Effect of the adhesive layer on mechanical properties and load distribution in multi-bolt composite joints

-

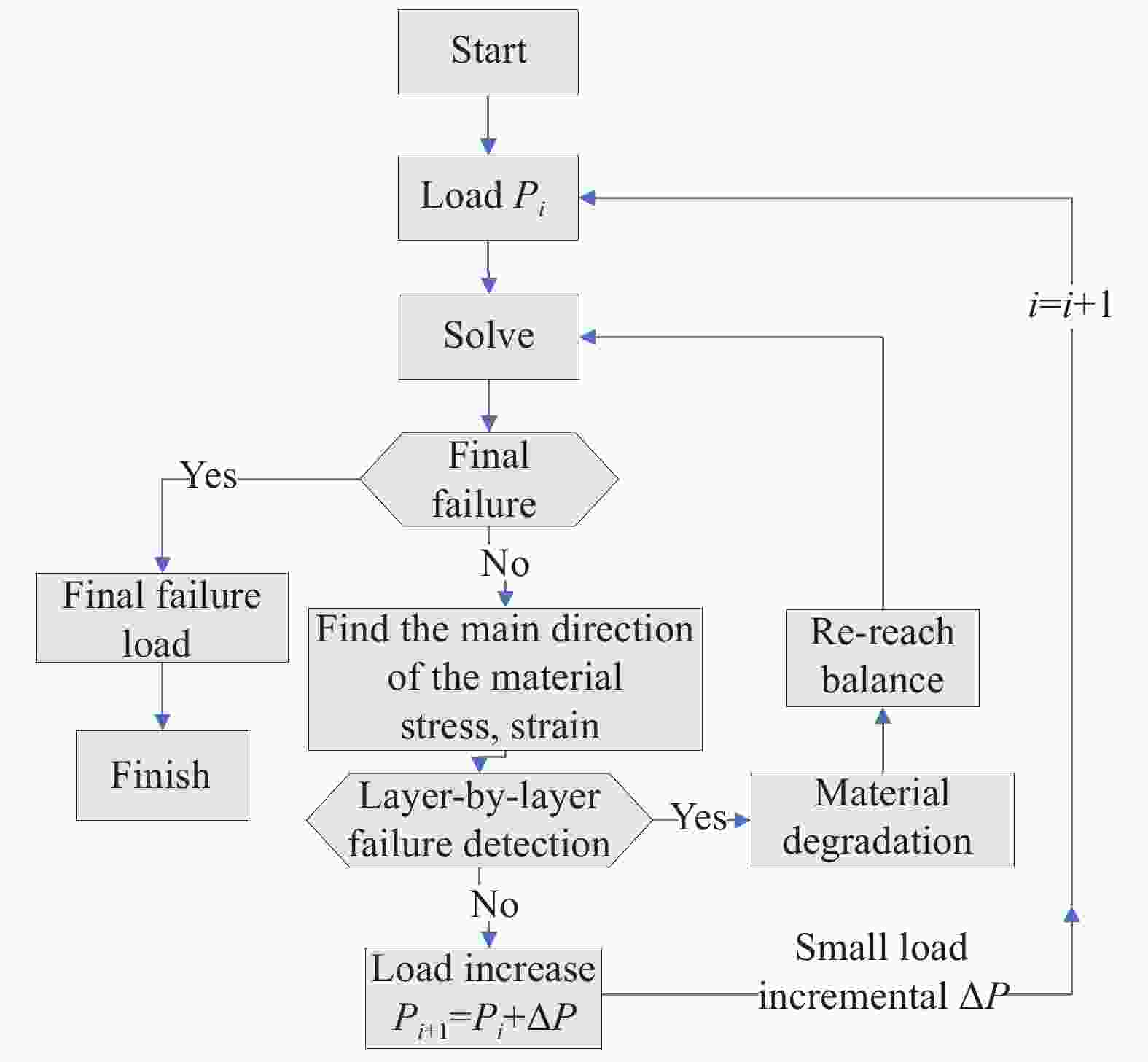

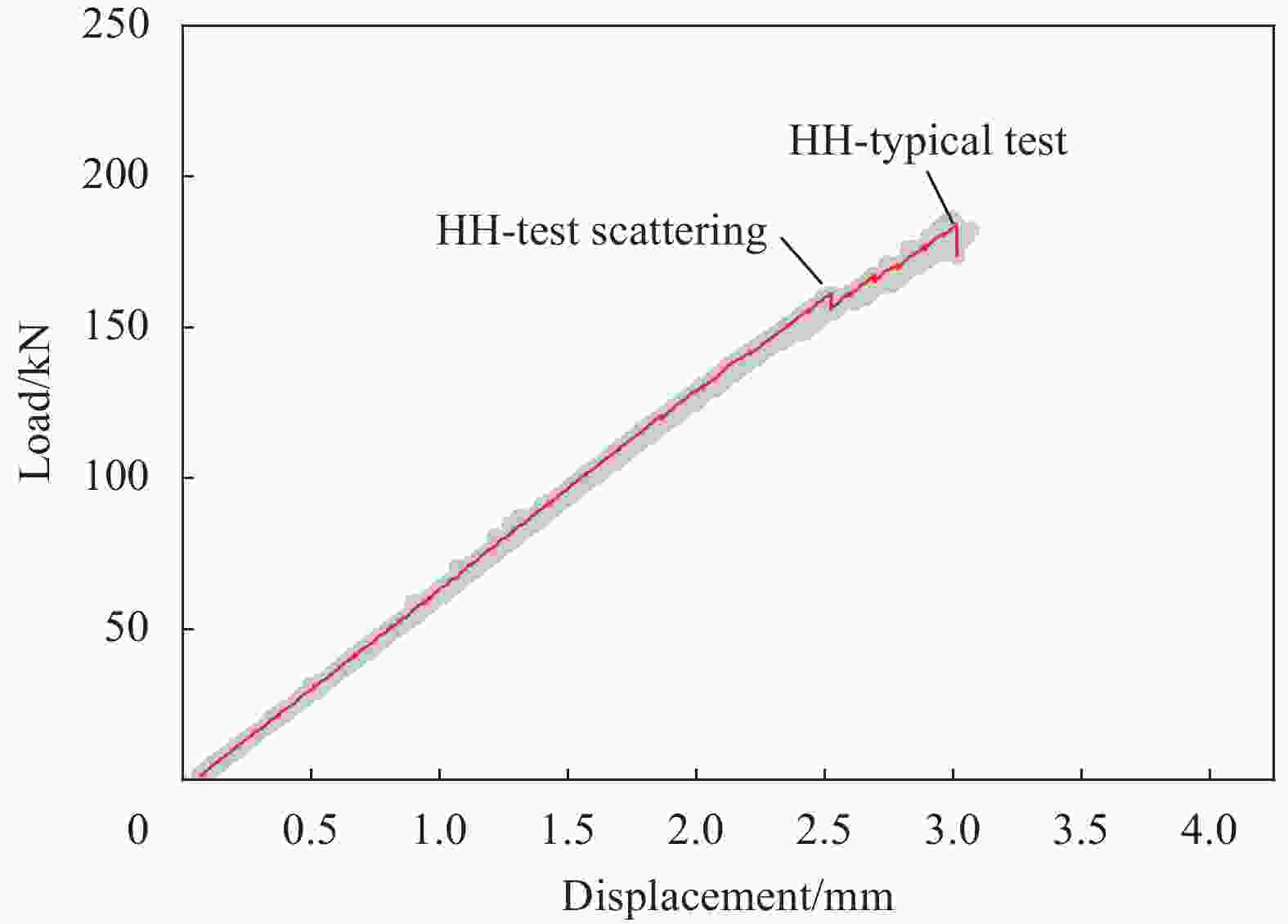

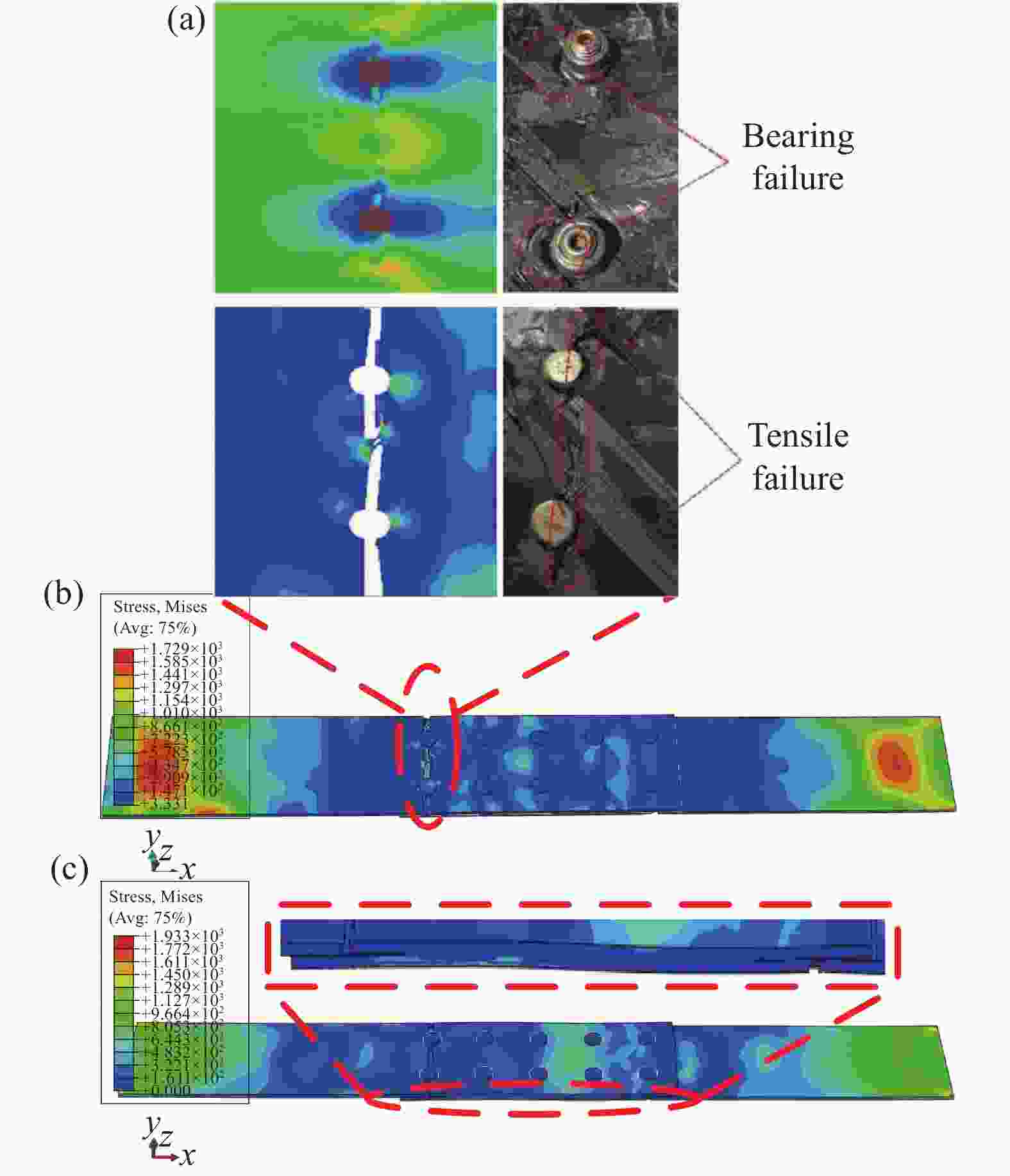

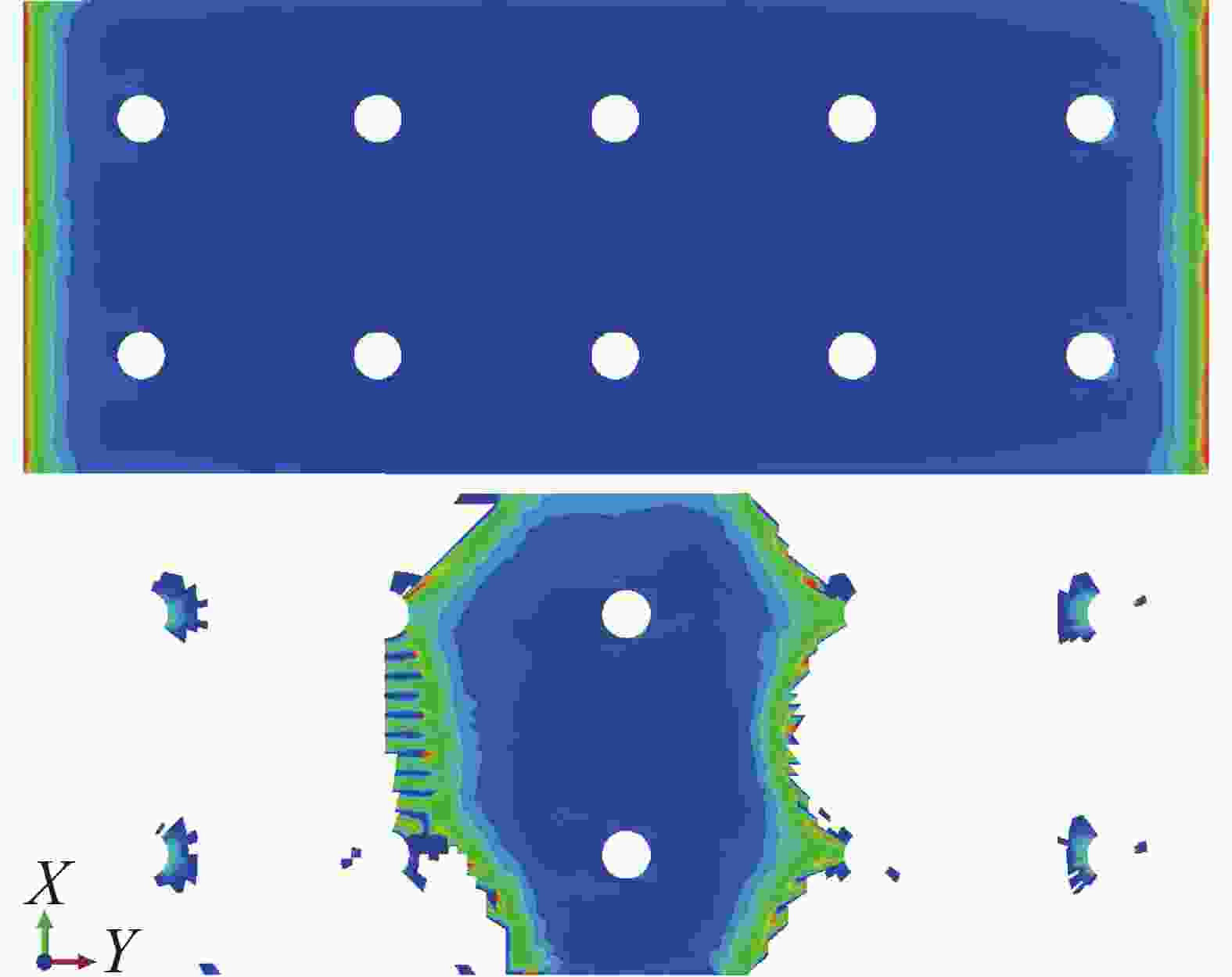

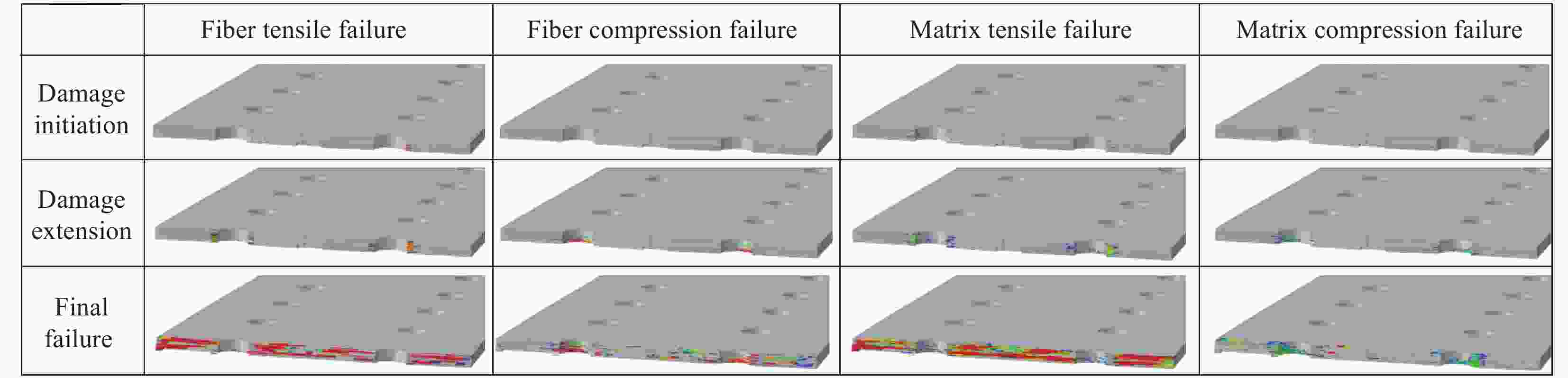

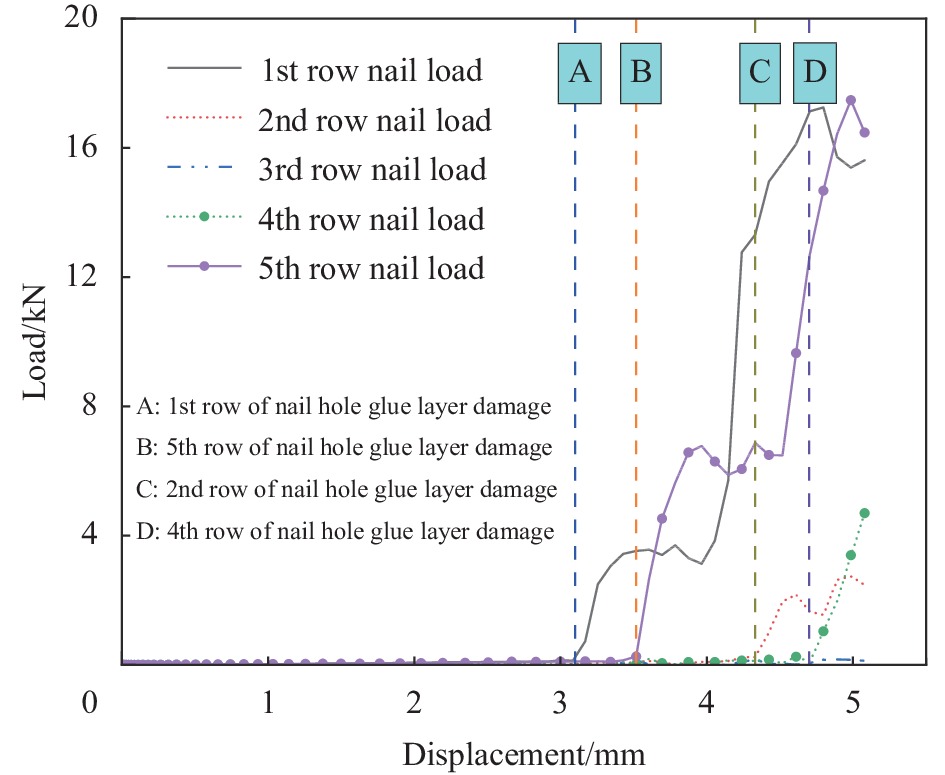

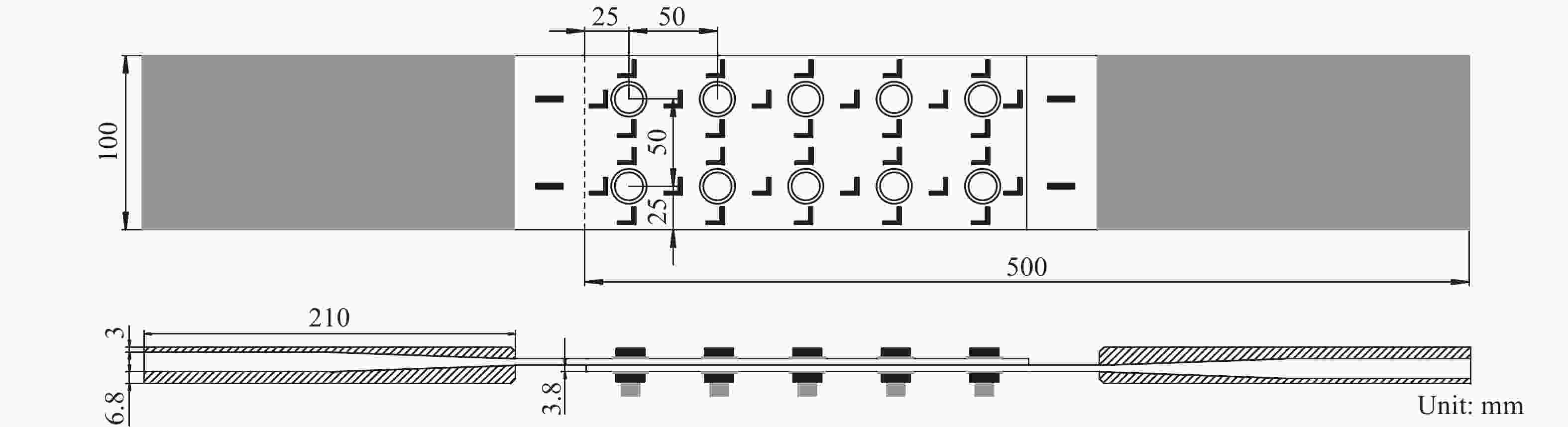

摘要: 通过试验和数值方法研究了单搭接复合材料胶螺混合连接在拉伸载荷下的力学性能及钉载分配。测试了多螺栓机械连接和胶螺混合连接的破坏载荷、失效模式和钉载分配,结果显示两种连接方式下连接层合板的破坏模式均为拉伸破坏与挤压破坏的混合失效模式,胶螺混合连接中胶层的破坏模式为胶层剥离。胶层的存在使混合连接的钉载分配更加不均衡,因此机械连接的整体结构破坏载荷要略大于胶螺混合连接。采用ABAQUS显示求解器建立了多螺栓机械连接和胶螺混合连接的渐进损伤模型,用VUMAT子程序预测复合材料的损伤,并利用粘结单元模拟胶层的失效。该模型可以有效预测结构的破坏载荷、失效模式和钉载分配。给出了混合连接中胶层的损伤演化过程,分析了加载过程中胶层对钉载分配的影响。钉载分配结果显示:机械连接的钉载分配呈现两边高,中间低的“盆状”分布,混合连接胶层延迟了螺栓受载,并改变了钉载分配的比例,使得最外侧螺栓承担了更大的载荷,加速了结构的破坏。Abstract: The mechanical properties and load distribution of single-lap composite hybrid bonded/bolted joints under tensile loading were investigated experimentally and numerically. The damage loads, failure modes, and load distribution of the multi-bolt mechanical joints and the hybrid bonded/bolted joints were tested. The results show that the failure modes of the laminates are a mixture of tensile and extrusion damage for both joints, and the failure mode of the adhesive layer is adhesive peeling in the hybrid bonded/bolted joints. The presence of the adhesive layer makes the load distribution of the hybrid joints more uneven, so the overall structural damage load of the mechanical joints is as slightly greater than that of the hybrid bonded/bolted joints. ABAQUS display solver was used to establish the progressive damage model for multi-bolt mechanical and hybrid bonded/bolted joints. The VUMAT subroutine was used to compile the damage criterion of the composite material and to simulate the failure of the adhesive layer using the cohesive element. The model can effectively predict the damage load, failure mode and load distribution of the structure. The hybrid joint's adhesive layer damage evolution mechanism was described, and the influence of the adhesive layer on the load distribution during the loading process was analyzed. The results of the load distribution indicate that the load distribution of the mechanical joints shows a "basin" distribution with high sides and low middle. The hybrid joints' adhesive layer delays the bolt loading and changes the ratio of load distribution, which makes the outermost bolt take more load and accelerates the damage to the structure.

-

表 1 X850-MG IM复合材料参数

Table 1. Composite material parameters of X850-MG IM

${E_{11}}$/GPa ${E_{22}}$/GPa ${E_{33}}$/GPa ${\nu _{12}}$/GPa ${\nu _{13}}$/GPa ${\nu _{23}}$/GPa ${G_{12}}$/GPa ${G_{13}}$/GPa ${G_{23}}$/GPa 175 8.37 8.37 0.34 0.34 0.34 4.49 4.49 3.5 ${X_{\text{T}}}$/MPa ${Y_{\text{T}}}$/MPa ${Z_{\text{T}}}$/MPa ${X_{\text{C}}}$/MPa ${Y_{\text{C}}}$/MPa ${Z_{\text{C}}}$/MPa ${S_{ 12}}$/MPa ${S_{ 13}}$/MPa ${S_{ 23}}$/MPa 3071 88 88 1747 271 271 143 143 143 Notes: IM—Intermediate modulus; E11, E22, E33—Elastic modulus in directions 1, 2 and 3; G12, G13, G23—Shear modulus in directions 12, 13 and 23; S12, S13, S23—Shear strength in directions 12, 13 and 23; ν12, ν13, ν23—Poisson's ratio in directions 12, 13 and 23; XT, YT, ZT—Tensile strength in directions X, Y and Z; XC, YC, ZC—Compressive strength in directions X, Y and Z. 表 2 多螺栓机械连接与胶螺混合连接复合材料试件试验与数值模拟破坏载荷对比

Table 2. Comparison of failure load between multi-bolt mechanical joints and hybrid bonded/bolted joints composite specimen test and numerical simulation

Text peak load/kN Average/kN Numerical simulation/kN Error/% Mechanical joints JX-1 208.7 205.6 192.2 6.5 JX-2 205.4 JX-3 208.6 JX-4 199.5 Hybrid bonded/bolted joints HH-1 184.3 183.3 181.7 0.09 HH-2 180.3 HH-3 186.1 HH-4 182.5 -

[1] LIU Fengrui, YAO Wanting, ZHAO Libin, et al. An improved 2D finite element model for bolt load distribution analysis of composite multi-bolt single-lap joints[J]. Composite Structures,2020,253:112770. [2] ZHANG Hongzhuang, LI Changyou, XU Mengtao, et al. A novel method for damage analysis of CFRP single-lap bolted, bonded and hybrid joints under compression[J]. Composite Structures,2020,251:112636. doi: 10.1016/j.compstruct.2020.112636 [3] BODJONA K, FIELDING S, HEIDARI-RARANI M, et al. Effect of adhesive layer compliance on strength of single-lap hybrid bonded-bolted joints[J]. Composite Structures,2021,261:113324. doi: 10.1016/j.compstruct.2020.113324 [4] ABDELKERIM D S E, WANG X, IBRAHIM H A, et al. Static and fatigue behavior of pultruded FRP multi-bolted joints with basalt FRP and hybrid steel-FRP bolts[J]. Composite Structures,2019,220:324-337. doi: 10.1016/j.compstruct.2019.03.085 [5] COELHO A M G, MOTTRAM J T. A review of the behaviour and analysis of bolted con-nections and joints in pultruded fibre reinforced polymers[J]. Materials & Design,2015,74:86-107. [6] ZHANG Hanyu, ZHANG Lei, LIU Zhao, et al. Numerical analysis of hybrid (bonded/bolted) FRP composite joints: A review[J]. Composite Structures,2021,262(2):113606. [7] LI Xiaoqi, CHENG Xiaoquan, GUO Xin, et al. Tensile pro-perties of a hybrid bonded/bolted joint: Parameter study[J]. Composite Structures,2020,245:112329. doi: 10.1016/j.compstruct.2020.112329 [8] 邹鹏, 倪迎鸽, 毕雪, 等. 胶螺混合连接在复合材料结构中的研究进展[J]. 航空工程进展, 2021, 12(1):1-12. doi: 10.16615/j.cnki.1674-8190.2021.01.001ZOU Peng, NI Yingge, BI Xue, et al. Research progress of glue-screw hybrid connection in composite structures[J]. Advances in Aeronautical Engineering,2021,12(1):1-12(in Chinese). doi: 10.16615/j.cnki.1674-8190.2021.01.001 [9] 张超禹, 郑艳萍, 熊勇坚, 等. CFRP与铝板胶螺混合连接结构拉伸性能研究[J]. 复合材料科学与工程, 2020(8):12-17.ZHANG Chaoyu, ZHENG Yanping, XIONG Yongjian, et al. Research on tensile properties of CFRP and aluminum plate glue-screw hybrid connection structure[J]. Compo-site Materials Science and Engineering,2020(8):12-17(in Chinese). [10] VALLÉE T, TANNERT T, MEENA R, et al. Dimensioning method for bolted, adhesively bonded, and hybrid joints involving fibre-reinforced-polymers[J]. Composites Part B: Engineering,2013,46:179-187. doi: 10.1016/j.compositesb.2012.09.074 [11] 胡春幸, 侯玉亮, 铁瑛, 等. 不同胶接参数对 CFRP 层合板单搭胶接结构强度的影响及优化设计[J]. 机械工程学报, 2021, 57(8):154-165. doi: 10.3901/JME.2021.08.154HU Chunxing, HOU Yuliang, TIE Ying, et al. Influence of different bonding parameters on the structural strength and optimal design of single-lap bonding of CFRP lami-nates[J]. Chinese Journal of Mechanical Engineering,2021,57(8):154-165(in Chinese). doi: 10.3901/JME.2021.08.154 [12] ARMENTANI E, LAISO M, CAPUTO, et al. Numerical FEM evaluation for the structural behaviour of a hybrid (bonded/bolted) single-lap composite joint[J]. Procedia Structural Integrity,2018,8:137-153. doi: 10.1016/j.prostr.2017.12.015 [13] SZEPTYŃSKI P, NOWAK M. Qualitative analysis of the influence of the non-linear material characteristics of flexible adhesive on the performance of lap joints[J]. Compo-site Structures,2021,260:113539. doi: 10.1016/j.compstruct.2020.113539 [14] 刘志明, 许昶. 碳纤维增强环氧树脂复合材料与铝板胶螺混合连接接头失效仿真[J]. 复合材料学报, 2019, 36(10):2308-2315. doi: 10.13801/j.cnki.fhclxb.20181217.002LIU Zhiming, XU Chang. Failure simulation of carbon fiber reinforced epoxy resin composites and aluminum plate glue-screw hybrid joints[J]. Journal of Composite Materials,2019,36(10):2308-2315(in Chinese). doi: 10.13801/j.cnki.fhclxb.20181217.002 [15] STEIN N, MARDANI H, BECKER W. An efficient analysis model for functionally graded adhesive single lap joints[J]. International Journal of Adhesion and Adhesives,2016,70:117-125. doi: 10.1016/j.ijadhadh.2016.06.001 [16] 陈龙, 陈普会. 复合材料-钛合金混合结构多钉连接钉载分布及有限元计算[J]. 航空工程进展, 2020, 11(5):679-685. doi: 10.16615/j.cnki.1674-8190.2020.05.010CHEN Long, CHEN Puhui. Load distribution and finite element calculation of composite material-titanium alloy hybrid structure multi-nail connection[J]. Advances in Aeronautical Engineering,2020,11(5):679-685(in Chinese). doi: 10.16615/j.cnki.1674-8190.2020.05.010 [17] EGAN B, MCCARTHY C T, MCCARTHY M A, et al. Static and high-rate loading of single and multi-bolt carbon-epoxy aircraft fuselage joints[J]. Composites Part A: Applied Science and Manufacturing,2013,53:97-108. doi: 10.1016/j.compositesa.2013.05.006 [18] ZHANG Fa, HU Zhendong, GAO Limin, et al. Investigation on in-plane shear behavior of large-size composite plates with multi-bolt joints[J]. Composite Structures,2020,232:111553. doi: 10.1016/j.compstruct.2019.111553 [19] ASTM. Standard test method for bearing response of polymer matrix composite laminates: ASTM-D5961/D5961 M[S]. West Conshohcken: ASTM, 1996. [20] ABAQUS. ABAQUS Version 6.10, Dassault Systemes[M]. Providence: ABAQUS, 2010. [21] 李鹏. 复材层合板多钉螺接钉载分配和强度预测方法的研究[D]. 南京: 南京航空航天大学, 2019.LI Peng. Research on the load distribution and strength prediction method of multi-nail screw connections of composite laminates[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2019(in Chinese). -

下载:

下载: