Enhancement of antistatic properties of conductive carbon black/waterborne polyurethane UV-curable coatings by metal-organic framework materials

-

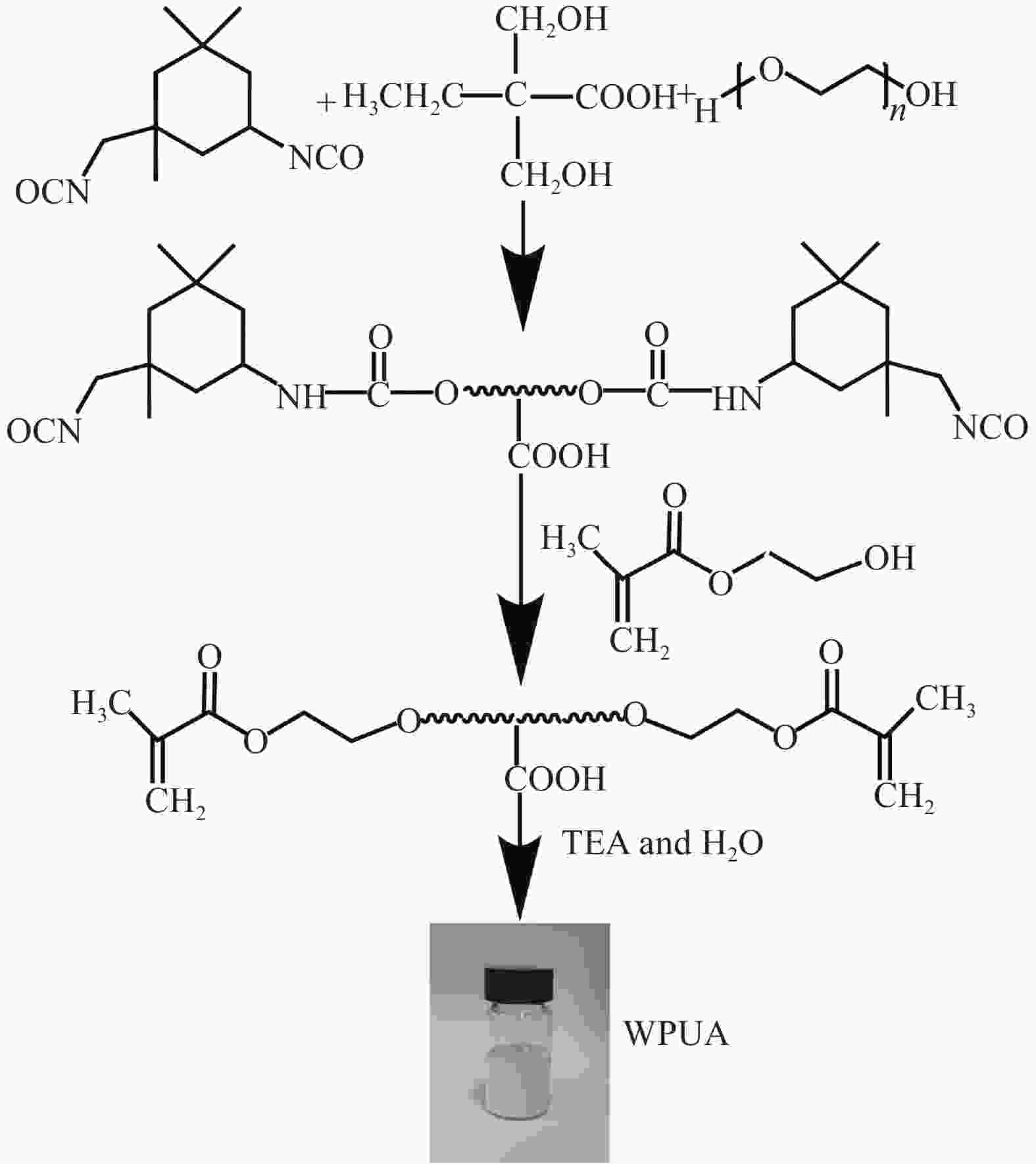

摘要: 紫外光固化水性聚氨酯(UV-WPUA)作为绿色环保高性能的高分子涂料,适用于塑料、金属、纸张、皮革等多种基材,但是水性聚氨酯本身绝缘,随着静电荷的累积,对设备及人体产生不良影响,严重的甚至会引发爆炸火灾等危险情况,所以赋予水性聚氨酯抗静电属性成为当下热点。本研究采用导电炭黑(CB)作为UV-WPUA的导电填料,制备具有抗静电性能的紫外光固化涂料。再加入不同含量的金属有机框架材料MOF-801,进一步降低涂层的表面电阻。采用傅立叶变换红外光谱(FT-IR)、核磁共振氢谱仪(1H NMR),确定UV-WPUA结构。采用扫描电子显微镜(SEM)、X射线衍射仪(XRD),确定MOF-801结构和微观形貌,以及MOF-801-CB/UV-WPUA涂层的分散性。结果表明,成功合成UV-WPUA乳液和MOF-801材料。在实验室恒温25 ℃,恒湿67%下,当CB质量比为15 wt%时,复合涂层表面电阻率为2.3×106 Ω。当在此涂料中加入1 wt%的MOF-801,涂层表面电阻率下降至1.7×105 Ω,且涂层硬度、附着力较好,双键转化率为70%,满足抗静电涂料的要求,证明金属有机框架材料的加入可以进一步提升紫外光固化涂层的抗静电性能。

-

关键词:

- 紫外光固化水性聚氨酯 /

- MOF-801 /

- CB /

- 抗静电 /

- 涂料

Abstract: UV curable waterborne polyurethane (UV-WPUA) is a green, environmentally friendly, efficient and high performance polymer coating suitable for a wide range of substrates such as plastics, metals, paper, leather and so on. However, waterborne polyurethane itself is insulated, and with the accumulation of static charges, it can have adverse effects on equipment and human health, and even cause dangerous situations such as explosions and fires. Therefore, endowing waterborne polyurethane with anti-static properties has become a current hot topic. This study used conductive carbon black (CB) as a conductive filler for UV-WPUA to prepare UV curable coatings with anti-static properties. The surface resistivity of the coating can be further reduced by adding MOF-801, an organic framework material with varying levels of content. Fourier transform infrared spectroscopy (FT-IR) and nuclear magnetic resonance (1H NMR) were used to determine the structure of UV-WPUA. Scanning electron microscopy (SEM) and X-ray diffraction (XRD) were used to determine the structure and microscopic morphology of MOF-801 and the dispersion of the MOF-801-CB/UV-WPUA coating. The results showed that the experiments were successful in synthesising UV-WPUA emulsion and MOF-801 materials. Under the constant temperature of 25℃ and humidity of 67% in the laboratory,the surface resistivity of the coating was 2.3×106 Ω when the mass content of CB was 15 wt%. When 1 wt% MOF-801 is added to this coating, the surface resistivity of the coating decreases to 1.7×105 Ω, the conversion of double bond is 70%, and the coating has good hardness and adhesion, meeting the requirements of anti-static coatings. It can be demonstrated that the addition of organic framework materials can further improve the antistatic performance of UV-cured coatings.-

Key words:

- UV-curable waterborne polyurethane /

- MOF-801 /

- CB /

- antistatic /

- coating

-

表 1 CB/UV-WPUA复合涂层配方

Table 1. CB/UV-WPUA Coating formula

Sample CB/wt% MOF-801/wt% 2959/wt% 1173/wt% UV-WPUA/wt% CB/UV-WPUA-1 0 0 4 3 93 CB/UV-WPUA-2 1 0 4 3 92 CB/UV-WPUA-3 3 0 4 3 90 CB/UV-WPUA-4 5 0 4 3 88 CB/UV-WPUA-5 7 0 4 3 85 CB/UV-WPUA-6 10 0 4 3 83 CB/UV-WPUA-7 15 0 4 3 78 CB/UV-WPUA-8 20 0 4 3 73 CB/UV-WPUA-9 25 0 4 3 68 CB/UV-WPUA-10 30 0 4 3 63 Notes: CB is a conductive carbon black; MOF-801 is a metal-organic framework; 2959 is a photoinitiator with the full name of 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone; 1173 is a photoinitiator with the full name of 2-hydroxy-2-methyl-1-phenyl-1-propanone; UV-WPUA is a UV-curing waterborne polyurethane acrylate. 表 2 MOF-801-CB/UV-WPUA复合涂层配方

Table 2. MOF-801-CB/UV-WPUA Coating formula

Sample CB/wt% MOF-801/wt% 2959/wt% 1173/wt% UV-WPUA/wt% MOF-801-CB/UV-WPUA-1 15 0.5 4 3 77.5 MOF-801-CB/UV-WPUA-2 15 1 4 3 77 MOF-801-CB/UV-WPUA-3 15 1.5 4 3 76.5 MOF-801-CB/UV-WPUA-4 15 2 4 3 76 MOF-801-CB/UV-WPUA-5 15 2.5 4 3 75.5 MOF-801-CB/UV-WPUA-6 15 3 4 3 75 表 3 CB含量对涂层表面电阻的影响

Table 3. The effect of CB content on the surface resistance of coatings

Sample CB wt/% surface resistance /Ω CB/UV-WPUA-1 5 5.3×1010 CB/UV-WPUA-2 10 2.5×109 CB/UV-WPUA-3 15 2.3×106 CB/UV-WPUA-4 20 3.4×104 CB/UV-WPUA-5 25 2.3×103 CB/UV-WPUA-6 30 4.3×102 表 4 涂层的基本性能

Table 4. Basic properties of coatings

Sample CBwt/% MOF-801/wt/% Pencil Hardness Pendulum Hardness/s Adhesion CB/UV-WPUA-1 0 0 2 H 324 0 CB/UV-WPUA-2 1 0 3 H 347 0 CB/UV-WPUA-3 3 0 3 H 359 0 CB/UV-WPUA-4 5 0 3 H 371 0 CB/UV-WPUA-5 7 0 HB 312 0 CB/UV-WPUA-6 10 0 B 247 0 CB/UV-WPUA-7 15 0 B 269 0 CB/UV-WPUA-8 20 0 B 224 2 CB/UV-WPUA-9 25 0 B 165 4 CB/UV-WPUA-10 30 0 B 169 4 表 5 MOF-801-CB/UV-WPUA复合涂层的基本性能

Table 5. Basic properties of MOF-801-CB/UV-WPUA composite coatings

Sample CBwt/% MOF-801 wt/% Pencil Hardness Pendulum Hardness/s Adhesion MOF-801-CB/UV-WPUA-1 15 0.5 B 237 0 MOF-801-CB/UV-WPUA-2 15 1 B 233 0 MOF-801-CB/UV-WPUA-3 15 1.5 B 238 0 MOF-801-CB/UV-WPUA-4 15 2 B 244 0 MOF-801-CB/UV-WPUA-5 15 2.5 B 248 2 MOF-801-CB/UV-WPUA-6 15 3 B 256 2 表 6 MOF-801 1wt%-CB 15wt%/UV-WPUA复合涂层在不同相对湿度下的基本性能

Table 6. Basic properties of MOF-801 1wt%-CB 15wt%/UV-WPUA composite coatings at different relative humidity

Sample Relative Humidity/% Pencil Hardness Pendulum Hardness/s Adhesion MOF-801 1wt%-CB 15wt%/UV-WPUA-1 11% B 238 0 MOF-801 1wt%-CB 15wt%/UV-WPUA-2 33% B 229 0 MOF-801 1wt%-CB 15wt%/UV-WPUA-3 43% B 225 0 MOF-801 1wt%-CB 15wt%/UV-WPUA-4 67% B 233 0 MOF-801 1wt%-CB 15wt%/UV-WPUA-5 75% B 241 0 MOF-801 1wt%-CB 15wt%/UV-WPUA-6 98% B 219 0 -

[1] DELPECH M C, COUTINHO F M B. Waterborne anionic polyurethanes and poly(urethane-urea)s: influence of the chain extender on mechanical and adhesive properties[J]. Polymer Testing, 2000, 19(8): 939-952. doi: 10.1016/S0142-9418(99)00066-5 [2] SHAO C H, HUANG J J, CHEN G N, et al. Thermal and combustion behaviors of aqueous-based polyurethane system with phosphorus and nitrogen containing curing agent[J]. Polymer Degradation and Stability, 1999, 65(3): 359-371. doi: 10.1016/S0141-3910(99)00025-7 [3] VAN DEN BERG K J, VAN DER VEN L G J, VAN DEN HAAK H J W. Development of waterborne UV-A curable clear coat for car refinishes[J]. Progress in Organic Coatings, 2008, 61(2-4): 110-118. doi: 10.1016/j.porgcoat.2007.09.037 [4] LIN X, ZHANG S, QIAN J. Synthesis and properties of a novel UV-curable waterborne hyperbranched polyurethane[J]. Journal of Coatings Technology and Research, 2013, 11(3): 319-328. [5] ATES S, AYDOGAN B, TORUN L, et al. Synthesis and characterization of triptycene type cross-linker and its use in photoinduced curing applications[J]. Polymer, 2010, 51(4): 825-831. doi: 10.1016/j.polymer.2010.01.005 [6] NIU Z, BIAN F. Synthesis and characterization of multiple cross-linking UV-curable waterborne polyurethane dispersions[J]. Iranian Polymer Journal, 2012, 21(4): 221-228. doi: 10.1007/s13726-012-0021-6 [7] SAEED A, SHABIR G. Synthesis of thermally stable high gloss water dispersible polyurethane/polyacrylate resins[J]. Progress in Organic Coatings, 2013, 76(9): 1135-1143. doi: 10.1016/j.porgcoat.2013.03.009 [8] ANJU C, PALATTY S. Ternary doped polyaniline-metal nanocomposite as high performance supercapacitive material[J]. Electrochimica Acta, 2019, 299: 626-635. doi: 10.1016/j.electacta.2019.01.030 [9] YOUSEFI E, DOLATI A, NAJAFKHANI H. Preparation of robust antistatic waterborne polyurethane coating[J]. Progress in Organic Coatings, 2020, 139: 105450. doi: 10.1016/j.porgcoat.2019.105450 [10] LI X, XU X, ZHANG F. Antistatic and antibacterial two-component waterborne polyurethane coating[J]. Journal of Coatings Technology and Research, 2022, 20(3): 869-881. [11] 李占齐, 周萌, 陈帅, et al. 水性抗静电涂料的研究进展[J]. 涂料工业, 2022, 52(11): 61-7+76. doi: 10.12020/j.issn.0253-4312.2022.11.61LI Z Q, ZHOU M, CHEN S, et al. Research Progress of Waterborne Antistatic Coatings[J]. Coatings Industry, 2022, 52(11): 61-7+76(in Chinese). doi: 10.12020/j.issn.0253-4312.2022.11.61 [12] PANTEA D, DARMSTADT H, KALIAGUINE S, et al. Electrical conductivity of conductive carbon blacks: influence of surface chemistry and topology[J]. Applied Surface Science, 2003, 217(1-4): 181-193. doi: 10.1016/S0169-4332(03)00550-6 [13] FENG Y, LI D, LIU J, et al. Carbon-Based Materials in Microbial Fuel Cells [M]. Microbial Electrochemical Technology. 2019: 49-74. [14] PANTEA D, DARMSTADT H, KALIAGUINE S, et al. Electrical conductivity of thermal carbon blacks -: Influence of surface chemistry[J]. Carbon, 2001, 39(8): 1147-1158. doi: 10.1016/S0008-6223(00)00239-6 [15] SOUSA E A, CASTRO LIMA T H, SILVA ARLINDO E P, et al. Multicomponent polyurethane-carbon black composite as piezoresistive sensor[J]. Polymer Bulletin, 2020, 77(6): 3017-3031. doi: 10.1007/s00289-019-02888-8 [16] GOEL S, GARG A, BASKEY H B, et al. Microwave absorption study of low-density composites of barium hexaferrite and carbon black in X-band[J]. Journal of Sol-Gel Science and Technology, 2021, 98(2): 351-363. doi: 10.1007/s10971-021-05492-3 [17] GAO Q, YE X, LUO A, et al. 3D printing of carbon black/polylactic acid/polyurethane composites for efficient microwave absorption[J]. Journal of Materials Science: Materials in Electronics, 2023, 34(23): 1672. doi: 10.1007/s10854-023-11036-y [18] CHUEH C-C, CHEN C-I, SU Y-A, et al. Harnessing MOF materials in photovoltaic devices: recent advances, challenges, and perspectives[J]. Journal of Materials Chemistry A, 2019, 7(29): 17079-17095. doi: 10.1039/C9TA03595H [19] 王紫阳. 羧酸基MOFs的合成、表征及性能研究 [D], 2023.WANG Z Y. Synthesis, characterization and properties of carboxylic acid MOFs [D], 2023(in Chinese). [20] LI Y, FENG J, WANG L, et al. High proton conduction in two highly stable phenyl imidazole dicarboxylate-based Cd(II)-MOFs[J]. Journal of Solid State Chemistry, 2023, 319: 121129. [21] TAO J, XU L, JIN H, et al. Selective coding dielectric genes based on proton tailoring to improve microwave absorption of MOFs[J]. Advanced Powder Materials, 2023, 2(1): 100091. doi: 10.1016/j.apmate.2022.100091 [22] SU J, HE W, LI X-M, et al. High Electrical Conductivity in a 2D MOF with Intrinsic Superprotonic Conduction and Interfacial Pseudo-capacitance[J]. Matter, 2020, 2(3): 711-722. doi: 10.1016/j.matt.2019.12.018 [23] QU J X, FU Y M, MENG X, et al. A porous Ti-based metal-organic framework for CO(2) photoreduction and imidazole-dependent anhydrous proton conduction[J]. Chem Commun (Camb), 2023, 59(8): 1070-1073. doi: 10.1039/D2CC06214C [24] TOMINAKA S, COUDERT F X, DAO T D, et al. Insulator-to-Proton-Conductor Transition in a Dense Metal-Organic Framework[J]. J Am Chem Soc, 2015, 137(20): 6428-6431. doi: 10.1021/jacs.5b02777 [25] ZHANG J, BAI H J, REN Q, et al. Extra Water- and Acid-Stable MOF-801 with High Proton Conductivity and Its Composite Membrane for Proton-Exchange Membrane[J]. ACS Appl Mater Interfaces, 2018, 10(34): 28656-28663. doi: 10.1021/acsami.8b09070 [26] 全国涂料和颜料标准化技术委员会. 漆膜硬度测定法摆杆阻尼试验: GB/T 1730—2007 [S]. 北京: 中国标准出版社, 2007.National Technical Committee on Paints & Pigments of Standardization Adminstration of China. Determination of hardness of the paint films—Pendulum damping test: GB/T 1730—2007 [S]. Beijing: China Standards Press, 2007(in Chinese). [27] 国家市场监督管理总局, 中国国家标准化管理委员会. 涂膜硬度铅笔测定法: GB/T 6739—2006 [S]. 北京: 中国标准出版社, 2006.State Adminstration for Market Regulation, Standardization Administration of China. Pencil Test Method for Determining the Hardness of Coatings: GB/T 6739—2006 [S]. Beijing: China Standards Press, 2006(in Chinese). [28] 常州涂料化工研究院, 色漆和清漆漆膜的划格试验: GB/T 9286—1998 [S]. 北京: 国家质量技术监督局, 1998.Changzhou Institute of Coatings and Chemical Engineering, Grid test of paints and varnishes: GB/T 9286—1998 [S]. Beijing: State Administration of Quality and Technology Supervision, 1998(in Chinese). [29] 中国石油化工总公司, 石油罐导静电涂料电阻率测定方法: GB/T 16906—1997 [S]. 北京: 中国标准出版社, 1997.China Petroleum and Chemical Corporation, Method for determination of resistivity of electrostatic conductive coatings for oil tanks: GB/T 16906—1997 [S]. Beijing: China Standards Press, 1997(in Chinese). [30] CHAI C, HOU J, YANG X, et al. Two-component waterborne polyurethane: Curing process study using dynamic in situ IR spectroscopy[J]. Polymer Testing, 2018, 69: 259-265. doi: 10.1016/j.polymertesting.2018.05.021 [31] YIN W, ZENG X, LI H, et al. Synthesis, photopolymerization kinetics, and thermal properties of UV-curable waterborne hyperbranched polyurethane acrylate dispersions[J]. Journal of Coatings Technology and Research, 2011, 8(5): 577-584. doi: 10.1007/s11998-011-9338-x -

点击查看大图

点击查看大图

计量

- 文章访问数: 56

- HTML全文浏览量: 29

- 被引次数: 0

下载:

下载: