Experiment on dynamic mechanical properties of steel and macro-polypropylene hybrid fibers reinforced recycled aggregate concrete under uniaxial compression

-

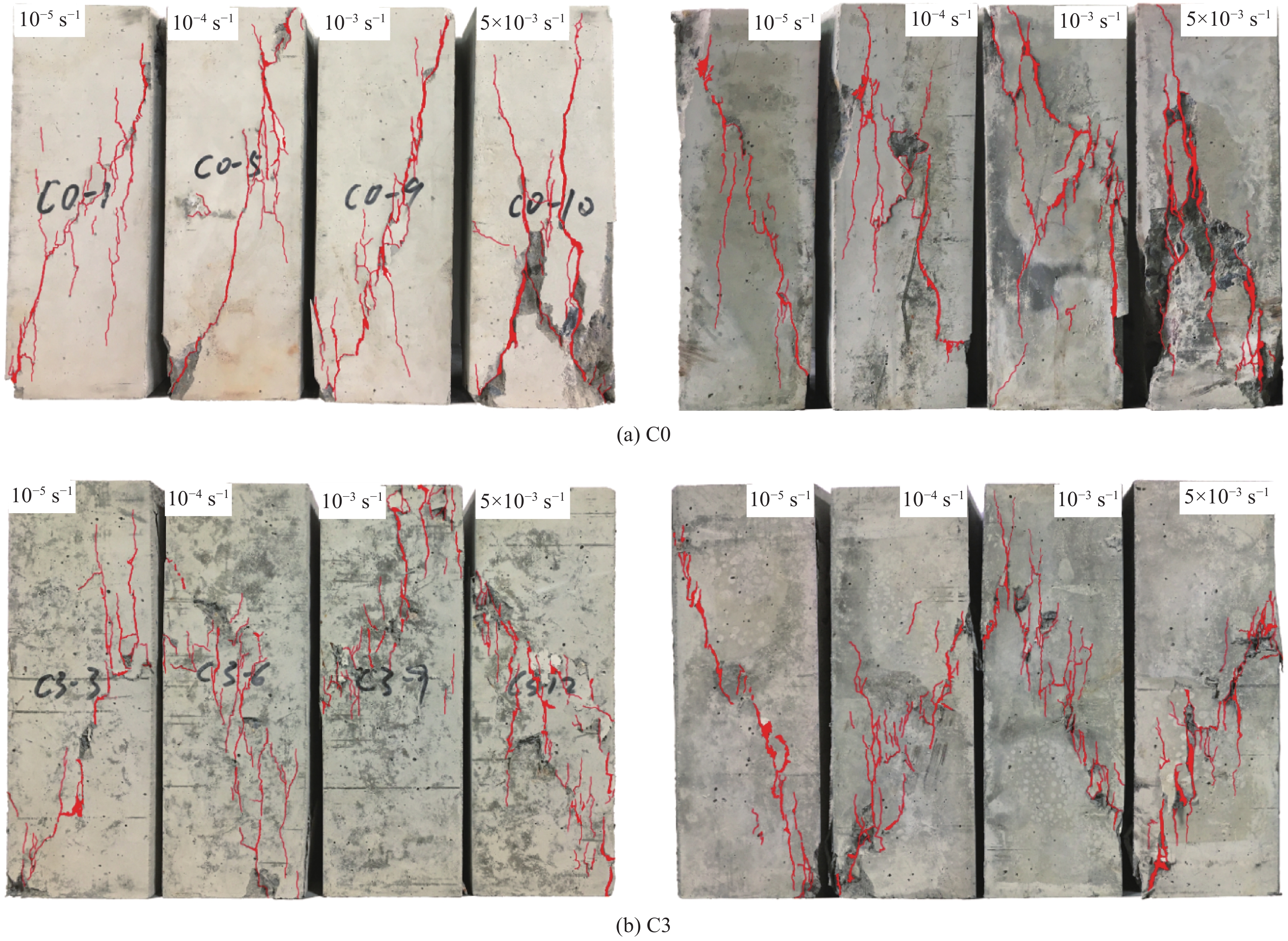

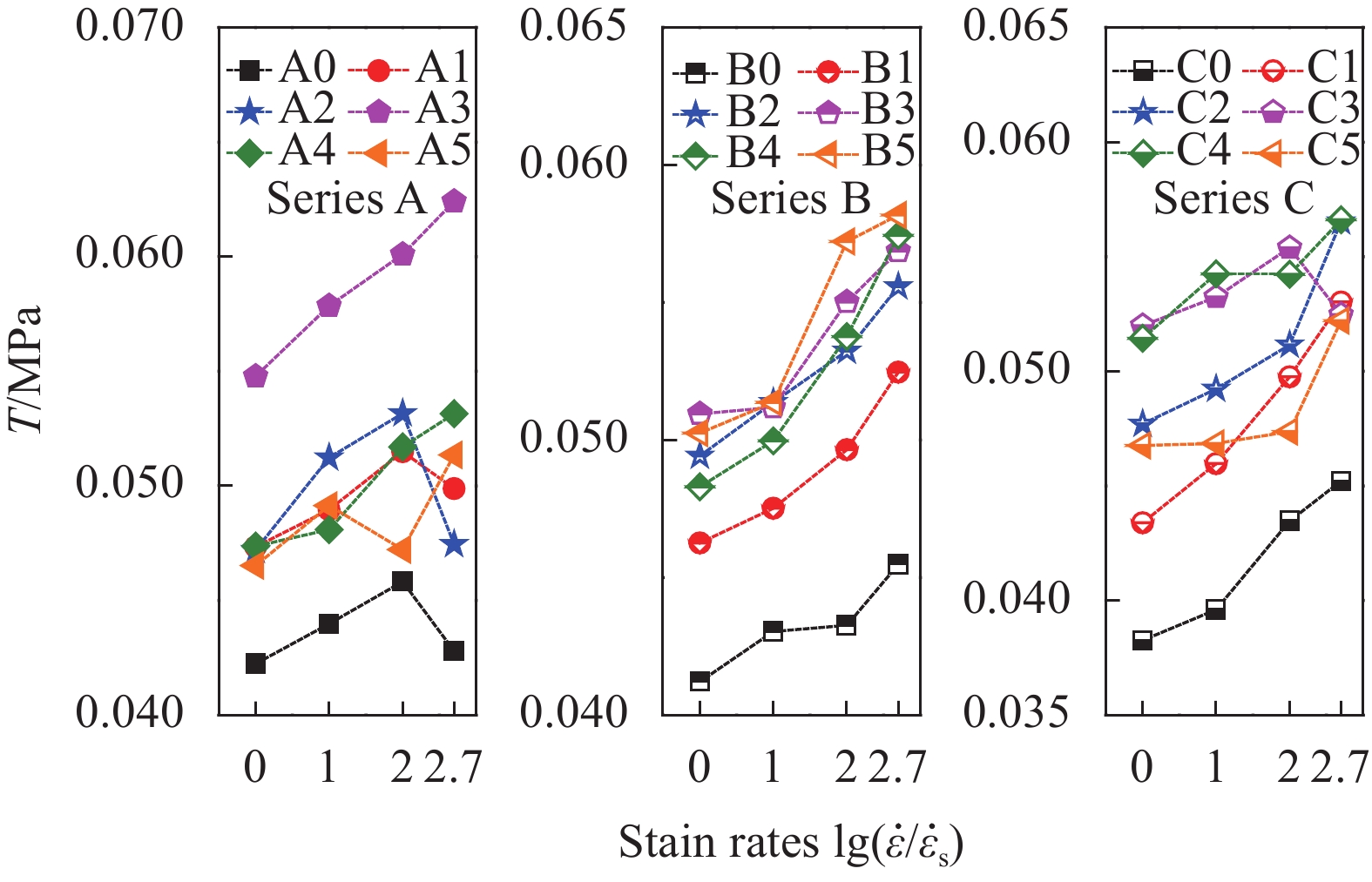

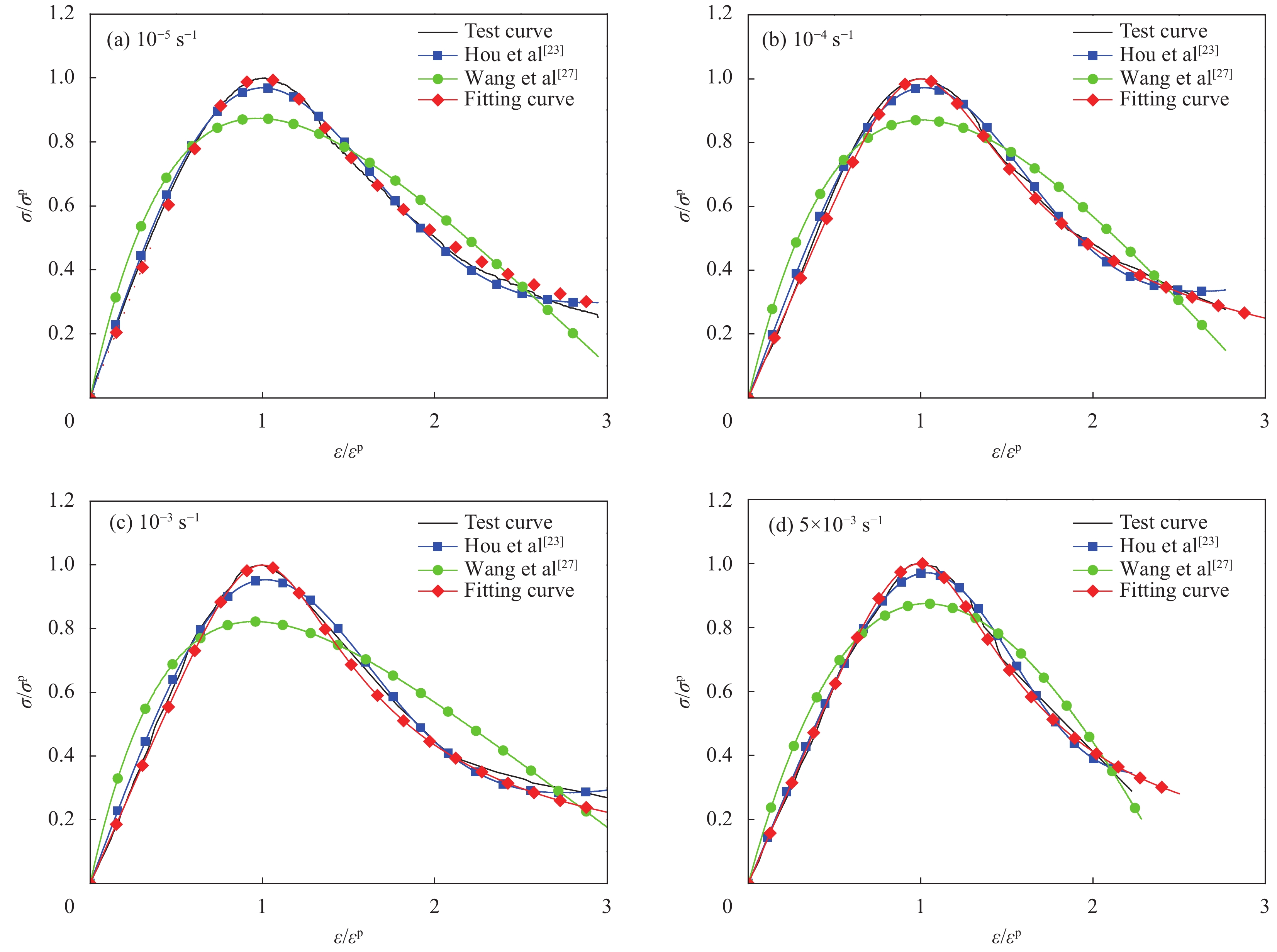

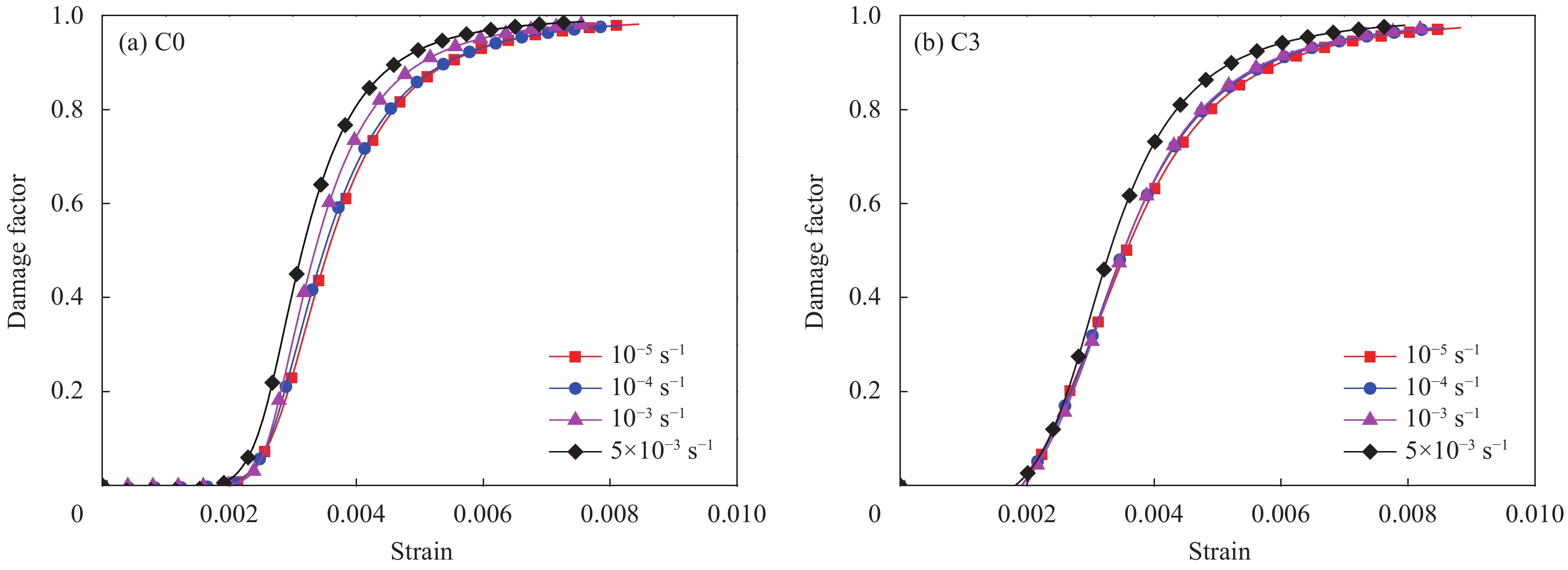

摘要: 为探究钢-塑钢混杂纤维再生混凝土的压缩动态力学性能,设计了A、B和C 3个系列混杂纤维再生混凝土包含3种再生粗骨料取代率和5种体积分数1.5vol%的钢纤维和塑钢混掺纤维组合,采用了4种加载应变率。试验表明:随应变率增加,混杂纤维再生混凝土峰值应力、弹性模量和压缩韧性增大,峰值应变减小。相较于基准组,在相同应变率下3个系列中的含纤维组峰值应力最大增幅分别为23%、16%和16%;峰值应变最大增幅分别为19%、12%和13%;弹性模量最大增幅分别为15%、14%和35%;压缩韧性最大增幅分别为46%、32%和37%。在试验应变率范围内,再生粗骨料显著提高峰值应力、弹性模量和压缩韧性的应变率敏感性,对峰值应变的应变率敏感性并无明显影响;掺入纤维降低混凝土峰值应变和弹性模量的应变率敏感性,提高普通混凝土峰值应力和压缩韧性的应变率敏感性,降低再生混凝土峰值应力和压缩韧性的应变率敏感性。提出的动态损伤本构模型考虑了纤维增强系数、再生粗骨料取代率和应变率,计算结果与试验结果吻合较好。Abstract: The dynamic compressive behavior of hooked-end steel (HES) and macro-polypropylene (MPP) hybrid fibers reinforced recycled aggregate concrete (HyF/RAC) was studied. Three series (A, B and C) of HyF/RAC specimens were designed, which include three different recycled coarse aggregates (RCA) replacement ratios and five combinations of hybrid fibers at the total volume fraction of 1.5vol%, and four different strain rates were conducted. The results show that with the increase of strain rate, the peak stress, elastic modulus and compressive toughness increase, while the peak strain decreases. Compared with control groups in three series under the same strain rate, the largest increases of peak stress for specimens with fibers are 23%, 16% and 16%, respectively. The largest increases of peak strain are 19%, 12% and 13%, respectively. The largest increases of elastics modulus are 15%, 14% and 35%, respectively. The largest increases of compressive toughness are 46%, 32% and 37%, respectively. In the strain rate range, the strain rate sensitivity of peak stress, elastic modulus and compressive toughness increase with the RCA, and the RCA replacement ratio does not affect the strain rate sensitivity of peak strain. The strain rate sensitivity of peak strain and elastics modulus decrease with the addition of fiber. The addition of fibers enhances the strain rate sensitivity of peak stress and compressive toughness for natural aggregate concrete (NAC). While the strain rate sensitivity of peak stress and compressive toughness decrease for recycled aggregate concrete (RAC). The dynamic constitutive damage model was proposed considering the reinforcing index of fibers, RCA replacement ratio and strain rates. And all the models agree well with the experimental curves.

-

近年来随着工业的快速发展,水污染问题受到越来越多的关注。其中的一部分污染是由抗生素引起的,如阿莫西林、青霉素、四环素等[1-5]。四环素(Tetracycline,TC)作为一种普遍使用的抗生素,因其独特的抗菌作用而被广泛应用于人类疾病的治疗。然而TC长期存在于水环境中难以自然降解,对生态环境和人类健康有很大危害[6-10]。因此,开发一种有效的解决方案来去除水环境中难降解的抗生素是极其重要的。半导体光催化技术因其具有环境友好、无污染、低能耗等优点引起了广泛的研究,成为当今处理有机污染物最有前景的方法之一[11-13]。

在各种光催化剂中,BiOX(X=Cl, Br, I)因其特殊的层状结构、适宜的禁带宽度和较高的稳定性,被广泛用于光降解有机污染物和光催化分解水[14-15]。其中BiOI具有较窄的禁带宽度(1.77~1.92 eV)和较宽的可见光响应范围,但由于光生电子空穴对的高复合率,其光催化性能并不理想。将BiOI与其他半导体材料相结合被认为是增强光催化性能最有前途的策略,2个或2个以上半导体相结合可以形成半导体/半导体异质结,通过提高光生电子空穴对的分离速率从而提高光催化活性。

Bi2O3的带隙介于2.1~2.8 eV之间,由于其具有较强的可见光区响应、无毒、电化学稳定性高、热稳定性好和低成本等特性[16-18],是一种很有前途的可见光光催化候选材料,可与其他半导体材料形成异质结结构。如CdS/BiOCl/Bi2O3[19]、GO/AgI/Bi2O3[20]、α-Bi2O3/g-C3N4[21]、Bi2O3/ZnS[22]等。

Wei等[23]采用一锅沉淀法在多孔Bi2O3纳米棒上成功沉积了BiOI纳米片。结果表明:与原始Bi2O3和BiOI相比,50% Bi2O3/BiOI复合材料具有更高的光生电子空穴对分离效率和更大的比表面积,在可见光照射下,其光催化还原Cr(VI)的活性显著增强。此外,50% Bi2O3/BiOI复合材料还具有优异的光化学稳定性和可回收性。Li等[24]采用化学刻蚀法制备了BiOI/Bi2O3异质结,在降解苯酚和4-氯苯酚(4-CP)方面表现出良好的光催化活性。其光催化性能的提高是由于BiOI/Bi2O3异质结的形成促进了电子空穴对的有效分离,并提出了光生电荷转移的过程。

目前所制备的同类光催化剂大多数用于去除水环境中的重金属离子和有机染料等,对降解抗生素类药物的研究较少。本文采用简单的溶剂热法制备了Bi2O3/BiOI复合光催化材料,在模拟太阳光照射下通过降解四环素研究了其光催化性能,探究了BiOI与Bi2O3不同摩尔比、反应温度、反应时间、pH等条件对光催化性能的影响。并通过活性物种捕捉实验提出了Bi2O3/BiOI复合光催化材料降解四环素可能的机制。

1. 实验材料和方法

1.1 原材料

五水硝酸铋(上海麦克林生化有限公司,AR)、碘化钾(天津市大茂化学试剂厂,AR)、乙二醇(天津市北辰方正试剂厂,AR)、四环素(上海麦克林生化有限公司,AR)。

1.2 实验仪器

EL104型电子天平(梅特勒-托利多有限公司)、HC-3018型高速离心机(安徽中科中佳科学仪器有限公司)、TGL-5A台式离心机(常州润华电器有限公司)、KSW-4D-I2型马弗炉(北京中兴伟业仪器有限公司)、HJ-1型磁力加热搅拌器(红杉实验设备厂)、101-1A型电热鼓风干燥箱(北京中兴伟业仪器有限公司)、721型可见分光光度计(上海仪电分析仪器有限公司)、KQ5200E型超声波清洗器(昆山市超声仪器有限公司)、250 W金卤灯(上海亚明)。

1.3 实验内容

1.3.1 BiOI光催化材料的制备

称取1 mmol五水硝酸铋置于15 mL乙二醇中,超声处理15 min以获得均匀悬浮液。在不断搅拌下向其中逐滴加入10 mL含1 mmol碘化钾的水溶液,继续搅拌2 h。将产物离心,用水和无水乙醇洗涤数次,在80℃下干燥12 h得到红色的BiOI。

1.3.2 Bi2O3光催化材料的制备

称取一定量的五水硝酸铋,在600℃的马弗炉里煅烧4 h,冷却至室温后,将产物研磨成粉末状,得到淡黄色的Bi2O3。

1.3.3 Bi2O3/BiOI复合光催化材料的制备

将1 mmol五水硝酸铋置于15 mL乙二醇中,超声处理15 min以获得均匀悬浮液。在不断搅拌下向其中逐滴加入10 mL含1 mmol碘化钾的水溶液,继续搅拌2 h。在此期间,用1 mol/L的H2SO4溶液将混合液的pH调至5。然后向上述溶液中加入0.8 mmol已制备好的Bi2O3,继续搅拌1 h。将得到的混合溶液转移至50 mL聚四氟乙烯内衬的不锈钢高压反应釜中,在180℃下反应20 h。自然冷却至室温后,将产物离心,用水和无水乙醇洗涤数次,在80℃下干燥12 h,得到Bi2O3/BiOI复合光催化材料。

1.3.4 光催化性能测试

使用250 W金卤灯模拟太阳光照射,通过降解四环素来评价所制备样品的光催化性能。取50 mg制得的光催化材料放入装有100 mL 25 mg/L TC溶液的烧杯中,黑暗搅拌30 min达到吸附-脱附平衡。然后将混合液置于光反应器中,光照开始计时,每隔20 min取3 mL样,将样品放入离心机中离心取其上层清液并测定吸光度。计算四环素的残余率:

η=C/C0×100%=A/A0×100% 式中:C和C0分别表示t时刻和初始四环素的质量浓度(mg·L−1);A和A0分别表示t时刻和初始四环素的吸光度。

2. 结果与讨论

2.1 Bi2O3/BiOI复合光催化材料的晶相结构

BiOI、Bi2O3和Bi2O3/BiOI的XRD图谱如图1所示。BiOI曲线在9.658°、29.645°、31.657°、37.392°、45.666°、51.345°、55.15°、66.344°和74.09°处出现的衍射峰分别对应BiOI(JCPDS 10-0445)的(001)、(102)、(110)、(112)、(104)、(114)、(212)、(214)和(302)晶面。Bi2O3在21.722°、25.757°、27.377°、33.241°、35.406°、37.595°、42.353°、46.305°、52.373°和58.563°处出现的衍射峰分别对应Bi2O3(JCPDS 41-1449)的(020)、(002)、(120)、(200)、(031)、(112)、(122)、(041)、(−321)和(−331)晶面。Bi2O3/BiOI同时出现了Bi2O3和BiOI的主要衍射峰,说明本实验成功制备了Bi2O3/BiOI复合光催化材料。

2.2 Bi2O3/BiOI复合光催化材料的微观形貌

通过SEM分析了所制备光催化材料的微观形貌,结果如图2所示。可以看出,所制备的BiOI是由纳米片自组装形成的花状微球;单一Bi2O3呈现出不同尺寸、不规则的块状结构。从图2(c)可以看出,当BiOI与Bi2O3复合后,块状Bi2O3均匀分散在花状微球的BiOI表面。

2.3 Bi2O3/BiOI复合光催化材料的结构

样品的FTIR图谱如图3所示。499 cm−1和760 cm−1处是BiOI的特征吸收峰,1617 cm−1处的吸收峰对应Bi2O3中Bi—O键的弯曲振动,再次表明BiOI和Bi2O3成功复合在一起。

2.4 Bi2O3/BiOI复合光催化材料的光学性能

利用UV-Vis DRS分析了所制备样品的光学吸收性能,如图4所示。可以看出,纯BiOI的吸收边缘位于681 nm处,纯Bi2O3的吸收边缘位于477 nm,Bi2O3/BiOI复合光催化材料的光吸收边缘位于617 nm。与纯BiOI相比,Bi2O3/BiOI复合光催化材料的光吸收边缘有轻微的蓝移,这是由于与Bi2O3耦合造成的,但其光吸收范围仍然很宽。

不同光催化材料的紫外漫反射(αhv)1/2-hv转换图如图5所示。根据Kubelka-Munk公式,纯BiOI、Bi2O3和Bi2O3/BiOI对应的禁带宽度Eg值分别为1.82 eV、2.60 eV和2.01 eV。

2.5 Bi2O3/BiOI复合光催化材料光生电子空穴对的分离

利用荧光强度来分析光生电子空穴对的复合速率,荧光强度越小,则光生电子复合速率越低,图6为不同光催化材料的荧光光谱。可以看出,在520 nm处,Bi2O3/BiOI的荧光强度低于单一BiOI和Bi2O3,表明复合光催化材料的光生电子空穴对复合速率最低,光催化活性最高。

通过电化学阻抗法研究了不同光催化材料的电荷转移效率,结果如图7所示。Bi2O3/BiOI的圆弧半径小于单一BiOI和Bi2O3,说明其电荷转移电阻较低,电导率增强。电化学阻抗图表明Bi2O3/BiOI能增强光生电子空穴对的电荷转移能力,提高其分离效率,这与荧光分析的结果一致。

2.6 Bi2O3/BiOI复合光催化材料的性能

2.6.1 不同制备条件对光催化性能的影响

通过探究反应物的不同摩尔比、反应温度、反应时间及pH对所制备材料的光催化性能的影响。从图8(a)~8(d)可以看出:当Bi2O3与BiOI的摩尔比为0.8∶1时,在pH=5、180℃下反应20 h得到的Bi2O3/BiOI复合光催化材料对四环素的降解效果最佳,在3 h内对四环素的降解率可达75%。

2.6.2 光催化性能

通过在模拟太阳光照射下降解四环素来评价所制备样品的光催化性能,图9(a)为模拟太阳光照射下降解四环素的曲线图。在3 h内,BiOI、Bi2O3、Bi2O3/BiOI对四环素的降解率分别为55%、57%、75%。图9(b)为模拟太阳光照射下降解四环素的动力学曲线,Bi2O3/BiOI的动力学速率常数(0.007 min−1)分别是BiOI(0.004 min−1)、Bi2O3(0.0045 min−1)的1.75倍、1.56倍。因此,所制备出的Bi2O3/BiOI具有较高的光催化活性。

2.7 Bi2O3/BiOI复合光催化材料降解四环素的机制

使用对苯醌(BQ)、乙二胺四乙酸二钠盐(EDTA-2Na)、异丙醇(IPA)作为·O2−、h+、·OH的捕捉剂,实验结果如图10所示。BiOI对四环素的降解率分别为50%、31%、53%、,由此可以得出h+是BiOI降解四环素的主要活性物质。Bi2O3对四环素的降解率分别为55%、52%、35%,由此可以得出·OH是Bi2O3降解四环素的主要活性物质。

当Bi2O3和BiOI复合后形成Z型异质结时,Bi2O3/BiOI光催化材料对四环素的降解率分别为35%、66%、66%,由此可以得出·O2−是光催化材料降解四环素的主要活性物质。

Bi2O3/BiOI异质结的形成可以提高光生电子空穴对的分离速率,从而提高光催化活性。BiOI 、Bi2O3的导带和价带可以通过下式计算:

ECB=X−Ee−0.5Eg Eg=EVB−ECB 式中:X为半导体的电负性,BiOI和Bi2O3的X值分别为5.94 eV 和6.23 eV;Ee为自由电子在氢标上的能量(约为4.50 eV);Eg为对应的带隙能量,由图3(b)可以得出BiOI和Bi2O3的Eg值分别为1.82 eV和2.60 eV。因此,BiOI和Bi2O3的导带(CB)边缘分别位于0.53 eV和0.43 eV,BiOI和Bi2O3的价带(VB)边缘分别位于2.35 eV和3.03 eV。在可见光照射下所制备的Bi2O3/BiOI异质结被激发并生成光生载流子且BiOI比Bi2O3的CB更正。事实上,在Bi2O3/BiOI异质结中,光子能量会激发BiOI CB上的电子到更高的电位位置(−0.68 eV),因此BiOI CB上的光生电子会转移到Bi2O3的CB上。同时,Bi2O3 VB上的空穴将转移到BiOI的VB上。而Bi2O3 CB上的电子不能与O2反应生成·O2−(O2/·O2−=−0.33 eV),·O2−是降解四环素的主要活性物质,这与捕获实验的结果不一致。结合以上结果,提出了一种更可能的光催化机制,如图11所示。BiOI和Bi2O3在可见光照射下都能产生光生电子空穴对,Bi2O3 CB上的光生电子和BiOI VB上的空穴在库仑力的作用下会重新组合。此外,BiOI的CB上的光生电子可以与O2反应生成·O2−,然后·O2−与TC反应,有效地实现了Bi2O3/BiOI异质结的光催化降解过程。综上所述,Bi2O3/BiOI异质结能够有效提高光生电子空穴对的分离效率,从而显著提高光催化性能。

3. 结 论

(1) 以五水硝酸铋为原料,采用溶剂热法制备了Bi2O3/BiOI复合光催化材料,在制备过程中加入Bi2O3可以提高单一BiOI的光催化性能,在3 h内对四环素的降解率为75%,是单一BiOI降解速率的1.75倍。

(2) BiOI、Bi2O3成功复合在一起并形成了异质结结构,Bi2O3/BiOI复合光催化材料通过提高光生电子空穴对的分离速率从而提高光催化活性。

(3) 降解机制研究表明,·O2−在降解四环素中起主要作用,且所制得的复合材料可应用于对四环素的降解,并有望进一步用于对其他抗生素的降解处理以解决实际问题。

-

表 1 端钩钢纤维(HES)和塑钢纤维(MPP)属性

Table 1 Properties of hooked-end steel fiber (HES) and macro-polypropylene fiber (MPP)

Fiber type Equivalent

diameter/mmLength/mm Aspect

ratioDensity/(kg·m−3) Tensile strength/MPa Young’s modulus/GPa HES 0.75 35 47 7800 1120 200.0 MPP 0.94 28 30 910 580 5.5 表 2 钢-塑钢混杂纤维再生混凝土(HyF/RAC)配合比设计

Table 2 Designed mix proportions of hybrid fiber reinforced recycled aggregate concrete (HyF/RAC)

kg/m3 Mix Notation Water Cement Sand RCA NCA HES MPP AW A0 NAC 251 467 639 0 1044 0 0.00 0 A1 1.5%HES/NAC 251 467 639 0 1044 117 0.00 0 A2 1.25%HES-0.25%MPP/NAC 251 467 639 0 1044 98 2.28 0 A3 1.0%HES-0.5%MPP/NAC 251 467 639 0 1044 78 4.55 0 A4 0.75%HES-0.75%MPP/NAC 251 467 639 0 1044 59 6.83 0 A5 0.5%HES-1.0%MPP/NAC 251 467 639 0 1044 39 9.10 0 B0 RAC(50%) 251 467 639 522 522 0 0.00 20 B1 1.5%HES/RAC(50%) 251 467 639 522 522 117 0.00 20 B2 1.25%HES-0.25%MPP/RAC(50%) 251 467 639 522 522 98 2.28 20 B3 1.0%HES-0.5%MPP/RAC(50%) 251 467 639 522 522 78 4.55 20 B4 0.75%HES-0.75%MPP/RAC(50%) 251 467 639 522 522 59 6.83 20 B5 0.5%HES-1.0%MPP/RAC(50%) 251 467 639 522 522 39 9.10 20 C0 RAC(100%) 251 467 639 1044 0 0 0.00 40 C1 1.5%HES/RAC(100%) 251 467 639 1044 0 117 0.00 40 C2 1.25%HES-0.25%MPP/RAC(100%) 251 467 639 1044 0 98 2.28 40 C3 1.0%HES-0.5%MPP/RAC(100%) 251 467 639 1044 0 78 4.55 40 C4 0.75%HES-0.75%MPP/RAC(100%) 251 467 639 1044 0 59 6.83 40 C5 0.5%HES-1.0%MPP/RAC(100%) 251 467 639 1044 0 39 9.10 40 Notes: NAC—Natural aggregate concrete; RAC—Recycled aggregate concrete; RCA—Recycled coarse aggregate; NCA—Natural coarse aggregate; AW—Absorbed water; In iHES-jMPP/RAC(k), i—Volume fraction of HES, j—Volume fraction of MPP, k—Replacement ratio by mass of RCA. 表 3 不同应变率下HyF/RAC峰值应力

σp Table 3 Results of peak stress

σp of HyF/RAC at different strain ratesMix 10−5 s−1 10−4 s−1 10−3 s−1 5×10−3 s−1 σp/MPa CV/% σp/MPa CV/% σp/MPa CV/% σp/MPa CV/% A0 31.3 1.58 32.4 2.84 33.7 3.15 34.7 0.00 A1 32.4 2.53 34.0 2.72 38.8 4.01 39.3 1.03 A2 32.9 4.31 36.3 0.98 39.1 1.27 40.1 5.14 A3 34.9 0.17 39.0 2.90 41.3 0.34 41.9 0.84 A4 31.5 3.59 32.8 5.40 35.2 4.22 36.9 4.41 A5 32.7 5.19 34.4 3.29 36.6 2.61 37.3 5.13 B0 28.3 1.00 29.1 3.87 32.4 1.46 34.0 2.29 B1 29.6 2.15 30.8 1.15 34.6 4.71 35.7 4.56 B2 31.9 1.30 33.6 5.27 34.2 3.93 36.1 3.73 B3 31.2 0.23 32.4 1.97 35.7 1.98 37.2 6.84 B4 30.4 1.51 32.3 1.99 35.3 3.13 36.1 0.78 B5 31.6 1.59 33.7 1.70 37.3 0.57 38.3 2.22 C0 24.6 8.57 26.9 2.74 30.6 4.48 32.5 0.22 C1 26.2 4.04 27.8 3.89 31.6 1.14 32.4 3.45 C2 26.8 2.24 28.8 0.72 32.2 2.64 32.8 1.72 C3 28.4 2.69 31.1 0.68 33.0 2.69 34.4 3.63 C4 27.8 0.95 30.0 6.21 32.7 2.60 33.1 5.32 C5 26.3 0.79 27.3 2.23 30.6 5.46 32.7 0.43 Note: CV—Coefficients of variation. 表 4 不同应变率下HyF/RAC峰值应变

εp Table 4 Results of peak strain

εp of HyF/RAC at different strain ratesMix 10−5 s−1 10−4 s−1 10−3 s−1 5×10−3 s−1 εp/10−3 CV/% εp/10−3 CV/% εp/10−3 CV/% εp/10−3 CV/% A0 2.376 4.73 2.330 8.37 2.224 1.67 2.101 9.02 A1 2.410 2.87 2.340 7.71 2.256 10.77 2.199 11.43 A2 2.413 1.55 2.390 0.74 2.378 11.52 2.321 6.02 A3 2.599 8.68 2.555 3.18 2.528 3.98 2.500 3.42 A4 2.419 2.70 2.425 6.95 2.413 10.11 2.312 11.72 A5 2.443 6.27 2.432 8.62 2.330 6.22 2.254 1.68 B0 2.593 3.67 2.469 0.79 2.370 3.18 2.325 6.08 B1 2.651 9.27 2.631 6.65 2.620 6.75 2.510 6.20 B2 2.673 3.61 2.645 9.62 2.592 5.28 2.481 9.76 B3 2.760 5.68 2.708 7.48 2.631 7.32 2.610 5.55 B4 2.583 0.39 2.544 2.43 2.544 7.28 2.533 8.45 B5 2.666 2.41 2.658 6.79 2.630 4.84 2.591 2.11 C0 2.814 4.46 2.726 3.44 2.621 2.51 2.524 2.73 C1 2.933 1.81 2.815 11.43 2.708 5.28 2.694 0.33 C2 2.950 1.47 2.813 1.33 2.769 2.75 2.733 2.20 C3 2.941 1.62 2.853 0.99 2.845 6.83 2.648 3.47 C4 3.041 3.67 2.996 4.01 2.891 0.79 2.861 9.33 C5 2.981 3.50 2.859 1.67 2.754 7.66 2.701 0.46 表 5 不同应变率下HyF/RAC弹性模量E

Table 5 Results of elastic modulus E of HyF/RAC at different strain rates

Mix 10−5 s−1 10−4 s−1 10−3 s−1 5×10−3 s−1 E/GPa CV/% E/GPa CV/% E/GPa CV/% E/GPa CV/% A0 29.5 3.86 33.2 9.20 37.6 9.87 41.2 2.37 A1 31.8 8.13 35.3 1.34 38.6 3.95 42.0 9.60 A2 32.1 7.05 34.3 1.09 38.3 4.35 41.4 4.92 A3 34.1 7.30 34.1 2.88 34.7 0.61 38.1 10.65 A4 32.5 7.19 33.7 5.58 35.7 4.14 37.4 11.49 A5 33.9 4.75 34.0 5.06 35.0 3.23 38.2 2.85 B0 24.8 7.61 26.2 8.55 28.6 3.24 30.8 2.69 B1 25.6 9.08 26.2 0.91 28.6 5.58 30.8 9.23 B2 27.1 0.22 28.1 11.70 29.4 8.73 33.9 8.52 B3 27.3 0.70 28.7 9.85 31.0 6.90 31.7 1.92 B4 28.2 1.65 29.9 3.60 33.2 0.66 33.6 6.38 B5 27.2 4.70 27.8 11.33 28.9 9.67 32.9 11.19 C0 18.7 3.06 21.9 11.63 24.9 6.18 26.7 9.24 C1 20.7 8.05 22.8 11.44 26.3 11.54 27.8 7.55 C2 23.2 7.56 24.3 2.31 26.1 1.54 29.5 10.99 C3 25.1 6.06 26.3 4.08 28.0 11.09 28.1 2.47 C4 22.9 0.56 23.3 2.43 25.2 4.69 28.3 9.75 C5 22.7 0.56 24.4 9.26 27.9 3.17 29.2 9.11 表 6 不同应变率下HyF/RAC压缩韧性T

Table 6 Results of compressive toughness T of HyF/RAC at different strain rates

Mix 10−5 s−1 10−4 s−1 10−3 s−1 5×10−3 s−1 T/MPa T/MPa T/MPa T/MPa A0 0.042 0.044 0.046 0.043 A1 0.047 0.049 0.051 0.050 A2 0.047 0.051 0.053 0.047 A3 0.055 0.058 0.060 0.062 A4 0.047 0.048 0.052 0.053 A5 0.047 0.049 0.047 0.051 B0 0.041 0.043 0.043 0.045 B1 0.046 0.048 0.050 0.052 B2 0.049 0.051 0.053 0.056 B3 0.051 0.051 0.055 0.057 B4 0.048 0.050 0.054 0.057 B5 0.050 0.051 0.057 0.058 C0 0.038 0.040 0.043 0.045 C1 0.043 0.046 0.050 0.053 C2 0.048 0.049 0.051 0.057 C3 0.052 0.053 0.055 0.052 C4 0.051 0.054 0.054 0.057 C5 0.047 0.047 0.047 0.052 表 7 现有压缩动态本构模型

Table 7 Review of dynamic constitutive models under compression

Reference Model Parameter Application range Ibrahim et al[21] y=Ax+(B−1)x21+(A−2)x+Bx2A(A−2)−B+1⩾ \begin{gathered} A = 3.6\exp \left( {9.0 \times {{10}^{ - 8}}\left( {\frac{{\dot \varepsilon }}{{{{\dot \varepsilon }_{\text{s}}}}}} \right)\left( {1 + 0.01R_V^{0.82}} \right)} \right) \\ B = 0.22\exp \left( {3.8 \times {{10}^{ - 7}}\left( {\frac{{\dot \varepsilon }}{{{{\dot \varepsilon }_{\text{s}}}}}} \right)\left( {1 + 0.002R_V^{0.82}} \right)} \right) \\ \end{gathered} \begin{gathered} 25{\text{ }}{{\text{s}}^{ - 1}} \leqslant \dot \varepsilon \leqslant 125{\text{ }}{{\text{s}}^{ - 1}} \\ 1.2{\text{% }} \leqslant V \leqslant 1.4\% \\ \end{gathered} Zhou et al[22] \begin{gathered} \sigma = {\sigma _{\text{m}}}\left( {1 - D} \right) = E\varepsilon \left( {1 - D} \right) \\ D = 1 - \exp \left[ { - {{\left( {\frac{\varepsilon }{{{F_0}}}} \right)}^m}} \right] \\ \end{gathered} \begin{gathered} {F_0} = 3.3578\ln \dot \varepsilon - 10.6562 \\ m = 1.2804\ln \dot \varepsilon - 1.8711 \\ \end{gathered} 19.8{\text{ }}{{\text{s}}^{ - 1}} \leqslant \dot \varepsilon \leqslant 281{\text{ }}{{\text{s}}^{ - 1}} Hou et al[23] \begin{gathered} \sigma = {\sigma _{\text{m}}}\left( {1 - {C_{\text{n}}}D} \right) = E\varepsilon \left( {1 - {C_{\text{n}}}D} \right) \\ D = 1 - \exp \left[ { - {{\left( {\frac{\varepsilon }{{{F_0}}}} \right)}^m}} \right] \\ \end{gathered} \begin{gathered} {F_0} = 0.0062 + 0.31{V^{1.7}} - 0.00167\left( {0.1 + V} \right)\ln \dot \varepsilon \\ m = - 0.56 + 3V + \left( {0.35 - 2V} \right)\ln \dot \varepsilon \\ {C_{\text{n}}} = 0.977 - 1.4V + \left( {0.004 + 0.25V} \right)\ln \dot \varepsilon \\ \end{gathered} \begin{gathered} \dot \varepsilon \leqslant 294{\text{ }}{{\text{s}}^{ - 1}} \\ V \leqslant 5\% \\ \end{gathered} Sun et al[25] \begin{gathered} \sigma = {\sigma _{\text{m}}}\left( {1 - D} \right) = E\varepsilon \left( {1 - D} \right) \\ \dot D = AD\left( {1 - D} \right) \\ \end{gathered} \begin{gathered} {D} = 0.35 - 8.2 \times {10^{ - 9} }\left( {\frac{ {\dot \varepsilon } }{ { { {\dot \varepsilon }_{\text{s} } } } } } \right) - \\ \qquad 4.4V + 1.3 \times {10^{ - 7} }\left( {\frac{ {\dot \varepsilon } }{ { { {\dot \varepsilon }_{\text{s} } } } } } \right)V \\ A = 234 + 1.3 \times {10^{ - 7} }\left( {\frac{ {\dot \varepsilon } }{ { { {\dot \varepsilon }_{\text{s} } } } } } \right) + \\ \qquad 1718V - 8.6 \times {10^{ - 5} }\left( {\frac{ {\dot \varepsilon } }{ { { {\dot \varepsilon }_{\text{s} } } } } } \right)V \\ \end{gathered} \begin{gathered} 53{\text{ }}{{\text{s}}^{ - 1}} \leqslant \dot \varepsilon \leqslant 152{{\text{s}}^{ - 1}} \\ V \leqslant 6.0\% \\ \end{gathered} Zhang et al[26] \begin{gathered} \sigma = \left( {1 - D} \right){\sigma _{\text{m}}} \\ {\sigma _{\text{m}}} = {\sigma _{\text{e}}}\left( \varepsilon \right) + {E_1}\int_0^t {\dot \varepsilon \exp \left( { - \frac{{t - \tau }}{{{\varphi _1}}}} \right){\rm{d}}\tau } + \\ \qquad {E_2}\int_0^t {\dot \varepsilon \exp \left( { - \frac{{t - \tau }}{{{\varphi _2}}}} \right){\rm{d}}\tau } \\ {\sigma _{\text{e}}}\left( \varepsilon \right) = E\varepsilon + \alpha {\varepsilon ^2} + \beta {\varepsilon ^3} \\ D = \left\{ \begin{gathered} 0{\text{ }}\qquad(\varepsilon \leqslant {\varepsilon ^{{\text{th}}}}) \\ 1 - \exp \left[ { - {{\left( {\frac{{\varepsilon - {\varepsilon ^{{\text{th}}}}}}{{{F_0}}}} \right)}^m}} \right]{\text{ }}\qquad(\varepsilon > {\varepsilon ^{{\text{th}}}}) \\ \end{gathered} \right. \\ \end{gathered} No fitting equation \begin{gathered} 27{\text{ }}{{\text{s}}^{ - 1}} \leqslant \dot \varepsilon \leqslant 94{\text{ }}{{\text{s}}^{ - 1}} \\ V \leqslant 0.2\% \\ \end{gathered} Wang et al[27] \begin{gathered} \sigma = \left( {1 - D} \right)\sigma \\ {\sigma _{\text{m}}} = {\sigma _{\text{e}}}\left( \varepsilon \right) + {E_1}\int_0^t {\dot \varepsilon \exp \left( { - \frac{{t - \tau }}{{{\varphi _1}}}} \right){\rm{d}}\tau } + \\ \qquad {E_2}\int_0^t {\dot \varepsilon \exp \left( { - \frac{{t - \tau }}{{{\varphi _2}}}} \right){\rm{d}}\tau } \\ D = \left\{ \begin{gathered} 0{\text{ }}\qquad(\varepsilon \leqslant {\varepsilon ^{{\text{th}}}} ) \\ {K_D}{{\dot \varepsilon }^{\lambda - 1}}{\left( {\varepsilon - {\varepsilon ^{{\text{th}}}}} \right)^\kappa }{\text{ }}\qquad(\varepsilon > {\varepsilon ^{{\text{th}}}} ) \\ \end{gathered} \right. \\ \end{gathered} No fitting equation {10^{ - 4}}{\text{ }}{{\text{s}}^{ - 1}} \leqslant \dot \varepsilon \leqslant {10^3}{\text{ }}{{\text{s}}^{ - 1}} Notes: y = {\sigma \mathord{\left/ {\vphantom {\sigma { {\sigma ^{\text{p} } } } } } \right. } { {\sigma ^{\text{p} } } }}, x = {\varepsilon \mathord{\left/ {\vphantom {\varepsilon { {\varepsilon ^{\text{p} } } } } } \right. } { {\varepsilon ^{\text{p} } } }}, \sigma —Stress, {\sigma ^{\text{p}}} —Peak stress, \varepsilon —Strain, {\varepsilon ^{\text{p}}} —Peak strain; RV—Reinforcing index of hybrid fibers; D—Damage parameter; t—Loading time; τ—Delay time of stress; E1, {\varphi _1} —Elastic modulus and relaxation time at a low strain rate and frequency; E2, {\varphi _2} —Elastic modulus and relaxation time at a high strain rate and frequency; α, β—Elastic constant; {K_D},{\text{ }}\lambda ,{\text{ }}\kappa —Material parameter; {\varepsilon ^{{\text{th}}}} —Strain threshold. 表 8 HyF/RAC修正模型参数

\alpha 拟合值Table 8 Fitted results of parameter

\alpha in modified constitutive models for HyF/RACMix \dot \varepsilon 10−5 s−1 10−4 s−1 10−3 s−1 5×10−3 s−1 Fitted value R2 Fitted value R2 Fitted value R2 Fitted value R2 A0 3.434 0.991 3.399 0.946 2.597 0.953 2.285 0.940 A1 1.882 0.978 1.175 0.998 1.699 0.986 1.352 0.973 A2 1.386 0.999 1.401 0.997 1.020 0.981 1.039 0.994 A3 1.442 0.997 1.912 0.992 1.607 0.965 1.650 0.974 A4 2.219 0.994 2.431 0.970 2.057 0.965 1.466 0.984 A5 2.600 0.998 2.633 0.984 2.288 0.971 1.757 0.992 B0 3.524 0.991 3.742 0.994 2.589 0.942 3.053 0.997 B1 1.440 0.976 1.125 0.983 1.225 0.997 1.873 0.996 B2 1.932 0.985 2.124 0.991 2.001 0.996 1.583 0.979 B3 2.026 0.994 1.636 0.999 2.274 0.988 2.297 0.984 B4 1.876 0.990 2.683 0.992 2.305 0.994 2.613 0.935 B5 2.457 0.994 3.036 0.997 2.873 0.940 2.496 0.984 C0 3.173 0.978 2.958 0.978 3.609 0.986 4.137 0.954 C1 1.552 0.993 1.657 0.976 2.280 0.976 2.749 0.993 C2 1.673 0.975 2.013 0.999 2.259 0.999 2.364 0.953 C3 2.059 0.998 2.149 0.999 2.278 0.998 2.732 0.996 C4 1.868 0.976 2.174 0.997 3.339 0.968 2.842 0.934 C5 2.218 0.971 2.859 0.990 3.483 0.964 3.394 0.993 -

[1] 高光发. 混凝土材料动态压缩强度的应变率强化规律[J]. 高压物理学报, 2017, 31(3):261-270. GAO Guangfa. Effect of strain-rate hardening on dynamic compressive strength of plain concrete[J]. Chinese Jour-nal of High Pressure Physics,2017,31(3):261-270(in Chinese).

[2] 王国盛, 路德春, 杜修力, 等. 混凝土材料真实动态强度及率效应机理研究[J]. 工程力学, 2018, 35(6):58-67. WANG Guosheng, LU Dechun, DU Xiuli, et al. Research on the actual dynamic strength and the rate effect mecha-nisms for concrete materials[J]. Engineering Mechanics,2018,35(6):58-67(in Chinese).

[3] 艾思平, 唐鹏. 考虑地震量级作用下橡胶纤维混凝土受压动力性能试验研究[J]. 建筑材料学报, 2021, 24(5): 1002-1010. AI Siping, TANG Peng. Experimental study on the dynamic behavior of rubber fiber reinforced concrete under the action of earthquake magnitude[J]. Journal of Building Material, 2021, 24(5): 1002-1010(in Chinese).

[4] 白卫峰, 李思蕾, 管俊峰, 等. 再生混凝土单轴压缩动态力学性能试验研究[J]. 建筑材料学报, 2022, 25(5): 498-508. BAI Weifeng, LI Silei, GUAN Junfeng, et al. Study on dynamic mechanical properties of recycled concrete under uniaxial compression[J]. Journal of Building Materials,2022, 25(5): 498-508(in Chinese).

[5] XIAO J, ZHANG K, ZHANG Q. Strain rate effect on compres-sive stress-strain curves of recycled aggregate concrete with seawater and sea sand[J]. Construction and Building Materials,2021,300:124014. DOI: 10.1016/j.conbuildmat.2021.124014

[6] 董海龙, 彭有开, 骆开静, 等. 粗骨料取代下的高性能再生混凝土率敏性研究[J]. 实验力学, 2019, 34(2):249-257. DONG Hailong, PENG Youkai, LUO Kaijing, et al. Study on rate sensitivity of high performance recycled concrete with different coarse aggregate replacement ratios[J]. Journal of Experimental Mechanics,2019,34(2):249-257(in Chinese).

[7] TANG Z, LI W, TAM V W Y, et al. Investigation on dynamic mechanical properties of fly ash/slag-based geopolymeric recycled aggregate concrete[J]. Composites Part B: Engi-neering,2020,185:107776. DOI: 10.1016/j.compositesb.2020.107776

[8] FENG J, YIN G, TUO H, et al. Parameter optimization and regression analysis for multi-index of hybrid fiber-reinforced recycled coarse aggregate concrete using orthogonal experimental design[J]. Construction and Building Materials,2021,267:121013. DOI: 10.1016/j.conbuildmat.2020.121013

[9] 陈宇良, 吉云鹏, 陈宗平, 等. 钢纤维再生混凝土三轴受压力学性能试验[J]. 复合材料学报, 2022, 39(8): 4005-4016. CHEN Yuliang, JI Yunpeng, CHEN Zongping, et al. Experiment on mechanical properties of steel fiber recycled aggregate concrete under triaxial compression[J]. Acta Materiae Compositae Sinica, 2022, 39(8): 4005-4016(in Chinese).

[10] 丁亚红, 郭书奇, 张向冈, 等. 玄武岩纤维对再生混凝土抗碳化性能的影响[J]. 复合材料学报, 2022, 39(3): 1228-1238. DING Yahong, GUO Shuqi, ZHANG Xianggang, et al. Influence of basalt fiber on the anti-carbonation performance of recycled aggregate concrete[J]. Acta Materiae Compositae Sinica, 2022, 39(3): 1228-1238(in Chinese).

[11] XIE J, KOU S, MA H, et al. Advances on properties of fiber reinforced recycled aggregate concrete: Experiments and models[J]. Construction and Building Materials,2021,277:122345. DOI: 10.1016/j.conbuildmat.2021.122345

[12] 王兴国, 姜茂林, 陈旭, 等. 不同预浸骨料-PVA纤维对再生混凝土力学性能影响[J]. 复合材料学报, 2022, 39(3): 1205-1214. WANG Xingguo, JIANG Maolin, CHEN Xu, et al. Effect of different pre-soaked aggregate-PVA fiber on the mechani-cal properties of recycled aggregate concrete[J]. Acta Materiae Compositae Sinica, 2022, 39(3): 1205-1214(in Chinese).

[13] 孔祥清, 何文昌, 周聪, 等. 混杂掺入钢/聚丙烯纤维再生混凝土力学性能及抗冲击性能试验研究[J]. 建筑科学, 2020, 36(3):94-99. KONG Xiangqing, HE Wenchang, ZHOU Cong, et al. Experimental investigation on the mechanical properties and impact resistance of steel and polypropylene hybrid fiber reinforced recycled aggregates concrete[J]. Building Science,2020,36(3):94-99(in Chinese).

[14] FENG J, YIN G, TUO H, et al. Uniaxial compressive behavior of hook-end steel and macro-polypropylene hybrid fibers reinforced recycled aggregate concrete[J]. Construction and Building Materials,2021,304:124559. DOI: 10.1016/j.conbuildmat.2021.124559

[15] 周宏宇, 麻全周, 赵晓花, 等. 考虑应变率效应的混凝土材料单轴压缩特性尺寸效应研究[J]. 混凝土, 2021(1):61-65, 69. DOI: 10.3969/j.issn.1002-3550.2021.01.015 ZHOU Hongyu, MA Quanzhou, ZHAO Xiaohua, et al. Experimental study on dynamic rate relevance of concrete size effect[J]. Concrete,2021(1):61-65, 69(in Chinese). DOI: 10.3969/j.issn.1002-3550.2021.01.015

[16] 肖诗云, 张剑. 不同应变率下混凝土受压损伤试验研究[J]. 土木工程学报, 2010, 43(3):40-45. XIAO Shiyun, ZHANG Jian. Compressive damage experiment of concrete at different strain rates[J]. China Civil Engineering Journal,2010,43(3):40-45(in Chinese).

[17] 焦楚杰, 孙伟, 张亚梅, 等. 钢纤维高强混凝土在不同应变率时的单轴受压性能[J]. 建筑结构, 2004, 34(8):65-67. JIAO Chujie, SUN Wei, ZHANG Yamei, et al. Mechanical properties of SFRHSC under uniaxial compression with different strain rates[J]. Building Structure,2004,34(8):65-67(in Chinese).

[18] 梁宁慧, 杨鹏, 刘新荣, 等. 高应变率下多尺寸聚丙烯纤维混凝土动态压缩力学性能研究[J]. 材料导报, 2018, 32(2):288-294. LIANG Ninghui, YANG Peng, LIU Xinrong, et al. A study on dynamic compressive mechanical properties of multi-size polypropylene fiber concrete under high strain rate[J]. Materials Reports,2018,32(2):288-294(in Chinese).

[19] 沈才华, 钱晋, 陈晓峰, 等. 纤维掺量对PVA纤维混凝土力学参数的影响及压缩韧性指标的计算方法[J]. 硅酸盐通报, 2020, 39(10):3152-3160. SHEN Caihua, QIAN Jin, CHEN Xiaofeng, et al. Influence of fiber content on mechanical parameters of PVA fiber concrete and method for calculating compression toughness index[J]. Bulletin of the Chinese Ceramic Society,2020,39(10):3152-3160(in Chinese).

[20] HE W, KONG X, FU Y, et al. Experimental investigation on the mechanical properties and microstructure of hybrid fiber reinforced recycled aggregate concrete[J]. Construction and Building Materials,2020,261:120488. DOI: 10.1016/j.conbuildmat.2020.120488

[21] IBRAHIM S M, ALMUSALLAM T H, AL-SALLOUM Y A, et al. Strain rate dependent behavior and modeling for compression response of hybrid fiber reinforced concrete[J]. Latin American Journal of Solids and Structures,2016,13:1695-1715. DOI: 10.1590/1679-78252717

[22] ZHOU J, CHEN X. Stress-strain behavior and statistical continuous damage model of cement mortar under high strain rates[J]. Journal of Materials in Civil Engineering,2013,25(1):120-130. DOI: 10.1061/(ASCE)MT.1943-5533.0000570

[23] HOU X, CAO S, RONG Q, et al. Effects of steel fiber and strain rate on the dynamic compressive stress-strain relationship in reactive powder concrete[J]. Construction and Building Materials,2018,170:570-581. DOI: 10.1016/j.conbuildmat.2018.03.101

[24] CUI T, HE H, YAN W, et al. Compression damage constitutive model of hybrid fiber reinforced concrete and its experimental verification[J]. Construction and Building Materials,2020,264:120026. DOI: 10.1016/j.conbuildmat.2020.120026

[25] SUN X, ZHAO K, LI Y, et al. A study of strain-rate effect and fiber reinforcement effect on dynamic behavior of steel fiber-reinforced concrete[J]. Construction and Building Materials,2018,158:657-669. DOI: 10.1016/j.conbuildmat.2017.09.093

[26] ZHANG H, WANG B, XIE A, et al. Experimental study on dynamic mechanical properties and constitutive model of basalt fiber reinforced concrete[J]. Construction and Building Materials,2017,152:154-167. DOI: 10.1016/j.conbuildmat.2017.06.177

[27] 王礼立, 胡时胜, 杨黎明, 等. 聊聊动态强度和损伤演化[J]. 爆炸与冲击, 2017, 37(2):169-179. WANG Lili, HU Shisheng, YANG Liming, et al. Talk about dynamic strength and damage evolution[J]. Explosion and Shock Waves,2017,37(2):169-179(in Chinese).

[28] CAO S, HOU X, RONG Q. Dynamic compressive properties of reactive powder concrete at high temperature: A review[J]. Cement and Concrete Composites,2020,110:103568. DOI: 10.1016/j.cemconcomp.2020.103568

[29] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB/T 50010—2010[S]. 北京: 中国建筑工业出版社, 2015. Ministry of Housing and Urban-Rural Development of the People's Republic of China. Code for design of concrete structures: GB/T 50010—2010[J]. Beijing: China Architecture and Building Press, 2015(in Chinese).

[30] 张聪, 余志辉, 韩世诚, 等. 混杂纤维增强应变硬化水泥基复合材料的压缩本构关系[J]. 复合材料学报, 2020, 37(5):1221-1226. ZHANG Cong, YU Zhihui, HAN Shicheng, et al. Compression constitutive relation of hybrid fiber reinforced strain hardening cementitous composites[J]. Acta Materiae Compositae Sinica,2020,37(5):1221-1226(in Chinese).

[31] SHI X, PARK P, REW Y, et al. Constitutive behaviors of steel fiber reinforced concrete under uniaxial compression and tension[J]. Construction and Building Materials,2020,233:117316. DOI: 10.1016/j.conbuildmat.2019.117316

[32] ABADEL A, ABBAS H, ALMUSALLAM T, et al. Mechanical properties of hybrid fibre-reinforced concrete-analytical modelling and experimental behaviour[J]. Magazine of Concrete Research,2016,68:823-843. DOI: 10.1680/jmacr.15.00276

[33] 施林林, 宋玉普, 沈璐. 不同应变率下大骨料及湿筛混凝土单轴受压试验研究[J]. 世界地震工程, 2016, 32(2):270-276. SHI Linlin, SONG Yupu, SHEN Lu. Experimental study on uniaxial compression properties of large aggregate and wet-screened concrete at different strain rates[J]. World Earthquake Engineering,2016,32(2):270-276(in Chinese).

[34] 李庆斌, 邓宗才, 张立翔. 考虑初始弹模变化的混凝土动力损伤本构模型[J]. 清华大学学报(自然科学版), 2003(8):1088-1091. DOI: 10.3321/j.issn:1000-0054.2003.08.025 LI Qingbin, DENG Zongcai, ZHANG Lixiang. Dynamic damage constitutive model for concrete accounting for the difference of the initial elastic modulus[J]. Journal of Tsinghua University (Science and Technology),2003(8):1088-1091(in Chinese). DOI: 10.3321/j.issn:1000-0054.2003.08.025

[35] DONG S, HAN B, YU X, et al. Dynamic impact behaviors and constitutive model of super-fine stainless wire reinforced reactive powder concrete[J]. Construction and Building Materials,2018,184:602-616. DOI: 10.1016/j.conbuildmat.2018.07.027

-

期刊类型引用(8)

1. 谭浩,张文彬,卢文玉,祁志强,蔡红珍,杨科研. 高粱秸秆负载HKUST-1对四环素的吸附行为与机制. 复合材料学报. 2025(01): 514-526 .  本站查看

本站查看

2. 李碧秋,李希成,熊俊夫,李金韩,贾博雅,汪长征. 铋系光电催化剂降解水中有机污染物的研究进展. 材料工程. 2024(06): 92-108 .  百度学术

百度学术

3. 黄鹏伟,李静,林博,王宜民,陈仪,谢楠耿. AgI/BiOI异质结光电催化甲醇氧化. 山西化工. 2024(07): 4-6+10 .  百度学术

百度学术

4. 杜书雅,王旭东,董永浩,吕嘉辰,李洁. MOF-808/AgBr的制备及光催化降解盐酸四环素性能研究. 功能材料. 2024(11): 11137-11146 .  百度学术

百度学术

5. 严惠儒,林水源,钟祥康,黄学帅,杨玉如,冯梓盈,朱淼,谢伟. Au/BiOI花状微米球的制备及其对抗生素的降解特性. 广州化工. 2023(05): 43-46 .  百度学术

百度学术

6. 王振宇,刘燕才,陈琨,乔江浩,李晓伟. 等离子喷涂-化学气相沉积制备α/β-Bi_2O_3薄膜的相结构调控和光催化降解性能. 硅酸盐学报. 2023(07): 1800-1810 .  百度学术

百度学术

7. 刘松林,王仲民,钱熹,王童,冉兆晋,黄志民,吴晨曦,李桂银. 磁性氮掺杂石墨烯改性柿单宁复合材料对四环素的吸附行为. 复合材料学报. 2023(07): 4048-4059 .  本站查看

本站查看

8. 袁亦雷,谢水波,刘岳林,史艳丹,刘迎九. g-C_3N_4-Bi_2O_3/Al_2O_3复合材料光催化还原水中U(Ⅵ). 化工环保. 2022(05): 609-615 .  百度学术

百度学术

其他类型引用(8)

-

下载:

下载: