Interlaminar shear behavior of glass-fibre reinforced polypropylene rod under seawater and sea sand concrete simulation environment

-

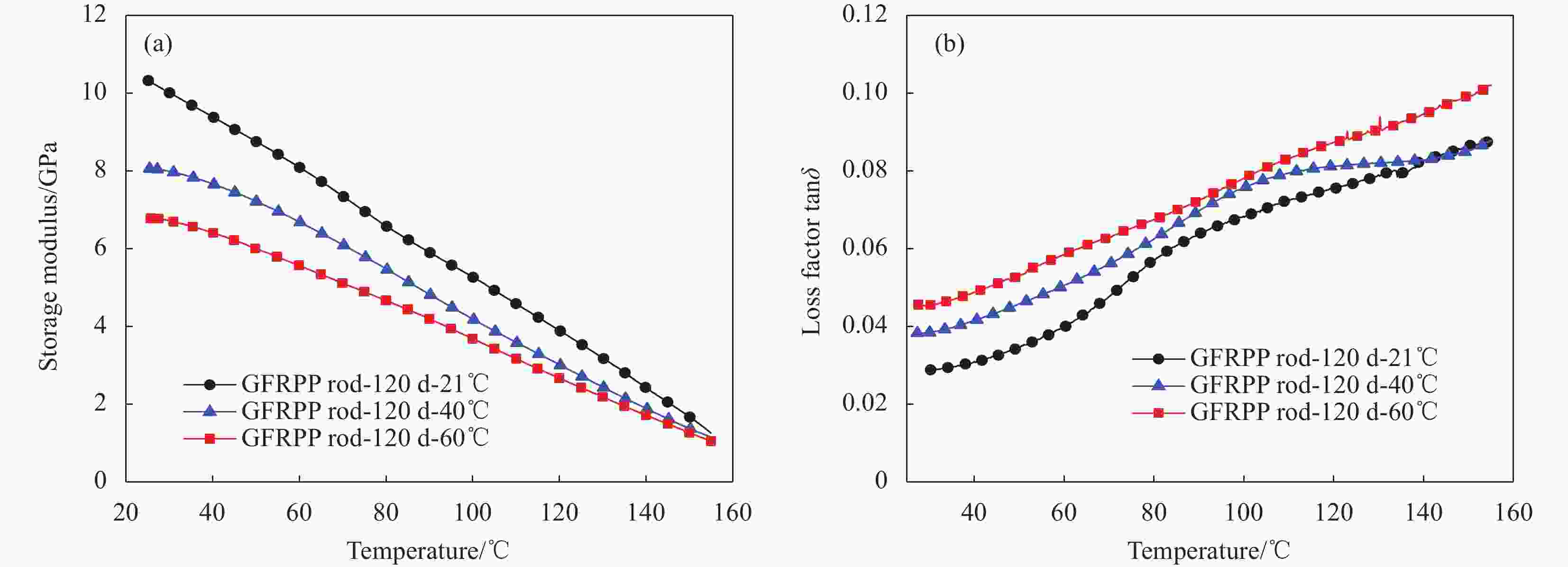

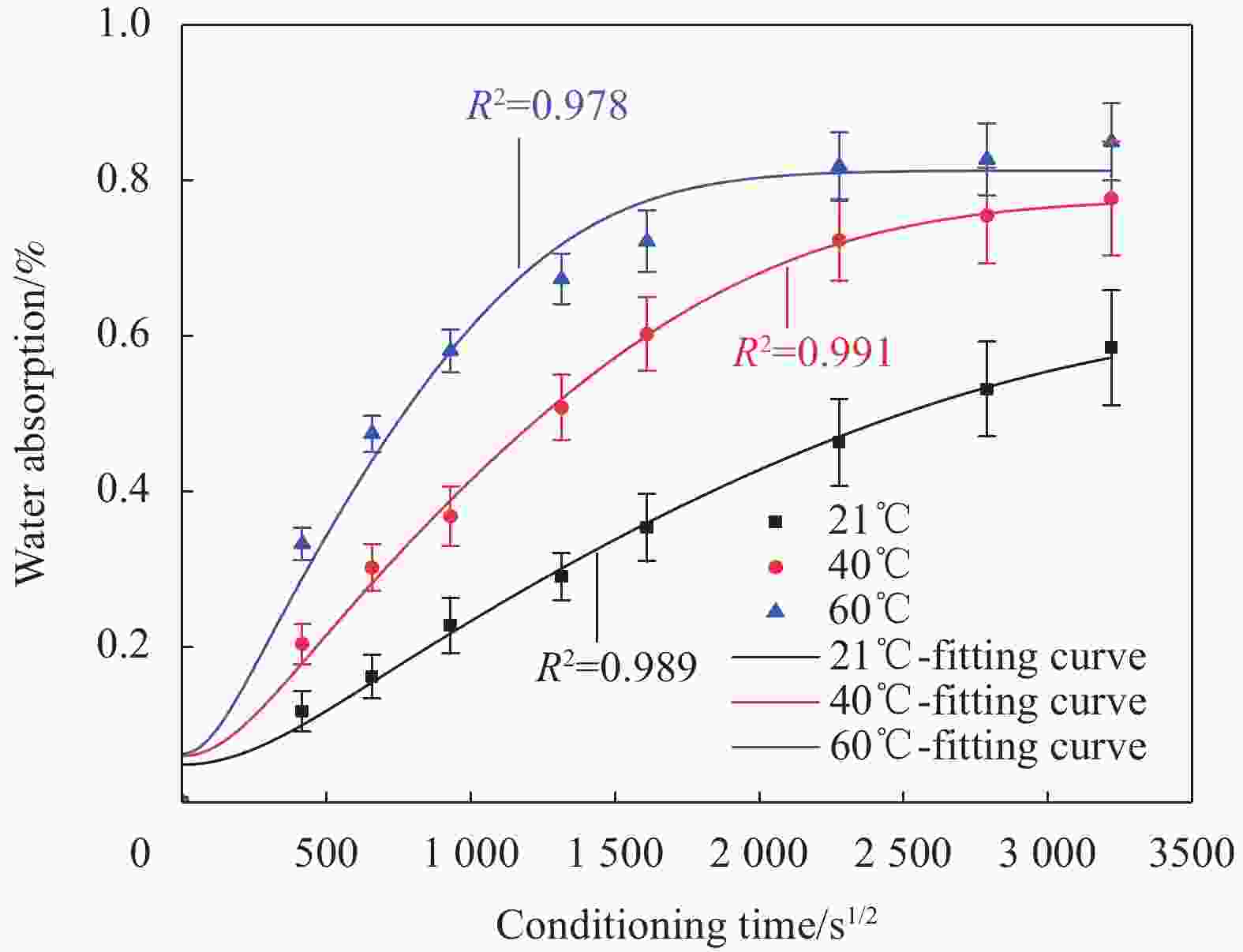

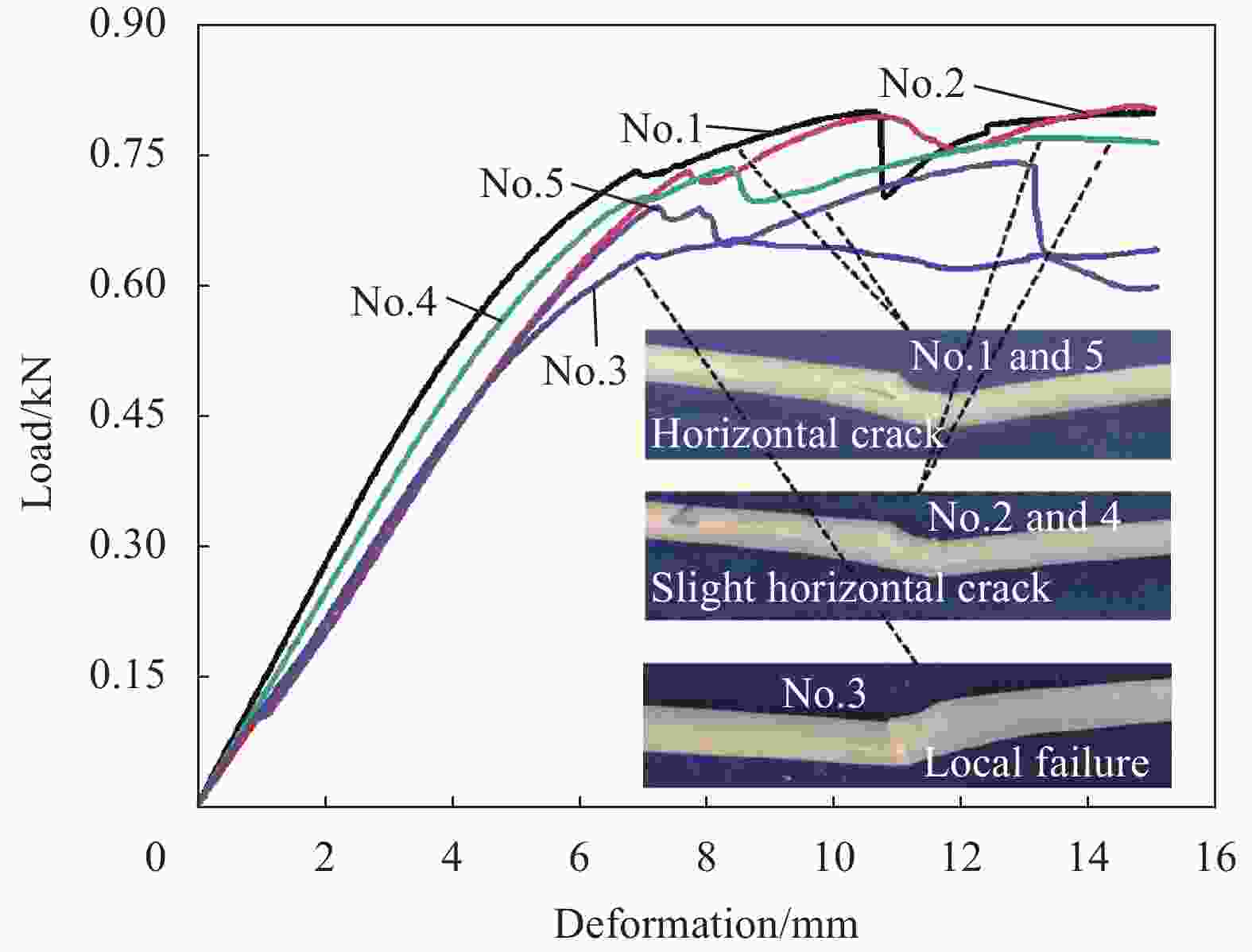

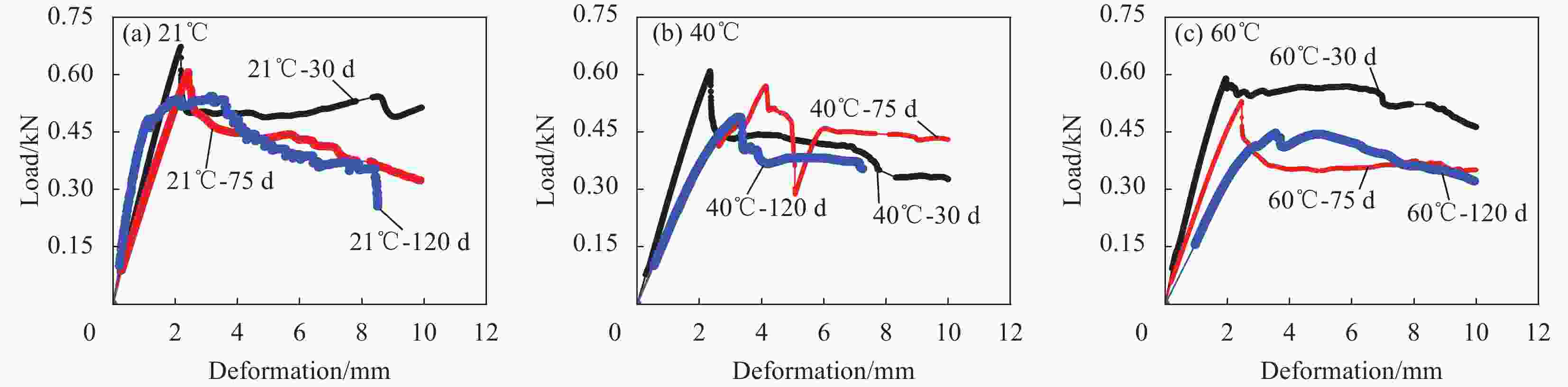

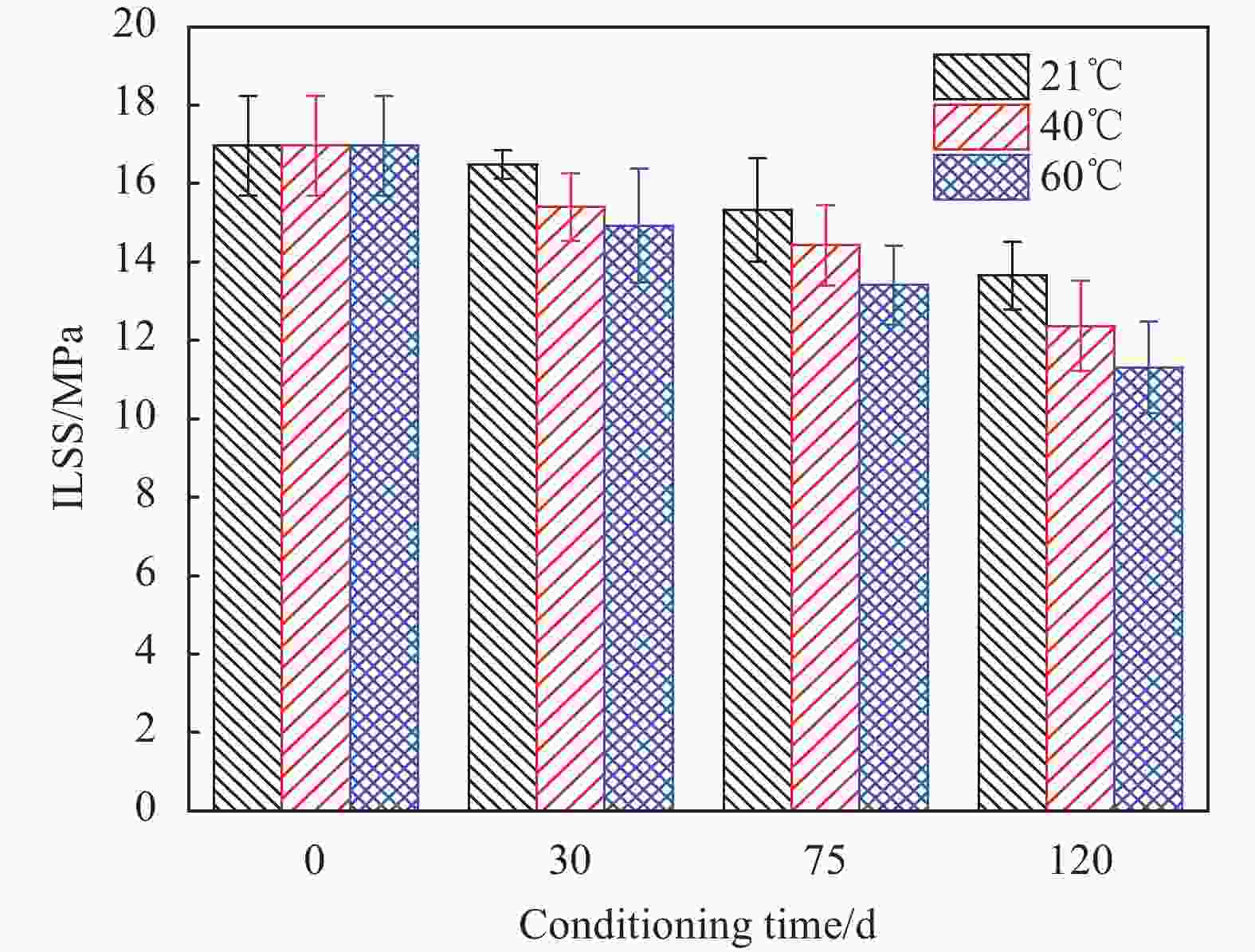

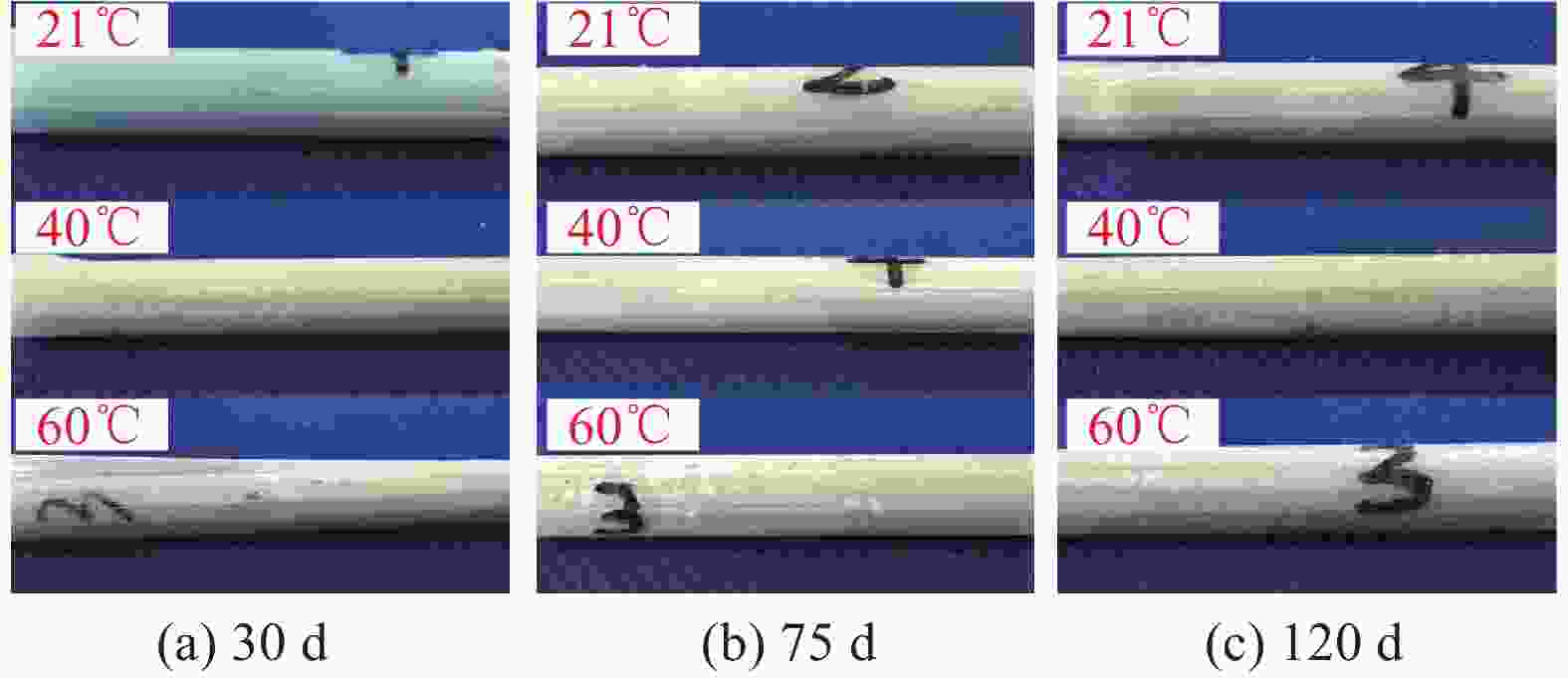

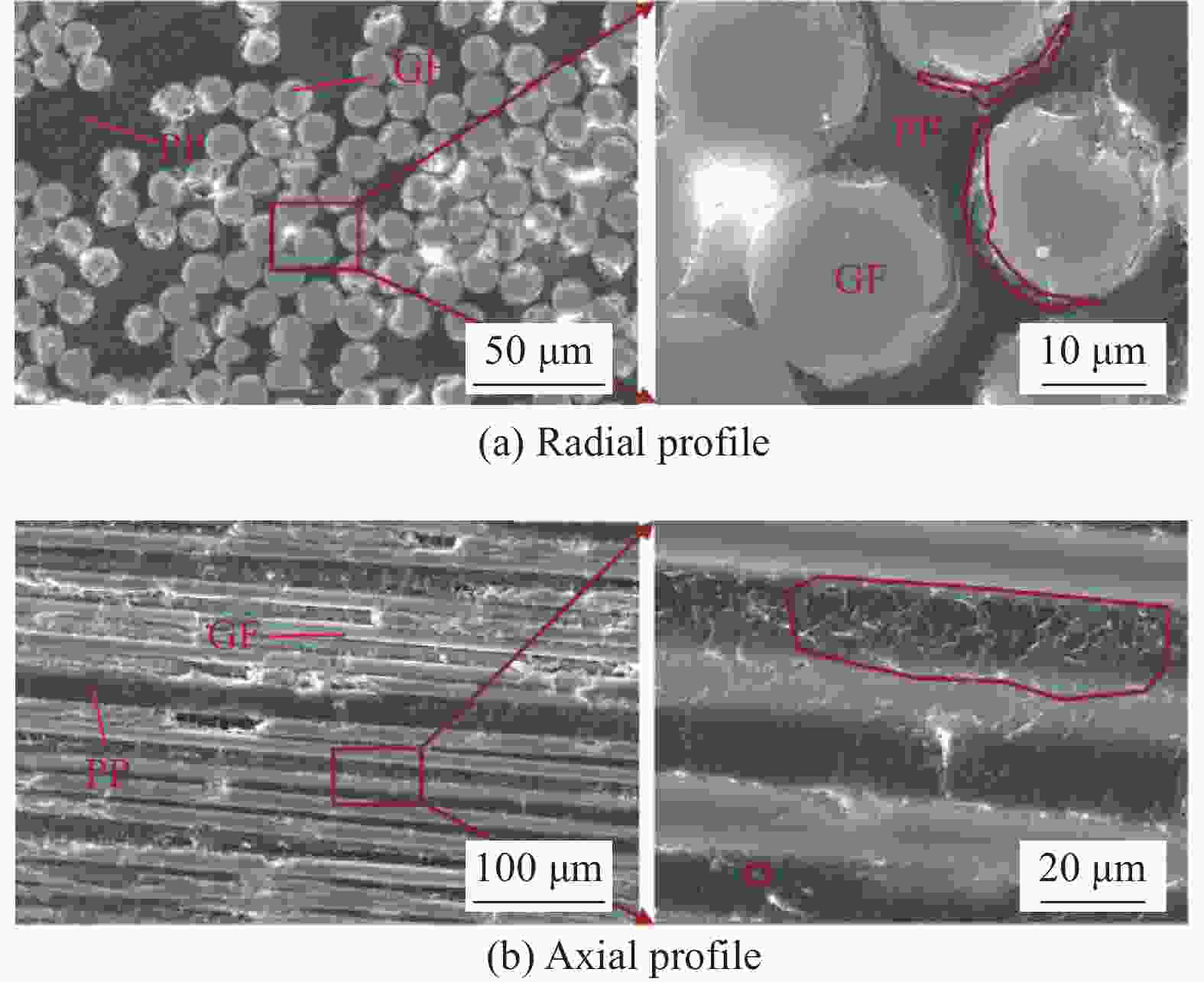

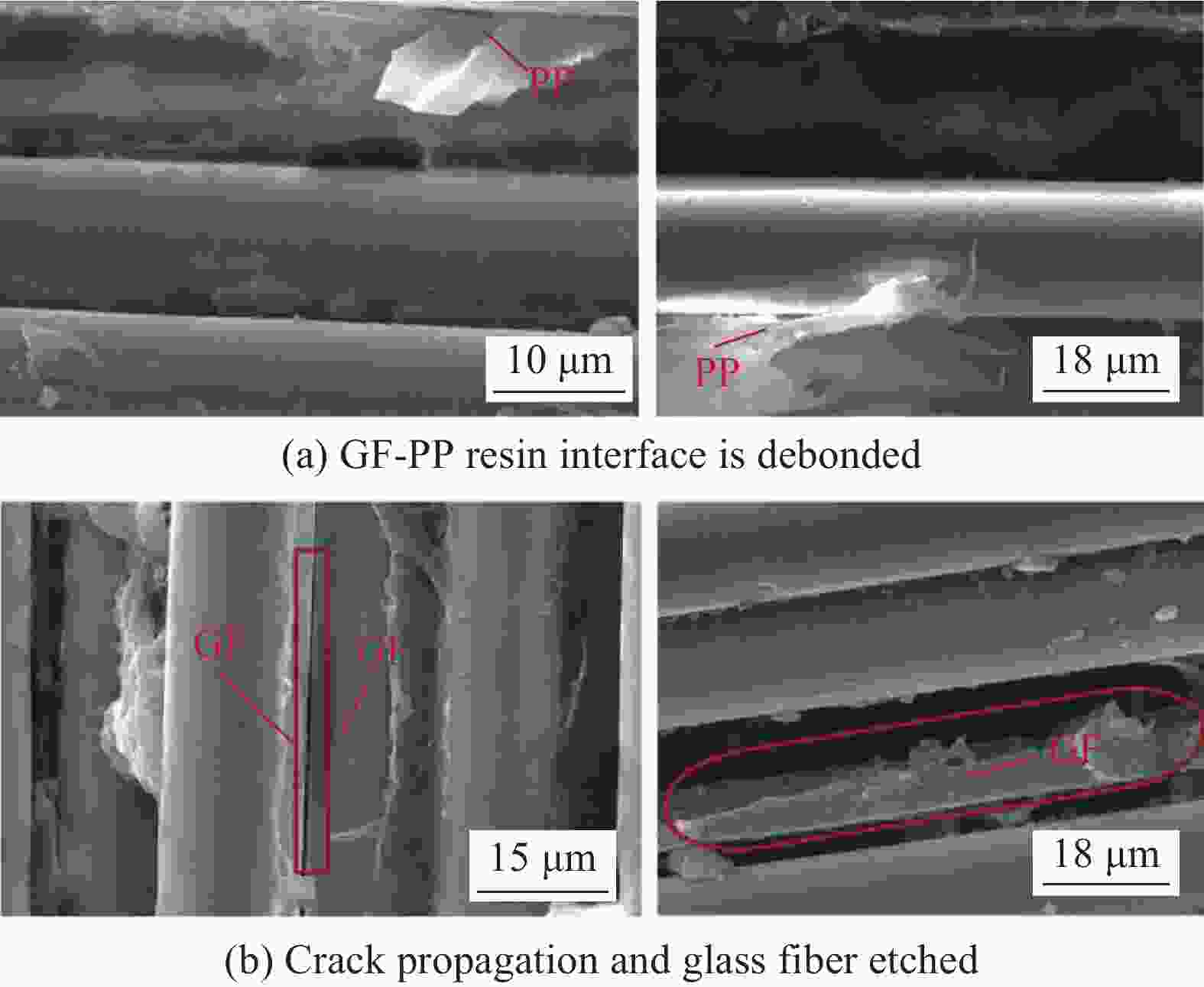

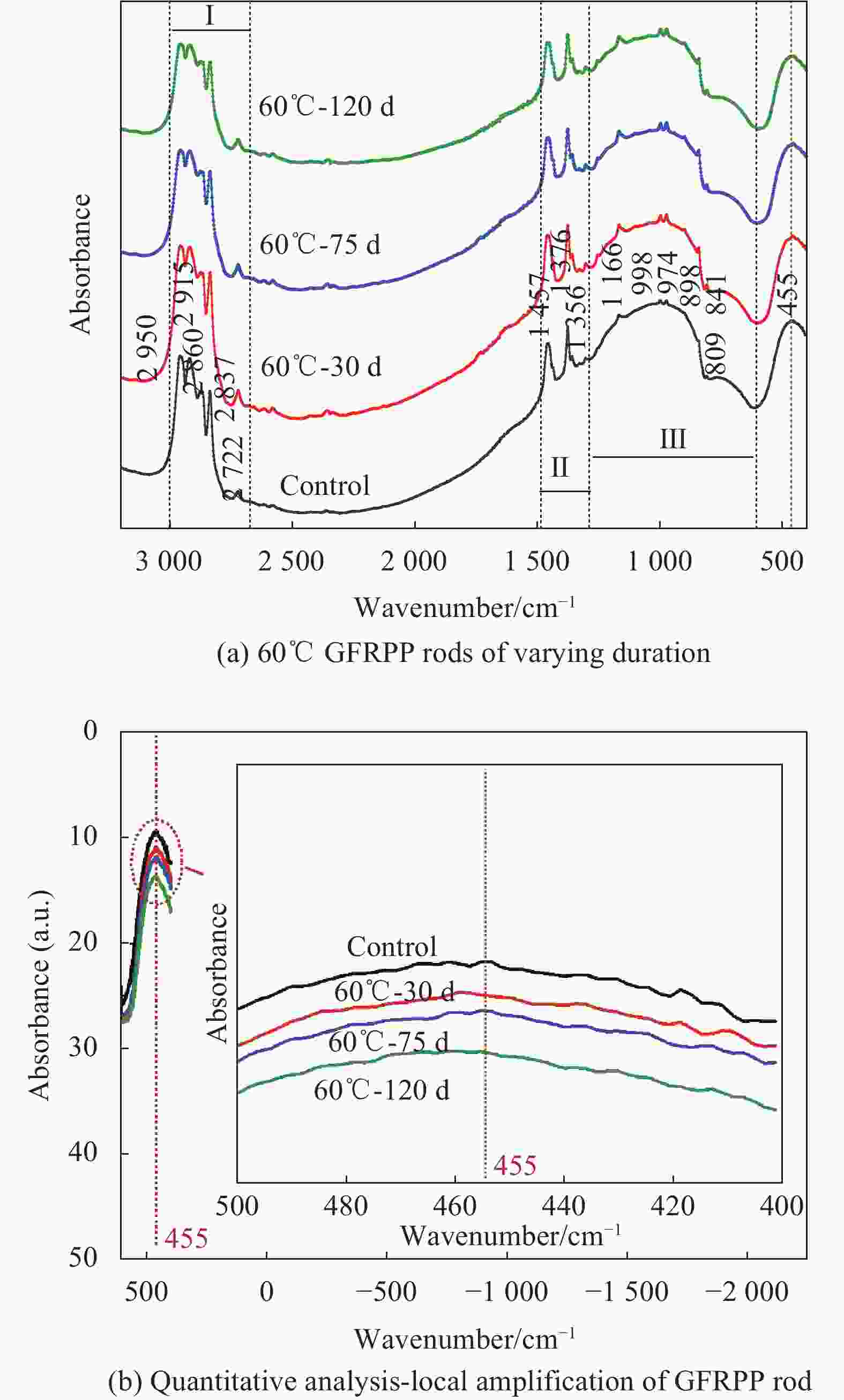

摘要: 连续玻璃纤维增强聚丙烯(GFRPP)复合材料杆集成了热塑性树脂可多次成型、环境友好、可回收利用和玻璃纤维高应变、低成本等优点,在混凝土结构领域,GFRPP复合材料有望替代钢筋和热固性纤维增强聚合物(FRP)筋成为新型热塑性复合材料。本文采用加速实验研究了模拟海水-海砂混凝土环境下GFRPP杆的水吸收及层间剪切性能长期演化规律与退化机制。研究结果表明:GFRPP杆吸水行为符合Fick定律,21℃、40℃和60℃浸泡温度下GFRPP杆的饱和吸水率分别为0.63%、0.78%和0.81%;经120天21℃、40℃和60℃模拟海水-海砂混凝土孔溶液浸泡后,GFRPP杆层间剪切强度保留率分别为80.5%、72.8%和66.5%。最后,结合SEM和FTIR表征技术,揭示模拟海水-海砂混凝土孔溶液浸泡下GFRPP杆性能退化机制。Abstract: Glass-fibre reinforced polypropylene (GFRPP) composite rod integrate the advantages of thermoplastic resin multi-molding, environmental friendliness, recyclability, and high strain and low cost of glass fiber. In the field of concrete structures, GFRPP rods are expected to replace steel bars and thermoset fibre reinforced polyer (FRP) bars as a new composite material. In this paper, accelerated experiments were used to study the long-term evolution of water absorption, interlaminar shear properties and degenerative mechanism of GFRPP rod under simulated seawater and sea sand concrete environment. The results show that the water absorption behavior of GFRPP rod conforms to Fick's law, and the saturation water absorption rates of GFRPP rods at immersion temperatures of 21°C, 40°C and 60°C are 0.63%, 0.78% and 0.81%, respectively. After 120 days of immersion in 21°C, 40°C and 60°C simulated seawater sea sand concrete pore solutions, the shear strength retention rates between GFRPP rods are 80.5%, 72.8% and 66.5%. Finally, the performance degradation mechanism of GFRPP rods under simulated seawater-sea sand concrete pore solution immersion was revealed by combining SEM and FTIR characterization techniques.

-

Mechanical

propertyTensile

strength/

MPaTensile

modulus/

GPaFlexural

strength/

MPaFlexural

modulus/

GPaMean 632.0 26.2 750.0 20.0 Standard

deviation31.4 2.2 118.0 2.7 表 2 GFRPP杆的水吸收拟合参数

Table 2. Water absorption fitting parameters of GFRPP rods

Temperature/℃ Dr/(10−13 m·s-1) M∞/% R2 21 3.02 0.63 0.989 40 6.73 0.78 0.991 60 16.03 0.81 0.978 Notes: Dr—Water absorption diffusion coefficient; M∞—Saturation water absorption rate. -

[1] 王自柯. FRP筋在模拟海水-海砂混凝土孔溶液浸泡下的耐久性研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.WANG Zike. Study on the durability performances of fiber reinforced polymer (FRP) bars exposed to simulated seawater and sea sand concrete pore solution[D]. Harbin: Harbin Institute of Technology, 2018(in Chinese). [2] KATANO K, TAKEDA N, ISHIZEKI Y, et al. Properties and application of concrete made with sea water and un-washed sea sand[C]. Proceedings of 3rd International Conference on Sustainable Construction Material and Technologies (SCMT3). Kyoto: Claisse, 2013: 10. [3] TAREK U M, HIDENORI H, TORU Y. Performance of seawater-mixed concrete in the tidal environment[J]. Cement and Concrete Research,2004,34:593-601. doi: 10.1016/j.cemconres.2003.09.020 [4] LI C G, YIN X L, LIU Y C, et al. Long-term service evaluation of a pultruded carbon/glass hybrid rod exposed to elevated temperature, hydraulic pressure and fatigue load coupling[J]. International Journal of Fatigue,2020,134:105480. doi: 10.1016/j.ijfatigue.2020.105480 [5] ZHOU P, LI C G, BAI Y B, et al. Durability study on the interlaminar shear behavior of glass-fibre reinforced polypropylene (GFRPP) bars for marine applications[J]. Construction and Building Materials,2022,349:128694. doi: 10.1016/j.conbuildmat.2022.128694 [6] WASIM M, TUAN D N, ABID M. Investigation of long-term corrosion resistance of reinforced concrete structures constructed with various types of concretes in marine and various climate environments[J]. Construction and Building Materials,2020,237:117701. doi: 10.1016/j.conbuildmat.2019.117701 [7] 霍瑞丽, 陈登场, 方海, 等. 不同温度环境下轻木夹芯复合材料板弯曲疲劳性能试验[J]. 南京工业大学学报(自然科学版), 2021, 43(3): 344-350.HUO Ruili, CHEN Dengchang, FANG Hai, et al. Flexural fatigue test of composite sandwich plate with light wood core in different temperatures[J]. Journal of Nanjing Tech University (Natural Science Edition), 2021, 43(3): 344-350(in Chinese). [8] CHANG Y F, WANG Y L, WANG M F, et al. Bond durability and degradation mechanism of GFRP bars in seawater sea-sand concrete under the coupling effect of seawater immersion and sustained load[J]. Construction and Building Materials,2021,307:124878. doi: 10.1016/j.conbuildmat.2021.124878 [9] 常鑫泉, 汪昕, 刘长源, 等. 预应力FRP板加固RC梁抗弯性能有限元模型可靠性评价[J]. 南京工业大学学报(自然科学版), 2021, 43(3): 318-328.CHANG Xinquan, WANG Xin, LIU Changyuan, et al. Reliability evaluation of finite element model for flexural behavior of RC beams reinforced with prestressed FRP laminates[J]. Journal of Nanjing Tech University (Natural Science Edition), 2021, 43(3): 318-328(in Chinese). [10] BENMOKRANE B, MOUSA S, MOHAMED K, et al. Physical, mechanical, and durability characteristics of newly developed thermoplastic GFRP bars for reinforcing concrete structures[J]. Construction and Building Materials,2021,276:122200. doi: 10.1016/j.conbuildmat.2020.122200 [11] 吴超强, 王俊, 李帅, 等. 玻璃纤维增强复合材料 钢复合筋混凝土夹芯墙板抗弯性能[J]. 南京工业大学学报(自然科学版), 2021, 43(6): 782-786.WU Chaoqiang, WANG Jun, LI Shuai, et al. Bending behavior of concrete sandwich wall panels with GFRP-steel bar connectors[J]. Journal of Nanjing Tech University (Natural Science Edition), 2021, 43(6): 782-786(in Chinese). [12] GAMBLE W L. Flexural strength and design analysis of circular reinforced concrete members with glass fiber-reinforced polymer bars and spirals[J]. ACI Structural Journal, 2019, 116(4): 301-302. [13] KAMAL A S M, BOULFIZA M. Durability of GFRP rebars in simulated concrete solutions under accelerated aging conditions[J]. Journal of Composites for Construction,2011,15(4):473-481. [14] WANG Z K, ZHAO X L, XIAN G J, et al. Effect of sustained load and seawater and sea sand concrete environment on durability of basalt- and glass-fibre reinforced polymer (B/GFRP) bars[J]. Corrosion Science,2018,138:200-218. doi: 10.1016/j.corsci.2018.04.002 [15] MOSSAB E, KHALED G, VAN S H. New thermoplastic CFRP bendable rebars for reinforcing structural concrete elements[J]. Composites Part B: Engineering,2013,45(1):1207-1215. doi: 10.1016/j.compositesb.2012.09.025 [16] SOUTIS C. Fibre reinforced composites in aircraft construction[J]. Progress in Aerospace Sciences,2005,41(2):143-151. doi: 10.1016/j.paerosci.2005.02.004 [17] ASENSIO M, ESFANDIARI P, MARQUES A, et al. Processing of pre-impregnated thermoplastic towpreg reinforced by continuous glass fibre and recycled PET by pultrusion[J]. Composites Part B: Engineering,2020,200:108365. doi: 10.1016/j.compositesb.2020.108365 [18] CHEN K, JIA M Y, SUN H, et al. Thermoplastic reaction injection pultrusion for continuous glass fiber-reinforced polyamide-6 composites[J]. Materials,2019,12(3):463. doi: 10.3390/ma12030463 [19] ALEXANDER V, KIRILL M, SERGEY G, et al. Effects of the pre-consolidated materials manufacturing method on the mechanical properties of pultruded thermoplastic composites[J]. Polymers,2022,14(11):2246. doi: 10.3390/polym14112246 [20] MAXIMILIAN V, JOANNA W, SHELLY A, et al. Pultrusion of large thermoplastic composite profiles up to Ø40 mm from glass-fibre/PET commingled yarns[J]. Composites Part B: Engineering,2021,227:109339. doi: 10.1016/j.compositesb.2021.109339 [21] CURRIER J, FOGSTAD C, WALRATH D, et al. Bond development of thermoplastic FRP shear reinforcement stirrups[C]. The 3rd Materials Engineering Conference. San Diego: ASCE, 1994: 6. [22] MEHRABI A E, VANDERPOOL D. Mechanical performance of thermoplastic fiber reinforced polymer rebars[Z]. Proceedings of the 6th International Symposium on FRP Reinforcement for Concrete Structures (FRPRCS-6). Singapore: World Scientific, 2003: 79-88. [23] MICELLI F, NANNI A. Durability of FRP rods for concrete structures[J]. Construction and Building Materials,2004,18(7):491-503. doi: 10.1016/j.conbuildmat.2004.04.012 [24] WANG X, PENG Z Q, DING L N, et al. Mechanical and bonding behavior of a bendable fiber-reinforced thermoplastic rebar[J]. Construction and Building Materials,2021,302:124222. doi: 10.1016/j.conbuildmat.2021.124222 [25] FERRIER E, RABINOVITCH O, MICHEL L. Mechanical behavior of concrete-resin/adhesive-FRP structural assemblies under low and high temperatures[J]. Construction and Building Materials,2016,127:1017-1028. doi: 10.1016/j.conbuildmat.2015.12.127 [26] American Society for Testing and Materials Committee. Standard test method for moisture absorption properties and equilibrium conditioning of polymer matrix composite materials: ASTM-D5229/D5229 M—14[S]. West Conshohocken: American Society for Testing and Materials Committee, 2014. [27] CHEN Y, JULIO F D, INDRAJIT R, et al. Accelerated aging tests for evaluations of durability performance of FRP reinforcing bars for concrete structures[J]. Composite Structures,2007,78(1):101-111. doi: 10.1016/j.compstruct.2005.08.015 [28] YU Y X, LIU S, PAN Y F, et al. Durability of glass fiber-reinforced polymer bars in water and simulated concrete pore solution[J]. Construction and Building Materials,2021,299:123995. doi: 10.1016/j.conbuildmat.2021.123995 [29] American Society for Testing and Materials Committee. Standard test method for apparent horizontal shear strength of pultruded reinforced plastic rods by the short-beam method: ASTM D4475—02[S]. West Conshohocken: American Society for Testing and Materials Committee, 2002. [30] GERARD J, PERRET P, CHABERT B. Study of carbon/epoxy interface (or interphase): Effect of surface treatment of carbon fibers on the dynamic mechanical behavior of carbon/epoxy unidirectional composites[M]. Controlled Interphases in Composite Materials. Cleveland: Springer, 1990: 449-456. [31] 杨国威, 梅志远, 李华东, 等. 典型舰用复合材料DMA动态力学性能试验研究[J]. 玻璃钢/复合材料, 2018(6):66-72.YANG Guowei, MEI Zhiyuan, LI Huadong, et al. Experimental study on dynamic mechanical properties of typical naval ship composite materials[J]. Fiber Reinforced Plastics/Composites,2018(6):66-72(in Chinese). [32] 李承高, 郭瑞, 王俊琦, 等. CFRP@GFRP 混杂复合材料杆体在水浸泡环境下的性能演化[J]. 复合材料学报, 2021, 38(10):3290-3301.LI Chenggao, GUO Rui, WANG Junqi, et al. Property evolution of CFRP@GFRP hybrid composite rod exposed in the distilled water[J]. Acta Materiae Compositae Sinica,2021,38(10):3290-3301(in Chinese). [33] DENG H, REYNOLDS C T, CABRERA N O, et al. The water absorption behaviour of all-polypropylene composites and its effect on mechanical properties[J]. Composites Part B: Engineering,2010,41(4):268-275. doi: 10.1016/j.compositesb.2010.02.007 [34] 王传伟, 肖玮佳, 刘晨光. 傅里叶变换红外光谱法快速测定聚丙烯/聚丁烯釜内合金的组分含量[J]. 青岛科技大学学报(自然科学版), 2022, 43(1):64-70. doi: 10.16351/j.1672-6987.2022.01.009WANG Chuanwei, XIAO Weijia, LIU Chenguang. Rapid determination of polypropylene/polybutene alloy composition by fourier transform infrared spectroscopy[J]. Journal of Qingdao University of Science and Technology (Natural Science Edition),2022,43(1):64-70(in Chinese). doi: 10.16351/j.1672-6987.2022.01.009 [35] AZZURRI F, FLORES A, ALFONSE G C, et al. Polymorphism of isotactic polybutene-1 as revealed by microindentation hardness. Part II: Correlations to microstructure[J]. Polymer,2003,44(5):1641-1645. doi: 10.1016/S0032-3861(02)00864-9 -

下载:

下载: