Accelerated aging behavior of glass fiber reinforced methacrylate-based cured-in-place-pipe lining in seawater and sulfuric acid

-

摘要:

原位固化管道(Cured-in-place-pipe,CIPP)内衬用于修复被生物硫酸腐蚀的排水管道,也用于市政排海管道。而玻璃纤维/甲基丙烯酸酯基复合材料用于CIPP内衬,在硫酸和海水环境下的耐久性尚不明确。设计了0.5%硫酸、模拟海水与高温(80℃)加速相耦合的老化实验,以纯水作为对照,基于吸水测试、三点弯曲测试、接触角分析、SEM和FTIR等表征测试方法,研究了玻璃纤维/甲基丙烯酸酯基CIPP内衬的老化行为。结果显示:0.5%硫酸、模拟海水和纯水加速老化

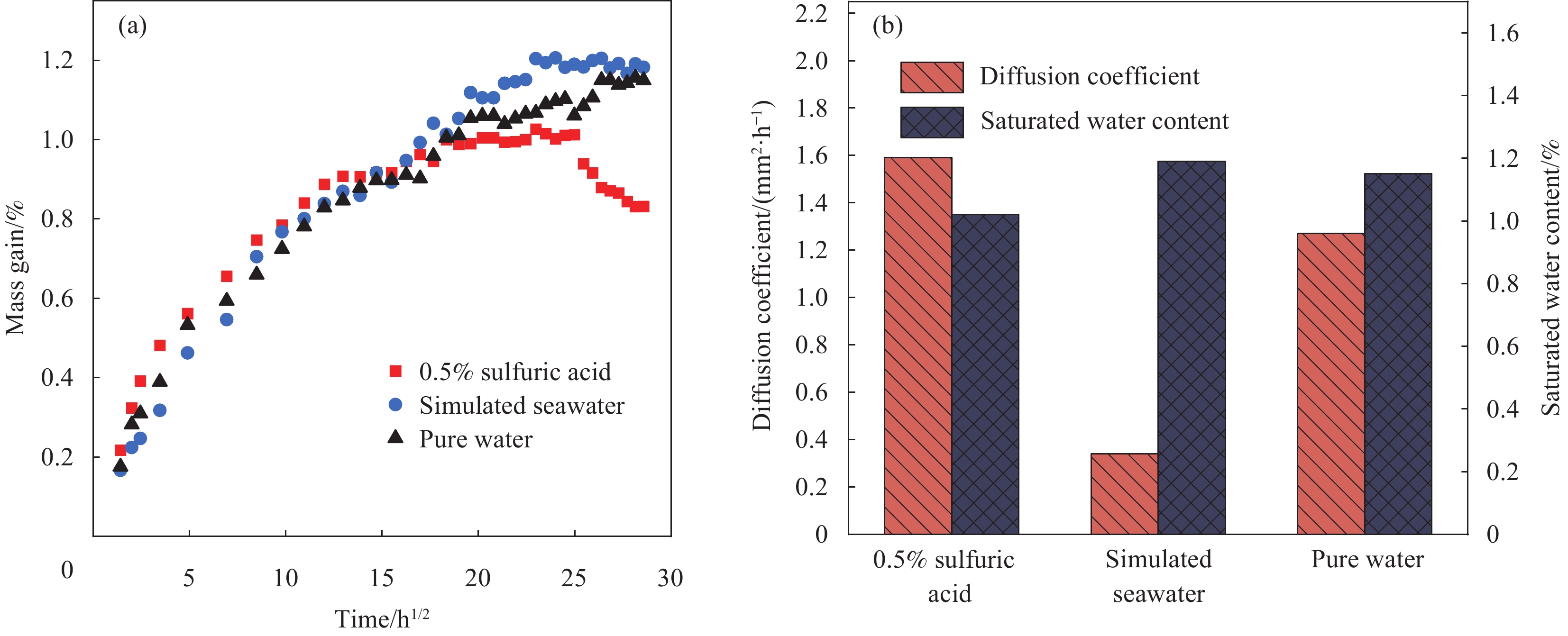

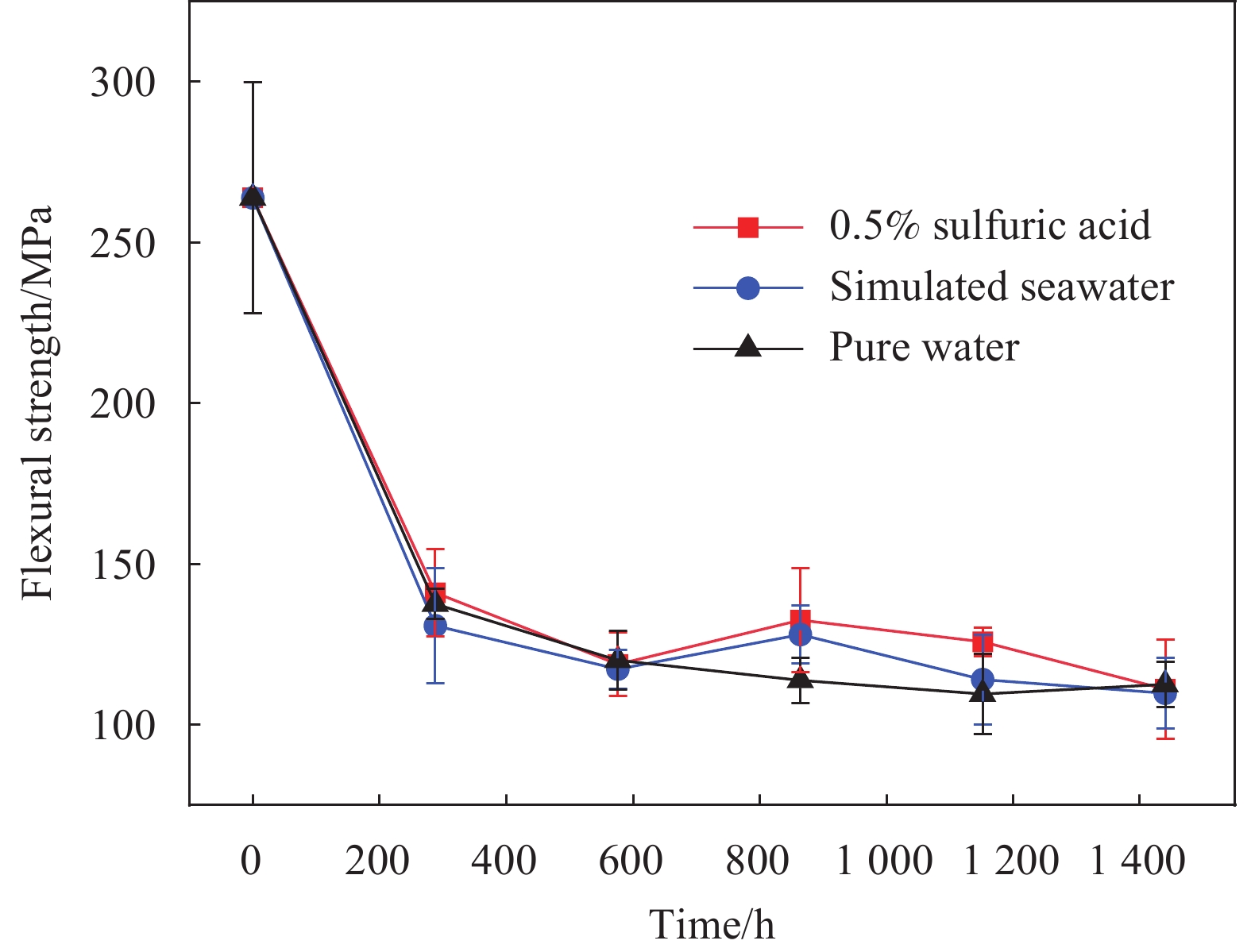

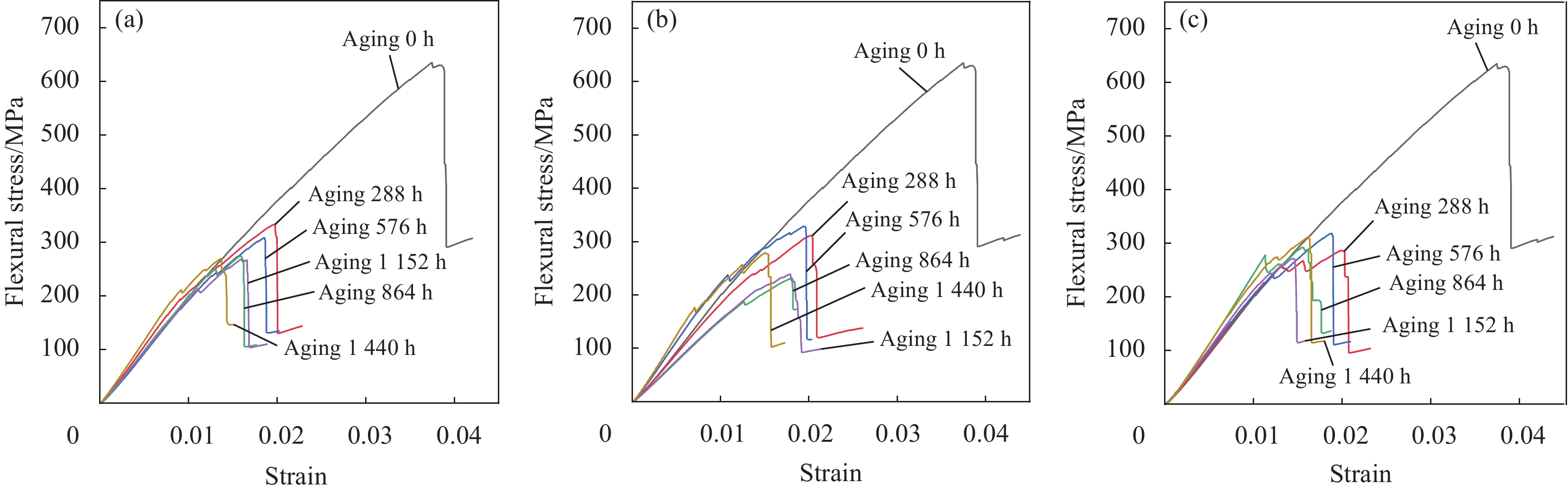

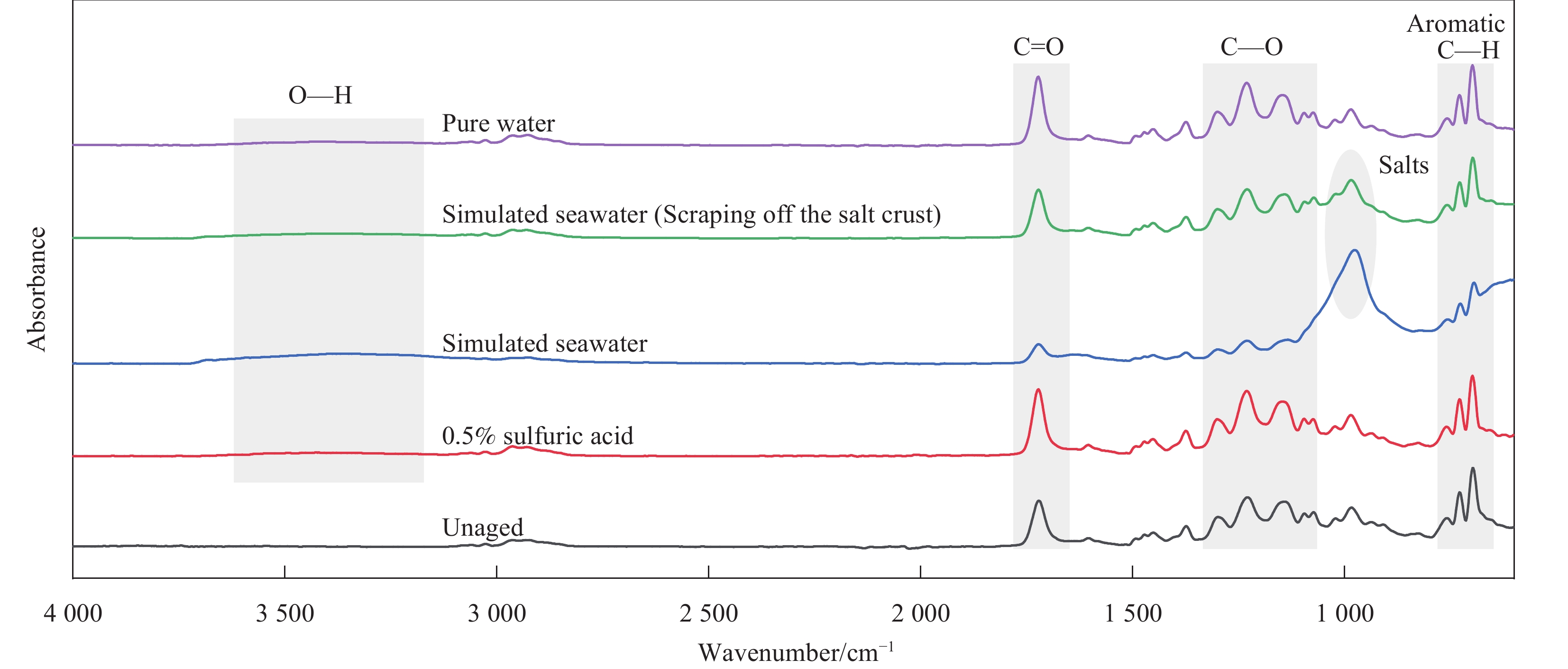

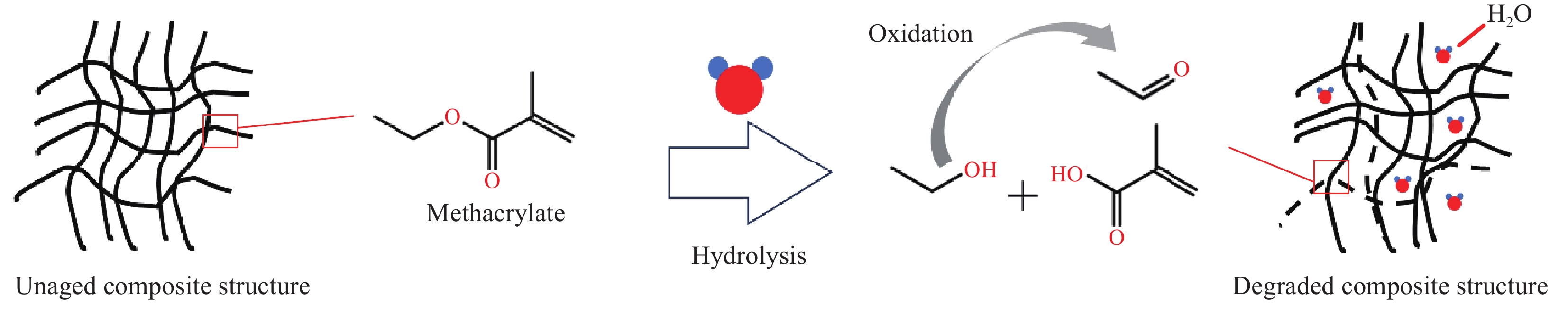

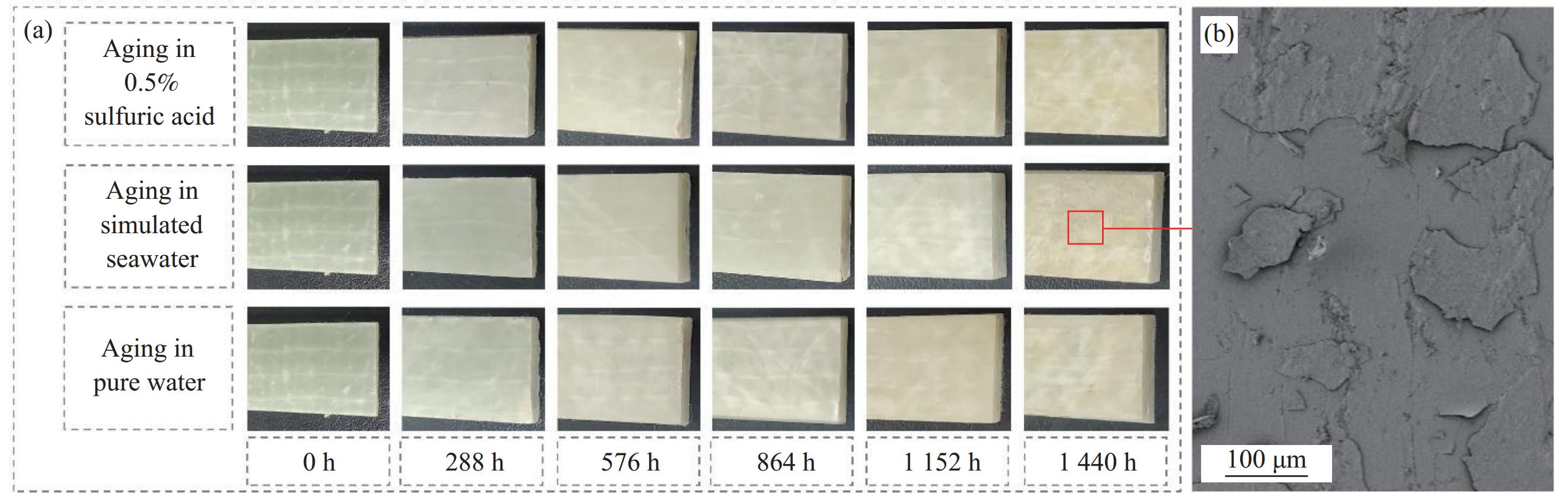

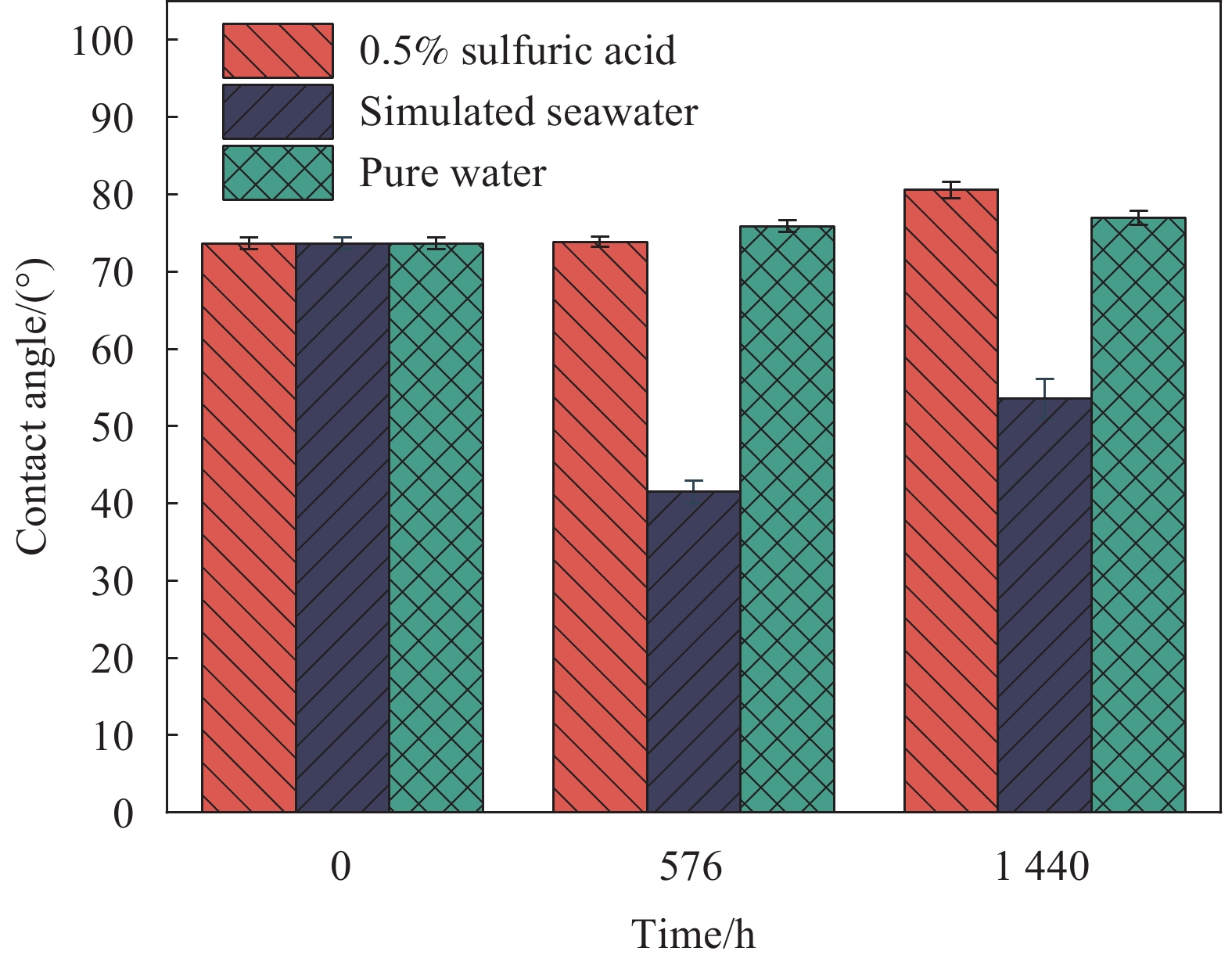

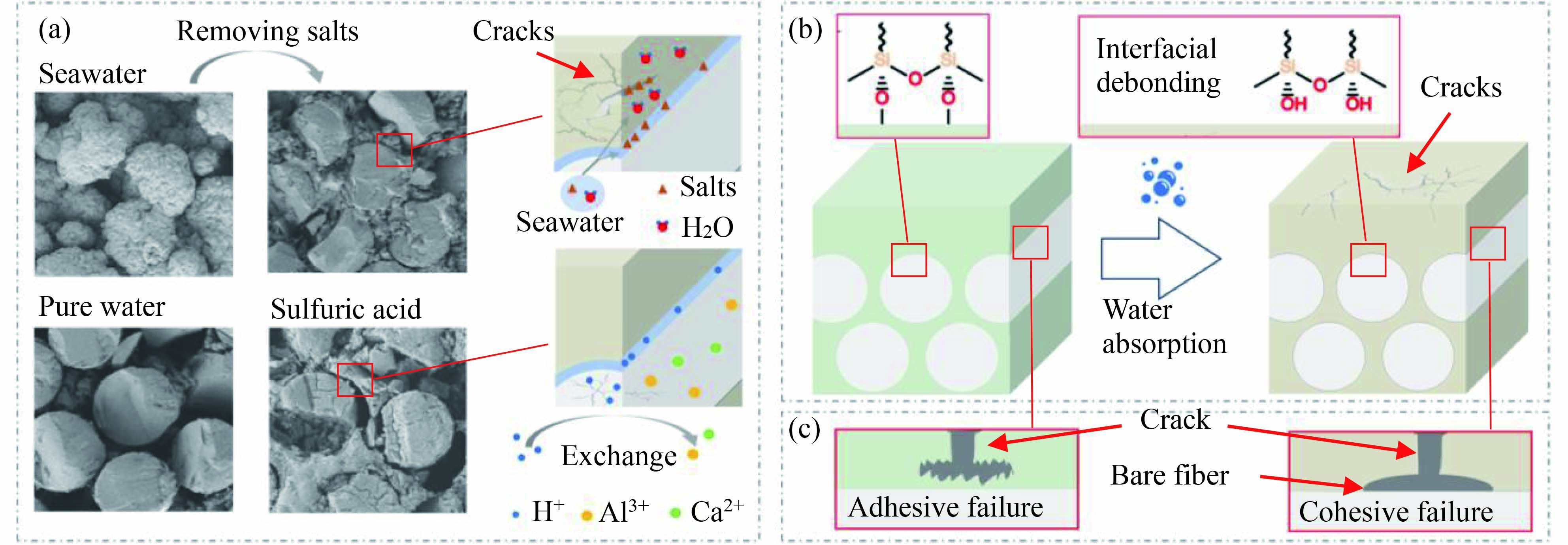

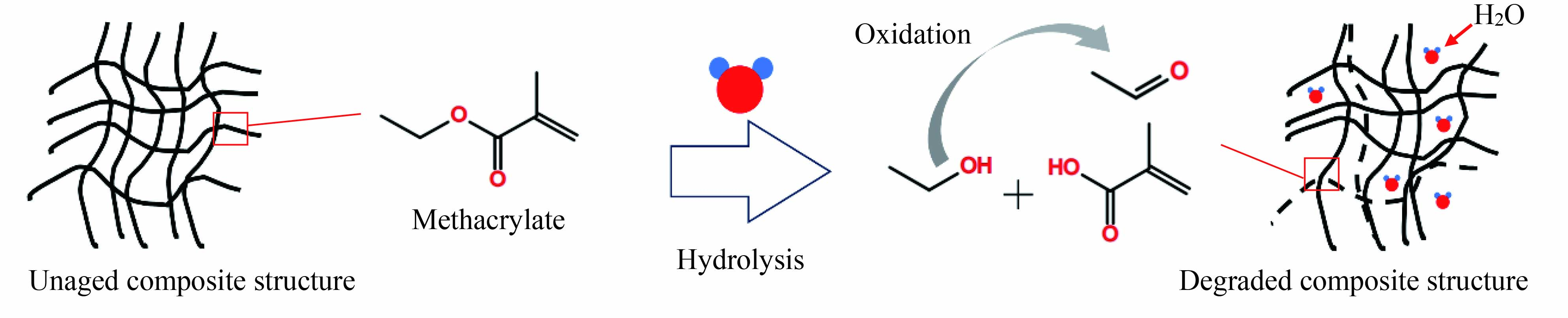

1440 h后,弯曲强度分别下降了57.9%、58.4%和57.4%,而弯曲模量没有明显下降;酯键水解生成的羟基部分被氧化为羰基,使树脂老化后颜色发黄;硫酸劣化了树脂表面使润湿性降低,也通过腐蚀表面玻璃纤维促进了水分扩散;海水中盐分析出结晶阻碍了水分扩散,也严重破坏了材料表面的树脂层,使润湿性增强。提高CIPP内衬的耐久性,重点应该抑制水分扩散劣化界面。可为甲基丙烯酸酯用于CIPP修复材料的耐久性评估提供参考依据。Abstract:Cured-in-place-pipe (CIPP) lining is used to repair drainage pipes corroded by biological sulfuric acid and is also used in municipal sea drainage pipes. However, the durability of glass fiber reinforced methacrylate-based composite materials used in CIPP lining in sulfuric acid and seawater environments is unclear. This study established two aging conditions: 0.5% sulfuric acid and simulated seawater, with the temperature of 80℃ to accelerate aging. Pure water was used as a control. Characterization and testing methods such as water absorption test, three-point bending test, contact angle analysis, SEM, and FTIR were used for the study to evaluate the aging behavior of glass fiber reinforced methacrylate-based CIPP lining. The results show that the bending strength decreases by 57.9%, 58.4%, and 57.4% respectively, after accelerated aging in 0.5% sulfuric acid, simulated seawater, and pure water for

1440 h. While the bending modulus does not show a significant decrease. The hydroxyl group generated by the hydrolysis of the ester bond is partially oxidized to a carbonyl group, causing the resin to turn yellow after aging. Sulfuric acid deteriorates the resin surface and reduces the wettability, and also promotes water diffusion by corroding the surface glass fiber. The crystallization of salt in seawater hinders the diffusion of water and severely damages the resin layer on the material surface, leading to enhanced wettability. To enhance CIPP lining durability, efforts should focus on inhibiting moisture diffusion and degradation at the interface. This study can provide a reference basis for the durability evaluation of methacrylate used in CIPP repair materials. -

聚四氟乙烯(Polytetrafluoroethylene, PTFE)具有摩擦系数低、耐腐蚀和热稳定性优异等特点,是轴承、齿轮等传动结构件的理想基础材料,但是,纯PTFE的磨损率较高且机械强度低,往往需要填充纤维进行改性以提高其综合性能[1]。

在多种PTFE的纤维填充相中,碳纤维(Carbon Fibre, CF)因其突出的轻质高强高弹模特性受到了广泛关注[2]。但是,CF表面类石墨结构使其反应活性较低,很难与PTFE基体产生牢固的界面结合,因此需要对其进行表面处理以提高CF与PTFE之间的浸润性[3]。近期研究发现,将纳米尺度的碳纳米管(Carbon Nanotube, CNT)粒子接枝于微米尺度的CF表面构建CF-CNT微纳多尺度增强体,可以提高纤维表面粗糙度与化学活性,改善CF与树脂基体的浸润性能[4]。在相关研究中,化学接枝法因其成本低廉、能耗低的特点成为了CF-CNT微纳多尺度增强体的主要制备方法[4, 5]。但是,化学接枝法主要基于剧烈氧化反应(强酸、强氧化剂等),易损伤CF表面、降低纤维力学性能并产生环境污染[6, 7]。而且,当前研究主要聚焦于CF-CNT多尺度增强体对树脂基复合材料力学性能的影响,而关于其对复合材料摩擦学性能影响的研究较少,尤其对PTFE基复合材料性能影响的研究还未见报道。

除此之外,在PTFE及其复合材料的摩擦学机制研究方面,已有研究对转移膜形成过程[8-10]、摩擦化学反应[11-13]等进行了深入探讨,但是,这些研究一般聚焦于摩擦试验结果(摩擦系数与磨损率),而对摩擦过程各个阶段,尤其是与起始摩擦阶段密切相关的材料表面能的细致讨论较少。

针对以上问题,本研究采用不损伤纤维表面的稀土处理方法制备CF-CNT微纳多尺度增强体,将其用于增强PTFE基复合材料并研究了材料表面性能及往复摩擦学性能,随后探讨了多尺度增强体对复合材料摩擦过程各个阶段的影响机制、以及试验参数对材料摩擦学行为的影响。本研究提出的CF-CNT微纳多尺度增强体制备方法具有显著的工艺优势和强化效果:(1)增强体制备方法不损伤纤维表面且无污染,相对传统化学法更加温和环保;(2)CF-CNT多尺度增强PTFE基复合材料的磨损率相对纯PTFE降低75.4%,相比同类研究有较大提高。此外,研究中对于摩擦过程各个阶段尤其是起始摩擦阶段的分析也丰富了PTFE基复合材料摩擦学理论体系。

1. 实验材料及方法

1.1 实验材料

CNT(纯度99%、长度0.5~2 μm、直径30~50 nm)购自南京先丰纳米材料科技有限公司,CF(纯度99%、长度<75 μm、直径7 μm)购自沧州中丽新材料科技有限公司,乙醇(AR)和尿素(AR)购自国药化学试剂有限公司,LaCl3(AR)购自上海展云化工有限公司,粒径15~260 μm的PTFE粉末,购自中昊晨光化工研究院有限公司。

1.2 多尺度增强体的合成

首先将CF浸入0.015 mol/L的LaCl3-乙醇溶液中,搅拌1小时左右,在室温下放置约6小时,然后过滤并在100℃干燥6小时得到RCF。然后,将CNT超声分散到0.015 mol/L的LaCl3-乙醇溶液中,并参考本团队已有研究结果向溶液中添加适量尿素[14, 15],再在室温静置约6小时。随后,将CNT过滤并在100℃下干燥6小时以获得RCNT。CNT与RCNT的沉降实验结果如图1所示,可见RCNT在乙醇中的分散性显著提高,这是由于其表面吸附有较多尿素分子[15]。接着将RCF涂布在玻璃基板上,再将RCNT超声分散在乙醇中得到浓度为0.4 g/L的分散液,使用滴管将分散液逐滴滴蘸到RCF表面,然后将所得混合物在100℃加热6小时。最后,将干燥后的样品在乙醇中超声清洗以去除多余的RCNT,并在60℃的真空烘箱中干燥12小时,得到RCF-RCNT多尺度增强体。为揭示RCF-RCNT多尺度增强体对复合材料的强化机制,本研究还使用CF和CNT,根据RCF-RCNT增强体的滴蘸制备方法制备了CF-CNT样品,并且,为保留CF表面的CNT,CF-CNT样品未经过超声清洗。

![]() 图 1 超声30 min所得浓度为1.0 g/L的分散系静置不同时刻的沉降结果对比图:碳纳米管(CNT)-乙醇分散系静置1 h (a)及24 h (b),RCNT-乙醇分散系静置1 h (c)及24 h (d)Figure 1. Comparison of the sedimentation results of the dispersion system with a concentration of 1.0 g/L obtained by ultrasonicating for 30 min at different times: Carbon nanotube (CNT)-ethanol dispersion system kept still for 1 h (a) and 24 h (b), RCNT-ethanol dispersion system kept still for 1 h (c) and 24 h (d)

图 1 超声30 min所得浓度为1.0 g/L的分散系静置不同时刻的沉降结果对比图:碳纳米管(CNT)-乙醇分散系静置1 h (a)及24 h (b),RCNT-乙醇分散系静置1 h (c)及24 h (d)Figure 1. Comparison of the sedimentation results of the dispersion system with a concentration of 1.0 g/L obtained by ultrasonicating for 30 min at different times: Carbon nanotube (CNT)-ethanol dispersion system kept still for 1 h (a) and 24 h (b), RCNT-ethanol dispersion system kept still for 1 h (c) and 24 h (d)1.3 PTFE基复合材料的制备

首先,将增强体以5wt.%的比例与PTFE粉料进行机械共混。然后,将混合粉料倒入金属模具中,缓慢加压至35 MPa,保持5分钟,然后缓慢卸掉压力,取出压制成型的坯料。接着,将坯料放入烘箱中,以约60℃/小时的速率升温到370℃并保持1小时进行烧结,然后停止加热,冷却至室温后取出试件。最后,通过机械加工将试件制备成测试所需试样形状。本研究中,以CF、RCF、CF-CNT、RCF-RCNT为填充相制得的复合材料分别记为CF/PTFE、RCF/PTFE、CF-CNT/PTFE、RCF-RCNT/PTFE。

1.4 表征与测试

使用FEI Sirion 200扫描电子显微镜(Scanning Electron Microscope, SEM)观察样品微观形貌,使用532 nm Ar激光源的Renishaw RM2000拉曼光谱仪进行拉曼光谱分析,使用德清盛泰芯电子科技有限公司生成的数显邵氏硬度计测量复合材料硬度,使用Rigaku Ultima IV型X射线衍射仪(Cu Kα辐射,λ = 0.154 nm,扫描步长0.02°)表征复合材料晶体结构,使用KRUSS DSA100液滴形状分析系统测量复合材料对水和二碘甲烷的接触角。使用兰州中科凯华公司生产的HSR-2M型往复摩擦磨损试验机,测量复合材料的摩擦系数及体积磨损率,对磨球材质为GCr15、直径6 mm,往复行程5 mm,摩擦时间为30分钟,实验时环境温度19~21℃,湿度42%~66%。使用Keyence VHX-500F数码显微镜观察摩擦后的对磨球表面形貌。

2. 结果与讨论

2.1 多尺度增强体表征

图2(a, b)为RCF-RCNT多尺度增强体微观形貌,可见RCNT在纤维表面均匀分布,形成了多尺度结构。图2(c)为三种样品的拉曼光谱,其中,1590 cm−1(G波段)和1350 cm−1(D波段)附近的吸收峰分别代表sp2杂化碳的面内振动和不定形碳,两吸收峰强度比ID/IG通常用于衡量CF表面石墨结构的无序程度,其值越高代表不定形碳越多[16]。本研究采用Gaussian-Lorentzian拟合计算ID/IG数值[17, 18],结果表明CF的ID/IG=1.84,与已有研究相近[18, 19]。一般认为,制备CF-CNT多尺度增强体的传统化学接枝法中,对CF采用的高温、强酸、电化学氧化改性方法会破坏CF表面石墨结构,引入无定形碳,从而使ID/IG数值升高[20, 21]。然而,本研究中RCF的ID/IG=1.83,略小于CF中的值,这表明LaCl3-乙醇处理不会引起明显的纤维表面损伤,同时,本研究中多尺度增强体的合成主要采用低毒低污染的LaCl3、尿素和乙醇[22],并不涉及强酸强氧化剂等有害物质的使用,因此相对传统化学法具有绿色环保的工艺优势。此外,在RCF-RCNT多尺度增强体中ID/IG=1.61,这是由于增强体中含有石墨化程度更高的CNT[23, 24]。

2.2 复合材料表面性能分析

2.2.1 硬度及晶体结构

本研究中PTFE复合材料的硬度如表1所示,可见,硬质的CF和CF-CNT填充相的加入使复合材料硬度明显提高,且提高程度相当。但是,RCF、RCF-RCNT填充相的加入使复合材料的硬度相对CF/PTFE和CF-CNT/PTFE进一步增加,这表明RCF/PTFE和RCF-RCNT/PTFE中可能出现了其他硬度较高的新相。因此,本研究对复合材料的晶体结构进行了分析。

表 1 不同复合材料的硬度Table 1. Hardness of different compositesSample Hardness (Shore D) PTFE 57.0±2.9 CF/PTFE 61.7±1.5 RCF/PTFE 62.3±0.6 CF-CNT/PTFE 61.3±1.4 RCF-RCNT/PTFE 62.7±0.2 图3(a)为不同复合材料的XRD光谱,2θ=18°、32°、37°、41°附近的衍射峰分别对应PTFE晶体中的(100)、(110)、(200)、(108)晶面[25]。图3(b)中2θ=16°附近的驼峰对应PTFE中的无定形晶粒,根据该驼峰强度和2θ=18.14°附近衍射主峰强度可计算得到复合材料结晶度

Xc ,本研究采用文献[26]所述方法计算结晶度,所得结果如图3(a)所示。可见,CF和CF-CNT填充相的加入使PTFE结晶度从35%上升到38%和41%,这是由CF及CNT的加入使液态PTFE形核结晶的位点增加,发生多点形核所致[27]。RCF、RCF-RCNT增强体的加入使结晶度进一步提高到44%,这是由于增强体合成过程中在表面吸附了La(III),而La(III)的络合能力较强,在PTFE结晶过程中具有成核剂的作用,这使成核率提高、结晶速率加快,因此结晶度明显增大[28, 29]。除此之外,由图3(c)可见,CF/PTFE (17.94°)及RCF/PTFE (17.94°)的主衍射峰相对纯PTFE (18.14°)明显左移,这是由于纤维增强体的加入在基体中产生了较大的内应力,引起晶格膨胀晶面间距增大,而CF-CNT和RCF-RCNT的加入使衍射峰分别右移至18.10°和18.30°,这是因为纳米级CNT粒子插入PTFE分子链,进而引起晶格收缩使晶面间距减小[25, 30]。综上所述,填充相使PTFE复合材料硬度提高的原因有二,其一是碳材料本身为硬质相,其二是填充相的加入提高了复合材料结晶度,因此CF和CF-CNT的加入使复合材料硬度变大,而RCF和RCF-RCNT的加入使硬度进一步提高。

2.2.2 接触角与表面能

材料表面能与其摩擦磨损性能,尤其是初始摩擦阶段的摩擦学行为密切相关,但是,当前研究对纤维增强复合材料的表面性能研究较少,针对这一问题,本研究采用Fowkes-Owens-Wendt-Kaelble模型[31-33]计算复合材料的表面能,在该模型中,复合材料表面能

γs 由下式给出γs=γps+γds (1) γl(1+cosθ)=2(√γplγps+√γdlγds) (2) 其中,

γp 由分子极性引起的吸引力γd 范德瓦尔斯力等其他力的和θ 接触角l 接触角测量时所用的液相s 接触角测量时所用的复合材料本研究中采用蒸馏水和二碘甲烷测量复合材料接触角,所得结果如表2所示。

表 2 不同复合材料的接触角Table 2. Contact angle of different compositesSample Contact angle/(°) Water Diiodomethane PTFE 109.0±4.4 78.1±5.9 CF/PTFE 120.8±0.5 76.4±1.8 RCF/PTFE 118.4±2.9 79.0±1.3 CF-CNT/PTFE 119.1±2.5 75.8±2.1 RCF-RCNT/PTFE 110.2±4.4 78.4±0.6 两种不同液相的表面能

γl 及分量γpl 、γdl 由参考文献[34]给出,如表3所示。表 3 所用液相的表面能Table 3. Surface tension of the used test liquidWetting

liquidsSurface

tension

γl/(mJ·m−2)Dispersion component

γdl/(mJ·m−2)Polar

component

γpl/(mJ·m−2)Water 72.8 21.8 51.0 Diiodomethane 50.8 48.5 2.3 将测量所得接触角及液滴参数代入式(1~2)计算得到的复合材料表面能如图4所示,可见CF和CF-CNT的加入使复合材料的表面能逐渐升高,这是由于CF与CNT的表面能相对PTFE较高[35, 36]。而RCF和RCF-RCNT的加入使复合材料表面能相对CF/PTFE和CF-CNT/PTFE明显降低,这是由于RCF/PTFE和RCF-RCNT/PTFE的结晶度较高,因此表面具有较多的惰性PTFE晶体结构。一般而言,复合材料表面能越低,在摩擦过程中与对磨件表面之间的黏着作用越弱、摩擦阻力越小。RCF-RCNT的加入大大降低了PTFE复合材料表面能,这将对PTFE复合材料产生显著的减摩降磨作用。

2.3 复合材料的摩擦学性能

2.3.1 多尺度增强PTFE复合材料的摩擦学性能

一 起始摩擦系数分析

不同复合材料的摩擦系数实时变化曲线图如图5所示。由图5(a)可知,PTFE、CF/PTFE、RCF/PTFE、CF-CNT/PTFE、RCF-RCNT/PTFE的起始摩擦系数分别为0.096、0.200、0.162、0.206、0.090。

在无润滑条件下,材料起始摩擦系数与摩擦副表面能密切相关,一般认为,较低的表面能意味着两摩擦副之间相对较弱的黏着作用以及较小的起始摩擦系数[37],Sinha等[37, 38]在Bradly[39]和Tabor[40]的研究基础上进一步提出了高分子薄膜起始摩擦系数与摩擦副表面能之间的下述关系:

μi=C1C2exp(nFo)F0.25+α (3) Fo=2πR(γ1+γ2−γ12) (4) γ12=(√γ1−√γ2)2 (5) 其中,

μi 起始摩擦系数F 载荷

C1,C2,α,n 常数Fo 牵引力R 圆形接触区域的半径γ1,γ2 两摩擦副材料表面能γ12 两摩擦副材料之间的界面能将式(4~5)代入式(3),有

μi=C1C2exp(4πnR√γ1γ2)F0.25+α (6) 由式(6)可知,起始摩擦系数

μi 与两摩擦副表面能乘积γ1γ2 大致成正相关关系。本研究中对磨球均为同种材料,γ2 可视为不变,而根据前文表面能测试结果知复合材料表面能大小顺序为:γ(CF-CNT/PTFE) ≈ γ(CF/PTFE) > γ(RCF/PTFE) > γ(PTFE) ≈ γ(RCF-RCNT/PTFE),这正与五种材料的起始摩擦系数大小顺序相同。二 摩擦学性能对比

由图5(b)可见,纯PTFE的摩擦系数在摩擦过程中先缓慢增加至0.17左右,在第20 min时突然升高至0.21左右,其平均摩擦系数为0.16。加入CF后,复合材料的摩擦系数先是缓慢升高到0.29左右,在第13.5 min后突然降为0.22左右,维持7.5 min后,在第21 min时又突然升高到0.29左右,而后在第28 min时再次出现相似的突变。与CF/PTFE相似的是,CF-CNT/PTFE复合材料的摩擦曲线也是先缓慢升高到0.3左右,而后在第6 min突然降低,但是此后一直维持在0.22左右不再发生突变。与PTFE、CF/PTFE、CF-CNT/PTFE三种材料不同的是,RCF/PTFE与RCF-RCNT/PTFE的摩擦系数始终未发生突变,其摩擦曲线经历前期的磨合后很快稳定,且RCF/PTFE达到稳定的时间较短。就整个摩擦过程而言,复合材料的平均摩擦系数及磨损率如图6所示。

由图6知,RCF-RCNT/PTFE复合材料的磨损率为79.0×10−6 mm3·N−1·m−1,相对于纯PTFE降低了75.4%。这一降磨效果与同类研究的对比如表4所示,可见,本研究中的降磨效果优于同类研究。

为揭示复合材料摩擦磨损机制,本研究对摩擦表面微观形貌进行了分析。

表 4 相关研究中PTFE基复合材料摩擦学性能对比Table 4. Tribological performance comparison of PTFE based composites in similar studiesRef. Composites Type of friction Test conditions Wear rate

/

(×10−6 mm3·N−1·m−1)Decrement of

wear rate/%[41] PTFE Reciprocating sliding Counterface: φ=10 mm steel ball,

load: 10 N, frequency: 10 Hz304.8 −48.1 30vol.% h-BN/AO/PTFE 158.2 [42] PTFE/AP Reciprocating sliding Counterface: φ=9 mm Si3N4 ball,

load: 10 N, frequency: 1 Hz3.2 −44.1 6wt.% modified CF/PTFE/AP 1.79 [43] PTFE Reciprocating sliding Counterface: φ=5 mm Si3N4 ball,

load: 3 N, frequency: 2 Hz2.5 −44.0 5wt.% CF/5wt.%BP/PTFE 1.4 [2] PTFE Continuous sliding Counterface: φ=6 mm steel ball,

load: 10 N,

rotational speed: 200 r/min390 −29.7 20wt.%CF/PTFE 274 [1] PTFE Reciprocating sliding Counterface: 5×5×25 mm steel pin,

load: 50 N, frequency: 2 Hz0.21 — 15wt.% AF/PTFE 0.23 +9.5 15wt.% CF/PTFE 0.24 +14.3 15wt.% GF/PTFE 0.18 −14.3 0.5wt.% BF/PTFE 0.15 −28.6 0.5wt.% BF+

10wt.%MoS2/PTFE0.17 −19.1 [20] PI Reciprocating sliding Counterface: φ=4 mm steel ball,

load: 4.5 N, velocity: 0.083 m/s6.44 −72.2 5wt.% CF-CNT reinforcer/PI 1.79 This study PTFE Reciprocating sliding Counterface: φ=6 mm steel ball, load: 16 N, frequency: 6 Hz 321.6 −75.4 5wt.% RCF-RCNT reinforcer/PTFE 79.0 Notes: h-BN—hexagonal boron nitride; AO—alumina particles; AP—aluminum dihydrogen phosphate; BP—black phosphorus; AF—aramid fiber; GF—glass fiber; BF—basalt fiber; PI—polyimide. 三 磨损面形貌分析

图7为复合材料的磨损面典型形貌。如图7(a)所示,低倍率下的纯PTFE的磨损面较为光滑,仅有些许细小的碎屑,光滑的表面意味着较低的摩擦阻力,这与纯PTFE较低的摩擦系数相符。相比之下,CF/PTFE及CF-CNT/PTFE的磨损面显得较为粗糙。CF/PTFE中出现了大块磨屑,如图7(d)所示,在高倍率下可见CF与基体部分脱粘的现象,如图7(e, f)所示,这表明二者间结合性能较差。CF-CNT/PTFE的磨损面出现了因CF拔出而留下的凹坑,如图7(j)所示,在高倍率下可见部分拔出后裸露的CF,但其并未与基体脱粘,这表明纤维与基体结合性能有一定提高。CF/PTFE及CF-CNT/PTFE中,脱粘后裸露、甚至脱落的硬质CF,在摩擦过程中容易对基体形成犁削,加剧材料磨损。相比之下,RCF/PTFE及RCF-RCNT/PTFE的磨损面较为光滑,视野中未见大块磨粒及CF脱落形成的凹坑。高倍率下可见RCF/PTFE中CF与基体结合紧密,基本未出现脱粘现象,如图7(h)所示,而RCF-RCNT/PTFE中CF则牢固镶嵌于基体中,如图7(n, o)所示,这都表明了纤维与基体之间良好的结合性能。

图8为复合材料对磨球的典型表面形貌。在图8(a)中,纯PTFE的对磨球表面可见由PTFE黏着形成的转移膜,且犁沟并不明显,这表明其磨损机制主要为黏着磨损。其余四种复合材料对磨球照片中,转移膜表面均出现了明显的犁沟,犁沟主要由摩擦过程中从基体脱落的磨屑尤其是硬质纤维刮擦所致,这表明四种复合材料的磨损机制包括黏着磨损及磨料磨损。此外,从图8(b)可见CF/PTFE中的犁沟较宽且较深,这是由于CF/PTFE中产生了大块磨粒及纤维脱粘现象严重,CF-CNT/PTFE和RCF/PTFE中的犁沟相对较浅,RCF-RCNT/PTFE的犁沟最浅最窄,这也与复合材料磨损率变化趋势相符。

四 摩擦磨损机制研究

基于以上分析,本研究提出以下的摩擦磨损机制:即五种复合材料的摩擦过程可分为(1)表面粘附阶段、(2)表面变形阶段、(3)转移膜形成阶段,由于CF/PTFE及CF-CNT/PTFE复合材料的对磨球中形成的转移膜与钢球结合力较弱,因此它们的摩擦过程还包括(4)转移膜脱落及再形成阶段。以上各阶段在摩擦曲线中的对应关系如图9所示,摩擦过程中磨粒脱落过程如图10所示。

(1)表面粘附阶段:此阶段主要包括摩擦过程起始阶段的数秒,此时摩擦系数与材料表面能基本成正相关关系。

(2)表面变形阶段:此阶段主要包括摩擦曲线中摩擦系数上升最快的部分,此时在对磨球的挤压下,材料变形使表面凹凸不平,摩擦阻力迅速增大。由于五种材料的硬度整体相对较低,形变过程迅速,此阶段的持续时间也较短。

(3)转移膜形成阶段:此阶段主要包括摩擦曲线中摩擦系数逐渐上升到最高值的部分。随着摩擦过程的进行,对磨球的反复挤压犁削及产生的摩擦热逐渐使表面材料脱落形成磨粒,并将磨粒软化、压平,然后黏着于钢球表面形成转移膜,转移膜的形成避免了对磨球与表面材料的直接接触,因此摩擦系数上升速度降低。

(4)转移膜脱落及再形成阶段:由于纯PTFE、CF/PTFE和CF-CNT/PTFE中形成的转移膜强度较低、与对磨球结合力较弱,因此摩擦一段时间后转移膜会被磨穿或发生脱落,这就导致了CF/PTFE摩擦曲线中的突然上升和下降。转移膜被磨穿或脱落后,对于纯PTFE,磨损机制由黏着磨损转变为磨料磨损,因此摩擦系数突然变大[44];对于CF/PTFE和CF-CNT/PTFE,磨损机制由黏着磨损—磨料磨损的混合磨损转变为以磨料磨损为主,使摩擦系数突然降低[45, 46]。

在摩擦过程中,纯PTFE表面摩擦产生的PTFE碎屑较软且有润滑作用,因此其全过程的摩擦系数均相对较小。CF/PTFE复合材料因为界面结合强度较低,纤维易与基体发生脱粘进而形成硬质磨粒,如图7(f)所示,进而产生三体磨料磨损,如图10(a)所示。CF-CNT/PTFE界面性能有所提高,但仍然会发生基体脱落使硬质纤维裸露,如图7(l)所示,从而易造成严重的磨粒磨损如图10(b)所示。但是,CF/PTFE和CF-CNT/PTFE的磨损率相对纯PTFE有明显下降,这主要是由于耐磨性较好的CF和CNT对基体的强化作用,以及CF和CF-CNT提高了PTFE结晶度使基体硬度也有所增加。

对于RCF/PTFE复合材料而言,其摩擦系数快速达到平稳阶段,且在整个摩擦过程始终未发生突变。这是由于RCF表面存在的La(III)可与PTFE基体分子中的F原子发生配位反应[47],从而提高界面结合性能,如图7(i)所示,减少了摩擦过程中从基体脱粘形成的纤维硬质点,而且La(III)还可提高钢球表面所形成转移膜的强度和稳定性[48-50],使其在整个摩擦过程中不易被磨穿或发生脱落,避免了三体磨料磨损,如图10(c)所示。同时,RCF的加入提高了复合材料硬度,使其挤压变形量较小且不易被硬质磨粒犁削。因此RCF/PTFE复合材料的摩擦系数及磨损率相对CF/PTFE和CF-CNT/PTFE均有所降低。

而RCF-RCNT的加入使得复合材料耐磨减摩性能进一步提高。这是由于RCF-RCNT增强体的多尺度结构使其与基体产生机械啮合作用,更加有效提高了界面结合性能,如图7(o)所示,而且RCF-RCNT表面存在更多La(III),更有效提高了转移膜强度和稳定性。这使纤维不易脱粘形成的硬质磨粒、转移膜不易被磨穿或脱落,进而避免了三体磨料磨损,如图10(d)所示。同时,复合材料的硬度也进一步提高,因此RCF-RCNT/PTFE复合材料的摩擦系数及磨损率进一步降低。

2.3.2 载荷对复合材料摩擦学行为的影响

图11为RCF-RCNT/PTFE复合材料在不同载荷下的摩擦系数、摩擦力、磨损率及磨损量,随着载荷的上升,RCF-RCNT/PTFE复合材料摩擦系数和磨损率均未产生明显的变化趋势,因此本研究从摩擦力和磨损量两方面进行分析。可见,摩擦力先上升后降低,磨损量则持续上升。关于载荷对摩擦力的影响,本研究从以下两方面考虑,即:

(1)载荷提高使对磨球与PTFE复合材料的接触面扩展,能量耗散及摩擦力显著变大,根据库仑定律可知此时摩擦系数上升。其中,根据Johnson-Kendall-Roberts接触模型知接触区半径

a 为[51]:a=[3R8(√8γ12πE∗+√8γ12πE∗+163RE∗F)]23 (7) 其中,

F 载荷R 对磨球半径E∗ 有效弹性模量γ12 两摩擦副材料之间的界面能(2)载荷提高使摩擦面上的凸起点被压平、粗糙度降低,摩擦力减小。

在载荷从12 N提高到18 N的过程中,摩擦副接触面扩展,同时载荷较小不足以压平摩擦表面的凸起点,因素(1)占主要地位,因此摩擦力上升。在载荷从18 N增加到20 N的过程中,由于载荷较大,摩擦面表面的凸起点逐渐被压平,同时,由式7知,载荷

F 较大时,增加载荷产生的接触半径a 增长较小,因此因素(2)此时占据主要地位,摩擦力减小。关于载荷对磨损量的影响,根据Johnson-Kendall-Roberts接触模型知接触区变形深度

d 为[51]:d=a2R+√2γ12πaE∗ (8) 联立式(7)和式(8)知接触区半径

a∝F1/3 ,变形深度d∝F2/3 ,同时,磨损量ΔV∝(d⋅a) ,即ΔV∝F ,因此RCF-RCNT/PTFE复合材料的磨损量随载荷的增大而增大。另外,材料体积磨损率W=ΔV/(F⋅L) (L 为摩擦长度),因此,W∝F0 ,即,由于本研究中载荷提高并未造成磨损机制及材料物性(弹性模量等)的变化,所以不同载荷下的磨损率无明显变化趋势。2.3.3 往复频率对复合材料摩擦学行为的影响

图12为不同往复频率下的RCF-RCNT/PTFE复合材料摩擦系数、磨损率及磨损量,图13为不同频率下的对磨球典型表面形貌。RCF-RCNT/PTFE复合材料摩擦系数随着往复频率从0.21先升高到0.26后降低到0.20。这是由于,往复频率较低时,随着频率提高,摩擦生热逐渐变快,摩擦面快速升温软化,加剧了钢球表面转移膜与基体材料的黏着磨损,从而导致4 Hz到8 Hz时的摩擦系数增大。但是,由图13可知,往复频率为10 Hz时对磨球表面转移膜相对6 Hz时较为连续且未见较深的犁沟,这表明当往复频率进一步升高时摩擦面继续升温,高温使磨粒快速软化,在摩擦副之间形成了连续的转移膜,阻碍了对摩球与表面材料的直接接触,从而使8 Hz到12 Hz时的摩擦系数降低。

此外,RCF-RCNT/PTFE复合材料磨损率随往复频率升高逐渐降低,磨损量随往复频率从4 Hz升高到12 Hz逐渐增加。摩擦过程是对磨球对磨合材料的磨削过程,较大的往复频率意味着较快的摩擦速度,这一方面增大了摩擦长度,提高了磨损量,另一方面也使摩擦表面温度升高,材料升温软化后粘附在钢球表面阻碍了钢球对复合材料的直接磨削,因此磨损量

ΔV 随往复频率f 提高的增加程度并不大,由于磨损率W=ΔV/(F⋅f⋅L0⋅t)(f 为往复频率,F,L0,t 分别为载荷、往复行程和摩擦时间),因此发生了磨损率的下降。3. 结 论

本研究采用绿色合成法制备碳纤维(Carbon Fibre, CF)-碳纳米管(Carbon Nanotube, CNT)微纳多尺度增强体,将其用于提高聚四氟乙烯(Polytetrafluoroethylene, PTFE)基复合材料摩擦学性能,从硬度、结晶度、表面能、界面结合性能等方面分析了增强体对复合材料起始摩擦系数、摩擦曲线和磨损率的影响机制,并探究了摩擦学试验中的往复频率及载荷对多尺度增强PTFE基复合材料摩擦学行为的影响。所得主要结论如下:

(1)本研究所提出的RCF-RCNT微纳多尺度增强体制备方法不损伤纤维,相对传统化学接枝法具有绿色环保的工艺优势。

(2)RCF-RCNT多尺度增强体提高了PTFE基复合材料的硬度,原因在于硬质纤维相不但能提高硬度,还能增加PTFE形核结晶位点,而且RCF-RCNT增强体表面稀土La(III)具有成核剂的作用,这使复合材料结晶度提高。

(3)PTFE基复合材料的起始摩擦系数与其表面能成正相关关系,RCF-RCNT/PTFE因其较高的结晶度而具有较低的表面能和起始摩擦系数。

(4)RCF-RCNT/PTFE复合材料的磨损率相对纯PTFE降低了75.4%,这一减磨程度优于同类研究,其原因在于:RCF-RCNT增强体的多尺度结构使其与基体产生机械啮合作用,而且其表面存在的La(III)与PTFE基体分子中的F原子发生配位反应,显著提高了界面结合性能及转移膜强度和稳定性,使纤维不易脱粘形成硬质点、转移膜不易脱落导致三体磨料磨损。同时,RCF-RCNT/PTFE复合材料硬度较高,挤压变形量较小且不易被硬质磨粒犁削。

(5)在RCF-RCNT/PTFE复合材料的往复摩擦学实验中,随着载荷增加,摩擦面扩展速度减缓但摩擦表面逐渐被压平,因此摩擦力先增大后减小,同时由于磨损机制及材料物性无明显改变,所以磨损量维持线性增长,磨损率并未产生明显变化;随着往复频率增加,软化的基体和磨料逐渐使钢球表面转移膜连续,磨损机制逐渐由黏着磨损与磨料磨损的混合磨损形式向单一黏着磨损转变,因此摩擦系数先增大后减小,而磨损率持续减小。总体而言,RCF-RCNT/PTFE复合材料在高往复频率、低载荷下的磨损率更低。

-

表 1 模拟海水成分

Table 1 Simulated seawater composition

Compound Concentration/(g·L−1) NaCl 24.53 MgCl2 5.20 Na2SO4 4.09 CaCl2 1.16 KCl 0.695 NaHCO3 0.201 KBr 0.101 H3BO3 0.027 SrCl2 0.025 NaF 0.003 表 2 玻璃纤维/甲基丙烯酸酯基CIPP内衬加速老化

1440 h前后的羰基指数和羟基指数Table 2 Carbonyl index and hydroxyl index of glass fiber reinforced methacrylate-based CIPP lining before and after accelerated aging 1 440 h

Condition Carbonyl index Hydroxyl index Before aging Aging 1440 hBefore aging Aging 1440 h0.5% sulfuric acid 0.560±0.025 0.807±0.026 0±0.01 0.038±0.028 Simulated seawater 0.591±0.019 0.056±0.023 Pure water 0.824±0.021 0.039±0.035 -

[1] DONALDSON B M. Environmental implications of cured-in-place pipe rehabilitation technology[J]. Transportation Research Record, 2009, 2123(1): 172-179. DOI: 10.3141/2123-19

[2] ZHU H, WANG T, WANG Y, et al. Trenchless rehabilitation for concrete pipelines of water infrastructure: A review from the structural perspective[J]. Cement and Concrete Composites, 2021, 123: 104193. DOI: 10.1016/j.cemconcomp.2021.104193

[3] LI S, GUO S C, YAO Y M, et al. The effects of aging in seawater and SWSSC and strain rate on the tensile performance of GFRP/BFRP composites: A critical review[J]. Construction and Building Materials, 2021, 282: 122534.

[4] NURUDDIN M, DECOCKER K, SENDESI S M T, et al. Influence of aggressive environmental aging on mechanical and thermo-mechanical properties of ultra violet (UV) cured in place pipe liners[J]. Journal of Composite Materials, 2020, 54(23): 3365-3379. DOI: 10.1177/0021998320913988

[5] RA K, SENDESI S M T, NURUDDIN M, et al. Considerations for emission monitoring and liner analysis of thermally manufactured sewer cured-in-place-pipes (CIPP)[J]. Journal of Hazardous Materials, 2019, 371: 540-549. DOI: 10.1016/j.jhazmat.2019.02.097

[6] GRAS-TRAVESSET F, ANDREU-TORRAS A, PÉREZ M A. A novel test procedure for evaluating the performance of composite cured-in-place-pipe liners in water pressure pipe rehabilitation[J]. Case Studies in Construction Materials, 2023, 19: e02381. DOI: 10.1016/j.cscm.2023.e02381

[7] VAHIDI E, JIN E, DAS M, et al. Environmental life cycle analysis of pipe materials for sewer systems[J]. Sustainable Cities and Society, 2016, 27: 167-174. DOI: 10.1016/j.scs.2016.06.028

[8] ALLOUCHE E, ALAM S, SIMICEVIC J, et al. A pilot study for retrospective evaluation of cured-in-place pipe (CIPP) rehabilitation of municipal gravity sewers[J]. Tunnelling and Underground Space Technology, 2014, 39: 82-93. DOI: 10.1016/j.tust.2012.02.002

[9] OKABE S, ODAGIRI M, ITO T, et al. Succession of sulfur-oxidizing bacteria in the microbial community on corroding concrete in sewer systems[J]. Applied and Environmental Microbiology, 2007, 73(3): 971-980. DOI: 10.1128/AEM.02054-06

[10] VALIX M, SHANMUGARAJAH K. Biogenic acids produced on epoxy linings installed in sewer crown and tidal zones[J]. Water Research, 2015, 80: 217-226. DOI: 10.1016/j.watres.2015.05.027

[11] 魏建辉, 刘明, 高进城, 等. 吸湿老化后碳纤维增强乙烯基脂树脂复合材料高低温力学性能[J]. 复合材料学报, 2023, 40(6): 3279-3290. WEI Jianhui, LIU Ming, GAO Jincheng, et al. Mechanical properties at elevated and cryogenic temperatures of carbon fiber reinforced vinylester resin composites after hygroscopic aging[J]. Acta Materiae Compositae Sinica, 2023, 40(6): 3279-3290(in Chinese).

[12] NODEHI M. Epoxy, polyester and vinyl ester based polymer concrete: A review[J]. Innovative Infrastructure Solutions, 2021, 7(1): 64.

[13] VIEIRA P S, DA SILVA G A, LOPES B J, et al. Hygrothermal aging of steel/frp pipe repair systems: A literature review[J]. International Journal of Pressure Vessels and Piping, 2023, 201: 104881. DOI: 10.1016/j.ijpvp.2022.104881

[14] 高坤, 史汉桥, 孙宝岗, 等. 湿热老化对玻璃纤维/环氧树脂复合材料性能的影响[J]. 复合材料学报, 2016, 33(6): 1147-1152. GAO Kun, SHI Hanqiao, SUN Baogang, et al. Effects of hydro-thermal aging on properties of glass fiber/epoxy composites[J]. Acta Materiae Compositae Sinica, 2016, 33(6): 1147-1152(in Chinese).

[15] AITHAL S, HOSSAGADDE P N, KINI M V, et al. Durability study of quasi-isotropic carbon/epoxy composites under various environmental conditions[J]. Iranian Polymer Journal, 2023, 32(7): 873-885. DOI: 10.1007/s13726-023-01172-x

[16] VISCO A M, BRANCATO V, CAMPO N. Degradation effects in polyester and vinyl ester resins induced by accelerated aging in seawater[J]. Journal of Composite Materials, 2011, 46(17): 2025-2040.

[17] HE W, LI X, LI P, et al. Experimental investigation on hygroscopic aging of glass fiber reinforced vinylester resin composites[J]. Polymers, 2022, 14(18): 3828. DOI: 10.3390/polym14183828

[18] 曹银龙, 于桢琪, 冯鹏, 等. 纤维增强环氧/乙烯基树脂复合材料性能优化与劣化机制研究进展[J]. 复合材料学报, 2024, 41(3): 1179-1191. CAO Yinlong, YU Zhenqi, FENG Peng, et al. Performance optimization and deterioration mechanism of fiber reinforced epoxy/vinyl resin composite materials: A review[J]. Acta Materiae Compositae Sinica, 2024, 41(3): 1179-1191(in Chinese).

[19] JOSÉ-TRUJILLO E, RUBIO-GONZÁLEZ C, RODRÍGUEZ-GONZÁLEZ J. Seawater ageing effect on the mechanical properties of composites with different fiber and matrix types[J]. Journal of Composite Materials, 2019, 53(23): 3229-3241. DOI: 10.1177/0021998318811514

[20] KANERVA M, JOKINEN J, SARLIN E, et al. Lower stiffness of GFRP after sulfuric acid-solution aging is due to degradation of fibre-matrix interfaces?[J]. Composite Structures, 2019, 212: 524-534. DOI: 10.1016/j.compstruct.2019.01.006

[21] LI H, GU P, WATSON J, et al. Acid corrosion resistance and mechanism of E-glass fibers: Boron factor[J]. Journal of Materials Science, 2013, 48(8): 3075-3087. DOI: 10.1007/s10853-012-7082-y

[22] 韦嘉盛, 戴磊, 贺瓶. 基于纤维素及其衍生物的凝胶材料设计[J]. 复合材料学报, 2022, 39(7): 3084-3103. WEI Jiasheng, DAI Lei, HE Ping. Design of gel materials with cellulose and its derivatives[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3084-3103(in Chinese).

[23] DEVINE M, BAJPAI A, OBANDE W, et al. Seawater ageing of thermoplastic acrylic hybrid matrix composites for marine applications[J]. Composites Part B: Engineering, 2023, 263: 110879. DOI: 10.1016/j.compositesb.2023.110879

[24] DAVIES P, LE GAC P Y, LE GALL M. Influence of sea water aging on the mechanical behaviour of acrylic matrix composites[J]. Applied Composite Materials, 2017, 24(1): 97-111. DOI: 10.1007/s10443-016-9516-1

[25] DUO Y, LIU X, LIU Y, et al. Environmental impact on the durability of FRP reinforcing bars[J]. Journal of Building Engineering, 2021, 43: 102909. DOI: 10.1016/j.jobe.2021.102909

[26] VISCO A, BRANCATO V, CAMPO N. Degradation effects in polyester and vinyl ester resins induced by accelerated aging in seawater[J]. Journal of Composite Materials, 2012, 46(17): 2025-2040. DOI: 10.1177/0021998311428533

[27] American Society for Testing and Materials International. Standard practice for preparation of substitute ocean water: ASTM D1141—98(2021)[S]. West Conshohocken: ASTM International, 2021.

[28] HONG B, XIAN G, LI H. Comparative study of the durability behaviors of epoxy-and polyurethane-based CFRP plates subjected to the combined effects of sustained bending and water/seawater immersion[J]. Polymers, 2017, 9(11): 603. DOI: 10.3390/polym9110603

[29] GRAMMATIKOS S A, EVERNDEN M, MITCHELS J, et al. On the response to hygrothermal aging of pultruded FRPs used in the civil engineering sector[J]. Materials & Design, 2016, 96: 283-295.

[30] 吴瑞, 李岩, 于涛. 不同种类纤维增强复合材料湿热老化性能对比[J]. 复合材料学报, 2022, 39(9): 4406-4419. WU Rui, LI Yan, YU Tao. Comparative study on the hygrothermal durability of different fiber reinforced composites[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4406-4419(in Chinese).

[31] American Society for Testing and Materials International. Standard test method for flexural properties of polymer matrix composite materials: ASTM D7264/D7264M—21[S]. West Conshohocken: ASTM International, 2021.

[32] AWAD S A, FELLOWS C M, SAEED MAHINI S. A comparative study of accelerated weathering of epoxy resins based on DGEBA and HDGEBA[J]. Journal of Polymer Research, 2018, 25: 1-8. DOI: 10.1007/s10965-017-1408-z

[33] ASLAN A, SALUR E, DÜZCÜKOĞLU H, et al. The effects of harsh aging environments on the properties of neat and MWCNT reinforced epoxy resins[J]. Construction and Building Materials, 2021, 272: 121929. DOI: 10.1016/j.conbuildmat.2020.121929

[34] FANG Y, WANG K, HUI D, et al. Monitoring of seawater immersion degradation in glass fibre reinforced polymer composites using quantum dots[J]. Composites Part B: Engineering, 2017, 112: 93-102. DOI: 10.1016/j.compositesb.2016.12.043

[35] LIU T, LIU X, FENG P. A comprehensive review on mechanical properties of pultruded FRP composites subjected to long-term environmental effects[J]. Composites Part B: Engineering, 2020, 191: 107958. DOI: 10.1016/j.compositesb.2020.107958

[36] BEURA S, CHAKRAVERTY A, PATI S, et al. Effect of salinity and strain rate on sea water aged GFRP composite for marine applications[J]. Materials Today Communications, 2023, 34: 105056. DOI: 10.1016/j.mtcomm.2022.105056

[37] FENG Z, SONG G L, WANG Z M, et al. Salt crystallization-assisted degradation of epoxy resin surface in simulated marine environments[J]. Progress in Organic Coatings, 2020, 149: 105932. DOI: 10.1016/j.porgcoat.2020.105932

[38] MA Y, YANG Y, SUGAHARA T, et al. A study on the failure behavior and mechanical properties of unidirectional fiber reinforced thermosetting and thermoplastic composites[J]. Composites Part B: Engineering, 2016, 99: 162-172. DOI: 10.1016/j.compositesb.2016.06.005

[39] WU C, MENG B C, TAM L H, et al. Yellowing mechanisms of epoxy and vinyl ester resins under thermal, UV and natural aging conditions and protection methods[J]. Polymer Testing, 2022, 114: 107708. DOI: 10.1016/j.polymertesting.2022.107708

[40] SMITH B. Infrared spectroscopy of polymers, VIII: Polyesters and the rule of three[J]. Spectroscopy, 2022, 37(10): 25-28.

[41] ARRIETA J S, RICHAUD E, FAYOLLE B, et al. Thermal oxidation of vinyl ester and unsaturated polyester resins[J]. Polymer Degradation and Stability, 2016, 129: 142-155. DOI: 10.1016/j.polymdegradstab.2016.04.003

[42] BAKLAN D, BILOUSOVA A, MYRONYUK O. UV aging of styrene-acrylic polymer SiO2 and TiO2 composites[J]. Materials Today Communications, 2024, 38: 107990. DOI: 10.1016/j.mtcomm.2023.107990

[43] YUAN Y, HAYS M P, HARDWIDGE P R, et al. Surface characteristics influencing bacterial adhesion to polymeric substrates[J]. RSC Advances, 2017, 7(23): 14254-14261. DOI: 10.1039/C7RA01571B

[44] WANG J, WU Y, CAO Y, et al. Influence of surface roughness on contact angle hysteresis and spreading work[J]. Colloid and Polymer Science, 2020, 298(8): 1107-1112. DOI: 10.1007/s00396-020-04680-x

[45] SANCHIS M, BLANES V, BLANES M, et al. Surface modification of low density polyethylene (LDPE) film by low pressure O2 plasma treatment[J]. European Polymer Journal, 2006, 42(7): 1558-1568. DOI: 10.1016/j.eurpolymj.2006.02.001

-

期刊类型引用(1)

1. 付强,李浩明,彭磊,李智,林木松,张丽,谢松瑜,唐征海,郭宝春. 填充型导热绝缘硅橡胶复合材料的研究进展. 绝缘材料. 2024(09): 1-14 .  百度学术

百度学术

其他类型引用(1)

-

其他相关附件

-

-

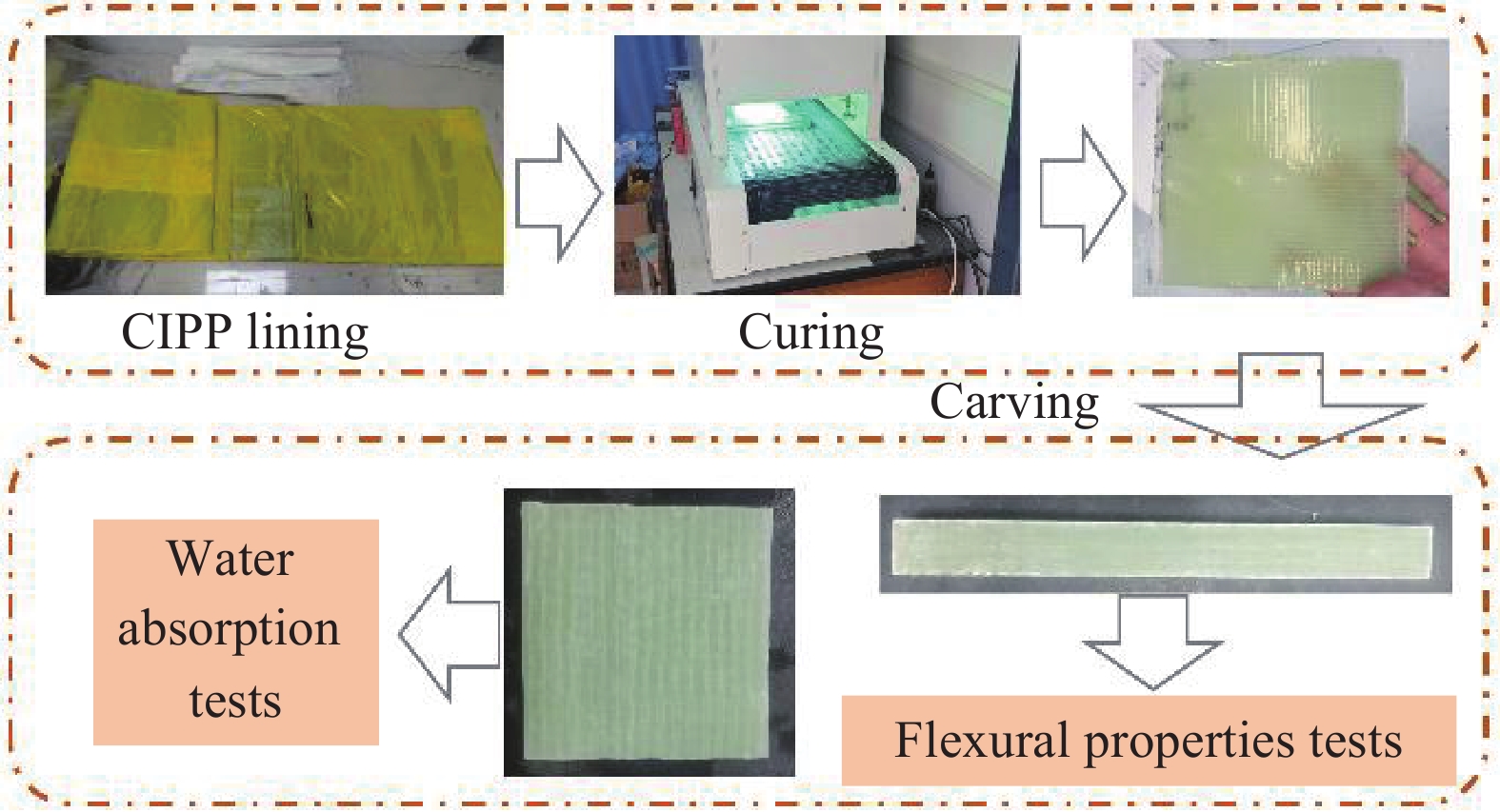

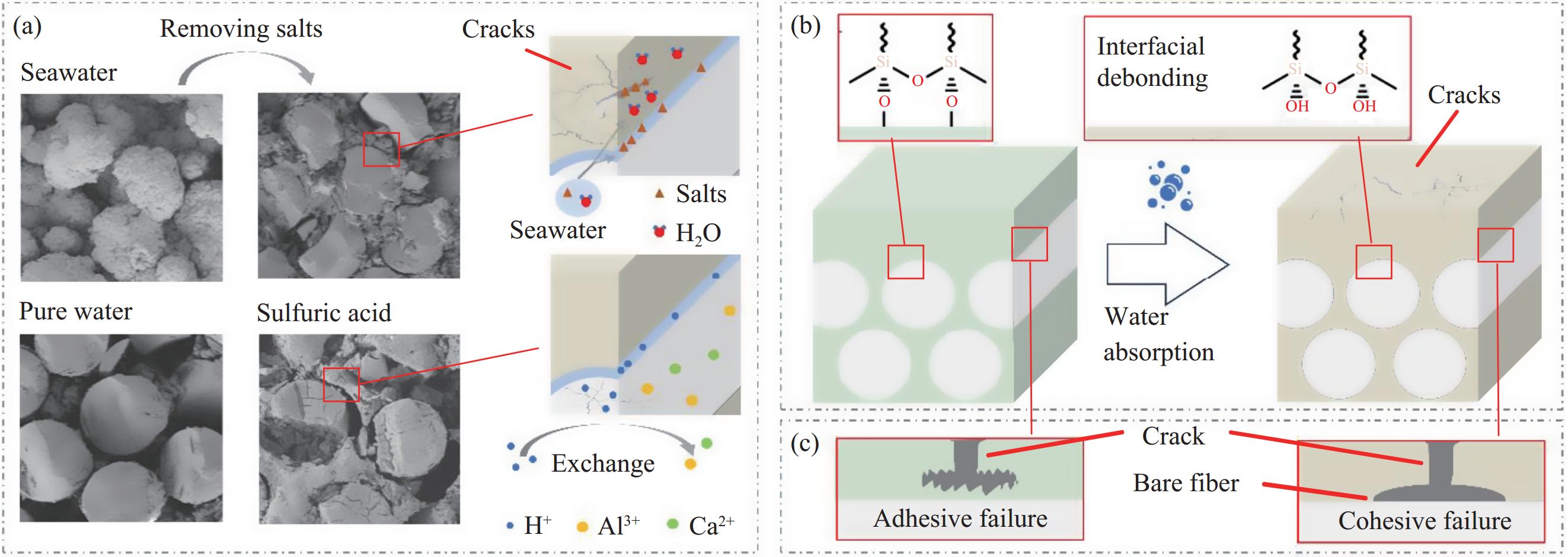

原位固化管道(Cured-in-place-pipe, CIPP)修复是目前市政排水管道非开挖修复常用的技术方法。该方法通过将热固性树脂和玻璃纤维组成的复合材料拉入到劣化管道内,固化后在管道内壁形成一层保护性管道内衬,保护排水管道免受生物硫酸的腐蚀,近年来也越来越多的应用于市政排海管道,抵抗海水的腐蚀,而硫酸和海水劣化玻璃纤维/甲基丙烯酸酯基CIPP内衬的机制尚不明确。

本文设计了0.5%硫酸、模拟海水和纯水(对照)三种老化条件,来模拟CIPP内衬服役环境,并通过高温(80℃)加速老化。结果显示:三种条件下加速老化1440 h后CIPP内衬弯曲强度显著下降,而弯曲模量没有明显变化;酯键水解出的羟基被氧化为羰基,导致了树脂老化后颜色发黄;硫酸通过腐蚀表面玻璃纤维促进了水分的扩散,但是H+离子没有大量沿界面向深处扩散,劣化内部玻璃纤维,硫酸老化也降低了表面润湿性,可能更有利于硫细菌黏附;海水在树脂表面的结晶阻碍了水分扩散,却严重破坏了树脂表面。分析了界面的劣化机制,提出了延缓CIPP内衬老化的建议:重点抑制水分向树脂基体的扩散、抑制水分沿界面的扩散,也应该改善树脂表面性能。

(a) 硫酸和海水腐蚀玻璃纤维/甲基丙烯酸酯基CIPP内衬;(b)树脂/纤维界面劣化;(c)弯曲断裂模式

树脂基体化学结构变化

下载:

下载: