Explosion resistance of hybrid GFRP-steel reinforced concrete slab

-

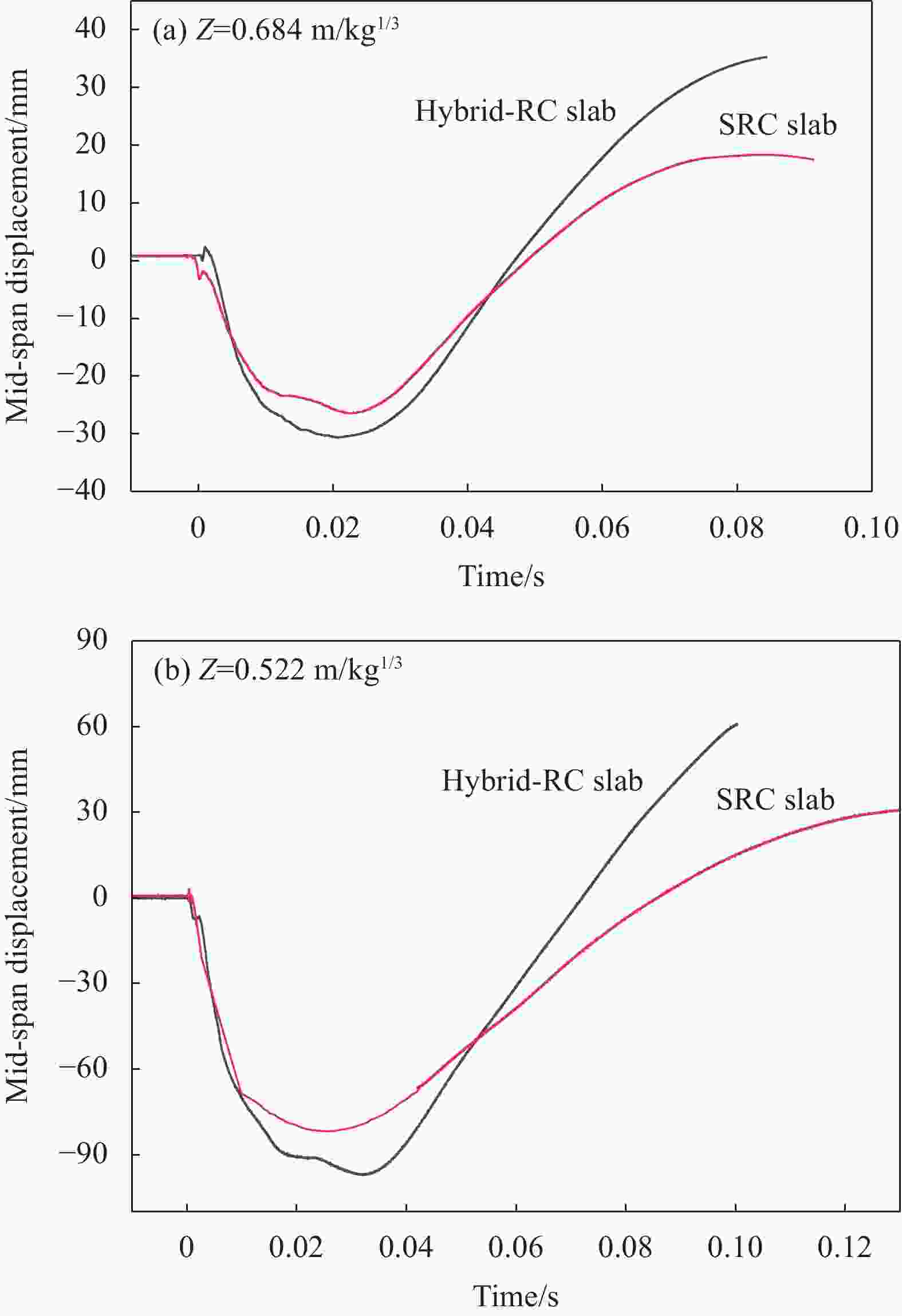

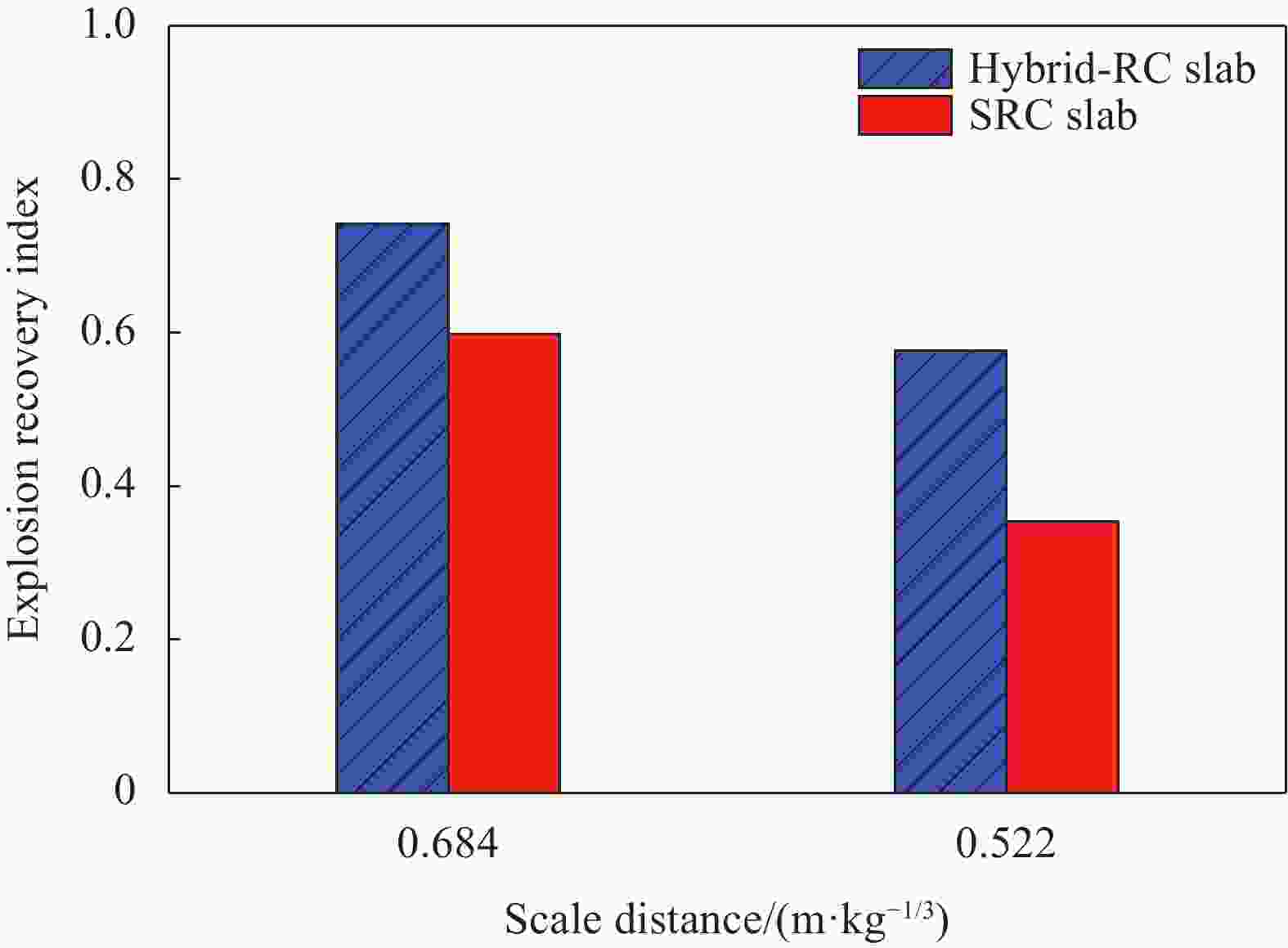

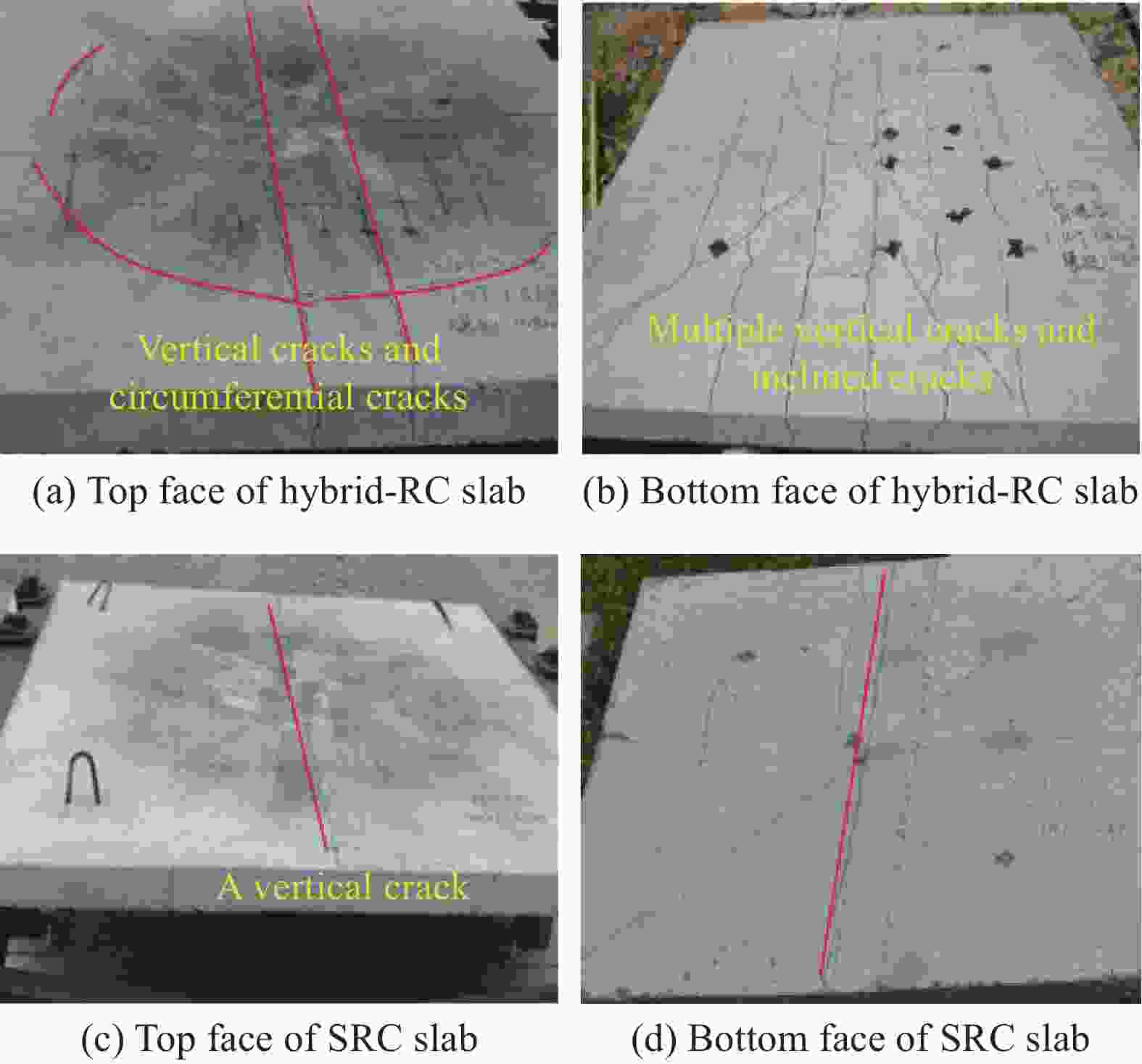

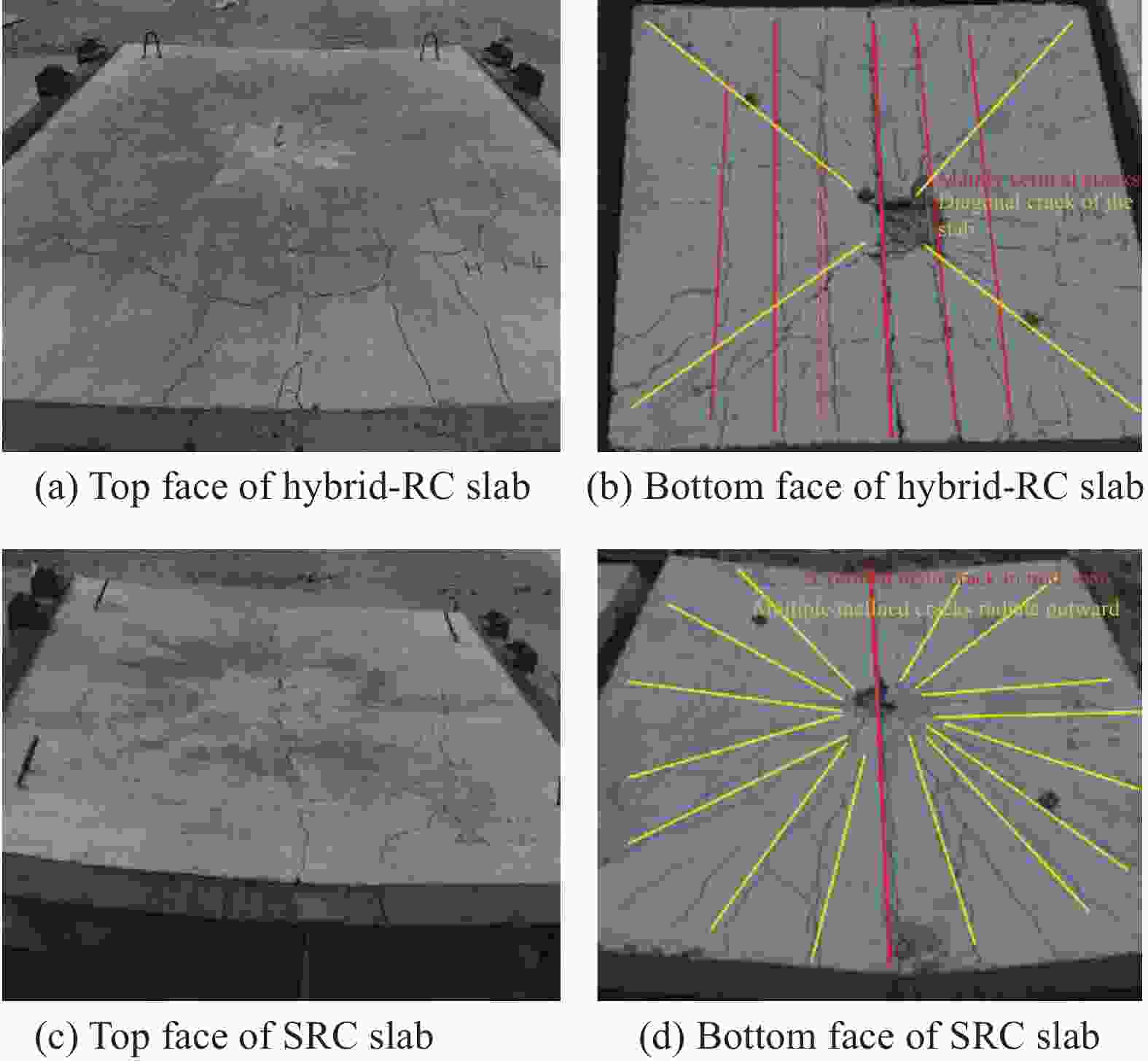

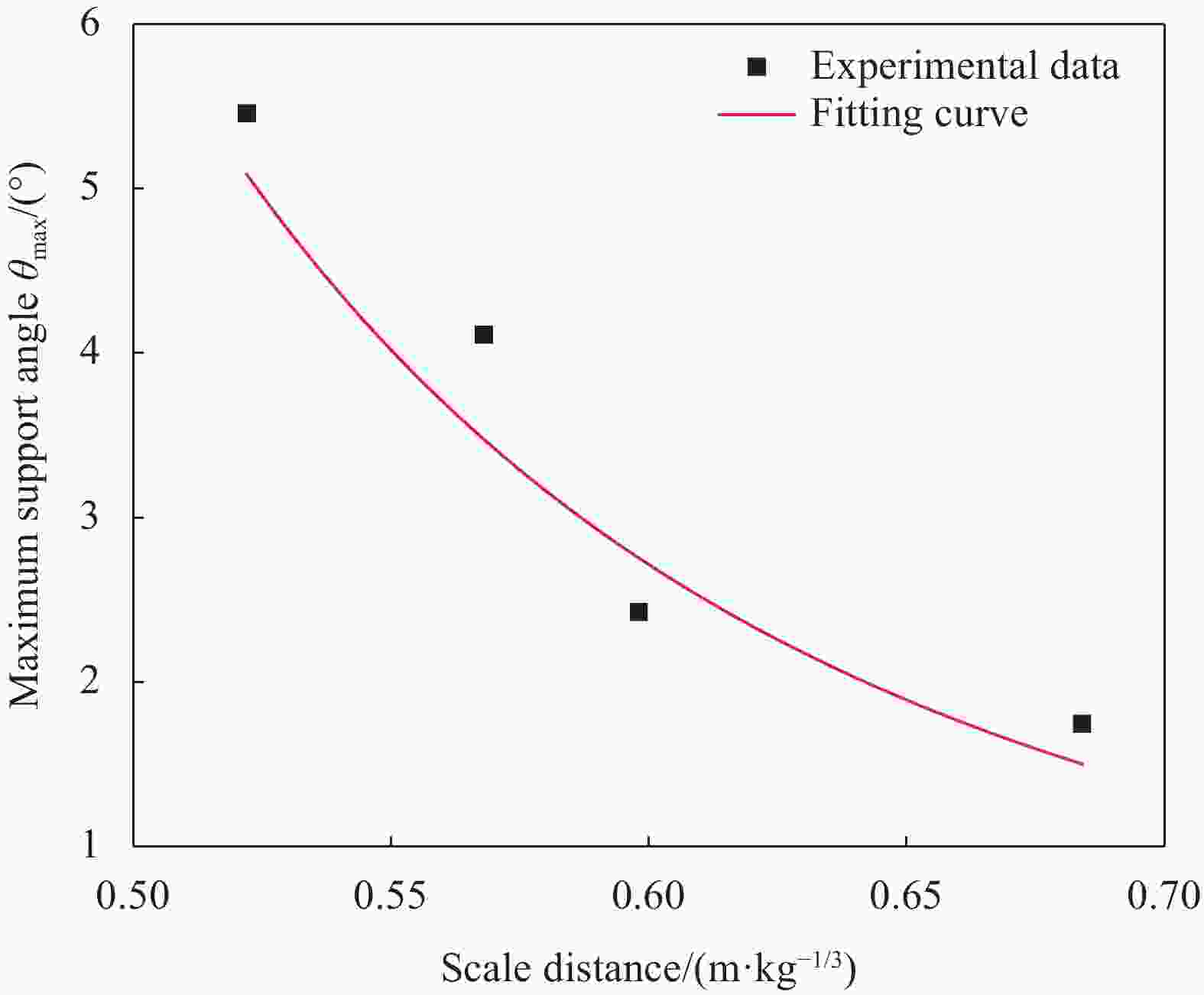

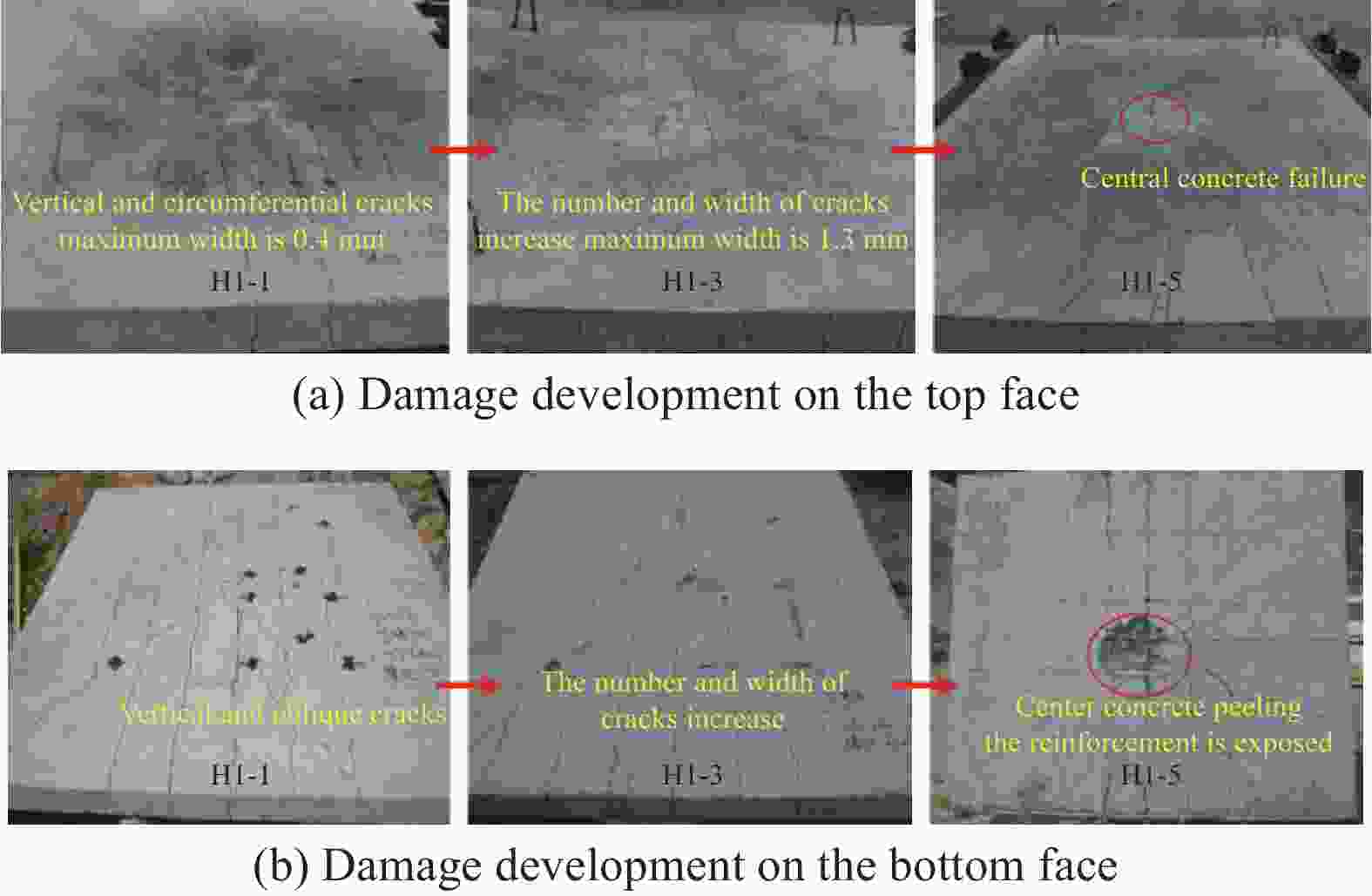

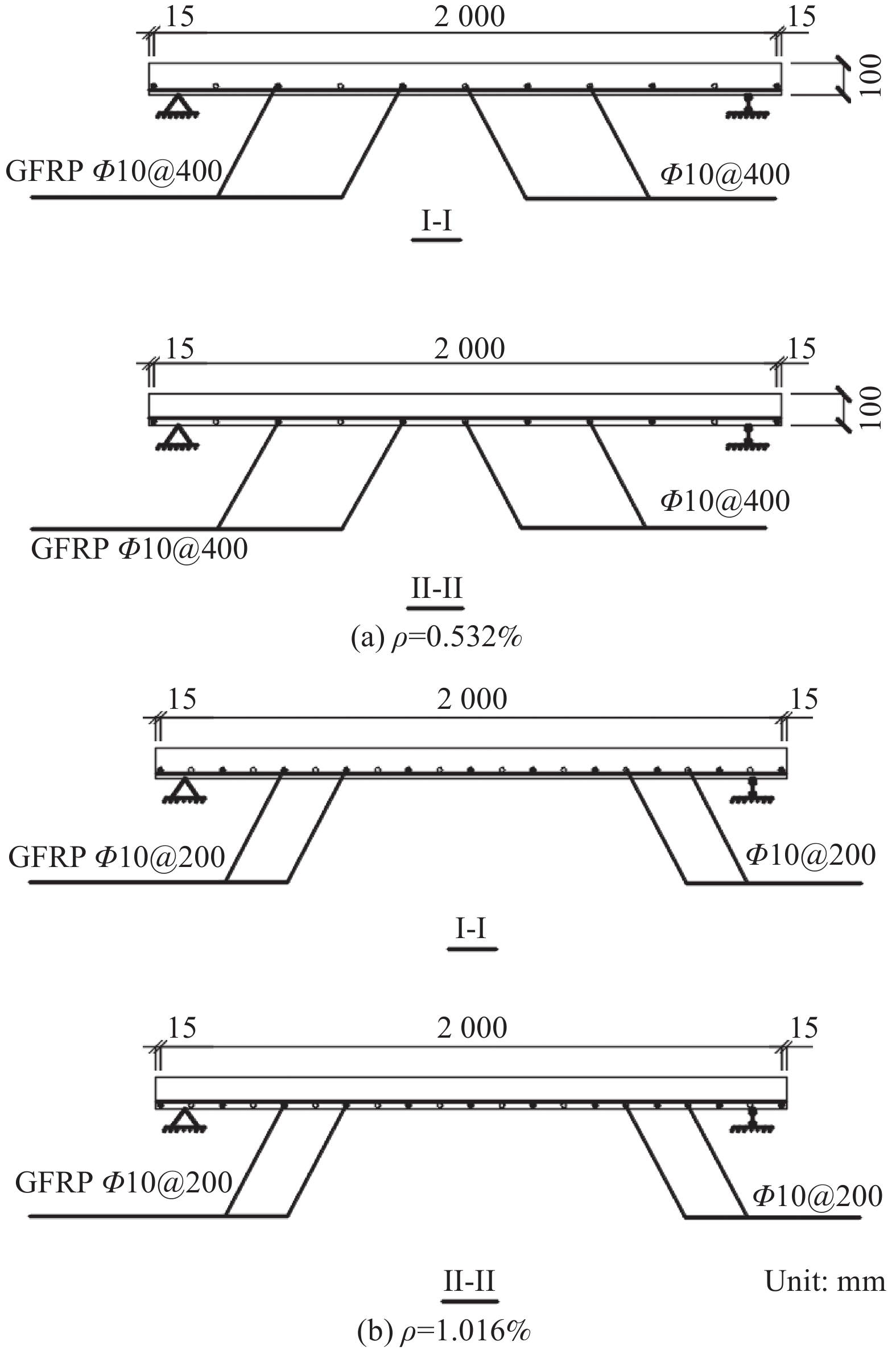

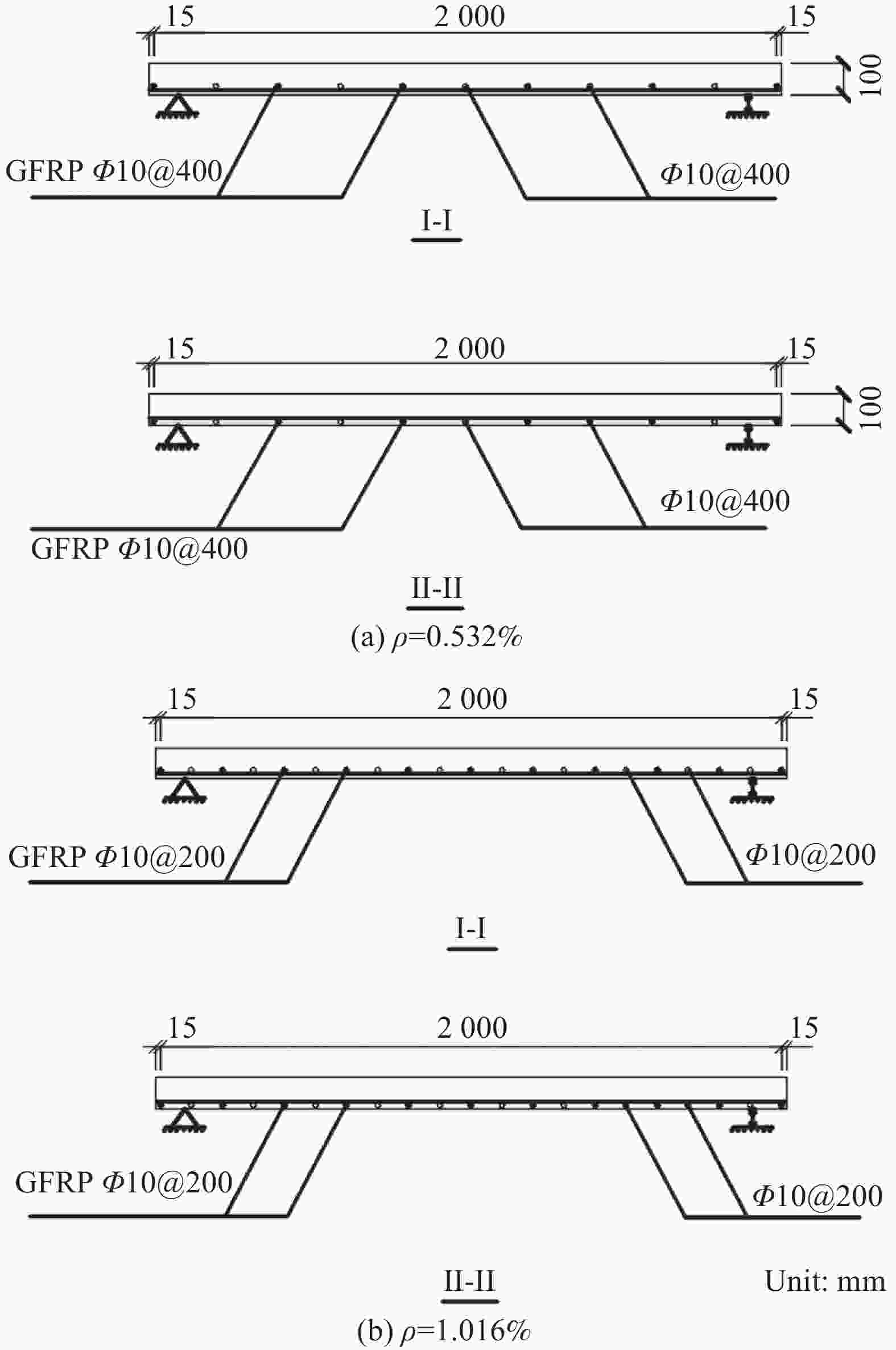

摘要: 混合配筋混凝土结构将钢筋和纤维复合材料(FRP)筋混合配置于混凝土,可较好地解决钢筋混凝土(SRC)结构的耐久性问题和FRP筋混凝土结构脆性破坏的问题,已广泛应用于土木工程中。为了研究混合配筋混凝土板的抗爆性能,开展了不同比例距离下混合配筋混凝土板和钢筋混凝土板的非接触爆炸试验,对比分析两种板抗爆性能差异和确定混合配筋混凝土板的破坏模式。结果表明:比例距离为0.684 m/kg1/3时,混合配筋混凝土板位移峰值比钢筋混凝土板位移峰值大19.2%,但残余变形比钢筋混凝土板残余变形小27.3%。引入爆炸恢复指数评估混凝土板爆炸恢复能力,混合配筋混凝土板爆炸恢复指数大于钢筋混凝土板,混合配筋混凝土板有着出色的爆炸后恢复能力。混合配筋混凝土板背爆面破坏出现多条竖向裂缝和板对角线处斜裂缝,而钢筋混凝土板仅出现一条较宽的竖向主裂缝,多条斜裂缝向外辐射。混合配筋混凝土板随着比例距离的减小,破坏模式从整体弯曲破坏发展为整体弯曲破坏和局部混凝土破坏并存。结合试验数据提出混合配筋混凝土板最大支座转角θ的预测公式。为混合配筋混凝土板抗爆设计提供参考。Abstract: Concrete structures reinforced with a combination of steel and fiber-reinforced polymer (FRP) bars can effectively solve the durability problem of steel-reinforced concrete (SRC) structures and the brittle failure problem of FRP-reinforced concrete structures. It has been widely used in civil engineering. In order to study the explosion resistance of hybrid FRP-steel-reinforced concrete (hybrid-RC) slab, the close-in explosion tests of hybrid-RC slabs and SRC slabs at different scale distances were carried out to compare and analyze the difference of explosion resistance between the two slabs and determine the failure mode of hybrid-RC slab. When the scale distance is 0.684 m/kg1/3, The maximum displacement of hybrid-RC slab is 19.2% larger than that of SRC slab, but the residual deformation is 27.3% smaller than that of SRC slab. The explosion recovery index is introduced to evaluate the explosion recovery capacity of concrete slabs. The explosion recovery index of hybrid-RC slabs is larger than that of SRC slabs. Hybrid-RC slabs have excellent explosion recovery capacity. The cracks on the back of the hybrid-RC slab depicts multiple vertical cracks and diagonal cracks, while the cracks on the back of the SRC slab depicts one vertical main crack and multiple diagonal cracks radiating outward. With the decrease of the scale distance, the failure mode of the hybrid-RC slab develops from the whole bending failure to the coexistence of the bending failure and the local concrete failure. According to the test data, the prediction formula of the maximum support angle is proposed. It provides a reference for the explosion design of hybrid-RC slab.

-

Key words:

- hybrid FRP-steel reinforcement /

- concrete slab /

- blast load /

- failure mode /

- explosion resistance

-

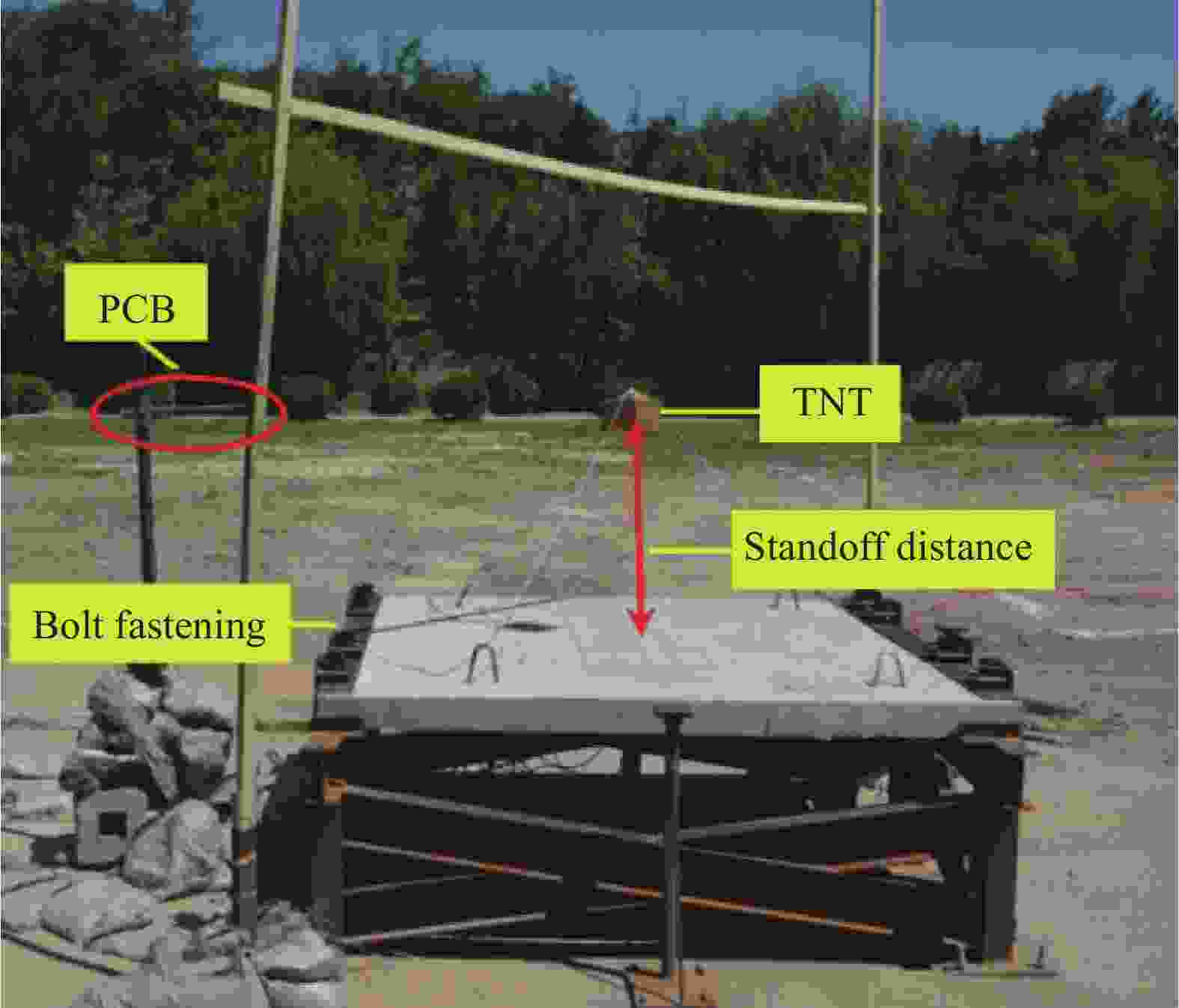

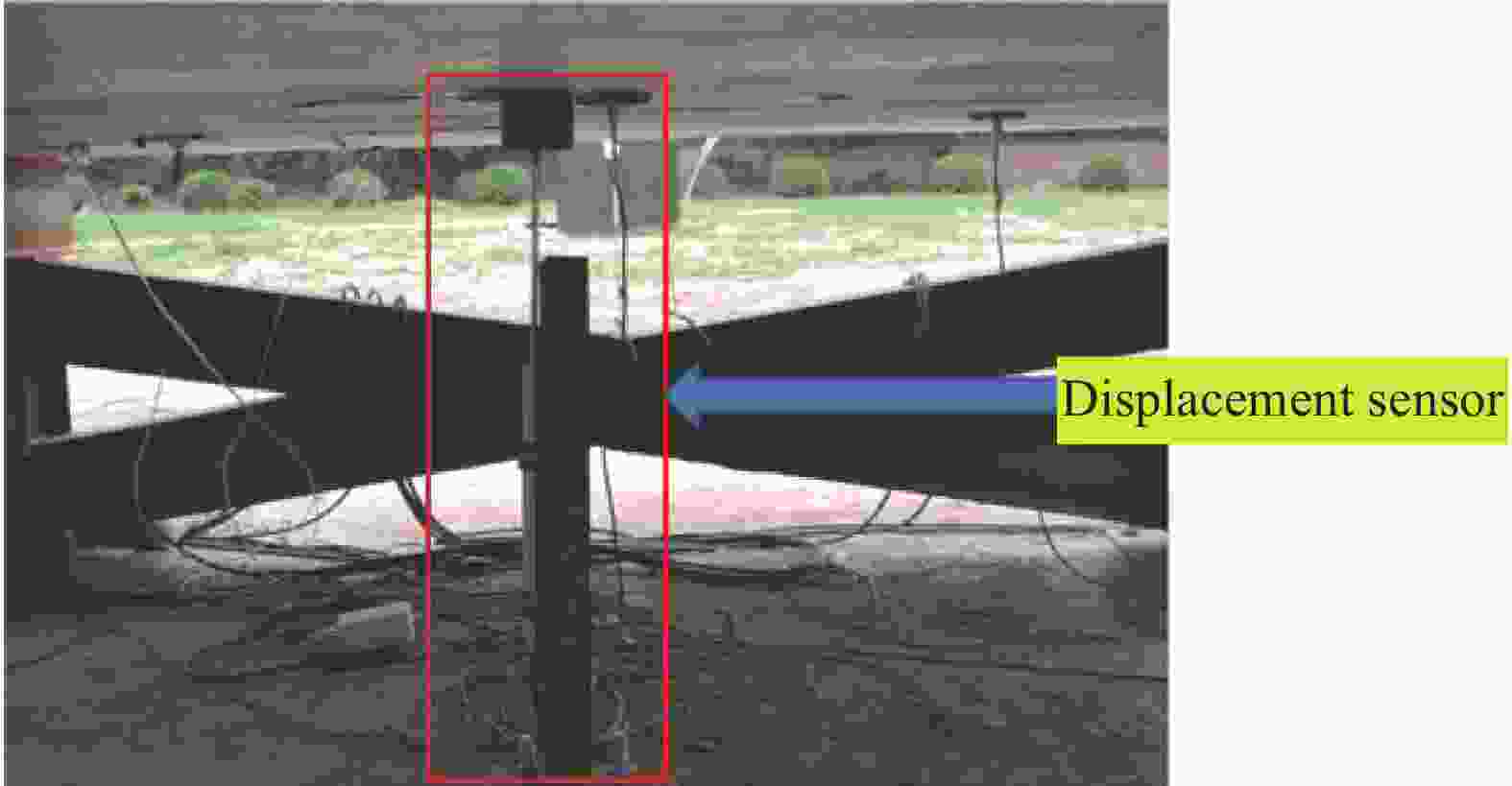

表 1 非接触爆炸板试件

Table 1. Non-contact explosion test specimen

Specimen number Type of

reinforcementReinforcement

ratio ρ/%TNT

/kgStandoff distance

/mScale

distance

/(m·kg−1/3)H1-1 GFRP-Steel 0.532 1.6 0.8 0.684 H1-2 GFRP-Steel 0.532 2.4 0.8 0.598 H1-3 GFRP-Steel 0.532 2.8 0.8 0.568 H1-4 GFRP-Steel 0.532 3.6 0.8 0.522 H1-5 GFRP-Steel 0.532 4.6 0.8 0.481 H2-1 GFRP-Steel 1.016 1.6 0.8 0.684 H2-2 GFRP-Steel 1.016 3.6 0.8 0.522 S1-1 Steel 0.532 1.6 0.8 0.684 S1-2 Steel 0.532 3.6 0.8 0.522 Notes: GFRP—Glass fiber reinforced polymer; TNT—Trinitrotoluene; H stands for hybrid GFRP-steel-reinforced concrete (hybrid-RC) slab; S stands for steel-reinforced concrete (SRC) slab; The first numerical number represents different reinforcement ratios, and the second numerical number represents different scale distances. 表 2 钢筋力学性能

Table 2. Mechanical properties of steel reinforcement

Type of steel bar Elastic modulus/

GPaYield strength/

MPaTensile strength

/MPaYield strain/% Ultimate strain

/%HRB400 E 209 458 633 0.22 >10 表 3 GFRP筋力学性能

Table 3. Mechanical properties of GFRP reinforcement

FRP bar Elastic modulus/

GPaTensile

strength/MPaUltimate

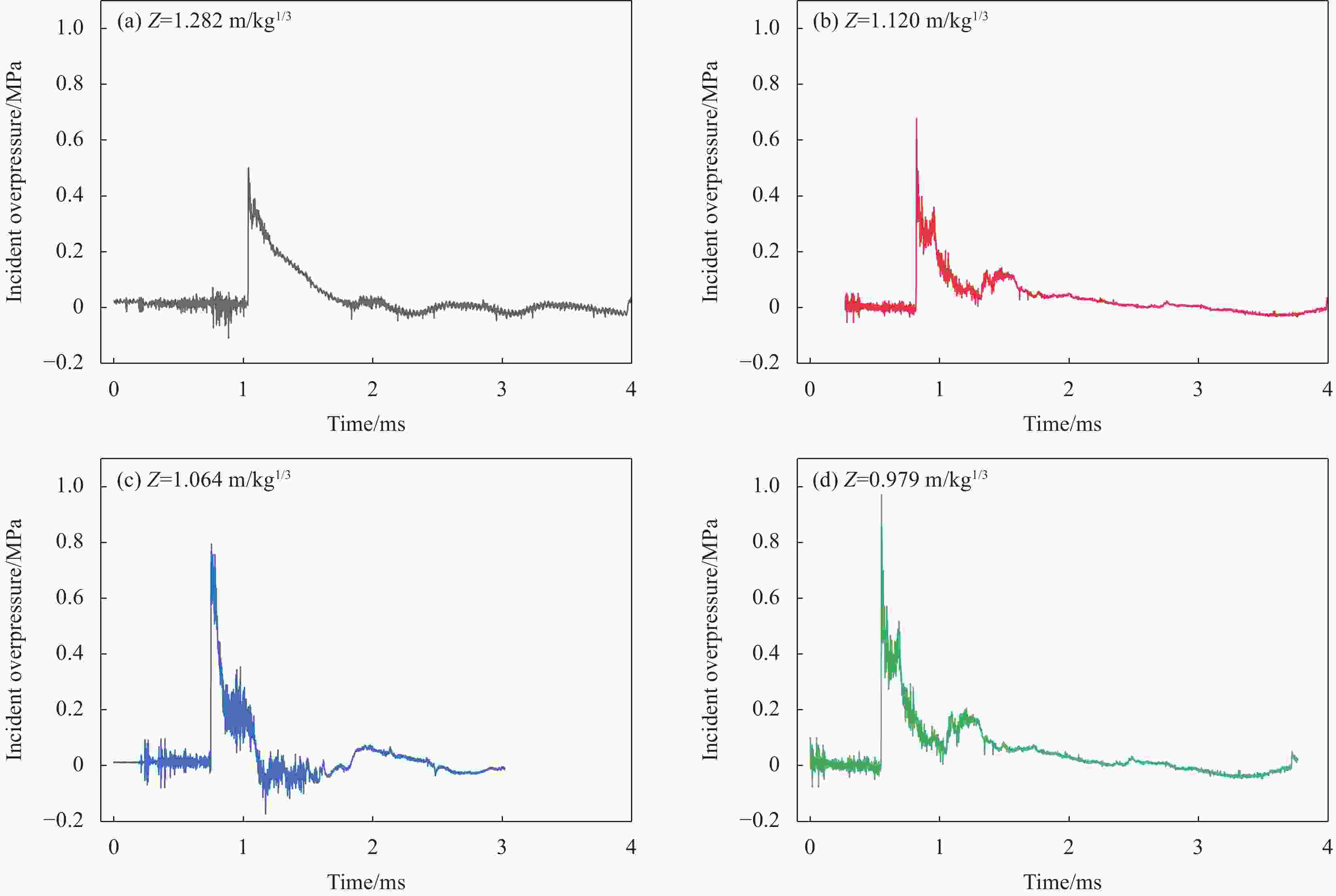

strain/%GFRP 49.4 1070 2.4 Note: FRP—Fiber reinforced polymer. 表 4 入射超压

Table 4. Incident overpressure

Scale distance/

(m·kg−1/3)Test value/

MPaEmpirical formula

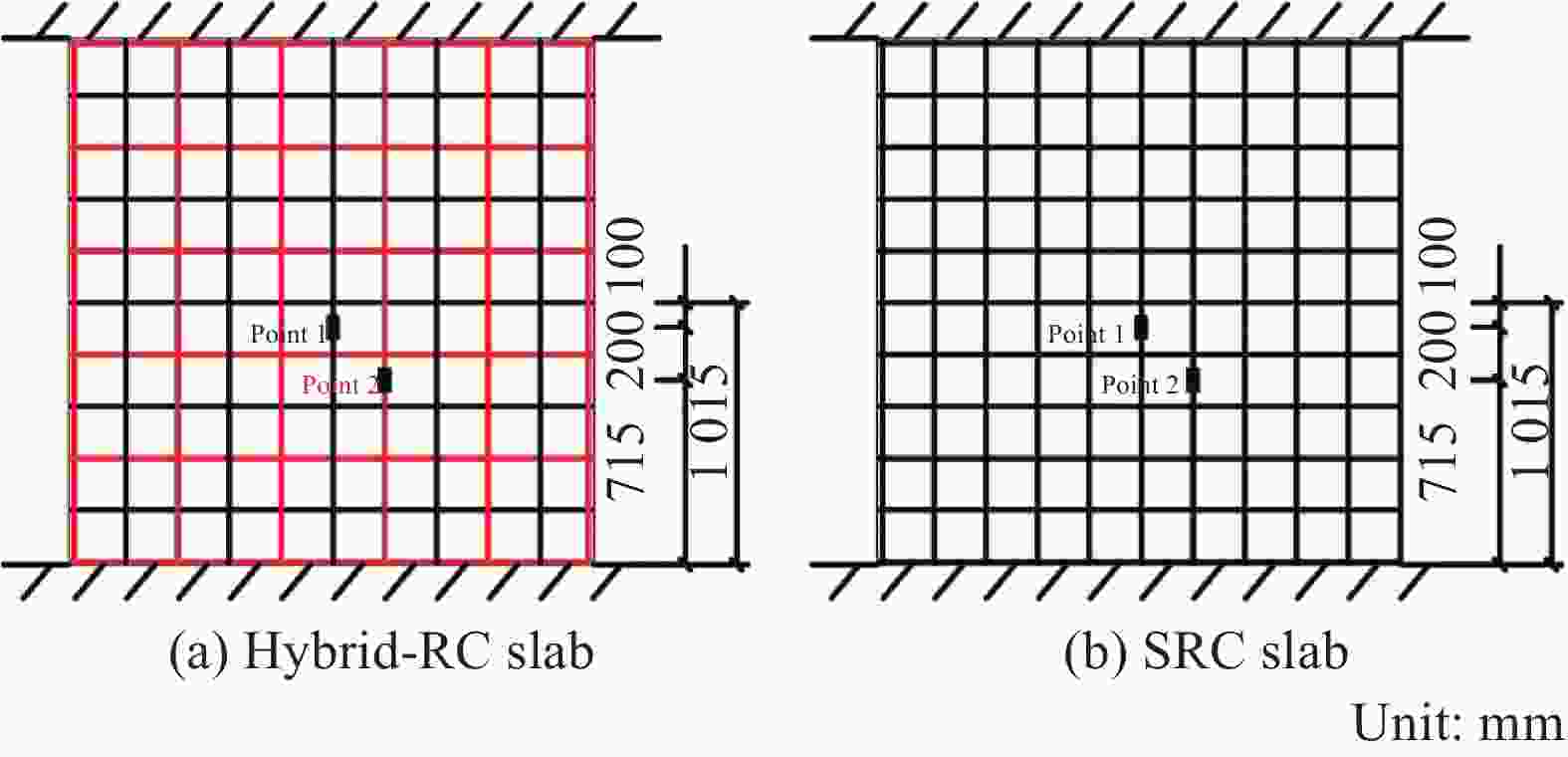

value/MPaError/% 1.282 0.502 0.454 10.57 1.120 0.678 0.616 10.06 1.064 0.78 0.693 12.55 0.979 0.952 0.826 15.25 表 5 不同加筋混凝土板应变峰值

Table 5. Peak strain of concrete slabs with different reinforcements

Specimen number Scale distance/

(m·kg−1/3)Peak value of point 1 Peak value of point 2 H1-1 0.684 1.20×10−2 2.82×10−3 S1-1 0.684 1.06×10−2 2.44×10−3 H1-4 0.522 2.36×10−2 6.75×10−3 S1-2 0.522 2.19×10−2 6.09×10−3 表 6 不同加筋混凝土板跨中位移数据

Table 6. Mid-span displacement data of concrete slabswith different reinforcements

Specimen number Scale distance/

(m·kg−1/3)Maximum

displacement/

mmResidual

deformation/

mmH1-1 0.684 31 8 S1-1 0.684 26 11 H1-4 0.522 97 39 S1-2 0.522 82 53 表 7 单向板损伤准则

Table 7. Damage criteria for unidirectional slab

Damage level Damage criterion Light θmax≤2° Moderate 2°≤θmax≤5° Severe 5°≤θmax≤12° Collapse θmax≥12° Note: θmax—Maximum support angle of the plate. 表 8 不同配筋率混凝土板跨中位移数据

Table 8. Mid-span displacement data of concrete slabs with different reinforcement ratios

Specimen number Reinforcement

ratio ρ/%Scale distance/

(m·kg−1/3)Maximum

displacement/mmResidual

deformation/mmExplosion recovery

indexH1-1 0.532 0.684 31 8 0.74 H2-1 1.016 0.684 20 0 1 H1-4 0.532 0.522 97 38 0.61 H2-2 1.016 0.522 64 16 0.75 -

[1] 董恒磊, 李东风, 王代玉. 螺旋缠绕挤压肋FRP筋与混凝土间的粘结性能[J]. 复合材料学报, 2022, 39(11): 5239-5250.DONG Henglei, LI Dongfeng, WANG Daiyu. Bond behavior between helically and tightly wound FRP bars and concrete[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5239-5250(in Chinese). [2] ZHOU B B, WU R Y, LU S Q, et al. A general numerical model for predicting the flexural behavior of hybrid FRP-steel reinforced concrete beams[J]. Engineering Structures,2021,239:112293. doi: 10.1016/j.engstruct.2021.112293 [3] LAU D, PAM H J. Experimental study of hybrid FRP reinforced concrete beams[J]. Engineering Structures,2010,32(12):3857-3865. doi: 10.1016/j.engstruct.2010.08.028 [4] QU W J, ZHANG X L, HUANG H Q. Flexural behavior of concrete beams reinforced with hybrid (GFRP and steel) bars[J]. Journal of Composites for Construction,2009,13(5):350-359. doi: 10.1061/(ASCE)CC.1943-5614.0000035 [5] KARA I F, AHOUR A F, KÖROĞLU M A. Flexural behavior of hybrid FRP/steel reinforced concrete beams[J]. Compo-site Structures,2015,129:111-121. doi: 10.1016/j.compstruct.2015.03.073 [6] ARABA A M, ASHOUR A F. Flexural performance of hybrid GFRP-Steel reinforced concrete continuous beams[J]. Composites Part B: Engineering,2018,154:321-336. doi: 10.1016/j.compositesb.2018.08.077 [7] RUAN X J, LU C H, XU K, et al. Flexural behavior and serviceability of concrete beams hybrid-reinforced with GFRP bars and steel bars[J]. Composite Structures,2020,235:111772. doi: 10.1016/j.compstruct.2019.111772 [8] ZHOU B B, WU R Y, LIU Y Q, et al. Flexural strength design of hybrid FRP-steel reinforced concrete beams[J]. Materials,2021,14(21):6400. doi: 10.3390/ma14216400 [9] 庞蕾, 屈文俊, 李昂. 混合配筋混凝土梁抗弯计算理论[J]. 中国公路学报, 2016, 29(7):81-88. doi: 10.3969/j.issn.1001-7372.2016.07.010PANG Lei, QU Wenjun, LI Ang. Calculation of flexural strength for concrete beams reinforced with hybrid (FRP and steel) bars[J]. China Journal of Highway and Transport,2016,29(7):81-88(in Chinese). doi: 10.3969/j.issn.1001-7372.2016.07.010 [10] 戚岩. 加筋混凝土构件抗弯统一计算理论研究[D]. 上海: 同济大学, 2018.QI Yan. Study on unified flexural calculation theory of reinforced concrete members[D]. Shanghai: Shanghai Tongji University, 2018(in Chinese). [11] 刘文博. 加筋混凝土构件抗剪统一计算理论研究[D]. 上海: 同济大学, 2018.LIU Wenbo. Study on uniform shear calculation theory for reinforced concrete members[D]. Shanghai: Shanghai Tongji University, 2018(in Chinese). [12] 屈俊楠. 加筋混凝土构件抗压弯统一计算理论研究[D]. 上海: 同济大学, 2018.QU Junnan. Study on unified calculation theory of reinforced concrete members under eccentric compression[D]. Shanghai: Shanghai Tongji University, 2018(in Chinese). [13] 许家婧, 朱鹏, 屈文俊. 钢筋-GFRP筋增强混凝土梁的疲劳力学性能[J]. 复合材料学报, 2022, 39(5):2318-2328. doi: 10.13801/j.cnki.fhclxb.20210809.001XU Jiajing, ZHU Peng, QU Wenjun. Fatigue behaviors of steel bars-GFRP bars reinforced concrete beams[J]. Acta Materiae Compositae Sinica,2022,39(5):2318-2328(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210809.001 [14] SUN Z Y, WU G, ZHANG J, et al. Experimental study on concrete columns reinforced by hybrid steel-fiber reinforced polymer (FRP) bars under horizontal cyclic loading[J]. Construction and Building Materials,2017,130:202-211. doi: 10.1016/j.conbuildmat.2016.10.001 [15] IBRAHIM A I, WU G, SUN Z Y. Experimental study of cyclic behavior of concrete bridge columns reinforced by steel basalt-fiber composite bars and hybrid stirrups[J]. Journal of Composites for Construction, 2017, 21(2): 04016091. [16] 杜修力, 王作虎, 詹界东. 预应力FRP筋混凝土梁的抗震性能试验研究[J]. 土木工程学报, 2012, 45(2):43-50. doi: 10.15951/j.tmgcxb.2012.02.016DU Xiuli, WANG Zuohu, ZHAN Jiedong. Experimental studies on the seismic performance of concrete beams prestressed with FRP tendons[J]. China Civil Engineering Journal,2012,45(2):43-50(in Chinese). doi: 10.15951/j.tmgcxb.2012.02.016 [17] 王晖, 查晓雄. 火灾下FRP筋混凝土柱性能[J]. 哈尔滨工业大学学报, 2009, 41(12):36-40. doi: 10.3321/j.issn:0367-6234.2009.12.007WANG Hui, ZHA Xiaoxiong. Performances of FRP rebar reinforced concrete columns under fire condition[J]. Jour-nal of Harbin Institute of Technology,2009,41(12):36-40(in Chinese). doi: 10.3321/j.issn:0367-6234.2009.12.007 [18] TIAN J B, ZHU P, QU W J. Study on fire resistance time of hybrid reinforced concrete beams[J]. Structural Concrete,2019,20(6):1941-1954. doi: 10.1002/suco.201800320 [19] 中国国家标准化管理委员会. 金属材料拉伸试验第1部分: 室温试验方法: GB/T 228.1—2010[S]. 北京: 中国标准出版社, 2010.Standardization Administration of China. Metallic materials-tensile testing at ambient temperature: GB/T 228.1—2010[S]. Beijing: China Standards Press, 2010(in Chinese). [20] 中国国家标准化管理委员会. 纤维增强复合材料筋基本力学性能试验方法: GB/T 30022—2013[S]. 北京: 中国标准出版社, 2013.Standardization Administration of China. Test method for basic mechanical properties of fiber reinforced polymer bar: GB/T 30022—2013[S]. Beijing: China Standards Press, 2013(in Chinese). [21] HENRYCH J. The dynamics of explosion and its use[M]. Amsterdam: Elsevier, 1979. [22] 中华人民共和国工业和信息化部. 石油化工控制室抗爆设计规范: SH/T 3160—2009[S]. 北京: 中国标准出版社, 2009.Ministry of Industry and Information Technology of People's Republic of China. Specification for design of blast resistant control building in petrochemical industry: SH/T 3160—2009[S]. Beijing: China Standards Press, 2009(in Chinese). [23] WANG W, ZHANG D, LU F Y, et al. Experimental study on scaling the explosion resistance of a one-way square reinforced concrete slab under a close-in blast loading[J]. International Journal of Impact Engineering,2012,49:158-164. doi: 10.1016/j.ijimpeng.2012.03.010 [24] JAMES C. Structures to resist the effects of accidental explosions: UFC3-340-02 (TM5-1300)[R]. US Department of the Army, 2008. -

下载:

下载: