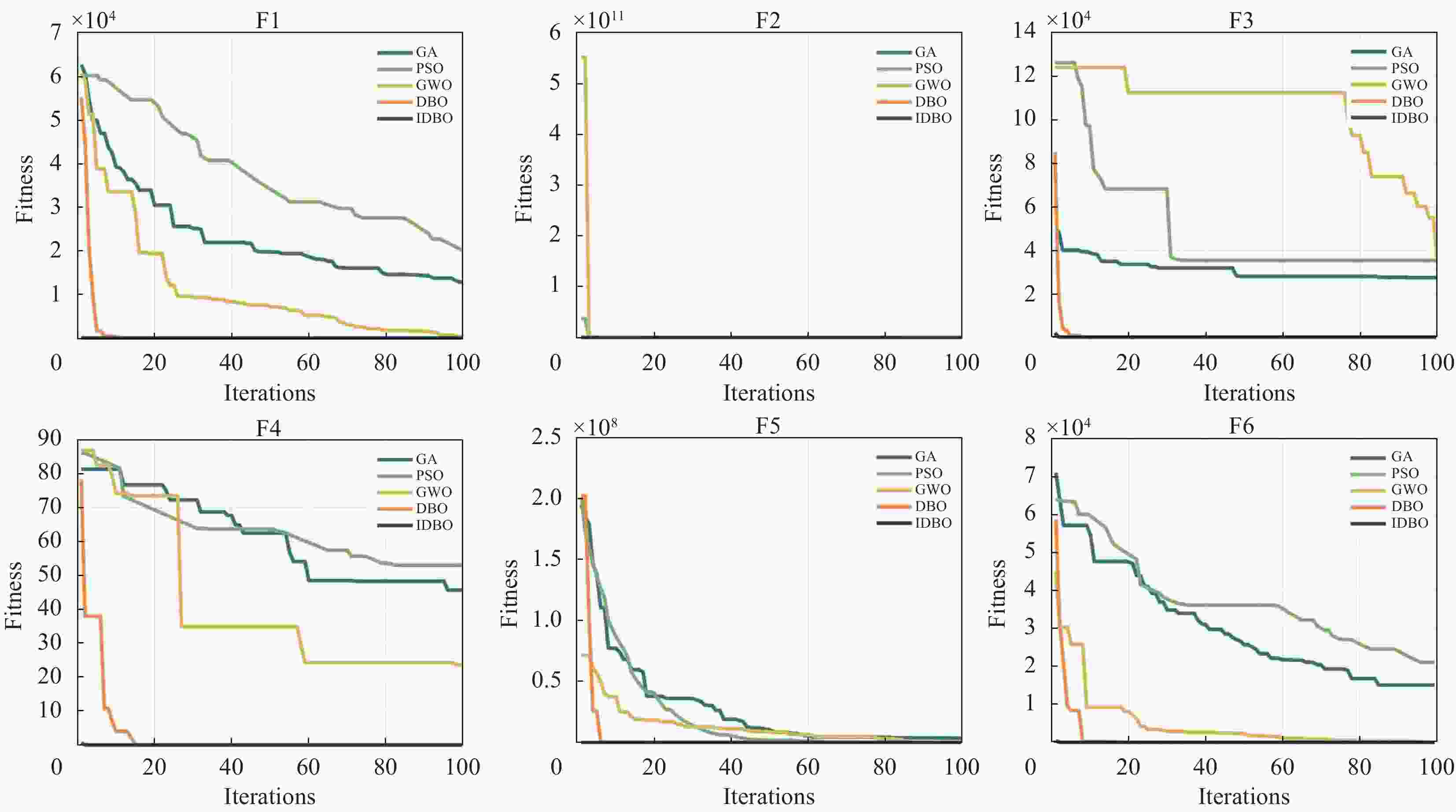

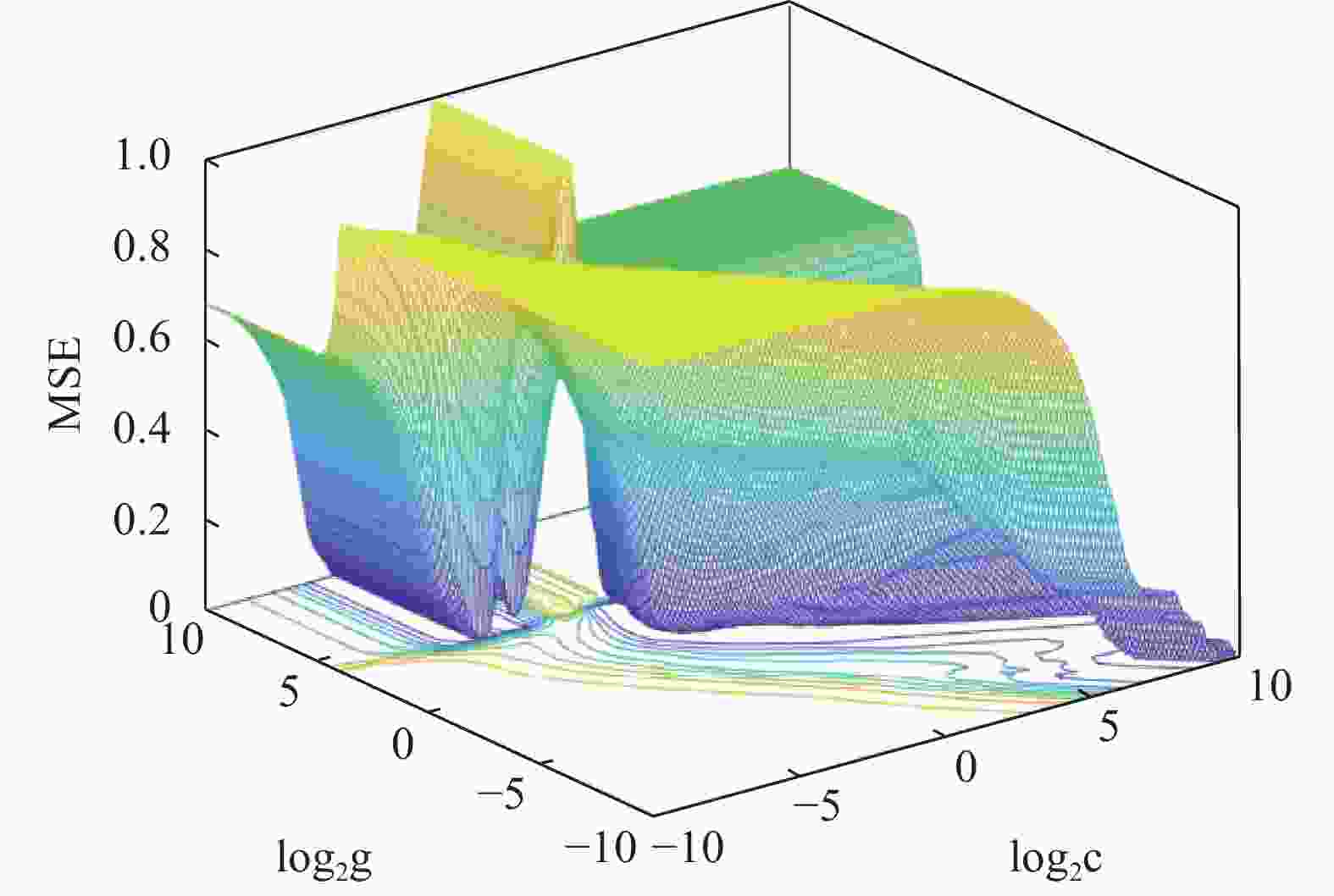

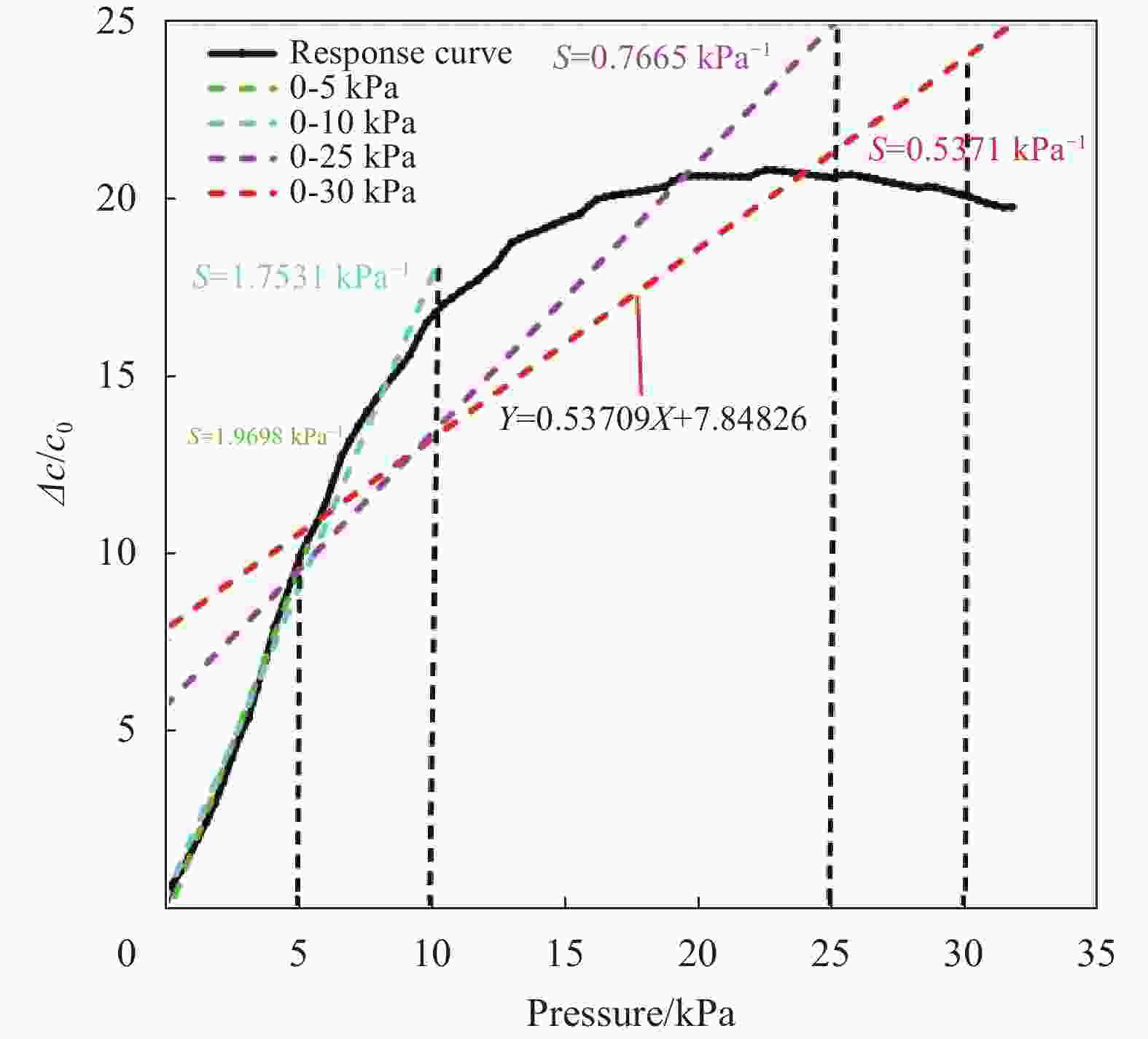

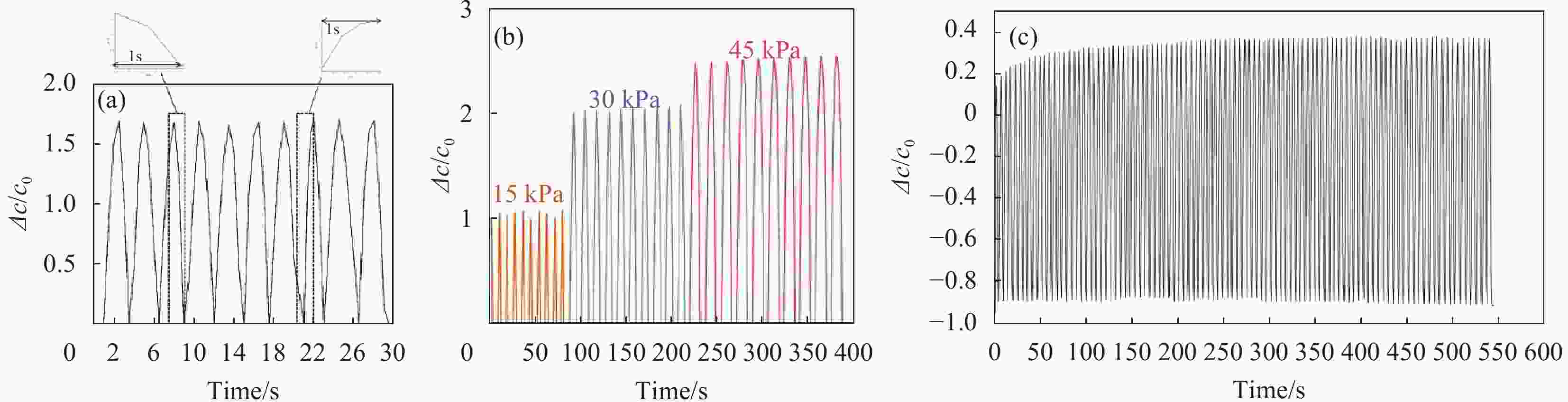

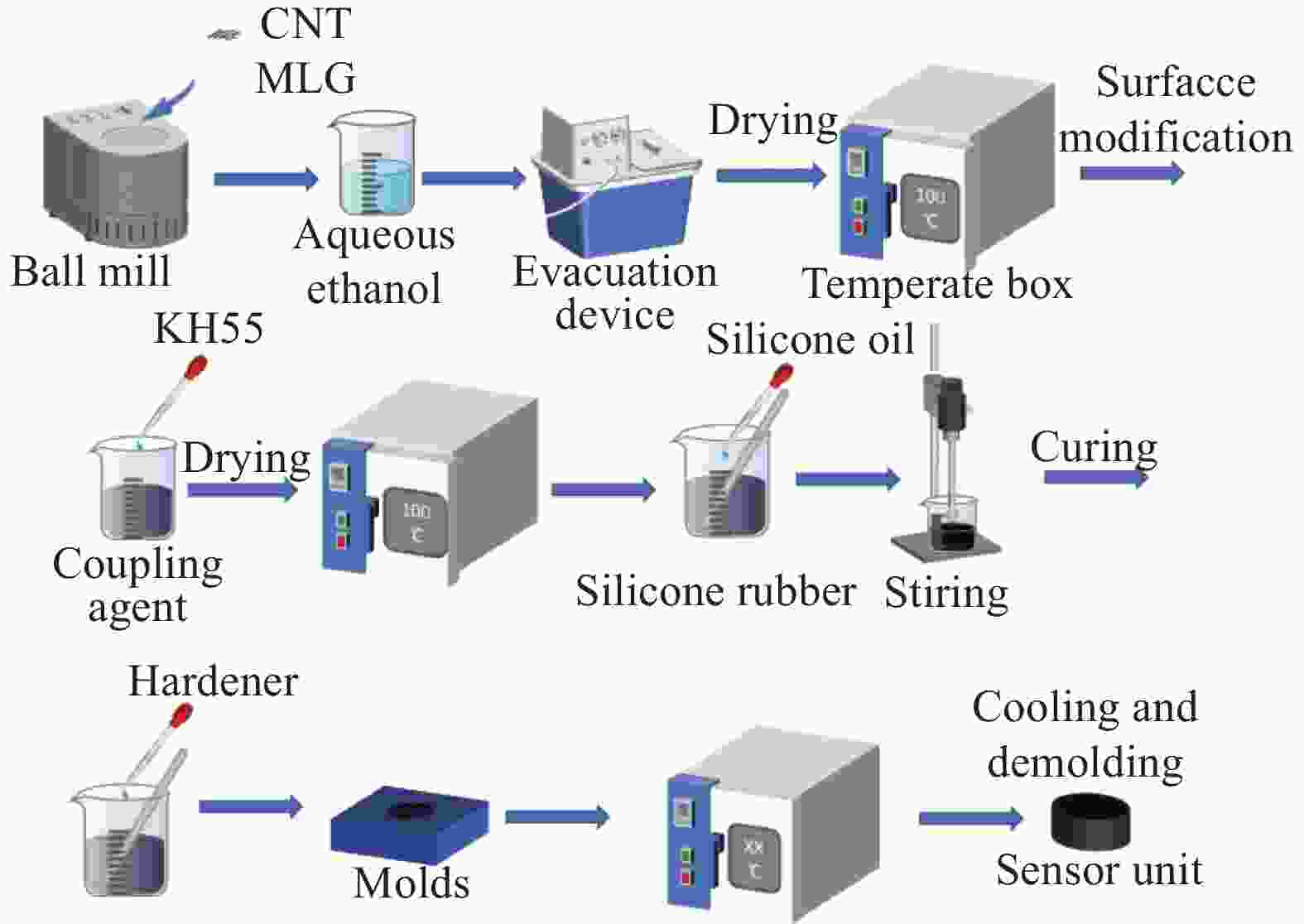

摘要: 为优化柔性压力传感单元制备工艺,提升传感器灵敏度特性。本研究通过建立灵敏度解析模型,确定了影响其性能表现的主要因素,采用机械共混的方式,通过调节碳纳米管(CNT)、多层石墨烯(MLG)、搅拌时间(Mixing time)、成型温度(Molding temperature)等参数优化了柔性传感单元的灵敏度性能。首先在单因素分析的基础上,应用实验设计(DOE)中的中心复合实验方法(CCD)进行多因素实验设计,通过响应面法(RSM)和支持向量机(SVR)对多因素的交互影响进行了分析,并分别建立了灵敏度预测模型。其次根据决定系数($ {R}^{2} $)、均方根误差(Rmse)和平均误差率(Mae)对两种模型进行评估与定型,模型性能对比结果表明,通过超参优化后的SVR模型表现出更高水平的准确性和可预测性。然后基于改进的蜣螂优化算法(IDBO)对模型进行迭代优化,得到了比早期实验更好的灵敏度性能。仿真结果显示在0~30kPa的单轴压力下,当CNTs含量为2.3wt%、MLG含量为1.9wt%、混合时间15 min、成型温度78℃时,灵敏度达到0.5512 kPa−1,经过实验验证,与实际灵敏度(0.5371 kPa−1)的相对误差为2.625%,且与同类型研究相比较,本研究的传感单元灵敏度性能也处较高水平。证明该方法有助于寻找最佳的传感器含量配比与制备工艺,提升实验效率,节约实验成本,为快速制备高性能电容式柔性压力传感单元提供了新思路。Abstract: To enhance the preparation process of flexible pressure sensors and improve their sensitivity characteristics, objective measures must be taken. This study identified the main factors affecting performance through a sensitivity analysis model. The sensitivity performance of the flexible sensing unit was optimized by adjusting the parameters of multi-walled carbon nanotubes (MWCNTs), multilayered graphene (MLGs), mixing time, and molding temperature using mechanical co-mingling. The study utilized the central combinatorial method (CCD) in design of experiments (DOE) for multi-factor experimental design. The interaction effects of the multi-factors were analyzed using response surface methodology (RSM) and support vector machine (SVR), based on single-factor analysis. Sensitivity prediction models were established accordingly. The two models were evaluated and finalized based on the coefficient of determination ($ {R}^{2} $), root mean square error (Rmse), and mean error rate (Mae). The results indicate that the SVR model, optimized by hyperparameterization, exhibits a higher level of accuracy and predictability. The model was then iteratively optimized using the Improved Dung Beetle Optimization (IDBO) algorithm, which yielded better sensitivity performance than earlier experiments. The simulation results show a sensitivity of 0.5512 kPa−1 at a uniaxial pressure of 0-30 kPa when the CNTs content is 2.3 wt%, the MLG content is 1.9 wt%, the mixing time is 15 min, and the molding temperature is 78°C. The experimentally verified relative error to the actual sensitivity (0.5371 kPa−1) is 2.625% and the sensitivity performance of the sensing unit in this study is also at a high level when compared with similar studies. It is proved that this method helps to find the optimal sensor content ratio and preparation process, improve the experimental efficiency, save the experimental cost, and provide a new idea for the rapid preparation of high-performance capacitive flexible pressure sensing units.

-

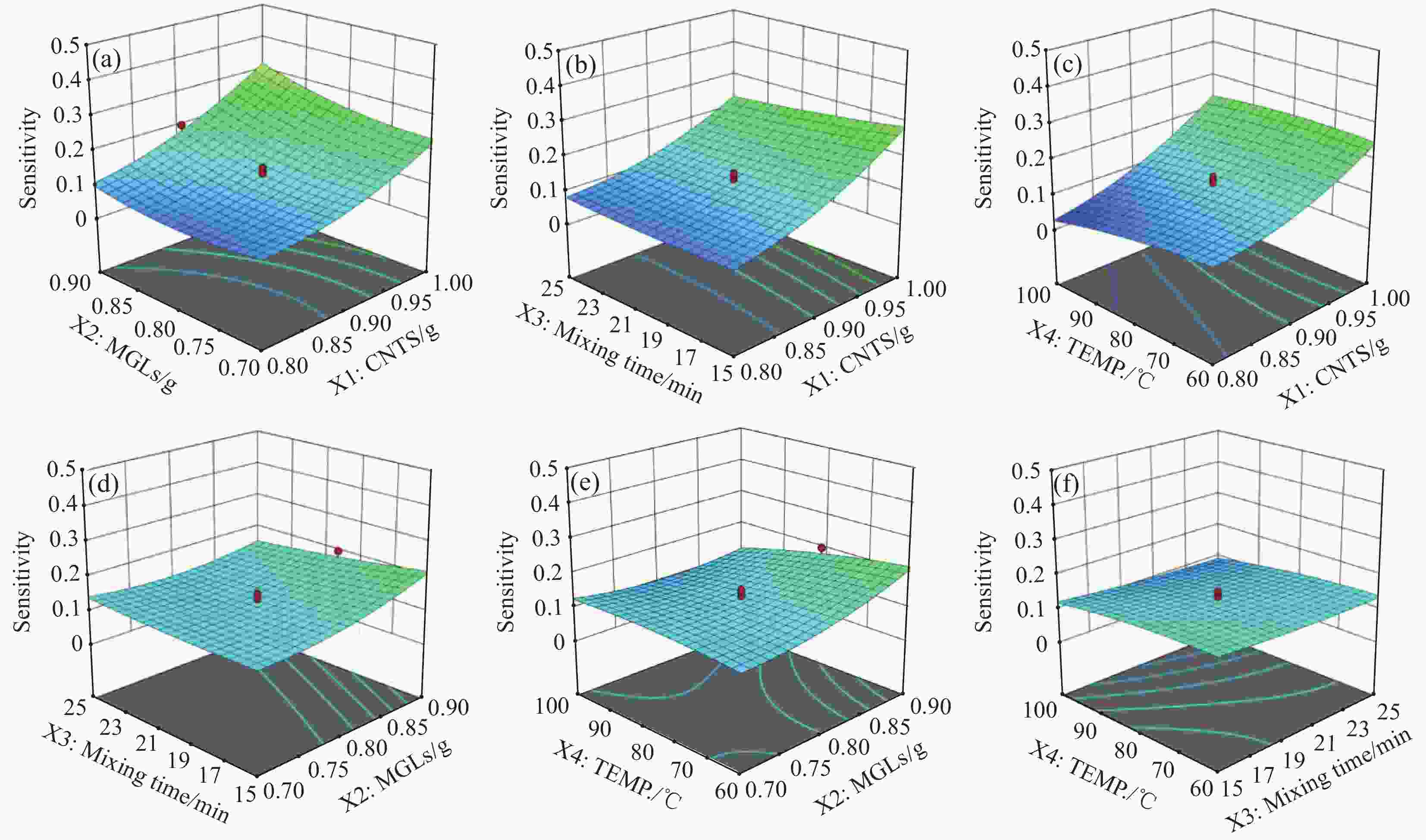

图 12 灵敏度三维响应面图:(a)碳纳米管(CNT)/石墨烯(MLG)相互作用;(b)CNT/搅拌时间相互作用;(c)CNT/成型温度相互作用;(d)MLG/搅拌时间相互作用;(e)MLG/成型温度相互作用;(f)搅拌/成型温度相互作用

Figure 12. Three-dimensional response surface plots of sensitivity: (a) Interaction between CNT/MLG content; (b) Interaction between CNT/mixing time; (c) Interaction between CNT/molding temperature; (d) Interaction between MLG/mixing time; (e) Interaction between MLG/molding temperature; (f) Interaction between mixing time/molding temperature

表 1 单因素实验方案

Table 1. Single-factor protocol

Index Content of CNTs/g Content of MLGs/g Mixing time/min Molding temperature/℃ Analysis of factors affecting 1 0.4,0.5,0.6,0.7,0.8,0.9,1.0,1.1 0.6 15 80 CNT 2 0.7 0.4,0.5,0.6,0.7,0.8,0.9,1.0,1.1 15 80 MLG 3 0.7 0.6 10,15,20,25,30 80 Mixing time 4 0.7 0.6 15 40,60,80,100,120 Molding temperature 表 2 四个因素的水平和编码

Table 2. Level and code of four factors

Code Levels Factor CNTs/g MLGs/g Mixing time/min Molding temperature/℃ −2 0.7 0.6 10 40 −1 0.8 0.7 15 60 0 0.9 0.8 20 80 1 1.0 0.9 25 100 2 1.1 1.0 30 120 表 3 多因素中心组合实验设计(CCD)与结果

Table 3. Multifactorial central combinatorial experimental design (CCD) and results

Run Factors Sensitivity CNT MLG Mixing time Molding temperature 1 1 −1 −1 1 0.227 2 0 0 2 0 0.13 3* 0 0 0 0 0.118 4 −1 −1 −1 1 0.058 5 1 1 1 1 0.191 6 1 −1 −1 −1 0.208 7 −1 1 1 1 0.025 8* 0 0 0 0 0.145 9 −1 1 −1 1 0.05 10 −1 −1 1 −1 0.125 11 −2 0 0 0 0.05 12 0 −2 0 0 0.185 13 0 0 −2 0 0.193 14 −1 1 1 −1 0.164 15 1 1 −1 −1 0.375 16 1 −1 1 −1 0.18 17* 0 0 0 0 0.135 18 1 1 1 −1 0.31 19 0 1 0 0 0.198 20 2 0 0 0 0.478 21 −1 1 −1 −1 0.178 22 0 0 0 0 0.154 23 1 1 −1 1 0.326 24 0 0 0 −2 0.124 25* 0 0 0 0 0.117 26* 0 0 0 0 0.112 27 −1 −1 −1 −1 0.078 28 1 −1 1 1 0.248 29 −1 −1 1 1 0.09 30 0 0 0 2 0.073 Note: *indicates the central repeated trials. 表 4 灵敏度响应的方差分析

Table 4. Analysis of variance for sensitivity response

Source Sum of squares df Mean square F-value P-value Status Model 0.2877 14 0.0205 32.91 < 0.0001 Significant $ {x}_{1} $-CNT 0.1931 1 0.1931 309.36 < 0.0001 $ {x}_{2} $-MLG 0.0117 1 0.0117 18.789 0.0006 $ {x}_{3} $-Mixing time 0.0036 1 0.0036 5.73 0.0302 $ {x}_{4} $-Temperature 0.0106 1 0.0106 17.02 0.0009 $ {x}_{1}{x}_{2} $ 0.0047 1 0.0047 7.46 0.0155 $ {x}_{1}{x}_{3} $ 0.0038 1 0.0038 6.11 0.0259 $ {x}_{1}{x}_{4} $ 0.0036 1 0.0036 5.81 0.0292 $ {x}_{2}{x}_{3} $ 0.0060 1 0.0060 9.68 0.0071 $ {x}_{2}{x}_{4} $ 0.0136 1 0.0136 21.83 0.0003 $ {x}_{3}{x}_{4} $ 0.0001 1 0.0001 0.2211 0.6449 $ {{x}_{1}}^{2} $ 0.0267 1 0.0267 42.79 < 0.0001 $ {{x}_{2}}^{2} $ 0.0085 1 0.0085 13.65 0.0022 $ {{x}_{3}}^{2} $ 0.0008 1 0.0008 1.26 0.2795 $ {{x}_{4}}^{2} $ 0.0030 1 0.0030 4.88 0.0432 Residual 0.0094 15 0.0006 Lack of fit 0.0079 10 0.0008 2.70 0.1422 Not significant Pure error 0.0015 5 0.0003 Cor total 0.2970 29 $ {R}^{2} $ 0.9685 $ {R}_{\mathrm{A}\mathrm{d}\mathrm{j}}^{2} $ 0.9390 $ {R}_{\mathrm{P}\mathrm{r}\mathrm{e}\mathrm{d}}^{2} $ 0.8311 C.V% 14.86 Adeq precision 23.8126 Notes: Cor total refers to the total number of correlation coefficients;$ {R}_{\mathrm{A}\mathrm{d}\mathrm{j}}^{2} $indicates adjusted coefficient of determination;$ {R}_{\mathrm{P}\mathrm{r}\mathrm{e}\mathrm{d}}^{2} $ indicates predicted R-squared; Adeq precision is an important statistical metric for evaluating the predictive ability of response surface models. 表 5 SVR模型的5折交叉验证预测性能评价指标

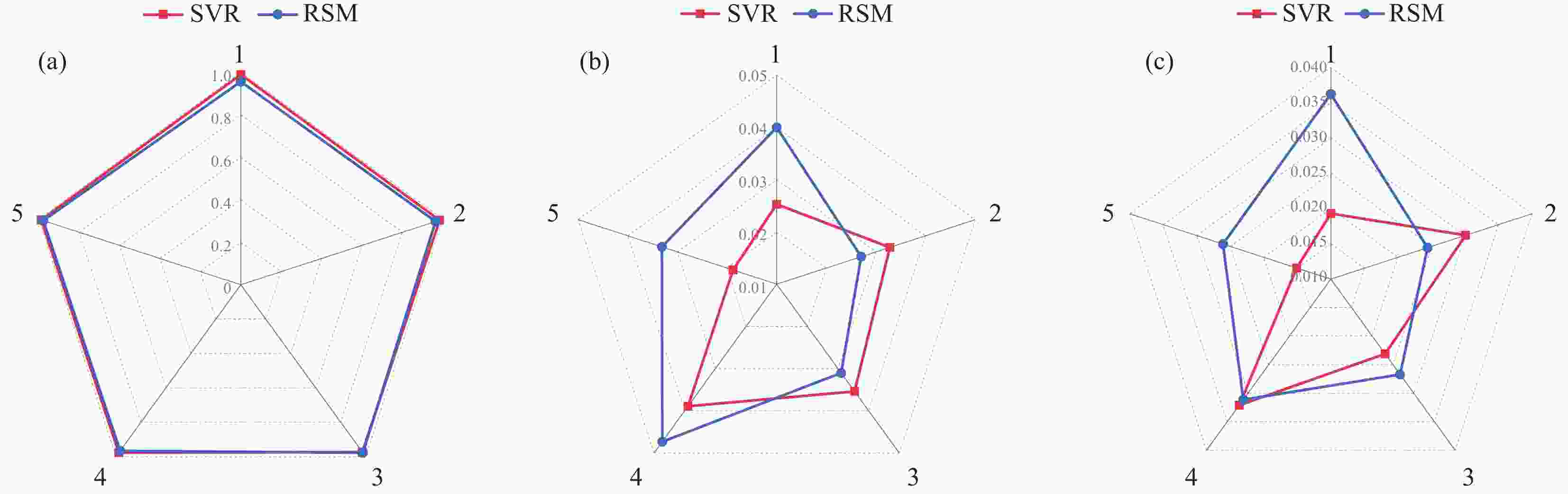

Table 5. Performance evaluation index of SVR model by cross validation

Index 1 2 3 4 5 Average $ {R}^{2} $ 0.9893 0.9841 0.9735 0.9769 0.9882 0.9824 Rmse 0.0253 0.0328 0.0354 0.0389 0.0188 0.0320 Mae 0.0193 0.0301 0.0231 0.0321 0.0151 0.0239 表 6 RSM模型的5折交叉验证预测性能评价指标

Table 6. Performance evaluation index of RSM model by cross validation

Index 1 2 3 4 5 Average R2 0.9563 0.9642 0.9778 0.9669 0.9782 0.96868 Rmse 0.04002 0.02701 0.03103 0.04731 0.03312 0.035698 Mae 0.03623 0.02443 0.02671 0.03113 0.02608 0.028916 表 7 传感单元灵敏度性能对比

Table 7. Comparison of sensitivity performance of sensing units

Reference Method Sensitivity /k$ \mathrm{P}{\mathrm{a}}^{-1} $ Pressure range /$ \mathrm{k}\mathrm{P}\mathrm{a} $ Comparison /k$ \mathrm{P}{\mathrm{a}}^{-1} $ [12] Microstructure design 0.451 0-25 0.7665 [42] Microstructure design 0.69 0-10 1.7531 [43] Microstructure design 1.01 0-25 0.7665 [44] mechanical blending 0.3850 0-30 0.5371 [45] Microstructure design 0.341 0-5 1.9698 This study mechanical blending 0.5371 0-30 - -

[1] GILIOPOULOS D, ZAMBOULIS A, GIANNAKOUDAKIS D, et al. Polymer/Metal Organic Framework (MOF) Nanocomposites for Biomedical Applications[J]. Molecules, 2020, 25(1): 185. doi: 10.3390/molecules25010185 [2] SHAH V, BHALIYA J, PATEL G M, et al. Advances in polymeric nanocomposites for automotive applications: A review[J]. Polymers for Advanced Technologies, 2022, 33(10): 3023-3048. doi: 10.1002/pat.5771 [3] CHEN S, YANG K, LENG X, et al. Perspectives in the design and application of composites based on graphene derivatives and bio-based polymers[J]. Polymer International, 2020, 69(12): 1173-1186. doi: 10.1002/pi.6080 [4] LIU J, HUI D, LAU D. Two-dimensional nanomaterial-based polymer composites: Fundamentals and applications[J]. Nanotechnology Reviews, 2022, 11(1): 770-792. doi: 10.1515/ntrev-2022-0041 [5] ZHU Y, LIU B, WANG S, et al. Development of a FBG Stress Sensor for Geostress Measurement Using RSR Method in Deep Soft Fractured Rock Mass[J]. Applied Sciences, 2022, 12(4): 1781. doi: 10.3390/app12041781 [6] ASYRAF M R M, ISHAK M R, SYAMSIRA, et al. Mechanical properties of oil palm fibre-reinforced polymer composites: A review[J]. Journal of Materials Research and Technology, 2022, 17: 33-65. doi: 10.1016/j.jmrt.2021.12.122 [7] DU H, FANG C, ZHANG J, et al. Segregated carbon nanotube networks in CNT-polymer nanocomposites for higher electrical conductivity and dielectric permittivity, and lower percolation threshold[J]. International Journal of Engineering Science, 2022, 173: 103650. doi: 10.1016/j.ijengsci.2022.103650 [8] ZHANG F, FENG Y, QIN M, et al. Stress controllability in thermal and electrical conductivity of 3D elastic graphene-crosslinked carbon nanotube sponge/polyimide nanocomposite[J]. Advanced Functional Materials, 2019, 29(25): 1901383. doi: 10.1002/adfm.201901383 [9] MOUSSA M, EL-KADY M F, ABDEL-AZEMS, et al. Compact, flexible conducting polymer/graphene nanocomposites for supercapacitors of high volumetric energy density[J]. Composites Science and Technology, 2018, 160: 50-59. doi: 10.1016/j.compscitech.2018.02.033 [10] LI X, XU W, XIN Y, et al. Supramolecular polymer nanocomposites for biomedical applications[J]. Polymers, 2021, 13(4): 513. doi: 10.3390/polym13040513 [11] 赵梁成, 李斌, 武思蕊, 等. 功能三维石墨烯-多壁碳纳米管/热塑性聚氨酯复合材料的制备及性能[J]. 复合材料学报, 2020, 37(2): 242-251.ZHAO Liangcheng, LI Bin, WU Sirui, et al. Preparation and properties of functional three-dimensional graphene-multi-walled carbon nanotubes/thermoplastic polyurethane composites[J]. Journal of Composite Materials, 2020, 37(2): 242-251(in Chinese). [12] 药芳萍, 黎相孟, 石强盛杰, 等. 石墨烯-聚合物柔性电容传感器制备及性能研究[J]. 中国机械工程, 2021, 32(24): 2909-2914. doi: 10.3969/j.issn.1004-132X.2021.24.002YAO Fangping, LI Xiangmeng, SHI Qiangshengjie, et al. Preparation and performance of graphene-polymer flexible capacitive sensors[J]. China Mechanical Engineering, 2021, 32(24): 2909-2914(in Chinese). doi: 10.3969/j.issn.1004-132X.2021.24.002 [13] XU B, YE F, CHEN R, et al. A wide sensing range and high sensitivity flexible strain sensor based on carbon nanotubes and MXene[J]. Ceramics International, 2022, 48(7): 10220-10226. doi: 10.1016/j.ceramint.2021.12.235 [14] 吴其皓, 廖鹏飞, 茅寅, 等. 高灵敏度电容式柔性压力传感器的设计与优化[J]. 传感器与微系统, 2023, 42(4): 107-110.WU Qihao, LIAO Pengfei, MAO Yin, et al. Design and Optimization of High Sensitivity Capacitive Flexible Pressure Sensors[J]. Sensors and Microsystems, 2023, 42(4): 107-110(in Chinese). [15] MA Z, ZHANG K, YANG S, et al. High-performancecapacitive pressure sensors Fabricated by introducing dielectric filler and conductive filler into a porous dielectric layer through a Biomimic strategy[J]. Composites Science and Technology, 2022, 227: 109595. doi: 10.1016/j.compscitech.2022.109595 [16] KE K, MCMASTER M, CHRISTOPHERSON W, et al. Highly sensitive capacitive pressure sensors basedon elastomer composites with carbon filler hybrids[J]. Composites Part A: Applied Science and Manufacturing, 2019, 126: 105614. doi: 10.1016/j.compositesa.2019.105614 [17] BI G, XIAO B, LIN Y, et al. Modeling and Optimization of Sensitivity and Creep for Multi-Component Sensing Materials[J]. Nanomaterials, 2023, 13(2): 298. doi: 10.3390/nano13020298 [18] 王苏, 白元元, 王书琪, 等. 基于MXene/多壁碳纳米管的柔性压力传感器[J]. 传感器与微系统, 2022, 41(7): 5-8.WANG Su, BAI Yuanyuan, WANG Shuqi, et al. Flexible pressure sensor based on MXene/multi-walled carbon nanotubes[J]. Sensors and Microsystems, 2022, 41(7): 5-8(in Chinese). [19] CHEN X, WEI Z, HE K. An Estimation of the Discharge Exponent of a Drip Irrigation Emitter by Response Surface Methodology and Machine Learning[J]. Water, 2022, 14(7): 1034. doi: 10.3390/w14071034 [20] 胡欣颖, 李洪军, 李少博, 等. 对比研究响应面法和BP神经网络-粒子群算法优化调理松板肉加工工艺[J]. 食品与发酵工业, 2019, 45(24): 179-187.HU Xinying, LI Hongjun, LI Shaobo, et al. Comparative study of response surface methodology and BP neural network-particle swarm algorithm for optimization of seasoned pine board meat processing process[J]. Food and Fermentation Industry, 2019, 45(24): 179-187(in Chinese). [21] LI X, CHEN S, ZHANG J, et al. Optimization of Ultrasonic-Assisted Extraction of Active Components and Antioxidant Activity from Polygala tenuifolia: A Comparative Study of the Response Surface Methodology and Least Squares Support Vector Machine[J]. Molecules, 2022, 27(10): 3069. doi: 10.3390/molecules27103069 [22] XUE J, SHEN B. Dung beetle optimizer: a new meta-heuristic algorithm for global optimization[J]. The Journal of Supercomputing, 2023, 79(7): 7305-7336. doi: 10.1007/s11227-022-04959-6 [23] MIRJALILI S. Genetic Algorithm[M/OL]//MIRJALILI S. Evolutionary Algorithms and Neural Networks: Theory and Applications. Cham: Springer International Publishing, 2019: 43-55. [24] KENNEDY J, EBERHART R. Particle swarm optimization[C/OL]//Proceedings of ICNN’95 - International Conference on Neural Networks, 1995: 1942-1948. [25] 隋东, 杨振宇, 丁松滨, 等. 基于EMSDBO算法的无人机三维航迹规划[J]. 系统工程与电子技术, 2024: 1-13.SUI Dong, YANG Zhenyu, DING Songbin, et al. Three-dimensional trajectory planning for unmanned aircraft based on EMSDBO algorithm[J]. Systems Engineering and Electronics, 2024: 1-13. (in Chinese). [26] 周亚中, 何怡刚, 邢致恺, 等. 基于IDBO-ARIMA的电力变压器振动信号预测[J]. 电子测量与仪器学报, 2023, 37(8): 11-20.ZHOU Yazhong, HE Yigang, XING Zhikai, et al. Vibration signal prediction of power transformer based on IDBO-ARIMA[J]. Journal of Electronic Measurement and Instrumentation, 2023, 37(8): 11-20 (in Chinese). [27] KHAN M Z, YOUSUF R I, SHOAIB M H, et al. A hybrid framework of artificial intelligence-based neural network model (ANN) and central composite design (CCD) in quality by design formulation development of orodispersible moxifloxacin tablets: Physicochemical evaluation, compaction analysis, and its in-silico PBPK modeling[J]. Journal of Drug Delivery Science and Technology, 2023, 82: 104323. doi: 10.1016/j.jddst.2023.104323 [28] 王建军, 白鹏翔, 董杰, 等. 基于硅烷偶联剂改性的炭黑-石墨烯在天然胶中的性能研究[J]. 橡塑技术与装备, 2023, 49(4): 16-20.WANG Jianjun, BAI Pengxiang, DONG Jie, et al. Study on the properties of carbon black-graphene in natural rubber based on silane coupling agent modification[J]. Rubber and Plastic Technology and Equipment, 2023, 49(4): 16-20. [29] 田玉玉, 何韧, 吴菊英, 等. 电容式柔性压力传感器的性能优化原理及研究进展[J]. 材料导报, 2023, (16): 1-23.TIAN Yuyu, HE Ren, WU Juying, et al. Principles of performance optimization and research progress of capacitive flexible pressure sensors[J]. Materials Herald, 2023, (16): 1-23(in Chinese). [30] XU J, WONG C P. Low-loss percolative dielectric composite[J]. Applied Physics Letters, 2005, 87(8): 082907. doi: 10.1063/1.2032597 [31] SHEN Y, LIN Y H, NAN C W. Interfacial Effect on Dielectric Properties of Polymer Nanocomposites Filled with Core/Shell-Structured Particles[J]. Advanced Functional Materials, 2007, 17(14): 2405-2410. doi: 10.1002/adfm.200700200 [32] YANG M, LI W, ZHAO Z, et al. Micromechanical modeling for the temperature-dependent yield strength of polymer-matrix nanocomposites[J]. Composites Science and Technology, 2022, 220: 109265. doi: 10.1016/j.compscitech.2022.109265 [33] KESHTEGAR B, HEDDAM S, SEBBAR A, et al. SVR-RSM: a hybrid heuristic method for modeling monthly pan evaporation[J]. Environmental Science and Pollution Research, 2019, 26(35): 35807-35826. doi: 10.1007/s11356-019-06596-8 [34] 张娜, 赵泽丹, 包晓安, 等. 基于改进的Tent混沌万有引力搜索算法[J]. 控制与决策, 2020, 35(4): 893900.ZHANG Na, ZHAO Zedan, BAO Xiao‘an, et al. Improved Tent-based chaotic universal gravity search algorithm[J]. Control and Decision Making, 2020, 35(4): 893900 (in Chinese). [35] 宁杰琼, 何庆. t-分布扰动策略和变异策略的花授粉算法[J]. 小型微型计算机系统, 2021, 42(1): 64-70. doi: 10.3969/j.issn.1000-1220.2021.01.012NING Jieqiong, HE Qing. Flower pollination algorithms with t-distribution perturbation strategy and variation strategy[J]. Small Microcomputer Systems, 2021, 42(1): 64-70(in Chinese). doi: 10.3969/j.issn.1000-1220.2021.01.012 [36] 郭琴, 郑巧仙. 多策略改进的蜣螂优化算法及其应用[J]. 计算机科学与探索, 2023: 1-22.GUO Qin, ZHENG Qiaoxian. Multi-strategy improved dung beetle optimization algorithm and its applications[J]. Computer Science and Exploration, 2023: 1-22. [37] LI S, LI J. Chaotic dung beetle optimization algorithm based on adaptive t-Distribution[C/OL]//2023 IEEE 3rd International Conference on Information Technology, Big Data and Artificial Intelligence (ICIBA). Chongqing, China: IEEE, 2023: 925-933[2024-01-24].https://ieeexplore.ieee.org/document/10165106/. DOI: 10.1109/ICIBA56860.2023.10165106. [38] 苏国士, 梁阚, 李虓, 等. 石墨烯/碳纳米管复合导电剂制备[J]. 炭素技术, 2022, 41(1): 23-27+40.SU Guoshi, LIANG Kan, LI Xiao, et al. Preparation of graphene/carbon nanotube composite conductive agent[J]. Carbon Technology, 2022, 41(1): 23-27+40(in Chinese). [39] 苏志强, 张晓媛, 赵鑫, 等. 基于碳纳米管/石墨烯界面修饰的碳纤维增强复合材料中力-电耦合关系探究[J]. 长春工业大学学报, 2022, 43(Z1): 354-359.SU Zhiqiang, ZHANG Xiaoyuan, ZHAO Xin, et al. Investigation of force-electricity coupling relationship in carbon fiber reinforced composites based on carbon nanotube/graphene interfacial modification[J]. Journal of Changchun University of Technology, 2022, 43(Z1): 354-359(in Chinese). [40] COLONNA S, BERNAL M M, GAVOCI G, et al. Effect of processing conditions on the thermal and electrical conductivity of poly (butylene terephthalate) nanocomposites prepared via ring-opening polymerization[J]. Materials & Design, 2017, 119: 124-132. [41] JAHANI Y, BAENA M, BARRIS C, et al. Influence of curing, post-curing and testing temperatures on mechanical properties of a structural adhesive[J]. Construction and Building Materials, 2022, 324: 126698. doi: 10.1016/j.conbuildmat.2022.126698 [42] 赵珂. 基于三维竖直石墨烯的微结构柔性压力传感器[D]. 山西大学, 2023.ZHAO Ke. Microstructured flexible pressure sensor based on 3D vertical graphene[D]. Shanxi University, 2023 (in Chinese). [43] 王菲菲, 彭海益, 姚晓刚. 基于多向冷冻法制备的高灵敏度柔性电容式压力传感器[J]. 复合材料学报, 2023, 40(5): 2680-2687.WANG Feifei, PENG Haiyi, YAO Xiaogang. Highly sensitive flexible capacitive pressure sensor prepared based on multidirectional freezing method[J]. Journal of Composite Materials, 2023, 40(5): 2680-2687(in Chinese). [44] YAN S, TANG Y, BI G, et al. Optimal Design of Carbon-Based Polymer Nanocomposites Preparation Based on Response Surface Methodology[J]. Polymers, 2023, 15(6): 1494. doi: 10.3390/polym15061494 [45] 张鹏, 陈昱丞, 张建, 等. 基于双层微结构电极的柔性电容式压力传感器[J]. 仪表技术与传感器, 2020, (5): 11-13+17. doi: 10.3969/j.issn.1002-1841.2020.05.003ZHANG Peng, CHEN Yucheng, ZHANG Jian, et al. Flexible capacitive pressure sensor based on double-layer microstructured electrodes[J]. Instrumentation Technology and Sensors, 2020, (5): 11-13+17(in Chinese). doi: 10.3969/j.issn.1002-1841.2020.05.003 -

点击查看大图

点击查看大图

计量

- 文章访问数: 45

- HTML全文浏览量: 75

- 被引次数: 0

下载:

下载: