Arc erosion resistance of Cu-Al2O3 composite effected by CNTs

-

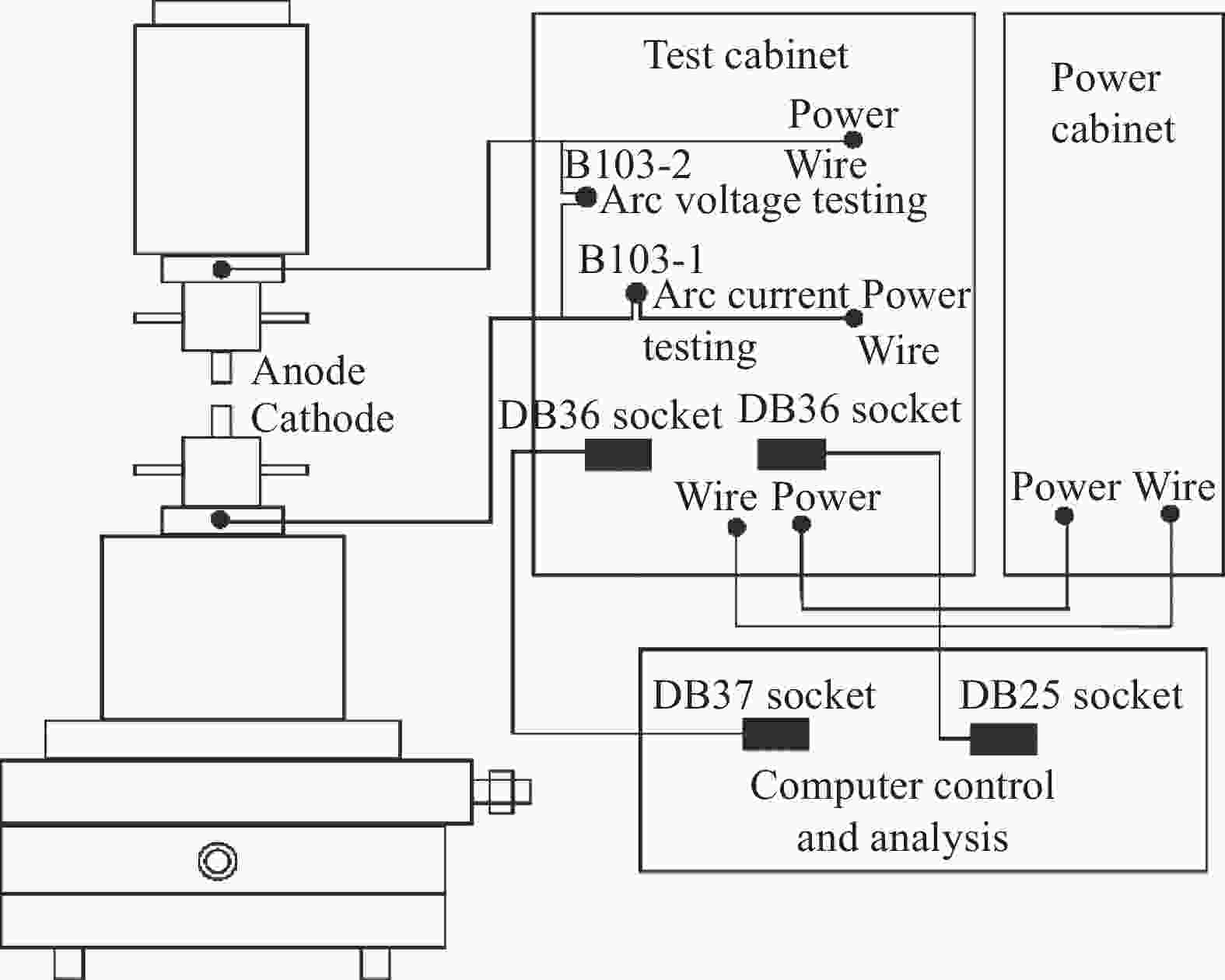

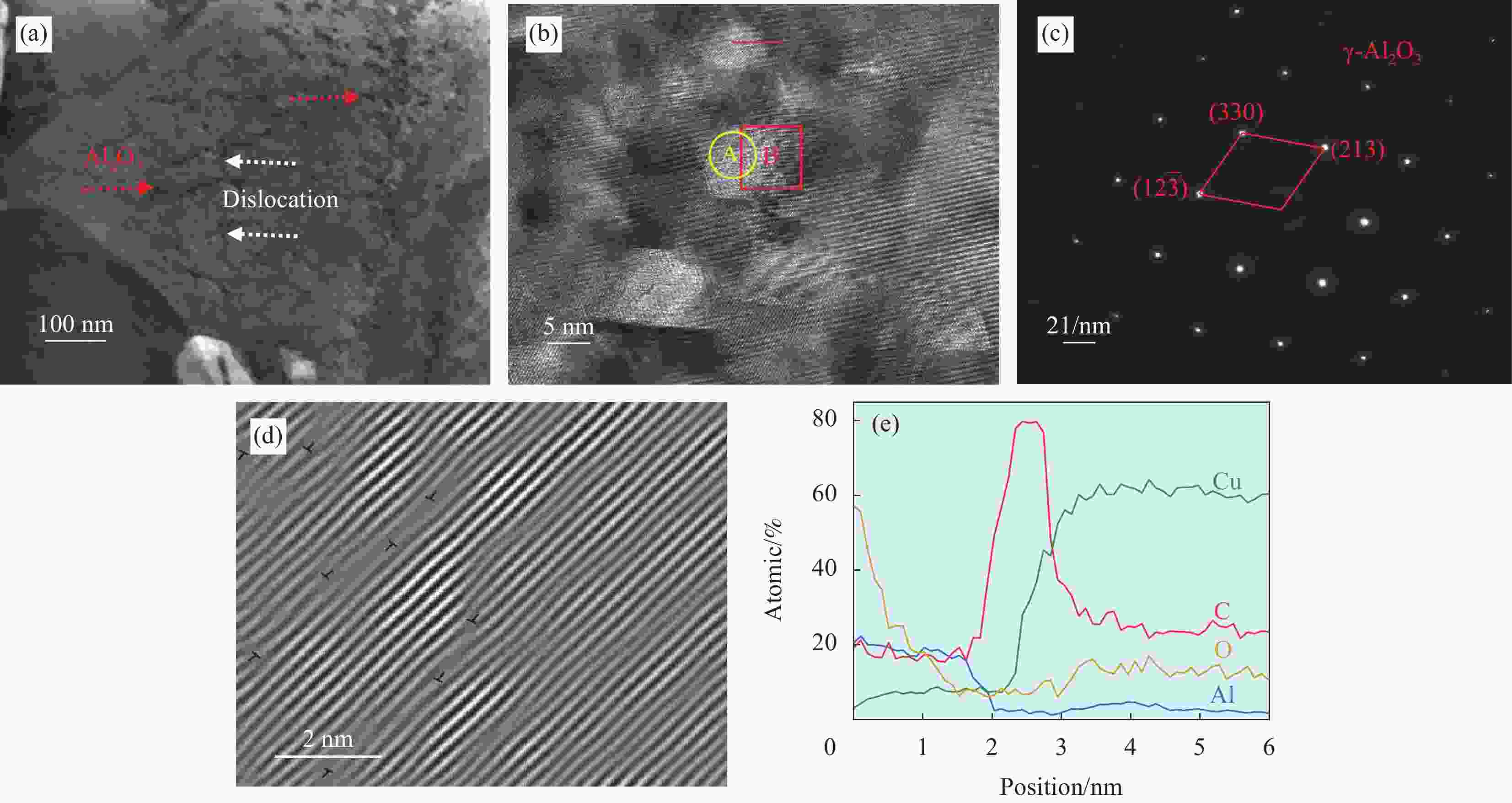

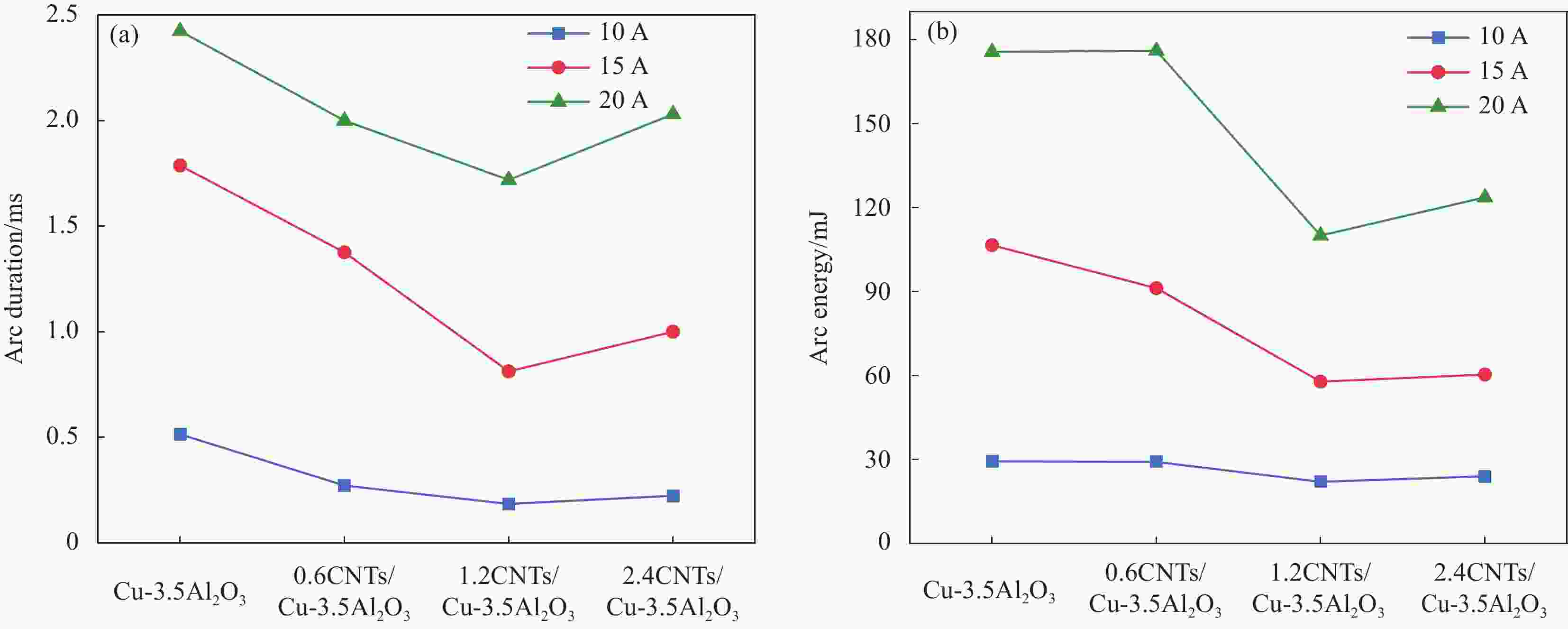

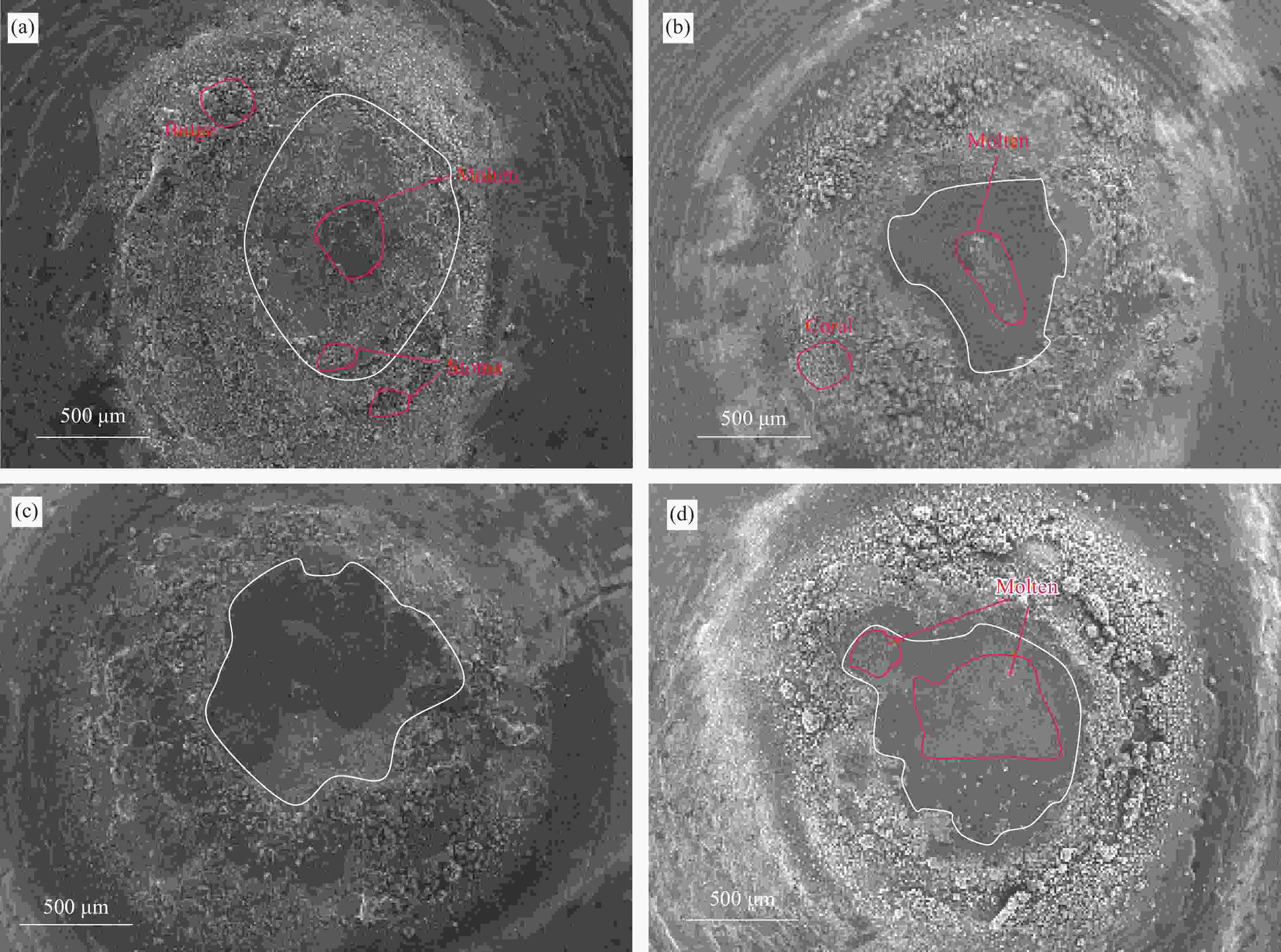

摘要: Cu-Al2O3复合材料具有优异的传导性能和力学性能,在耐磨材料领域具有广阔的应用前景。为进一步提升电摩擦条件下复合材料的耐电弧侵蚀性能,本文采用内氧化法与粉末冶金法相结合制备了不同碳纳米管 (CNTs) 含量的CNTs/Cu-Al2O3复合材料,观察了CNTs/Cu-Al2O3复合材料中增强相的分布及其与基体界面结合情况,研究了添加不同含量CNTs对Cu-Al2O3复合材料传导性能和力学性能的影响,重点探究了CNTs/Cu-Al2O3复合材料的耐电弧侵蚀机制。结果表明:原位生成的纳米Al2O3颗粒钉扎位错及对CNTs分布具有调控作用,使CNTs弥散分布在铜基体中。与Cu-Al2O3复合材料相比,CNTs/Cu-Al2O3复合材料燃弧时间和燃弧能量明显降低,波动更平稳。在电弧侵蚀过程中,熔池中的CNTs会上浮至表面分散电弧,减小集中侵蚀区域;纳米Al2O3颗粒可以稳定熔池,减小熔融液滴的喷溅,有效减小CNTs/Cu-Al2O3复合材料质量损失。其中添加1.2vol%CNTs的CNTs/Cu-3.5Al2O3复合材料的燃弧时间和燃弧能量最低、最稳定。这一研究结果对耐烧蚀材料的研究提供有利的理论依据。Abstract: Cu-Al2O3 composite has excellent conductivity and mechanical properties, and it widely used in the field of wear-resistant materials. In order to further improve the arc erosion resistance of composite under the condition of electro-friction, CNTs/Cu-Al2O3 composites with different contents of carbon nanotubes (CNTs) were prepared by internal oxidation combining with powder metallurgy. The distribution of reinforcing phase and the interface between CNTs and matrix in CNTs/Cu-Al2O3 composites were observed. The conductivity and mechanical properties of Cu-Al2O3 composites effected by CNTs were studied. The arc erosion resistance mechanism of CNTs/Cu-Al2O3 composites was mainly explored. The results show that in-situ nano-Al2O3 particles pin dislocation, CNTs are dispersed in the copper matrix due to the regulation of CNTs distribution by Al2O3 particles. Compared with Cu-Al2O3 composites, the arc duration and energy of CNTs/Cu-Al2O3 composites are obviously reduced and fluctuate more stable. In the process of arc erosion, CNTs in the molten pool will float to the surface to disperse the arc and reduce the concentrated erosion area. Nano-Al2O3 particles can stabilize the molten pool, reduce the splash of molten droplets and the mass loss of CNTs/Cu-Al2O3 composites. Among them, CNTs/Cu-3.5Al2O3 composites with 1.2vol%CNTs has the lowest and most stable arc duration and energy. This research result provides a favorable theoretical basis for the research of ablation resistant materials.

-

Key words:

- carbon nanotubes (CNTs) /

- metal matrix composites /

- microstructure /

- arc erosion /

- stabilize molten pool /

- Cu /

- nano-Al2O3 particles

-

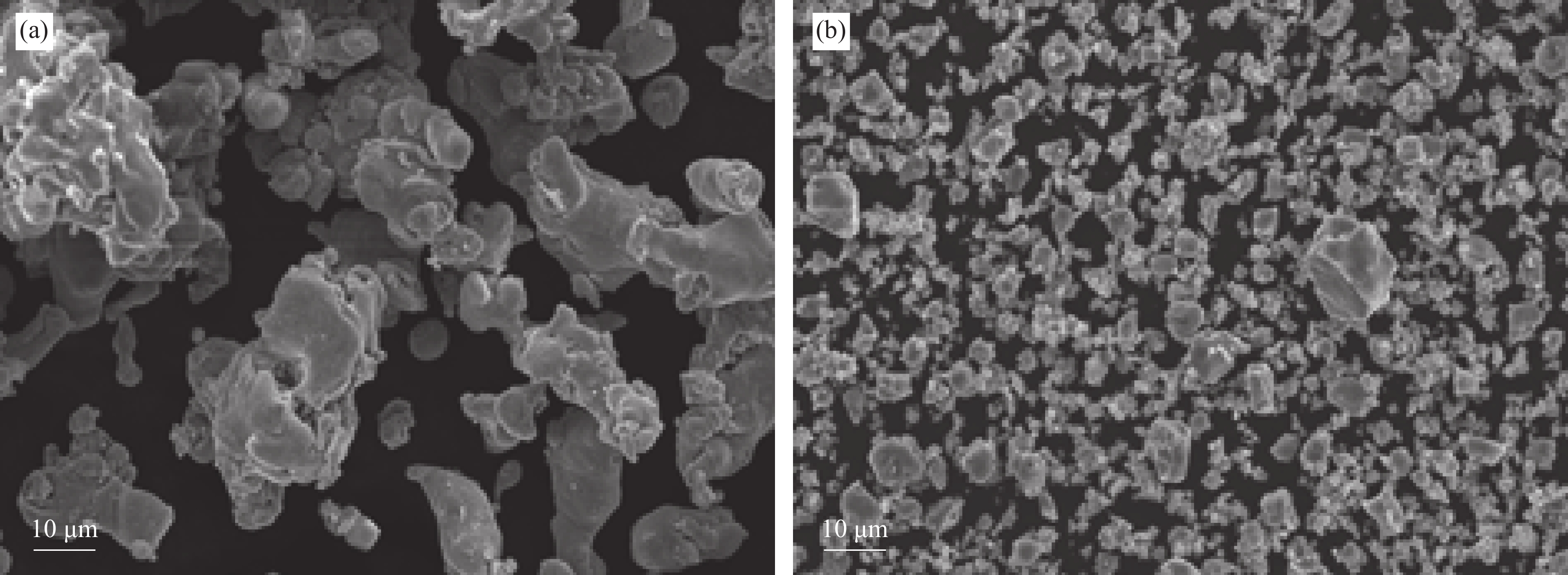

图 3 CNTs及混合粉末的微观结构:(a) 原始CNTs的SEM图像;(b) 酸洗后CNTs的TEM图像;(c) 镀铜CNTs的TEM图像;(d) 球磨前混合粉末的SEM图像;(e) 球磨后混合粉末的SEM图像;(f) 粉末的XRD图谱

Figure 3. Microstructure of CNTs and mixed powder: (a) SEM image of raw CNTs; (b) TEM image of pickled CNTs; (c) TEM image of copper-coated CNTs; (d) SEM image of mixed powder before ball milling; (e) SEM image of mixed powder after ball milling; (f) XRD patterns of powder

图 4 CNTs/Cu-Al2O3复合材料的微观组织:(a) 纳米级Al2O3颗粒及位错;(b) 纳米级Al2O3颗粒的HRTEM图像;(c) 图4(b)中A区域快速傅立叶逆变换(IFFT)图像;(d) 图4(b)中B区域IFFT图像;(e) 图4(b)中纳米级Al2O3颗粒与铜基体界面处元素线扫描图像

Figure 4. Microstructure of CNTs/Cu-Al2O3 composite: (a) Nano-Al2O3 particles and dislocation; (b) HRTEM image of nano-Al2O3 particles; (c) Inverse fast fourier transform (IFFT) image of A in Fig. 4(b); (d) IFFT image of B in Fig. 4(b); (e) EDS corresponding element line scanning of nano-Al2O3 particles and Cu in Fig. 4(b)

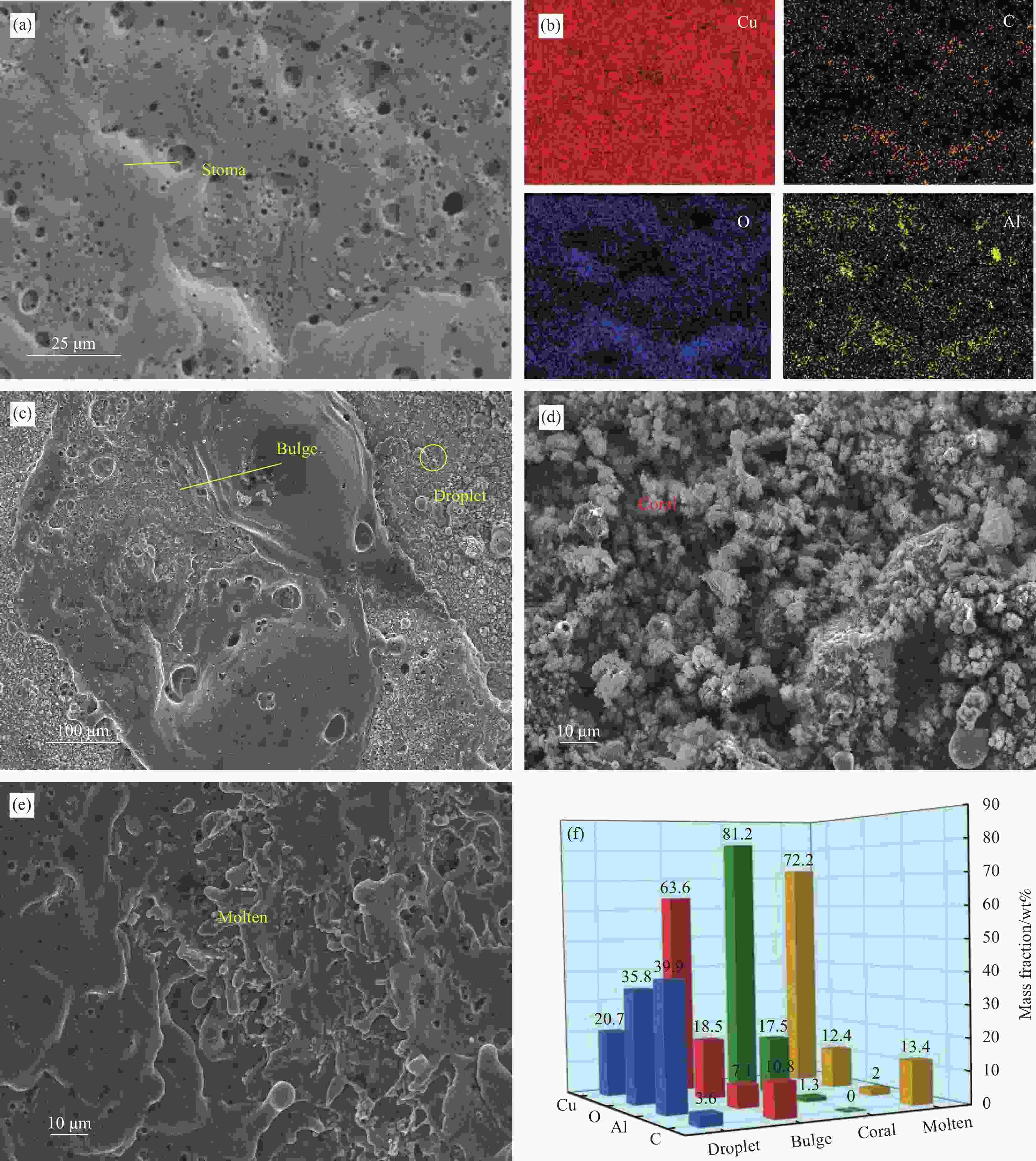

图 8 1.2CNTs/Cu-3.5Al2O3复合材料电弧侵蚀典型形貌:(a) 气泡区;(b) 图8(a)面扫描;(c) 凸起、融滴区;(d) 珊瑚区;(e) 熔池区;(f) 典型区域元素分析

Figure 8. Typical morphologies of the anode of 1.2CNTs/Cu-3.5Al2O3 composite: (a) Stoma; (b) Surface scanning of Fig. 8(a); (c) Bulge and droplet; (d) Coral; (e) Molten; (f) Element analysis of typical regional

表 1 碳纳米管(CNTs)/Cu-Al2O3复合材料的成分配比

Table 1. Composition ratio of carbon nanotubes (CNTs)/Cu-Al2O3 composite

Composite Al2O3/vol% CNTs/vol% Cu/vol% Cu-3.5Al2O3 3.5 0.0 96.5 0.6CNTs/Cu-3.5Al2O3 3.5 0.6 95.9 1.2CNTs/Cu-3.5Al2O3 3.5 1.2 95.3 2.4CNTs/Cu-3.5Al2O3 3.5 2.4 94.1 表 2 CNTs/Cu-Al2O3复合材料的综合性能

Table 2. Comprehensive performances of CNTs/Cu-Al2O3 composites

Composite Relative density/% Electrical conductivity/%IACS Hardness/HBW Strength/MPa Cu-3.5Al2O3 98.8 72.0±0.8 120.8±1.2 358.2±7 0.6CNTs/Cu-3.5Al2O3 98.0 69.5±0.6 130.7±2.1 434.7±5 1.2CNTs/Cu-3.5Al2O3 97.9 65.4±0.4 151.5±0.9 504.9±6 2.4CNTs/Cu-3.5Al2O3 97.5 60.5±0.6 106.7±1.1 315.3±6 Notes: IACS—International annealed copper standard; HBW—Brinell hardness. -

[1] RAJKOVIC V, BOZIC D, DEVECERSKI A, et al. Characteristic of copper matrix simultaneously reinforced with nano- and micro-sized Al2O3 particles[J]. Materials Characterization,2012,67:129-137. doi: 10.1016/j.matchar.2012.02.022 [2] GUO X H, SONG K X, LIANG S H, et al. Effect of Al2O3 particle size on electrical wear performance of Al2O3/Cu composites[J]. Tribology Transactions,2016,59(1):170-177. doi: 10.1080/10402004.2015.1061079 [3] 张雪辉, 魏星, 刘美霞, 等. Al2O3/Cu复合材料的高温变形行为[J]. 复合材料学报, 2017, 34(8):1825-1832.ZHANG Xuehui, WEI Xing, LIU Meixia, et al. High temperature deformation behavior of Al2O3/Cu composite[J]. Acta Materiae Compositae Sinica,2017,34(8):1825-1832(in Chinese). [4] 刘贵民, 杨忠须, 闫涛, 等. 电磁轨道炮导轨失效研究现状及展望[J]. 材料导报, 2015, 29(7):63-70.LIU Guimin, YANG Zhongxu, YAN Tao, et al. Current status and prospect on rail failures of electromagnetic railgun[J]. Materials Reports,2015,29(7):63-70(in Chinese). [5] 毛保全, 张天意, 白向华, 等. 电磁轨道炮抗烧蚀枢轨结构设计[J]. 兵器装备工程学报, 2020, 41(3):67-71. doi: 10.11809/bqzbgcxb2020.03.013MAO Baoquan, ZHANG Tianyi, BAI Xianghua, et al. Design of anti-ablation armature structure for electromagnetic rail gun[J]. Ordnance Equipment Engineering,2020,41(3):67-71(in Chinese). doi: 10.11809/bqzbgcxb2020.03.013 [6] 高翔. 电磁轨道炮枢轨磨损特性分析[D]. 秦皇岛: 燕山大学, 2020.GAO Xiang. Analysis of the wear characteristics of the rail-armature of electromagnetic railgun[D]. Qinhuangdao: Yanshan University, 2020(in Chinese). [7] 黄海明, 杜善义, 吴林志, 等. C/C复合材料烧蚀性能分析[J]. 复合材料学报, 2001, 18(3):76-80. doi: 10.3321/j.issn:1000-3851.2001.03.018HUANG Haiming, DU Shanyi, WU Linzhi, et al. Analysis of the ablation of C/C composite[J]. Acta Materiae Compositae Sinica,2001,18(3):76-80(in Chinese). doi: 10.3321/j.issn:1000-3851.2001.03.018 [8] 吴皇, 易茂中, 周文艳, 等. ZrC-Cu-C/C复合材料的烧蚀性能及烧蚀机制[J]. 复合材料学报, 2017, 34(1):152-159.WU Huang, YI Maozhong, ZHOU Wenyan, et al. Ablation property and mechanism of ZrC-Cu-C/C composites[J]. Acta Materiae Compositae Sinica,2017,34(1):152-159(in Chinese). [9] 关集俱, 刘德利, 王勇, 等. 碳纳米管/油酸复合物制备的纳米流体导电与润湿性能[J]. 复合材料学报, 2020, 37(10):2582-2589.GUAN Jiju, LIU Deli, WANG Yong, et al. Electroconductivity and wettability of nanofluids prepared by carbon nanotubes/oleic acid composite[J]. Acta Materiae Compositae Sinica,2020,37(10):2582-2589(in Chinese). [10] MURGESAN R, GOPAL M, MURALI G. Effect of Cu, Ni addition on the CNTs dispersion, wear and thermal expansion behavior of Al-CNT composites by molecular mixing and mechanical alloying[J]. Applied Surface Science,2019,495:143542. doi: 10.1016/j.apsusc.2019.143542 [11] JANG I, JOO H G, JANG Y H. Effects of carbon nanotubes on electrical contact resistance of a conductive Velcro system under low frequency vibration[J]. Tribology International,2016,104:45-56. doi: 10.1016/j.triboint.2016.08.019 [12] 易建宏, 杨平, 沈涛. 碳纳米管增强金属基复合材料电学性能研究进展[J]. 复合材料学报, 2016, 33(4):689-703.YI Jianhong, YANG Ping, SHEN Tao. Research progress of electrical properties for carbon nanotubes reinforced metal matrix composites[J]. Acta Materiae Compositae Sinica,2016,33(4):689-703(in Chinese). [13] FU S L, CHEN X H, LIU P. Preparation of CNTs/Cu composites with good electrical conductivity and excellent mechanical properties[J]. Materials Science & Engineering: A,2020,771:138656. [14] ZHAO L, YAO P P, ZHOU H B, et al. Effect of CNTs in copper matrix on mechanical characteristics and tribological behavior under dry sliding and boundary lubrication conditions[J]. Materials,2019,12(13):2203. doi: 10.3390/ma12132203 [15] 龙飞, 贾淑果, 国秀花, 等. CNTs和TiB2混杂增强铜基复合材料的电弧侵蚀行为[J]. 复合材料学报, 2019, 36(12):2869-2877.LONG Fei, JIA Shuguo, GUO Xiuhua, et al. Arc erosion behavior of carbon nanotubes and TiB2 hybrid reinforced copper composites[J]. Acta Materiae Compositae Sinica,2019,36(12):2869-2877(in Chinese). [16] GUO X H, YANG Y B, SONG K X, et al. Arc erosion resistance of hybrid copper matrix composites reinforced with CNTs and micro-TiB2 particles[J]. Journal of Materials Research and Technology,2021,11:1469-1479. doi: 10.1016/j.jmrt.2021.01.084 [17] SONG K X, XING J D, DONG Q M, et al. Internal oxidation of dilute Cu-Al alloy powers with oxidant of Cu2O[J]. Materials Science and Engineering: A,2004,380(1-2):117-122. doi: 10.1016/j.msea.2004.03.042 [18] 王虎, 朱延玲. 碳纳米管预处理及表面化学镀铜[J]. 表面技术, 2019, 48(11):211-218.WANG Hu, ZHU Yanling. Pretreatment and copper plating of carbon nanotubes by electroless deposition[J]. Surface Technology,2019,48(11):211-218(in Chinese). [19] WANG H, ZHANG Z H, ZHANG H M, et al. Novel synthesizing and characterization of copper matrix composites reinforced with carbon nanotubes[J]. Materials Science and Engineering: A,2017,696:80-89. doi: 10.1016/j.msea.2017.04.055 [20] LONG F, GUO X H, SONG K X, et al. An internai-oxidation-based strategy induced high-density alumina in-situ nanoprecipitation and carbon nanotube interface optimization for co-reinforcing copper matrix composites[J]. Composites Part B: Engineering,2022,229:109455. doi: 10.1016/j.compositesb.2021.109455 [21] BRAUNOVIC M, KONCHITS V. Electrical contacts: Foundamentals, applications and technology[C]. New York: CRC Press, Taylor & Francis Group, 2006: 205-247. [22] ZHANG X H, ZHANG Y, TIAN B H, et al. Graphene oxide effecte on the properties of Al2O3-Cu/35W5Cr composite[J]. Materials Science and Technology,2020,37(2):185-199. [23] SHEHATA F, FATHY A, ABDELHAMEED M, et al. Preparation and properties of Al2O3 nanoparticle reinforced copper matrix composites by in situ processing[J]. Materials and Design,2009,30(7):2756-2762. doi: 10.1016/j.matdes.2008.10.005 [24] SADOUN A M, MOHAMMED M M, FATHY A, et al. Effect of Al2O3 addition on hardness and wear behavior of Cu-Al2O3 electroless coated Ag nanocomposite[J]. Materials Research and Technology,2020,9(3):5024-5033. doi: 10.1016/j.jmrt.2020.03.020 [25] 国秀花. 颗粒特征参量对铜基复合材料载流摩擦磨损性能的影响[D]. 西安: 西安理工大学, 2015.GUO Xiuhua. Effects of characteristic parameters of reinforced particles on electrical wear performances of copper matrix composites[D]. Xi’an: Xi’an University of Technology, 2015(in Chinese). -

下载:

下载: